Abstract

This research aims to develop self-healing geopolymer concrete (SHG) to address the limitations of conventional repair methods, including reduced thermal conductivity and density, while promoting sustainable construction. The incorporation of the self-healing method (SHM), crushed brick (CB), and minced water bottles (F-PET) resulted in reduced thermal conductivity, maintenance costs, and environmental impact. This study investigated the effects of varying amounts of CB, F-PET, and SHM on several properties, including flowability, setting times, densities, ductility index (DI), and mechanical strengths, across 13 different mixtures. Additionally, water absorption (WA%), residual weight loss (WL%), and relative dynamic modulus of elasticity (RDME%) were assessed following freeze–thaw cycles, alongside SEM analysis and thermal transport measurements of the SHG mixtures. The inclusion of up to 50% CB enhanced density and thermal conductivity but negatively affected other properties. In contrast, incorporating 25% F-PET led to modest improvements in mechanical, thermal, and durability properties; however, it did not reduce density and thermal conductivity as effectively as CB. Among the three mixtures containing both CB and F-PET, the formulation with 37.5% CB and 12.5% F-PET exhibited the lowest density (1650 kg/m3) and thermal conductivity (1.083 W/m·K). The self-healing capacity of SHM was demonstrated through its ability to close cracks, facilitated by the deposition of CaCO3 under combined durability conditions. Incorporating 2%, 3%, and 4% SHM into the 37.5% CB and 12.5% F-PET mixture significantly improved key properties, including strength, water absorption, freeze–thaw resistance, SEM characteristics, density, and thermal conductivity. The addition of 4% SHM enhanced the mechanical performance of the geopolymer concrete (GVC) after 28 days, resulting in increases of 27% in compressive strength, 40.5% in tensile strength, 81% in flexural strength, and 61.6% in ductility index. Further, the inclusion of SHM improved density, reduced WA% and WL%, and enhanced RDME% after 300 freeze–thaw cycles. Specifically, thermal conductivity decreased from 1.8 W/m·K to 0.88 W/m·K, and density reduced from 2480 kg/m3 to 1760 kg/m3. Meanwhile, WA%, WL%, and RDME% improved from 3%, 4.5%, and 45% to 2%, 2.5%, and 50%, respectively.

1. Introduction

Concrete is among the most widely used construction materials globally owing to its unique properties, such as high heat capacity (often referred to as calorific capacity), which makes it highly resistant to thermal degradation; excellent compressive strength; wide availability; adaptability; cost-effectiveness; flame resistance; and compatibility with reinforced steel bars [1]. Despite these advantages, the long-term durability of concrete structures is often compromised by crack formation, which significantly reduces structural integrity. Cracks can develop in concrete during its service life, regardless of the mix design or type, due to numerous internal and external factors such as overloading, shrinkage, exposure to severe environmental conditions, or design flaws [2,3,4]. Portland cement (PC), although widely used in the construction industry, is known for its considerable environmental drawbacks [5,6,7].

The production of ordinary Portland cement (OPC) alone contributes to approximately 8% of global CO2 emissions, largely due to its extensive use in construction, which is one of the world’s most resource-intensive industries [5]. As a result, there is a growing demand for sustainable alternatives to OPC that meet structural performance requirements while minimizing environmental harm [8]. In recent years, geopolymers have emerged as a promising substitute for OPC and have been extensively investigated for their potential as eco-friendly cementitious materials [9,10]. Geopolymers enable the production of geopolymer-based concrete, mortars, and pastes, offering a compelling alternative to traditional Portland cement-based materials due to their numerous beneficial properties [11,12,13]. Geopolymer binders are formed by activating aluminosilicate-rich materials, such as clay, using an alkaline (inorganic) solution, which triggers a chemical reaction leading to the polycondensation of aluminosilicate species [14,15,16,17]. This reaction yields a solid, inorganic, three-dimensional network, resulting in a durable and resilient material capable of withstanding harsh environmental conditions.

Recent research has shown that the production of geopolymers generates approximately five times less CO2 emissions than the manufacture of Portland cement [18,19,20]. In addition to their lower carbon footprint, geopolymers have demonstrated superior performance compared to OPC, including higher compressive strength [21,22,23,24], enhanced chemical resistance against acid attacks and other corrosive reactions [25], and reduced permeability, which enhances water resistance and provides better protection for embedded steel reinforcement against corrosion [26]. These advantages make geopolymer mortars an attractive and sustainable alternative to OPC mortars for a wide range of construction applications. Moreover, the use of geopolymer materials offers opportunities to enhance performance while reducing environmental impact. Geopolymer binders are often produced from industrial byproducts, which are commonly generated as waste from various manufacturing processes and are associated with significant disposal and environmental challenges. Utilizing these byproducts in geopolymer production not only mitigates waste management issues but also supports the recycling of substantial volumes of industrial waste, thereby addressing a major environmental concern.

For self-healing concrete to effectively retain healing agents, the presence of pores is essential. Due to its inherent high porosity, lightweight aggregate concrete (LWC) is particularly well-suited for encapsulating and storing self-healing chemicals. When cracks propagate and intersect these pores, lightweight aggregates (LWAs) release the embedded healing agents. In addition to this functionality, LWC offers the advantage of reduced weight, making it suitable for structural applications such as long-span bridges and modern high-rise buildings with parametric designs [27,28]. LWAs have been successfully employed in repairing damaged concrete, confirming their suitability as carriers of healing compounds in self-healing concrete systems. Stuckrath et al. [29] demonstrated this approach by infusing LWAs with both chemical and biological healing solutions.

To evaluate the healing performance of lightweight self-healing concrete (LWSHC), they incorporated crystalline admixtures, a sufflaminate-based expansion agent, and calcium hydrogen phosphate as healing components within the cementitious matrix. In this system, the LWAs served as carriers for a sodium carbonate solution [14]. To further assess the biomineralization-based self-healing capability of LWSHC, Huynh et al. [30] used LWAs as protective carriers for Bacillus subtilis natto. Yu et al. enhanced the self-healing characteristics of lightweight, high-strength engineered cementitious composites by using hollow fly ash microspheres and rubber crumbs as LWAs, which helped reduce density, matrix toughness, and crack width. Multiple studies have explored the self-healing efficiency of LWSHC by impregnating LWAs with various healing substances [31].

A robust bacteria-based self-healing method (SHM) can detect cracks and trigger the release of biological healing agents. SHMs are particularly effective for repairing microcracks in concrete. For surface crack repair, autogenous healing mechanisms have shown notable success. Among ureolytic microorganisms, Bacillus sphaericus has gained considerable attention in bio-cementation techniques [32]. Bacillus sphaericus is commonly found in both terrestrial and marine ecosystems. These Gram-positive, aerobic bacilli are non-pathogenic [33] and exhibit urease activity that functions efficiently in highly alkaline environments [34]. These microorganisms enzymatically convert urea into carbonate and ammonium ions. The resulting ammonia raises the pH, promoting calcite (CaCO3) precipitation within microscopic fractures, thereby effectively sealing the cracks [35]. Integrating sustainable and eco-friendly biomaterials into construction practices offers a viable alternative to traditional chemical-based approaches. This method minimizes environmental and health hazards typically associated with conventional materials [36]. Following the precipitation of CaCO3, a layer of bacterial material accumulates over the concrete cracks [37,38].

Since concrete is naturally alkaline, the introduced bacteria can survive and function effectively in such an environment [39]. The biologically induced CaCO3 not only fills microcracks but also enhances the bond between concrete components such as sand and aggregates [40]. The ability of these microorganisms to precipitate calcite can significantly enhance the durability of concrete. Bacterial concrete (BC) can induce CaCO3 precipitation in highly alkaline conditions by enzymatically breaking down urea into carbonate and ammonium ions [41]. While conventional concrete can seal cracks smaller than 0.3 mm, it fails to self-seal wider cracks, thereby allowing harmful agents to penetrate the structure. In self-healing concrete (SHC), the formation of cracks activates dormant bacterial agents. These agents resume metabolic activity, producing CaCO3, which penetrates and seals the cracks. Once healing is complete, the bacterial agents return to a dormant state. This biological response is immediate; once a crack forms, the bacteria initiate the repair process. This process, known as microbiologically induced calcium carbonate precipitation (MICP), enables bacteria to serve as long-term, autonomous healing agents [42].

This research is not focused solely on developing self-healing geopolymer concrete (SHG) by incorporating sustainable waste materials and bacterial self-healing techniques but rather on developing concrete that not only fulfills its primary functions, resisting compressive and tensile stresses, but also endures extreme environmental conditions. Thirteen variations of self-healing geopolymer concrete (SHG) were manufactured by replacing ordinary Portland cement with fly ash. Crushed lightweight bricks were used as a substitute for natural coarse aggregate, while fine plastic waste was used in place of sand. The target application is the development of durable, lightweight, and thermally insulated construction elements suitable for environmentally conscious and cost-effective building projects. The use of polypropylene fibers was incorporated to improve crack bridging and postcracking ductility, which are essential for optimizing the conditions necessary for effective self-healing.

2. Performance Investigation

2.1. Materials and Methods

The materials used are itemized below. Fly ash (FA) was used as an aluminosilicate material in place of cement. The fly ash (FA) utilized complies with the ASTM C618 standard [43] and is classified as low-calcium (Class F). It possesses a specific gravity of 2.23 and a specific surface area of 3300 cm2/g. The chemical composition of the FA is detailed in Table 1. FA, sourced from Sika, is a by-product with minimal calcium content (below 10%). An alkaline activator solution, comprising 14M NaOH and Na2SiO3 solutions, was employed to initiate the polymerization process. These solutions were used to chemically activate the FA. The monofilament polypropylene fibers consist of ultra-fine individual strands, sourced from Sika, with a diameter of 18 microns and a length of 18 mm. These fibers were selected to meet maximum aggregate size limitations and surface finish criteria, as illustrated in Figure 1. The fibers are coated with a surfactant to improve initial dispersion and bonding, and they conform to ASTM -1116-00 [44].

Table 1.

Chemical composition (% by mass) of FA.

Figure 1.

Monofilament polypropylene fibers photo (PF).

The bacteria used were Bacillus sphaericus DSM 396, as shown in Figure 2. The sample was sourced from MTCC1684 and acquired from the Microbial Type Culture Collection and Gene Bank in Sadat, Egypt. Wheat bran was utilized as a cultivation medium for bacterial cultures. A pure culture was inoculated into a 100 mL flask containing 25 mL of nutrient broth, and the growth conditions were maintained at a temperature of 37 °C while shaken on a 125 rpm orbital shaker. To cultivate the bacteria, a nutrient extract at 5 g/L, beef extract at 5 g/L, and wheat bran at 20 g/L were employed. Calcium lactate, used as the nutrient source, is known as calcium salt pentahydrate and has the chemical formula C6H10CaO6. It is a white powder and exhibits efflorescence. The bacteria were added along with the nutrient source to the alkaline activator solution. Sand was used, according to ASTM C33-03 [45] specifications.

Figure 2.

Bacillus sphaericus DSM 396 bacteria (SHM).

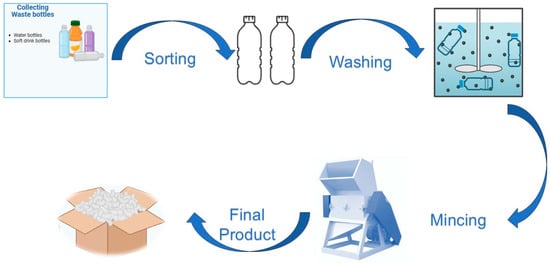

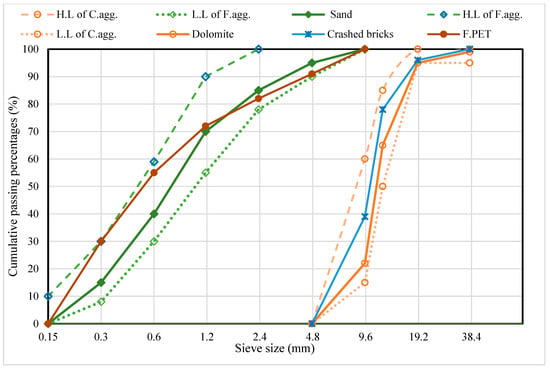

Crushed dolomite (D) and sand (S) were used as a natural coarse and fine aggregate, and crushed lightweight bricks (CB) were used as a lightweight coarse aggregate. These bricks were gathered and subsequently crushed in the lab to produce brick aggregates, as shown in Figure 3. The bricks were manually crushed, then sifted into different size categories, with flaky particles removed. The chemical and physical properties of D, S, and CB are illustrated in Table 2 and Table 3. Minced plastic waste bottles (F-PET), made of polyethylene terephthalate, were used as a lightweight fine aggregate. The PET was gathered from the Mahta landfills in Kafr Elsheikh and thoroughly cleaned to eliminate contaminants. It is important to note that PET is commonly used worldwide to manufacture plastic water bottles, and the PET sourced from Kafr Elsheikh does not differ significantly from that of other regions. Recycled plastic aggregate was created by melting PET at its melting point of 255 °C. The molten PET was then poured onto a tray containing fine aggregate, with additional fine aggregate spread on top, as shown in Figure 4. Figure 5 illustrates the grading curve of the aggregates in relation to the lower and upper limits for fine aggregates (L.L of F.agg., H.L of F.agg.) and coarse aggregates (L.L of C.agg., H.L of C.agg.). It is important to note that all fine and coarse aggregates, such as sand, dolomite, and crushed brick, were employed in a saturated-surface-dry state.

Figure 3.

Crushed coarse lightweight brick.

Table 2.

The chemical properties of course and fine aggregates.

Table 3.

The physical properties of course and fine aggregate.

Figure 4.

Preparation of fine lightweight water bottle (F-PET) by mincing.

Figure 5.

The grain size distribution curves for dolomite, sand, crashed brick, and F-PET are compared with the upper and lower limits.

2.2. Sample Preparation

In this study, thirteen different mixes were prepared, and we divided them into five groups, one of which was the control mix (GVC). Table 4 presents the detailed proportions of these mixes, where C represents the replacement percentage of dolomite with CB, and F represents the replacement percentage of sand with F-PET. This study designed all mixes to set and cure under ambient conditions, unlike traditional fly ash-based geopolymer systems that require elevated-temperature curing. The geopolymer paste was made using a strong alkaline solution (14 M NaOH) and a mix of sodium silicate and NaOH in a ratio of 2.5, which allowed it to react well and harden at room temperature. This formulation facilitates the dissolution of aluminosilicate precursors even without external heating. All specimens were mixed, cast, and cured at an average ambient temperature of 23 ± 2 °C with a relative humidity of 60 ± 5%. Molds were sealed with plastic sheets to minimize moisture loss during the initial 24 h [46]. After demolding, samples were stored under the same ambient conditions until the time of testing. The observed setting behavior and strength development indicate that ambient-temperature curing is effective when appropriate alkaline concentrations and mix proportions are employed.

Table 4.

Components of SHG mixes (kg/m3).

The CB group (CG) consists of three mixtures in which dolomite is replaced with 25%, 37.5%, and 50% CB, as in mixes C25, C37.5, and C50. On the other hand, the F-PET group (FG) contains three mixtures in which sand is replaced with 25%, 50% and 75% F-PET as in mixes (F25, F50, and F75). The third group (CFG) incorporates both CB and F-PET with a total replacement percentage of 50% in three different ratios. The final group, the self-healing mix group (SHMG), includes three mixes that have 2%, 3%, and 4% SHM added to the optional mix F12.5+C37.5. This optimized mix was selected due to its lowest density, reduced thermal conductivity, and other favorable performance characteristics.

The mixtures were prepared using a procedure similar to that of conventional concrete production. Initially, 80% of the alkaline activator solution was blended with the binder materials, followed by the incorporation of both coarse and fine aggregates. The fly ash and aggregates were first dry-mixed in a pan mixer for two minutes. Subsequently, the alkaline solution was added and mixed for five minutes to ensure uniform dispersion and homogeneity of the paste. The remaining 20% of the alkaline solution was combined with the bacterial solution and then added to the mixture, followed by an additional two minutes of mixing to ensure even distribution. After mixing, the fresh concrete was cast into molds with dimensions of 100 × 100 × 100 mm (cubes), 100 × 150 mm (cylinders), and 100 × 100 × 500 mm (beams), as illustrated in Figure 6. The samples were allowed to set for 24 h. After this initial period, the specimens were demolded and subjected to ambient curing for 28 days to facilitate compressive strength testing, in accordance with IS 456:2000 guidelines. All specimens were cured at room temperature without the application of external heat or oven curing.

Figure 6.

The prepared samples of SHG mixes.

2.3. Testing Mechanism

The initial and final setting times of all mixtures were tested in accordance with BS EN 196-3 [47]. The consistency of the self-healing geopolymer (SHG) mix was evaluated using the slump test, conducted as per ASTM C143/C143M-15a [48]. For each mix, three 100 × 100 mm cube specimens were used to determine average values for the following properties: wet, dry, and oven-dried densities; compressive strength; water absorption percentage; and resistance to freezing and thawing. In addition, two cylindrical specimens (100 × 200 mm) and two beam specimens (500 × 100 × 100 mm) were cast to assess indirect tensile strength and flexural strength, respectively. All tests were conducted at 28 days except for compressive strength, which was evaluated at 7, 28, and 56 days. The densities of the different SHG mixes were measured according to BS 12350-6 [49]. Compressive strength, indirect tensile strength, and four-point flexural strength were assessed in accordance with ASTM C39/C39M-17, ASTM C496/C496M-18, and ASTM C1609/C1609M-16 [50,51,52], respectively.

Water absorption and freeze–thaw resistance tests were conducted at 28 days, in accordance with ASTM C1585-13 and ASTM C666/C666M-15 [53,54], respectively. For the freeze–thaw test, the freezing temperature range was maintained between −23 °C and −20 °C, while the thawing temperature range was maintained between 8 °C and 10 °C. Each freeze–thaw cycle was completed within 2 to 4 h, with the thawing phase comprising at least 25% of the total cycle duration. The transition time between freezing and thawing phases did not exceed 10 min. Concrete specimens were removed from the curing chamber and maintained under controlled temperature and humidity conditions, and their initial weight, length, and height were recorded. The specimens were then placed in a freeze–thaw testing apparatus compliant with ASTM standards and subjected to repeated cycles as specified. Upon completion of the designated number of cycles, each specimen was retrieved from the apparatus, and its weight, length, and height were remeasured. These values, along with mass loss, were documented. Additionally, specimens were visually inspected for surface deterioration or crack formation after each cycle. Weight loss (WL%) and relative dynamic modulus of elasticity (RDME%) were calculated to assess durability. WL% was determined using the following formula:

WL% = [(Initial Weight − Weight after freeze-thaw cycles)/Initial Weight] × 100

RDME%, representing the ratio of dynamic modulus of elasticity after freeze–thaw cycles (DMEn) to the initial value (DMEi), was calculated using the following equation:

RDME% = (DMEn/DMEi) × 100

RDME% reflects the stiffness degradation, with a decline over successive cycles indicating reduced elastic performance under low-stress dynamic loading.

Thermal transport properties, including thermal conductivity, thermal diffusivity, and specific heat capacity, were evaluated using the Transient Plane Source (TPS) method. This technique utilizes a planar sensor composed of a double-helix nickel filament embedded between two Kapton insulating layers. During testing, the sensor functions as both a heat source and temperature detector. A brief electrical pulse is applied to the sensor, inducing a temperature increase of a few degrees. The voltage response of the sensor is continuously monitored, allowing for the real-time determination of thermal parameters. This method is comparable to the transient hot wire and hot strip techniques but offers improved flexibility in specimen geometry and thermal contact. To ensure the accuracy of measurements and minimize boundary interference, recording times were carefully limited such that the heat transfer was effectively confined within a region behaving as a semi-infinite solid.

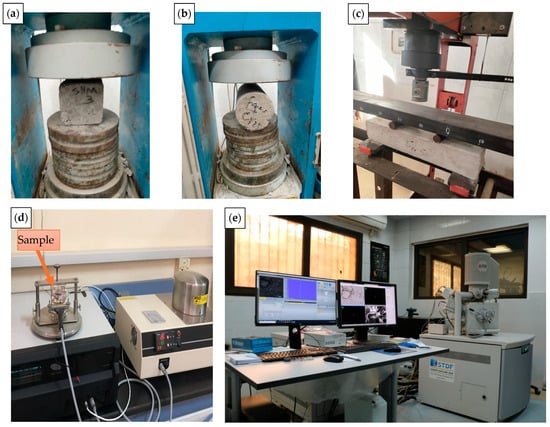

Microstructural analysis played a critical role in this study, offering insights into the relationships between mix constituents and the formation of internal structures. This analysis was used to identify microcracks, pore distribution, and material bonding, which in turn supported the interpretation of results obtained from mechanical testing and pH monitoring. Scanning Electron Microscopy (SEM) was conducted using a JEOL JSM IT-100 microscope. Samples were extracted from the core of previously tested specimens, and a cube section approximately 1 cm3 in size was selected. Each sample was prepared by mechanical polishing with silicon carbide papers of increasing grit sizes, ranging from 500 to 2000. After imaging, the SEM micrographs were analyzed using Python-based image processing techniques, which included particle clustering, shape and orientation quantification, and surface roughness characterization. Photographs of the experimental testing apparatus, including the TPS and SEM setups, are presented in Figure 7.

Figure 7.

Experimental photos of (a) compressive, (b) tensile, and (c) flexural strengths, (d) thermal transport parameters, and (e) analyzing microstructures tests.

3. Results and Discussion

3.1. Fresh Properties

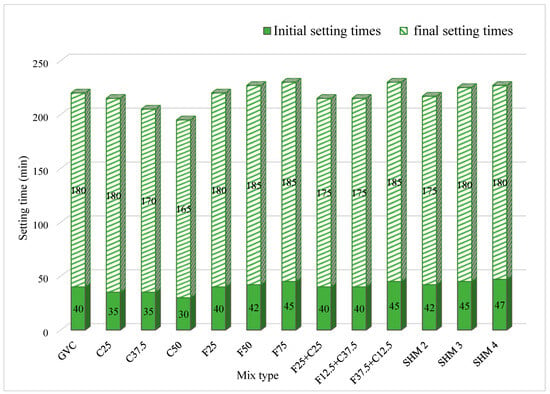

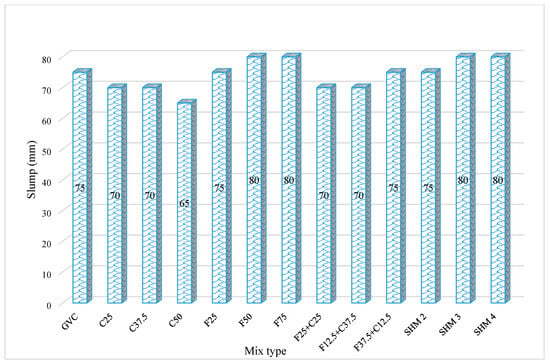

The initial and final setting times (IS and FS) are critical parameters that define the workability window and the commencement of curing for self-healing geopolymer (SHG) mixes, as illustrated in Figure 8. The partial replacement of dolomite (D) with crushed brick (CB) at replacement levels of 25%, 37.5%, and 50% resulted in reductions in the initial setting time by 12.5%, 12.5%, and 25%, respectively. The final setting time remained unchanged at 25% CB replacement but decreased by 5.6% and 8.3% with 37.5% and 50% CB replacement, respectively. Workability, assessed by slump height and shown in Figure 9, also declined with increasing CB content. The slump values decreased by 6.7%, 6.7%, and 13.3% for CB replacement levels of 25%, 37.5%, and 50%, respectively. These reductions in both setting times and consistency are primarily attributed to the higher water absorption capacity (WA%) of CB compared to dolomite. The WA% values for CB and dolomite were 12.5% and 2.1%, respectively.

Figure 8.

Initial and final setting times of SHG mixes incorporation SHM.

Figure 9.

Slump height of SHG mixes incorporating SHM.

To counteract the reduction in available mixing fluid, saturated surface-dry (SSD) CB and dolomite were employed during batching. Nonetheless, the porous and rough-textured surface of CB allowed it to absorb a portion of the alkaline activator solution, thereby reducing the volume of free liquid necessary for geopolymerization reactions. This absorption delayed the dissolution of aluminosilicate species and subsequent polymerization, leading to a decrease in setting time and consistency. These observations are consistent with the findings of Suleiman et al. [55], who reported similar trends in geopolymer mixtures incorporating porous recycled materials.

Conversely, the replacement of sand with fine polyethylene terephthalate (F-PET) at levels of 25%, 50%, and 75% led to increases in the initial setting time (IS) by 0%, 5%, and 12.5%, respectively, and in the final setting time (FS) by 0%, 2.8%, and 2.8%, respectively. Similarly, the slump height exhibited slight increases of 0%, 6.7%, and 6.7%, respectively, with increasing F-PET content. The trends observed in Figure 8 and Figure 9 demonstrate that higher F-PET incorporation is associated with slight improvements in workability and delayed setting times.

At a 25% replacement level, F-PET had no significant effect on either slump or setting times. However, as the replacement level increased to 50% and 75%, modest enhancements were noted. These changes are primarily attributed to the spherical morphology and smooth surface texture of F-PET particles, which reduce internal friction within the mix compared to natural sand, thereby facilitating improved flow and delaying setting. The lower surface roughness and angularity of F-PET particles minimize mechanical interlocking, contributing to extended workability. These findings align with the results reported by Choi et al. [56], who similarly observed enhanced workability and slightly delayed setting times in concrete mixtures incorporating recycled PET aggregates.

Furthermore, the simultaneous incorporation of crushed brick (CB) and fine PET (F-PET) involved a combined 50% replacement of natural coarse and fine aggregates. Among the three combined mixtures, F25+C25 and F12.5+C37.5 demonstrated similar effects on the initial setting time (IS), final setting time (FS), and slump height, indicating a balanced interaction between the two waste-based aggregates. In contrast, the F37.5+C12.5 mix exhibited a notable increase in IS and FS by 12.5% and 2.78%, respectively, while maintaining a balanced effect on slump, suggesting that higher F-PET content may exert a slightly more significant influence on setting behavior due to its smoother surface texture. Overall, the combined use of CB and F-PET did not significantly alter the fresh properties of the geopolymer concrete, indicating a compensatory effect between the high absorption capacity of CB and the low-friction surface of F-PET. Additionally, the incorporation of 2%, 3%, and 4% bacterial content into the F12.5+C37.5 mix slightly enhanced the fresh properties. Specifically, the IS improved from 40 min to 42, 45, and 47 min, while the FS increased from 175 min to 175, 180, and 180 min, and the slump improved from 70 mm to 75, 80, and 80 mm, respectively.

These results are in agreement with the findings of Asamenew et al. [57], who noted that the addition of bacteria can influence setting behavior in two contrasting ways. First, the metabolic activity of the bacteria may alter the local pH and ionic concentrations, promoting the early precipitation of calcium carbonate, which contributes to microstructural densification and initial matrix stiffening, thereby slightly accelerating setting. Conversely, higher bacterial dosages may introduce biological residues or excess water, potentially leading to a delay in setting time if the added content becomes excessive. Thus, a careful optimization of bacterial content is essential to achieve the desired balance between improved fresh properties and early-age performance.

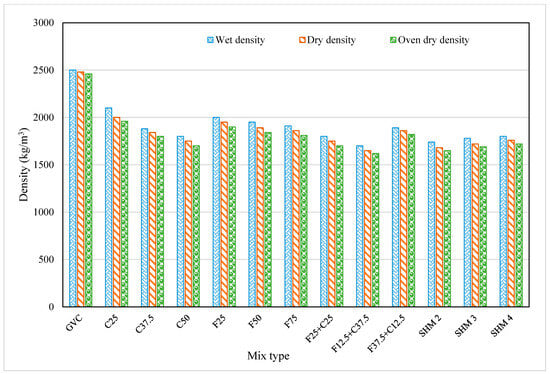

3.2. Densities

The fresh, hardened, and oven-dry densities of the self-healing geopolymer (SHG) mixtures, incorporating various proportions of crushed brick (CB), fine polyethylene terephthalate (F-PET), or both, alongside the addition of self-healing microorganisms (SHM), were evaluated and compared to the geopolymer reference concrete (GVC), as depicted in Figure 10. The GVC exhibited densities of 2500 kg/m3 (fresh), 2480 kg/m3 (hardened), and 2460 kg/m3 (oven-dry). Substituting dolomite with 25%, 37.5%, and 50% CB led to progressive reductions in all three density states, with the greatest reduction observed at the 37.5% replacement level, yielding 1880, 1840, and 1800 kg/m3 for fresh, hardened, and oven-dry densities, respectively. Similarly, replacing sand with F-PET at 25%, 50%, and 75% also resulted in consistent decreases in densities. The 50% F-PET replacement produced values of 1950, 1890, and 1840 kg/m3 for fresh, hardened, and oven-dry states, respectively.

Figure 10.

Fresh, dry, and oven-dry densities of SHG mixes incorporation SHM.

Moreover, mixtures combining both CB and F-PET demonstrated the lowest densities across all conditions, exceeding the reductions achieved by individual substitutions. The mixture F12.5+C37.5 was identified as the lightest formulation, with densities of 1700 kg/m3 (fresh), 1650 kg/m3 (hardened), and 1620 kg/m3 (oven-dry). These significant reductions are primarily attributed to the lower specific gravity of CB and the inherently low density of F-PET, as supported by previous studies [56,58]. The inclusion of self-healing bacteria at 2%, 3%, and 4% concentrations contributed to a gradual increase in all density states. Specifically, the fresh densities increased to 1740, 1780, and 1800 kg/m3, the hardened densities to 1680, 1720, and 1760 kg/m3, and the oven-dry densities to 1650, 1690, and 1720 kg/m3, respectively. These outcomes are in agreement with the observations reported by Buller et al. [59], suggesting that bacterial incorporation may lead to the formation of denser internal microstructures through biomineralization processes, thereby slightly enhancing the composite’s overall density.

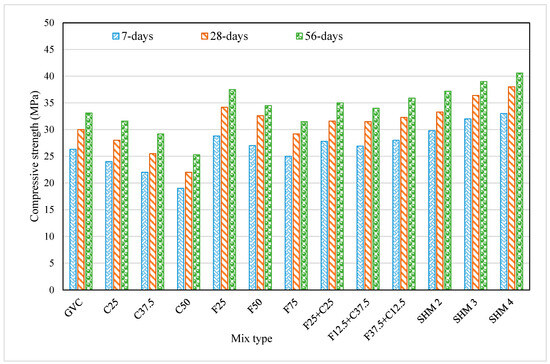

3.3. Compressive Strength

The compressive strengths of self-healing geopolymer (SHG) mixes incorporating various proportions of crushed brick (CB), fine PET (F-PET), or both, along with different dosages of self-healing microorganisms (SHM), were evaluated at 7, 28, and 56 days and compared with the geopolymer reference concrete (GVC), as presented in Figure 11. The compressive strengths of GVC at these respective ages were 26.3 MPa, 31 MPa, and 31 MPa. The replacement of dolomite with 25%, 37.5%, and 50% CB consistently led to declines in compressive strength across all tested ages. The magnitude of reduction increased with higher CB content. For instance, a 37.5% CB replacement resulted in compressive strength decreases of 24.0%, 21.7%, and 23.6% at 7, 28, and 56 days, respectively. A 50% CB replacement further reduced strength by 28.0%, 27.0%, and 24.0% at the corresponding ages.

Figure 11.

Compressive strength of SHG mixes incorporating SHM.

These reductions align with earlier findings [60,61], which reported diminished compressive strength when CB was employed as a partial or full substitute for natural coarse aggregates. The performance deterioration is often attributed to the porous nature and lower mechanical integrity of CB particles, which may compromise the load-bearing efficiency of the matrix and contribute to higher water absorption and weaker interfacial bonding. Nevertheless, it is important to note that under certain conditions, such as optimized mix designs or enhanced curing regimes, some studies [62] have reported improved compressive strength for concrete containing broken brick, possibly due to better matrix densification or pozzolanic reactivity from finely ground brick particles.

In contrast, the incorporation of 25% fine PET (F-PET) as a replacement for sand enhanced compressive strength across all curing ages. Specifically, replacing 25% of sand with F-PET resulted in strength gains of approximately 9.4%, 14.0%, and 13.0% at 7, 28, and 56 days, respectively. This improvement is likely attributed to the moderate increase in workability, reflected by improved slump and setting times, which facilitated better internal matrix formation and particle packing efficiency. The finely shredded F-PET particles are believed to act as micro-fillers, occupying voids within the geopolymer matrix and thereby reducing porosity and enhancing compactness. This higher packing density contributes to a more homogeneous microstructure, which improves load-transfer capability and mitigates stress concentration points, ultimately enhancing the overall mechanical strength of the composite. However, when the F-PET content was increased beyond 25%, specifically up to 75% replacement, a gradual decline in compressive strength was observed. This deterioration is likely due to the low stiffness and hydrophobic nature of PET, which can impair the interfacial bonding between the PET particles and the surrounding geopolymer matrix.

At higher replacement levels, these limitations begin to outweigh the benefits of microstructural densification, leading to reduced mechanical integrity of the composite material. The reduction in compressive strength observed with F-PET content exceeding 25% is primarily attributed to the inert nature and poor bonding characteristics of F-PET. The smooth, hydrophobic surface of PET particles inhibits chemical bonding with the surrounding geopolymer matrix. As the proportion of F-PET increases, these particles interrupt matrix continuity and compromise the load-transfer mechanism, resulting in a decline in structural integrity. Additionally, the low surface energy and non-absorptive properties of F-PET diminish packing efficiency, especially at higher replacement levels. This leads to the formation of voids and weak interfacial transition zones (ITZs), which significantly increase microstructural porosity, a key factor in reducing compressive strength [63,64].

Furthermore, mixtures incorporating both crushed brick (CB) and F-PET exhibited a balanced mechanical response due to the complementary characteristics of these materials. While F-PET slightly enhances workability and contributes to matrix densification at lower dosages, its smooth texture and flexibility generally weaken the interfacial bond. In contrast, CB particles, characterized by their rough, angular surfaces and high water absorption, promote stronger mechanical interlocking and improved adhesion with the geopolymer paste [65]. When used in moderate ratios, the combination of CB and F-PET helps to mitigate the adverse effects of each individual component. Specifically, CB improves packing density and offsets the weak ITZs introduced by F-PET, leading to a more homogeneous and mechanically stable microstructure [64]. This optimized composite configuration leads to a more uniform stress distribution under applied loads.

Scanning Electron Microscopy (SEM) analyses revealed no evidence of new mineral phases or chemical interactions between crushed brick (CB), fine PET (F-PET), and the geopolymer matrix. Consequently, the observed improvements in compressive strength are attributed to physical synergy and enhanced microstructural configuration rather than chemical bonding mechanisms. Among the combined aggregate substitutions, the mix incorporating 25% CB and 25% F-PET exhibited compressive strength increases of 5.6%, 5.3%, and 5.7% at 7, 28, and 56 days, respectively. The 37.5% CB + 12.5% F-PET mixture resulted in improvements of 2.2%, 5%, and 2.7%, while the 12.5% CB + 37.5% F-PET mix achieved the highest gains across all tested blended mixes, with increases of 7.1%, 11%, and 12.4% at the same respective intervals. These findings identify F37.5+C12.5 as the optimum mixture in terms of compressive strength, whereas F12.5+C37.5, despite slightly lower strength, attained the lowest density, qualifying it as a lightweight concrete. These trends align with previous investigations by Rahmani et al. [66] and Dawood et al. [67], which emphasized the effectiveness of low-percentage PET replacements in enhancing mechanical performance.

Moreover, the inclusion of self-healing microorganisms (SHM) at 2%, 3%, and 4% in the F12.5+C37.5 mix further elevated compressive strength by 25.4%, 26.7%, and 23% at 7, 28, and 56 days, respectively. These enhancements corroborate the findings of Buller et al. [59], who demonstrated that bacterial inclusion promotes internal matrix densification and facilitates the healing of microcracks. However, it is important to note that SHM contents exceeding 4% led to strength reductions, likely due to the introduction of excess biological residues or free water that compromised matrix integrity. The microbial-induced calcium carbonate precipitation (MICP) process, facilitated by the presence of water, plays a central role in the self-healing mechanism. To verify this phenomenon, specimens were deliberately cracked under compressive loading, and progressive self-healing was observed weekly for up to eight weeks post-casting, consistent with observations reported by [67].

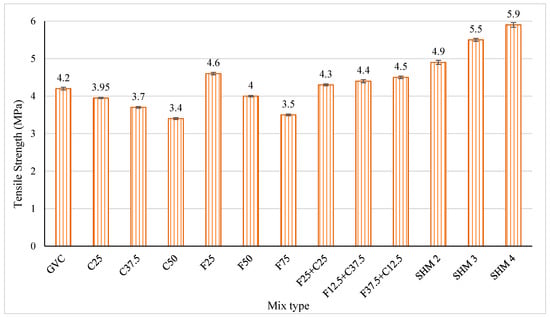

3.4. Indirect Tensile Strength

The indirect tensile strength (ft) at 28 days of self-healing geopolymer (SHG) mixes incorporating varying percentages of crushed brick (CB), fine PET (F-PET), and self-healing microorganisms (SHM) was evaluated and compared with the geopolymer reference concrete (GVC), as presented in Figure 12. The reference ft value for GVC was 4.2 MPa. Replacing dolomite with 25%, 37.5%, and 50% CB resulted in progressive reductions in ft by 6%, 12%, and 19%, respectively, reflecting the trend observed in compressive strength, where increased CB content reduced mechanical performance due to its lower strength and higher porosity relative to natural coarse aggregates. Conversely, the incorporation of 25% F-PET led to a 9.5% increase in tensile strength, attributed to enhanced ductility and improved stress distribution within the geopolymer matrix. However, further increases in F-PET content to 50% and 75% caused reductions in ft, with the 75% F-PET mix exhibiting a 16.67% decrease relative to GVC. These declines are associated with particle clustering, low interfacial bonding, and matrix discontinuities, resulting from the inert, hydrophobic, and smooth surface nature of PET, especially at high replacement levels.

Figure 12.

Indirect tensile strength of SHG mixes incorporating SHM.

Additionally, the mass-to-volume ratio of F-PET compared to sand causes a higher number of PET particles to be introduced at the same volumetric replacement, exacerbating dispersion challenges and further weakening tensile cohesion. Among the hybrid mixes, the 25% CB + 25% F-PET combination achieved a 9.5% increase in ft, while the 12.5% CB + 37.5% F-PET mix showed a 7.1% increase, both benefiting from the complementary physical characteristics of the two materials. In contrast, the 37.5% CB + 12.5% F-PET mix, despite achieving the lowest density, exhibited an ft 2.4% lower than GVC, suggesting that density reductions do not always correlate with strength improvements, particularly when coarse aggregate replacement dominates. The tensile strength gains observed with low F-PET contents are primarily linked to the enhanced ductility, soft surface texture, and reduced internal friction provided by PET particles, which improve crack bridging and strain distribution within the matrix [66].

However, as the PET content increases, reduced bonding, particle aggregation, and microstructural voids compromise the integrity of the interfacial transition zones (ITZs), contributing to mechanical degradation. Significantly, the inclusion of 2%, 3%, and 4% bacteria in the F37.5+C12.5 mix led to notable improvements in tensile strength, with ft increasing by 16.7%, 31%, and 40.5%, respectively. These enhancements are consistent with corresponding gains in compressive strength and align with the findings of Buller et al. [59], who demonstrated that bacterial additions enhance microstructural densification, promote microcrack healing, and facilitate microbially induced calcium carbonate precipitation (MICP). This biochemical activity contributes to improved bonding across the matrix and elevated mechanical performance.

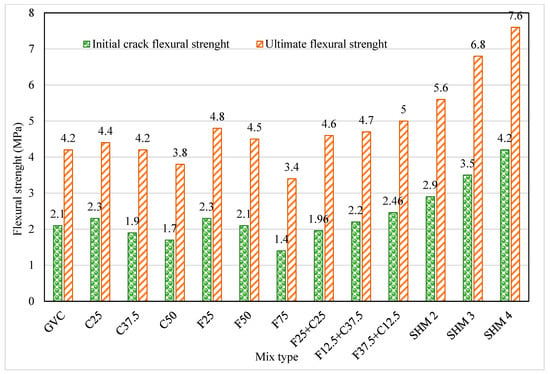

3.5. Flexural Strength

The initial cracking strength (fbi) and ultimate flexural strength (fbu) at 28 days were determined for self-healing geopolymer (SHG) concrete mixes incorporating various proportions of crushed brick (CB), fine PET (F-PET), and self-healing microorganisms (SHM). These results were compared to those of the geopolymer reference concrete (GVC), as illustrated in Figure 13. The reference GVC exhibited fbi and fbu values of 2.1 MPa and 4.2 MPa, respectively. Incorporation of 25% CB led to improvements in both fbi and fbu by 9.5% and 4.8%, respectively. However, increasing CB content to 37.5% and 50% resulted in fbi reductions of 9.5% and 19% and in fbu reductions of 0% and 9.5%, respectively. These trends mirror those observed in compressive strength results and can be attributed to the lower mechanical integrity and higher porosity of crushed brick when used as a coarse aggregate replacement. In contrast, the replacement of 25% sand with F-PET enhanced fbi and fbu by 9.5% and 14.3%, respectively, due to the ductile nature of PET particles, better matrix packing, and improved energy absorption during flexural loading.

Figure 13.

Initial cracking and ultimate flexural strength of SHG mixes incorporating SHM.

However, increasing F-PET content to 50% and 75% resulted in notable reductions. At 75% F-PET, fbi and fbu declined by 33% and 19%, respectively. These reductions align with the declines in compressive and tensile strengths and are consistent with findings by Dawood et al. [66], highlighting the detrimental effects of excessive PET, such as poor interfacial bonding, particle agglomeration, and increased matrix discontinuities. When CB and F-PET were combined, their flexural performance varied depending on their proportions. The F25 + C25 mix decreased fbi by 6.7%, but improved fbu by 9.5%, indicating enhanced ductility despite lower crack resistance. The F12.5 + C37.5 mix improved fbi and fbu by 4.8% and 11.9%, respectively, suggesting that moderate CB content can reinforce PET-modified matrices. Notably, the F37.5 + C12.5 mix demonstrated the most significant improvements, with fbi and fbu increasing by 17% and 19%, respectively. These enhancements indicate a synergistic interaction between the flexible F-PET and the angular, high-absorption CB, resulting in better mechanical interlocking, stress distribution, and flexural toughness.

Moreover, the addition of 2%, 3%, and 4% SHM to the F37.5 + C12.5 mix yielded substantial gains in both fbi and fbu. Specifically, fbi increased by 38%, 67%, and 100%, and fbu rose by 33%, 61%, and 81%, respectively. These improvements are attributed to bacteria-induced calcium carbonate precipitation, which enhances microstructural integrity and actively heals microcracks within the matrix. The presence of moisture initiates bacterial metabolic activity, promoting gradual autogenous healing and matrix densification over time. These findings are consistent with prior research by Buller et al. [59] and support the observed enhancements across other mechanical properties, including compressive and tensile strengths.

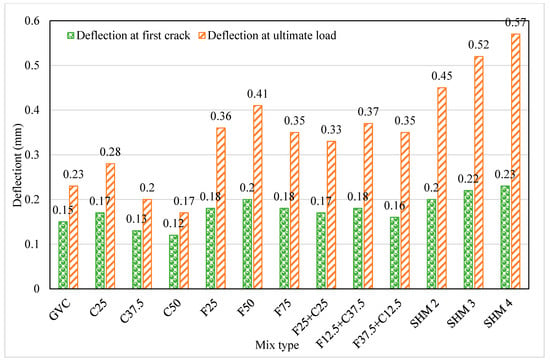

The deflection behavior of SHG mixtures incorporating F-PET, crushed brick (CB), or a combination of both revealed distinct and non-linear trends, reflecting complex interactions between the aggregate replacements and the geopolymer matrix, as illustrated in Figure 14. In the F-PET series, the inclusion of F-PET initially improved ductility and deformation capacity, attributed to the flexible, energy-absorbing nature of PET particles. This improvement peaked at a 50% sand replacement, beyond which ductility declined sharply. The reduction at higher F-PET contents is likely due to loss of matrix integrity, increased internal porosity, and poor interfacial bonding between PET particles and the geopolymer binder. These factors collectively impair stress distribution and energy dissipation, resulting in reduced deformation capacity under load [63,64].

Figure 14.

Initial cracking and ultimate deflection of SHG mixes incorporating SHM.

Conversely, the CB series exhibited a predictable, gradual decrease in ductility as CB content increased. This trend is consistent with the porous structure, angular morphology, and lower mechanical strength of crushed bricks, which adversely affect matrix cohesion, flexibility, and stiffness [62]. The incorporation of CB diminishes the composite’s ability to deform plastically, contributing to brittle failure modes at higher replacement levels. Interestingly, the CB–F-PET (CF) series demonstrated a non-monotonic trend in deflection behavior. For instance, mixes containing 37.5% CB and low F-PET contents (e.g., 6.25%) showed reduced ductility relative to GVC. However, as F-PET content increased moderately (e.g., to 12.5%), deflection capacity increased again. This behavior suggests a compensatory interaction between CB and F-PET: at low F-PET levels, the plastic component is insufficient to offset the structural degradation introduced by CB. Yet at moderate F-PET levels, its contribution to crack bridging, flexural softening, and energy absorption becomes significant, partially restoring and enhancing ductility within an otherwise disrupted matrix.

Furthermore, while the incorporation of self-healing microorganisms (SHM) does not directly enhance ductility in the conventional sense, it significantly improves the durability and resilience of the matrix over time. This enhancement occurs through microbially induced calcium carbonate precipitation (MICP), wherein bacteria metabolize urea and other nutrients to precipitate calcium carbonate. This process fills microcracks and pores, thereby enhancing structural integrity and long-term resistance to mechanical degradation [68]. Consequently, SHM integration contributes indirectly to deflection performance by prolonging crack resistance, mitigating progressive failure, and improving postcrack load recovery.

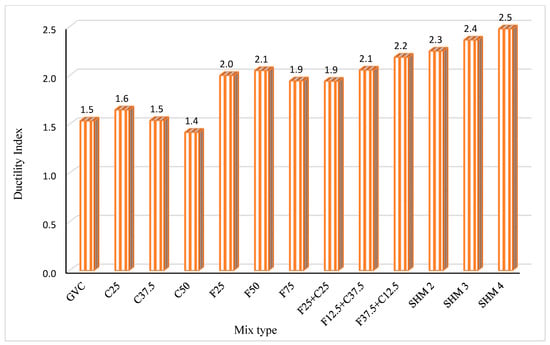

The initial cracking deflection (Δbi), ultimate deflection (Δbu), and ductility index (DI) at 28 days for self-healing geopolymer (SHG) concrete mixes incorporating varying percentages of crushed brick (CB), fine PET (F-PET), or their combinations, with and without self-healing microorganisms (SHM), were evaluated and compared to conventional geopolymer concrete (GVC), as shown in Figure 14 and Figure 15. The GVC control mix exhibited Δbi of 0.15 mm, Δbu of 0.23 mm, and a DI of 1.5. Replacing 25% of dolomite with CB resulted in a modest increase in ductility, likely due to enhanced surface roughness and interfacial bonding. However, further increases in CB content (37.5% and 50%) led to declines in Δbi, Δbu, and DI, attributed to the brittle nature and porous microstructure of crushed brick, which compromises deformation capacity and energy absorption under flexural loading. In contrast, the incorporation of 25% F-PET yielded improvements in all three parameters, Δbi, Δbu, and DI. Enhanced results were also observed at 50% F-PET despite an associated reduction in flexural strength at this replacement level. This improvement in deflection behavior is attributed to the flexible and ductile characteristics of PET particles, which enhance crack bridging and deformation capacity.

Figure 15.

Ductility index of SHG mixes incorporating SHM.

However, increasing F-PET content to 75% led to reductions in Δbi, Δbu, and DI, in agreement with the observed deterioration in flexural strength. These trends align with previous findings by Sabar and Dawood [69]. The combined use of CB and F-PET produced favorable effects on deflection behavior and ductility. Notably, the F37.5 + C12.5 mix demonstrated the highest ductility, showing the best balance between strength and deformability among all tested mixes. This synergistic effect can be attributed to the complementary roles of CB (enhancing mechanical interlocking) and F-PET (enhancing flexibility and crack distribution control). Furthermore, the addition of self-healing microorganisms (SHM) significantly enhanced Δbi, Δbu, and DI. Increasing the SHM content to 4% led to the most pronounced improvements, with Δbi, Δbu, and DI increasing by 53%, 147.8%, and 61.6%, respectively, compared to the reference mix. These enhancements are linked to the microbially induced calcium carbonate precipitation (MICP), which seals microcracks and reinforces the matrix, thereby improving both flexural strength and postcracking ductility [70]. The failure modes, illustrated in Figure 16, confirm these findings. Specimens with 3% and 4% SHM exhibited more distributed cracking patterns and delayed failure, indicating improved energy dissipation and higher ductility, in line with the increased DI values observed.

Figure 16.

Flexural failure modes of SHG mixes incorporating SHM.

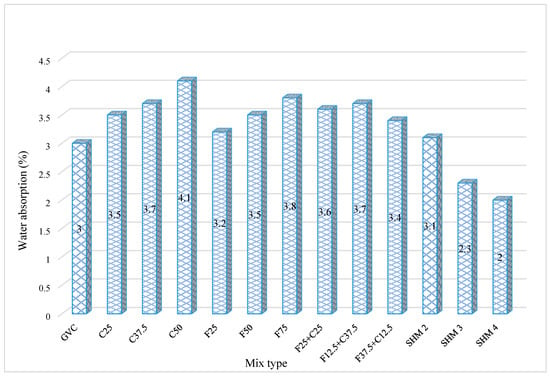

3.6. Water Absorption

The ASTM C1585 technique was employed to determine water absorption in both alternately healed and non-healed SHG samples. The capillary pores in the mixtures were directly correlated with their water absorption capacity. The extent of crack closure in relation to water infiltration was evaluated through the water absorption test. The results for water absorption percentage (WA%) at 28 days for SHG mixes incorporating various percentages of CB, F-PET, or both, as well as the addition of SHM, were measured and compared with GVC (as shown in Figure 17). The WA% of GVC was 3%. The incorporation of 25%, 37.5%, and 50% CB increased the WA% to 3.5%, 3.7%, and 4.1%, respectively. Replacing 25%, 50%, and 75% of sand with F-PET increased the WA% to 3.2%, 3.5%, and 3.8%, respectively. The results for the combination of 25% CB and 25% F-PET did not align with previous findings, whereas the other combinations were consistent with earlier results. These findings are in agreement with those reported by Kumar [71] and Dawood et al. [66].

Figure 17.

Water absorption of SHG mixes incorporating SHM, taken at 28 days.

When PET aggregate was substituted for sand or CB replaced dolomite the increase in WA% was attributed to the sharp edges and irregular shapes of PET and CB aggregates, which resulted in increased voids and porosity within the concrete matrix, particularly adjacent to the internal pores of CB. The incorporation of both materials, F25+C25, F12.5+C37.5, and F37.5+C12.5, increased WA% to 3.6%, 3.7%, and 3.4%, respectively. Moreover, the incorporation of tested bacteria at 2%, 3%, and 4% into the selected mix led to a reduction in WA%, with greater reductions observed as the bacterial concentration increased, reaching 3.1%, 2.3%, and 2.0%, respectively. While the addition of CB and F-PET increased the WA% of SHG, the incorporation of bacteria significantly decreased it. This reduction is attributed to the bacteria, when activated solely by water, enhancing the internal matrix of the concrete and effectively sealing fissures through the formation of calcium carbonate. The bacteria are believed to interact with the entire surface of the sample, generating CaCO3, which leads to lower water absorption due to enhanced pore closure. Additionally, crack-healing phenomena were observed to develop over time. These results are consistent with the findings of Buller et al. [59] and align with the compressive strength trends.

3.7. The Weight Loss Percentage and Relative Dynamic Modulus of Elasticity (RDMR) Due to Thawing and Freezing Cycles

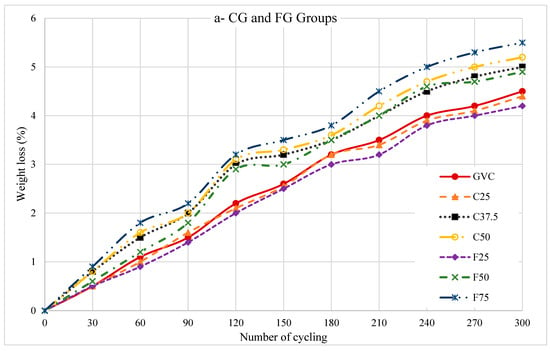

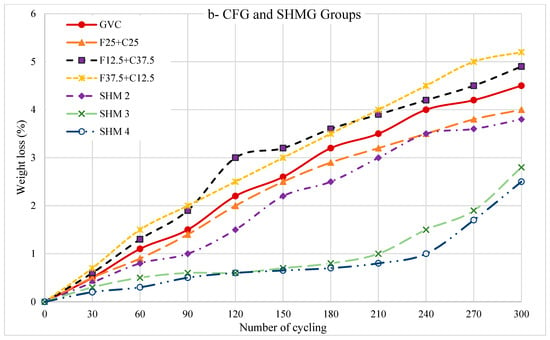

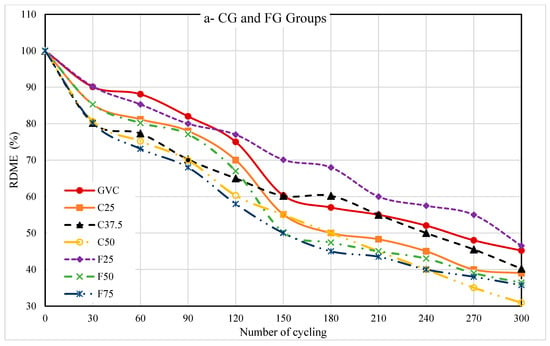

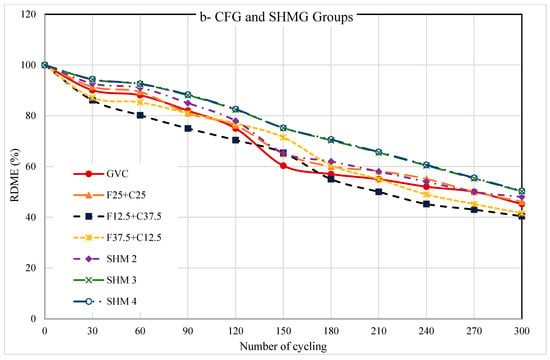

The percentages of weight loss (WL%) and relative dynamic modulus of elasticity (RDME%) for SHG samples containing various amounts of CB, F-PET, and SHM were measured every 30 freeze–thaw cycles, up to 300 cycles, and are presented in Figure 18 and Figure 19. RDME% was calculated by comparing the dynamic modulus of elasticity after a specific number of freeze–thaw cycles to the original value prior to cycling. The dynamic modulus of elasticity is defined as the ratio of stress to strain under minimal dynamic loading. A decrease in the dynamic modulus with increasing freeze–thaw cycles reflects a reduction in elastic performance.

Figure 18.

Weight loss of SHG concrete mix groups after freeze–thaw cycle exposure compared with GVC mix.

Figure 19.

RDME % of SHG concrete mix groups after freeze–thaw cycle exposure compared with GVC mix.

The results showed that WL% increased and RDME% decreased with an increasing number of freeze–thaw cycles. The incorporation of 25% CB or 25% F-PET slightly enhanced freeze–thaw resistance up to 300 cycles. Specifically, the addition of 25% CB and 25% F-PET reduced WL% from 4.5% to 4.4% and 4.2%, respectively, and slightly improved RDME% after 300 cycles. However, increasing the CB content to 37.5% and 50% resulted in greater weight losses of 5.0% and 5.2%, respectively, and a reduction in RDME% to 35.0% and 30.9%. Similarly, increasing the F-PET content to 50% and 75% led to WL% values of 4.9% and 5.2% and decreased RDME% to 36.4% and 35.7%, respectively. In general, the WL% and RDME% associated with F-PET incorporation were more favorable than those observed with CB at equivalent replacement levels (25% and 50%).

The incorporation of combined replacements, F25+C25, F12.5+C37.5, and F37.5+C12.5, resulted in WL% values of 4.0%, 4.9%, and 5.2% and RDME% values of 46.0%, 40.4%, and 41.6%, respectively, after 300 cycles. Among these, the F25+C25 mix consistently exhibited the lowest WL% across all cycles, reaching 4.0% at 300 cycles, whereas F12.5+C37.5 and F37.5+C12.5 exhibited progressively increasing WL% trends throughout the testing period. The F25+C25 mix was identified as the most effective among all tested CVG, CG, FG, and CFG groups, demonstrating the lowest WL% and highest RDME%. Furthermore, the addition of 2%, 3%, and 4% SHM bacteria significantly improved durability. Compared to the F37.5+C12.5 mix, bacterial incorporation reduced WL% from 4.9% to 3.8%, 2.8%, and 2.5% and increased RDME% from 40.4% to 48.0%, 50.2%, and 50.3%, respectively.

Using F-PET as a partial replacement for sand in small proportions can enhance the strength of the cementitious mixture due to its rough surface texture resulting from the mincing process. However, under freeze–thaw cycling conditions, temperature fluctuations in recycled brick aggregate concrete occur more gradually, which delays the formation and melting of ice. In contrast, rapid temperature changes can lead to uneven thermal expansion and contraction within the concrete, thereby increasing internal stresses and the potential for damage [72]. Nevertheless, increasing the replacement levels of F-PET or CB beyond 25% has an adverse effect, reducing both mechanical properties and durability. At higher contents, CB and F-PET may exhibit insufficient adhesion to the cement paste, resulting in weak interfacial bonding and diminished cohesiveness within the concrete matrix. Generally, the reduced density of these additives correlates with a decline in mechanical strength and durability, weakening the particle-to-particle connections essential for structural integrity.

During freeze–thaw cycles, water inside the concrete expands upon freezing and contracts upon thawing, creating internal stresses. If the concrete includes elevated proportions of F-PET or CB, materials that already compromise interfacial bonding and surface integrity, it becomes more vulnerable to cracking and spalling. Additionally, F-PET and CB have thermal expansion coefficients that differ significantly from those of sand and cement paste. These mismatches in thermal behavior induce differential movement during temperature fluctuations, leading to microcracks and reduced overall structural cohesion [21]. Furthermore, both F-PET and CB are predominantly hydrophobic and lack the moisture absorption capacity of natural sand. This impairs their ability to interact effectively with the cement matrix, particularly under freeze–thaw exposure, where uneven moisture distribution increases the likelihood of localized damage. Substituting sand with plastic particles may also reduce the total aggregate volume, thereby compromising packing density and the ability of the concrete to distribute mechanical loads uniformly, which can lead to increased brittleness [22,23].

Moreover, some plastic particles may be chemically incompatible with the highly alkaline environment of concrete. This incompatibility can result in the gradual degradation of plastic components, further compromising the structural integrity of the concrete and increasing its susceptibility to failure during repeated freeze–thaw cycles. The incorporation of bacteria has been shown to improve the internal matrix of concrete and promote effective crack healing. Water plays a critical role in this process by enabling the precipitation of calcium carbonate, which seals fissures. Under experimental conditions, cracks were intentionally induced using a compression machine, and signs of healing became evident within the first week, continuing until the ninth week after casting [67]. One of the key challenges in using recycled plastics in concrete remains the weak interfacial bonding between plastic particles and the cement matrix. These particles often fail to establish strong physical or chemical interactions, resulting in poor adhesion and a reduction in the overall strength and durability of the concrete [73,74,75,76].

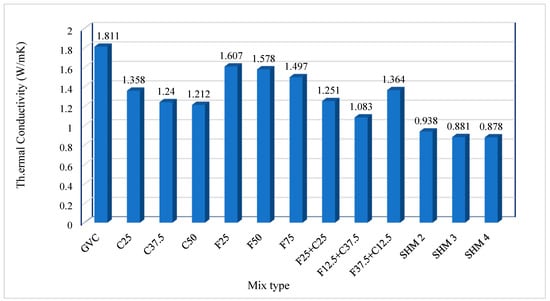

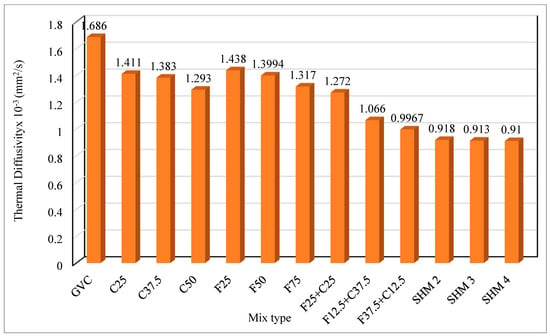

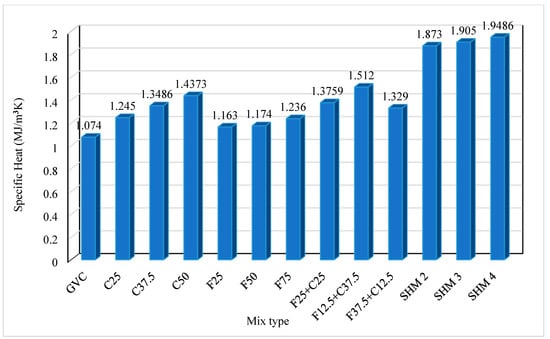

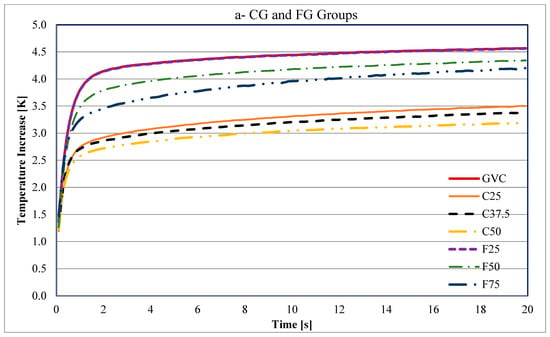

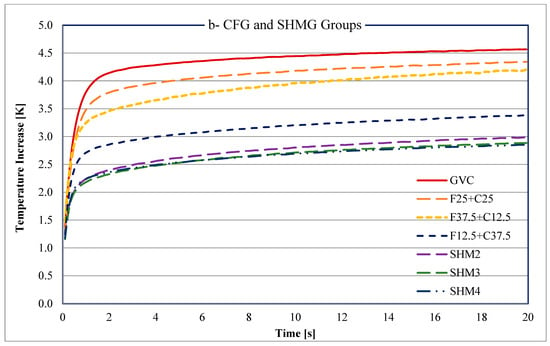

3.8. Thermal Conductivity

Thermal conductivity quantifies the ability of a material’s atoms or molecules to transfer heat, while thermal diffusivity measures the rate at which heat propagates through a material. The specific heat capacity (Cp) refers to the amount of energy required to raise the temperature of one kilogram of the substance by one degree Celsius (°C). The thermal conductivity (k), thermal diffusivity (α), specific heat capacity (Cp), and heat transfer characteristics of the tested samples were measured and are presented in Figure 20, Figure 21, Figure 22 and Figure 23. For the GVC sample, the measured values were as follows: k = 1.811 W/m·K, α = 1.686 mm2/s, and Cp = 1.074 MJ/m3·K. Replacing dolomite with 25%, 37.5%, and 50% CB resulted in reductions in k by 25.0%, 16.3%, and 15.9%, reductions in α by 16.3%, 18.0%, and 23.3%, and increases in Cp by 15.9%, 25.6%, and 33.8%, respectively. Similarly, replacing sand with 25%, 50%, and 75% F-PET led to reductions in k by 11.3%, 12.9%, and 17.3%, reductions in α by 14.7%, 17.0%, and 21.9%, and increases in Cp by 8.3%, 9.3%, and 15.0%, respectively.

Figure 20.

Thermal conductivity of SHG mixes incorporating SHM, taken at 28 days.

Figure 21.

Thermal diffusivity of SHG mixes incorporating SHM, taken at 28 days.

Figure 22.

Specific heat of SHG mixes incorporating SHM, taken at 28 days.

Figure 23.

Heat transient values of SHG mixes incorporating SHM, taken 28 days.

These results demonstrate that the incorporation of CB or F-PET enhanced the thermal insulation performance of the concrete. These findings are consistent with the observed density trends and align with the studies of Zhu and Ahmed et al. [77,78]. Moreover, CB replacement was found to be more effective than F-PET in reducing the thermal conductivity of geopolymer concrete. The incorporation of combined CB and F-PET replacements totaling 50% of the aggregate content produced varying effects on thermal properties; however, all combinations resulted in lower thermal conductivity compared to the GVC mix. Improvements in k, α, and Cp were observed with increasing CB and F-PET content up to a total replacement level of 50%. Among all tested mixes in the CG, FG, and CFG groups, the F12.5+C37.5 combination proved to be the most effective, exhibiting the lowest thermal conductivity. This mix achieved reductions in k and α by 40.2% and 36.8%, respectively, and an increase in Cp by 40.8%, which aligns with the corresponding density results. Furthermore, the incorporation of self-healing material (SHM) significantly reduced both thermal conductivity and diffusivity, with improvements becoming more pronounced as the SHM content increased, up to 4%. These outcomes are in agreement with the findings of Huang et al. [79]. Specifically, the addition of 4% SHM led to a 51.5% reduction in k, a 46.0% reduction in α, and an 81.4% increase in Cp.

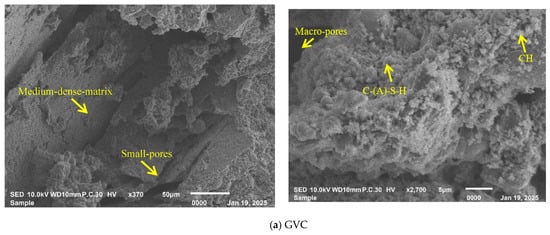

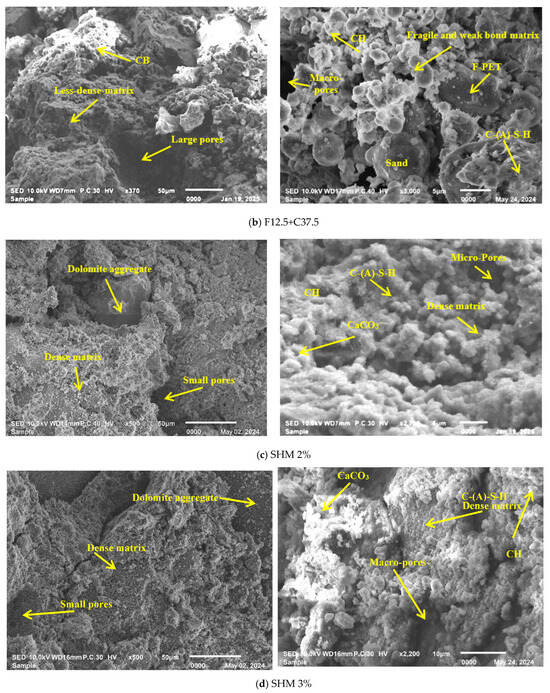

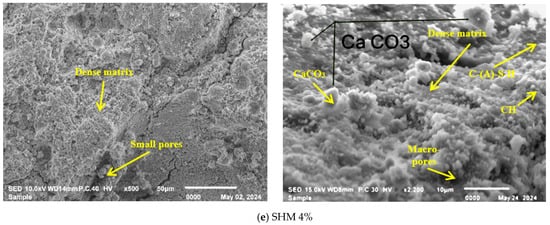

3.9. SEM Analysis

Figure 24 presents the morphologies of five selected mixes at 50× and 3000× magnifications. It is well established that the choice of raw materials significantly influences the microstructure of geopolymers, which in turn affects their thermal and physical properties. The SEM image of the GVC mix highlights the reactivity of fly ash (FA) with alkalis and demonstrates the beneficial influence of monofilament polypropylene fibers. These observations align with previous morphological insights into alkali-activated composites and the formation of geopolymerization products, particularly N-A-S-H gel and C-(A)-S-H phases. The formation of C-(A)-S-H was also confirmed in earlier sections using XRD analysis, consistent with similar experimental findings [80]. The principal elements identified in the geopolymer paste included silicon, calcium, sodium, and aluminum, with only trace amounts of magnesium. Energy-dispersive spectroscopy (EDS) was used to determine the chemical composition of the hydration products [81]. Figure 24a shows the GVC mix’s moderately dense matrix, characterized by macro-pores and a notable amount of C-(A)-S-H. Figure 24b presents the SEM images of a mix where 12.5% of sand was replaced with F-PET and 37.5% of dolomite with CB, resulting in reduced matrix density and modified pore structures.

Figure 24.

SEM of SHG mixes incorporating SHM, taken at 28 days.

Although mechanical and durability results indicate that incorporating 12.5% F-PET had positive effects, the 37.5% CB replacement negatively impacted the matrix, particularly by weakening the interfacial bond with CB particles. The SEM micrographs of the F12.5+C37.5 mix reveal an increased pore volume, which contributed to weight reduction but also weakened the inner matrix. In certain regions, the microstructure appeared loosely connected, suggesting poor cohesiveness. However, the addition of Bacillus sphaericus at 2%, 3%, and 4% to the F12.5+C37.5 mix significantly improved the matrix by filling voids and healing microcracks through the formation of calcium carbonate (CaCO3). These improvements were proportional to the SHM dosage, with 4% SHM exhibiting the most pronounced effect. The development of durable cementitious materials through the integration of Bacillus sphaericus, a self-healing microorganism (SHM), enables crack repair and enhances mechanical strength via biomineralization. This bio-based approach is non-toxic and environmentally compatible, and it enhances the longevity and structural integrity of concrete. Bacillus sphaericus DSM 396 produces the enzyme urease, which catalyzes the hydrolysis of urea into carbon dioxide and ammonia, raising the pH. This increase in alkalinity facilitates the precipitation of carbonate (CO32−) and calcium ions (Ca2+) as CaCO3, thereby promoting calcite formation. The SEM micrographs clearly show CaCO3 precipitates both on the geopolymer matrix and within microcracks, confirming the efficacy of the bacterial self-healing mechanism. Moreover, Bacillus sphaericus DSM 396 has been shown to survive in geopolymer mortars, making it a viable candidate for long-term self-repair applications in cementitious systems.

The healing process in geopolymer concrete involves microbially induced calcium carbonate precipitation (MICP), a biological mechanism wherein Bacillus sphaericus metabolizes nutrients, such as calcium lactate, to produce CaCO3 crystals that seal microcracks. Upon crack formation, water and oxygen infiltrate the concrete, activating dormant bacterial spores embedded within the matrix. The bacteria then produce CO2, which reacts with free calcium ions in the pore solution to precipitate calcium carbonate (CaCO3), thereby filling the cracks [82]. However, sufficient moisture is essential for this process; in its absence, bacterial germination is delayed or inhibited, significantly diminishing the healing efficiency [83]. Additionally, chemical carbonation does not occur on polypropylene (PP) fibers, as PP is chemically inert, non-polar, and hydrophobic. It does not react with CO2 or calcium ions to produce CaCO3, thereby playing no direct role in the chemical self-healing mechanism [84].

4. Conclusions

In this study, self-healing geopolymer (SHG) concrete was investigated using a mix design comprising 500 kg of fly ash and 9 kg of polypropylene fibers (PF). A total of thirteen mixes were prepared and categorized into three groups. Crushed brick (CB) was used to partially replace dolomite, while finely shredded polyethylene terephthalate (F-PET) was used to partially replace sand. In addition, a self-healing microorganism (SHM) was incorporated at 2%, 3%, and 4% by weight. To evaluate the fresh and hardened properties, slump, initial and final setting times, and densities (wet, dry, and oven-dry) were measured for all mixes. The mechanical performance was assessed through tests for compressive strength (fc), splitting tensile strength (ft), flexural strength (ff), and the ductility index. Water absorption (WA%), weight loss (WL%), and relative dynamic modulus of elasticity (RDME%) were evaluated after 300 freeze–thaw cycles to assess durability. In addition, thermal transport properties, including thermal conductivity (k) and thermal diffusivity (α), were measured. To support observations related to material behavior and self-healing performance, scanning electron microscopy (SEM) was employed for microstructural analysis. These comprehensive evaluations led to the following key findings:

- Incorporating 25% F-PET as a partial replacement for sand led to notable improvements in mechanical performance, including increases in compressive strength (fc) by 14%, splitting tensile strength (ft) by 9.5%, flexural strength (ff) by 14.3%, and the ductility index (DI) by 30.4%.

- A slight improvement was also observed in the relative dynamic modulus of elasticity (RDME%). Additionally, reductions were recorded in density, thermal conductivity (k), and thermal diffusivity (α) by 21%, 11.3%, and 14.7%, respectively, indicating enhanced thermal insulation properties.

- Increasing the F-PET replacement level to 50% and 75% resulted in a notable decline in mechanical performance and did not yield significant further improvements in thermal properties or density. This suggests that excessive F-PET content adversely affects the structural integrity and efficiency of the concrete.

- The incorporation of CB, particularly at a 37.5% replacement level, led to reductions in compressive strength (fc), tensile strength (ft), flexural strength (ff), and the ductility index (DI) by 14%, 9.5%, 14.3%, and 30.4%, respectively. It also decreased water absorption (WA%) and reduced the relative dynamic modulus of elasticity (RDME%) from 45% to 35%, indicating compromised mechanical durability.

- CB incorporation significantly improved thermal insulation characteristics, as reflected by reductions in density, thermal conductivity (k), and thermal diffusivity (α) by 25.5%, 31.5%, and 19%, respectively. These results suggest that while CB reduces mechanical strength, it can effectively enhance the thermal performance of geopolymer concrete when used in moderate proportions.

- A combined 50% total aggregate replacement using 37.5% F-PET and 12.5% CB yielded the most balanced performance in terms of mechanical strength, reduced water absorption, and enhanced thermal insulation. Moreover, with the inclusion of 4% SHM, the concrete achieved maximum performance improvements: compressive strength (fc) increased by 26.7%, tensile strength (ft) by 40.5%, flexural strength (ff) by 81%, and the ductility index (DI) improved by 53%.

- Incorporating Bacillus sphaericus DSM 396 at levels ranging from 2% to 4% improved all key mechanical, thermal, and durability properties, including reductions in water absorption and enhanced freeze–thaw resistance. The SHM-enhanced mixes withstood 300 freeze–thaw cycles, reducing weight loss (WL%) to 2.5% and maintaining the relative dynamic modulus of elasticity (RDME%) at 50%, indicating strong resistance to frost-induced degradation. Additionally, water absorption was reduced from 3.7% to 2% at 4% SHM content.

- All of CB, F-PET, and SHM contributed to reductions in thermal conductivity and thermal diffusivity. Notably, the incorporation of 12.5% F-PET, 37.5% CB, and 4% SHM resulted in a thermal conductivity reduction exceeding 50%.

- SEM images revealed enhanced matrix integrity, reduced voids, effective crack filling, and improved interfacial bonding resulting from the synergistic interaction between bacterial activity and the fly ash-based geopolymer matrix. The incorporation of industrial waste materials, CB, F-PET, and SHM, demonstrated the potential to produce durable, robust, and low-carbon concrete.

5. Future Work

- Include performance under aggressive chemical environments, testing for corrosion resistance of embedded steel reinforcement.

- Conduct Life Cycle Assessment (LCA) and Carbon Footprint assessment comparing SHG mixes to traditional concrete and geopolymer variants.

Author Contributions

Conceptualization, T.I.A. and D.E.T.; methodology, T.I.A. and D.E.T.; formal analysis, T.I.A. and D.E.T.; investigation, T.I.A. and D.E.T.; resources, T.I.A.; data curation, D.E.T.; writing—original draft preparation, T.I.A. and D.E.T.; writing—review and editing, T.I.A., A.S.R. and D.E.T.; visualization, A.S.R. and D.E.T. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Acknowledgments

The authors gratefully acknowledge the Materials Strength Laboratory at the Higher Institute of Engineering and Technology, Kafrelsheikh, and its dedicated staff for their support in conducting the mechanical testing. Special thanks are also extended to the Nanotechnology Center at Kafrelsheikh University for facilitating the remaining experimental analyses and providing access to advanced testing equipment.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Li, X.; Wang, C.; Zeng, Y.; Li, P.; Xie, T.; Zhang, Y. Bacteria-assisted preparation of nano α-Fe2O3 red pigment powders from waste ferrous sulfate. J. Hazard. Mater. 2016, 317, 563–569. [Google Scholar] [CrossRef] [PubMed]

- Horszczaruk, E.; Sikora, P.; Cendrowski, K.; Mijowska, E. The effect of elevated temperature on the properties of cement mortars containing nanosilica and heavyweight aggregates. Constr. Build. Mater. 2017, 137, 420–431. [Google Scholar] [CrossRef]

- Luhar, S.; Luhar, I.; Shaikh, F.U.A. A Review on the Performance Evaluation of Autonomous Self-Healing Bacterial Concrete: Mechanisms, Strength, Durability, and Microstructural Properties. J. Compos. Sci. 2022, 6, 23. [Google Scholar] [CrossRef]

- Raza, A.; El Ouni, M.H.; Khan, Q.u.Z.; Azab, M.; Khan, D.; Elhadi, K.M.; Alashker, Y. Sustainability assessment, structural performance and challenges of self-healing bio-mineralized concrete: A systematic review for built environment applications. J. Build. Eng. 2023, 66, 105839. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, R.; Ding, Z. Influence of Crystalline Admixtures and Their Synergetic Combinations with Other Constituents on Autonomous Healing in Cracked Concrete—A Review. Materials 2022, 15, 440. [Google Scholar] [CrossRef]

- Van Mullem, T.; Anglani, G.; Dudek, M.; Vanoutrive, H.; Bumanis, G.; Litina, C.; Kwiecień, A.; Al-Tabbaa, A.; Bajare, D.; Stryszewska, T.; et al. Addressing the need for standardization of test methods for self-healing concrete: An inter-laboratory study on concrete with macrocapsules. Sci. Technol. Adv. Mater. 2020, 21, 661–682. [Google Scholar] [CrossRef]

- Litina, C.; Bumanis, G.; Anglani, G.; Dudek, M.; Maddalena, R.; Amenta, M.; Papaioannou, S.; Pérez, G.; García Calvo, J.L.; Asensio, E.; et al. Evaluation of Methodologies for Assessing Self-Healing Performance of Concrete with Mineral Expansive Agents: An Interlaboratory Study. Materials 2021, 14, 2024. [Google Scholar] [CrossRef] [PubMed]

- Assi, L.; Carter, K.; Deaver, E.; Anay, R.; Ziehl, P. Sustainable concrete: Building a greener future. J. Clean. Prod. 2018, 198, 1641–1651. [Google Scholar] [CrossRef]

- Zha, Y.; Yu, J.; Wang, R.; He, P.; Cao, Z. Effect of ion chelating agent on self-healing performance of Cement-based materials. Constr. Build. Mater. 2018, 190, 308–316. [Google Scholar] [CrossRef]

- Jiang, S.; Wang, X.; Qi, K.; Wan, X. Preparation and performance of a fast-hardening red mud based geopolymer repair mortar complexed with FGD. J. Build. Eng. 2025, 108, 112980. [Google Scholar] [CrossRef]

- Li, D.; Chen, B.; Chen, X.; Fu, B.; Wei, H.; Xiang, X. Synergetic effect of superabsorbent polymer (SAP) and crystalline admixture (CA) on mortar macro-crack healing. Constr. Build. Mater. 2020, 247, 118521. [Google Scholar] [CrossRef]

- Wang, X.; Fang, C.; Li, D.; Han, N.; Xing, F. A self-healing cementitious composite with mineral admixtures and built-in carbonate. Cem. Concr. Compos. 2018, 92, 216–229. [Google Scholar] [CrossRef]

- Tomczak, K.; Jakubowski, J. The effects of age, cement content, and healing time on the self-healing ability of high-strength concrete. Constr. Build. Mater. 2018, 187, 149–159. [Google Scholar] [CrossRef]

- Nguyen Ngoc Tri, H.; Kei-ichi, I.; Chizuru, K. A Study on Biomineralization using Bacillus Subtilis Natto for Repeatability of Self-Healing Concrete and Strength Improvement. J. Adv. Concr. Technol. 2019, 17, 700–714. [Google Scholar] [CrossRef]

- Suleiman, A.R.; Nelson, A.J.; Nehdi, M.L. Visualization and quantification of crack self-healing in cement-based materials incorporating different minerals. Cem. Concr. Compos. 2019, 103, 49–58. [Google Scholar] [CrossRef]

- Snoeck, D.; Dewanckele, J.; Cnudde, V.; De Belie, N. X-ray computed microtomography to study autogenous healing of cementitious materials promoted by superabsorbent polymers. Cem. Concr. Compos. 2016, 65, 83–93. [Google Scholar] [CrossRef]

- Hwalla, J.; El-Hassan, H.; Assaad, J.J.; El-Maaddawy, T. Fiber-reinforced geopolymers made with recycled aggregates for screed flooring and repair applications. Clean. Mater. 2025, 15, 100293. [Google Scholar] [CrossRef]

- Jing, X.; Xianzhi, W.; Junqing, Z.; Xiaoyan, L. Self-Healing of Concrete Cracks by Ceramsite-Loaded Microorganisms. Adv. Mater. Sci. Eng. 2018, 2018, 5153041. [Google Scholar] [CrossRef]

- Han, S.; Choi, E.K.; Park, W.; Yi, C.; Chung, N. Effectiveness of expanded clay as a bacteria carrier for self-healing concrete. Appl. Biol. Chem. 2019, 62, 19. [Google Scholar] [CrossRef]

- Roig-Flores, M.; Moscato, S.; Serna, P.; Ferrara, L. Self-healing capability of concrete with crystalline admixtures in different environments. Constr. Build. Mater. 2015, 86, 1–11. [Google Scholar] [CrossRef]

- Wu, M.; Johannesson, B.; Geiker, M. A review: Self-healing in cementitious materials and engineered cementitious composite as a self-healing material. Constr. Build. Mater. 2012, 28, 571–583. [Google Scholar] [CrossRef]

- Lv, L.; Yang, Z.; Chen, G.; Zhu, G.; Han, N.; Schlangen, E.; Xing, F. Synthesis and characterization of a new polymeric microcapsule and feasibility investigation in self-healing cementitious materials. Constr. Build. Mater. 2016, 105, 487–495. [Google Scholar] [CrossRef]

- Hung, C.-C.; Su, Y.-F.; Hung, H.-H. Impact of natural weathering on medium-term self-healing performance of fiber reinforced cementitious composites with intrinsic crack-width control capability. Cem. Concr. Compos. 2017, 80, 200–209. [Google Scholar] [CrossRef]

- Qiu, J.; Tan, H.S.; Yang, E.-H. Coupled effects of crack width, slag content, and conditioning alkalinity on autogenous healing of engineered cementitious composites. Cem. Concr. Compos. 2016, 73, 203–212. [Google Scholar] [CrossRef]

- Nain, N.; Surabhi, R.; Yathish, S.R.; Krishnamurthy, V.; Deepa, T.; Tharannum, S. Enhancement in strength parameters of concrete by application of Bacillus bacteria. Constr. Build. Mater. 2019, 202, 904–908. [Google Scholar] [CrossRef]

- Deshpande, Y.S.; Hiller, J.E. Pore characterization of manufactured aggregates: Recycled concrete aggregates and lightweight aggregates. Mater. Struct. 2012, 45, 67–79. [Google Scholar] [CrossRef]

- Hasar, U.C.; Eren, N.A.; Ozturk, H.; Izginli, M.; Korkmaz, H.; Cevik, A.; Nis, A.; Irshidat, M.R. Mechanical and Electromagnetic Properties of Self-Compacted Geopolymer Concretes with Nano Silica and Steel Fiber Additives. IEEE Trans. Instrum. Meas. 2022, 71, 8003508. [Google Scholar] [CrossRef]

- Stuckrath, C.; Serpell, R.; Valenzuela, L.M.; Lopez, M. Quantification of chemical and biological calcium carbonate precipitation: Performance of self-healing in reinforced mortar containing chemical admixtures. Cem. Concr. Compos. 2014, 50, 10–15. [Google Scholar] [CrossRef]

- Huang, F.; Zhou, S. A Review of Lightweight Self-Healing Concrete. Materials 2022, 15, 7572. [Google Scholar] [CrossRef]

- Yu, K.; Zhu, H.; Hou, M.; Li, V.C. Self-healing of PE-fiber reinforced lightweight high-strength engineered cementitious composite. Cem. Concr. Compos. 2021, 123, 104209. [Google Scholar] [CrossRef]

- Jonkers, H.M.; Thijssen, A.; Muyzer, G.; Copuroglu, O.; Schlangen, E. Application of bacteria as self-healing agent for the development of sustainable concrete. Ecol. Eng. 2010, 36, 230–235. [Google Scholar] [CrossRef]

- Veerasamy, S.k.; Thangaraj, P.; Vijayakumar, V.N. Comparative studies on strength characteristics of microbial cement mortars. Int. J. ChemTech Res. 2014, 6, 578–590. [Google Scholar]