Ceramics 3D Printing: A Comprehensive Overview and Applications, with Brief Insights into Industry and Market

Abstract

1. Introduction

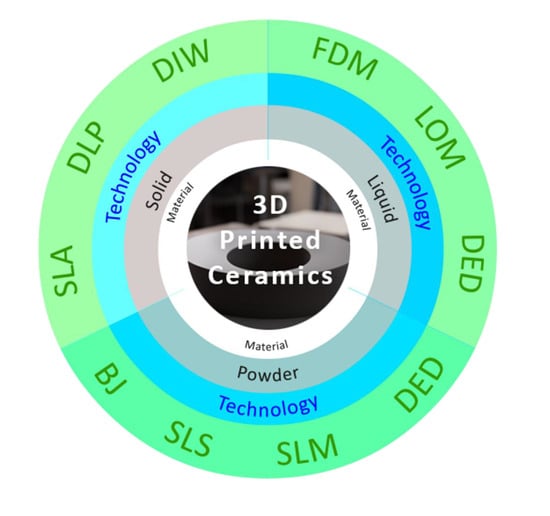

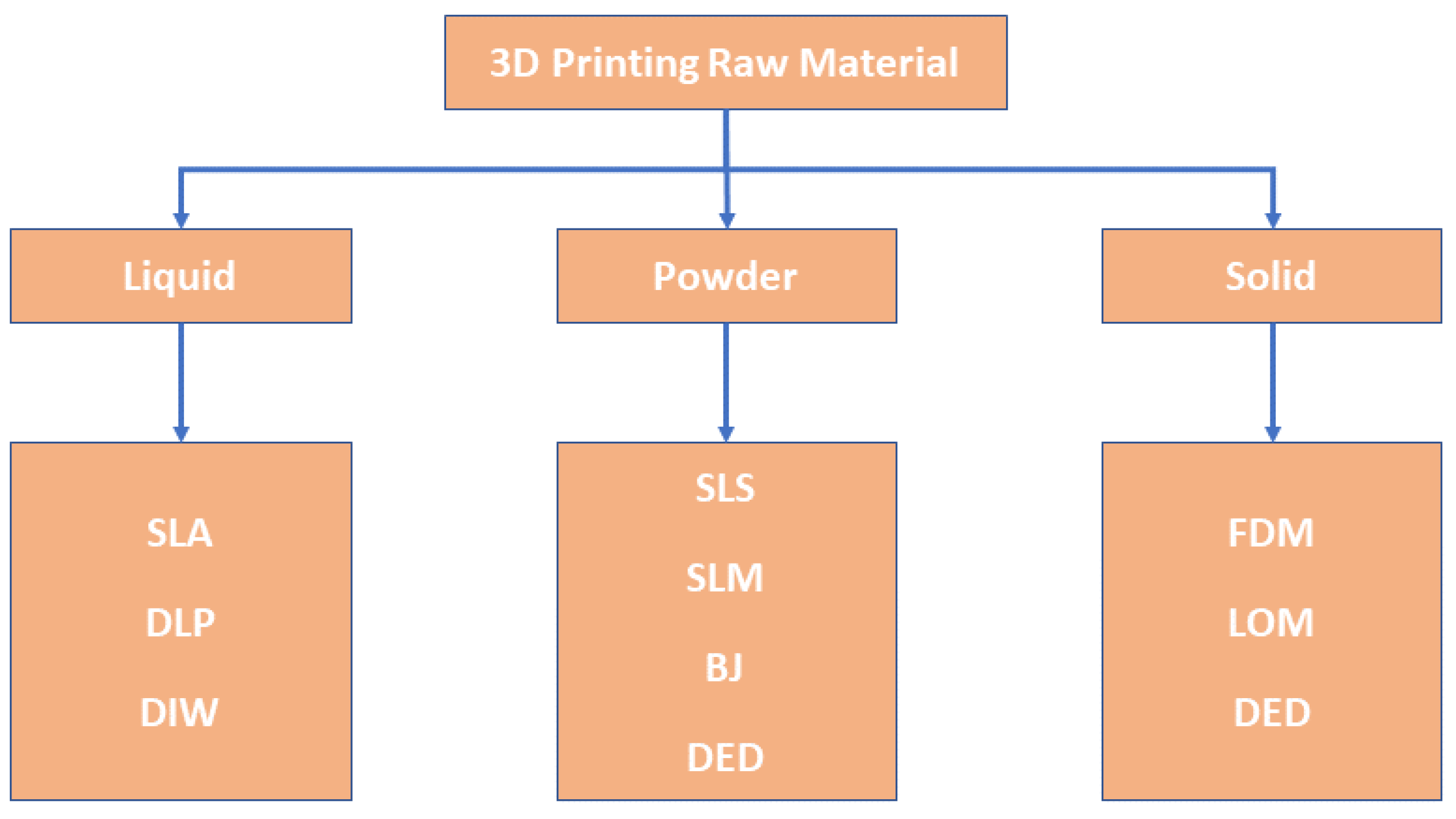

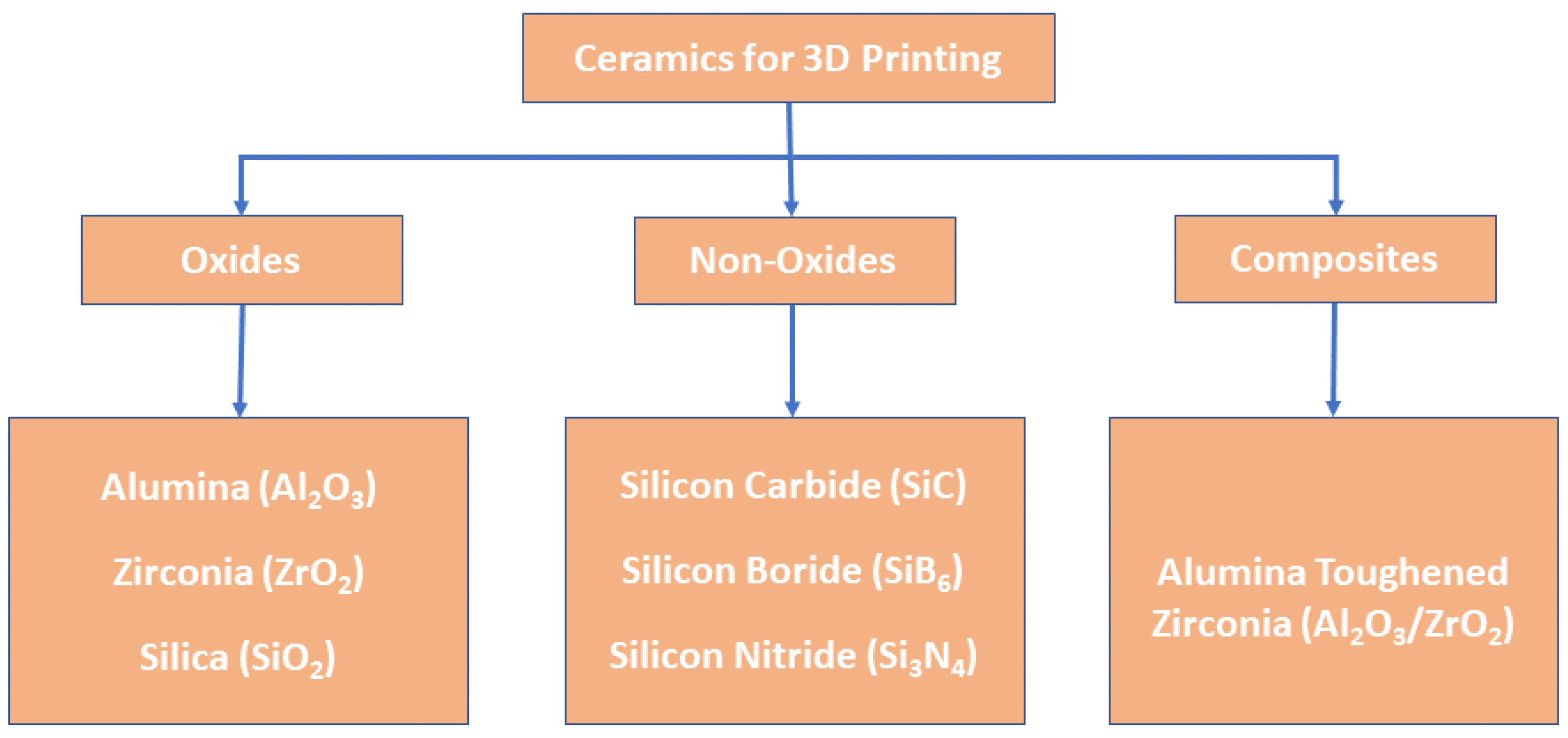

2. Ceramics 3D Printing Methods

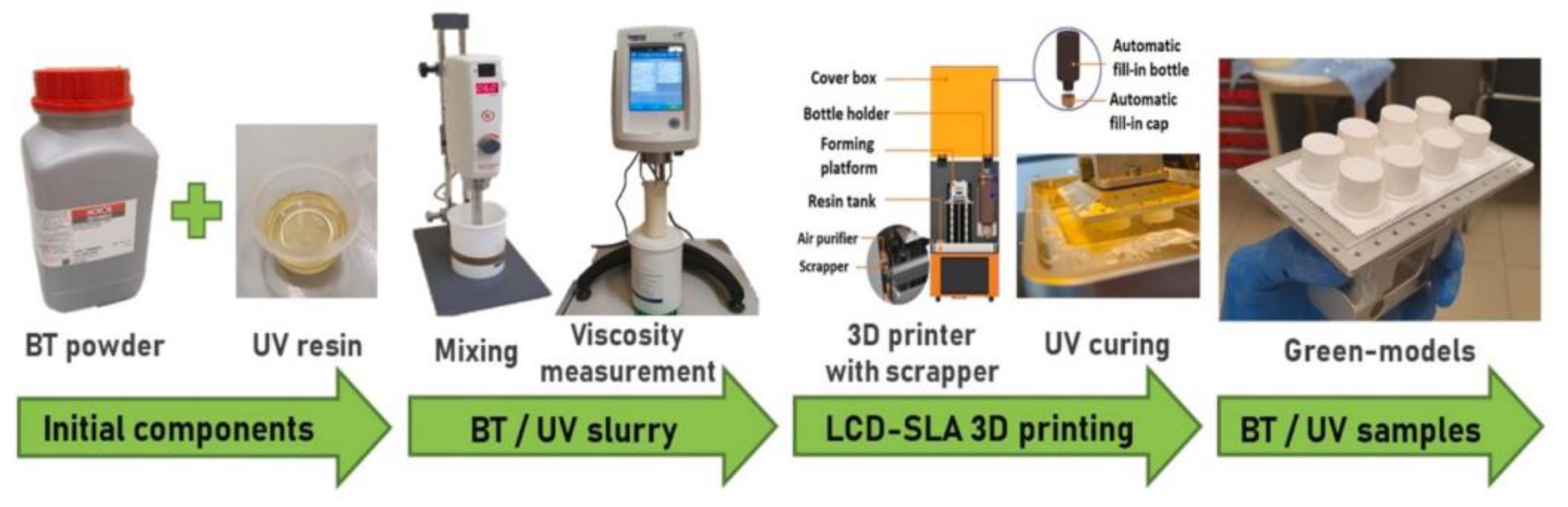

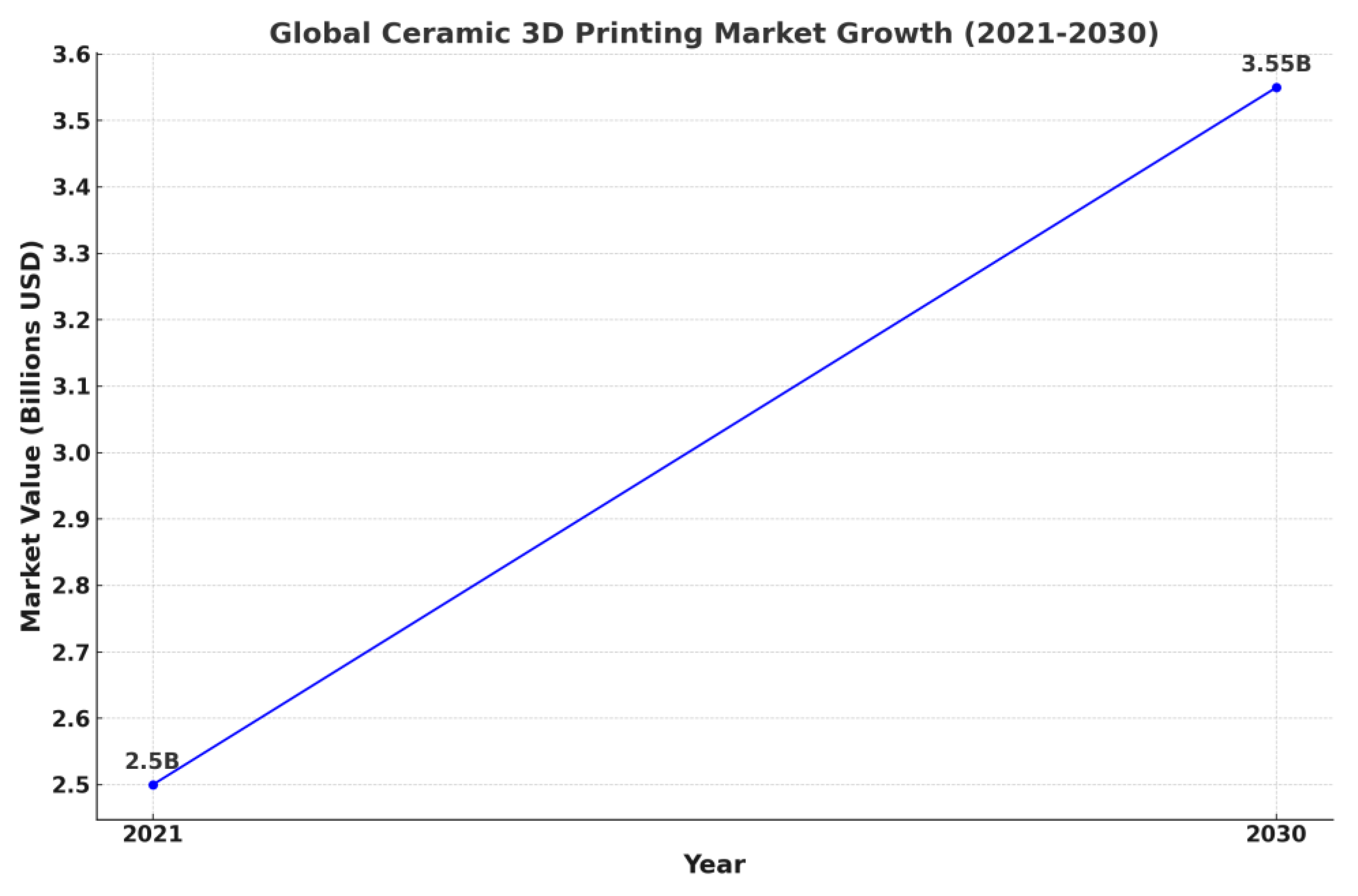

2.1. Stereolithography (SLA)

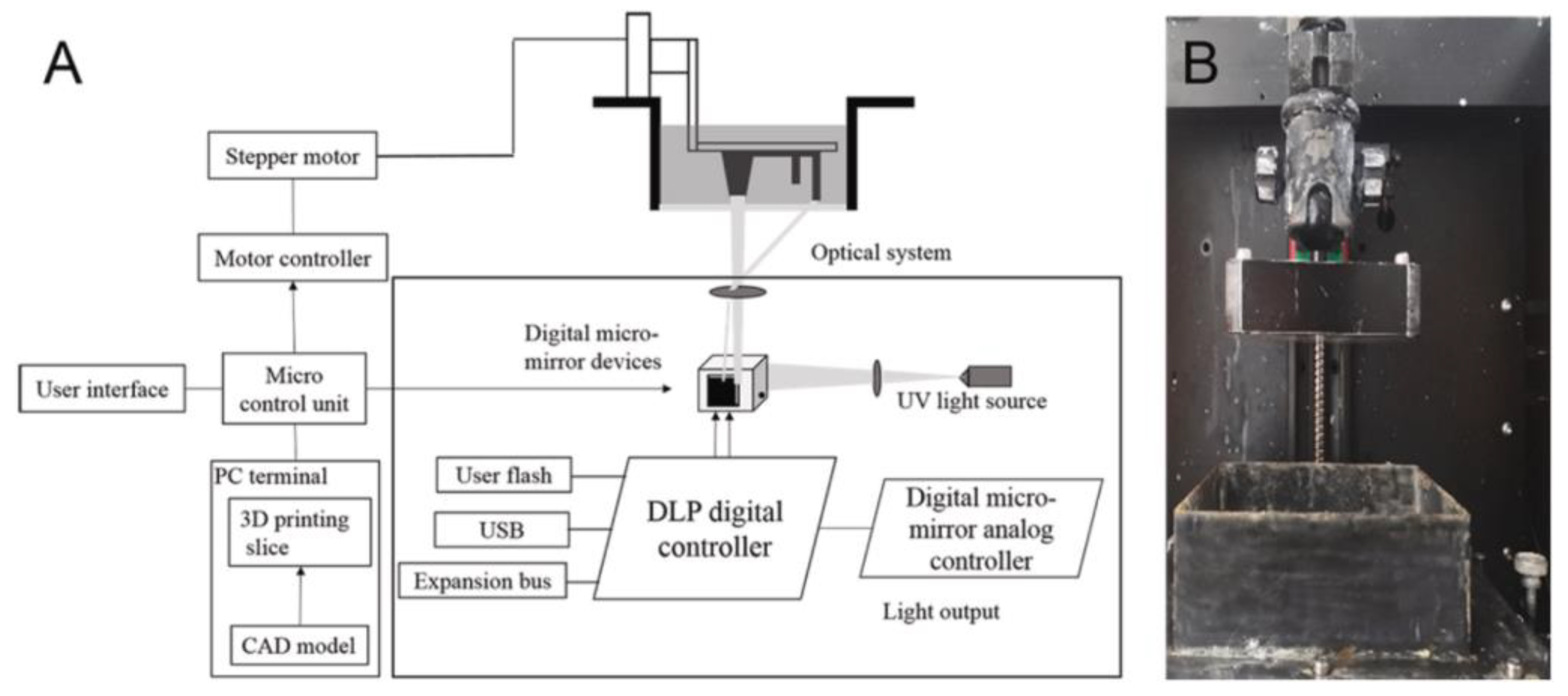

2.2. Digital Light Processing (DLP)

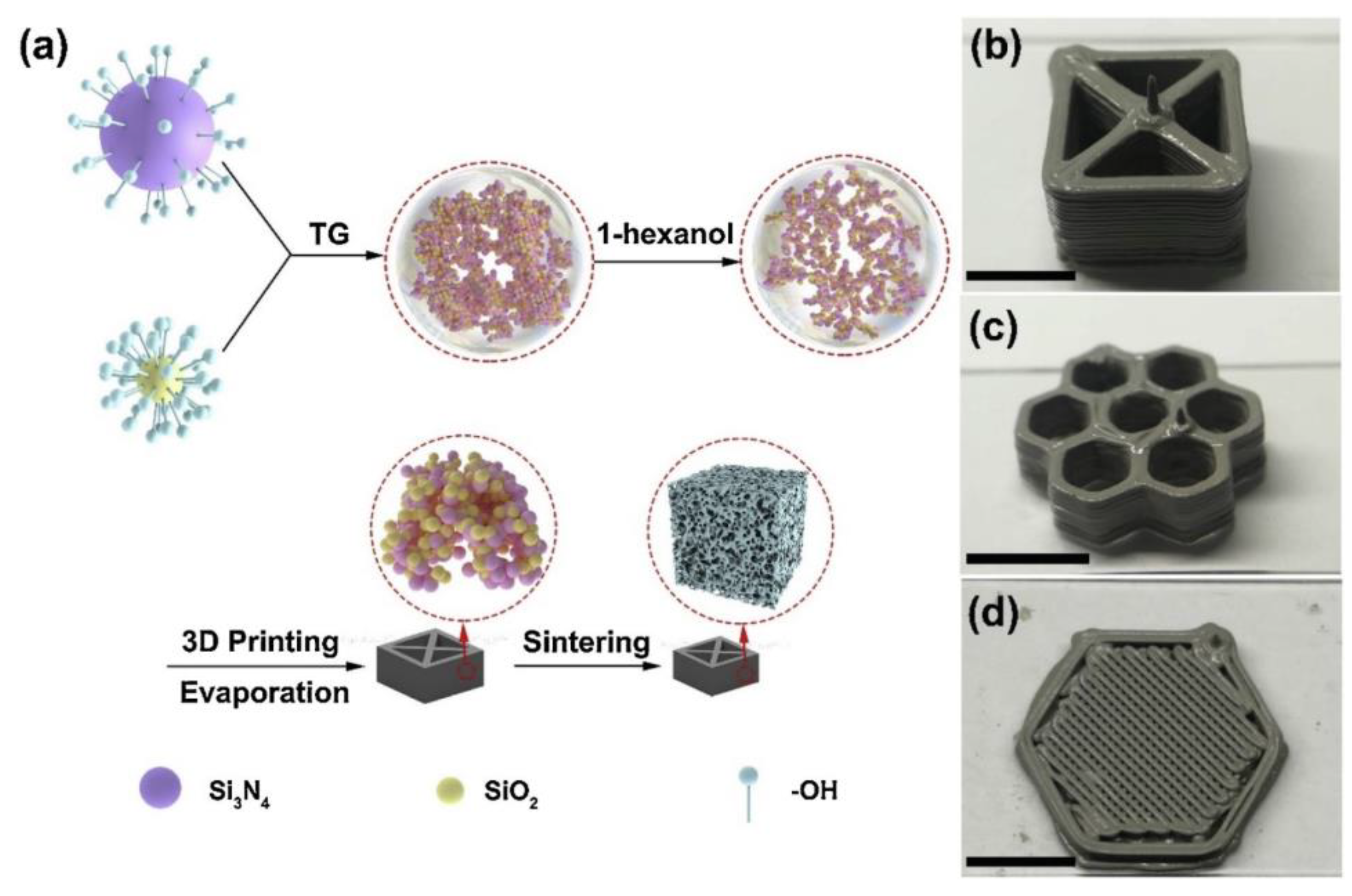

2.3. Direct-Ink-Writing (DIW)

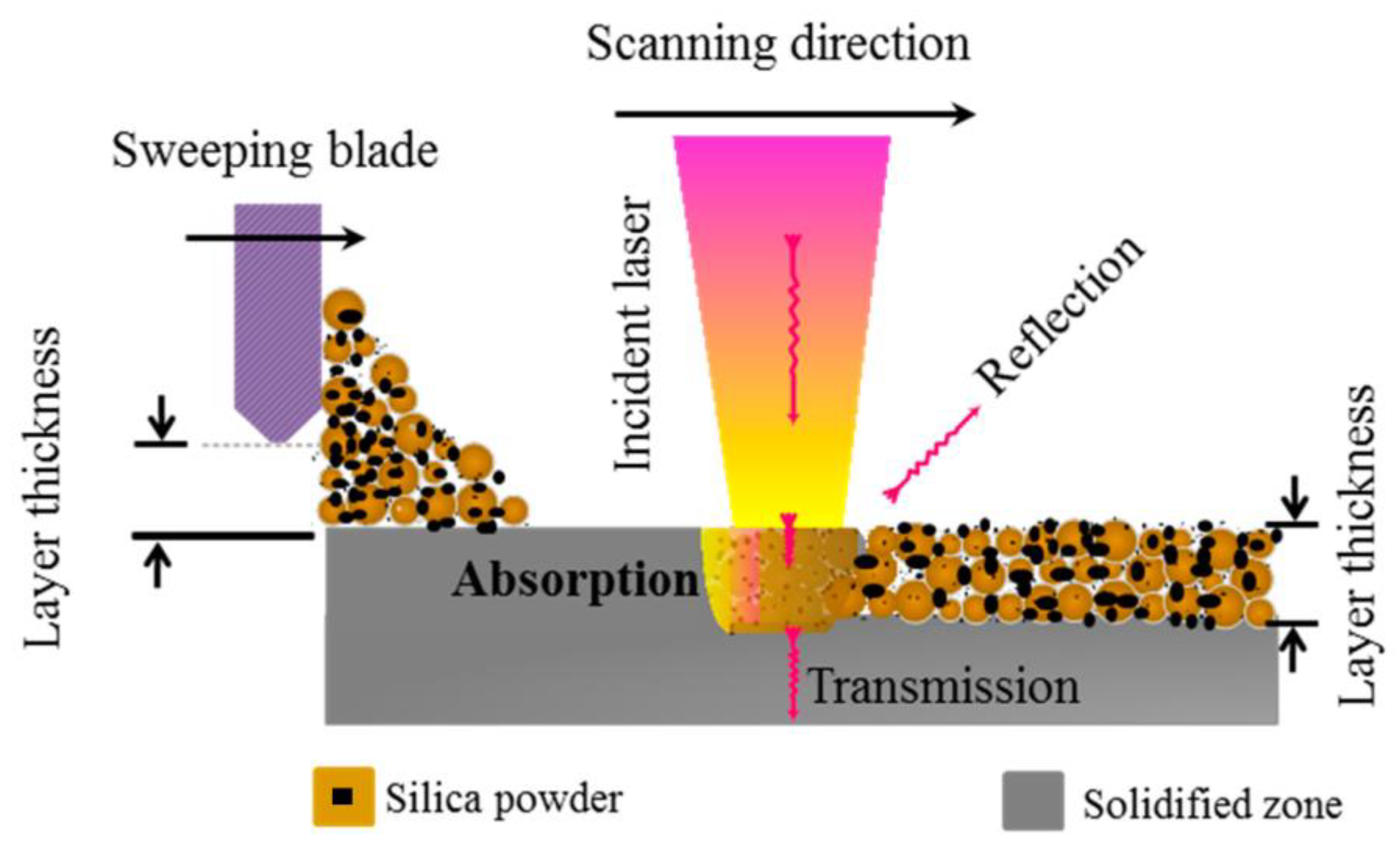

2.4. Selective Laser Sintering (SLS)

2.5. Selective Laser Melting (SLM)

2.6. Binder Jetting (BJ)

2.7. Fused Deposition Modeling (FDM)

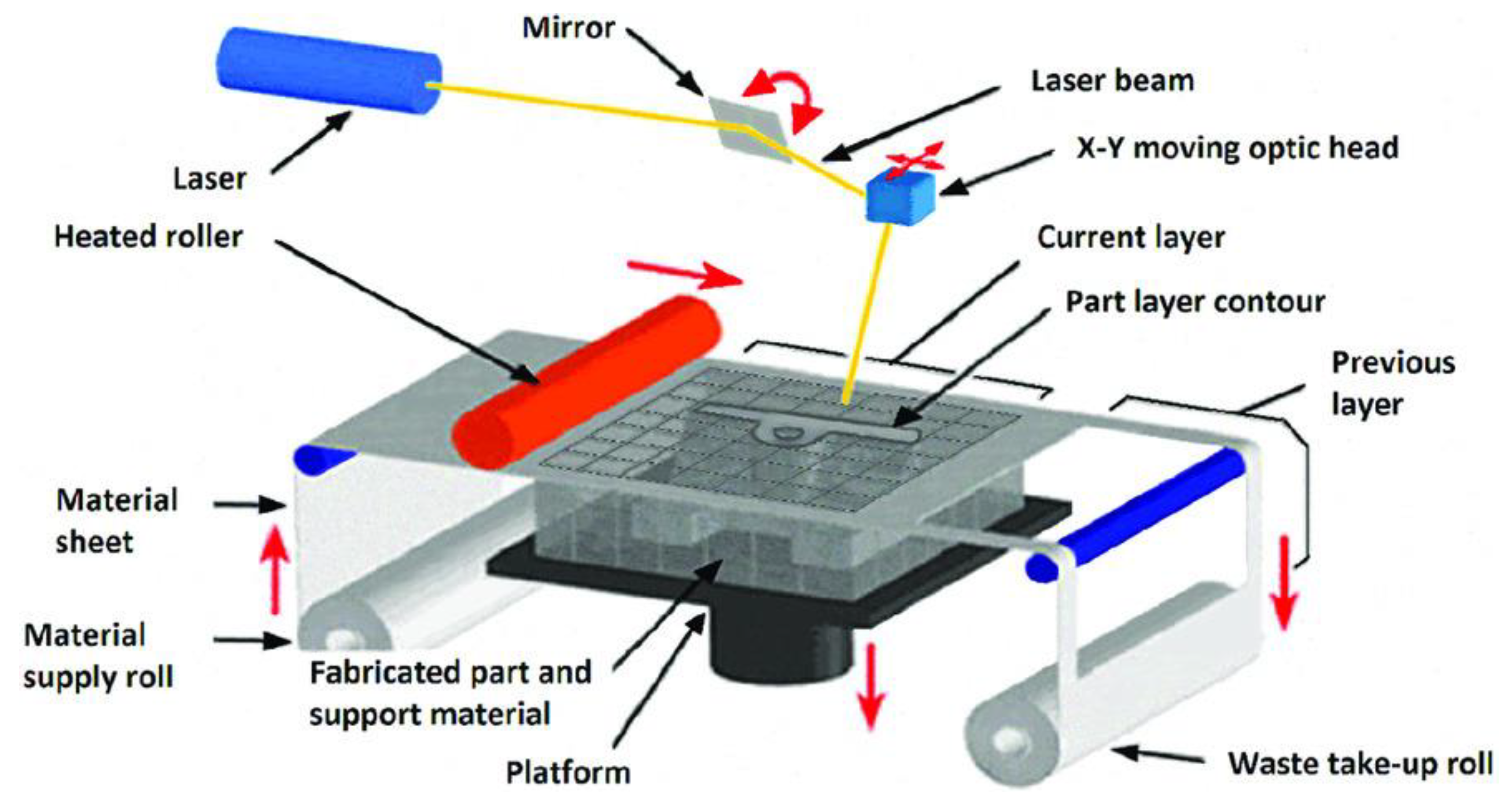

2.8. Laminated Object Manufacturing (LOM)

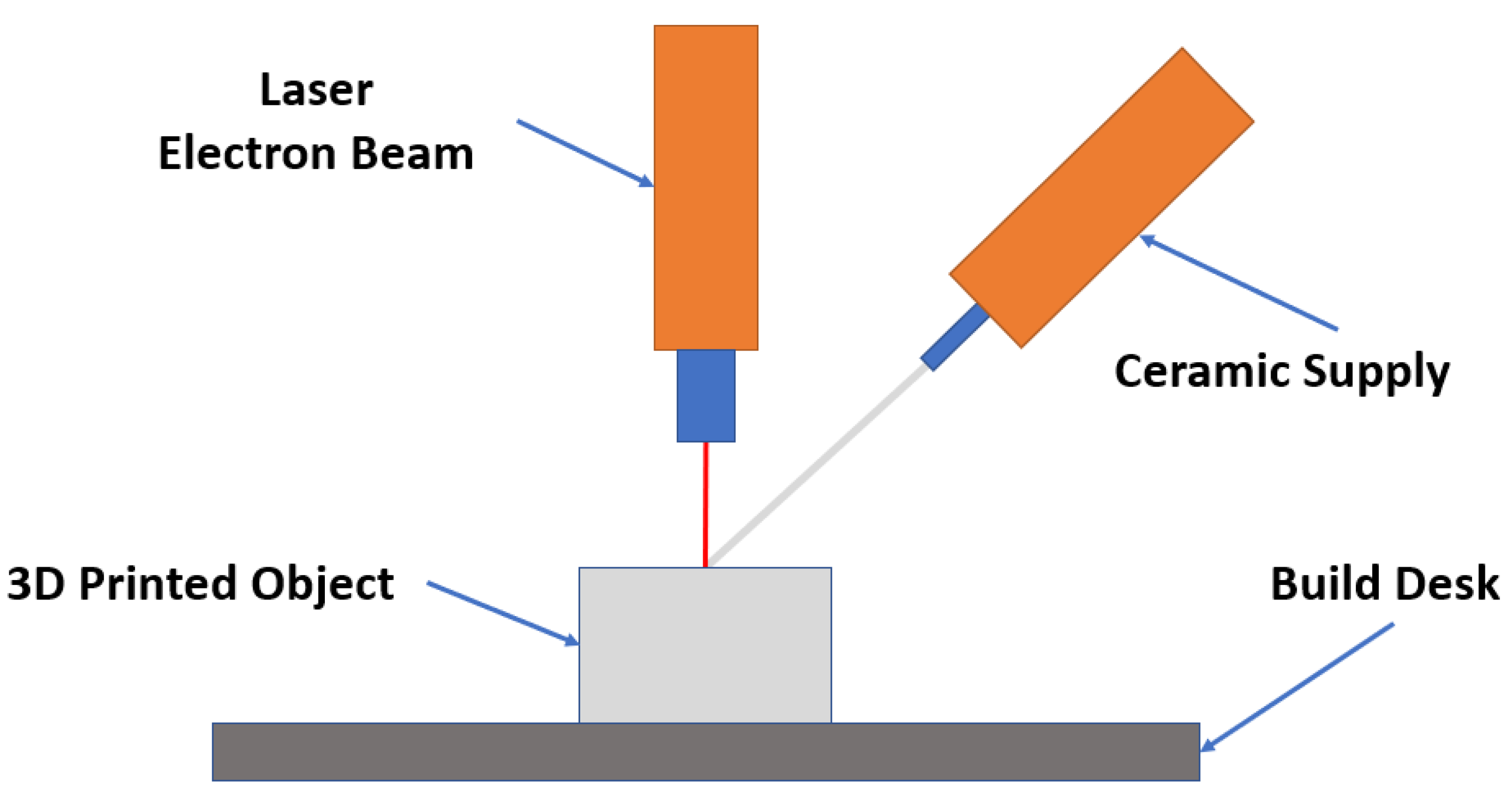

2.9. Directed Energy Deposition (DED)

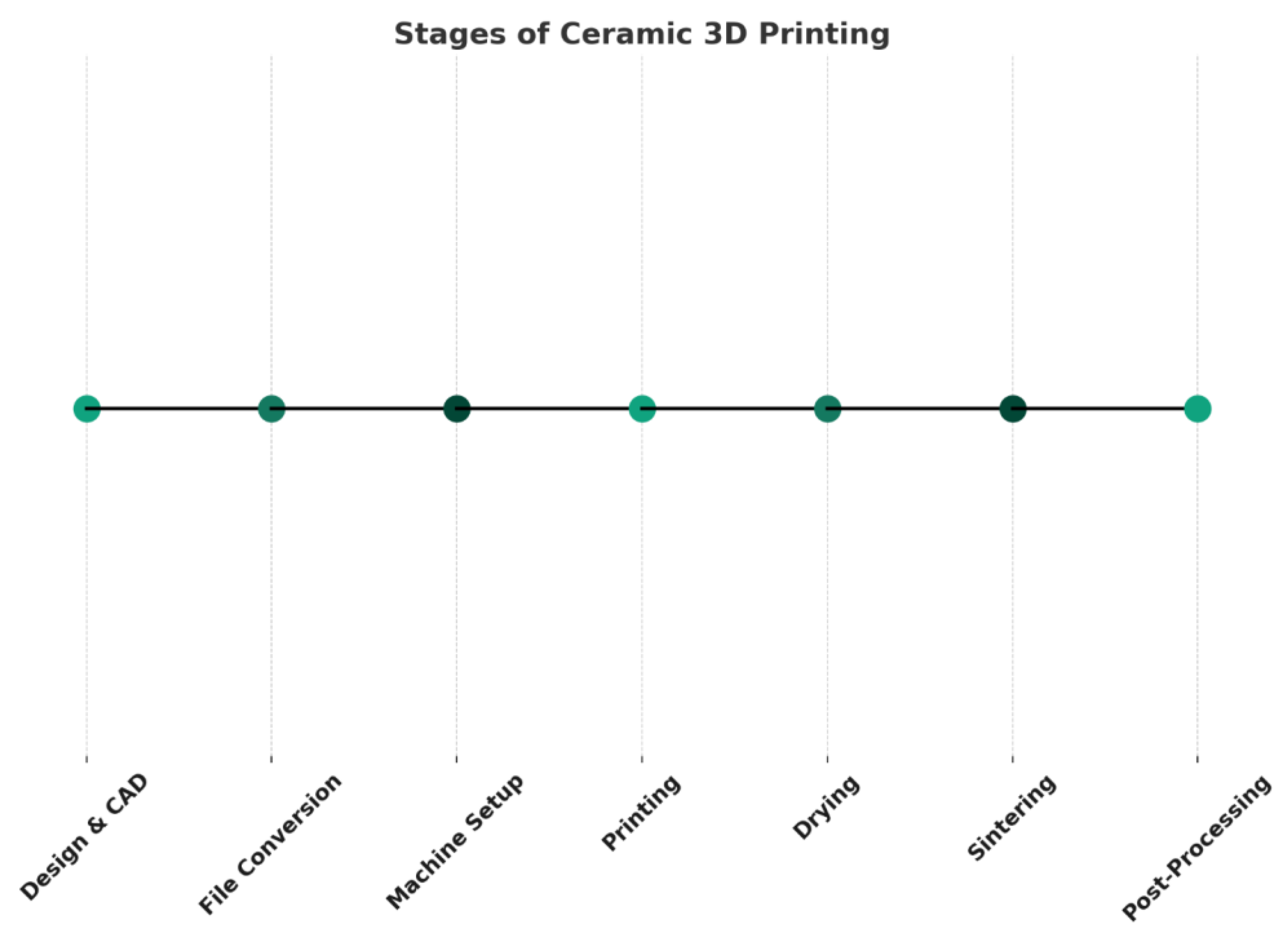

3. Post-Processing and Finishing

- Debinding

- 2.

- Sintering

- 3.

- Surface finishing

4. Applications and Market

4.1. Biomedical Implants and Devices

- Customization and Personalization: 3D printing allows for the creation of implants and devices that are custom fitted to individual patients. This personalization ensures better compatibility and comfort, leading to improved patient outcomes.

- Complex Structures: 3D printing makes it possible to create structures with intricate geometries that mimic the natural complexity of human tissues and bones. This capability is crucial for implants that need to integrate seamlessly with the body’s own systems.

- Material Diversity: The use of various materials, including ceramics, polymers, and metals, in 3D printing provides flexibility in terms of mechanical properties and biocompatibility. Ceramics, for instance, are particularly useful for their bone-like properties and durability.

- Rapid Prototyping: The technology enables quick production and iteration of prototypes. This rapid prototyping is essential in the medical field, where time is often a critical factor.

- Cost-Effectiveness: Producing custom implants and devices traditionally is expensive. 3D printing can reduce these costs, making personalized medical care more accessible.

- Improved Healing and Integration: 3D printed materials can be designed to encourage tissue growth and integration, leading to faster and more effective healing.

- Innovation in Treatment: The ability to print complex devices opens new possibilities in treating conditions that were previously difficult to manage with standard implants.

- Reduced Surgical Time: Customized implants that fit perfectly can reduce the duration of surgeries and the associated risks.

4.2. Aerospace and Automotive Components

- Enhanced Material Properties: Ceramics are known for their high strength, thermal resistance, and durability, making them ideal for aerospace and automotive applications. 3D printing allows for the production of ceramic parts that are lighter yet stronger, significantly improving the performance and efficiency of vehicles and aircraft.

- Complex Geometries: Traditional manufacturing methods often fall short in creating complex shapes required in aerospace and automotive engineering. 3D printing excels at this, allowing for the creation of components with intricate designs and internal structures that were previously impossible or too costly to produce.

- Reduced Weight and Increased Efficiency: In both aerospace and automotive sectors, weight is a critical factor. 3D printed ceramic parts contribute to significant weight reduction, leading to improved fuel efficiency and lower emissions, crucial in an era where environmental impact is a major concern.

- Customization and Rapid Prototyping: 3D printing enables the quick production of customized parts tailored to specific requirements. This flexibility is invaluable for prototyping and testing new designs, speeding up the development process and allowing for more innovation and experimentation.

- Cost Reduction: Manufacturing complex parts often involves high costs, especially in small volumes. 3D printing reduces these costs by simplifying the production process and minimizing material waste, making it a cost-effective solution for both small-scale prototypes and larger production runs.

- Improved Performance: The unique properties of ceramics, combined with the precision of 3D printing, result in parts that perform better under extreme conditions. This is particularly important in aerospace applications where components need to withstand high temperatures and pressures.

- Sustainability: The additive manufacturing process of 3D printing is more sustainable compared to traditional subtractive methods. It produces less waste and consumes less energy, aligning with the growing trend towards more environmentally friendly manufacturing practices in these industries.

4.3. Consumer Electrical Goods and Electronics

- In-House Manufacturing: With 3D printing technology, companies can produce PCBs in-house. This capability is crucial in circumventing supply chain issues, a common challenge in traditional manufacturing. It ensures a more stable and reliable production flow, thereby reducing the dependency on external suppliers and mitigating risks related to delays or disruptions.

- Complex Circuit Design: 3D printing allows for the creation of more intricate and complex circuit designs than traditional methods. This flexibility enables the development of advanced electronic devices with enhanced capabilities, as 3D printing can accurately produce fine details and accommodate unique geometric configurations.

- Speed and Cost-Effectiveness: The process of 3D printing PCBs is generally faster compared to traditional manufacturing techniques. This efficiency is due to the direct-from-design-to-production approach, which eliminates several steps involved in conventional manufacturing. Moreover, 3D printing can be more cost-effective, especially for small batch production and prototyping, as it requires less material waste and reduces the need for multiple tools and molds.

- Customization and Prototyping: 3D printing offers unparalleled customization options. Designers can quickly alter designs and produce prototypes without the need for extensive retooling, facilitating rapid prototyping and testing. This agility accelerates the development cycle, allowing for faster iteration and innovation.

- Environmental Impact: The additive nature of 3D printing, where material is added rather than removed, leads to less waste compared to subtractive manufacturing processes. This aspect contributes to more sustainable manufacturing practices, aligning with the growing emphasis on environmental responsibility in the electronics industry.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yang, J.; Li, N.; Shi, J.; Tang, W.; Zhang, G.; Zhang, F. Foundation of 3D Printing and CAD File Formats Used in the Industry. In Multimaterial 3D Printing Techology; Elsevier: Amsterdam, The Netherlands, 2021; pp. 17–42. ISBN 978-0-08-102991-6. [Google Scholar]

- Zhang, L.; Zhou, L.; Xiao, L. 3D Printing with Cloud Manufacturing. In Customized Production through 3D Printing in Cloud Manufacturing; Elsevier: Amsterdam, The Netherlands, 2023; pp. 27–38. ISBN 978-0-12-823501-0. [Google Scholar]

- Blachowicz, T.; Ehrmann, A. 3D Printed MEMS Technology—Recent Developments and Applications. Micromachines 2020, 11, 434. [Google Scholar] [CrossRef] [PubMed]

- Pagliano, S.; Marschner, D.E.; Maillard, D.; Ehrmann, N.; Stemme, G.; Braun, S.; Villanueva, L.G.; Niklaus, F. Micro 3D Printing of a Functional MEMS Accelerometer. Microsyst. Nanoeng. 2022, 8, 105. [Google Scholar] [CrossRef] [PubMed]

- Sakin, M.; Kiroglu, Y.C. 3D Printing of Buildings: Construction of the Sustainable Houses of the Future by BIM. Energy Procedia 2017, 134, 702–711. [Google Scholar] [CrossRef]

- Wu, P.; Wang, J.; Wang, X. A Critical Review of the Use of 3-D Printing in the Construction Industry. Autom. Constr. 2016, 68, 21–31. [Google Scholar] [CrossRef]

- Habibovic, P.; Gbureck, U.; Doillon, C.; Bassett, D.; Vanblitterswijk, C.; Barralet, J. Osteoconduction and Osteoinduction of Low-Temperature 3D Printed Bioceramic Implants. Biomaterials 2008, 29, 944–953. [Google Scholar] [CrossRef]

- Li, Z.; Wang, Q.; Liu, G. A Review of 3D Printed Bone Implants. Micromachines 2022, 13, 528. [Google Scholar] [CrossRef]

- Ballard, D.H.; Mills, P.; Duszak, R.; Weisman, J.A.; Rybicki, F.J.; Woodard, P.K. Medical 3D Printing Cost-Savings in Orthopedic and Maxillofacial Surgery: Cost Analysis of Operating Room Time Saved with 3D Printed Anatomic Models and Surgical Guides. Acad. Radiol. 2020, 27, 1103–1113. [Google Scholar] [CrossRef]

- Formisano, M.; Iuppariello, L.; Mirone, G.; Cinalli, G.; Casaburi, A.; Guida, P.; Clemente, F. 3D Printed Anatomical Model for Surgical Planning: A Pediatric Hospital Experience. In Proceedings of the 2021 International Conference on e-Health and Bioengineering (EHB), Iasi, Romania, 18 November 2021; IEEE, Piscataway, NJ, USA, 2021; pp. 1–4. [Google Scholar]

- Garmabi, M.M.; Shahi, P.; Tjong, J.; Sain, M. 3D Printing of Polyphenylene Sulfide for Functional Lightweight Automotive Component Manufacturing through Enhancing Interlayer Bonding. Addit. Manuf. 2022, 56, 102780. [Google Scholar] [CrossRef]

- Teniente, J.; Iriarte, J.C.; Caballero, R.; Valcazar, D.; Goni, M.; Martinez, A. 3-D Printed Horn Antennas and Components Performance for Space and Telecommunications. Antennas Wirel. Propag. Lett. 2018, 17, 2070–2074. [Google Scholar] [CrossRef]

- Tuazon, B.J.; Custodio, N.A.V.; Basuel, R.B.; Delos Reyes, L.A.; Dizon, J.R.C. 3D Printing Technology and Materials for Automotive Application: A Mini-Review. KEM 2022, 913, 3–16. [Google Scholar] [CrossRef]

- Yap, Y.L.; Yeong, W.Y. Additive Manufacture of Fashion and Jewellery Products: A Mini Review: This Paper Provides an Insight into the Future of 3D Printing Industries for Fashion and Jewellery Products. Virtual Phys. Prototyp. 2014, 9, 195–201. [Google Scholar] [CrossRef]

- Chakraborty, S.; Biswas, M.C. 3D Printing Technology of Polymer-Fiber Composites in Textile and Fashion Industry: A Potential Roadmap of Concept to Consumer. Compos. Struct. 2020, 248, 112562. [Google Scholar] [CrossRef]

- Boccaccini, A.R. Ceramics. In Biomaterials, Artificial Organs and Tissue Engineering; Elsevier: Amsterdam, The Netherlands, 2005; pp. 26–36. ISBN 978-1-85573-737-2. [Google Scholar]

- Kichkailo, O.V.; Levitskii, I.A. Lithium-Bearing Heat-Resistant Ceramics (A Review). Glass Ceram. 2005, 62, 178–183. [Google Scholar] [CrossRef]

- Hu, H.; Mao, L.; Yin, S.; Liao, H.; Zhang, C. Wear-Resistant Ceramic Coatings Deposited by Liquid Thermal Spraying. Ceram. Int. 2022, 48, 33245–33255. [Google Scholar] [CrossRef]

- Alizadeh-Osgouei, M.; Li, Y.; Wen, C. A Comprehensive Review of Biodegradable Synthetic Polymer-Ceramic Composites and Their Manufacture for Biomedical Applications. Bioact. Mater. 2019, 4, 22–36. [Google Scholar] [CrossRef]

- Hong, K.; Lee, T.H.; Suh, J.M.; Yoon, S.-H.; Jang, H.W. Perspectives and Challenges in Multilayer Ceramic Capacitors for next Generation Electronics. J. Mater. Chem. C 2019, 7, 9782–9802. [Google Scholar] [CrossRef]

- Zeb, A.; Milne, S.J. High Temperature Dielectric Ceramics: A Review of Temperature-Stable High-Permittivity Perovskites. J. Mater. Sci. Mater. Electron. 2015, 26, 9243–9255. [Google Scholar] [CrossRef]

- Wang, T.; Lu, X.; Wang, A. A Review: 3D Printing of Microwave Absorption Ceramics. Int. J. Appl. Ceram. Technol. 2020, 17, 2477–2491. [Google Scholar] [CrossRef]

- Chen, Z.; Li, Z.; Li, J.; Liu, C.; Lao, C.; Fu, Y.; Liu, C.; Li, Y.; Wang, P.; He, Y. 3D Printing of Ceramics: A Review. J. Eur. Ceram. Soc. 2019, 39, 661–687. [Google Scholar] [CrossRef]

- Filippov, Y.Y.; Murashko, A.M.; Evdokimov, P.V.; Safronova, T.V.; Putlayev, V.I. Stereolithography 3D Printed Calcium Pyrophosphate Macroporous Ceramics for Bone Grafting. Open Ceram. 2021, 8, 100185. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhu, J.; He, W.; Liu, Y.; Sang, X.; Liu, R. 3D Printing of Unsupported Multi-Scale and Large-Span Ceramic via near-Infrared Assisted Direct Ink Writing. Nat. Commun. 2023, 14, 2381. [Google Scholar] [CrossRef] [PubMed]

- 3D Printing|Advanced Ceramics. Available online: https://www.bosch-advanced-ceramics.com/implementations/processes/3d-printing/ (accessed on 20 November 2023).

- 3D Printed Ceramics. Available online: https://www.sme.org/technologies/articles/2022/june/3d-printed-ceramics/ (accessed on 20 November 2023).

- Ranjan, R.; Kumar, D.; Kundu, M.; Chandra Moi, S. A Critical Review on Classification of Materials Used in 3D Printing Process. Mater. Today Proc. 2022, 61, 43–49. [Google Scholar] [CrossRef]

- Izdebska-Podsiadły, J. Classification of 3D Printing Methods. In Polymers for 3D Printing; Elsevier: Amsterdam, The Netherlands, 2022; pp. 23–34. ISBN 978-0-12-818311-3. [Google Scholar]

- Different Types of Ceramics (Oxides, Non-Oxides and Composites). Available online: https://www.thomasnet.com/articles/custom-manufacturing-fabricating/types-of-ceramics/ (accessed on 20 November 2023).

- Kurian, M.; Thankachan, S. Introduction: Ceramics Classification and Applications. In Ceramic Catalysts; Elsevier: Amsterdam, The Netherlands, 2023; pp. 1–17. ISBN 978-0-323-85746-8. [Google Scholar]

- Ceramics: Properties, Application and Classification of Ceramics. Available online: https://www.sciencedoze.com/2021/02/ceramics-properties-application-classification.html (accessed on 20 November 2023).

- Regassa Hunde, B.; Debebe Woldeyohannes, A. Future Prospects of Computer-Aided Design (CAD)—A Review from the Perspective of Artificial Intelligence (AI), Extended Reality, and 3D Printing. Results Eng. 2022, 14, 100478. [Google Scholar] [CrossRef]

- Baumann, W.; Schuermann, F.; Odefey, M.; Pfeil, U.M. From GCode to STL: Reconstruct Models from 3D Printing as a Service. IOP Conf. Ser. Mater. Sci. Eng. 2017, 280, 012033. [Google Scholar] [CrossRef]

- Duong, T.H.; Jaksic, N.I.; DePalma, J.L.; Ansaf, B.; Daniel, D.M.; Armijo, J.; Galaviz, M. G-Code Visualization and Editing Program for Inexpensive Metal 3D Printing. Procedia Manuf. 2018, 17, 22–28. [Google Scholar] [CrossRef]

- Karakurt, I.; Lin, L. 3D Printing Technologies: Techniques, Materials, and Post-Processing. Curr. Opin. Chem. Eng. 2020, 28, 134–143. [Google Scholar] [CrossRef]

- Chavez, L.A.; Ibave, P.; Wilburn, B.; Alexander, D.; Stewart, C.; Wicker, R.; Lin, Y. The Influence of Printing Parameters, Post-Processing, and Testing Conditions on the Properties of Binder Jetting Additive Manufactured Functional Ceramics. Ceramics 2020, 3, 65–77. [Google Scholar] [CrossRef]

- Dong, D.; Su, H.; Li, X.; Fan, G.; Zhao, D.; Shen, Z.; Liu, Y.; Guo, Y.; Yang, C.; Liu, L.; et al. Microstructures and Mechanical Properties of Biphasic Calcium Phosphate Bioceramics Fabricated by SLA 3D Printing. J. Manuf. Process. 2022, 81, 433–443. [Google Scholar] [CrossRef]

- Sotov, A.; Kantyukov, A.; Popovich, A.; Sufiiarov, V. LCD-SLA 3D Printing of BaTiO3 Piezoelectric Ceramics. Ceram. Int. 2021, 47, 30358–30366. [Google Scholar] [CrossRef]

- Yao, Y.; Qin, W.; Xing, B.; Sha, N.; Jiao, T.; Zhao, Z. High Performance Hydroxyapatite Ceramics and a Triply Periodic Minimum Surface Structure Fabricated by Digital Light Processing 3D Printing. J. Adv. Ceram. 2021, 10, 39–48. [Google Scholar] [CrossRef]

- Liu, S.; Mo, L.; Bi, G.; Chen, S.; Yan, D.; Yang, J.; Jia, Y.-G.; Ren, L. DLP 3D Printing Porous β-Tricalcium Phosphate Scaffold by the Use of Acrylate/Ceramic Composite Slurry. Ceram. Int. 2021, 47, 21108–21116. [Google Scholar] [CrossRef]

- Guo, J.; Zeng, Y.; Li, P.; Chen, J. Fine Lattice Structural Titanium Dioxide Ceramic Produced by DLP 3D Printing. Ceram. Int. 2019, 45, 23007–23012. [Google Scholar] [CrossRef]

- Jin, H.; Yang, Z.; Zhong, J.; Cai, D.; Li, H.; Jia, D.; Zhou, Y. Mechanical and Dielectric Properties of 3D Printed Highly Porous Ceramics Fabricated via Stable and Durable Gel Ink. J. Eur. Ceram. Soc. 2019, 39, 4680–4687. [Google Scholar] [CrossRef]

- Chen, Z.; Li, D.; Zhou, W.; Wang, L. Curing Characteristics of Ceramic Stereolithography for an Aqueous-Based Silica Suspension. Proc. Inst. Mech. Eng. Part. B J. Eng. Manuf. 2010, 224, 641–651. [Google Scholar] [CrossRef]

- Gao, B.; Zhao, H.; Peng, L.; Sun, Z. A Review of Research Progress in Selective Laser Melting (SLM). Micromachines 2022, 14, 57. [Google Scholar] [CrossRef]

- Chang, S.; Li, L.; Lu, L.; Fuh, J. Selective Laser Sintering of Porous Silica Enabled by Carbon Additive. Materials 2017, 10, 1313. [Google Scholar] [CrossRef] [PubMed]

- Ratna, D. Properties and Processing of Thermoset Resin. In Recent Advances and Applications of Thermoset Resins; Elsevier: Amsterdam, The Netherlands, 2022; pp. 173–292. ISBN 978-0-323-85664-5. [Google Scholar]

- Gibson, I.; Rosen, D.; Stucker, B.; Khorasani, M. Binder Jetting. In Additive Manufacturing Technologies; Springer International Publishing: Cham, Switzerland, 2021; pp. 237–252. ISBN 978-3-030-56126-0. [Google Scholar]

- Lv, X.; Ye, F.; Cheng, L.; Fan, S.; Liu, Y. Binder Jetting of Ceramics: Powders, Binders, Printing Parameters, Equipment, and Post-Treatment. Ceram. Int. 2019, 45, 12609–12624. [Google Scholar] [CrossRef]

- Zocca, A.; Colombo, P.; Gomes, C.M.; Günster, J. Additive Manufacturing of Ceramics: Issues, Potentialities, and Opportunities. J. Am. Ceram. Soc. 2015, 98, 1983–2001. [Google Scholar] [CrossRef]

- Masuda, H.; Ohta, Y.; Kitayama, M. Additive Manufacturing of SiC Ceramics with Complicated Shapes Using the FDM Type 3D-Printer. J. Mater. Sci. Chem. Eng. 2019, 7, 1–12. [Google Scholar] [CrossRef]

- Zhang, G.; Guo, J.; Chen, H.; Cao, Y. Organic Mesh Template-Based Laminated Object Manufacturing to Fabricate Ceramics with Regular Micron Scaled Pore Structures. J. Eur. Ceram. Soc. 2021, 41, 2790–2795. [Google Scholar] [CrossRef]

- Dermeik, B.; Travitzky, N. Laminated Object Manufacturing of Ceramic-Based Materials. Adv. Eng. Mater. 2020, 22, 2000256. [Google Scholar] [CrossRef]

- Svetlizky, D.; Das, M.; Zheng, B.; Vyatskikh, A.L.; Bose, S.; Bandyopadhyay, A.; Schoenung, J.M.; Lavernia, E.J.; Eliaz, N. Directed Energy Deposition (DED) Additive Manufacturing: Physical Characteristics, Defects, Challenges and Applications. Mater. Today 2021, 49, 271–295. [Google Scholar] [CrossRef]

- Lalegani Dezaki, M.; Serjouei, A.; Zolfagharian, A.; Fotouhi, M.; Moradi, M.; Ariffin, M.K.A.; Bodaghi, M. A Review on Additive/Subtractive Hybrid Manufacturing of Directed Energy Deposition (DED) Process. Adv. Powder Mater. 2022, 1, 100054. [Google Scholar] [CrossRef]

- Li, H.; Liu, Y.; Liu, Y.; Zeng, Q.; Hu, K.; Lu, Z.; Liang, J. Effect of Debinding Temperature under an Argon Atmosphere on the Microstructure and Properties of 3D-Printed Alumina Ceramics. Mater. Charact. 2020, 168, 110548. [Google Scholar] [CrossRef]

- Li, H.; Liu, Y.; Liu, Y.; Hu, K.; Lu, Z.; Liang, J. Effects of Solvent Debinding on the Microstructure and Properties of 3D-Printed Alumina Ceramics. ACS Omega 2020, 5, 27455–27462. [Google Scholar] [CrossRef] [PubMed]

- Liu, K.; Hu, J.; Du, Y.; Shi, Y.; Sun, Y.; Zhang, S.; Tu, R.; Zhang, Q.; Huang, S.; Sun, H. Influence of Particle Size on 3D-printed Piezoelectric Ceramics via Digital Light Processing with Furnace Sintering. Int. J. Appl. Ceram. Tech. 2022, 19, 2461–2471. [Google Scholar] [CrossRef]

- Li, H.; Hu, K.; Liu, Y.; Lu, Z.; Liang, J. Improved Mechanical Properties of Silica Ceramic Cores Prepared by 3D Printing and Sintering Processes. Scr. Mater. 2021, 194, 113665. [Google Scholar] [CrossRef]

- Curto, H.; Thuault, A.; Jean, F.; Violier, M.; Dupont, V.; Hornez, J.-C.; Leriche, A. Coupling Additive Manufacturing and Microwave Sintering: A Fast Processing Route of Alumina Ceramics. J. Eur. Ceram. Soc. 2020, 40, 2548–2554. [Google Scholar] [CrossRef]

- Tarafder, S.; Balla, V.K.; Davies, N.M.; Bandyopadhyay, A.; Bose, S. Microwave-Sintered 3D Printed Tricalcium Phosphate Scaffolds for Bone Tissue Engineering: 3D Printed TCP Scaffolds for Bone Tissue Engineering. J. Tissue Eng. Regen. Med. 2013, 7, 631–641. [Google Scholar] [CrossRef]

- Torresani, E.; Carrillo, M.; Haines, C.; Martin, D.; Olevsky, E. Fabrication of Powder Components with Internal Channels by Spark Plasma Sintering and Additive Manufacturing. J. Eur. Ceram. Soc. 2023, 43, 1117–1126. [Google Scholar] [CrossRef]

- Brucculeri, R.; Airoldi, L.; Baldini, P.; Vigani, B.; Rossi, S.; Morganti, S.; Auricchio, F.; Anselmi-Tamburini, U. Spark Plasma Sintering of Complex Metal and Ceramic Structures Produced by Material Extrusion. 3d Print. Addit. Manuf. 2023, 3dp.2022.0279. [Google Scholar] [CrossRef]

- Xing, H.; Zou, B.; Li, S.; Fu, X. Study on Surface Quality, Precision and Mechanical Properties of 3D Printed ZrO2 Ceramic Components by Laser Scanning Stereolithography. Ceram. Int. 2017, 43, 16340–16347. [Google Scholar] [CrossRef]

- Shetty, S.; Nandish, B.T.; Amin, V.; Jayaprakash, K.; Shahira; Stanly Selva Kumar, G.S.; Khan, F.; Harish, P. 3D Printed Polyether Ether Ketone (PEEK), Polyamide (PA) and Its Evaluation of Mechanical Properties and Its Uses in Healthcare Applications. IOP Conf. Ser. Mater. Sci. Eng. 2022, 1224, 012005. [Google Scholar] [CrossRef]

- Das, M.; Ambekar, R.S.; Panda, S.K.; Chakraborty, S.; Tiwary, C.S. 2D Nanomaterials in 3D/4D-Printed Biomedical Devices. J. Mater. Res. 2021, 36, 4024–4050. [Google Scholar] [CrossRef]

- Mamo, H.B.; Adamiak, M.; Kunwar, A. 3D Printed Biomedical Devices and Their Applications: A Review on State-of-the-Art Technologies, Existing Challenges, and Future Perspectives. J. Mech. Behav. Biomed. Mater. 2023, 143, 105930. [Google Scholar] [CrossRef]

- Hales, S.; Tokita, E.; Neupane, R.; Ghosh, U.; Elder, B.; Wirthlin, D.; Kong, Y.L. 3D Printed Nanomaterial-Based Electronic, Biomedical, and Bioelectronic Devices. Nanotechnology 2020, 31, 172001. [Google Scholar] [CrossRef]

- Ceramics, Refractories, and Glasses. In Materials Handbook; Springer: London, UK, 2008; pp. 593–689. ISBN 978-1-84628-668-1.

- Mantripragada, V.P.; Lecka-Czernik, B.; Ebraheim, N.A.; Jayasuriya, A.C. An Overview of Recent Advances in Designing Orthopedic and Craniofacial Implants. J. Biomed. Mater. Res. 2013, 101, 3349–3364. [Google Scholar] [CrossRef]

- Dahotre, N.B.; Kadolkar, P.; Shah, S. Refractory Ceramic Coatings: Processes, Systems and Wettability/Adhesion. Surf. Interface Anal. 2001, 31, 659–672. [Google Scholar] [CrossRef]

- Using Ceramic 3D Printing to Achieve Complex Aerospace Structures—3Dnatives. Available online: https://www.3dnatives.com/en/using-ceramic-3d-printing-to-achieve-complex-aerospace-structures-150520234/ (accessed on 16 November 2023).

- How Are Lithoz Ceramic Materials Revolutionizing Aerospace?—3Dnatives. Available online: https://www.3dnatives.com/en/how-are-lithoz-ceramic-materials-revolutionizing-aerospace-070320225/ (accessed on 16 November 2023).

- Alhendi, M.; Alshatnawi, F.; Abbara, E.M.; Sivasubramony, R.; Khinda, G.; Umar, A.I.; Borgesen, P.; Poliks, M.D.; Shaddock, D.; Hoel, C.; et al. Printed Electronics for Extreme High Temperature Environments. Addit. Manuf. 2022, 54, 102709. [Google Scholar] [CrossRef]

- Lakhdar, Y.; Tuck, C.; Binner, J.; Terry, A.; Goodridge, R. Additive Manufacturing of Advanced Ceramic Materials. Prog. Mater. Sci. 2021, 116, 100736. [Google Scholar] [CrossRef]

- Pelz, J.S.; Ku, N.; Meyers, M.A.; Vargas-Gonzalez, L.R. Additive Manufacturing of Structural Ceramics: A Historical Perspective. J. Mater. Res. Technol. 2021, 15, 670–695. [Google Scholar] [CrossRef]

- Dadkhah, M.; Tulliani, J.-M.; Saboori, A.; Iuliano, L. Additive Manufacturing of Ceramics: Advances, Challenges, and Outlook. J. Eur. Ceram. Soc. 2023, 43, 6635–6664. [Google Scholar] [CrossRef]

- 3D Systems. Available online: https://www.3dsystems.com/ (accessed on 4 December 2023).

- Industrial 3D Printing & 3D Printer Manufacturer|Voxeljet. Available online: https://www.voxeljet.com/ (accessed on 4 December 2023).

- ADMATEC—Advanced Ceramic and Metal 3D Printing on One System Using Digital Light Processing or Stereo Lithography Based Additive Manufacturing Technology. Available online: https://admateceurope.com/ (accessed on 4 December 2023).

- Lithoz: 3D-Druck Für Keramik—Eine Weitere WordPress-Website. Available online: https://lithoz.com/en/ (accessed on 4 December 2023).

- 3D Printers|WASP. Available online: https://www.3dwasp.com/en/ (accessed on 4 December 2023).

- Tethon 3D. Available online: https://tethon3d.com/ (accessed on 4 December 2023).

- 3DCeram l Ceramic 3D Printer: The Process Turnkey Provider. Available online: https://3dceram.com/ (accessed on 4 December 2023).

- Prodways|MOVINGLight® and SLS® 3D Printers for Industrial and Dental Applications. Available online: https://www.prodways.com/en/ (accessed on 4 December 2023).

- 3D Potter—Real Clay 3D Ceramic Printers. Available online: https://3dpotter.com/ (accessed on 4 December 2023).

- Nanoe—Development of Ceramic Materials for the Industries. Available online: https://nanoe.com/en/ (accessed on 10 January 2024).

- Ceramic 3D Printing Market Size, Share and Forecast to 2030. Available online: https://www.sphericalinsights.com/reports/ceramic-3d-printing-market (accessed on 20 November 2023).

| Raw Material | Technology | Structure Joining Method | Energy Source | Printing Resolution | The Need for Part Support | Raw Material Cost | Printing Cost | Refs. |

|---|---|---|---|---|---|---|---|---|

| Liquid | SLA | Polymerization | Laser | μm | Yes | High | middle | [38,39] |

| Liquid | DLP | Polymerization | Laser | μm | Yes | High | Middle | [41,42] |

| Liquid | BJ | Bond | Mechanical | mm-cm | No | Middle | Low | [48,49,50] |

| Liquid | DIW | Extrusion | Heat | μm-mm | Yes | Low | Low | [43] |

| Powder | SLS/DED | Powder fusion | Laser | μm-mm | No | Low | High | [23,44] |

| Powder | SLM | Powder fusion | Laser | μm-mm | No | Low | High | [47] |

| Solid | LOM | Layer bonding | Laser | μm-mm | No | Middle | Low | [52,53] |

| Solid | FDM | Extrusion | Heat | mm | No | Middle | Middle | [51] |

| Type of Ceramic | Properties | Application Sector | Ref. |

|---|---|---|---|

| Oxides | High thermal stability, electrical insulation | Electronics, aerospace | [23] |

| Non-Oxides | Enhanced mechanical strength, chemical resistance | Biomedical implants, chemical processing | [75] |

| Composites | Improved toughness, multi-functional characteristics | Automotive, aerospace components | [76] |

| Hybrids | Synergistic properties, customizable | Electronics, biomedical devices | [77] |

| Dense | High density, uniform microstructure | Optical components, energy storage | [23] |

| Cellular | Lightweight, porous structure | Filtration systems, scaffolds in tissue engineering | [75] |

| Company | Technologies Used | Products/Contributions | General Insights | Ref. |

|---|---|---|---|---|

| 3D Systems (Rock Hill, SC, USA) | Various 3D printing technologies | A wide range of 3D printers and materials, including ceramics | Known for pioneering in 3D printing, with a focus on innovation and versatility. | [78] |

| Voxeljet AG (Friedberg, Germany) | Powder Bed Fusion (PBF), Binder Jetting | Large-format industrial 3D printing systems, especially for complex ceramic components | Specializes in high-speed, large-scale 3D printing solutions. | [79] |

| Admatec BV (Goirle, The Neitherlands) | Lithography-based Ceramic Manufacturing (LCM) | Advanced ceramic 3D printers for high-quality ceramic parts | Focuses on precision and quality in ceramic 3D printing. | [80] |

| Lithoz (Wien, Austria) | LCM technology | Ceramic 3D printers and materials, including the recent LithaGlass | Renowned for high-precision ceramic printing and innovative material development. | [81] |

| Wasp S.r.l. (Massa Lombarda, Italy) | Delta 3D printing technology | 3D printers capable of handling ceramic materials | Known for sustainable and cost-effective 3D printing solutions. | [82] |

| Tethon 3D (Omaha, NE, USA) | Various 3D printing technologies | Ceramic powders, 3D printing services, and proprietary 3D printing technologies including their own Tethonite® ceramic powders and Bison 1000 DLP printer | Tethon 3D stands out for its focus on proprietary materials and printers tailored for ceramic 3D printing, bridging the gap between art and industry with a comprehensive approach | [83] |

| 3Dceram (Bonnac-la-Côte, France) | Stereolithography (SLA) | Customized ceramic components and 3D printers | Offers a unique blend of 3D printing services and ceramic expertise. | [84] |

| Prodways (Montigny-le-Bretonneux, France) | Moving Light technology | Industrial 3D printers for ceramics and other materials | Known for its high-resolution printers and innovative technologies. | [85] |

| 3D Potter (Stuart, FL, USA) | Custom 3D printing solutions- Clay printing | Specializes in large format 3D printers for ceramics | Focuses on versatility and custom solutions in 3D printing. | [86] |

| Nanoe (Ballainvilliers, France) | Zetamix technology | Ceramic filaments and 3D printers for accessible ceramic printing | Innovates in making ceramic 3D printing more accessible and versatile. | [87] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abdelkader, M.; Petrik, S.; Nestler, D.; Fijalkowski, M. Ceramics 3D Printing: A Comprehensive Overview and Applications, with Brief Insights into Industry and Market. Ceramics 2024, 7, 68-85. https://doi.org/10.3390/ceramics7010006

Abdelkader M, Petrik S, Nestler D, Fijalkowski M. Ceramics 3D Printing: A Comprehensive Overview and Applications, with Brief Insights into Industry and Market. Ceramics. 2024; 7(1):68-85. https://doi.org/10.3390/ceramics7010006

Chicago/Turabian StyleAbdelkader, Mohamed, Stanislav Petrik, Daisy Nestler, and Mateusz Fijalkowski. 2024. "Ceramics 3D Printing: A Comprehensive Overview and Applications, with Brief Insights into Industry and Market" Ceramics 7, no. 1: 68-85. https://doi.org/10.3390/ceramics7010006

APA StyleAbdelkader, M., Petrik, S., Nestler, D., & Fijalkowski, M. (2024). Ceramics 3D Printing: A Comprehensive Overview and Applications, with Brief Insights into Industry and Market. Ceramics, 7(1), 68-85. https://doi.org/10.3390/ceramics7010006