Limitations and Research Priorities in 3D-Printed Geopolymer Concrete: A Perspective Contribution

Abstract

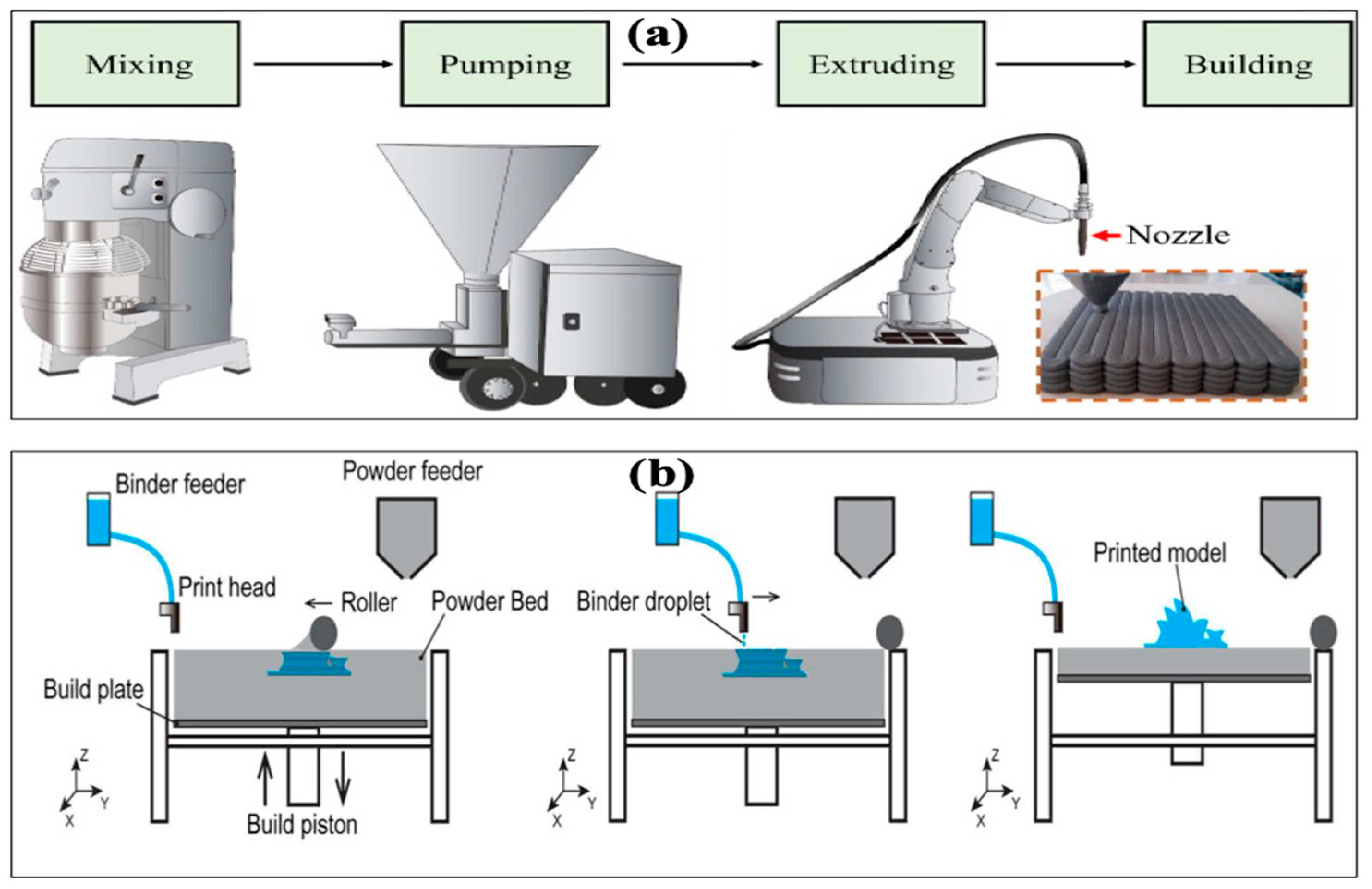

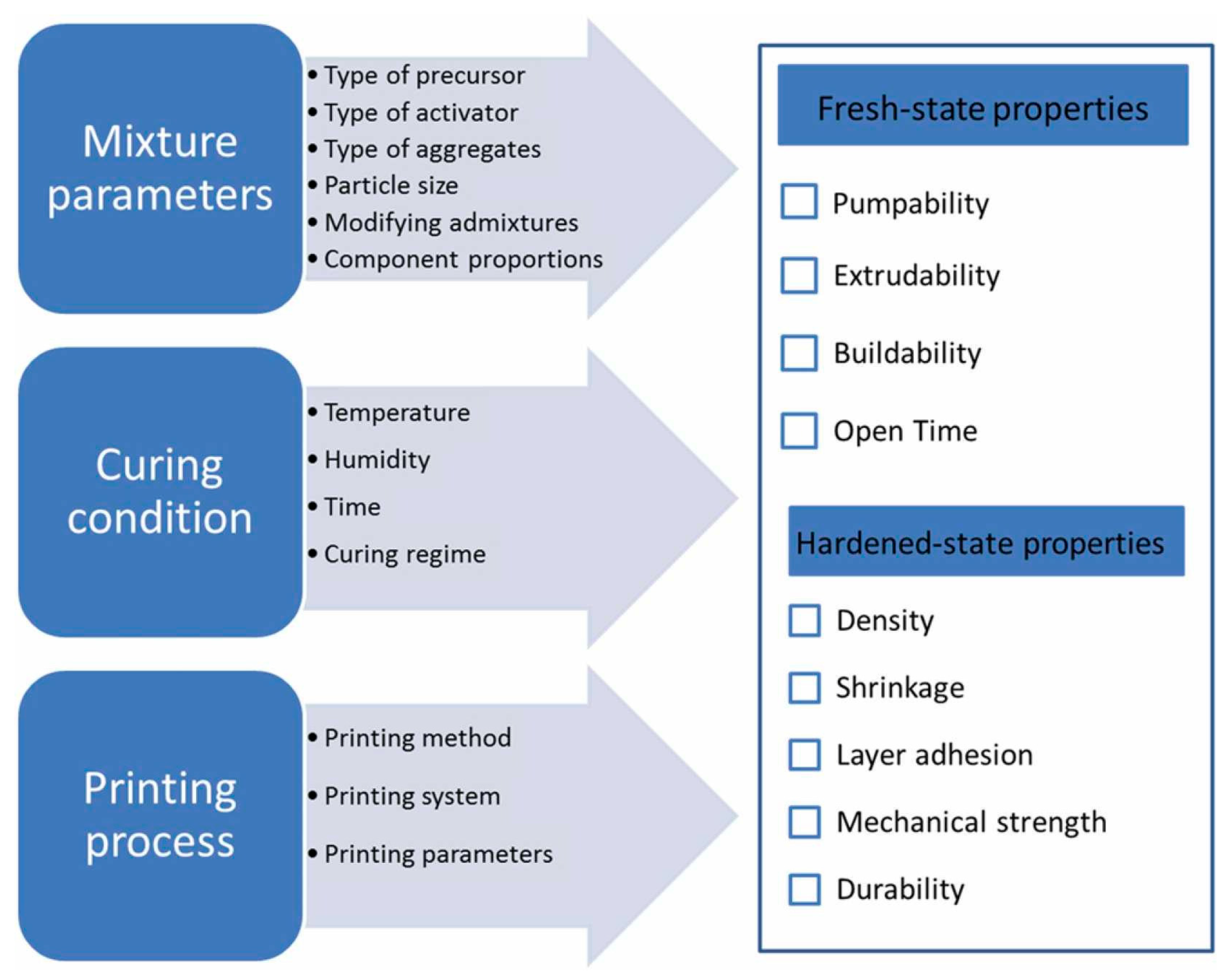

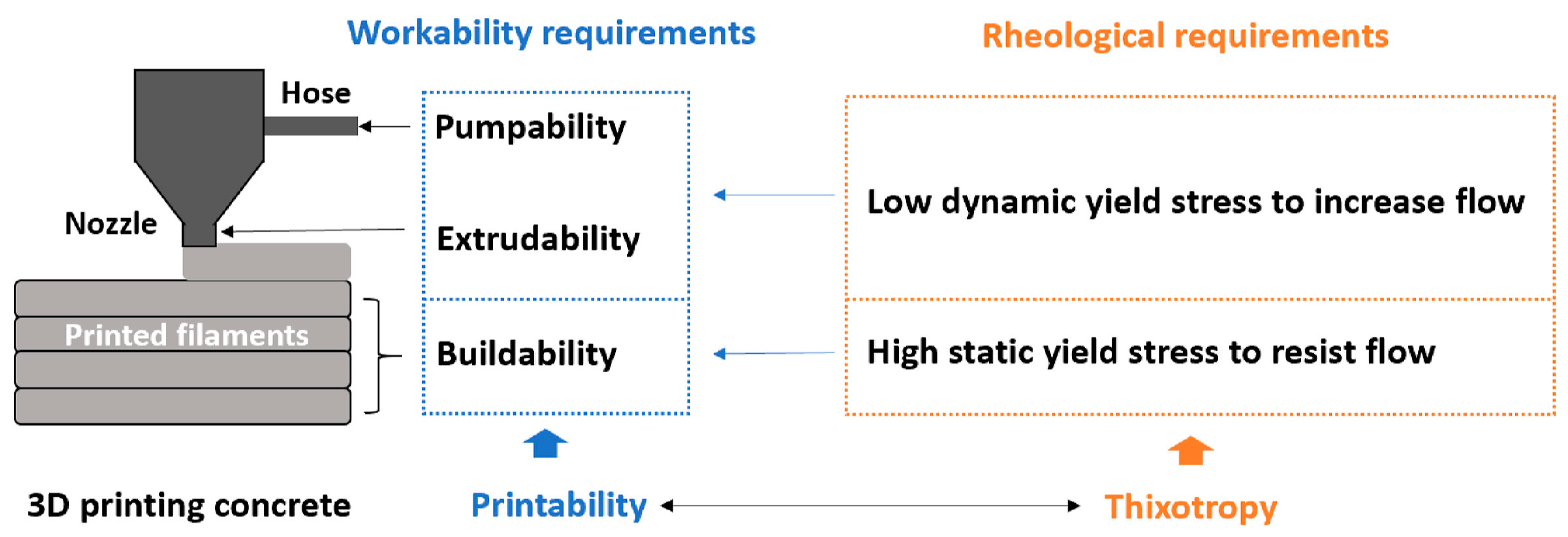

1. Introduction

2. Key Limitations

2.1. Material

2.2. Structural

2.3. Technical

2.4. Economic

2.5. Durability

2.6. Sustainability

2.7. Regulatory Framework

2.8. Skilled Workforce and On-Field Applications

3. Research Priorities—The Way Forward

3.1. Improvement in Inter-Layer Bonding

3.2. Transition Towards Seismic Resilient 3DPGPC

3.3. Development of Design Standards and Guidelines

3.4. Innovations in Materials and Increasing Sustainability

3.5. Data Availability Regarding Long-Term Durability

3.6. Automation and Novel 3D Printers Through AI-Enabled Systems

3.7. Integration into Academic Curriculum and Other Major Initiatives

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| 3DPGPC | 3D-printed geopolymer concrete |

| FA | Fly ash |

| GGBS | Ground granulated blast furnace slag |

| RHA | Rice husk ash |

| MK | Metakaolin |

| MT | Mine tailings |

| SF | Silica fume |

References

- Global Construction Futures. Available online: https://www.oxfordeconomics.com/resource/global-construction-futures/ (accessed on 2 February 2025).

- Regona, M.; Yigitcanlar, T.; Hon, C.; Teo, M. Artificial Intelligence and Sustainable Development Goals: Systematic Literature Review of the Construction Industry. Sustain. Cities Soc. 2024, 108, 105499. [Google Scholar] [CrossRef]

- Oyejobi, D.O.; Firoozi, A.A.; Fernández, D.B.; Avudaiappan, S. Integrating Circular Economy Principles into Concrete Technology: Enhancing Sustainability through Industrial Waste Utilization. Results Eng. 2024, 24, 102846. [Google Scholar] [CrossRef]

- Volpe, S.; Sangiorgio, V.; Fiorito, F.; Varum, H. Overview of 3D Construction Printing and Future Perspectives: A Review of Technology, Companies and Research Progression. Archit. Sci. Rev. 2024, 67, 1–22. [Google Scholar] [CrossRef]

- Alotaibi, B.S.; Shema, A.I.; Ibrahim, A.U.; Abuhussain, M.A.; Abdulmalik, H.; Dodo, Y.A.; Atakara, C. Assimilation of 3D Printing, Artificial Intelligence (AI) and Internet of Things (IoT) for the Construction of Eco-Friendly Intelligent Homes: An Explorative Review. Heliyon 2024, 10, e36846. [Google Scholar] [CrossRef]

- Khan, M.; McNally, C. Recent Developments on Low Carbon 3D Printing Concrete: Revolutionizing Construction through Innovative Technology. Clean. Mater. 2024, 12, 100251. [Google Scholar] [CrossRef]

- Xia, M.; Nematollahi, B.; Sanjayan, J.G. Chapter 11—Development of Powder-Based 3D Concrete Printing Using Geopolymers. In 3D Concrete Printing Technology; Sanjayan, J.G., Nazari, A., Nematollahi, B., Eds.; Butterworth-Heinemann: Oxford, UK, 2019; pp. 223–240. ISBN 978-0-12-815481-6. [Google Scholar]

- Singh, N.; Colangelo, F.; Farina, I. Sustainable Non-Conventional Concrete 3D Printing—A Review. Sustainability 2023, 15, 10121. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, J.; Dong, S.; Yu, X.; Han, B. A Review of the Current Progress and Application of 3D Printed Concrete. Compos. Part Appl. Sci. Manuf. 2019, 125, 105533. [Google Scholar] [CrossRef]

- Jaji, M.B.; van Zijl, G.P.A.G.; Babafemi, A.J. Slag-Modified Metakaolin-Based 3D Printed Geopolymer: Mechanical Characterisation, Microstructural Properties, and Nitrogen Physisorption Pore Analysis. J. Build. Eng. 2024, 81, 108166. [Google Scholar] [CrossRef]

- Chen, L.; Yang, M.; Chen, Z.; Xie, Z.; Huang, L.; Osman, A.I.; Farghali, M.; Sandanayake, M.; Liu, E.; Ahn, Y.H.; et al. Conversion of Waste into Sustainable Construction Materials: A Review of Recent Developments and Prospects. Mater. Today Sustain. 2024, 27, 100930. [Google Scholar] [CrossRef]

- Wudil, Y.S.; Al-Fakih, A.; Al-Osta, M.A.; Gondal, M.A. Intelligent Optimization for Modeling Carbon Dioxide Footprint in Fly Ash Geopolymer Concrete: A Novel Approach for Minimizing CO2 Emissions. J. Environ. Chem. Eng. 2024, 12, 111835. [Google Scholar] [CrossRef]

- Liu, S.; Liu, Z.; Harada, K.; Takasu, K.; Suyama, H.; Yamamoto, H. Investigating the Use of Bamboo Charcoal to Reduce Carbon Emissions in Geopolymer Mortar. Constr. Build. Mater. 2024, 434, 136781. [Google Scholar] [CrossRef]

- Zhong, H.; Zhang, M. 3D Printing Geopolymers: A Review. Cem. Concr. Compos. 2022, 128, 104455. [Google Scholar] [CrossRef]

- Nematollahi, B.; Xia, M.; Sanjayan, J. Post-Processing Methods to Improve Strength of Particle-Bed 3D Printed Geopolymer for Digital Construction Applications. Front. Mater. 2019, 6. [Google Scholar] [CrossRef]

- Lazorenko, G.; Kasprzhitskii, A. Geopolymer Additive Manufacturing: A Review. Addit. Manuf. 2022, 55, 102782. [Google Scholar] [CrossRef]

- Shilar, F.A.; Ganachari, S.V.; Patil, V.B.; Bhojaraja, B.E.; Yunus Khan, T.M.; Almakayeel, N. A Review of 3D Printing of Geopolymer Composites for Structural and Functional Applications. Constr. Build. Mater. 2023, 400, 132869. [Google Scholar] [CrossRef]

- Chen, K.; Liu, Q.; Chen, B.; Zhang, S.; Ferrara, L.; Li, W. Effect of Raw Materials on the Performance of 3D Printing Geopolymer: A Review. J. Build. Eng. 2024, 84, 108501. [Google Scholar] [CrossRef]

- Ricciotti, L.; Apicella, A.; Perrotta, V.; Aversa, R. Geopolymer Materials for Extrusion-Based 3D-Printing: A Review. Polymers 2023, 15, 4688. [Google Scholar] [CrossRef]

- Al-Noaimat, Y.A.; Ghaffar, S.H.; Chougan, M.; Al-Kheetan, M.J. A Review of 3D Printing Low-Carbon Concrete with One-Part Geopolymer: Engineering, Environmental and Economic Feasibility. Case Stud. Constr. Mater. 2023, 18, e01818. [Google Scholar] [CrossRef]

- Raza, M.H.; Zhong, R.Y.; Khan, M. Recent Advances and Productivity Analysis of 3D Printed Geopolymers. Addit. Manuf. 2022, 52, 102685. [Google Scholar] [CrossRef]

- Yousaf, A.; Al Rashid, A.; Koç, M. 3D Printing of Alkali-Activated Geopolymers for Sustainable and Circular Economy Advancements. Circ. Econ. 2024, 3, 100101. [Google Scholar] [CrossRef]

- Sakhare, V.; Najar, M.; Deshpande, S. Printing Performance of 3D-Printed Geopolymer through Pumpability–Extrudability–Buildability Properties—A Review. Archit. Sci. Rev. 2024, 1–25. [Google Scholar] [CrossRef]

- Qaidi, S.; Yahia, A.; Tayeh, B.A.; Unis, H.; Faraj, R.; Mohammed, A. 3D Printed Geopolymer Composites: A Review. Mater. Today Sustain. 2022, 20, 100240. [Google Scholar] [CrossRef]

- Hanani Ismail, A.; Kusbiantoro, A.; Tajunnisa, Y.; Jaya Ekaputri, J.; Laory, I. A Review of Aluminosilicate Sources from Inorganic Waste for Geopolymer Production: Sustainable Approach for Hydrocarbon Waste Disposal. Clean. Mater. 2024, 13, 100259. [Google Scholar] [CrossRef]

- Zhang, P.; Zheng, Y.; Wang, K.; Zhang, J. A Review on Properties of Fresh and Hardened Geopolymer Mortar. Compos. Part B Eng. 2018, 152, 79–95. [Google Scholar] [CrossRef]

- Swathi, B.; Vidjeapriya, R. Influence of Precursor Materials and Molar Ratios on Normal, High, and Ultra-High Performance Geopolymer Concrete—A State of Art Review. Constr. Build. Mater. 2023, 392, 132006. [Google Scholar] [CrossRef]

- Constâncio Trindade, A.C.; Ribeiro de Avillez, R.; Letichevsky, S.; de Andrade Silva, F. Influence of Precursor Materials on the Fresh State and Thermo-Chemo-Mechanical Properties of Sodium-Based Geopolymers. Ceram. Int. 2022, 48, 19806–19817. [Google Scholar] [CrossRef]

- Zhu, X.; Wang, J.; Kashif Anwar, M.; Zhang, Y.; Gilabert, F.A. Robust Optimization of Formulation Ratios for the Mechanical, Microstructural and Printing Performance of Cost-Effective 3D Printing Geopolymer. 2024. [Google Scholar]

- Słomka-Słupik, B.; Wiśniewska, P.; Bargieł, W. Multicomponent Low Initial Molar Ratio of SiO2/Al2O3 Geopolymer Mortars: Pilot Research. Materials 2022, 15, 5943. [Google Scholar] [CrossRef]

- Zhou, Z.; Geng, J.; Jin, C.; Liu, G.; Xia, Z. Influence of Residue Soil on the Properties of Fly Ash–Slag-Based Geopolymer Materials for 3D Printing. Materials 2024, 17, 2992. [Google Scholar] [CrossRef]

- Guo, X.; Yang, J.; Xiong, G. Influence of Supplementary Cementitious Materials on Rheological Properties of 3D Printed Fly Ash Based Geopolymer. Cem. Concr. Compos. 2020, 114, 103820. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, L.; Wei, K.; Gao, H.; Liu, Z.; She, Y.; Chen, F.; Gao, H.; Yu, Q. Rheology Control and Shrinkage Mitigation of 3D Printed Geopolymer Concrete Using Nanocellulose and Magnesium Oxide. Constr. Build. Mater. 2024, 429, 136421. [Google Scholar] [CrossRef]

- Kondepudi, K.; Subramaniam, K.V.L. Formulation of Alkali-Activated Fly Ash-Slag Binders for 3D Concrete Printing. Cem. Concr. Compos. 2021, 119, 103983. [Google Scholar] [CrossRef]

- Sun, C.; Xiang, J.; Xu, M.; He, Y.; Tong, Z.; Cui, X. 3D Extrusion Free Forming of Geopolymer Composites: Materials Modification and Processing Optimization. J. Clean. Prod. 2020, 258, 120986. [Google Scholar] [CrossRef]

- Rahemipoor, S.; Hasany, M.; Mehrali, M.; Almdal, K.; Ranjbar, N.; Mehrali, M. Phase Change Materials Incorporation into 3D Printed Geopolymer Cement: A Sustainable Approach to Enhance the Comfort and Energy Efficiency of Buildings. J. Clean. Prod. 2023, 417, 138005. [Google Scholar] [CrossRef]

- Kondepudi, K.; Subramaniam, K.V.L.; Nematollahi, B.; Bong, S.H.; Sanjayan, J. Study of Particle Packing and Paste Rheology in Alkali Activated Mixtures to Meet the Rheology Demands of 3D Concrete Printing. Cem. Concr. Compos. 2022, 131, 104581. [Google Scholar] [CrossRef]

- Ma, S.; Fu, S.; Yang, T.; Li, K.; Chen, G.; Dong, Q.; He, P.; Sun, Z.; Duan, X.; Jia, D.; et al. Unveiling the Critical Role of Rheology Modifiers in Additive Manufacturing of Geopolymers and Their Mechanical Properties. Addit. Manuf. 2023, 78, 103826. [Google Scholar] [CrossRef]

- Albar, A.; Chougan, M.; Al- Kheetan, M.J.; Swash, M.R.; Ghaffar, S.H. Effective Extrusion-Based 3D Printing System Design for Cementitious-Based Materials. Results Eng. 2020, 6, 100135. [Google Scholar] [CrossRef]

- Jaji, M.B.; van Zijl, G.P.A.G.; Babafemi, A.J. Slag-Modified Metakaolin-Based Geopolymer for 3D Concrete Printing Application: Evaluating Fresh and Hardened Properties. Clean. Eng. Technol. 2023, 15, 100665. [Google Scholar] [CrossRef]

- Kamseu, E.; Alzari, V.; Nuvoli, D.; Sanna, D.; Lancellotti, I.; Mariani, A.; Leonelli, C. Dependence of the Geopolymerization Process and End-Products to the Nature of Solid Precursors: Challenge of the Sustainability. J. Clean. Prod. 2021, 278, 123587. [Google Scholar] [CrossRef]

- Xu, W.; Tang, Z.; Song, Y.; Xie, Y.; Lei, B.; Yu, H.; Long, G.; Kai, M. Drying Shrinkage of Geopolymeric Recycled Aggregate Concrete. Constr. Build. Mater. 2023, 395, 132220. [Google Scholar] [CrossRef]

- Khan, I.; Xu, T.; Castel, A.; Gilbert, R.I.; Babaee, M. Risk of Early Age Cracking in Geopolymer Concrete Due to Restrained Shrinkage. Constr. Build. Mater. 2019, 229, 116840. [Google Scholar] [CrossRef]

- Panda, B. 3D Printing of High-Volume Fly Ash Mixtures for Digital Concrete Construction. Ph.D. Thesis, Nanyang Technological University, Singapore, 2019. [Google Scholar]

- Yuan, Q.; Gao, C.; Huang, T.; Zuo, S.; Yao, H.; Zhang, K.; Huang, Y.; Liu, J. Factors Influencing the Properties of Extrusion-Based 3D-Printed Alkali-Activated Fly Ash-Slag Mortar. Materials 2022, 15, 1969. [Google Scholar] [CrossRef] [PubMed]

- Jaji, M.B.; van Zijl, G.P.A.G.; Babafemi, A.J. Durability and Pore Structure of Metakaolin-Based 3D Printed Geopolymer Concrete. Constr. Build. Mater. 2024, 422, 135847. [Google Scholar] [CrossRef]

- Rabi, M.; Shamass, R.; Cashell, K.A. Structural Performance of Stainless Steel Reinforced Concrete Members: A Review. Constr. Build. Mater. 2022, 325, 126673. [Google Scholar] [CrossRef]

- Chen, W.; Pan, J.; Zhu, B.; Ma, X.; Zhang, Y.; Chen, Y.; Li, X.; Meng, L.; Cai, J. Improving Mechanical Properties of 3D Printable ‘One-Part’ Geopolymer Concrete with Steel Fiber Reinforcement. J. Build. Eng. 2023, 75, 107077. [Google Scholar] [CrossRef]

- Li, Z.; Wang, L.; Ma, G. Mechanical Improvement of Continuous Steel Microcable Reinforced Geopolymer Composites for 3D Printing Subjected to Different Loading Conditions. Compos. Part B Eng. 2020, 187, 107796. [Google Scholar] [CrossRef]

- Kaufmann, J.; Lübben, J.; Schwitter, E. Mechanical Reinforcement of Concrete with Bi-Component Fibers. Compos. Part Appl. Sci. Manuf. 2007, 38, 1975–1984. [Google Scholar] [CrossRef]

- Hack, N.; Lauer, W.V. Mesh-Mould: Robotically Fabricated Spatial Meshes as Reinforced Concrete Formwork. Archit. Des. 2014, 84, 44–53. [Google Scholar] [CrossRef]

- Asprone, D.; Auricchio, F.; Menna, C.; Mercuri, V. 3D Printing of Reinforced Concrete Elements: Technology and Design Approach. Constr. Build. Mater. 2018, 165, 218–231. [Google Scholar] [CrossRef]

- Lim, J.H.; Panda, B.; Pham, Q.-C. Improving Flexural Characteristics of 3D Printed Geopolymer Composites with In-Process Steel Cable Reinforcement. Constr. Build. Mater. 2018, 178, 32–41. [Google Scholar] [CrossRef]

- Li, V.C.; Bos, F.P.; Yu, K.; McGee, W.; Ng, T.Y.; Figueiredo, S.C.; Nefs, K.; Mechtcherine, V.; Nerella, V.N.; Pan, J.; et al. On the Emergence of 3D Printable Engineered, Strain Hardening Cementitious Composites (ECC/SHCC). Cem. Concr. Res. 2020, 132, 106038. [Google Scholar] [CrossRef]

- Nematollahi, B.; Vijay, P.; Sanjayan, J.; Nazari, A.; Xia, M.; Naidu Nerella, V.; Mechtcherine, V. Effect of Polypropylene Fibre Addition on Properties of Geopolymers Made by 3D Printing for Digital Construction. Materials 2018, 11, 2352. [Google Scholar] [CrossRef] [PubMed]

- Perrot, A.; Jacquet, Y.; Caron, J.F.; Mesnil, R.; Ducoulombier, N.; De Bono, V.; Sanjayan, J.; Ramakrishnan, S.; Kloft, H.; Gosslar, J.; et al. Snapshot on 3D Printing with Alternative Binders and Materials: Earth, Geopolymers, Gypsum and Low Carbon Concrete. Cem. Concr. Res. 2024, 185, 107651. [Google Scholar] [CrossRef]

- Patel, C.D.; Chen, C.-H. Digital Manufacturing: The Industrialization of “Art to Part” 3D Additive Printing; Elsevier: Amsterdam, The Netherlands, 2022; ISBN 978-0-323-95063-3. [Google Scholar]

- Xia, M.; Sanjayan, J. Method of Formulating Geopolymer for 3D Printing for Construction Applications. Mater. Des. 2016, 110, 382–390. [Google Scholar] [CrossRef]

- Rehman, A.U.; Kim, J.-H. 3D Concrete Printing: A Systematic Review of Rheology, Mix Designs, Mechanical, Microstructural, and Durability Characteristics. Materials 2021, 14, 3800. [Google Scholar] [CrossRef]

- Panda, B.; Paul, S.C.; Hui, L.J.; Tay, Y.W.D.; Tan, M.J. Additive Manufacturing of Geopolymer for Sustainable Built Environment. J. Clean. Prod. 2017, 167, 281–288. [Google Scholar] [CrossRef]

- Panda, B.; Singh, G.B.; Unluer, C.; Tan, M.J. Synthesis and Characterization of One-Part Geopolymers for Extrusion Based 3D Concrete Printing. J. Clean. Prod. 2019, 220, 610–619. [Google Scholar] [CrossRef]

- Ma, G.; Yan, Y.; Zhang, M.; Sanjayan, J. Effect of Steel Slag on 3D Concrete Printing of Geopolymer with Quaternary Binders. Ceram. Int. 2022, 48, 26233–26247. [Google Scholar] [CrossRef]

- Muthukrishnan, S.; Ramakrishnan, S.; Sanjayan, J. Effect of Alkali Reactions on the Rheology of One-Part 3D Printable Geopolymer Concrete. Cem. Concr. Compos. 2021, 116, 103899. [Google Scholar] [CrossRef]

- Panda, B.; Paul, S.C.; Mohamed, N.A.N.; Tay, Y.W.D.; Tan, M.J. Measurement of Tensile Bond Strength of 3D Printed Geopolymer Mortar. Measurement 2018, 113, 108–116. [Google Scholar] [CrossRef]

- Kashani, A.; Ngo, T.D. Optimisation of Mixture Properties for 3D Printing of Geopolymer Concrete. In Proceedings of the 35th International Symposium on Automation and Robotics in Construction (ISARC 2018), Berlin, Germany, 20–25 July 2018; pp. 1–8. [Google Scholar]

- Munir, Q.; Peltonen, R.; Kärki, T. Printing Parameter Requirements for 3D Printable Geopolymer Materials Prepared from Industrial Side Streams. Materials 2021, 14, 4758. [Google Scholar] [CrossRef]

- Zhang, C.; Nerella, V.N.; Krishna, A.; Wang, S.; Zhang, Y.; Mechtcherine, V.; Banthia, N. Mix Design Concepts for 3D Printable Concrete: A Review. Cem. Concr. Compos. 2021, 122, 104155. [Google Scholar] [CrossRef]

- Dudek, M.; Sitarz, M. Analysis of Changes in the Microstructure of Geopolymer Mortar after Exposure to High Temperatures. Materials 2020, 13, 4263. [Google Scholar] [CrossRef] [PubMed]

- Noushini, A.; Castel, A. The Effect of Heat-Curing on Transport Properties of Low-Calcium Fly Ash-Based Geopolymer Concrete. Constr. Build. Mater. 2016, 112, 464–477. [Google Scholar] [CrossRef]

- Zhao, J.; Wang, K.; Wang, S.; Wang, Z.; Yang, Z.; Shumuye, E.D.; Gong, X. Effect of Elevated Temperature on Mechanical Properties of High-Volume Fly Ash-Based Geopolymer Concrete, Mortar and Paste Cured at Room Temperature. Polymers 2021, 13, 1473. [Google Scholar] [CrossRef]

- Palomo, A.; Grutzeck, M.W.; Blanco, M.T. Alkali-Activated Fly Ashes: A Cement for the Future. Cem. Concr. Res. 1999, 29, 1323–1329. [Google Scholar] [CrossRef]

- Perera, D.S.; Uchida, O.; Vance, E.R.; Finnie, K.S. Influence of Curing Schedule on the Integrity of Geopolymers. J. Mater. Sci. 2007, 42, 3099–3106. [Google Scholar] [CrossRef]

- Singh, B.; Ishwarya, G.; Gupta, M.; Bhattacharyya, S.K. Geopolymer Concrete: A Review of Some Recent Developments. Constr. Build. Mater. 2015, 85, 78–90. [Google Scholar] [CrossRef]

- Yousefi Oderji, S.; Chen, B.; Jaffar, S.T.A. Effects of Relative Humidity on the Properties of Fly Ash-Based Geopolymers. Constr. Build. Mater. 2017, 153, 268–273. [Google Scholar] [CrossRef]

- Wang, H.; Zheng, Y.; Yu, Z. Influence of Ambient Relative Humidity on the Shrinkage Strain of Engineered Geopolymer Composites Based on Orthogonal Experimental Design. Materials 2024, 17, 4321. [Google Scholar] [CrossRef]

- García-Mejía, T.A.; Chávez-García, M.d.L. Compressive Strength of Metakaolin-Based Geopolymers: Influence of KOH Concentration, Temperature, Time and Relative Humidity. Mater. Sci. Appl. 2016, 7, 772–791. [Google Scholar] [CrossRef]

- Munir, Q.; Kärki, T. Cost Analysis of Various Factors for Geopolymer 3D Printing of Construction Products in Factories and on Construction Sites. Recycling 2021, 6, 60. [Google Scholar] [CrossRef]

- Fernández-Jiménez, A.; Palomo, A. Characterisation of Fly Ashes. Potential Reactivity as Alkaline Cements☆. Fuel 2003, 82, 2259–2265. [Google Scholar] [CrossRef]

- Kumar, S.; Mucsi, G.; Kristály, F.; Pekker, P. Mechanical Activation of Fly Ash and Its Influence on Micro and Nano-Structural Behaviour of Resulting Geopolymers. Adv. Powder Technol. 2017, 28, 805–813. [Google Scholar] [CrossRef]

- Tome, S.; Nana, A.; Tchakouté, H.K.; Temuujin, J.; Rüscher, C.H. Mineralogical Evolution of Raw Materials Transformed to Geopolymer Materials: A Review. Ceram. Int. 2024, 50, 35855–35868. [Google Scholar] [CrossRef]

- Kriven, W.M.; Leonelli, C.; Provis, J.L.; Boccaccini, A.R.; Attwell, C.; Ducman, V.S.; Ferone, C.; Rossignol, S.; Luukkonen, T.; van Deventer, J.S.J.; et al. Why Geopolymers and Alkali-Activated Materials Are Key Components of a Sustainable World: A Perspective Contribution. J. Am. Ceram. Soc. 2024, 107, 5159–5177. [Google Scholar] [CrossRef]

- Figueiredo, R.A.M.; Brandão, P.R.G.; Soutsos, M.; Henriques, A.B.; Fourie, A.; Mazzinghy, D.B. Producing Sodium Silicate Powder from Iron Ore Tailings for Use as an Activator in One-Part Geopolymer Binders. Mater. Lett. 2021, 288, 129333. [Google Scholar] [CrossRef]

- Assi, L.N.; Carter, K.; Deaver, E.; Ziehl, P. Review of Availability of Source Materials for Geopolymer/Sustainable Concrete. J. Clean. Prod. 2020, 263, 121477. [Google Scholar] [CrossRef]

- Nanda, B.; Mishra, J.; Patro, S.K. Synthesis of Rice Husk Ash Based Alkaline Activators for Geopolymer Binder Systems: A Review. J. Build. Eng. 2024, 91, 109694. [Google Scholar] [CrossRef]

- Abbas, R.; Khereby, M.A.; Ghorab, H.Y.; Elkhoshkhany, N. Preparation of Geopolymer Concrete Using Egyptian Kaolin Clay and the Study of Its Environmental Effects and Economic Cost. Clean Technol. Environ. Policy 2020, 22, 669–687. [Google Scholar] [CrossRef]

- Rao, G.M.; Kumar, Y.A.; Vengala, J.; Venu, M. Performance of Fly Ash and Ggbs Based Geopolymer Concrete Using Single Alkaline Activator Solution and Its Cost Analysis. IOP Conf. Ser. Mater. Sci. Eng. 2020, 998, 012051. [Google Scholar] [CrossRef]

- Mechtcherine, V.; Nerella, V.N.; Will, F.; Näther, M.; Otto, J.; Krause, M. Large-Scale Digital Concrete Construction—CONPrint3D Concept for on-Site, Monolithic 3D-Printing. Autom. Constr. 2019, 107, 102933. [Google Scholar] [CrossRef]

- El-Sayegh, S.; Romdhane, L.; Manjikian, S. A Critical Review of 3D Printing in Construction: Benefits, Challenges, and Risks. Arch. Civ. Mech. Eng. 2020, 20, 34. [Google Scholar] [CrossRef]

- Khan, M.S.; Sanchez, F.; Zhou, H. 3-D Printing of Concrete: Beyond Horizons. Cem. Concr. Res. 2020, 133, 106070. [Google Scholar] [CrossRef]

- Buchli, J.; Giftthaler, M.; Kumar, N.; Lussi, M.; Sandy, T.; Dörfler, K.; Hack, N. Digital in Situ Fabrication—Challenges and Opportunities for Robotic in Situ Fabrication in Architecture, Construction, and Beyond. Cem. Concr. Res. 2018, 112, 66–75. [Google Scholar] [CrossRef]

- Mancke, R.; Stephan, D.; Firdous, R. Case Study—Sustainable Concrete Development: Assessing Social, Environmental, and Performance Factors of Geopolymers and CEM-I Concretes. Case Stud. Constr. Mater. 2024, 21, e03448. [Google Scholar] [CrossRef]

- Kruger, J.; van Zijl, G. A Compendious Review on Lack-of-Fusion in Digital Concrete Fabrication. Addit. Manuf. 2021, 37, 101654. [Google Scholar] [CrossRef]

- Kruger, J.; du Plessis, A.; van Zijl, G. An Investigation into the Porosity of Extrusion-Based 3D Printed Concrete. Addit. Manuf. 2021, 37, 101740. [Google Scholar] [CrossRef]

- Malan, J.D.; van Rooyen, A.S.; van Zijl, G.P.A.G. Chloride Induced Corrosion and Carbonation in 3D Printed Concrete. Infrastructures 2022, 7, 1. [Google Scholar] [CrossRef]

- Van Der Putten, J.; De Volder, M.; Van den Heede, P.; Deprez, M.; Cnudde, V.; De Schutter, G.; Van Tittelboom, K. Transport Properties of 3D Printed Cementitious Materials with Prolonged Time Gap between Successive Layers. Cem. Concr. Res. 2022, 155, 106777. [Google Scholar] [CrossRef]

- Basiago, A.D. Methods of Defining ‘Sustainability’. Sustain. Dev. 1995, 3, 109–119. [Google Scholar] [CrossRef]

- Habert, G.; d’Espinose de Lacaillerie, J.B.; Roussel, N. An Environmental Evaluation of Geopolymer Based Concrete Production: Reviewing Current Research Trends. J. Clean. Prod. 2011, 19, 1229–1238. [Google Scholar] [CrossRef]

- Adesanya, E.; Perumal, P.; Luukkonen, T.; Yliniemi, J.; Ohenoja, K.; Kinnunen, P.; Illikainen, M. Opportunities to Improve Sustainability of Alkali-Activated Materials: A Review of Side-Stream Based Activators. J. Clean. Prod. 2021, 286, 125558. [Google Scholar] [CrossRef]

- Raza, M.H.; Zhong, R.Y. A Sustainable Roadmap for Additive Manufacturing Using Geopolymers in Construction Industry. Resour. Conserv. Recycl. 2022, 186, 106592. [Google Scholar] [CrossRef]

- Borno, I.B.; Nair, N.; Ashraf, W. Alkali Thermal Fusion: A Prospective Route to Enhance the Reactivity of Low-Grade Clay and Utilize as Supplementary Cementitious Material (SCM). Cem. Concr. Compos. 2024, 147, 105417. [Google Scholar] [CrossRef]

- Alberici, S.; de Beer, J.; van der Hoorn, I.; Staats, M. Fly Ash and Blast Furnace Slag for Cement Manufacturing; Department for Business, Energy, and Industrial Strategy (BEIS): London, UK, 2017; pp. 1–34. [Google Scholar]

- Colangelo, F.; Navarro, T.G.; Farina, I.; Petrillo, A. Comparative LCA of Concrete with Recycled Aggregates: A Circular Economy Mindset in Europe. Int. J. Life Cycle Assess. 2020, 25, 1790–1804. [Google Scholar] [CrossRef]

- Green Geopolymer Concretes for Australian Construction Industry|ANSTO. Available online: https://www.ansto.gov.au/our-facilities/australian-synchrotron/case-studies/advanced-manufacturing/green-geopolymer-concretes (accessed on 26 March 2025).

- Zhang, P.; Gao, Z.; Wang, J.; Guo, J.; Hu, S.; Ling, Y. Properties of Fresh and Hardened Fly Ash/Slag Based Geopolymer Concrete: A Review. J. Clean. Prod. 2020, 270, 122389. [Google Scholar] [CrossRef]

- Martínez, A.; Miller, S.A. A Review of Drivers for Implementing Geopolymers in Construction: Codes and Constructability. Resour. Conserv. Recycl. 2023, 199, 107238. [Google Scholar] [CrossRef]

- Alami, A.H.; Olabi, A.G.; Ayoub, M.; Aljaghoub, H.; Alasad, S.; Abdelkareem, M.A. 3D Concrete Printing: Recent Progress, Applications, Challenges, and Role in Achieving Sustainable Development Goals. Buildings 2023, 13, 924. [Google Scholar] [CrossRef]

- van Deventer, J.S.J.; Provis, J.L.; Duxson, P.; Brice, D.G. Chemical Research and Climate Change as Drivers in the Commercial Adoption of Alkali Activated Materials. Waste Biomass Valorization 2010, 1, 145–155. [Google Scholar] [CrossRef]

- Shivendra, B.T.; Shahaji; Sharath Chandra, S.; Singh, A.K.; Kumar, R.; Kumar, N.; Tantri, A.; Naganna, S.R. A Path towards SDGs: Investigation of the Challenges in Adopting 3D Concrete Printing in India. Infrastructures 2024, 9, 166. [Google Scholar] [CrossRef]

- Babafemi, A.J.; Kolawole, J.T.; Miah, M.J.; Paul, S.C.; Panda, B. A Concise Review on Interlayer Bond Strength in 3D Concrete Printing. Sustainability 2021, 13, 7137. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, Y.; Xie, Y.; Zhang, Z.; Banthia, N. Unraveling Pore Structure Alternations in 3D-Printed Geopolymer Concrete and Corresponding Impacts on Macro-Properties. Addit. Manuf. 2022, 59, 103137. [Google Scholar] [CrossRef]

- Özkılıç, H.; İlcan, H.; Aminipour, E.; Tuğluca, M.S.; Aldemir, A.; Şahmaran, M. Bond Properties and Anisotropy Performance of 3D-Printed Construction and Demolition Waste-Based Geopolymers: Effect of Operational- and Material-Oriented Parameters. J. Build. Eng. 2023, 78, 107688. [Google Scholar] [CrossRef]

- Pan, Y.; Jiang, L.; Wang, J.; Ma, J.; Bao, S.; Lin, Y.; Shi, K. Mapping and Evaluating Spatiotemporal Patterns of Urban Expansion in Global Earthquake-Affected Areas: A Nighttime Light Remote Sensing Perspective. Int. J. Digit. Earth 2024, 17, 2419938. [Google Scholar] [CrossRef]

- Huang, Q.; Meng, S.; He, C.; Dou, Y.; Zhang, Q. Rapid Urban Land Expansion in Earthquake-Prone Areas of China. Int. J. Disaster Risk Sci. 2019, 10, 43–56. [Google Scholar] [CrossRef]

- Tran, T.T.; Pham, T.M.; Huang, Z.; Chen, W.; Ngo, T.T.; Hao, H.; Elchalakani, M. Effect of Fibre Reinforcements on Shear Capacity of Geopolymer Concrete Beams Subjected to Impact Load. Int. J. Impact Eng. 2022, 159, 104056. [Google Scholar] [CrossRef]

- Hao, H.; Bi, K.; Chen, W.; Pham, T.M.; Li, J. Towards next Generation Design of Sustainable, Durable, Multi-Hazard Resistant, Resilient, and Smart Civil Engineering Structures. Eng. Struct. 2023, 277, 115477. [Google Scholar] [CrossRef]

- Mostofizadeh, S.; Tee, K.F. Review of Next-Generation Earthquake-Resistant Geopolymer Concrete. Discov. Mater. 2024, 4, 62. [Google Scholar] [CrossRef]

- Passuello, A.; Rodríguez, E.D.; Hirt, E.; Longhi, M.; Bernal, S.A.; Provis, J.L.; Kirchheim, A.P. Evaluation of the Potential Improvement in the Environmental Footprint of Geopolymers Using Waste-Derived Activators. J. Clean. Prod. 2017, 166, 680–689. [Google Scholar] [CrossRef]

- Sona, S.; Sangeetha, S.P. Eco-Friendly Alternative Activators Derived from Industrial Wastes for the Sustainable Production of Two-Part Geopolymer Concrete at Low Cost. Constr. Build. Mater. 2025, 467, 140374. [Google Scholar] [CrossRef]

- Kallamalayil Nassar, A.; Kathirvel, P. Effective Utilization of Agricultural Waste in Synthesizing Activator for Sustainable Geopolymer Technology. Constr. Build. Mater. 2023, 362, 129681. [Google Scholar] [CrossRef]

- Nematollahi, B.; Xia, M.; Sanjayan, J.; Vijay, P. Effect of Type of Fiber on Inter-Layer Bond and Flexural Strengths of Extrusion-Based 3D Printed Geopolymer. Mater. Sci. Forum 2018, 939, 155–162. [Google Scholar] [CrossRef]

- Zhu, H.; Zhang, Z.; Deng, F.; Cao, Y. The Effects of Phase Changes on the Bonding Property of Geopolymer to Hydrated Cement. Constr. Build. Mater. 2013, 48, 124–130. [Google Scholar] [CrossRef]

- Nasvi, M.M.C.; Gamage, R.P.; Jay, S. Geopolymer as Well Cement and the Variation of Its Mechanical Behavior with Curing Temperature. Greenh. Gases Sci. Technol. 2012, 2, 46–58. [Google Scholar] [CrossRef]

- Ng, W.L.; Goh, G.L.; Goh, G.D.; Ten, J.S.J.; Yeong, W.Y. Progress and Opportunities for Machine Learning in Materials and Processes of Additive Manufacturing. Adv. Mater. 2024, 36, 2310006. [Google Scholar] [CrossRef]

- Baduge, S.K.; Thilakarathna, S.; Perera, J.S.; Arashpour, M.; Sharafi, P.; Teodosio, B.; Shringi, A.; Mendis, P. Artificial Intelligence and Smart Vision for Building and Construction 4.0: Machine and Deep Learning Methods and Applications. Autom. Constr. 2022, 141, 104440. [Google Scholar] [CrossRef]

| Technique | Advantages | Drawbacks |

|---|---|---|

| Extrusion-based |

|

|

| Powder-based |

|

|

| Articles Reviewed | Review Focus | Reference |

|---|---|---|

| 134 |

| [17] |

| 164 |

| [18] |

| 140 |

| [14] |

| 204 |

| [19] |

| 127 |

| [20] |

| 152 |

| [16] |

| 191 |

| [21] |

| 167 |

| [22] |

| 132 |

| [23] |

| 296 |

| [24] |

| Precursor and Additives | Alkaline Activator | Shear Rate | Rheological Properties | Reference | |

|---|---|---|---|---|---|

| Yield Stress (Pa) | Viscosity (Pa·s) | ||||

| FA, GGBS | NaOH+ Na2SiO3 | Increased from 0 s−1 to 50 s−1 in 100 s and then decreased from 50 s−1 to 0 s−1 in 100 s | * SYS: 1496.4–3196.6 * DYS: 131.9–504.6 | 5.73–10.49 | [31] |

| FA, GGBS, SF | Anhydrous Na2SiO3 powder | Increased from 6.751 s−1 to 40.46 s−1 in 180 s and then decreased from 40.46 s−1 to 6.751 s−1 in 180 s | 6.74–103.97 | 5.5–8.80 | [32] |

| FA, GGBS, nanocellulose, magnesium oxide (MgO) | NaOH+ Na2SiO3 | Increased from 0 s−1 to 25 s−1 in 60 s, rested for 30 s, and then decreased from 25 s−1 to 0 s−1 in 60 s | 37.12–79.68 | 1.84–2.4 | [33] |

| FA, GGBS, microsilica, clay | NaOH | Pre-shear at 20 s−1 for 300 s, increased to 40 s−1 at a ramp rate of 0.33 s−2 (hysteresis test), and then reduced to zero | * SYS: 8.6–1000 * DYS: 2.86–72 | 0.35–17 | [34] |

| GGBS, calcium carbonate powder | NaOH+ Na2SiO3 | Pre-shear at 100 s−1 for 60 s, increased from 0.1 s−1 to 10 s−1 in 60 s, and increased again from 10 s−1 to 100 s−1 in 60 s. Finally, decreased to 10 s−1 in 60 s and decreased from 10 s−1 to 0.1 s−1 in 60 s. | 1–70 | 10.08–75 | [35] |

| FA, microencapsulated phase-change materials | NaOH+ Na2SiO3 | Increased from 0.2 to 30 s−1 over 20 data points and then decreased from 30 to 0.2 s−1 in a similar way (logarithmic distribution) | 30–530 | 10–90 | [36] |

| FA, GGBS, nanoclay | NaOH+ Na2SiO3 | Constant angular rotation of 0.6 rpm; angular velocity raised to 30 rpm in 2 min and lowered in 2 min (hysteresis loop test) | 615–6000 | 16–39 | [37] |

| Kaolin, polyethylene glycol, polyvinyl alcohol | NaOH+KOH+ CsOH+ | Ranged from 10−2 to 101 s−1 | 308.0–1765.9 | 28.3–180.7 | [38] |

| FA, GGBS, SF | NaOH+ Na2SiO3 | Dynamically varied between 0.1 s−1 and 30 s−1 across 22 intervals | 25.98–56.29 | 8.75–17.06 | [39] |

| MK, ground granulated corex slag (GGCS) | NaOH+ Na2SiO3 | 2.6 s−1 to 0.26 s−1 | * SYS: 1898–1900 * DYS: 1452–1482 | 180.32–207.41 | [40] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mishra, J.; Babafemi, A.J.; Combrinck, R. Limitations and Research Priorities in 3D-Printed Geopolymer Concrete: A Perspective Contribution. Ceramics 2025, 8, 47. https://doi.org/10.3390/ceramics8020047

Mishra J, Babafemi AJ, Combrinck R. Limitations and Research Priorities in 3D-Printed Geopolymer Concrete: A Perspective Contribution. Ceramics. 2025; 8(2):47. https://doi.org/10.3390/ceramics8020047

Chicago/Turabian StyleMishra, Jyotirmoy, Adewumi John Babafemi, and Riaan Combrinck. 2025. "Limitations and Research Priorities in 3D-Printed Geopolymer Concrete: A Perspective Contribution" Ceramics 8, no. 2: 47. https://doi.org/10.3390/ceramics8020047

APA StyleMishra, J., Babafemi, A. J., & Combrinck, R. (2025). Limitations and Research Priorities in 3D-Printed Geopolymer Concrete: A Perspective Contribution. Ceramics, 8(2), 47. https://doi.org/10.3390/ceramics8020047