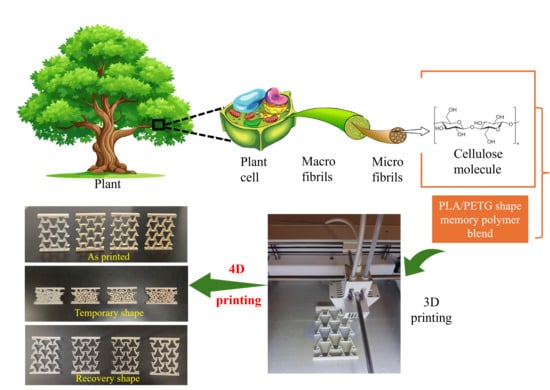

Four-Dimensional Printing of Auxetic Structures Using Nanocellulose-Reinforced PLA/PETG Blends

Abstract

1. Introduction

2. Materials and Methods

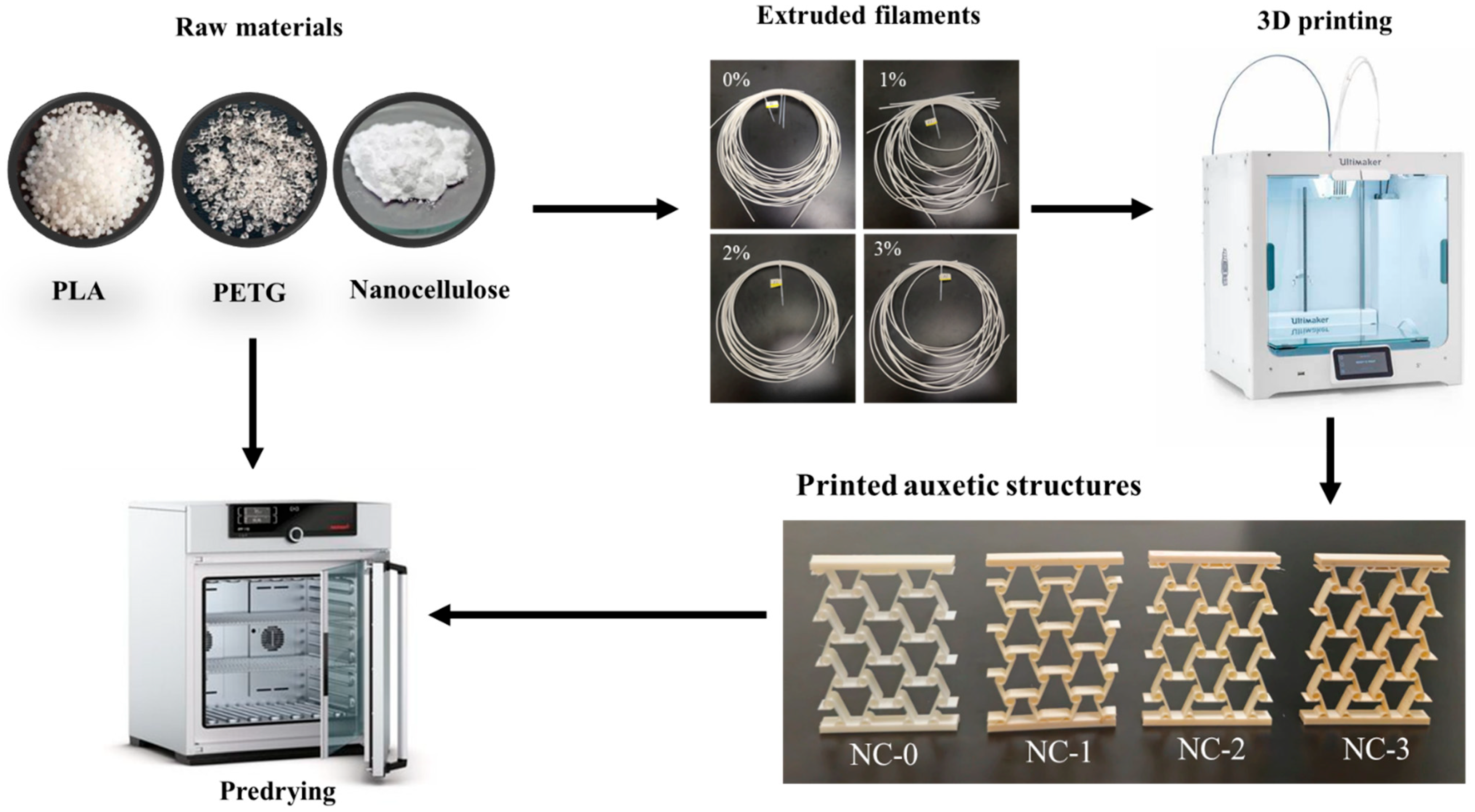

2.1. Samples Preparation

2.1.1. Materials

2.1.2. Preparation of Blends and Nanocomposite

2.2. Three-Dimensional Printing by Fused Filament Fabrication (FFF)

2.3. Characterization

2.3.1. Tensile Test

2.3.2. Compression of Auxetic Anti-Trichiral Structures

2.3.3. Finite Element Modeling (FEM)

2.3.4. Infrared Spectroscopy (FTIR)

2.3.5. X-Ray Diffraction (XRD)

2.3.6. Shape Memory Test

3. Results and Discussions

3.1. Infrared Spectroscopy (FTIR)

3.2. X-Ray Diffraction (XRD)

3.3. Mechanical Properties

3.4. U-Shape Memory Performances

3.5. Anti-Tri-Chiral Auxetic Structures

3.5.1. Mechanical Performance Under Compression

3.5.2. Shape Memory Behavior Process

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ding, A.; Tang, F.; Alsberg, E. 4D printing: A comprehensive review of technologies, materials, stimuli, design, and emerging applications. Chem. Rev. 2025, 125, 3663–3771. [Google Scholar] [CrossRef]

- Wang, Z.; Ma, D.; Liu, J.; Xu, S.; Qiu, F.; Hu, L.; Liu, Y.; Ke, C.; Ruan, C. 4D printing polymeric biomaterials for adaptive tissue regeneration. Bioact. Mater. 2025, 48, 370–399. [Google Scholar] [CrossRef]

- Bouguermouh, K.; Habibi, M.; Laperrière, L.; Li, Z.; Abdin, Y. Designing advanced 4D printing thermo-sensitive shape memory polymer blends for enhanced mechanical and shape memory performances. Prog. Addit. Manuf. 2025, 10, 6507–6526. [Google Scholar] [CrossRef]

- Bouguermouh, K.; Habibi, M.; Laperrière, L.; Li, Z.; Abdin, Y. Advanced 4D Printing of Flax Fiber-Reinforced PLA/PETG Blends for Enhanced Mechanical, Thermal, and Shape Memory Properties. Polymer 2025, 333, 128587. [Google Scholar] [CrossRef]

- Kouka, M.A.; Abbassi, F.; Habibi, M.; Chabert, F.; Zghal, A.; Garnier, C. 4D printing of shape memory polymers, blends, and composites and their advanced applications: A comprehensive literature review. Adv. Eng. Mater. 2023, 25, 2200650. [Google Scholar] [CrossRef]

- Megdich, A.; Habibi, M.; Laperrière, L. A review on 4D printing: Material structures, stimuli and additive manufacturing techniques. Mater. Lett. 2023, 337, 133977. [Google Scholar] [CrossRef]

- Megdich, A.; Habibi, M.; Laperrière, L.; Li, Z.; Abdin, Y. Advanced nanocomposites for 4D printing: High-performance electroactive shape memory polymers for smart applications. Appl. Mater. Today 2025, 44, 102702. [Google Scholar] [CrossRef]

- Saska, S.; Pilatti, L.; Blay, A.; Shibli, J.A. Bioresorbable polymers: Advanced materials and 4D printing for tissue engineering. Polymers 2021, 13, 563. [Google Scholar] [CrossRef]

- Kafle, A.; Luis, E.; Silwal, R.; Pan, H.M.; Shrestha, P.L.; Bastola, A.K. 3D/4D printing of polymers: Fused deposition modelling (FDM), selective laser sintering (SLS), and stereolithography (SLA). Polymers 2021, 13, 3101. [Google Scholar] [CrossRef]

- Franco Urquiza, E.A. Advances in additive manufacturing of polymer-fused deposition modeling on textiles: From 3D printing to innovative 4D printing—A review. Polymers 2024, 16, 700. [Google Scholar] [CrossRef]

- Sajjad, R.; Chauhdary, S.T.; Anwar, M.T.; Zahid, A.; Khosa, A.A.; Imran, M.; Sajjad, M.H. A review of 4D printing–technologies, shape shifting, smart polymer based materials, and biomedical applications. Adv. Ind. Eng. Polym. Res. 2024, 7, 20–36. [Google Scholar] [CrossRef]

- Shen, Z.; Qin, M.; Xiong, F.; Zou, R.; Zhang, J. Nanocellulose-based composite phase change materials for thermal energy storage: Status and challenges. Energy Environ. Sci. 2023, 16, 830–861. [Google Scholar] [CrossRef]

- Latif, M.; Jiang, Y.; Kumar, B.; Kim, J. 3D printing of nanocellulose structures infused Epofix resin with improved mechanical properties. In Proceedings of the 2022 2nd International Conference on Digital Futures and Transformative Technologies (ICoDT2), Rawalpindi, Pakistan, 24–26 May 2022; IEEE: Piscataway, NJ, USA, 2022. [Google Scholar]

- Latif, M.; Jiang, Y.; Kumar, B.; Kim, J. One-pot cellulose nanofibrillation, surface-modification and grafting by deep eutectic solvent towards high performance 3D printing nanocellulose-enriched bionanocomposites. Ind. Crops Prod. 2024, 210, 118134. [Google Scholar]

- Zhou, S.; Han, C.; Ni, Z.; Yang, C.; Ni, Y.; Lv, Y. Gelatin-oxidized nanocellulose hydrogels suitable for extrusion-based 3D bioprinting. Processes 2022, 10, 2216. [Google Scholar] [CrossRef]

- Barkane, A.; Jurinovs, M.; Briede, S.; Platnieks, O.; Onufrijevs, P.; Zelca, Z.; Gaidukovs, S. Biobased resin for sustainable stereolithography: 3D printed vegetable oil acrylate reinforced with ultra-low content of nanocellulose for fossil resin substitution. 3D Print. Addit. Manuf. 2023, 10, 1272–1286. [Google Scholar] [CrossRef]

- Jovic, T.H.; Nicholson, T.; Arora, H.; Nelson, K.; Doak, S.H.; Whitaker, I.S. A comparative analysis of pulp-derived nanocelluloses for 3D bioprinting facial cartilages. Carbohydr. Polym. 2023, 321, 121261. [Google Scholar] [CrossRef]

- Jovic, T.H.; Nicholson, T.; Arora, H.; Nelson, K.; Doak, S.H.; Whitaker, I.S. Design and development of 4D-printed cellulose nanofibers reinforced shape memory polymer composites: Application for self-deforming plant bionic soft grippers. Addit. Manuf. 2023, 70, 103544. [Google Scholar]

- Bai, H.; Li, Y.; Zhang, S.; Ma, P.; Dong, W. Photo-crosslinkable poly (vinyl alcohol)/nanocrystalline cellulose composites with controllable performance and exceptional water vapor barrier property for packaging application. Cellulose 2022, 29, 7721–7734. [Google Scholar] [CrossRef]

- Bouguermouh, K.; Habibi, M.; Laperrière, L. 4D printing of fiber-reinforced auxetic structures: The building blocks: A review. Smart Mater. Struct. 2024, 33, 063001. [Google Scholar] [CrossRef]

- Yousuf, M.H.; Abuzaid, W.; Egilmez, M. 4D Printing of Magnetic Shape Memory Polymer—La0.7Sr0.3MnO3 Nanocomposite. Adv. Eng. Mater. 2025, 27, 2402423. [Google Scholar] [CrossRef]

- Zhang, W.; Yan, Z.; Zhang, J.; Wang, H.; Han, F.; Jiang, P.; Wu, T.; Qin, Q. On in-plane crushing behavior of an improved double-arrow auxetic metamaterial with two-step deformation mode. Eng. Struct. 2024, 303, 117482. [Google Scholar] [CrossRef]

- Saleh, M.; Anwar, S.; Al-Ahmari, A.M.; Alfaify, A. Compression performance and failure analysis of 3D-printed carbon fiber/PLA composite TPMS lattice structures. Polymers 2022, 14, 4595. [Google Scholar] [CrossRef]

- Etemadi, E.; Hosseinabadi, M.; Gholikord, M.; Abbaslou, M.; Imani, M.; Hu, H. Dynamic performance of arc-shaped auxetic structures through split Hopkinson pressure bar tests. Smart Mater. Struct. 2025, 34, 085022. [Google Scholar] [CrossRef]

- Li, Z.; Yu, Q.; Zhao, X.; Yu, M.; Shi, P.; Yan, C. Crashworthiness and lightweight optimization to applied multiple materials and foam-filled front end structure of auto-body. Adv. Mech. Eng. 2017, 9, 1687814017702806. [Google Scholar] [CrossRef]

- Galea Mifsud, R.; Muscat, G.A.; Grima-Cornish, J.N.; Dudek, K.K.; Cardona, M.A.; Attard, D.; Farrugia, P.S.; Gatt, R.; Evans, K.E.; Grima, J.N. Auxetics and FEA: Modern materials driven by modern simulation methods. Materials 2024, 17, 1506. [Google Scholar] [CrossRef]

- Garg, A.; Sharma, A.; Zheng, W.; Li, L. A review on artificial intelligence-enabled mechanical analysis of 3D printed and FEM-modelled auxetic metamaterials. Virtual Phys. Prototyp. 2025, 20, e2445712. [Google Scholar] [CrossRef]

- Wojno, S.; Ahlinder, A.; Altskär, A.; Stading, M.; Abitbol, T.; Kádár, R. Percolation and phase behavior in cellulose nanocrystal suspensions from nonlinear rheological analysis. Carbohydr. Polym. 2023, 308, 120622. [Google Scholar] [CrossRef] [PubMed]

- Wojno, S.; Fazilati, M.; Nypelö, T.; Westman, G.; Kádár, R. Phase transitions of cellulose nanocrystal suspensions from nonlinear oscillatory shear. Cellulose 2022, 29, 3655–3673. [Google Scholar] [CrossRef]

- Gupta, A.; Mekonnen, T.H. Cellulose nanocrystals enabled sustainable polycaprolactone based shape memory polyurethane bionanocomposites. J. Colloid Interface Sci. 2022, 611, 726–738. [Google Scholar] [CrossRef]

- Bouguermouh, K.; Habibi, M.; Laperrière, L.; Li, Z.; Abdin, Y. 4D-printed PLA-PETG polymer blends: Comprehensive analysis of thermal, mechanical, and shape memory performances. J. Mater. Sci. 2024, 59, 11596–11613. [Google Scholar] [CrossRef]

- ASTM D638-22; Standard Test Method for Tensile Properties of Plastics. ASTM International: West Conshohocken, PA, USA, 2022.

- Abdelhamid, Z.; Mohamed, H.; Kelouwani, S. The use of machine learning in process–structure–property modeling for material extrusion additive manufacturing: A state-of-the-art review. J. Braz. Soc. Mech. Sci. Eng. 2024, 46, 70. [Google Scholar] [CrossRef]

- Ziadia, A.; Habibi, M.; Kelouwani, S. Machine learning study of the effect of process parameters on tensile strength of FFF PLA and PLA-CF. Eng 2023, 4, 2741–2763. [Google Scholar] [CrossRef]

- Vinyas, M.; Athul, S.J.; Harursampath, D.; Nguyen Thoi, T. Mechanical characterization of the Poly lactic acid (PLA) composites prepared through the Fused Deposition Modelling process. Mater. Res. Express 2019, 6, 105359. [Google Scholar] [CrossRef]

- Thirugnanasambandam, A.; Dutta, H.; Gnanasagaran, C.L.; Kechagias, J.D. Development of 3D printed novel multi-polymer component based on blended filaments of polylactic acid and polyethylene terephthalate glycol. Prog. Addit. Manuf. 2024, 10, 1147–1160. [Google Scholar] [CrossRef]

- Zhou, Y.; Wang, F.; Yang, Z.; Hu, X.; Pan, Y.; Lu, Y.; Jiang, M. 3D printing of polyurethane/nanocellulose shape memory composites with tunable glass transition temperature. Ind. Crops Prod. 2022, 182, 114831. [Google Scholar] [CrossRef]

- Zain, N.M.; Yusop, S.M.; Ahmad, I. Preparation and characterization of cellulose and nanocellulose from pomelo (Citrus grandis) albedo. J. Nutr. Food Sci. 2014, 5, 334. [Google Scholar]

- Yakkan, E.; Uysalman, T.; Atagür, M.; Sever, K.; Seydibeyoğlu, M.Ö. Nanocellulose-polypropylene nanocomposites enhanced with coupling agent. Bartın Orman Fakültesi Derg. 2018, 20, 491–502. [Google Scholar]

- Wei, L.; Luo, S.; McDonald, A.G.; Agarwal, U.P.; Hirth, K.C.; Matuana, L.M.; Sabo, R.C.; Stark, N.M. Preparation and Characterization of the Nanocomposites from Chemically Modified Nanocellulose and Poly (lactic acid). J. Renew. Mater. 2017, 5, 410–422. [Google Scholar] [CrossRef]

- Mukherjee, T.; Tobin, M.J.; Puskar, L.; Sani, M.A.; Kao, N.; Gupta, R.K.; Pannirselvam, M.; Quazi, N.; Bhattacharya, S. Chemically imaging the interaction of acetylated nanocrystalline cellulose (NCC) with a polylactic acid (PLA) polymer matrix. Cellulose 2017, 24, 1717–1729. [Google Scholar] [CrossRef]

- Mukherjee, T.; Tobin, M.J.; Puskar, L.; Sani, M.A.; Kao, N.; Gupta, R.K.; Pannirselvam, M.; Quazi, N.; Bhattacharya, S. Properties of polylactic acid reinforced by hydroxyapatite modified nanocellulose. Polymers 2019, 11, 1009. [Google Scholar] [CrossRef]

- Park, J.Y.; Hwang, S.Y.; Yoon, W.J.; Yoo, E.S.; Im, S.S. Compatibility and physical properties of poly (lactic acid)/poly (ethylene terephthalate glycol) blends. Macromol. Res. 2012, 20, 1300–1306. [Google Scholar] [CrossRef]

- Chi, K.; Catchmark, J.M. Enhanced dispersion and interface compatibilization of crystalline nanocellulose in polylactide by surfactant adsorption. Cellulose 2017, 24, 4845–4860. [Google Scholar] [CrossRef]

- Wang, Q.; Ji, C.; Sun, J.; Zhu, Q.; Liu, J. Structure and properties of polylactic acid biocomposite films reinforced with cellulose nanofibrils. Molecules 2020, 25, 3306. [Google Scholar] [CrossRef]

- Ambone, T.; Torris, A.; Shanmuganathan, K. Enhancing the mechanical properties of 3D printed polylactic acid using nanocellulose. Polym. Eng. Sci. 2020, 60, 1842–1855. [Google Scholar] [CrossRef]

- Popescu, D.; Zapciu, A.; Amza, C.; Baciu, F.; Marinescu, R. FDM process parameters influence over the mechanical properties of polymer specimens: A review. Polym. Test. 2018, 69, 157–166. [Google Scholar] [CrossRef]

- Tian, C.; Xue, H.; Fang, K.; Zhang, K.; Tian, G. Multi-material 3D-printing nozzle design based on the theory of inventive problem solving and knowledge graph. Designs 2023, 7, 103. [Google Scholar] [CrossRef]

- Sztorch, B.; Brząkalski, D.; Pakuła, D.; Frydrych, M.; Špitalský, Z.; Przekop, R.E. Natural and synthetic polymer fillers for applications in 3D printing—FDM technology area. Solids 2022, 3, 508–548. [Google Scholar] [CrossRef]

- Shrestha, S. Effect of Nanocellulose Reinforcement on the Properties of Polymer Composites. Doctoral Dissertation, Purdue University, West Lafayette, IN, USA, 2019. [Google Scholar]

- Uetani, K.; Hatori, K. Thermal conductivity analysis and applications of nanocellulose materials. Sci. Technol. Adv. Mater. 2017, 18, 877–892. [Google Scholar] [CrossRef]

- Markandan, K.; Lai, C.Q. Fabrication, properties and applications of polymer composites additively manufactured with filler alignment control: A review. Compos. Part B Eng. 2023, 256, 110661. [Google Scholar] [CrossRef]

- Gorbunova, M.; Anokhin, D.; Badamshina, E. Recent advances in the synthesis and application of thermoplastic semicrystalline shape memory polyurethanes. Polym. Sci. Ser. B 2020, 62, 427–450. [Google Scholar] [CrossRef]

- Ma, X.; Tian, S.; Li, X.; Fan, H.; Fu, S. Combined polyhexamethylene guanidine and nanocellulose for the conservation and enhancement of ancient paper. Cellulose 2021, 28, 8027–8042. [Google Scholar] [CrossRef]

- Zhang, X.Y.; Ren, X.; Zhang, Y.; Xie, Y.M. A novel auxetic metamaterial with enhanced mechanical properties and tunable auxeticity. Thin-Walled Struct. 2022, 174, 109162. [Google Scholar] [CrossRef]

- Li, Y.; Chen, Z.; Xiao, D.; Wu, W.; Fang, D. The Dynamic response of shallow sandwich arch with auxetic metallic honeycomb core under localized impulsive loading. Int. J. Impact Eng. 2020, 137, 103442. [Google Scholar] [CrossRef]

- Lakes, R.S. Negative-Poisson’s-ratio materials: Auxetic solids. Annu. Rev. Mater. Res. 2017, 47, 63–81. [Google Scholar] [CrossRef]

- Yang, C.; Vora, H.D.; Chang, Y. Behavior of auxetic structures under compression and impact forces. Smart Mater. Struct. 2018, 27, 025012. [Google Scholar] [CrossRef]

- Zhang, Y.; Jiang, W.Z.; Jiang, W.; Zhang, X.Y.; Dong, J.; Xie, Y.M.; Evans, K.E.; Ren, X. Recent advances of auxetic metamaterials in smart materials and structural systems. Adv. Funct. Mater. 2025, 35, 2421746. [Google Scholar] [CrossRef]

- Li, X.; Wang, Q.; Yang, Z.; Lu, Z. Novel auxetic structures with enhanced mechanical properties. Extrem. Mech. Lett. 2019, 27, 59–65. [Google Scholar] [CrossRef]

- Zhou, Y.; Li, Y.; Jiang, D.; Chen, Y.; Xie, Y.M.; Jia, L.J. In-plane impact behavior of 3D-printed auxetic stainless honeycombs. Eng. Struct. 2022, 266, 114656. [Google Scholar] [CrossRef]

- Salama, A.; Abouzeid, R.; Leong, W.S.; Jeevanandam, J.; Samyn, P.; Dufresne, A.; Bechelany, M.; Barhoum, A. Nanocellulose-based materials for water treatment: Adsorption, photocatalytic degradation, disinfection, antifouling, and nanofiltration. Nanomaterials 2021, 11, 3008. [Google Scholar] [CrossRef] [PubMed]

- Salama, A.; Abouzeid, R.; Leong, W.S.; Jeevanandam, J.; Samyn, P.; Dufresne, A.; Bechelany, M.; Barhoum, A. Nanocellulose-based thermoplastic polyurethane biocomposites with shape memory effect. J. Compos. Sci. 2023, 7, 168. [Google Scholar] [CrossRef]

- Aranguren, M.I.; Auad, M.L.; Richardson, T.; Adanur, S.; Orts, W.J.; Medeiros, E.S.; Mattoso, L.H.C.; Mosiewicki, M.A.; Marcovich, N.E. Polyaniline Modified Nanocellulose as Reinforcement of a Shape Memory Polyurethane. 2008. Available online: https://d1wqtxts1xzle7.cloudfront.net/81414383/2629-libre.pdf?1645923003=&response-content-disposition=inline%3B+filename%3DPolyaniline_Modified_Nanocellulose_as_Re.pdf&Expires=1762829933&Signature=L1JZMANJcBzh3D~hykJmfTpttl5qEVlFnet7Wmt7Ddlll1B8faM1qPwt~-SGsIswseb5pun8RuxvmPW1iQEU~hF4SBCXxWBfPaDdLv3CcECMEIBfSWhHUKD0bWsz9of6N1haFHZajY~0tpdwlQRZ0eJjdQjtMOFAzRJ3bQDPIC8RwVwtS5MAj48LLWYHfbaHj0H9gFPrrUGz~NX4rm67vPyfxFsopGAI8FM59azT~iq2lzwGoH2LfChbMECZbkk1cboecL40aLBZJqaE3TKuwQOFlzRdRZjHej9wSfKWoHpix8Mp6M1utzPr9lyBaJrM37YqGol-MOtnIUQ-5cGCdg__&Key-Pair-Id=APKAJLOHF5GGSLRBV4ZA (accessed on 19 October 2025).

- Peng, X.-L.; Bargmann, S. A design method for metamaterials: 3D transversely isotropic lattice structures with tunable auxeticity. Smart Mater. Struct. 2021, 31, 025011. [Google Scholar] [CrossRef]

- Günaydın, K.; Rea, C.; Kazancı, Z. Energy absorption enhancement of additively manufactured hexagonal and re-entrant (auxetic) lattice structures by using multi-material reinforcements. Addit. Manuf. 2022, 59, 103076. [Google Scholar]

- Fu, S.; Tian, C. Nanocellulose and its application for shape-memory materials. In Eco-Friendly Polymer Nanocomposites: Chemistry and Applications; Springer: New Delhi, India, 2015; pp. 101–135. [Google Scholar]

- Auad, M.L.; Contos, V.S.; Nutt, S.; Aranguren, M.I.; Marcovich, N.E. Characterization of nanocellulose- reinforced shape memory polyurethanes. Polym. Int. 2008, 57, 651–659. [Google Scholar] [CrossRef]

| Samples | Nozzle Temperature (°C) | Plate Temperature (°C) | Print Speed (mm/s) | Flow (%) | Layer Height (mm) | Line Width (mm) | Extrusion Temperatures (°C) |

|---|---|---|---|---|---|---|---|

| PLA-75/PETG-25 | 245 | 100 | 20 | 110 | 0.2 | 0.45 | 180–185 |

| PLA-75/PETG-25/NC-1 | 245 | 100 | 20 | 110 | 0.2 | 0.45 | 180–185 |

| PLA-75/PETG-25/NC-2 | 240 | 100 | 20 | 110 | 0.2 | 0.45 | 180–185 |

| PLA-75/PETG-25/NC-3 | 240 | 100 | 20 | 110 | 0.2 | 0.45 | 180–185 |

| Auxetic structure | r (mm) | l (mm) | t (mm) | θ (°) |

| Anti-tri-chiral | 2.5 | 15 | 1 | 60 |

| Strain (%) | 0 | 10 | 30 | 50 | 70 | |

| NC Content (wt%) | ||||||

| 0 |  |  |  |  |  | |

| 1 |  |  |  |  |  | |

| 2 |  |  |  |  |  | |

| 3 |  |  |  |  |  | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bouguermouh, K.; Habibi, M.; Megdich, A.; Laperrière, L.; Monplaisir, D. Four-Dimensional Printing of Auxetic Structures Using Nanocellulose-Reinforced PLA/PETG Blends. J. Compos. Sci. 2025, 9, 637. https://doi.org/10.3390/jcs9110637

Bouguermouh K, Habibi M, Megdich A, Laperrière L, Monplaisir D. Four-Dimensional Printing of Auxetic Structures Using Nanocellulose-Reinforced PLA/PETG Blends. Journal of Composites Science. 2025; 9(11):637. https://doi.org/10.3390/jcs9110637

Chicago/Turabian StyleBouguermouh, Karima, Mohamed Habibi, Amal Megdich, Luc Laperrière, and Daniel Monplaisir. 2025. "Four-Dimensional Printing of Auxetic Structures Using Nanocellulose-Reinforced PLA/PETG Blends" Journal of Composites Science 9, no. 11: 637. https://doi.org/10.3390/jcs9110637

APA StyleBouguermouh, K., Habibi, M., Megdich, A., Laperrière, L., & Monplaisir, D. (2025). Four-Dimensional Printing of Auxetic Structures Using Nanocellulose-Reinforced PLA/PETG Blends. Journal of Composites Science, 9(11), 637. https://doi.org/10.3390/jcs9110637