Recycling Face Mask Fibers in Geopolymer-Based Matrices for Sustainable Building Materials

Abstract

1. Introduction

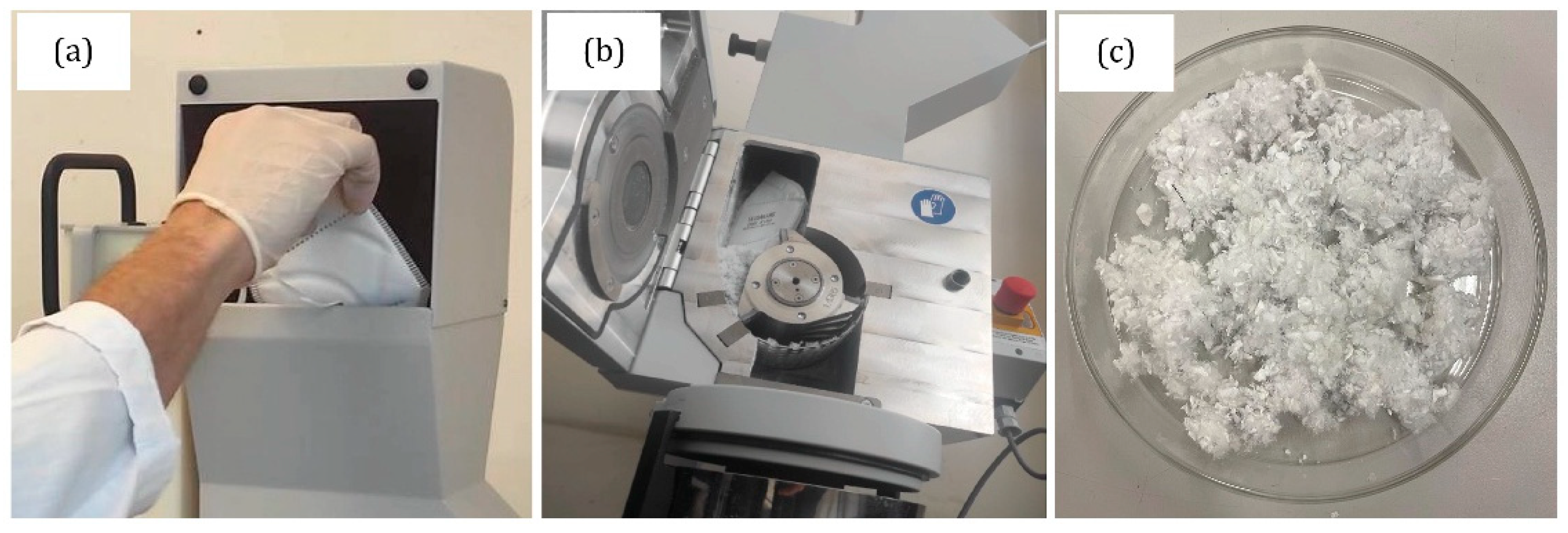

2. Materials and Methods

2.1. Geopolymer Synthesis

2.2. Mechanical Testing

2.3. Thermal Measurements

3. Results

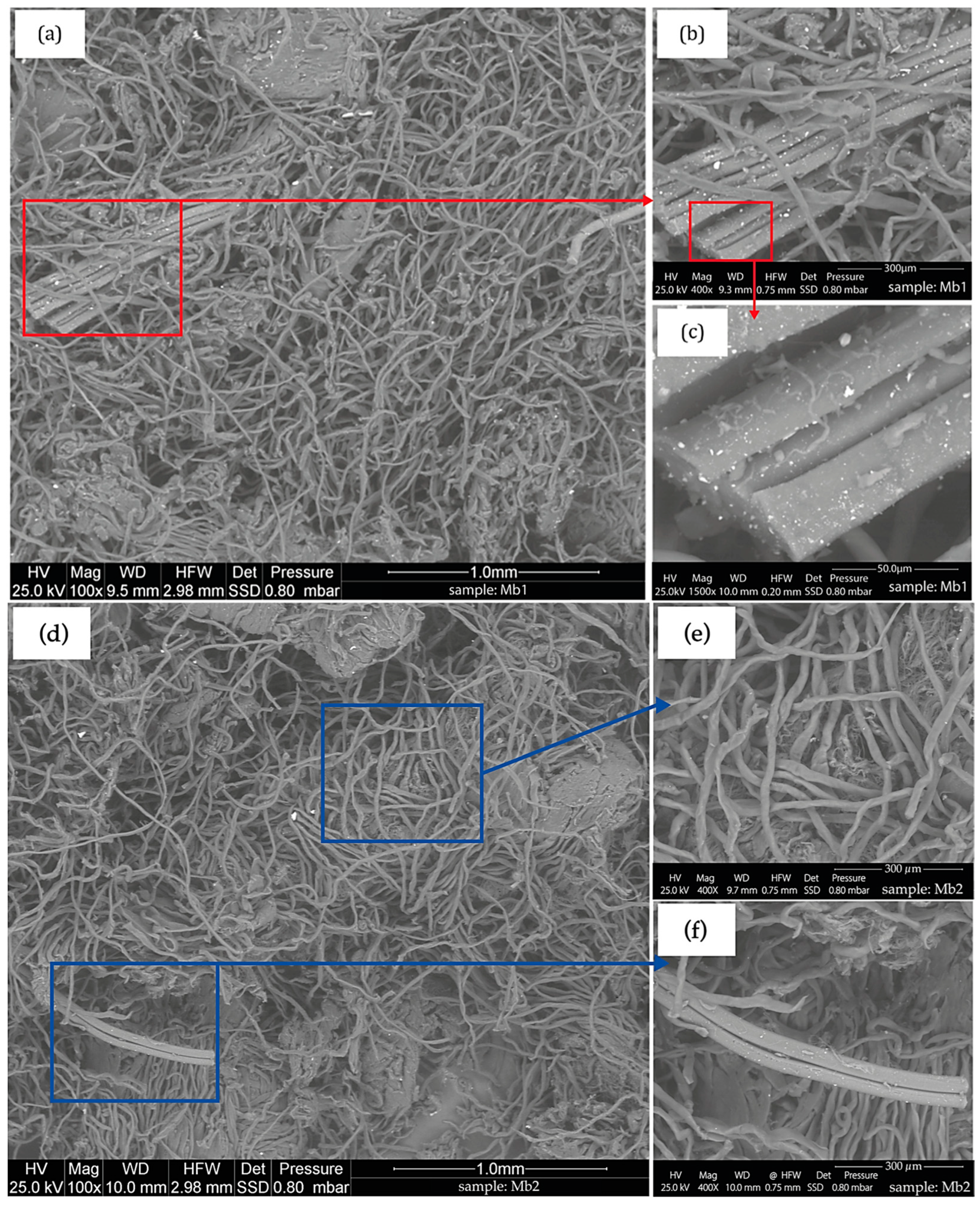

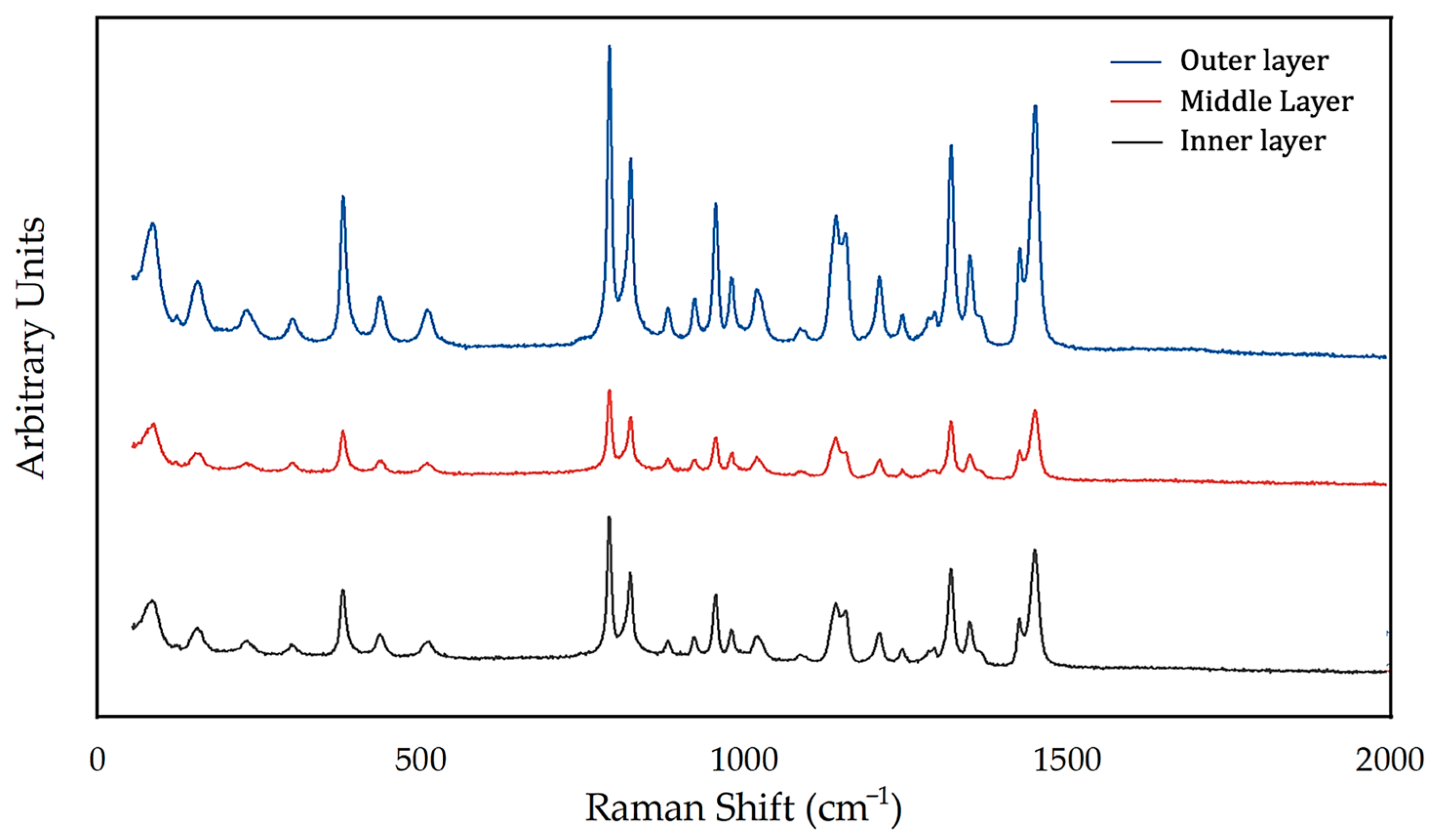

3.1. Characterization of Starting Materials

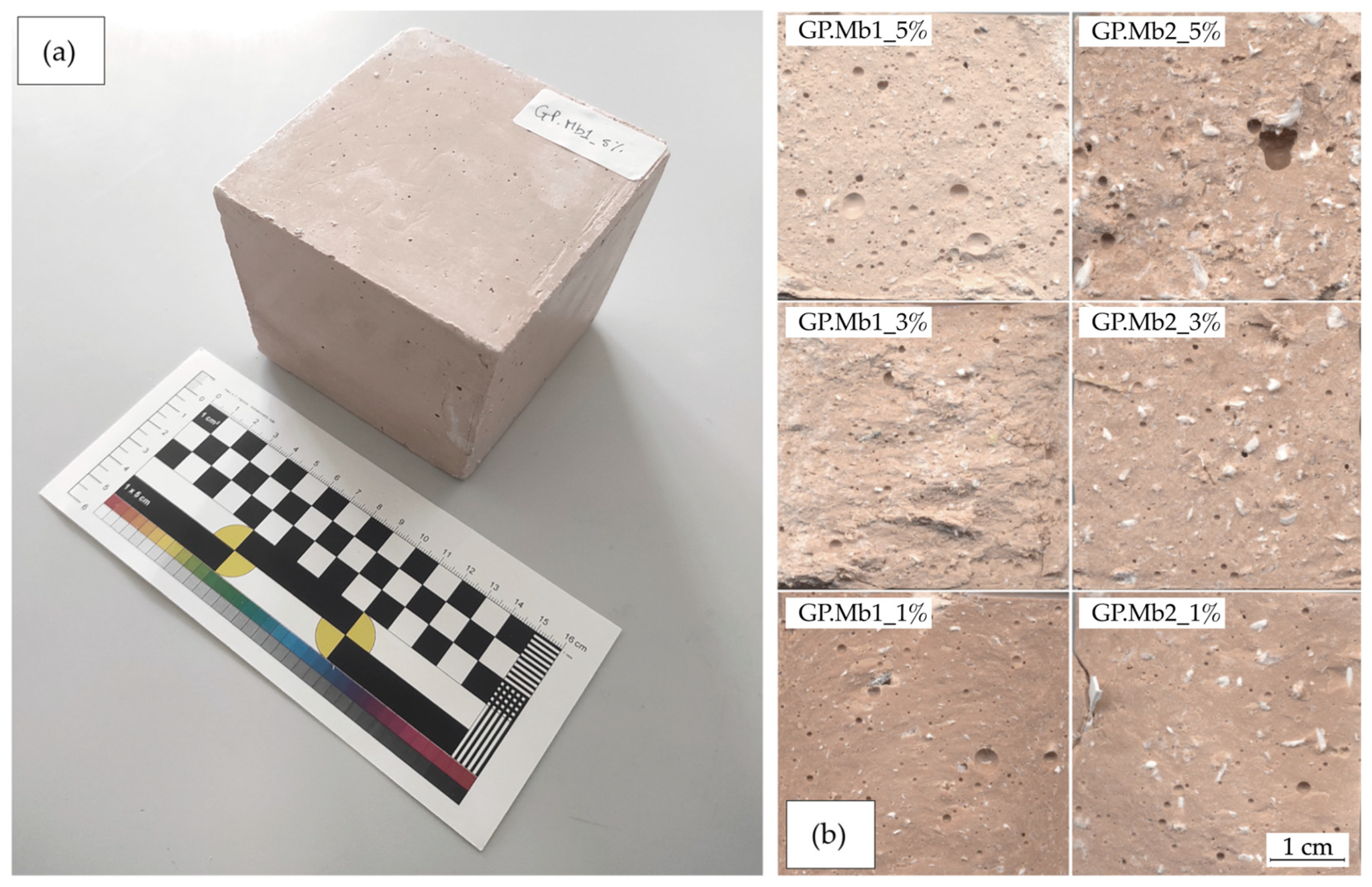

3.2. Geopolymer Samples

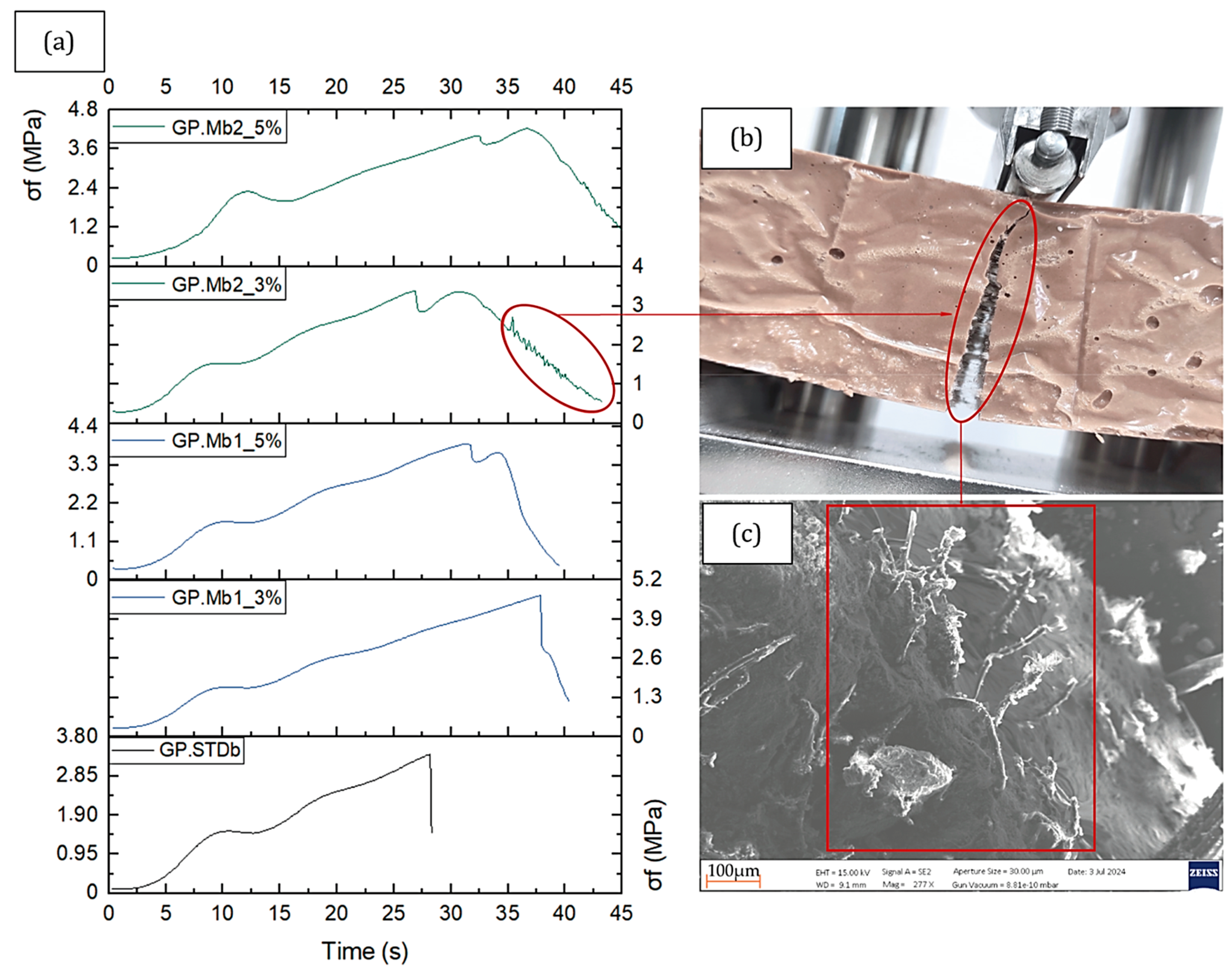

3.2.1. Mechanical Properties

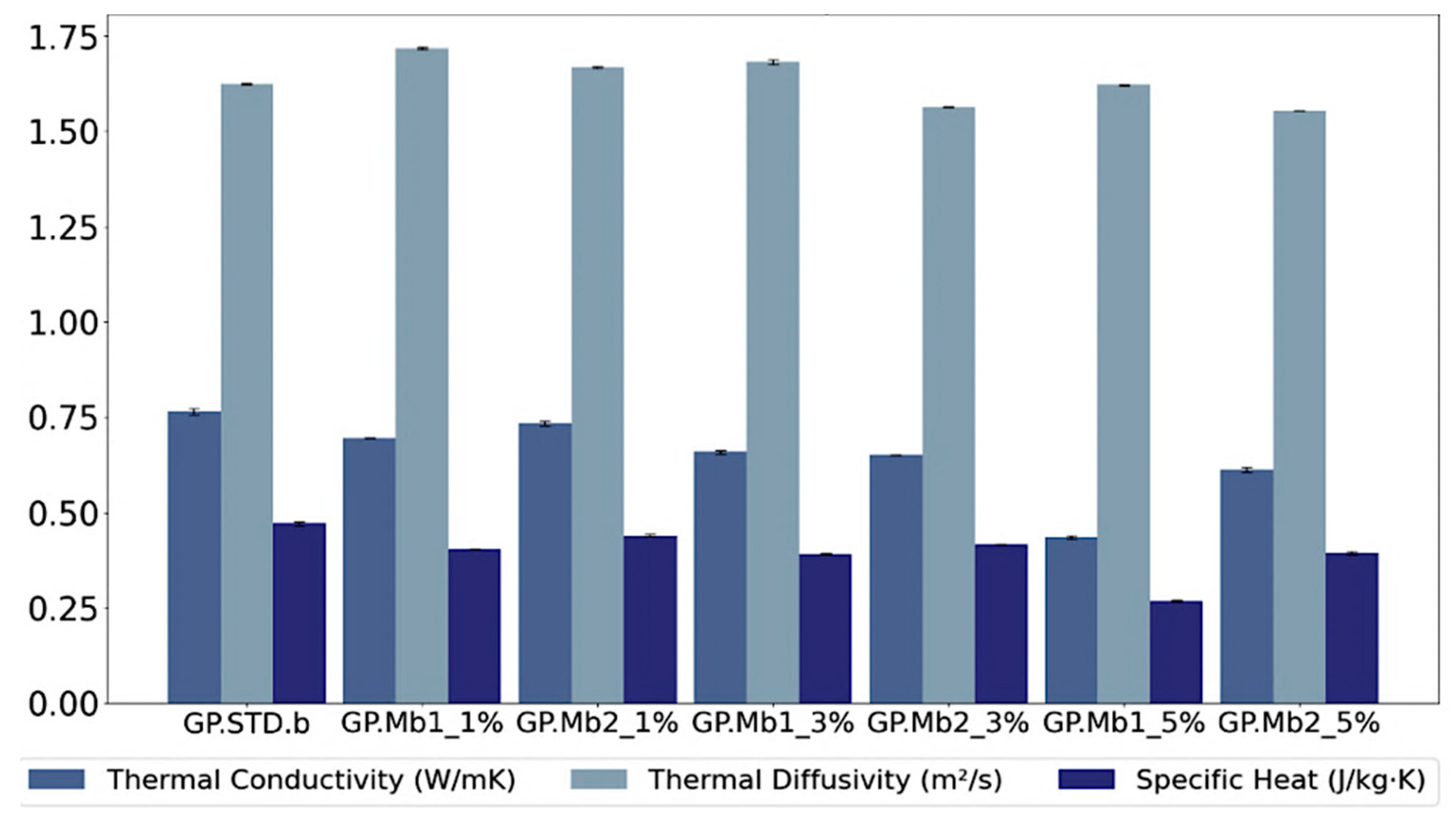

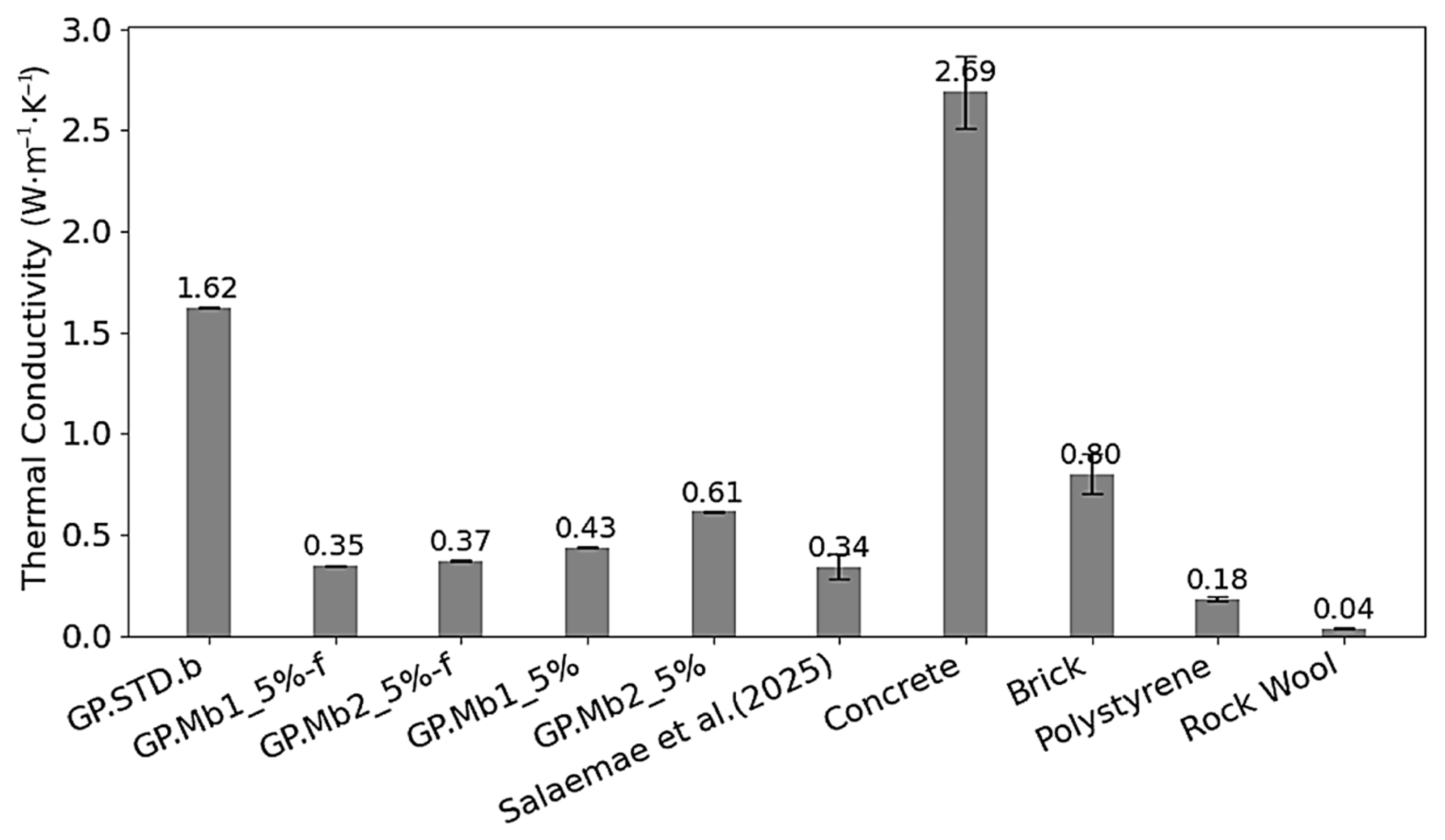

3.2.2. Thermal Properties

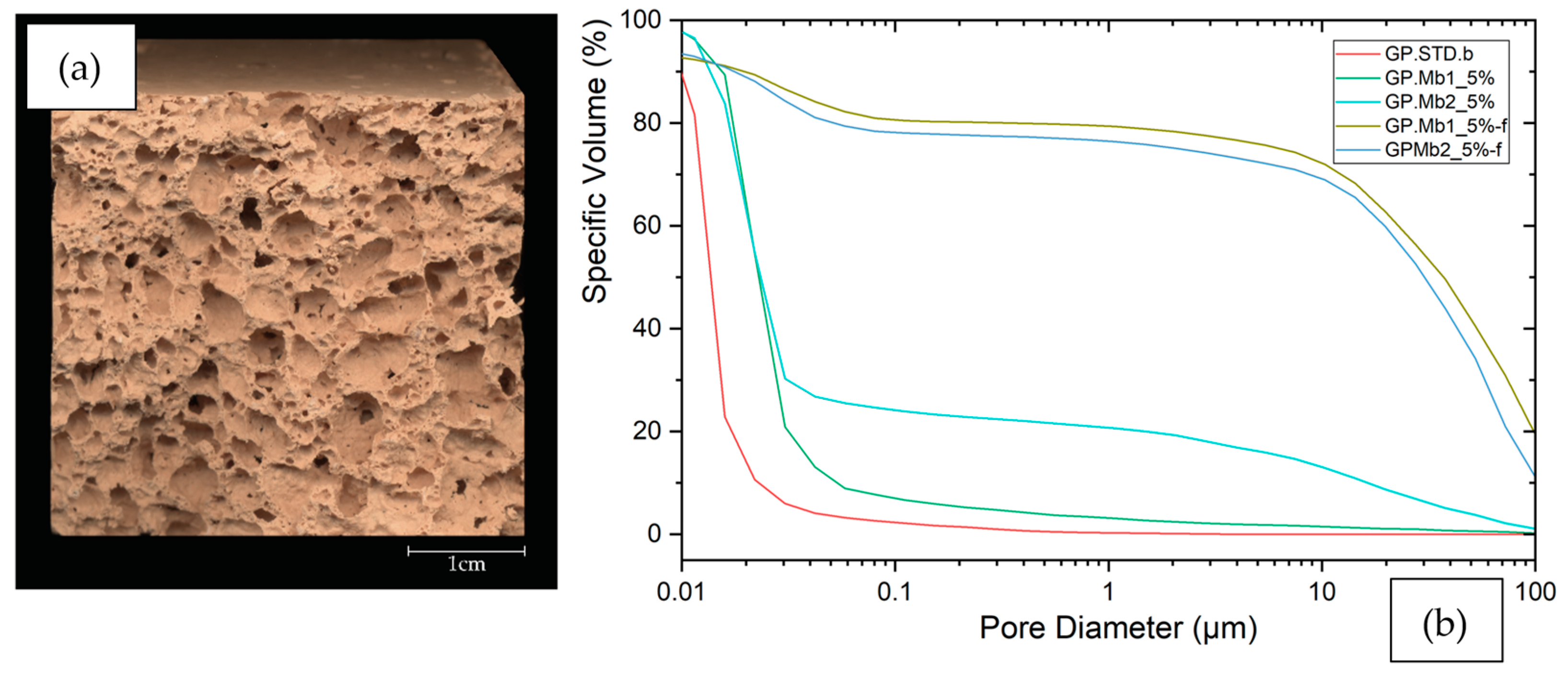

3.3. Foamed Geopolymers

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- European Parliament. Directive (EU) 2018/850 of the European Parliament and of the Council, of 30 May 2018, amending Directive 1999/31/EC on the landfill of waste. Off. J. Eur. Union L 2018, 150, 100–108. [Google Scholar]

- European Parliament. Directive (EU) 2018/844 of the European Parliament and of the Council, of 30 May 2018, amending Directive 2010/31/EU on the energy performance of buildings and Directive 2012/27/EU on energy efficiency. Off. J. Eur. Union L 2018, 156, 75–91. [Google Scholar]

- Kan, C.-W.; Zille, A.; Rahman, M.Z.; Hoque, M.E.; Alam, M.R.; Rouf, M.A.; Islam Khan, S.; Xu, H.; Ramakrishna, S. Face Masks to Combat Coronavirus (COVID-19)—Processing, Roles, Requirements, Efficacy, Risk and Sustainability. Polymers 2022, 14, 1296. [Google Scholar] [CrossRef]

- Geyer, R.; Jambeck, J.R.; Law, K.L. Production, use, and fate of all plastics ever made. Sci. Adv. 2017, 3, e1700782. [Google Scholar] [CrossRef] [PubMed]

- World Health Organization (WHO). Novel Coronavirus (2019-nCoV) Situation Report; COVID-19 Report No. 3/2020; WHO: Geneva, Switzerland, 2024; Available online: https://iris.who.int/handle/10665/330762 (accessed on 20 March 2025).

- Ajaj, R.; Al Dweik, R.; Ali, S.A.S.; Stietiya, M.H. Understanding the environmental impacts of facemasks: A review on the facemask industry and existing life cycle assessment studies. Sustain. Environ. Res. 2023, 33, 20. [Google Scholar] [CrossRef]

- Maloba, J.W.; Kiambigi, J.M.; Kabubo, C.K. Reutilizing Single-Use Surgical Face Masks to Improve the Mechanical Properties of Concrete: A Feasibility Study. Eng. Technol. Appl. Sci. Res. 2023, 13, 10511–10516. [Google Scholar] [CrossRef]

- United States Environmental Protection Agency (EPA). National Recycling Strategy: Building a Circular Economy for All. 2024. Available online: https://www.epa.gov/sites/default/files/2020-10/documents/draft_national_recycling_strategy.pdf (accessed on 20 March 2025).

- Saitta, L.; Rizzo, G.; Tosto, C.; Cicala, G.; Blanco, I.; Pergolizzi, E.; Ciobanu, R.; Recca, G. Chemical Recycling of Fully Recyclable Bio-Epoxy Matrices and Reuse Strategies: A Cradle-to-Cradle Approach. Polymers 2023, 15, 2809. [Google Scholar] [CrossRef]

- Furtos, G.; Prodan, D.; Sarosi, C.; Moldovan, M.; Korniejenko, K.; Miller, L.; Fiala, L.; Novakova, I. Mechanical Properties of MiniBars Basalt Fiber-Reinforced Geopolymer Composites. Materials 2024, 17, 248. [Google Scholar] [CrossRef] [PubMed]

- Andrew, R.M. Global CO2 emissions from cement production, 1928–2018. Earth Syst. Sci. Data 2018, 10, 221–236. [Google Scholar] [CrossRef]

- Jabar, T.; Abed, M.; Alzuhairi, M.A. A comprehensive review on geopolymer materials: Preparation, properties, applications, and challenges. In Proceedings of the 4th International Conference on Innovation in IoT, Robotics and Automation (IIRA 4.0), Moradabad, India, 15–16 March 2024. [Google Scholar] [CrossRef]

- Muda, I.; Dias, R.; Chetthamrongchai, P.; Jalil, A.T. An Environmentally Friendly Solution for Waste Facial Masks Recycled in Construction Materials. Sustainability 2022, 14, 8739. [Google Scholar] [CrossRef]

- Oberg, T.; Brosseau, L.M. Surgical mask filter and fit performance. Am. J. Infect. Control 2008, 36, 276–282. [Google Scholar] [CrossRef] [PubMed]

- EN 14683:2019+AC:2019; Medical Face Masks—Requirements and Test Methods. European Committee for Standardization (CEN): Brussels, Belgium, 2019.

- UNI EN 196-3:2017; Metodi di Prova per Cementi—Parte 3: Determinazione del Tempo di Presa e della Stabilità di Volume. Ente Nazionale Italiano di Unificazione (UNI): Milano, Italy, 2017.

- UNI EN 196-1:2016; Metodi di Prova per Cementi—Parte 1: Determinazione della Resistenza a Compressione. Ente Nazionale Italiano di Unificazione (UNI): Milano, Italy, 2016.

- ASTM C1363-19; Standard Test Method for Thermal Performance of Building Materials and Envelope Assemblies by Means of a Hot Box Apparatus. ASTM International: West Conshohocken, PA, USA, 2019.

- Biel, O.; Rożek, P.; Florek, P.; Mozgawa, W.; Król, M. Alkaline Activation of Kaolin Group Minerals. Crystals 2020, 10, 268. [Google Scholar] [CrossRef]

- Ercoli, R.; Laskowska, D.; Nguyen, V.V.; Le, V.S.; Louda, P.; Łoś, P.; Ciemnicka, J.; Prałat, K.; Renzulli, A.; Paris, E.; et al. Mechanical and Thermal Properties of Geopolymer Foams (GFs) Doped with By-Products of the Secondary Aluminum Industry. Polymers 2022, 14, 703. [Google Scholar] [CrossRef] [PubMed]

- Nguyen, V.V.; Le, V.S.; Louda, P.; Szczypiński, M.M.; Ercoli, R.; Růžek, V.; Łoś, P.; Prałat, K.; Plaskota, P.; Pacyniak, T.; et al. Low-Density Geopolymer Composites for the Construction Industry. Polymers 2022, 14, 304. [Google Scholar] [CrossRef]

- Ossoli, E.; Volpintesta, F.; Stabile, P.; Reggiani, A.; Santulli, C.; Paris, E. Upcycling of composite materials waste into geopolymer-based mortars for applications in the building sector. Mater. Lett. 2022, 333, 133625. [Google Scholar] [CrossRef]

- Kharun, M.; Svintsov, A.P. Polystyrene concrete as the structural thermal insulating material. Int. J. Adv. Appl. Sci. 2017, 4, 40–45. [Google Scholar] [CrossRef]

- Ablaoui, E.M.; Malendowski, M.; Szymkuc, W.; Pozorski, Z. Determination of Thermal Properties of Mineral Wool Required for the Safety Analysis of Sandwich Panels Subjected to Fire Loads. Materials 2023, 16, 5852. [Google Scholar] [CrossRef]

- Pagola, M.A.; Jensen, R.L.; Madsen, S.; Poulsen, S.E. Measurement of Thermal Properties of Soil and Concrete Samples; DCE Technical Reports, No. 235; Aalborg University, Department of Civil Engineering: Aalborg, Denmark, 2017. [Google Scholar]

- Khomenko, O.S.; Sribniak, N.; Ivchenko, V.; Ujma, A.; Pomada, M. Thermal conductivity study of different engobed ceramic bricks. Cerâmica 2024, 70, 6–102. [Google Scholar] [CrossRef]

- Salaemae, P.; Abdulmatin, A.; Prachasaree, W.; Hawa, A. Enhancing geopolymer mortars: The role of surgical face masks in modifying mechanical and thermal properties. Eng. Appl. Sci. Res. 2025, 52, 1–6. [Google Scholar] [CrossRef]

- Thoudam, K.; Hossiney, N.; Kumar, S.L.; Alex, J. Recycled surgical mask waste as a resource material in sustainable geopolymer bricks. Recycling 2023, 8, 93. [Google Scholar] [CrossRef]

- Win, T.T.; Jongvivatsakul, P.; Jirawattanasomkul, T.; Prasittisopin, L.; Likitlersuang, S. Use of polypropylene fibers extracted from recycled surgical face masks in cement mortar. Constr. Build. Mater. 2023, 391, 131845. [Google Scholar] [CrossRef]

- Ranjbar, N.; Mehrali, M.; Behnia, A.; Javadi Pordsari, A.; Mehrali, M.; Alengaram, U.J.; Jumaat, M.Z. A Comprehensive Study of the Polypropylene Fiber Reinforced Fly Ash Based Geopolymer. PLoS ONE 2016, 11, e0147546. [Google Scholar] [CrossRef] [PubMed]

| Instruments | Model | Experimental Conditions |

|---|---|---|

| Mechanical Shredder | SM 300, Retsch GmbH, Haan, Germany | 1500 rpm |

| Mechanical Mixer | 60010020, Automix Controls, Milan, Italy | Following Norm EN 196-3:2017 [16], mixing time: 10 min |

| Environmental Scanning Electron Microscope (ESEM) | Ametek, Edax Inc., Mahwah, NJ, USA | kV: 25.00, Tilt: 0.00, Take-off: 35.00, AmpT: 51.2, Det Type: SUTW, Sapphire Res: 132.40, Lsec: 100 |

| Raman Spectrometer (RAMAN) | iHR320, Horiba Scientific, Longjumeau, France | Acquisition time: 5 s, Accumulations: 10, Windows: 5, Objective: 100x, Laser: 532 nm |

| Pycnometer | Ultrapyc 5000, Anton Paar GmbH, Graz, Austria | Acquisition time: 10 sGas: Nitrogen |

| Porosimeter | PASCAL 240, Thermo Fisher Scientific Inc., Waltham, MA, USA | Pressure: 0.01–200 MPa Pore Size Range: 0.01–100 µm |

| Mechanical Tester | 70-T2502, Controls, Milan, Italy | Following Norm EN 196-1:2016 [17] |

| Thermal Properties Tester | ISOMET 2114, Applied Precision Machines, Lake County, IL, USA | Following Norm ASTM C1363-19 [18] |

| Metaver I | Reoflux A | |

|---|---|---|

| SiO2 (wt.%) | 53.5 ± 3.0 | 26.70 ± 2.10 |

| Al2O3 (wt.%) | 42.0 ± 2.0 | – |

| Fe2O3 (wt.%) | <2.0 | – |

| K2O (wt.%) | <2.0 | 20.50 ± 0.60 |

| Specific density (kg⋅m−3) | 2600 ± 30 | 1410 ± 10 |

| pH | – | 13.5 ± 0.5 |

| Ratios | Values | |

| n (SiO2/Al2O3) | 1.97 | |

| n (SiO2/(Na2O + K2O)) | 3.38 | |

| n (Al2O3/(Na2O + K2O)) | 1.71 | |

| Solid/Liquid (kg⋅L−1) | 0.9–1.0 | |

| Geopolymer Sample (GP.) | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Parameter | STD.b | Mb1_1% | Mb2_1% | Mb1_3% | Mb2_3% | Mb1_5% | Mb2_5% | Mb1_5%-f | Mb2_5%-f |

| Mask content mf (wt.%) | 0 | 1 | 1 | 3 | 3 | 5 | 5 | 5 | 5 |

| Fiber length l (mm) | 0 | 2 | 6 | 2 | 6 | 2 | 6 | 2 | 6 |

| Density ρ (kg·m−3) | 1777.50 ± 14.83 | 1686.81 ± 17.71 | 1682.59 ± 15.18 | 1639.91 ± 27.45 | 1680.37 ± 22.65 | 1579.05 ± 3.20 | 1607.19 ± 13.73 | 580.39 ± 20.13 | 600.83 ± 21.20 |

| Porosity φ (%) | 21.6 | 27.5 | 26.6 | 32.3 | 31.7 | 35.8 | 34.4 | 53.0 | 50.9 |

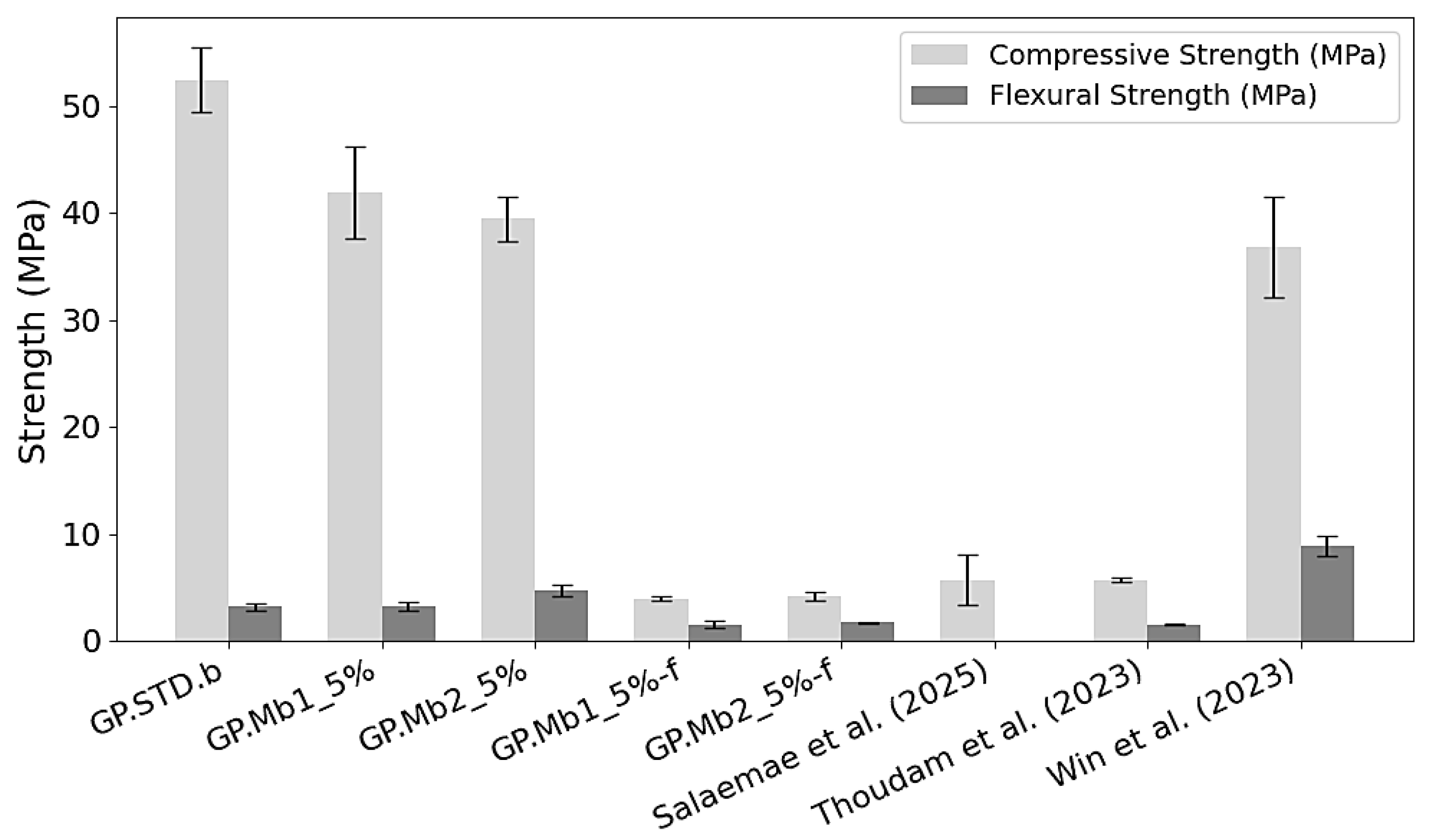

| Compressive strength σc (MPa) | 52.42 ± 3.06 | 54.78 ± 2.08 | 52.49 ± 3.69 | 48.71 ± 2.43 | 47.34 ± 1.38 | 41.96 ± 4.29 | 39.46 ± 2.06 | 3.30 ± 0.37 | 4.80 ± 0.56 |

| Flexural strength σf (MPa) | 3.23 ± 0.38 | 3.77 ± 0.14 | 3.49 ± 0.34 | 4.56 ± 0.23 | 3.78 ± 0.46 | 4.00 ± 0.21 | 4.20 ± 0.36 | 1.58 ± 0.34 | 1.79 ± 0.06 |

| Thermal conductivity λ (W·m−1·K−1) | 0.7658 ± 0.0082 | 0.6951 ± 0.0010 | 0.7342 ± 0.0063 | 0.6592 ± 0.0056 | 0.6514 ± 0.0002 | 0.4346 ± 0.0043 | 0.6125 ± 0.0057 | 0.3456 ± 0.0007 | 0.3710 ± 0.0007 |

| Specific heat Cp (J·kg−1·K−1) | 0.4714 ± 0.0047 | 0.4046 ± 0.0005 | 0.4403 ± 0.0035 | 0.3919 ± 0.0019 | 0.4167 ± 0.0003 | 0.2681 ± 0.0026 | 0.3941 ± 0.0037 | 0.2235 ± 0.0007 | 0.2512 ± 0.0004 |

| Thermal diffusivity α (m2·s−1) | 1.6245 ± 0.0024 | 1.7178 ± 0.0036 | 1.6677 ± 0.0022 | 1.6822 ± 0.0061 | 1.5632 ± 0.0008 | 1.6211 ± 0.0009 | 1.5542 ± 0.0005 | 1.5463 ± 0.0035 | 1.4768 ± 0.0001 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ercoli, R.; Stabile, P.; Ossoli, E.; Luconi, I.; Renzulli, A.; Paris, E. Recycling Face Mask Fibers in Geopolymer-Based Matrices for Sustainable Building Materials. Ceramics 2025, 8, 54. https://doi.org/10.3390/ceramics8020054

Ercoli R, Stabile P, Ossoli E, Luconi I, Renzulli A, Paris E. Recycling Face Mask Fibers in Geopolymer-Based Matrices for Sustainable Building Materials. Ceramics. 2025; 8(2):54. https://doi.org/10.3390/ceramics8020054

Chicago/Turabian StyleErcoli, Roberto, Paola Stabile, Elena Ossoli, Irene Luconi, Alberto Renzulli, and Eleonora Paris. 2025. "Recycling Face Mask Fibers in Geopolymer-Based Matrices for Sustainable Building Materials" Ceramics 8, no. 2: 54. https://doi.org/10.3390/ceramics8020054

APA StyleErcoli, R., Stabile, P., Ossoli, E., Luconi, I., Renzulli, A., & Paris, E. (2025). Recycling Face Mask Fibers in Geopolymer-Based Matrices for Sustainable Building Materials. Ceramics, 8(2), 54. https://doi.org/10.3390/ceramics8020054