Research Progress on the Sintering Techniques of Zirconia in Prosthetic Dentistry

Abstract

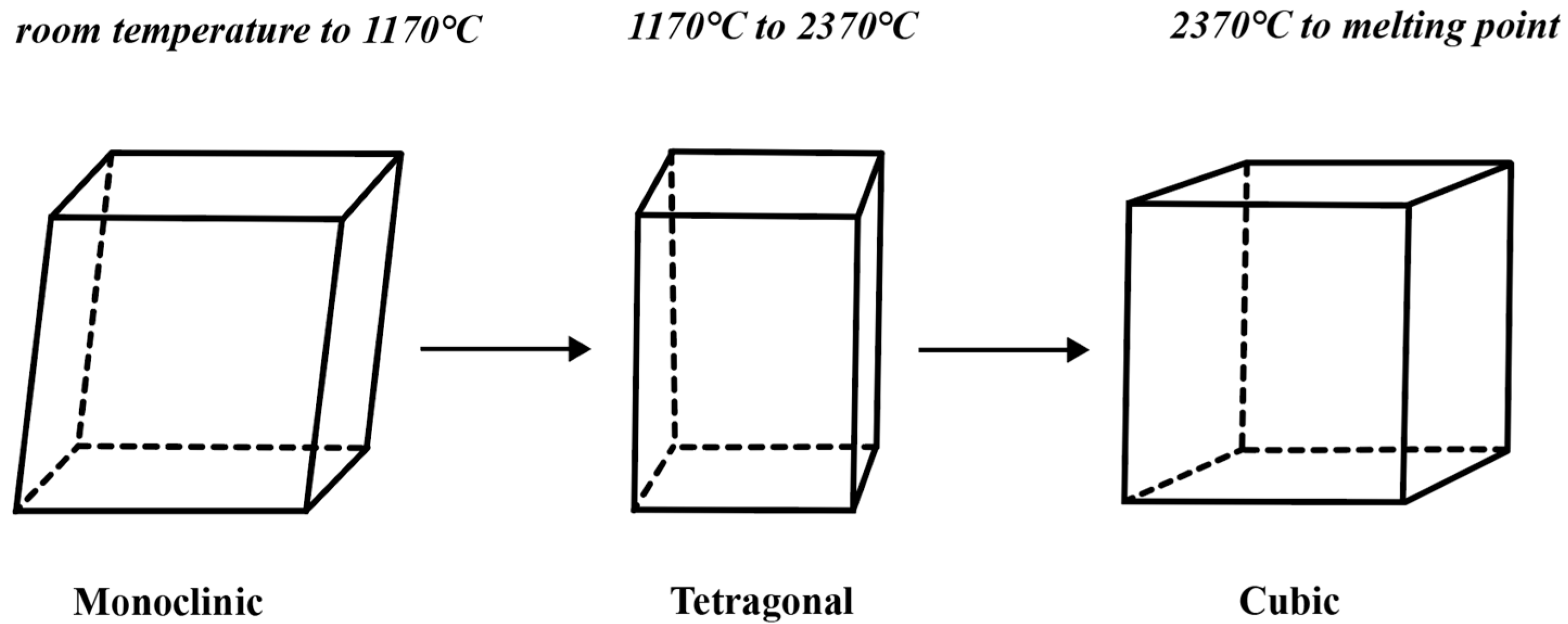

1. Introduction

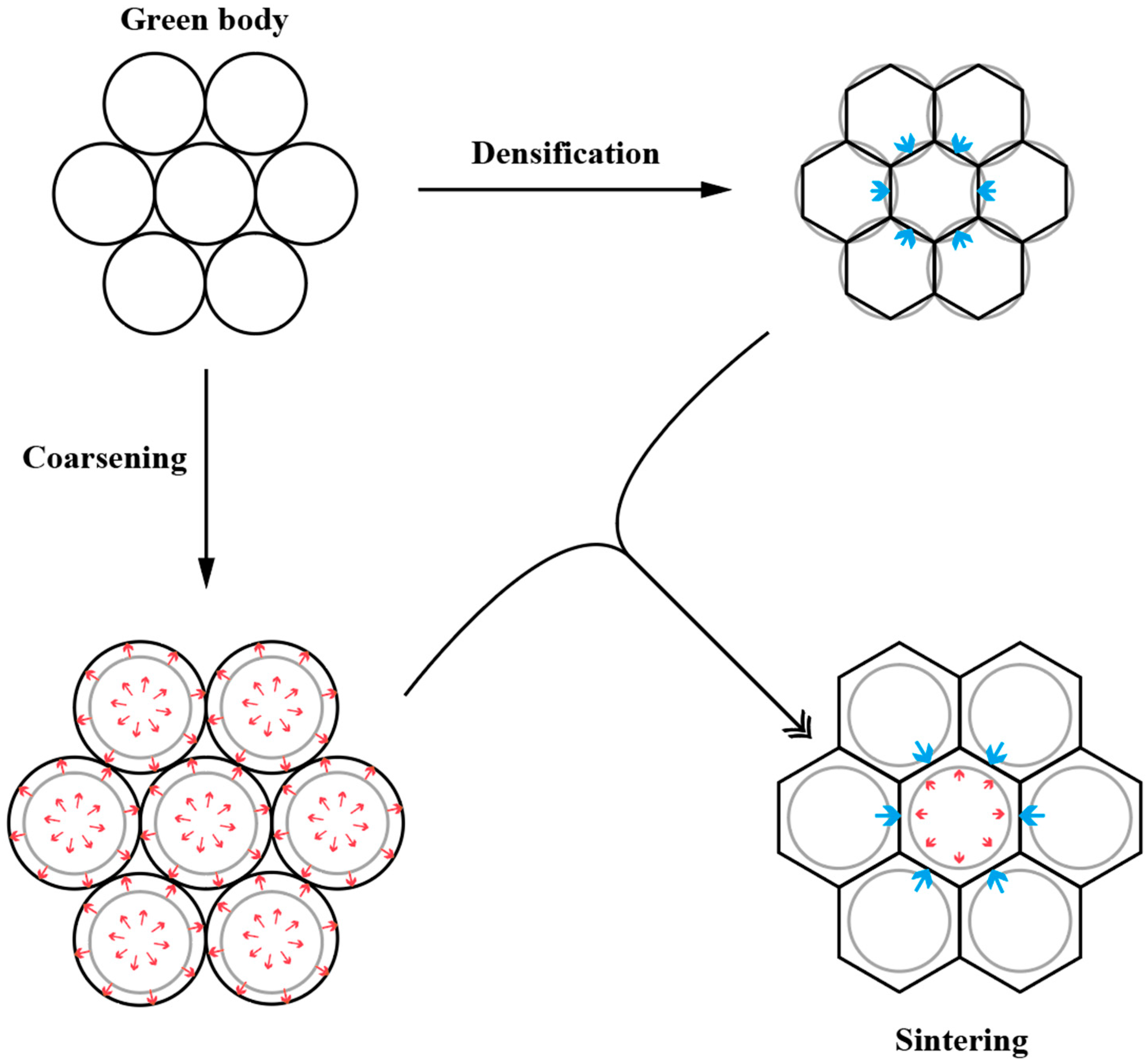

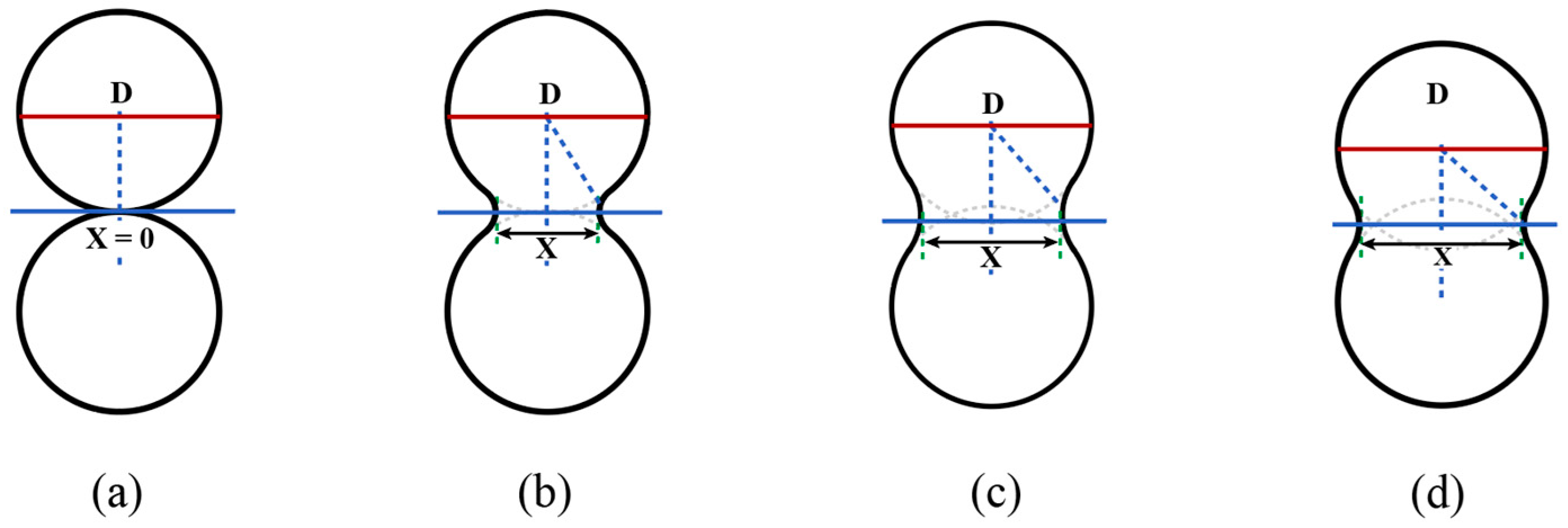

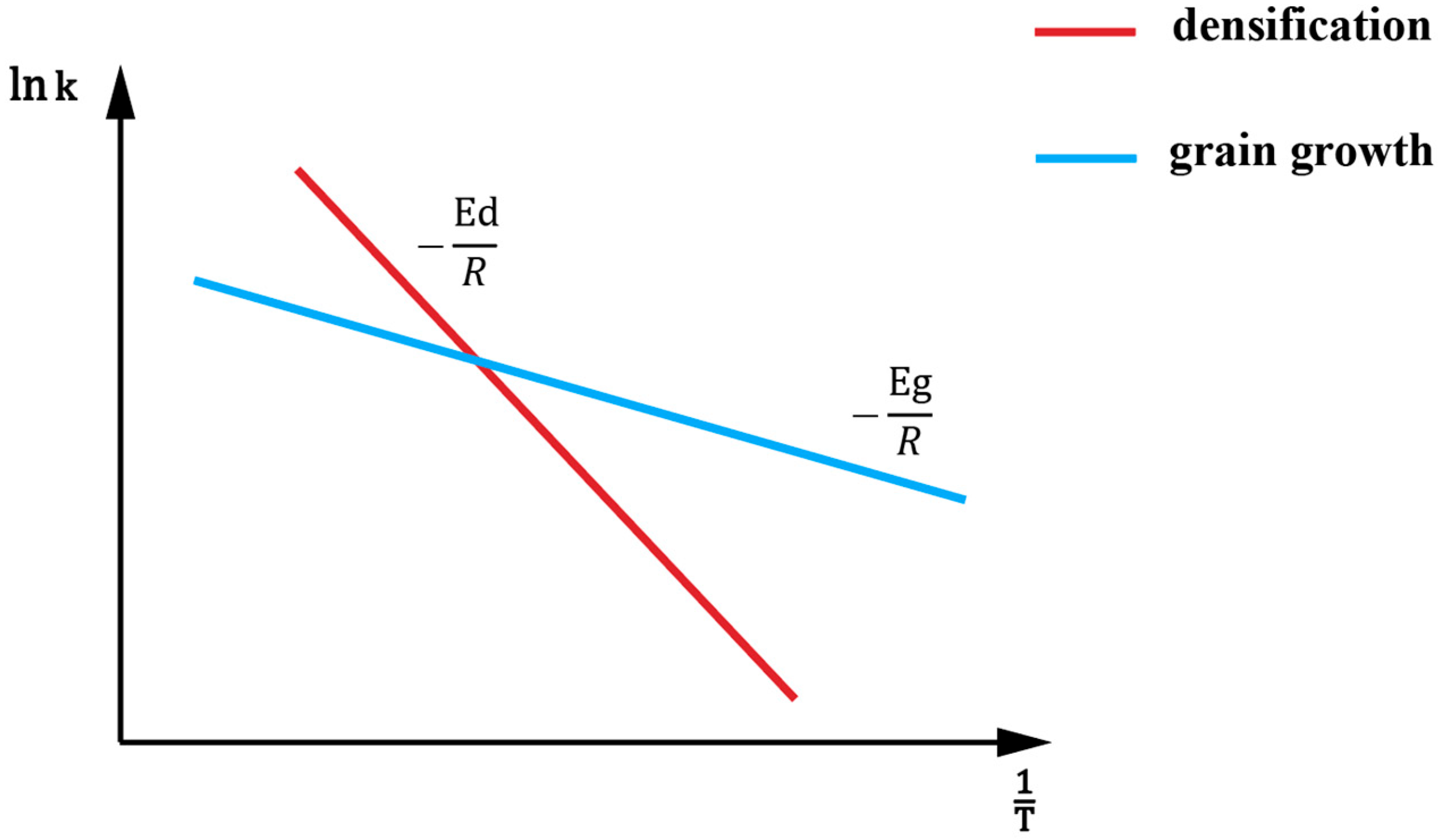

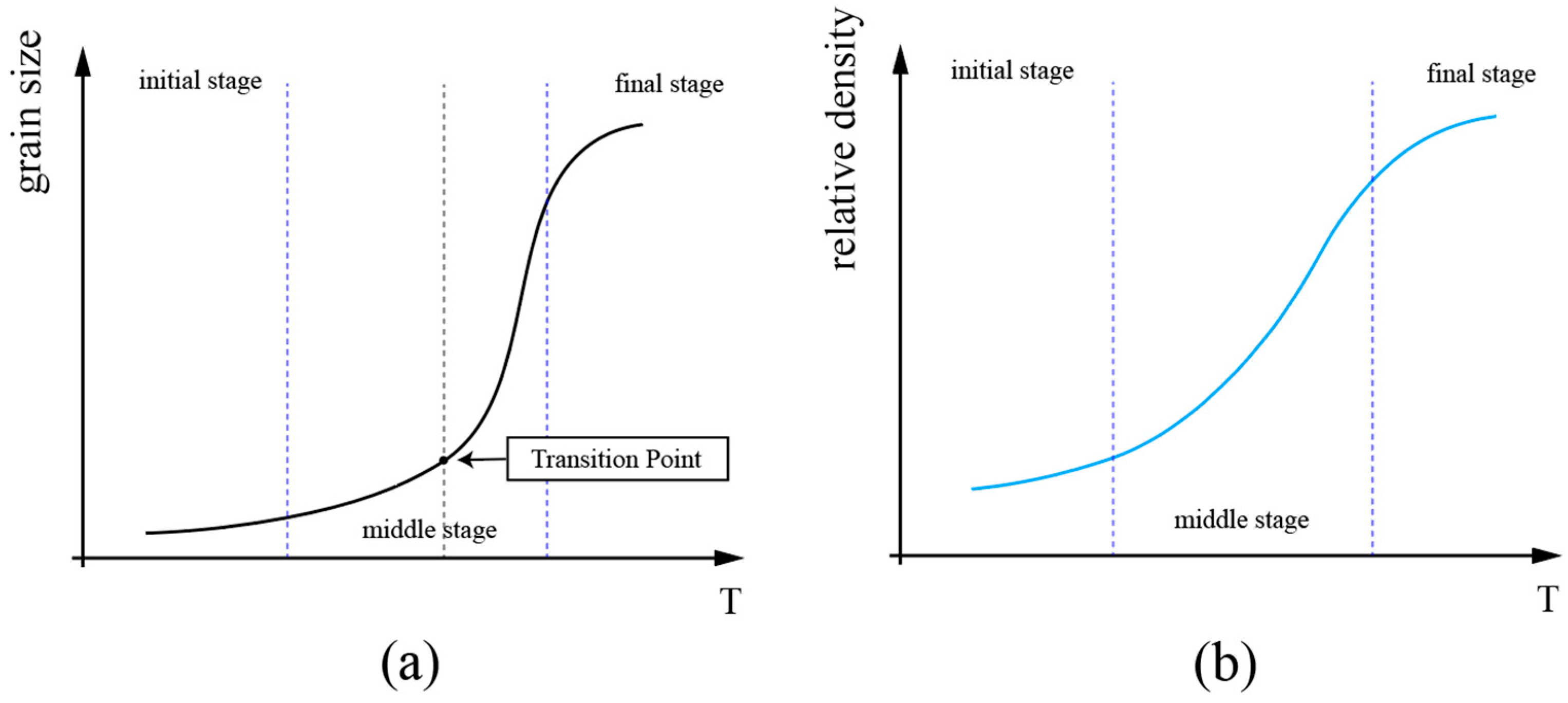

2. Fundamentals of Sintering

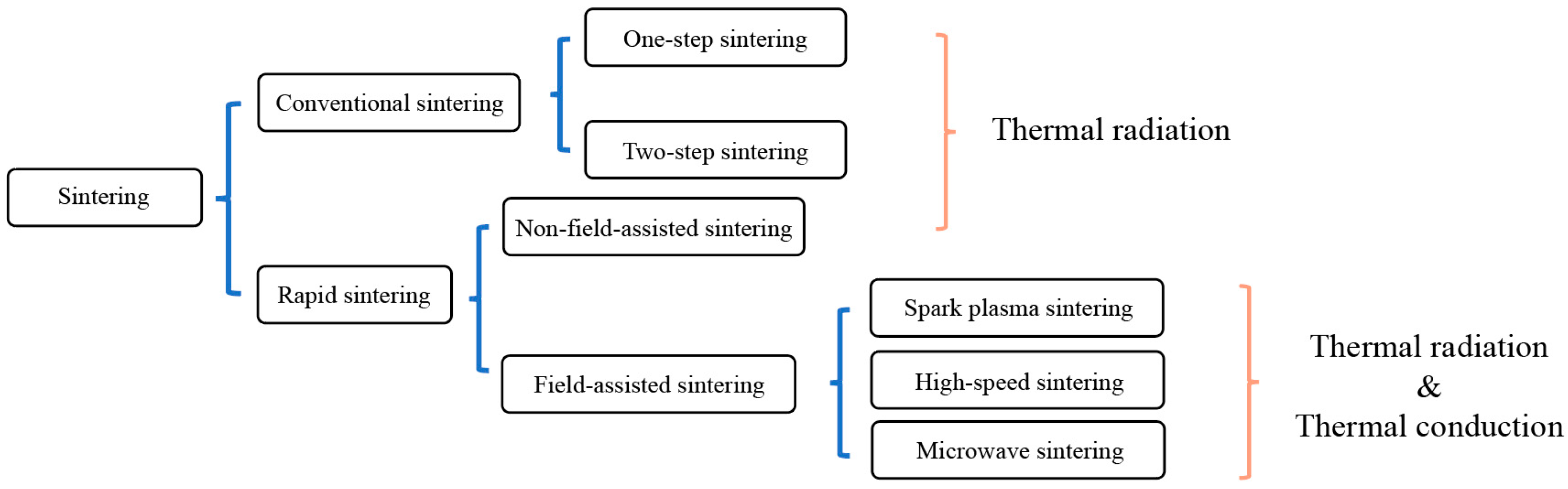

3. Sintering Techniques

3.1. Conventional Sintering

3.2. Rapid Sintering

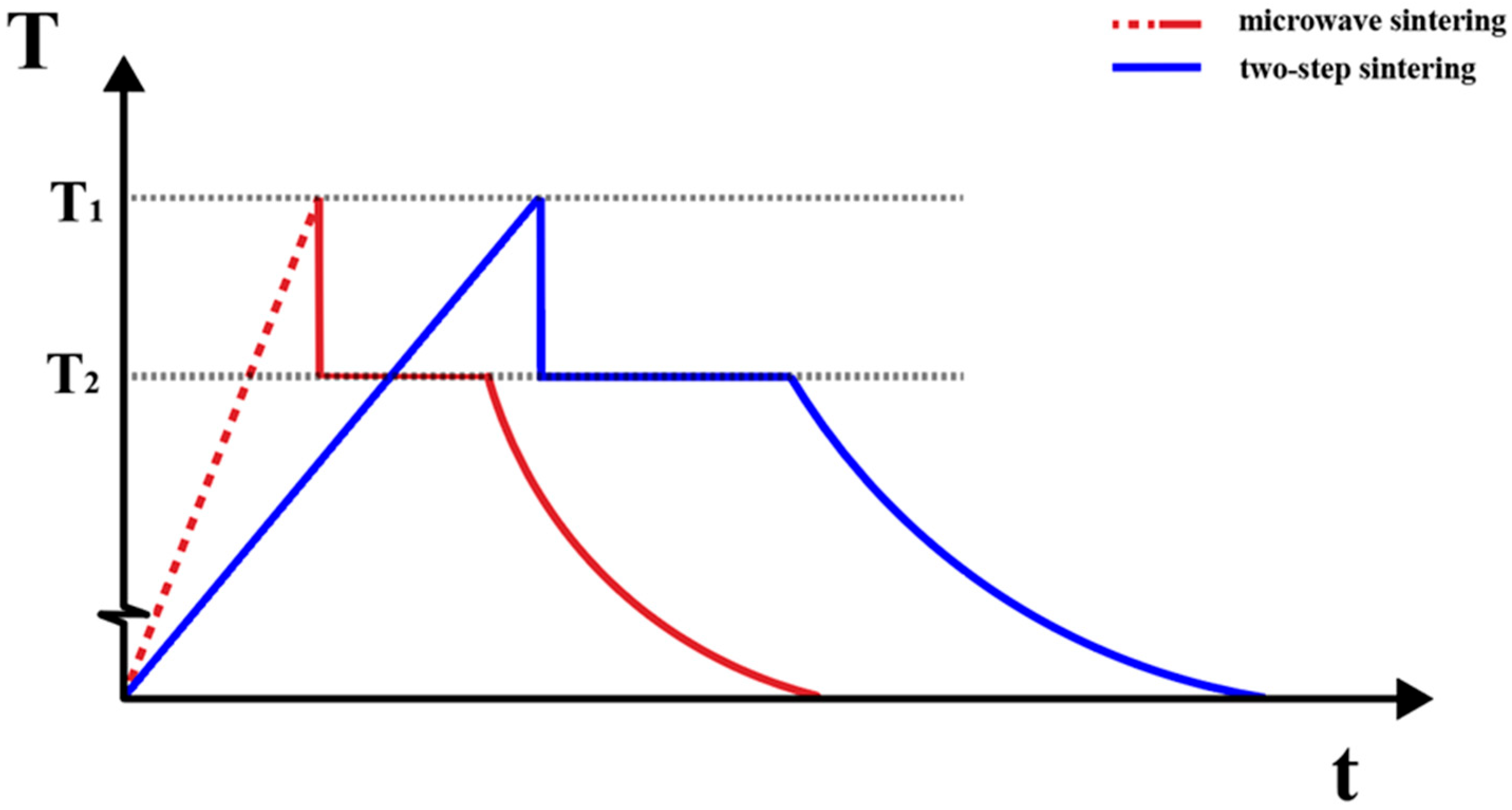

3.2.1. Non-Field-Assisted Sintering

3.2.2. Field-Assisted Sintering

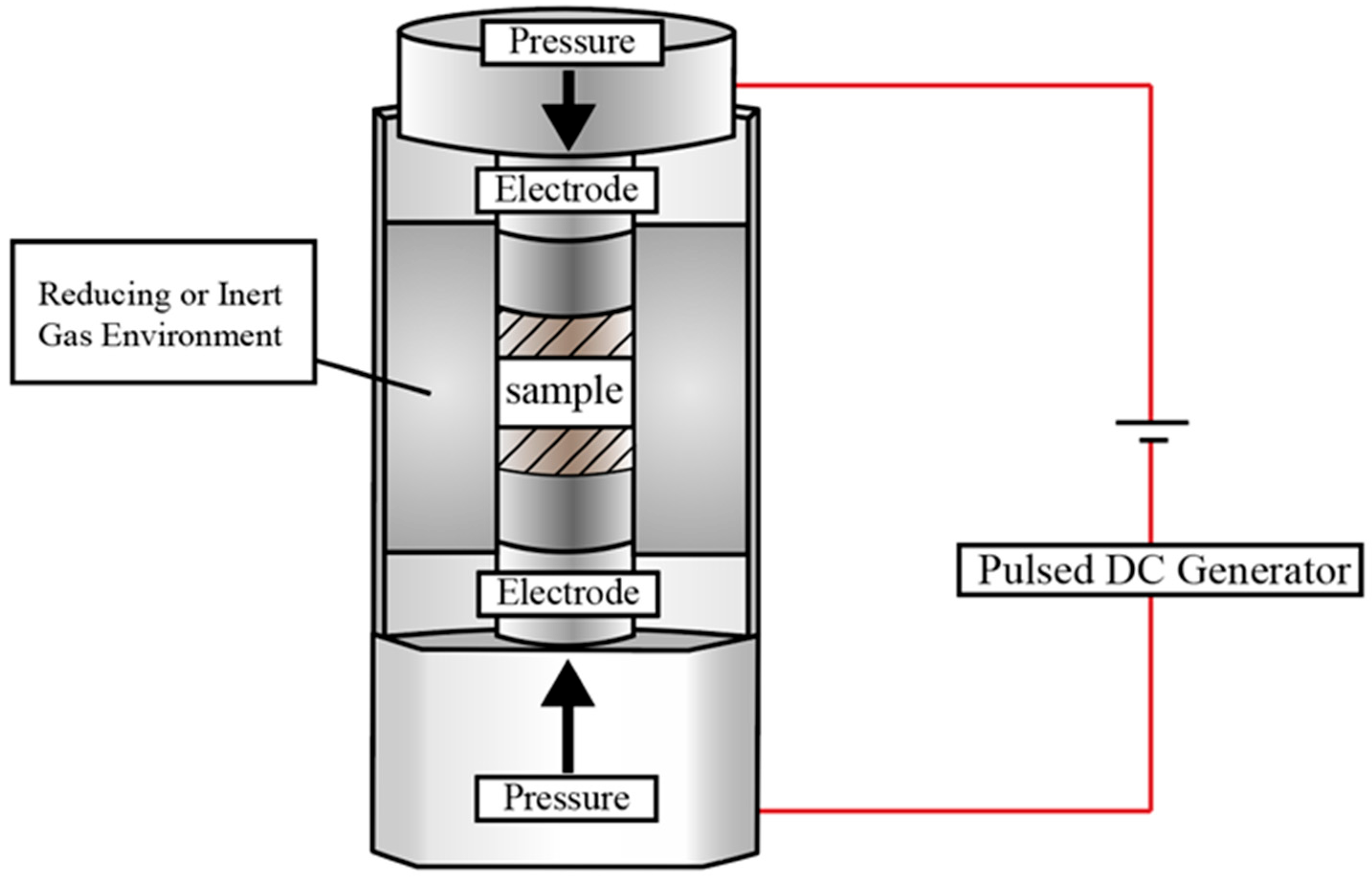

Spark Plasma Sintering

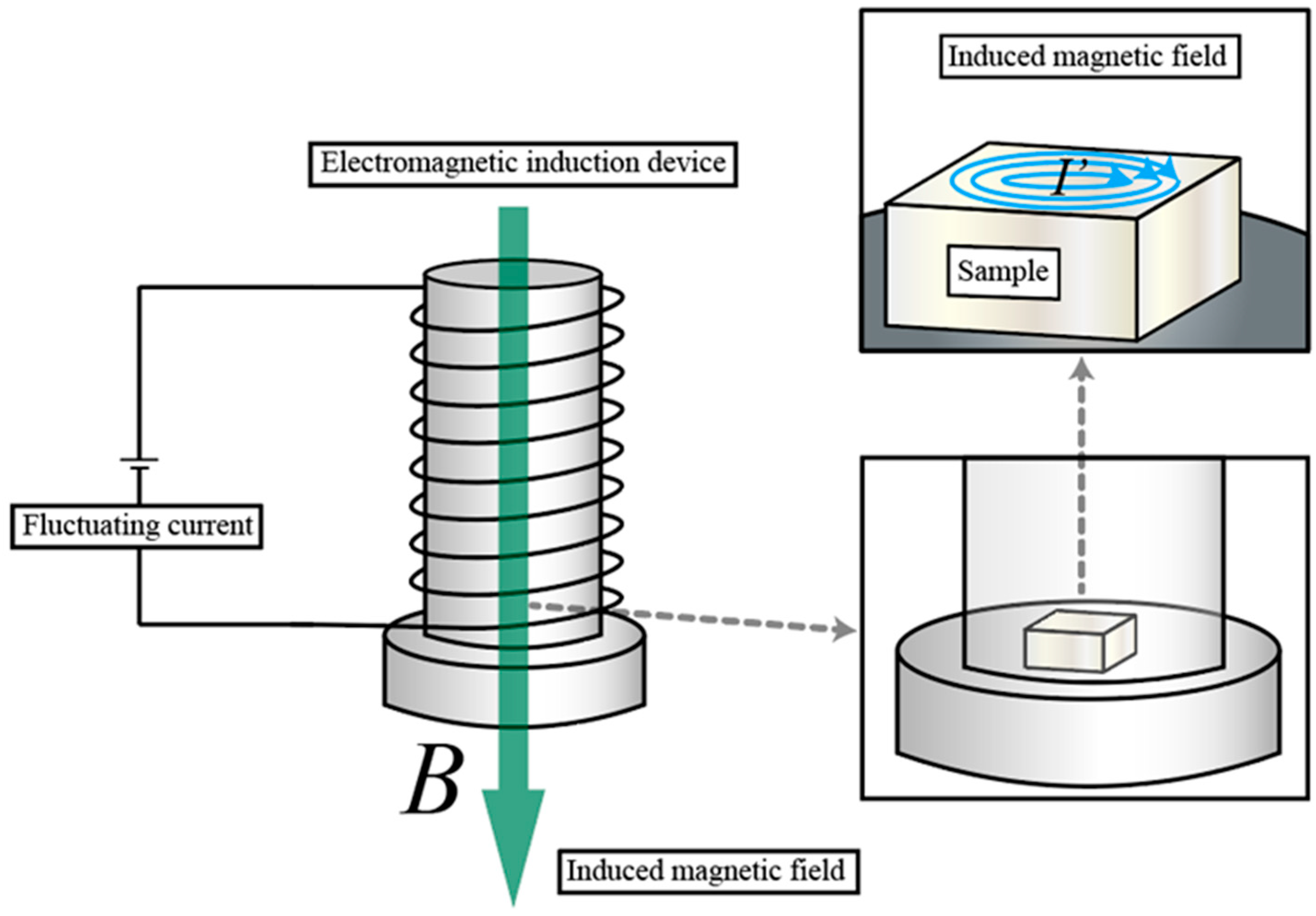

Induction Sintering

Microwave Sintering

4. Effects of Sintering Methods on Properties

4.1. Optical Performance

4.2. Crystal Stability

4.3. Microstructure

4.4. Mechanical Properties

4.4.1. Flexural Strength

4.4.2. Fracture Toughness

4.4.3. Microhardness

4.4.4. Low Temperature Degradation

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Grech, J.; Antunes, E. Zirconia in dental prosthetics: A literature review. J. Mater. Res. Technol. 2019, 8, 4956–4964. [Google Scholar] [CrossRef]

- Fedorov, P.P.; Yarotskaya, E.G. Zirconium dioxide. Review. Kcmf 2021, 23, 169–187. [Google Scholar] [CrossRef]

- de Araújo-Júnior, E.N.S.; Bergamo, E.T.P.; Bastos, T.M.C.; Jalkh, E.B.B.; Lopes, A.C.; Monteiro, K.N.; Cesar, P.F.; Tognolo, F.C.; Migliati, R.; Tanaka, R.; et al. Ultra-translucent zirconia processing and aging effect on microstructural, optical, and mechanical properties. Dent. Mater. 2022, 38, 587–600. [Google Scholar] [CrossRef]

- Manicone, P.F.; Rossi Iommetti, P.; Raffaelli, L. An overview of zirconia ceramics: Basic properties and clinical applications. J. Dent. 2007, 35, 819–826. [Google Scholar] [CrossRef] [PubMed]

- Hajhamid, B.; Bozec, L.; Tenenbaum, H.; De Souza, G.; Somogyi-Ganss, E. Effect of artificial aging on optical properties and crystalline structure of high-translucency zirconia. J. Prosthodont. 2024, 33, 61–69. [Google Scholar] [CrossRef] [PubMed]

- Piconi, C.; Maccauro, G. Zirconia as a Ceramic Biomaterial; Elsevier Ltd.: Oxford, UK, 1999; Volume 20, pp. 1–25. [Google Scholar]

- Matsui, K.; Yoshida, H.; Ikuhara, Y. Nanocrystalline, ultra-degradation-resistant zirconia: Its grain boundary nanostructure and nanochemistry. Sci. Rep. 2014, 4, 4758. [Google Scholar] [CrossRef] [PubMed]

- Borrell, A.; Salvador, M.D.; Rayón, E.; Penaranda-Foix, F.L. Improvement of microstructural properties of 3y-TZP materials by conventional and non-conventional sintering techniques. Ceram. Int. 2012, 38, 39–43. [Google Scholar] [CrossRef]

- Faeghinia, A.; Ebadzadeh, T. Effect of microwave conditions on sintering of hydroxyapatite ceramics. Sci. Sinter. 2020, 52, 469–479. [Google Scholar] [CrossRef]

- Kang, S.L. Sintering: Densification, Grain Growth and Microstructure; Elsevier Butterworth-Heinemann: Oxford, UK, 2005. [Google Scholar]

- Juntavee, N.; Attashu, S. Effect of different sintering process on flexural strength of translucency monolithic zirconia. J. Clin. Exp. Dent. 2018, 10, e821–e830. [Google Scholar] [CrossRef] [PubMed]

- Khaledi, A.A.R.; Vojdani, M.; Farzin, M.; Pirouzi, S. The effect of sintering program on the compressive strength of zirconia copings. J. Dent. 2018, 19, 206–211. [Google Scholar]

- Ahmed, W.M. Evaluation of Distortion of Monolithic Zirconia Crowns Under the Influence of Different Preparation Designs and Sintering Techniques. Ph.D. Thesis, The University of British Columbia, Vancouver, BC, Canada, 2019. [Google Scholar]

- Olevsky, E.A. Theory of sintering: From discrete to continuum. Mater. Sci. Eng. R Rep. Rev. J. 1998, 23, 41–100. [Google Scholar] [CrossRef]

- Lu, K. Nanoparticulate Materials: Synthesis, Characterization, and Processing; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2013. [Google Scholar]

- Lu, K. Sintering of nanoceramics. Int. Mater. Rev. 2008, 1, 21–38. [Google Scholar] [CrossRef]

- Yin, Y.; Xu, J.; Ji, M.; Li, L.; Chen, M. A critical review on sintering and mechanical processing of 3y-TZP ceramics. Ceram. Int. 2023, 49, 1549–1571. [Google Scholar] [CrossRef]

- Mazlan, M.R.; Jamadon, N.H.; Rajabi, A.; Sulong, A.B.; Mohamed, I.F.; Yusof, F.; Jamal, N.A. Necking mechanism under various sintering process parameters—A review. J. Mater. Res. Technol. 2023, 23, 2189–2201. [Google Scholar] [CrossRef]

- Ferrage, L.; Bertrand, G.; Lenormand, P. Dense yttria-stabilized zirconia obtained by direct selective laser sintering. Addit. Manuf. 2018, 21, 472–478. [Google Scholar] [CrossRef]

- Balod, A.O.; Al Sarraf, Z.; Mattie, A.A. Determination of the neck size between powders during sintering process using finite element methods. JoCEF 2020, 1, 29–36. [Google Scholar] [CrossRef]

- Lavagnini, I.R.; Campos, J.V.; Pallone, E.M.J.A. Microstructure evaluation of 3YSZ sintered by two-step flash sintering. Ceram. Int. 2021, 47, 21618–21624. [Google Scholar] [CrossRef]

- Jansen, J.U.; Lümkemann, N.; Letz, I.; Pfefferle, R.; Sener, B.; Stawarczyk, B. Impact of high-speed sintering on translucency, phase content, grain sizes, and flexural strength of 3y-TZP and 4y-TZP zirconia materials. J. Prosthet. Dent. 2019, 122, 396–403. [Google Scholar] [CrossRef] [PubMed]

- Kauling, A.E.; Güth, J.F.; Erdelt, K.; Edelhoff, D.; Keul, C. Influence of speed sintering on the fit and fracture strength of 3-unit monolithic zirconia fixed partial dentures. J. Prosthet. Dent. 2020, 124, 380–386. [Google Scholar] [CrossRef]

- Denkena, B.; Breidenstein, B.; Busemann, S.; Lehr, C.M. Impact of hard machining on zirconia based ceramics for dental applications. Procedia CIRP 2017, 65, 248–252. [Google Scholar] [CrossRef]

- Oghbaei, M.; Mirzaee, O. Microwave versus conventional sintering: A review of fundamentals, advantages and applications. J. Alloys Compd. 2010, 494, 175–189. [Google Scholar] [CrossRef]

- Luz, J.N.; da Rosa Kaizer, M.; de Carvalho Ramos, N.; Anami, L.C.; Thompson, V.P.; Saavedra, G.D.S.F.A.; Zhang, Y. Novel speed sintered zirconia by microwave technology. Dent. Mater. 2021, 37, 875–881. [Google Scholar] [CrossRef]

- Ahsanzadeh-Vadeqani, M.; Razavi, R.S. Spark plasma sintering of zirconia-doped yttria ceramic and evaluation of the microstructure and optical properties. Ceram. Int. 2016, 42, 18931–18936. [Google Scholar] [CrossRef]

- Salamon, D.; Maca, K.; Shen, Z. Rapid sintering of crack-free zirconia ceramics by pressure-less spark plasma sintering. Scr. Mater. 2012, 66, 899–902. [Google Scholar] [CrossRef]

- Fregeac, A.; Ansart, F.; Selezneff, S.; Estournès, C. Relationship between mechanical properties and microstructure of yttria stabilized zirconia ceramics densified by spark plasma sintering. Ceram. Int. 2019, 45, 23740–23749. [Google Scholar] [CrossRef]

- Yousry, M.A.; Hammad, I.A.; El Halawani, M.T.; Aboushelib, M.N. Effect of sintering time on microstructure and optical properties of yttria-partially stabilized monolithic zirconia. Dent. Mater. 2023, 39, 1169–1179. [Google Scholar] [CrossRef]

- Jerman, E.; Wiedenmann, F.; Eichberger, M.; Reichert, A.; Stawarczyk, B. Effect of high-speed sintering on the flexural strength of hydrothermal and thermo-mechanically aged zirconia materials. Dent. Mater. 2020, 36, 1144–1150. [Google Scholar] [CrossRef]

- Al-Haj Husain, N.; Özcan, M.; Dydyk, N.; Joda, T. Conventional, speed sintering and high-speed sintering of zirconia: A systematic review of the current status of applications in dentistry with a focus on precision, mechanical and optical parameters. JCM 2022, 11, 4892. [Google Scholar] [CrossRef]

- Chao, M.; Ning, L.; Zhikai, W.; Jing, T.; Jiazhen, Y. Influence on microstructure of dental zirconia ceramics prepared by two-step sintering. West. China J. Stomatol. 2013, 31, 496–499. [Google Scholar] [CrossRef]

- Mazaheri, M.; Simchi, A.; Golestani-Fard, F. Densification and grain growth of nanocrystalline 3y-tzp powder compacts during two-step sintering. In Proceedings of the 2nd Conference on Nanostructure, Kish University, Kish Island, Iran, 11–14 March 2008. [Google Scholar]

- Liu, W.L. Advanced Ceramic Processing, 1st ed.; Wuhan University of Technology Press: Wuhan, China, 2004. [Google Scholar]

- Grech, J.; Antunes, E. Optimization of two-step sintering conditions of zirconia blanks for dental restorations. Ceram. Int. 2020, 46, 24792–24798. [Google Scholar] [CrossRef]

- Chen, I.W.X. Sintering dense nanocrystalline ceramics without final-stage grain growth. Nature 2000, 404, 168–171. [Google Scholar] [CrossRef]

- Wang, S.F.; Zhang, J.; Luo, D.W.; Gu, F.; Tang, D.Y.; Dong, Z.L.; Tan, G.E.; Que, W.X.; Zhang, T.S.; Li, S.; et al. Transparent ceramics: Processing, materials and applications. Prog. Solid. State Chem. 2013, 41, 20–54. [Google Scholar] [CrossRef]

- Rajabi, J.; Muhamad, N.; Sulong, A.B. Effect of nano-sized powders on powder injection molding: A review. Microsyst. Technol. 2012, 18, 1941–1961. [Google Scholar] [CrossRef]

- Olevsky, E.A. Field-Assisted Sintering: Science and Applications; Springer International Publishing AG: Cham, Switzerland, 2018. [Google Scholar]

- Hu, Z.Y.; Zhang, Z.H.; Cheng, X.W.; Wang, F.C.; Zhang, Y.F.; Li, S.L. A review of multi-physical fields induced phenomena and effects in spark plasma sintering: Fundamentals and applications. Mater. Des. 2020, 191, 108662. [Google Scholar] [CrossRef]

- Kang, S.L. What we should consider for full densification when sintering. Materials 2020, 13, 3578. [Google Scholar] [CrossRef]

- Tran, T.B. Electric Field-Assisted Sintering of Nanocrystalline Hydroxyapatite for Biomedical Applications. Ph.D. Thesis, University of California, Oakland, CA, USA, 2010. [Google Scholar]

- Ahmed, W.M.; Troczynski, T.; McCullagh, A.P.; Wyatt, C.C.; Carvalho, R.M. The influence of altering sintering protocols on the optical and mechanical properties of zirconia: A review. J. Esthet. Restor. Dent. 2019, 31, 423–430. [Google Scholar] [CrossRef] [PubMed]

- Lubauer, J.; Schuenemann, F.H.; Belli, R.; Lohbauer, U. Speed-sintering and the mechanical properties of 3–5 mol% y2o3-stabilized zirconias. Odontology 2023, 111, 883–890. [Google Scholar] [CrossRef] [PubMed]

- Groza, J.R.; Zavaliangos, A. Sintering activation by external electrical field. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 2000, 287, 171–177. [Google Scholar] [CrossRef]

- Grasso, S.; Sakka, Y.; Maizza, G. Electric current activated/assisted sintering (ECAS): A review of patents 1906–2008. Sci. Technol. Adv. Mater. 2009, 10, 53001. [Google Scholar] [CrossRef] [PubMed]

- Wei, X.; Back, C.; Izhvanov, O.; Haines, C.D.; Olevsky, E.A. Zirconium carbide produced by spark plasma sintering and hot pressing: Densification kinetics, grain growth, and thermal properties. Materials 2016, 9, 577. [Google Scholar] [CrossRef]

- Zhang, J.; Zavaliangos, A.; Groza, J.R. Field activated sintering techniques: A comparison and contrast. P/M Sci. Technol. Briefs 2003, 5, 17–21. [Google Scholar]

- Yang, C.C.; Ding, S.J.; Lin, T.H.; Yan, M. Mechanical and optical properties evaluation of rapid sintered dental zirconia. Ceram. Int. 2020, 46, 26668–26674. [Google Scholar] [CrossRef]

- Suárez, M.; Fernández, A.; Menéndez, J.L.; Torrecillas, R.; Kessel, H.U.; Hennicke, J. Challenges and opportunities for spark plasma sintering: A key technology fora new generation of materials. In Sintering Applications; InTech: Nappanee, IN, USA, 2013. [Google Scholar]

- Lawson, N.C.; Maharishi, A. Strength and translucency of zirconia after high-speed sintering. J. Esthet. Restor. Dent. 2020, 32, 219–225. [Google Scholar] [CrossRef]

- Sulaiman, T.A.; Abdulmajeed, A.A.; Donovan, T.E.; Vallittu, P.K.; Närhi, T.O.; Lassila, L.V. The effect of staining and vacuum sintering on optical and mechanical properties of partially and fully stabilized monolithic zirconia. Dent. Mater. J. 2015, 34, 605–610. [Google Scholar] [CrossRef]

- Kaizer, M.R.; Gierthmuehlen, P.C.; Dos Santos, M.B.; Cava, S.S.; Zhang, Y. Speed sintering translucent zirconia for chairside one-visit dental restorations: Optical, mechanical, and wear characteristics. Ceram. Int. 2017, 43, 10999–11005. [Google Scholar] [CrossRef]

- Stawarczyk, B.; Özcan, M.; Hallmann, L.; Ender, A.; Mehl, A.; Hämmerlet, C.H. The effect of zirconia sintering temperature on flexural strength, grain size, and contrast ratio. Clin. Oral. Investig. 2013, 17, 269–274. [Google Scholar] [CrossRef]

- Lee, S.; Choi, G.; Choi, J.; Kim, Y.; Kim, H.K. Effect of high-speed sintering on the marginal and internal fit of CAD/CAM-fabricated monolithic zirconia crowns. Sci. Rep. 2023, 13, 17215. [Google Scholar] [CrossRef]

- Rybakov, K.I.; Olevsky, E.A.; Krikun, E.V. Microwave sintering: Fundamentals and modeling. J. Am. Ceram. Soc. 2013, 96, 1003–1020. [Google Scholar] [CrossRef]

- Amikam Birnboim, D.G.L.C. Comparative study of microwave sintering of zinc oxide at 2.45, 30, and 83 GHz. I. Am. Ceram. Soc. 1998, 81, 1493–1501. [Google Scholar] [CrossRef]

- Wang, J.; Binner, J.; Vaidhyanathan, B.; Joomun, N.; Kilner, J.; Dimitrakis, G.; Cross, T.E. Evidence for the microwave effect during hybrid sintering. J. Am. Ceram. Soc. 2006, 89, 1977–1984. [Google Scholar] [CrossRef]

- Binner, J.; Annapoorani, K.; Paul, A.; Santacruz, I.; Vaidhyanathan, B. Dense nanostructured zirconia by two stage conventional/hybrid microwave sintering. J. Eur. Ceram. Soc. 2008, 28, 973–977. [Google Scholar] [CrossRef]

- Aman, B.; Acharya, S.; Reeja Jayan, B. Making the case for scaling up microwave sintering of ceramics. Adv. Eng. Mater. 2024, 26, 2302065. [Google Scholar] [CrossRef]

- Menezes, R.R.; Kiminami, R.H.G.A. Microwave sintering of alumina–zirconia nanocomposites. J. Mater. Process. Technol. 2008, 203, 513–517. [Google Scholar] [CrossRef]

- Ersoy, N.M.; Aydoğdu, H.M.; Değirmenci, B.Ü.; Çökük, N.; Sevimay, M. The effects of sintering temperature and duration on the flexural strength and grain size of zirconia. Acta Biomater. Odontol. Scand. 2015, 1, 43–50. [Google Scholar] [CrossRef]

- Aziz, A.G.A. The Effect of Artificial Aging (LTD) on the Mechanical and Optical Properties of Conventional and Translucent Zirconia for Fixed Prosthodontics. Ph.D. Thesis, University of Leeds, Leeds, UK, 2018. [Google Scholar]

- Liu, H.; Inokoshi, M.; Xu, K.; Tonprasong, W.; Minakuchi, S.; Van Meerbeek, B.; Vleugels, J.; Zhang, F. Does speed-sintering affect the optical and mechanical properties of yttria-stabilized zirconia? A systematic review and meta-analysis of in-vitro studies. Jpn. Dent. Sci. Rev. 2023, 59, 312–328. [Google Scholar] [CrossRef]

- Salah, K.; Sherif, A.H.; Mandour, M.H.; Nossair, S.A. Optical effect of rapid sintering protocols on different types of zirconia. J. Prosthet. Dent. 2023, 130, 251–253. [Google Scholar] [CrossRef]

- Zhang, F.; Inokoshi, M.; Batuk, M.; Hadermann, J.; Naert, I.; Van Meerbeek, B.; Vleugels, J. Strength, toughness and aging stability of highly-translucent y-TZP ceramics for dental restorations. Dent. Mater. 2016, 32, e327–e337. [Google Scholar] [CrossRef]

- Ebeid, K.; Wille, S.; Hamdy, A.; Salah, T.; El-Etreby, A.; Kern, M. Effect of changes in sintering parameters on monolithic translucent zirconia. Dent. Mater. 2014, 30, e419–e424. [Google Scholar] [CrossRef]

- Jiang, L.; Liao, Y.; Wan, Q.; Li, W. Effects of sintering temperature and particle size on the translucency of zirconium dioxide dental ceramic. J. Mater. Sci. Mater. Med. 2011, 22, 2429–2435. [Google Scholar] [CrossRef]

- Almazdi, A.A.; Khajah, H.M.; Monaco Jr, E.A.; Kim, H. Applying microwave technology to sintering dental zirconia. J. Prosthet. Dent. 2012, 108, 304–309. [Google Scholar] [CrossRef]

- Huang, W.; Qiu, H.; Zhang, Y.; Zhang, F.; Gao, L.; Omran, M.; Chen, G. Microstructure and phase transformation behavior of al2o3–ZrO2 under microwave sintering. Ceram. Int. 2023, 49, 4855–4862. [Google Scholar] [CrossRef]

- Arellano Moncayo, A.M.; Peñate, L.; Arregui, M.; Giner-Tarrida, L.; Cedeño, R. State of the art of different zirconia materials and their indications according to evidence-based clinical performance: A narrative review. Dent. J. 2023, 11, 18. [Google Scholar] [CrossRef]

- Camposilvan, E.; Leone, R.; Gremillard, L.; Sorrentino, R.; Zarone, F.; Ferrari, M.; Chevalier, J. Aging resistance, mechanical properties and translucency of different yttria-stabilized zirconia ceramics for monolithic dental crown applications. Dent. Mater. 2018, 34, 879–890. [Google Scholar] [CrossRef]

- Ji, M.; Xu, J.; Yu, D.; Chen, M.; El Mansori, M. Influence of sintering temperatures on material properties and corresponding milling machinability of zirconia ceramics. J. Manuf. Process. 2021, 68, 646–656. [Google Scholar] [CrossRef]

- Fan, D.; Chen, L. Computer simulation of grain growth and ostwald ripening in alumina-zirconia two-phase composites. J. Am. Ceram. Soc. 1997, 80, 1773–1780. [Google Scholar] [CrossRef]

- Ayata, M.; Albayrak, H.; Eraslan, R. Does fast sintering affect the optical properties, fracture strength, and microstructure of monolithic zirconia? Odontology 2025. [Google Scholar] [CrossRef] [PubMed]

- Kulyk, V.; Duriagina, Z.; Vasyliv, B.; Kovbasiuk, T.; Lyutyy, P.; Vira, V.; Vavrukh, V. Effect of sintering temperature on crack growth resistance characteristics of yttria-stabilized zirconia. Acta Phys. Pol. A 2022, 141, 323–327. [Google Scholar] [CrossRef]

- Chen, P.; Li, X.; Tian, F.; Liu, Z.; Hu, D.; Xie, T.; Liu, Q.; Li, J. Fabrication, microstructure, and properties of 8 mol% yttria-stabilized zirconia (8YSZ) transparent ceramics. J. Adv. Ceram. 2022, 11, 1153–1162. [Google Scholar] [CrossRef]

- Huang, Z.; Wang, L.; Dou, R. Ultrafast high-temperature sintering of 3d-printed yttria-stabilized zirconia: Microstructure and mechanical insights. Ceram. Int. 2025, 51, 43125–43136. [Google Scholar] [CrossRef]

- Cokic, S.M.; Vleugels, J.; Van Meerbeek, B.; Camargo, B.; Willems, E.; Li, M.; Zhang, F. Mechanical properties, aging stability and translucency of speed-sintered zirconia for chairside restorations. Dent. Mater. 2020, 36, 959–972. [Google Scholar] [CrossRef]

- Chevalier, J.; Cales, B.; Drouin, J.M. Low-temperature aging of y-TZP ceramics. J. Am. Ceram. Soc. 1999, 82, 2150–2154. [Google Scholar] [CrossRef]

- Ramesh, S.; Sara Lee, K.Y.; Tan, C.Y. A review on the hydrothermal ageing behaviour of y-TZP ceramics. Ceram. Int. 2018, 44, 20620–20634. [Google Scholar] [CrossRef]

- Cattani-Lorente, M.; Durual, S.; Amez-Droz, M.; Wiskott, H.A.; Scherrer, S.S. Hydrothermal degradation of a 3y-TZP translucent dental ceramic: A comparison of numerical predictions with experimental data after 2 years of aging. Dent. Mater. 2016, 32, 394–402. [Google Scholar] [CrossRef]

- Guo, X.; He, J. Hydrothermal degradation of cubic zirconia. Acta Mater. 2003, 51, 5123–5130. [Google Scholar] [CrossRef]

- Kohal, R.; Douillard, T.; Sanon, C.; Kocjan, A.; Chevalier, J. Signs of in-vivo aging of zirconia from explanted dental implants with porous coating after several years in function. Acta Biomater. 2025, 194, 498–513. [Google Scholar] [CrossRef] [PubMed]

- Aragón-Duarte, M.C.; Nevarez-Rascón, A.; Esparza-Ponce, H.E.; Nevarez-Rascón, M.M.; Talamantes, R.P.; Ornelas, C.; Mendez-Nonell, J.; González-Hernández, J.; Yacamán, M.J.; Hurtado-Macías, A. Nanomechanical properties of zirconia- yttria and alumina zirconia- yttria biomedical ceramics, subjected to low temperature aging. Ceram. Int. 2017, 43, 3931–3939. [Google Scholar] [CrossRef]

- Ban, S.; Sato, H.; Suehiro, Y.; Nakanishi, H.; Nawa, M. Biaxial flexure strength and low temperature degradation of Ce-TZP/Al2O3 nanocomposite and y-TZP as dental restoratives. J. Biomed. Mater. Res. 2008, 87B, 492–498. [Google Scholar] [CrossRef]

- Chevalier, J. Critical effect of cubic phase on aging in 3mol% yttria-stabilized zirconia ceramics for hip replacement prosthesis. Biomaterials 2004, 25, 5539–5545. [Google Scholar] [CrossRef]

- Kocjan, A.; Cotič, J.; Kosmač, T.; Jevnikar, P. In vivo aging of zirconia dental ceramics—Part i: Biomedical grade 3y-TZP. Dent. Mater. 2021, 37, 443–453. [Google Scholar] [CrossRef]

- Cotič, J.; Kocjan, A.; Panchevska, S.; Kosmač, T.; Jevnikar, P. In vivo ageing of zirconia dental ceramics—part II: Highly-translucent and rapid-sintered 3y-TZP. Dent. Mater. 2021, 37, 454–463. [Google Scholar] [CrossRef]

- Pereira, G.K.R.; Venturini, A.B.; Silvestri, T.; Dapieve, K.S.; Montagner, A.F.; Soares, F.Z.M.; Valandro, L.F. Low-temperature degradation of y-TZP ceramics: A systematic review and meta-analysis. J. Mech. Behav. Biomed. Mater. 2016, 55, 151–163. [Google Scholar] [CrossRef] [PubMed]

- Sutharsini, U.; Thanihaichelvan, M.; Ting, C.H.; Ramesh, S.; Tan, C.Y.; Chandran, H.; Sarhan, A.A.; Urriés, I. Effect of two-step sintering on the hydrothermal ageing resistance of tetragonal zirconia polycrystals. Ceram. Int. 2017, 43, 7594–7599. [Google Scholar] [CrossRef]

- Kongkiatkamon, S.; Peampring, C. Effect of speed sintering on low temperature degradation and biaxial flexural strength of 5y-TZP zirconia. Molecules 2022, 27, 5272. [Google Scholar] [CrossRef] [PubMed]

- Uwanyuze, R.S.; Ramesh, S.; King, M.K., Jr.; Lawson, N.; Mahapatra, M.K. Mechanical properties, translucency, and low temperature degradation (LTD) of yttria (3–6 mol%) stabilized zirconia. Ceram. Int. 2021, 47, 15868–15874. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, C.; Liu, X. Research Progress on the Sintering Techniques of Zirconia in Prosthetic Dentistry. Ceramics 2025, 8, 118. https://doi.org/10.3390/ceramics8030118

Yang C, Liu X. Research Progress on the Sintering Techniques of Zirconia in Prosthetic Dentistry. Ceramics. 2025; 8(3):118. https://doi.org/10.3390/ceramics8030118

Chicago/Turabian StyleYang, Chuyue, and Xiaoqiang Liu. 2025. "Research Progress on the Sintering Techniques of Zirconia in Prosthetic Dentistry" Ceramics 8, no. 3: 118. https://doi.org/10.3390/ceramics8030118

APA StyleYang, C., & Liu, X. (2025). Research Progress on the Sintering Techniques of Zirconia in Prosthetic Dentistry. Ceramics, 8(3), 118. https://doi.org/10.3390/ceramics8030118