1. Introduction

Climate change has become one of the most critical and urgent environmental challenges of this century, posing a significant threat to human survival and socio-economic activities. Given the increasing tension between the need to address climate change and the necessity of economic development, adopting a balanced approach to these issues remains a crucial consideration in global climate governance [

1,

2,

3]. We must address this challenge in depth and rigorously to promote sustainable solutions. It is urgent to reduce carbon emissions during the manufacturing process to implement sustainable development strategies [

4,

5,

6].

Additive manufacturing is undergoing a noteworthy transformation from prototype development to mass production. This technology has several advantages, including design flexibility, efficient material utilization, and the ability to customize solutions [

7,

8]. The global additive manufacturing market shows strong growth potential, with a compound annual growth rate exceeding 20%. The forecast suggests that by 2030, this number may exceed

$100 billion, indicating a promising future for this innovative field [

9]. In addition, the share of industrial-grade applications is expected to expand, especially in high-end manufacturing and rapid maintenance scenarios, which is crucial for improving operational efficiency. FDM has attracted attention due to its cost-effectiveness, user friendliness, and material diversity [

10,

11]. Looking ahead, the integration of sustainable materials and hybrid manufacturing systems is expected to enhance the importance of FDM in promoting sustainable manufacturing practices and distributed production, thereby supporting economic and environmental goals [

12]. AM is a new manufacturing technology that utilizes computer-aided design data to deposit materials layer by layer, thereby manufacturing solid objects. This method is in sharp contrast to traditional subtractive manufacturing techniques, which involve removing material from the blank [

13,

14,

15]. The “bottom-up” approach of additive manufacturing offers significant advantages, including shortened manufacturing cycles and reduced production costs, making it an ideal solution for rapidly producing small batches, customized components, and complex geometries. Currently, additive manufacturing has been effectively applied in various fields. Additive manufacturing is positioned as a key force for the sustainable development of the manufacturing industry. Among numerous additive manufacturing technologies, fused deposition modeling is one of the most widely used methods [

16,

17,

18].

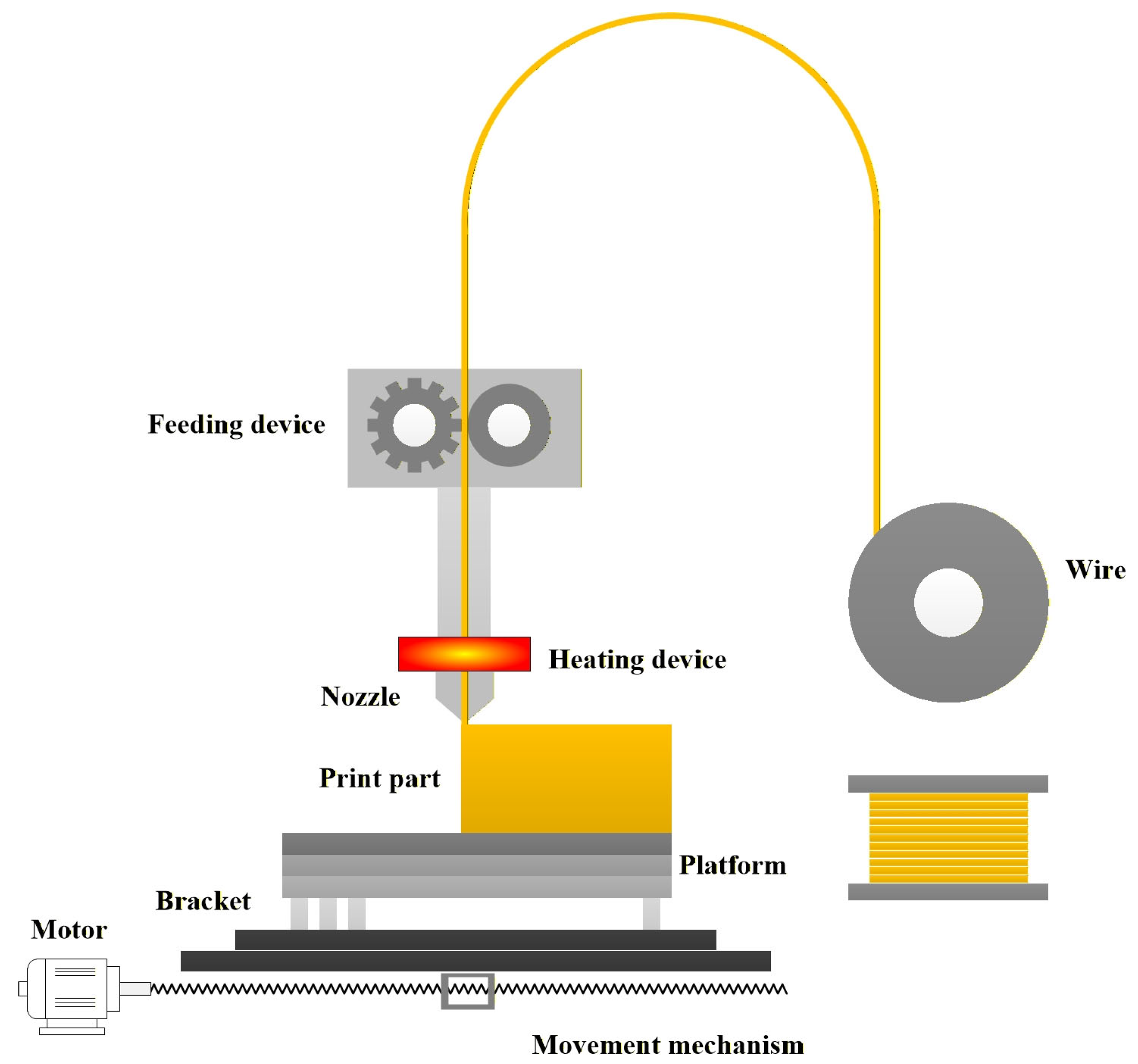

FDM 3D printing technology is a digital manufacturing technique that produces three-dimensional entities by stacking materials layer by layer, enabling the rapid transformation of designs into physical objects and accelerating production cycles [

19,

20,

21,

22]. The schematic diagram of FDM 3D printing is shown in

Figure 1. Compared with traditional manufacturing techniques, it can achieve precise material usage and reduce waste. Due to its high degree of production freedom and resource utilization, 3D printing has become a widely used manufacturing technology, with its applications in aerospace, medical, automotive, and precision manufacturing fields becoming increasingly widespread [

23,

24,

25]. The FDM printing process can be primarily divided into three stages: feeding, melt extrusion, and deposition moulding [

26,

27]. Each stage is not only closely related to printing materials, but also inseparable from printing equipment and pre-printing preparation work [

28].

The characteristics of FDM include its economic efficiency, simplicity of operation, compatibility with various materials, and high production efficiency. Although FDM technology has significant advantages, it also faces some challenges that may hinder its long-term effectiveness [

29]. The limited dimensional accuracy, insufficient surface quality, and poor mechanical performance pose significant obstacles. Therefore, improving the quality of FDM-manufactured parts is an urgent issue that requires attention. Addressing these challenges is crucial for fully unleashing the potential of this innovative technology and advancing its application in the manufacturing industry [

30]. The process parameters related to fused deposition modeling play a crucial role in determining the quality of plastic parts during layer-by-layer printing [

31,

32]. These parameters are interrelated and jointly affect fundamental performance indicators, including dimensional accuracy, mechanical strength, surface smoothness, and overall component durability. By setting reasonable process parameters, it is possible to improve the quality of parts significantly, meet the requirements of various specific applications, and expand the application scope of FDM technology across multiple industries [

33,

34].

In studies conducted by numerous scholars, Marsavina et al. [

35] investigated the performance characteristics of various FDM printers in generating tensile and fracture specimens from PLA. Their analysis carefully considered several manufacturing parameters, including forming direction, structural direction, and printer type. It evaluated the influence of process parameters on the tensile and fracture properties of the specimens. The results emphasise the importance of each parameter in influencing performance outcomes, highlighting the complexity of the FDM process. The work of Daly et al. [

36] demonstrated a significant contribution to the effect of different FDM printing speeds on the tensile strength of ABS specimens. Similarly, Ouazzani et al. [

37] identified printing speed, layer thickness, and extrusion temperature as key variables. They attempted to analyse the influence of FDM (Fused Deposition Modeling) process parameters on the surface quality of ABS parts using Taguchi experiments. The research results indicate that layer thickness has the most significant impact on surface quality. To improve surface quality, it is recommended to implement higher scanning speeds, reduce layer thickness, and select appropriate extrusion temperatures. In addition, Yankin et al. [

38] employed orthogonal experiments and finite element analysis methods to investigate the effects of internal geometry, printing speed, and nozzle diameter on the fatigue life of FDM-printed ABS and nylon. Their analysis emphasises that nylon typically has better fatigue performance than ABS.

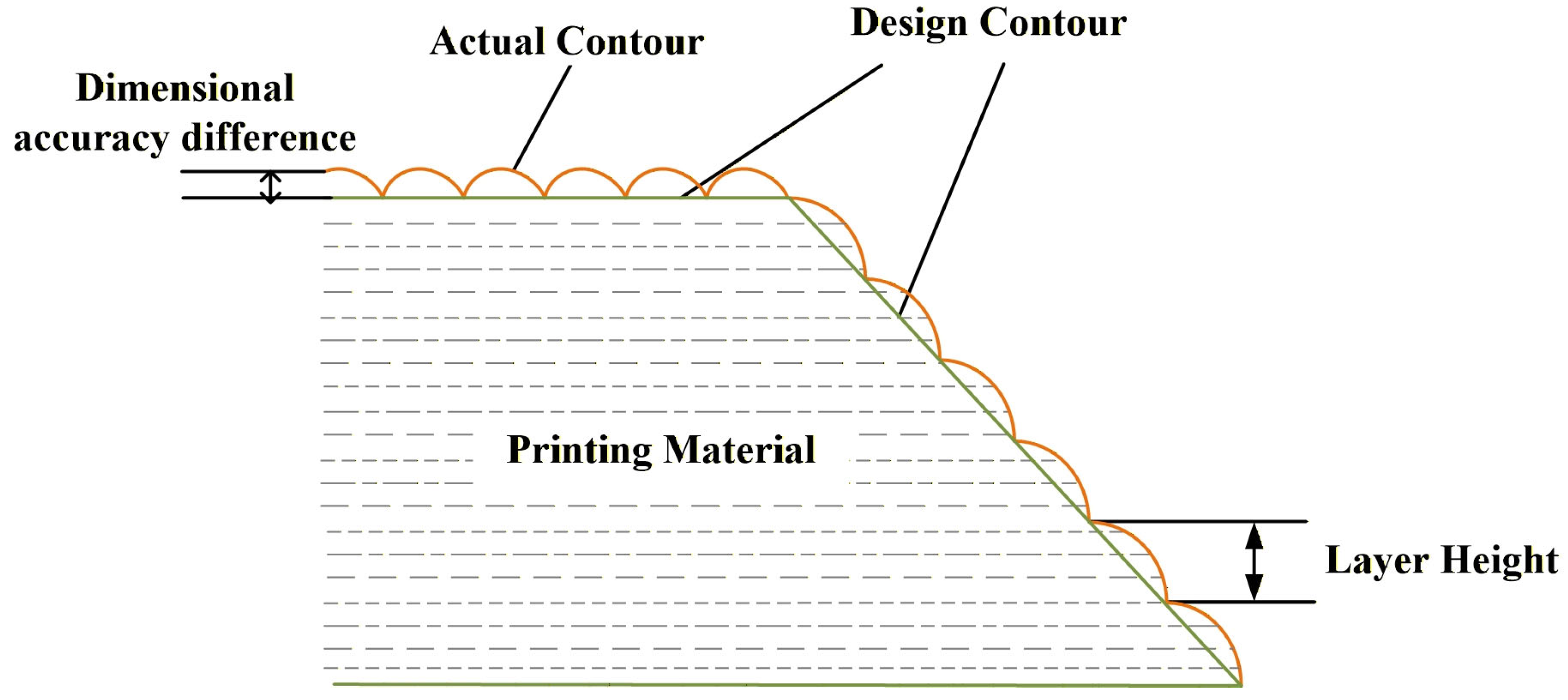

Figure 2 shows the surface microstructure of FDM melt deposition [

39]. Additionally, printing platforms are typically designed with preset temperatures to enhance interlayer fusion and minimise the risk of warping. To improve the printing process, a fan cooling system is usually combined to cool the printing layer and protect the equipment [

40,

41].

The quality of fused deposition modeling products is closely related to the specific printing conditions used in the manufacturing process. The traditional printing configuration encompasses several key factors, including nozzle temperature, platform temperature, printing speed, grating angle, filling density, and layer thickness [

42]. These factors are interrelated and collectively affect the mechanical strength and lifespan of the final product. Raising the temperature of the nozzle and platform can increase the available energy of the printing process, thereby enhancing the flowability and formability of the material [

43]. This enhancement can improve the infiltration and diffusion of sedimentary filaments between layers, promote adequate interlayer adhesion, and significantly reduce the risk of warping [

44]. In contrast, excessively high printing speeds may lead to incomplete and intermittent filament deposition, which can have adverse effects on the adhesion properties of the material [

45]. In addition, the grating angle and filling density are key factors determining the mechanical strength of the final product. Higher filling density is usually associated with a smoother surface finish. In addition, specific porosity and filling structures help improve the damping and energy absorption capacity of printed components [

46]. A significant advancement by Benié et al. [

47]. The use of innovative dynamic simulations to correlate printing parameters with the diffusion, entanglement, and crystallisation phenomena of polymer chains. This method can predict the microstructure of printed products, enabling the accurate evaluation of their mechanical properties.

The dimensional accuracy of 3D-printed products is an essential indicator of whether they can be put into production use [

26,

29,

48]. The moulding process parameters of plastic parts often affect their strength and stiffness, determining their service life [

49,

50]. Many researchers have conducted extensive research on improving the performance of 3D printed products [

51,

52,

53]. Wang et al. [

54] found through experiments that FDM process parameters can affect the quality of printed materials, including interlayer adhesion strength, air gap, and other factors, which are the main reasons for the different mechanical properties of printed materials. Hsueh et al. [

55] found that printing angle and grating angle significantly affect the tensile properties of PLA materials. At the same time, UV curing reduces their ductility and increases brittleness. This rule was verified through experiments with different parameters. Rodríguez Panes et al. [

56] conducted a comparative analysis of the tensile properties of PLA and ABS, two commonly used thermoplastic materials in FDM additive manufacturing. The study focused on investigating the influence of layer height, filling density, and layer direction on the mechanical properties of the materials. Yadav et al. [

57] investigated the effects of filling density, material density, and extrusion temperature on the mechanical properties of multi-material parts printed using ME technology. In recent years, many researchers have studied the process parameters of FDM. To study the influence of process parameters on dimensional accuracy, a large number of experiments are required [

58,

59,

60,

61,

62,

63]. Reasonable experimental design is conducive to reducing experimental errors [

64].

Fused Deposition Modeling (FDM) printing utilizes various materials, primarily derived from thermoplastic polymers. In industrial applications, commonly used materials include PEEK, PLA, acrylonitrile butadiene styrene (ABS), and polyvinyl alcohol (PVA) [

65,

66,

67,

68]. ABS has several beneficial properties, with a printing temperature range of 215 to 250 °C [

68]. It has significant strength, high modulus, high temperature resistance, and UV radiation resistance, making it an ideal choice for shell applications. PVA is considered a water-soluble material, characterized by a printing temperature range of 160 to 230 °C, which allows for effective utilization at relatively low nozzle temperatures [

67]. This material is mainly used as a support structure for hanging components during the printing process. On the contrary, PEEK requires a higher nozzle temperature of 340 to 440 °C [

66]. It is known for its excellent mechanical properties, lubrication ability, and chemical resistance, making it an excellent choice for high-temperature environments, such as those encountered in aerospace applications and competitive racing. Polylactic acid (PLA) is a wholly organic and environmentally sustainable material recognized for its excellent biocompatibility and biodegradability [

69]. It operates within a printing temperature range of 160 to 230 °C, making it highly suitable for processing. PLA is suitable for a wide range of applications, including basic applications and advanced fields such as biosensors and tissue engineering. The biological and chemical production technology of PLA has been established and demonstrated to be a low-cost, biodegradable, and recyclable material. Its utilization rate is showing a continuous upward trend, indicating that PLA has excellent potential for widespread use as a 3D printing material in the industrial field [

70].

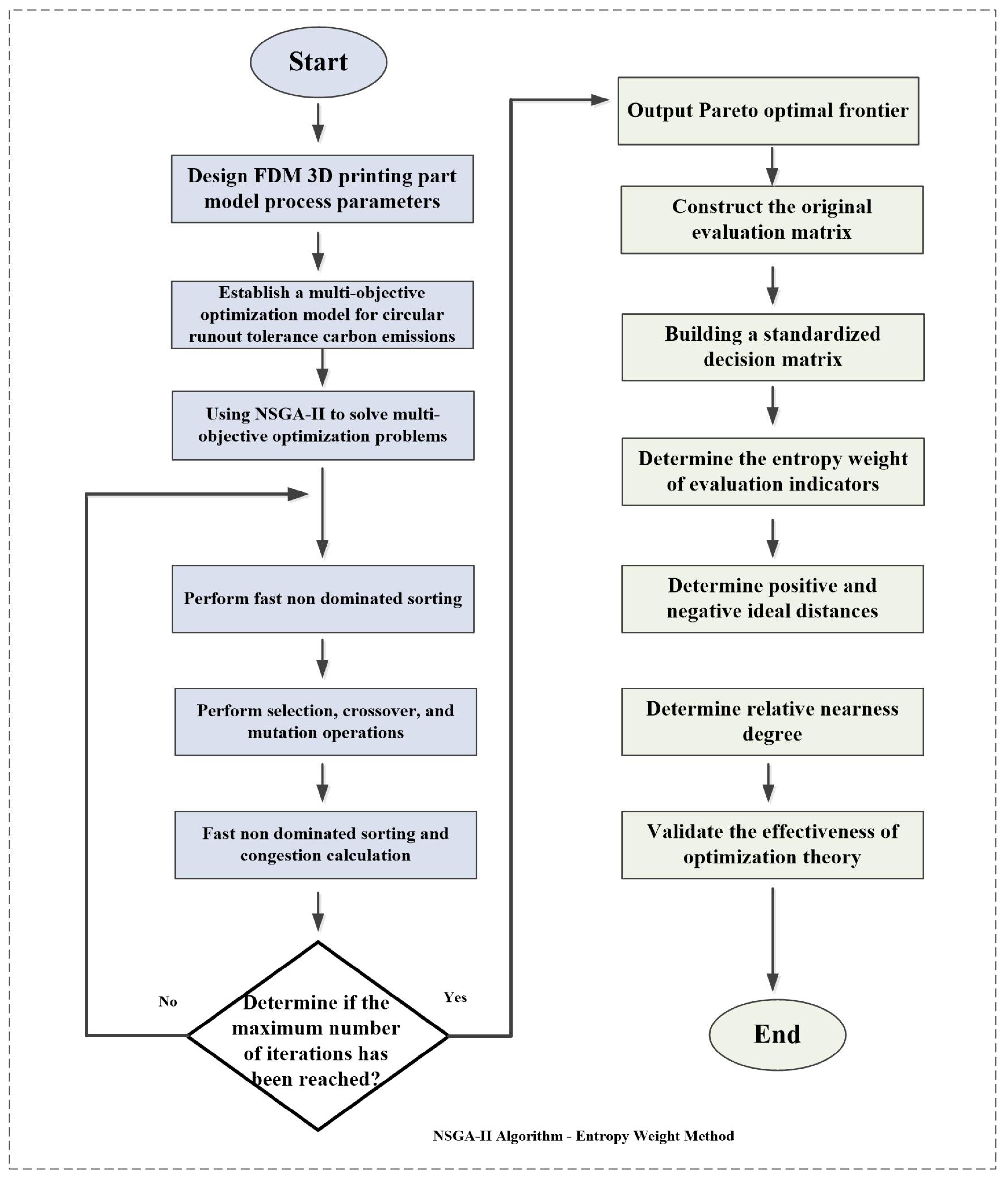

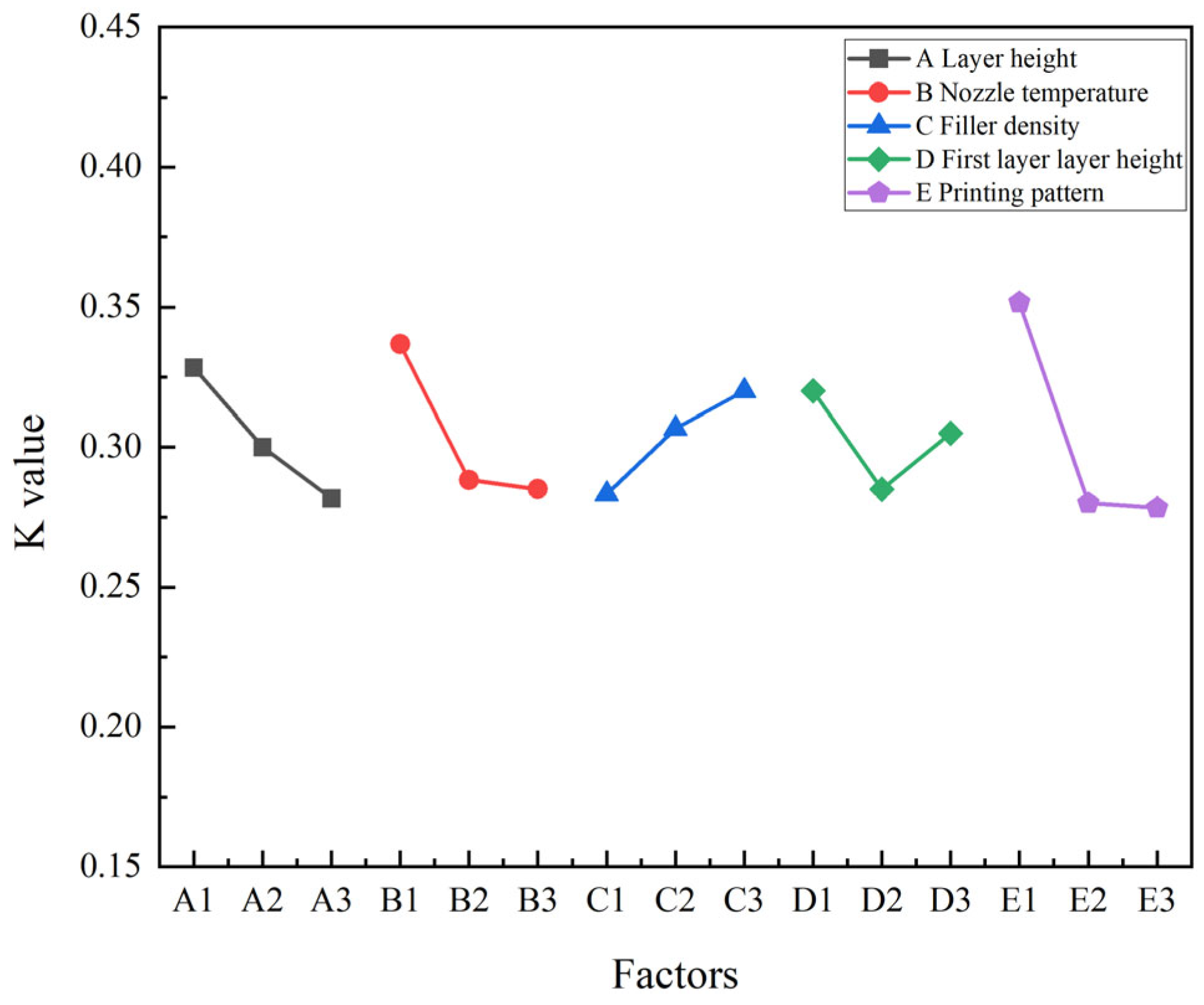

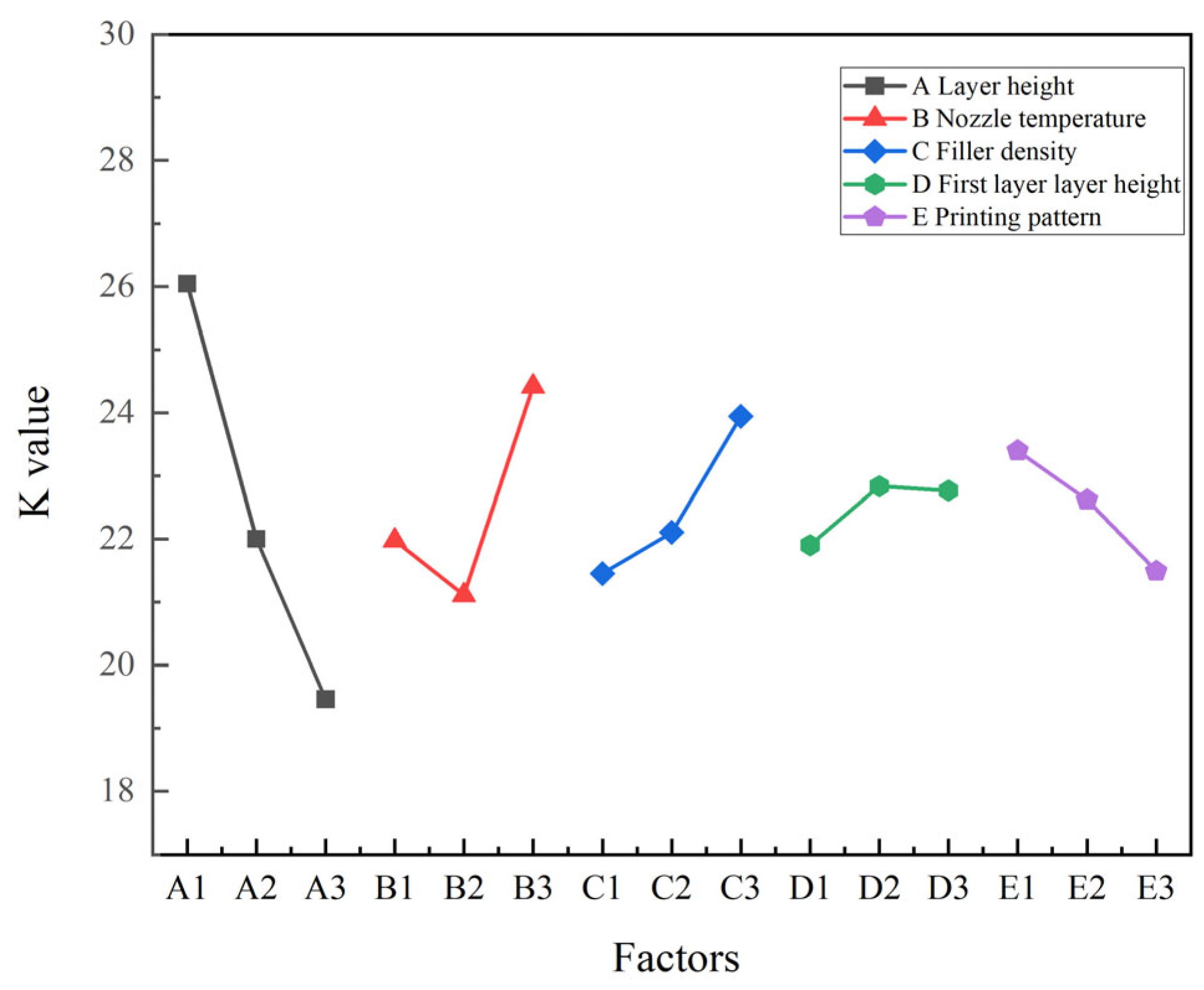

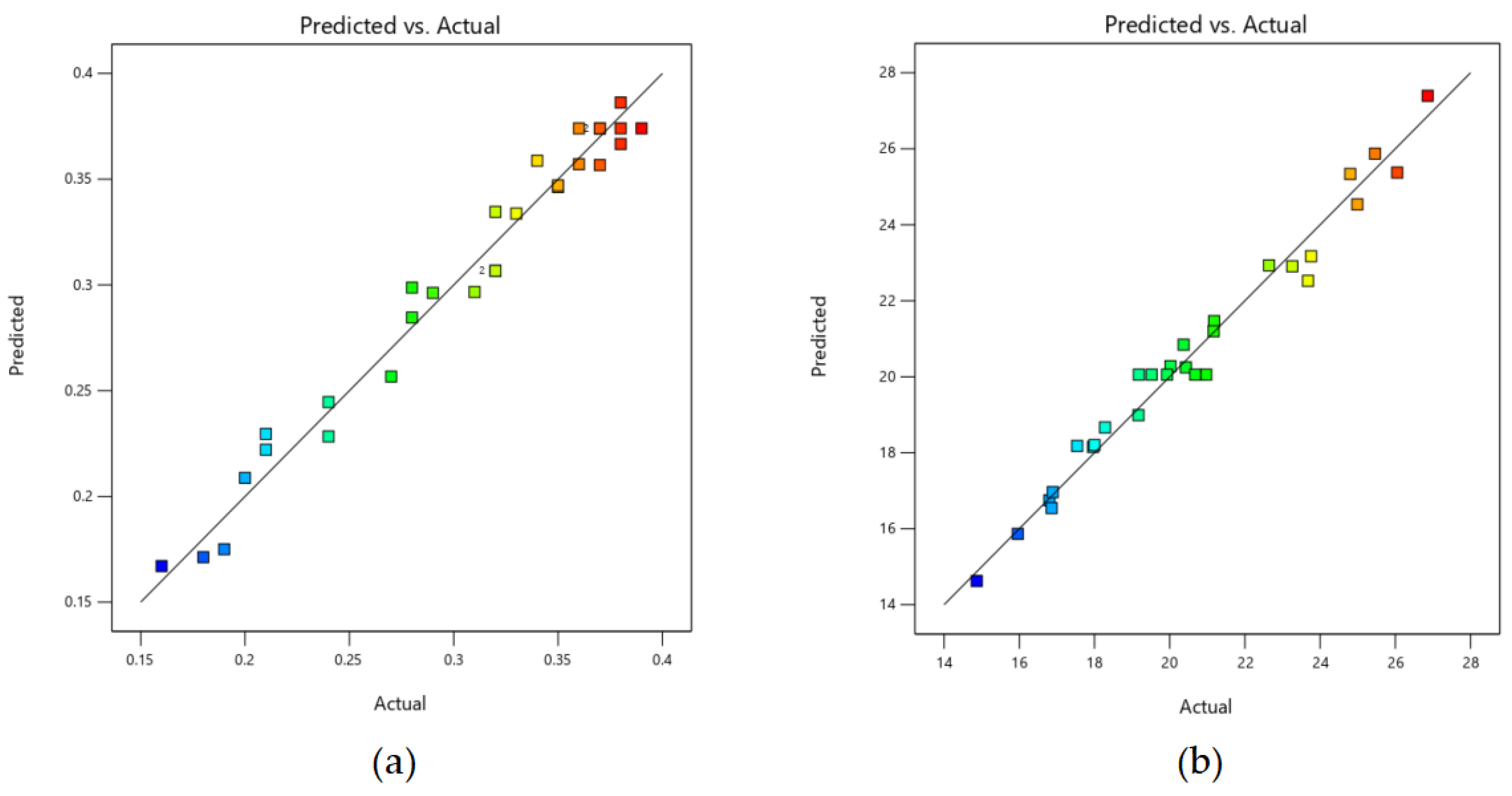

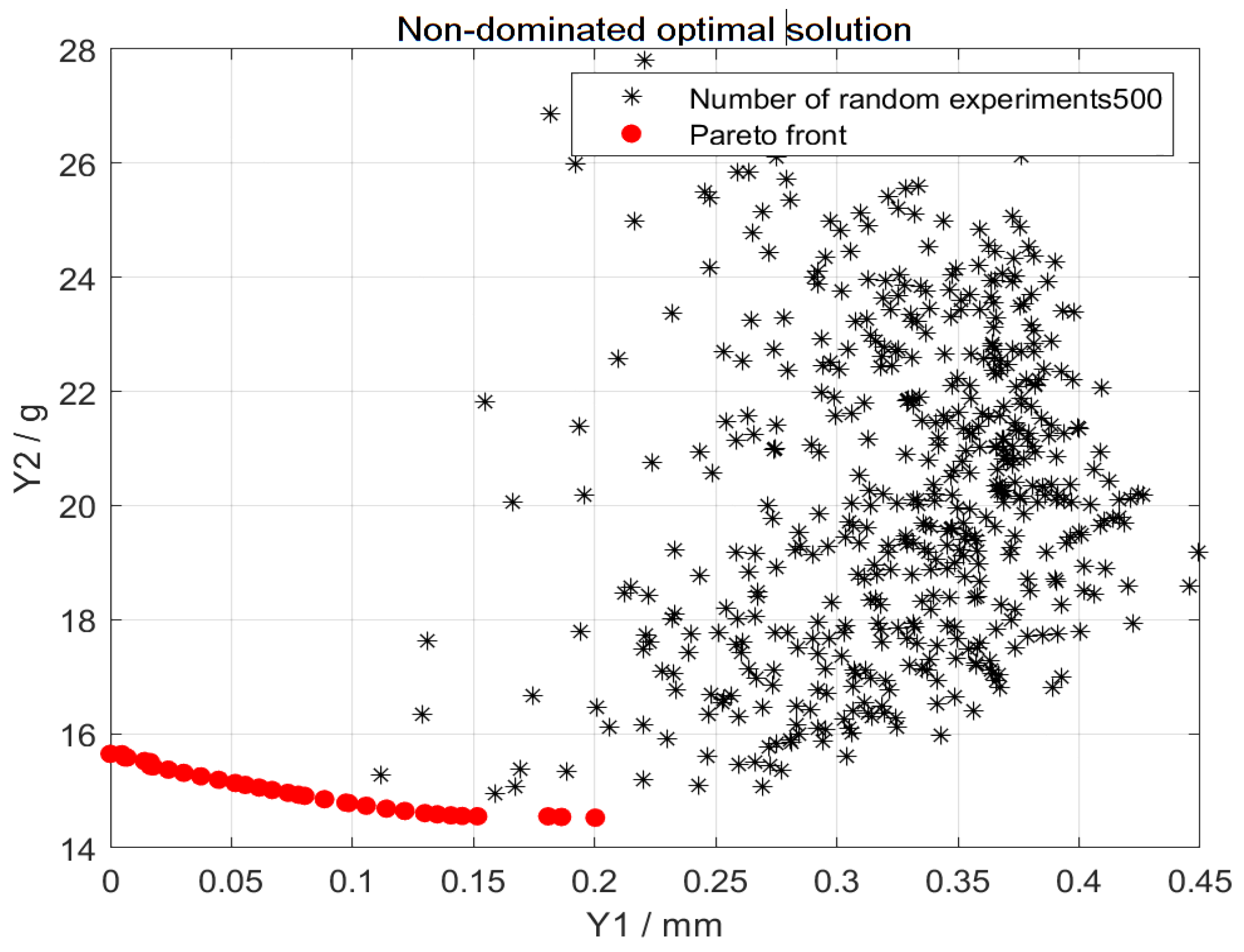

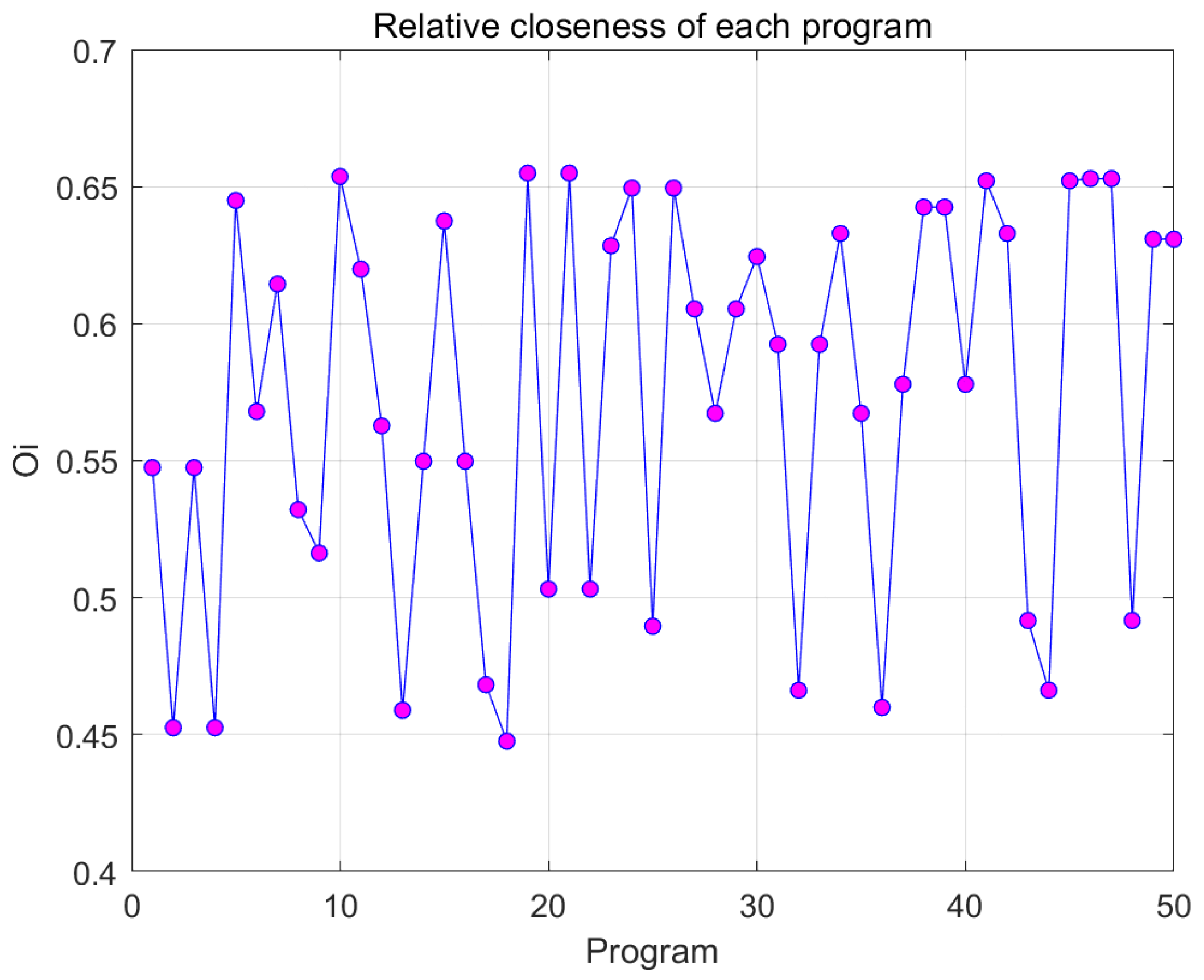

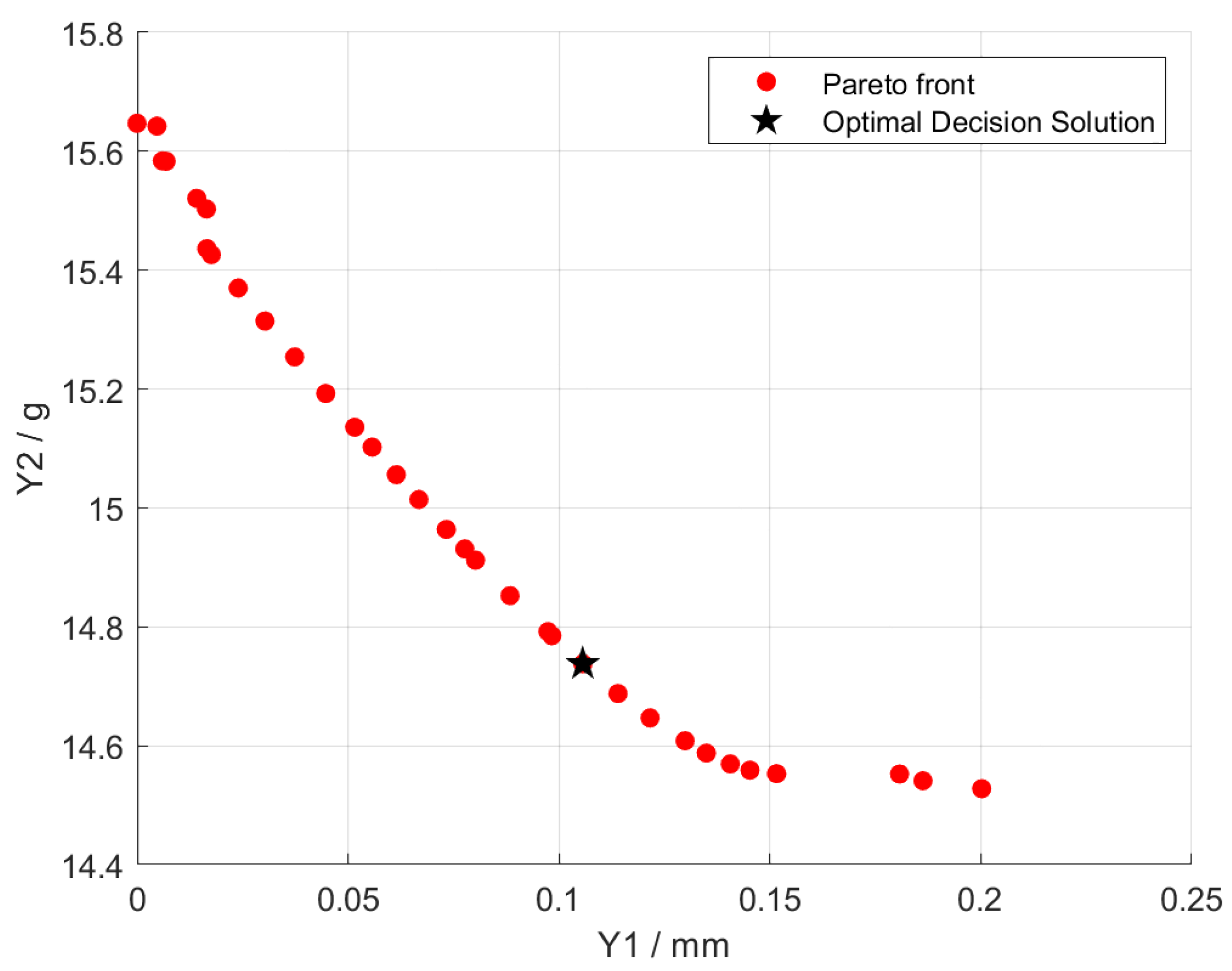

With the continuous development of modern processing technology, it is necessary to achieve sustainable development strategies, reduce carbon emissions during the manufacturing process, and enhance FDM printing accuracy. FDM printing equipment and printing moulding process parameters have become key factors in the manufacturing process. To enhance the stability of 3D printing in terms of dimensional accuracy and carbon emissions, this study optimised and analysed the influencing factors of dimensional accuracy and carbon emissions using the orthogonal experimental method, NSGA-II, and the entropy weight method. Taking layer height, nozzle temperature, filling density, first layer height, and filling pattern as factor variables, and plastic part circular runout tolerance and carbon emissions as optimization objectives, an L18 orthogonal experimental design was established to explore the effects of various parameters on tolerance and carbon emissions at different factor levels. Using the Box-Behnken experimental design method in RSM, a prediction model for jump tolerance and carbon emissions is established. The NSGA-II coupled entropy weight TOPSIS method is then employed to determine the optimal combination scheme for comprehensive performance. This article aims to develop a production system that reduces greenhouse gas emissions and improves FDM printing accuracy.

2. Materials and Methods

The flowchart of the specific experimental procedure is shown in

Figure 3.

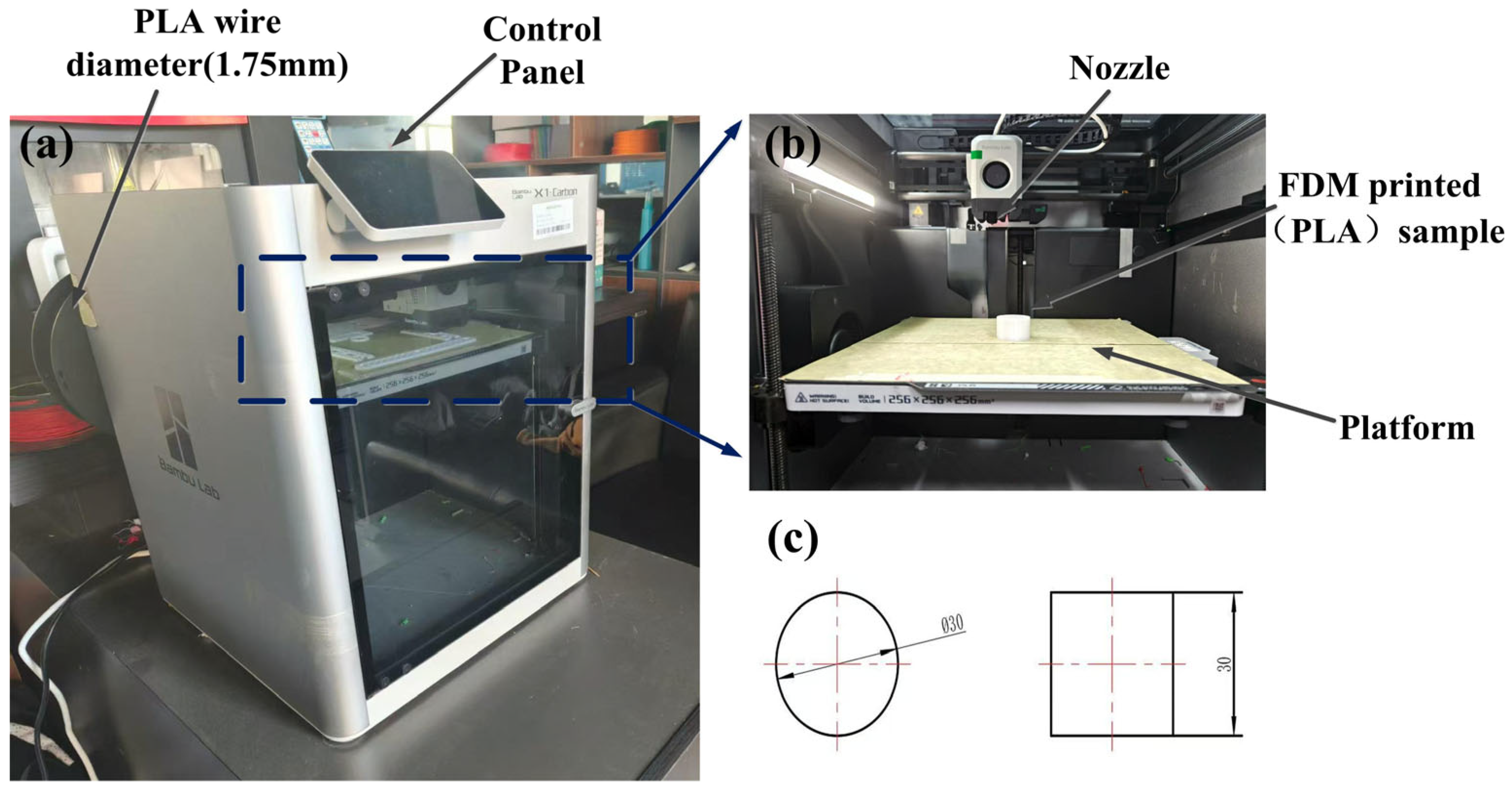

The experiment used Bambu Lab X1 FDM 3D printing equipment, as shown in

Figure 4a. The main components of the FDM 3D printer include the bed, nozzle, and stepper motor, as shown in

Figure 4b. The 3D printing consumables used are PLA with a diameter of 1.75 mm. Three-dimensional printing requires designing and printing parts in modeling software, with dimensions of 30 mm in diameter and 30 mm in height, as shown in

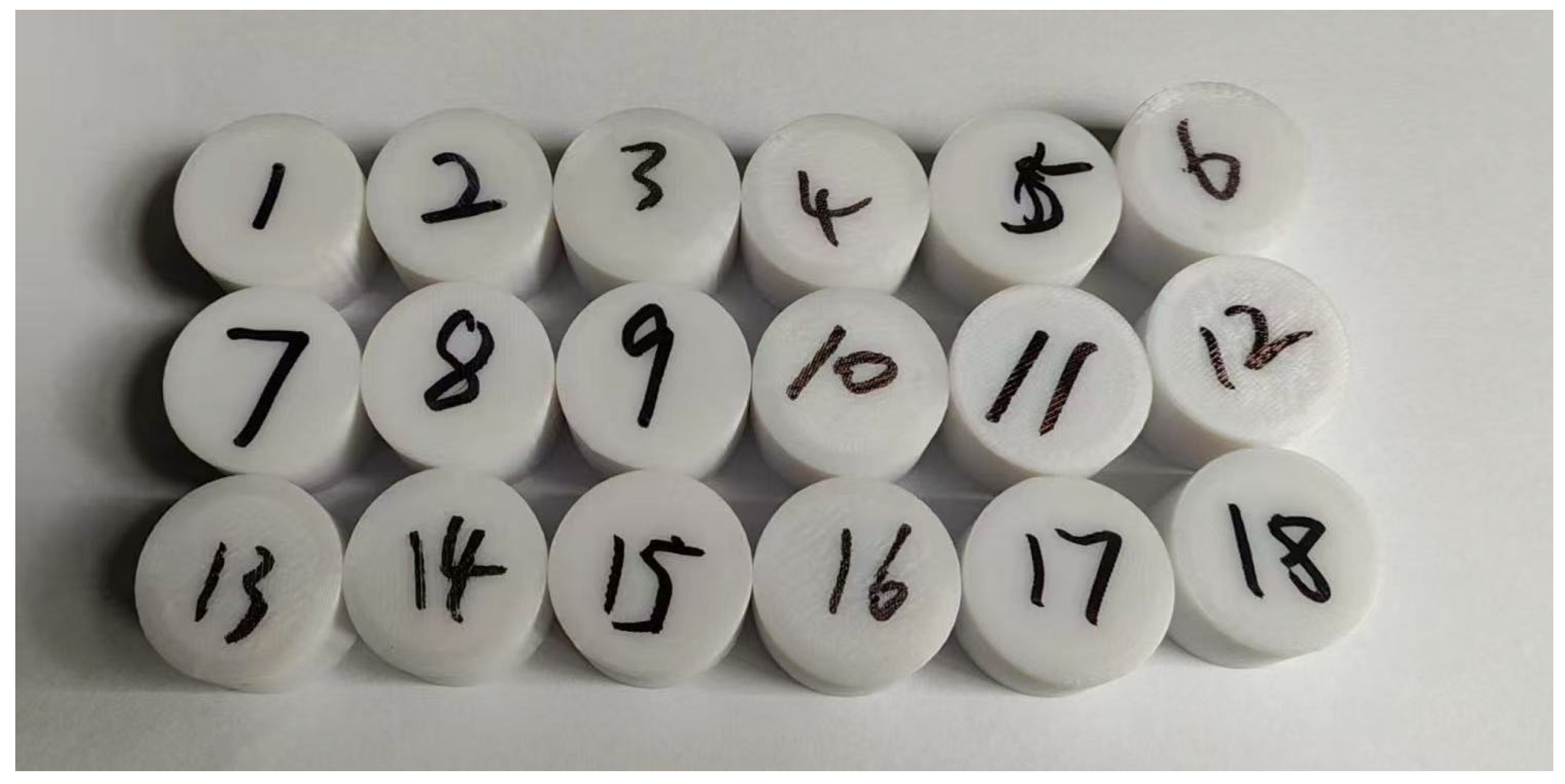

Figure 4c, and importing files from modeling software into Bambu Studio slicing software (Linux version) in STL format. After completing the parameter settings, the automatically generated G-code file should be saved to the 3D printer for printing.

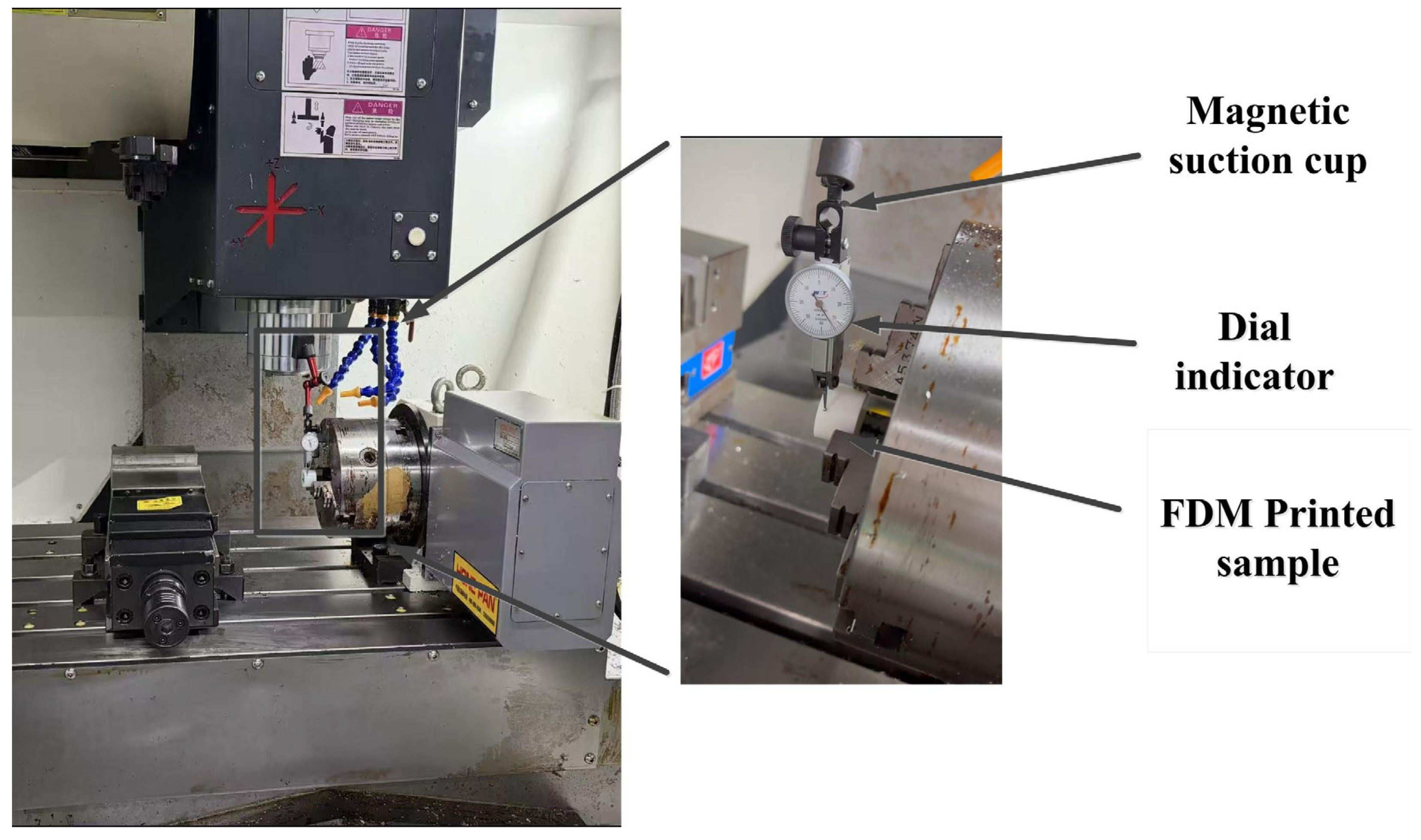

The printer has four main stages throughout the entire printing process: standby, preheating, printing, and cooling. After printing, all samples were left at room temperature for 5 h and allowed to cool naturally to a stable state. As shown in

Figure 5, the FDM printed part is fixed onto the chuck fixture with a wrench, and a dial gauge is used to measure the circular runout tolerance value of the workpiece. Magnetic suction cups are used to fix the dial gauge on the spindle lifting platform and adjust the spindle lifting platform to select the appropriate measurement angle (perpendicular to the C-axis direction). As shown in

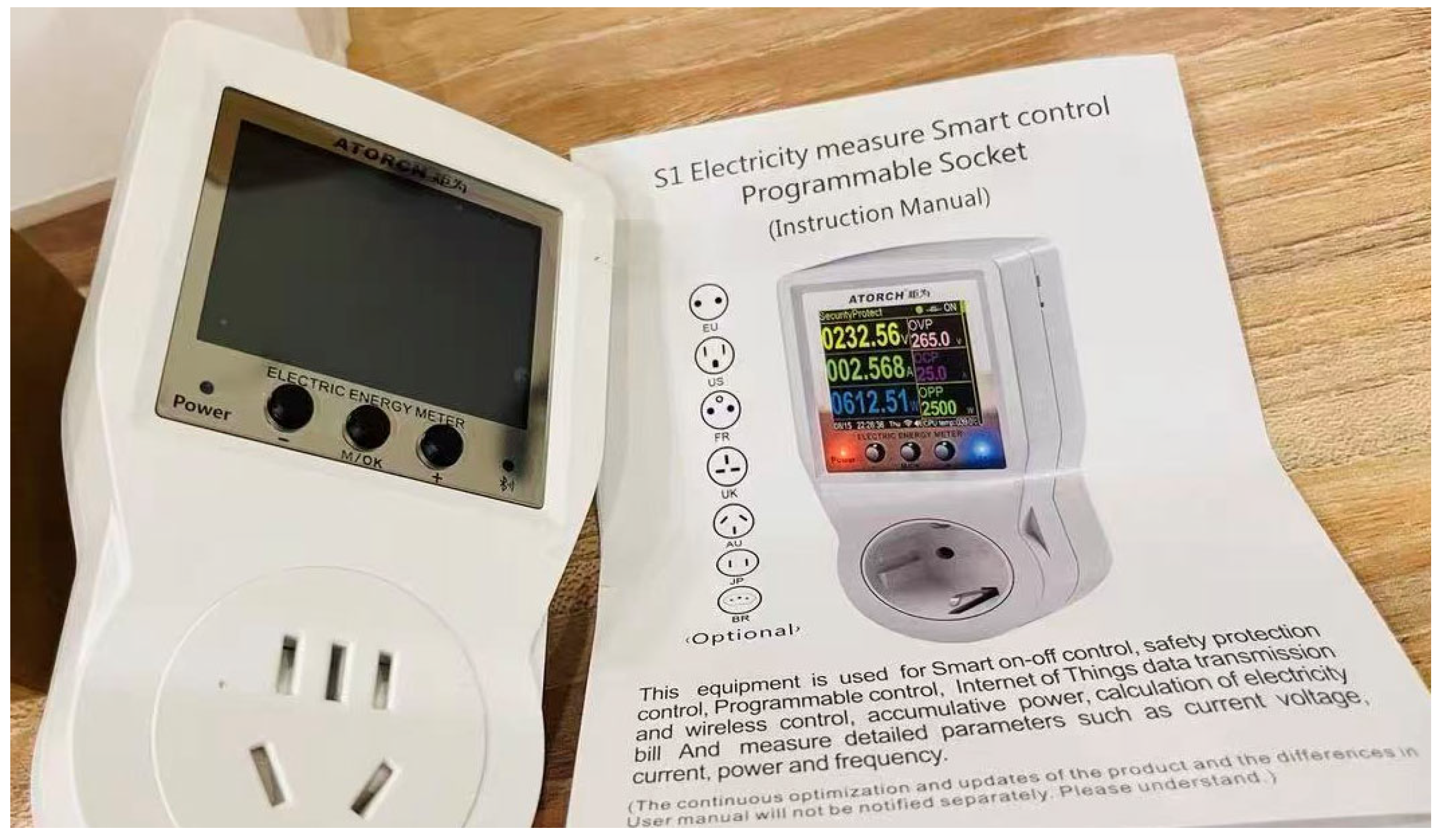

Figure 6, the power consumption of each FDM 3D printed part was measured using a WiFi intelligent socket monitoring device (Shenzhen Juwei Technology Co., Ltd., Shenzhen, China), which is made of PCB/ABS, and the device model is S1BW.

During FDM printing, uneven cooling of the printing material can lead to severe dimensional warping of the printed components. Therefore, it is necessary to choose appropriate process parameter values to maximize the dimensional accuracy and quality stability of the parts. The following factors were selected for the experiment: layer height (A), nozzle temperature (B), filling density (C), first layer layer height (D), and printing pattern (E), with circular runout tolerance value and carbon emissions as the main objectives, and an orthogonal experimental design was adopted. The orthogonal experimental factor level table is shown in

Table 1. The L18 orthogonal experimental platform was selected, orthogonal experiments were designed according to

Table 1, and 18 experimental schemes were obtained as shown in

Table 2. The actual printed sample is shown in

Figure 7.