Abstract

With increasing traffic loads and the continuous deterioration of asphalt pavements, it has become necessary to explore alternative materials that enhance both performance and sustainability. This study aims to investigate the effect of using cement kiln dust (CKD) as a filler substitute in hot mix asphalt composites, focusing on the mechanical and durability properties of pavements. The results indicate that replacing conventional filler with CKD in different proportions (1.5%, 3%, 4.5%, and 6%) positively affects the properties of asphalt mixtures. Marshall stability values increased by 58.4% when using 100% CKD, indicating a significant improvement in the mixture’s ability to withstand traffic loads. Flow tests revealed that replacing CKD by up to 50% enhances the flexibility of the mixture, but exceeding this percentage makes the mixture stiffer, which may lead to premature cracking. In terms of moisture sensitivity, incorporating CKD by 25% improves the mixture’s resistance to water damage, while increasing it to 100% reduces this resistance, highlighting the need to improve the adhesion properties of asphalt. Indirect tensile strength tests have confirmed that CKD enhances the cohesion of the mixture, reducing the likelihood of cracking under pressure and contributing to longer pavement life. Based on these results, it is recommended that CKD be used for up to 50% to achieve a balanced combination of strength, flexibility, and moisture resistance, with further studies being needed to evaluate the long-term performance and potential improvements through additional material modifications.

1. Introduction

Rising traffic loads and volumes result in increased stresses and strains on roadways, putting pavement layers at risk of deterioration [1]. Consequently, there is an increasing demand for asphalt mixes capable of withstanding these external stresses while minimizing cracking and improving overall performance. The designed life span for pavements is usually 20 years, with consideration of the expected traffic loads. A high stiffness modulus in asphalt contributes to pavements that can endure heavy traffic without experiencing fatigue throughout their service life. Hence, the use of recycled materials contributes positively to a more sustainable approach to construction and reconstruction practices [2].

Many previous researchers have confirmed that using waste or by-product materials to replace coarse or fine aggregates or fillers results in a promising evolution in asphalt concrete mechanical properties and durability [3,4,5].

Filler has a great effect on the life span of the asphalt mix because it increases the resistance to water penetration and improves asphalt viscosity, in addition to its significant influence on strength. Therefore, the properties of the filler materials in asphalt mix design are very important in physical and chemical aspects [6]. In addition, the demand for construction materials, especially in road construction, is rising, while natural resources remain limited [7]. Fillers are one of the most important components and have a significant influence on the characteristics of the asphalt mixture because their particles have a large surface area that facilitates the interaction with the asphalt binder. Fine particles, such as rock dust, fly ash, hydrated lime, and other materials with particle sizes smaller than 75 microns, are used as fillers in asphalt mixtures [8].

The demand for natural aggregates in construction projects is consistently rising with the rapid increase in infrastructure projects in developed and developing countries. Natural quarry materials are increasingly scarce, and the environmental concerns and economic costs of using these limited resources are increasing rapidly. Cement kiln dust (CKD) is a by-product of cement manufacturing. It is a fine, powdery material similar in appearance to Portland cement [9,10]. It is composed of micronized particles collected from electrostatic precipitators during the production of cement clinker. Fresh CKD can be classified as belonging to one of the four categories, depending upon the kiln process used and the degree of separation in the dust collection system [11].

There are two types of cement kiln processes: wet-process kilns, which take feed materials in slurry form, and dry-process kilns, which accept feed materials in a dry-ground form. In both processes, CKD can be collected in the following two ways: (i) some of the dust can be separated and returned to the kiln from the dust collection system (cyclone) close to the kiln, or (ii) the entire quantity of dust generated can be recycled or discarded [12]. The cement industry is considered one of the biggest waste-producing industries. Producing 1 ton of cement requires about 1.5 to 1.7 tons of raw materials, 0.1 ton of coal, and 1 ton of clinker. The most important pollutants in the process of cement production come from the raw materials and fuel preparation, clinker heating, and cement milling. According to the latest available information, in 2013, the global production volume of cement was more than 4 billion tons [13]. Typically, the production volume of CKD represents 15% to 20% of the total cement produced [14].

Due to its chemical composition, CKD has many potential applications. It can be recycled back into the cement production process to reduce waste and raw material consumption. Additionally, it is used in soil stabilization, as filler in building materials, and in waste treatment processes. However, the high alkali content and variability in composition may limit its direct use in some applications. CKD is one of the waste materials, a fine substance like cement, and is generated at cement factories. The major compounds of CKD are silica, lime, and alumina. The primary role of CKD is its cementitious property. CKD can be incorporated as a replacement for other cementitious substances, i.e., blast furnace slag cement, Portland cement, and Portland pozzolan cement [15].

Although a part of CKD returns to the cement production process by using a CKD collector, due to different reasons—including production process suspension, the cooling of these materials, and poor quality—a portion of CKD is deposited as waste materials. Due to the fine size of the CKD, the area of release of these pollutant materials sometimes reaches 10 km from the plant. The presence of this fine dust in the air can cause the emergence of respiratory problems and diseases for inhabitants who live near the plant [13]. CKD consists primarily of calcium carbonate and silicon dioxide, similar to the cement kiln raw feed. The particle size of CKD depends upon the kiln operation type. For example, the dust collected from dry kilns is finer than that from wet and semi-wet/semi-dry kilns. This is true for both returned dust and discarded specks of dust [16]. Also, the grinding and reshaping mechanism of the resulting clinker material, the number of stages, the number of cycles through which the materials will be returned to the kiln to be ground again, and the control and adjustment factors available in the plant during operation will have a significant impact as well.

CKD plays an essential role in stabilizing and hardening various waste materials, providing a cost-effective alternative to traditional curing agents, such as cement and lime. Due to its high adsorption capacity and alkaline nature, CKD effectively reduces the moisture content of the waste, which in turn enhances its load-bearing capacity and overall structural stability. This property makes CKD particularly valuable in waste management applications, where controlling the moisture levels is essential for long-term environmental safety. Additionally, CKD has been successfully used to treat a wide range of waste materials, including coal mine waste, demonstrating its versatility and effectiveness in mitigating environmental risks while providing a sustainable waste treatment solution [17,18].

CKD has been effectively used as a mineral filler in asphalt concrete mixes, enhancing the performance and durability of paving materials. When CKD is blended into the asphalt cement binder before mixing with hot aggregate, it forms a modified binder (paste) that improves the overall stability and durability of the asphalt mixture. One of the major benefits of this approach is the significant reduction in asphalt cement requirements, which typically range from 15% to 25% by volume. This not only reduces material costs, but also contributes to the more efficient use of resources, making CKD a valuable additive in asphalt pavement construction [19]. CKD improves pavement performance by enhancing abrasion resistance, helping to prevent moisture damage, and extending the life of asphalt surfaces. Additionally, CKD can substitute for Portland cement or hydrated lime in mortar seals—a mixture of fine aggregates and emulsified asphalt—providing a cost-effective and sustainable alternative. Studies have shown that even when using abrasion-prone fine aggregates, mortar seal mixes containing 2% CKD achieve excellent results in abrasion resistance tests. This demonstrates the potential of CKD to improve the durability and longevity of road surfaces while improving material utilization in pavement construction [20,21]. Modarres, Ramyar, and Ayar [13] reported that using CKD as a filler material in HMA not only had no negative effects on the mixture’s technical qualities, but also had advantages from an environmental perspective, such as lowering the amount of accumulated CKD in the environment and lowering the risk of pollution of the air and water.

The importance of CKD as a binder, especially when combined with fly ash, should be acknowledged. CKD contains alkali, sulfate, and free lime, which can affect its concrete performance. When mixed with fly ash, CKD promotes hydration reactions, forming ettringite and calcium silicate hydrate gel (C-S-H). These compounds improve the mechanical properties of the binder, contributing to better strength development. However, variations in the composition of CKD, particularly in the alkali and sulfate content, can impact its effectiveness as a sustainable binder in concrete applications [22]. Cement dust contains a mixture of raw feed, as well as burnt materials with some volatile salts [23]. Cement production contributes to environmental pollution and the depletion of natural resources, and its use may lead to increased construction costs [24].

Considering the availability and accumulation of CKD in the cement industrial areas of Karbala Governorate, Iraq, this study was carried out to establish foundational strategies for dealing with and controlling this material. CKD may contain a mixture of chemical compounds and harmful substances, and it has the potential to spread rapidly and widely over large areas, raising both environmental and health concerns. Economically, CKD is completely free and does not require any special preparation or manufacturing. Many of its properties are compatible with those of the traditional filler materials used in asphalt mixtures and allow it to perform the same function. Based on the tests presented in Section 2, CKD is considered a highly promising material to replace conventional filler, particularly in view of its performance results. Ultimately, the goal is to develop asphalt mixtures that are resilient, cost-effective, and capable of withstanding environmental and traffic-related challenges, ensuring long-term pavement performance with minimal maintenance.

2. Methods and Materials

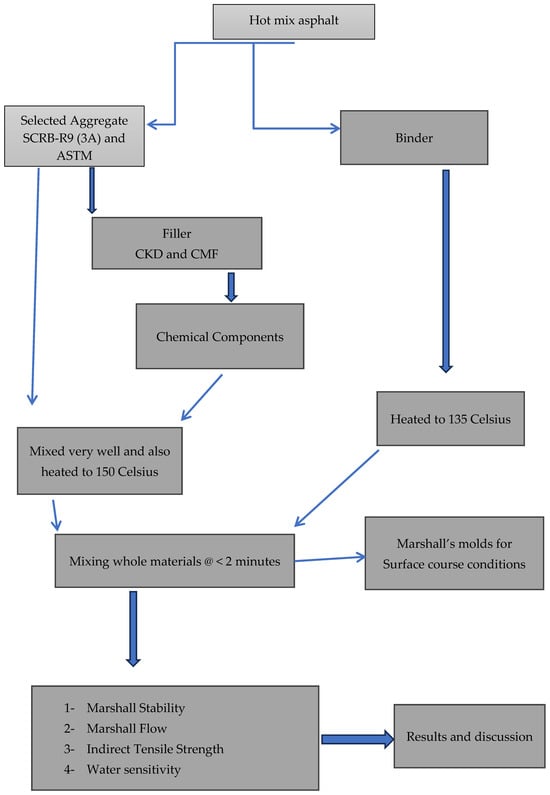

The asphalt mixture consists of a combination of aggregate and asphalt binder, which work together to create a cohesive and durable pavement structure. The aggregate provides strength and stability, and its properties—such as size, shape, and texture—vary depending on the source. The asphalt binder acts as the adhesive that holds the aggregate particles together, offering flexibility and resistance to cracking. If certain materials prove inadequate, they may be replaced or modified to enhance performance, ensuring the asphalt mixture is optimized for different climatic conditions and traffic loads [25]. Engineers may adjust the material proportions, select alternative sources, or use additives such as polymers and anti-stripping agents to improve adhesion and resistance. Figure 1 illustrates the experimental procedure followed in this study.

Figure 1.

Experimental work procedure.

2.1. Aggregate

Characterizing the raw materials in terms of their physical, chemical, and mechanical properties is crucial for assessing their suitability as alternative materials. In asphalt mixtures, aggregates constitute approximately 95% of the total mass and serve as the primary structural component, efficiently transferring loads to the underlying layers while minimizing deformation. The strength and stiffness of the aggregate directly influence the pavement’s ability to endure heavy traffic and fluctuating environmental conditions. Additionally, a rough surface texture enhances tire–road interaction, improving friction and reducing the risk of skidding, particularly during wet conditions [26].

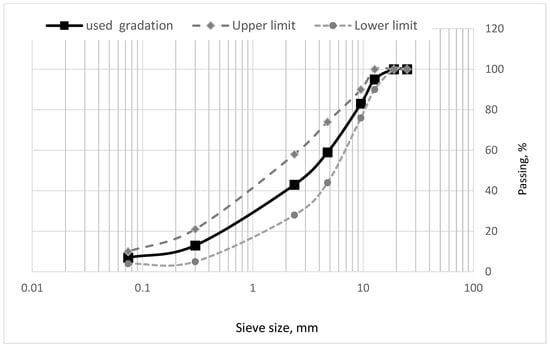

The aggregates used in this study were sourced from quarries in Karbala Governorate. Their suitability for use in asphalt mixtures was confirmed through standard testing. Following the Iraqi State Commission of Roads and Bridges (SCRB) Section R9 [27], the aggregates were sieved, sorted, and graded to meet the gradation needed for the surface layer. Figure 2 displays the surface layer gradation following GSRB Section R9, while Table 1 shows the physical and chemical aggregate characteristics.

Figure 2.

Surface coarse gradation (3A).

Table 1.

Aggregate’s characteristics (physical and chemical).

2.2. Selected Fillers

Two fillers were used in this study: CKD and conventional mineral filler (CMF), as described below. CKD was used as a secondary filler, replacing part or all of the primary filler, CMF. CKD is a fine powder by-product generated during cement manufacturing. It consists of partially burned raw materials, unreacted lime, alkali salts, and small amounts of heavy metals. It is collected from kiln exhaust gases in cement plants using air pollution control devices such as electrostatic precipitators and filter bags.

In this study, CKD was supplied by the Karbala Cement Plant, a producer of anti-sulfate Portland cement. CMF was obtained from the bypass collector of the aggregate crushing process and is commonly used in local hot mix asphalt (HMA) applications.

The chemical compositions of CKD and CMF, analyzed using an energy dispersive X-ray fluorescence (EDXRF) spectrometer, are presented in Table 2. According to the table, CKD is composed of alkalis, sulfates, SiO2, and CaO, with a high pH value indicating its strong alkalinity. It is worth mentioning that the pH of the CKD is 12.9.

Table 2.

Chemical characterization of the selected filler materials.

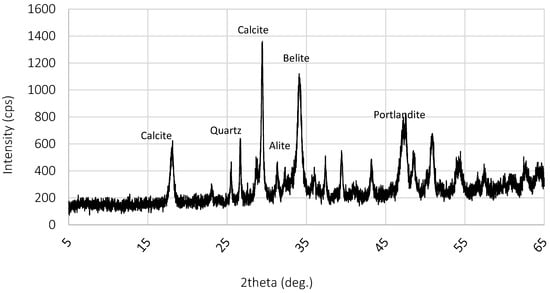

Calcite (CaCO3) dominates the CKD sample’s XRD pattern (Figure 3), with prominent peaks corresponding to it. The presence of the typical clinker phases belite (C3S) and alite (C3S) is indicated by peaks around 32–34°. Quartz (SiO2) is indicated by a prominent peak at 26.6°, whereas portlandite or other hydration products may be represented by smaller peaks.

Figure 3.

X-ray diffraction pattern of the CKD.

2.3. Asphalt Binder

The properties of the asphalt play a crucial role in influencing the performance of asphalt mixtures. Key properties such as penetration, ductility, softening point, and fire resistance determine the behavior of bitumen at different temperatures and loading conditions. To evaluate these properties, standardized test procedures, including those developed by the American Society for Testing and Materials (ASTM), are used to assess the suitability of bitumen for road construction projects. The test results obtained for the bitumen sample, as shown in Table 3, confirm its compliance with fundamental ASTM standards.

Table 3.

Physical and chemical characteristics of asphalt.

The permeability test at 25 °C gave a penetration value of 4.7 mm, which falls within the standard range of 4 to 5 mm (ASTM D5). This parameter is particularly significant, as it reflects the consistency and hardness of the bitumen, which directly affects its workability and ability to resist deformation under applied loads. An optimal penetration value promotes strong adhesion to the aggregate while preserving resistance to abrasion and cracking.

3. Hot Mix Asphalt Experimental Program

Asphalt mixture is a basic material used in road construction consisting of a homogeneous blend of raw materials (coarse and fine) and bitumen as a binding agent. It plays a crucial role in pavement layers, ensuring strength, durability, and resistance to deformation caused by traffic loads and environmental factors such as temperature fluctuations and humidity changes. The performance of asphalt mixtures depends on the quality of their components, proper mix design, and effective compaction during construction, making careful formulation essential to ensure long-lasting and safe road surfaces [40].

The basic components of the asphalt mixture include raw materials, bitumen, and air voids. The raw materials form the structural framework of the mixture, providing mechanical strength and stability. Coarse aggregates contribute to load-bearing capacity and abrasion resistance, while fine raw materials enhance workability and compaction. Bitumen acts as an adhesive, binding the raw material particles together and providing flexibility to accommodate pavement movements caused by temperature fluctuations and traffic loads. In addition, the air voids within the mixture are carefully controlled to maintain an optimum balance between durability and flexibility, preventing cracking and premature deformation [26].

In this study, CKD filler replaced the conventional filler. Five different CKD percentages, ranging from 0% to 25%, 50%, 75%, and 100%, were used. The amounts of CKD and conventional filler were expressed as a percentage of the total mix by weight. After compression, the freshly prepared samples were allowed to cool to room temperature before determining their specific gravity according to ASTM D 2726. The Marshall stability and flow values of each test sample were then evaluated according to ASTM D 1559 guidelines. Following these tests, specific gravity and void analyses were performed to determine the percentage of air voids within the mineral aggregate, the percentage of air voids in the compacted mix, and the voids filled with bitumen. Any values determined to be irregular were excluded before averaging the results.

The Marshall method has been used to prepare asphalt mixes, followed by mechanical tests to evaluate their performance, as detailed in Table 4. The properties of HMA are influenced by the proportions of the total bitumen mixture, which in turn depends on the distribution of its components.

As presented in Table 5, asphalt mix samples were prepared using five different replacement ratios of CKD with CMF, namely 0%, 25%, 50%, 75%, and 100%. To ensure statistical reliability and reduce variability, three replicates were tested for each replacement level. This approach facilitated a comprehensive evaluation of the effect of CKD incorporation on the mechanical and volumetric properties of the asphalt mixture. A constant 4.8% asphalt content was used during the preparation process to maintain consistency across all tested samples. This uniform approach ensures that variations in performance can be attributed solely to changes in filler composition rather than fluctuations in binder content. Previous studies have also indicated that the difference in optimum binder content when using different types of fillers remains small, typically within the range of less than 0.2% [41,42].

Table 5.

Percentages of filler materials in the asphalt mix.

Table 4.

Mechanical tests performed in this study.

Table 4.

Mechanical tests performed in this study.

| Mechanical Tests | Specifications |

|---|---|

| Marshall stability (MS) | ASTM D6927-AASHTO T 245 [43] |

| Marshall flow (MF) | ASTM D6927-AASHTO T 245 [43] |

| Indirect tensile strength | ASTM D6931-17 [44] |

| Water sensitivity | ASTM D4867-14 [45] |

3.1. Marshall Stability Test

Marshall stability tests were conducted to evaluate the mechanical behavior of the mixtures [46]. This is a fundamental procedure used to evaluate the load-bearing capacity and resistance of asphalt mixtures to deformation under traffic loads. This test provides critical insights into the mechanical performance of asphalt pavements by measuring the maximum load a compacted sample can withstand before failure.

A higher stability value generally indicates a well-compacted and dense mixture, which enhances resistance to deformation and wear over time. Stability is affected by the aggregate structure and distribution of the binder within the mixture. A properly designed asphalt mixture with optimum stability ensures better load transfer, reducing premature failures such as cracking or surface deterioration.

Furthermore, maintaining a balanced relationship between stability and flow is essential for preserving pavement flexibility while preventing excessive deformation under repeated traffic loads. The results obtained from the Marshall stability test play a crucial role in determining the suitability of asphalt mixtures for different traffic conditions.

In engineering practice, ensuring that the stability value meets or exceeds internationally recognized standards—typically set at a minimum of 8 kN—contributes to the development of long-lasting, durable pavements. By improving stability properties, engineers can design high-performance asphalt pavements that can withstand heavy traffic loads while maintaining the integrity of the infrastructure over extended service lives.

3.2. Marshall Flow Test

The Marshall flow test is one of the primary criteria used in conjunction with the Marshall stability test to evaluate the performance of asphalt mixtures. While stability measures the load-bearing capacity, the flow test assesses the ability of the material to undergo controlled deformation before failure. This test provides valuable insights into the flexibility and workability of the mixture, ensuring that it can absorb the stresses of traffic without excessive deformation or cracking [47].

A key aspect of the flow test is its ability to indicate the binder content within the asphalt mixture. Excessively high flow values may suggest an overabundance of binder, which can lead to issues such as reduced structural integrity over time. Conversely, very low flow values may indicate brittleness, increasing the pavement’s susceptibility to cracking under traffic loads.

To meet global performance standards, the recommended flow range is typically between 2 mm and 4 mm. Maintaining flow values within this range ensures a balanced mix design, ensuring both durability and flexibility. This contributes to the development of long-lasting, resilient pavements capable of withstanding varying traffic demands and environmental conditions.

3.3. Water Sensitivity Test

The water sensitivity test is a critical evaluation method used to assess the durability of asphalt mixtures when exposed to moisture. This test measures the potential vulnerability of asphalt pavements to water infiltration, which can weaken the bond between the binder and the aggregate, leading to stripping, reduced cohesion, and premature pavement deterioration. By determining the resistance of an asphalt mixture to moisture damage, this test plays an important role in ensuring the long-term performance of the pavement under diverse environmental conditions [48,49].

One of the key indicators obtained from the water sensitivity test is the retained strength of asphalt samples before and after moisture treatment. A significant decrease in strength following water exposure indicates a higher susceptibility to moisture damage, which may result in surface distress, potholes, and overall pavement failure. Therefore, enhancing the mixture design to improve water resistance is essential for maintaining structural integrity and extending pavement life [50].

To comply with international standards, asphalt mixtures must exhibit a retention strength value above the minimum, ensuring adequate resistance against moisture-induced deterioration. The proper selection of materials, including high-quality aggregates and moisture-resistant binders, combined with effective compaction techniques, can significantly enhance the water-sensitivity performance of asphalt mixtures, contributing to more durable and resilient pavements [51].

3.4. Indirect Tensile Strength Test

The indirect tensile strength (ITS) test is a fundamental method used to evaluate the tensile properties and crack resistance of asphalt mixtures. This test measures the ability of a compacted asphalt sample to withstand tensile stress, which is critical to determining the resistance of the mixture to cracking under traffic loads and environmental conditions. Since asphalt pavements are primarily subjected to compressive loads from vehicles, tensile failure often occurs due to repeated stress cycles, making ITS a key indicator of pavement durability [52,53].

During ITS testing, a cylindrical asphalt sample is subjected to a radial compressive load applied across its vertical diameter, producing horizontal tensile stresses that simulate real-world pavement conditions. A higher ITS value indicates greater resistance to tensile cracking, thereby lowering the risk of fatigue failure and thermal cracking in asphalt pavements [54].

Maintaining an optimal ITS value is essential to ensuring long-term pavement performance. Cracks can develop in a mixture with insufficient tensile strength over time, leading to moisture infiltration, loss of structural integrity, and premature deterioration. By optimizing binder content, aggregate gradation, and compaction methods, engineers can significantly enhance the ITS performance of asphalt mixtures, improving their ability to withstand heavy traffic loads and environmental stresses while contributing to more durable and resilient pavements [55].

4. Results and Discussion

4.1. Marshall Stability

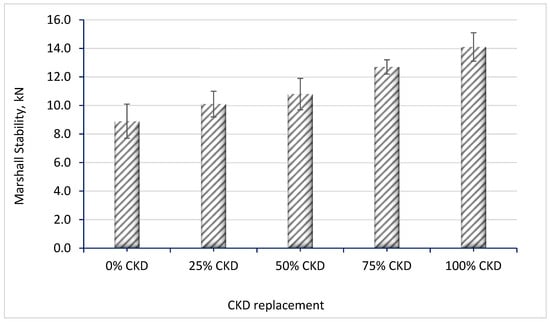

Figure 4 shows the results of the Marshall stability test for HMA incorporating different replacement ratios of CKD as filler. The values displayed on the bars represent the stability of the mixture at each replacement ratio, indicating that all tested mixes met the minimum stability requirement of 8 kN, as specified by the Iraqi standard [56].

Figure 4.

Results of Marshall stability with CKD.

From the analysis of the results, it is clear that increasing the content of CKD significantly enhanced the stability of the asphalt mixture. At 0% CKD, the stability was 8.9 kN. However, when CKD replaced 25% of the filler, stability increased to 10.1 kN, representing a 13.5% improvement over the control mixture (0% CKD). At 50% CKD, the stability reached 10.8 kN, an increase of 21.3%. With 75% CKD, stability further improved to 12.7 kN, corresponding to a 42.7% increase. The highest stability value was recorded at 100% CKD replacement, reaching 14.1 kN, which reflects a 58.4% improvement compared to the control sample.

These results indicate that replacing conventional filler with CKD significantly enhanced the stability of asphalt mixtures, particularly at higher replacement ratios. However, care must be taken to ensure that increased CKD content does not negatively impact gradation or mixture homogeneity, as these are essential for maintaining the optimal performance of the asphalt surface layer [56].

The presence of Portlandite, the main mineral component of CKD (as indicated by Choudhary et al. [57]), likely contributes to the increased Marshall stability by enhancing the adhesion between the bitumen and the filler.

As a measure of test consistency, the Marshall stability values were calculated using the average of five specimens for each mixture, ensuring the repeatability and reliability of the results.

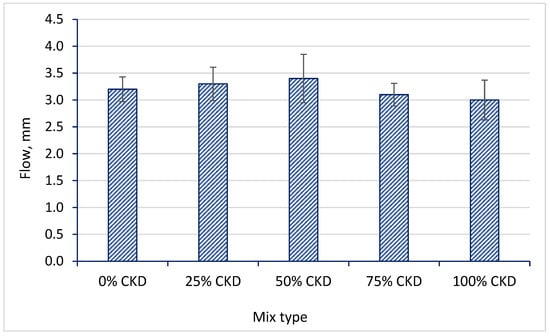

4.2. Marshall Flow

Figure 5 clearly illustrates the flow behavior of HMA when using different proportions of CKD as a partial or complete replacement. The analysis of the data reveals that the flow value gradually increases as the CKD content increases from 0% to 50%, from 3.2 mm to 3.4 mm. This indicates that replacing fine aggregate with moderate amounts of CKD improves the mixture’s ability to deform under load, enhancing its resilience to withstand external physical conditions that conventional asphalt pavements cannot endure without this property. This improvement is attributed to the fact that CKD, at moderate concentrations, reduces micro voids in the mixture to an optimal level and acts as a fine filler, contributing to improved particle movement during loading.

Figure 5.

Flow values with CKD.

However, when the CKD content exceeds 50%, the flow value begins to decline, reaching 3.1 mm at 75% CKD, and decreasing further to 3.0 mm at 100% CKD. This decrease reflects an increase in the mixture’s stiffness and a decrease in its deformability. This may negatively impact the mixture’s ability to return to its original shape after the load is removed, potentially leading to permanent deformation.

This behavior is likely due to an excessive percentage of CKD, which leads to overstressing and a loss of the necessary elasticity in the mixture. Furthermore, a high CKD content may negatively impact the adhesion between the aggregate and the bitumen, reducing the mixture’s ability to deform before collapse occurs.

Therefore, it can be concluded that CKD can be effectively used as a replacement material at up to 50% to improve the elasticity of an asphalt mixture. However, exceeding this percentage results in increased stiffness at the expense of elasticity, which may negatively impact pavement performance under various service conditions.

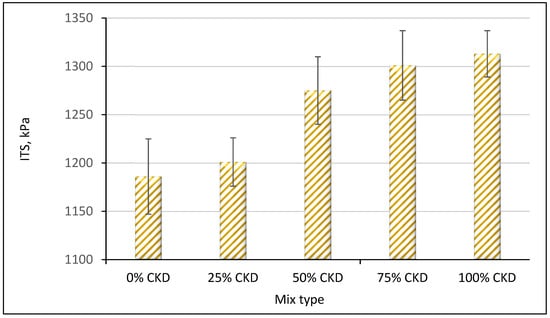

4.3. Indirect Tensile Strength (ITS)

The results clearly shown in Figure 6 indicate a continuous and consistent improvement in the indirect tensile strength (ITS) with increasing CKD content within the asphalt mixture. The ITS value at 0% CKD is recorded at 1186 kPa, while the highest value, which corresponds to 100% CKD, reaches 1313 kPa. This gradual increase in strength indicates that the incorporation of CKD has a significant positive effect on the mechanical properties of the asphalt mixture.

Figure 6.

ITS results with CKD.

One possible explanation for this improvement is that CKD acts as a filler, reducing voids and improving particle interlocking, thus enhancing cohesion and bonding within the mixture. In addition, the presence of CKD may contribute to pozzolanic reactions, increasing the structural integrity and stiffness of the mixture. This trend suggests that CKD is beneficial in strengthening the asphalt mix, making it more resistant to tensile forces and potential cracking under load conditions.

However, while the results indicate improvement in strength, further analysis is needed to evaluate other critical factors, such as durability, elasticity, and wettability. The long-term performance of CKD-modified asphalt should be carefully examined to determine the optimal CKD content that balances strength and durability, ensuring a sustainable and cost-effective paving solution.

Finally, we can predict that the increase is due to several interconnected factors. One of the main reasons for this is that CKD acts as a fine filler, filling the voids within the mix, which reduces air voids and increases the density and cohesion of the mixture. Additionally, the chemical composition of CKD, particularly its content of pozzolanic compounds such as free lime and silica, contributes to the formation of additional cementitious products, enhancing the structural strength of the mix. Furthermore, the angular shape and rough surface of the CKD particles enhance the mechanical interlocking between aggregate particles, leading to improved cohesion and resistance of the mix to tensile forces.

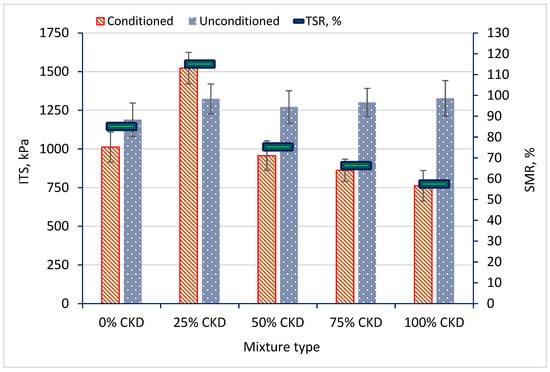

4.4. Water Sensitivity

The results indicate that the tensile strength ratio (TSR) varies significantly with different CKD replacement ratios, reflecting the effect of CKD content on wettability. The highest TSR value (115.0%) was observed at 25% CKD, indicating improved moisture resistance due to enhanced adhesion and decreased watertightness. However, as the CKD content increases beyond this point, the TSR values decrease, reaching 57.4% at 100% CKD, indicating a higher susceptibility to moisture damage.

The unconditional ITS values remain relatively stable across different CKD contents, while the conditional ITS values decrease with increasing CKD, especially beyond the 25% replacement level. This trend suggests that, while CKD can enhance adhesion at optimal dosages, excessive CKD content may result in decreased cohesion under moisture exposure. Therefore, a balanced CKD content is essential to increase toughness while reducing water sensitivity, as shown in Figure 7.

Figure 7.

Water sensitivity with CKD.

Alkaline materials form strong bonds with bitumen due to its mildly acidic nature [58], which enhances resistance to water action and improves resistance to stripping [59]. Shoaib et al. [23] reported that, due to the increase in alkalies, sulfates, and chlorides, which affect the amount of CSH and aluminates hydrates, the compressive strength of hardened concrete mixes with high dust values decreased. This resulted in the formation of significant amounts of hydrated sulfo-aluminates and chloro-aluminates, which facilitate expansion and softening.

This explains why high percentages of CKD (75% and 100%) reduce the water resistance of asphalt mixes, as shown in Figure 7. Thus, it can also be said that, when the CKD replacement ratio exceeds 30%, several negative effects begin to accumulate, leading to a significant decrease in the moisture resistance of the mixture. The first of these is the accumulation of water-soluble salts such as sulfates and chlorides, which react with moisture to form hydrated sulfo-aluminates and chloro-aluminates. These compounds cause the internal expansion and softening of the mixture, weakening its internal structure.

This deterioration of structural components gradually reduces internal cohesion and increases the mixture’s susceptibility to moisture damage, reducing its ability to resist water impacts. Consequently, these changes are reflected in a gradual and continuous decrease in modal ITS and TSR at higher CKD replacement levels.

5. Conclusions

This study demonstrates that using cement kiln dust (CKD) as a filler replacement in asphalt mixes can significantly improve the mechanical properties and durability of pavements, making them a promising alternative to conventional fillers. The following conclusions can be drawn:

- The Marshall stability test showed a 58.4% increase in stability when using 100% CKD instead of a conventional limestone filler. This indicates improved structural strength and suitability for heavy traffic conditions.

- Replacing up to 50% of the filler with CKD maintained an effective balance between elasticity and stiffness. This ensures adequate elasticity and abrasion resistance. However, exceeding this percentage increases stiffness, which can lead to premature cracking.

- At 25% CKD replacement, cement kiln dust enhanced moisture resistance, reducing water damage. However, higher replacement levels (over 50%) increased the susceptibility to moisture, highlighting the need for anti-erosion agents.

- Indirect tensile strength tests showed increased internal cohesion and resistance to tensile stresses, reducing cracking under repeated loads and reducing maintenance requirements.

- The fine CKD particles effectively filled the air voids, resulting in a denser, more cohesive asphalt mixture with enhanced structural integrity.

- A 50% CKD replacement ratio was determined as the optimal level for achieving maximum mechanical strength, elasticity, and moisture resistance without compromising the workability or long-term durability of the mixture.

Although CKD offers an economical alternative to natural aggregates, and the use of CKD in asphalt mixes supports sustainable construction, replacement levels above 50% negatively impact the mix’s workability and long-term durability, requiring careful proportioning and optimized mix design. In addition, while the short-term results are promising, long-term studies under varying environmental and loading conditions are needed to confirm the durability and reliability of CKD. Future research should explore the development of a modified asphalt binder with CKD, which may enhance the binder’s properties, such as improving its stiffness, stability, and resistance to deformation under heavy loads.

Author Contributions

A.D.: Project administration, Supervision, Conceptualization, Methodology, Visualization, Investigation, Formal analysis, Writing—original draft, and Writing—review and editing. Y.N.K.: Conceptualization, Methodology, Investigation, Software, Data curation, Visualization, Writing—original draft, and Writing—review and editing. H.A.I.: Investigation, Conceptualization, Methodology, Formal analysis, and Writing—review and editing. R.A.H.: Investigation, Conceptualization, Methodology, Formal analysis, and Writing—review and editing. G.J.K.: Investigation, Conceptualization, Methodology, Formal analysis, and Writing—review and editing. J.M.d.A.A.: Writing—original draft, Data curation, Formal analysis, and Visualization. L.F.A.B.: Conceptualization, Writing—original draft, Writing—review and editing, and Formal analysis. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author(s).

Acknowledgments

The authors express sincere gratitude for the support received from Kerbala University in Iraq.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Kadhim, Y.N.; Abdulrasool, A.T.; Dulaimi, A.; Pinto, H.A.S.; Bernardo, L.F.A. Influence of Walnut Shell Ash and Limestone Filler in Hot Mix Asphalt. J. Compos. Sci. 2025, 9, 22. [Google Scholar] [CrossRef]

- Gkyrtis, K.; Pomoni, M. An overview of the recyclability of alternative materials for building surface courses at pavement structures. Buildings 2024, 14, 1571. [Google Scholar] [CrossRef]

- Akhtar, M.N.; Albatayneh, O.; Akhtar, J.N.; Koting, S. Porous asphalt pavement design by incorporating recycled coarse aggregate for sustainable urban drainage: An experimental study. Results Eng. 2025, 25, 103751. [Google Scholar] [CrossRef]

- Sarı, F.A.; Öztürk, İ.Ş.; Gönen, T.; Emiroğlu, M. Evaluation of waste metallic powder as fine aggregate replacement in Roller compacted concrete: Impact on physical and mechanical properties. Constr. Build. Mater. 2025, 468, 140386. [Google Scholar] [CrossRef]

- Al Nageim, H.; Dulaimi, A.; Ruddock, F.; Seton, L. Development of a new cementitious filler for use in fast-curing cold binder course in pavement application. In Proceedings of the 38th International Conference on Cement Microscopy, Lyon, France, 17–21 April 2016; pp. 167–180. [Google Scholar]

- Al Nageim, H.; Dulaimi, A.; Al-Busaltan, S.; Kadhim, M.A.; Al-Khuzaie, A.; Seton, L.; Croft, J.; Drake, J. The development of an eco-friendly cold mix asphalt using wastewater sludge ash. J. Environ. Manag. 2023, 329, 117015. [Google Scholar] [CrossRef]

- Kadhim, Y.N.; Hussain, W.A.M.; Abdulrasool, A.T. The effect of animal bone ash on the mechanical properties of asphalt concrete. Civ. Eng. J. 2021, 7, 1741–1752. [Google Scholar] [CrossRef]

- Kadhim, Y.N.; Hussain, W.A.M.; Abdulrasool, A.T.; Ibrahim, I.K. The influence of using Barley Husk Ash as a filler on the mechanical properties of asphalt. Proc. AIP Conf. Proc. 2023, 2743, 020020. [Google Scholar]

- Arulrajah, A.; Mohammadinia, A.; D’Amico, A.; Horpibulsuk, S. CKD and fly ash blends as an alternative binder for the stabilization of demolition aggregates. Constr. Build. Mater. 2017, 145, 218–225. [Google Scholar] [CrossRef]

- Al-Khafaji, R.; Dulaimi, A.; Jafer, H.; Mashaan, N.S.; Qaidi, S.; Obaid, Z.S.; Jwaida, Z. Stabilization of Soft Soil by a Sustainable Binder Comprises Ground Granulated Blast Slag (GGBS) and CKD (CKD). Recycling 2023, 8, 10. [Google Scholar] [CrossRef]

- Collins, R.J.; Emery, J. Kiln Dust-Fly Ash Systems for Highway Bases and Subbases; Federal Highway Administration: Washington, DC, USA, 1983.

- Siddique, R. Cement Kiln Dust. In Waste Materials and By-Products in Concrete; Springer: Berlin/Heidelberg, Germany, 2008; pp. 351–380. [Google Scholar]

- Modarres, A.; Ramyar, H.; Ayar, P. Effect of CKD on the low-temperature durability and fatigue life of hot mix asphalt. Cold Reg. Sci. Technol. 2015, 110, 59–66. [Google Scholar] [CrossRef]

- Lanzerstorfer, C.; Feichtinger, K. CKD: Characterization of dust collected in various fields of electrostatic precipitators. Environ. Eng. Sci. 2016, 33, 200–206. [Google Scholar] [CrossRef]

- Al-Hdabi, A.; Al-Jumaili, M.; Abdulzahra, H. Incorporating of CKD in binder course cold asphalt emulsion mixtures. Pollack Period. 2021, 16, 25–31. [Google Scholar] [CrossRef]

- Adaska, W.S.; Taubert, D.H. Beneficial uses of CKD. In Proceedings of the 2008 IEEE Cement Industry Technical Conference Record, Miami, FL, USA, 18–22 May 2008; pp. 210–228. [Google Scholar]

- Kramer, G.W.; Haynes, B.W. Anion Characterization of Florida Phosphate Rock Mining Materials and US CKD by Ion Chromatography; US Department of the Interior, Bureau of Mines: Washington, DC, USA, 1982.

- Ahmed, H.Y.; Othman, A.M.; Mahmoud, A.A. Effect of using waste cement dust as a mineral filler on the mechanical properties of hot mix asphalt. Ass. Univ. Bull. Environ. Res. 2006, 9, 51–60. [Google Scholar]

- Kraszewski, L.; Emery, J. Use of CKD as a filler in asphalt mixes. In Proceedings of the ORF/CANMET Symposium on Mineral Fillers, Toronto, ON, Canada, 20–21 October 1981; pp. 274–283. [Google Scholar]

- Siddique, R. Utilization of CKD (CKD) in cement mortar and concrete—An overview. Resour. Conserv. Recycl. 2006, 48, 315–338. [Google Scholar] [CrossRef]

- Dulaimi, A.; Al-Busaltan, S.; Kadhim, M.A.; Al-Khafaji, R.; Sadique, M.; Al Nageim, H.; Ibrahem, R.K.; Awrejcewicz, J.; Pawłowski, W.; Mahdi, J.M. A sustainable cold mix asphalt mixture comprising paper sludge ash and CKD. Sustainability 2022, 14, 10253. [Google Scholar] [CrossRef]

- Chaunsali, P.; Peethamparan, S. Influence of the composition of CKD on its interaction with fly ash and slag. Cem. Concr. Res. 2013, 54, 106–113. [Google Scholar] [CrossRef]

- Shoaib, M.; Balaha, M.; Abdel-Rahman, A. Influence of CKD substitution on the mechanical properties of concrete. Cem. Concr. Res. 2000, 30, 371–377. [Google Scholar] [CrossRef]

- Apaza, F.R.A.; Guimarães, A.C.R.; Vivoni, A.M.; Schroder, R. Evaluation of the performance of iron ore waste as potential recycled aggregate for micro-surfacing type cold asphalt mixtures. Constr. Build. Mater. 2021, 266, 121020. [Google Scholar] [CrossRef]

- Abdel-Wahed, T.; Dulaimi, A.; Shanbara, H.K.; Al Nageim, H. The impact of CKD and cement on cold mix asphalt characteristics at different climate. Sustainability 2022, 14, 4173. [Google Scholar] [CrossRef]

- Al-Busaltan, S.; Al Nageim, H.; Atherton, W.; Sharples, G. Mechanical Properties of an Upgrading Cold-Mix Asphalt Using Waste Materials. J. Mater. Civ. Eng. 2012, 24, 1484–1491. [Google Scholar] [CrossRef]

- SCRB State Commission of Roads and Bridges. General Specification for Roads and Bridges; Republic of Iraq, Ministry of Housing and Construction, Department of Planning and Studies: Baghdad, Iraq, 2003.

- ASTM C127-15; Standard Test Method for Relative Density (Specific Gravity) and Absorption of Coarse Aggregate. ASTM International: West Conshohocken, PA, USA, 2015.

- ASTM C128-15; Standard Test Method for Relative Density (Specific Gravity) and Absorption of Fine Aggregate. ASTM International: West Conshohocken, PA, USA, 2015.

- ASTM C131-14; Standard Test Method for Resistance to Degradation of Small-Size Coarse Aggregate by Abrasion and Impact in the Los Angeles Machin. ASTM International: West Conshohocken, PA, USA, 2014.

- ASTM C114-15; Standard Test Methods for Chemical Analysis of Hydraulic Cement. ASTM International: West Conshohocken, PA, USA, 2015.

- ASTM C142-17; Standard Test Method for Clay Lumps and Friable Particles in Aggregates. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM D5-13; Standard Test Method for Penetration of Bituminous Materials. ASTM International: West Conshohocken, PA, USA, 2013.

- ASTM D113-17; Standard Test Method for Ductility of Bituminous Materials. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM D92-20; Standard Test Method for Flash and Fire Points by Cleveland Open Cup Tester. ASTM International: West Conshohocken, PA, USA, 2020.

- ASTM D36-21; Standard Test Method for Softening Point of Bitumen (Ring-and-Ball Apparatus). ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM D70-20; Standard Test Method for Density of Semi-Solid Bituminous Materials (Pycnometer Method). ASTM International: West Conshohocken, PA, USA, 2020.

- ASTM D4057-22; Standard Practice for Manual Sampling of Petroleum and Petroleum Products. ASTM International: West Conshohocken, PA, USA, 2022.

- ASTM D2007-18; Standard Test Method for Flakiness Index of Coarse Aggregate. ASTM International: West Conshohocken, PA, USA, 2018.

- Ebels, L.-J. Characterisation of Material Properties and Behaviour of Cold Bituminous Mixtures for Road Pavements; Stellenbosch University: Stellenbosch, South Africa, 2008. [Google Scholar]

- Dulaimi, A.; Shanbara, H.K.; Jafer, H.; Sadique, M. An evaluation of the performance of hot mix asphalt containing calcium carbide residue as a filler. Constr. Build. Mater. 2020, 261, 119918. [Google Scholar] [CrossRef]

- Shishehboran, M.; Ziari, H.; Korayem, A.H.; Hajiloo, M. Environmental and mechanical impacts of waste incinerated acidic sludge ash as filler in hot mix asphalt. Case Stud. Constr. Mater. 2021, 14, e00504. [Google Scholar] [CrossRef]

- AASHTO T245-15; Standard Method of Test for Determining the Resistance to Plastic Flow of Asphalt Mixtures Using Marshall Apparatus. AASHTO Provisional Standards: Washington, DC, USA, 2015.

- ASTM D6931-17; Standard Test Method for Indirect Tensile (IDT) Strength of Bituminous Mixtures. ASTM International: West Conshohocken, PA, USA, 2018.

- ASTM D4867-14; Standard Test Method for Effect of Moisture on Asphalt Concrete Mixtures. ASTM International: West Conshohocken, PA, USA, 2014.

- Pasandín, A.R.; Pérez, I.; Ramírez, A.; Cano, M.M. Moisture damage resistance of hot-mix asphalt made with paper industry wastes as filler. J. Clean. Prod. 2016, 112, 853–862. [Google Scholar] [CrossRef]

- Mohammed, A.; Aliyu, I.; Sulaiman, T.; Yunusa, I. Mechanical Properties of Asphalt Concrete with Crumb Rubber as Partial Replacement for Coarse Aggregate. Niger. J. Eng. 2021, 28, 75–79. [Google Scholar]

- Sengoz, B.; Agar, E. Effect of asphalt film thickness on the moisture sensitivity characteristics of hot-mix asphalt. Build. Environ. 2007, 42, 3621–3628. [Google Scholar] [CrossRef]

- Masri, K.; Awang, H.; Jaya, R.P.; Ali, M.; Ramli, N.; Arshad, A. Moisture susceptibility of porous asphalt mixture with Nano silica modified asphalt binder. IOP Conf. Ser. Earth Environ. Sci. 2019, 244, 012028. [Google Scholar] [CrossRef]

- Zaniewski, J.; Viswanathan, A.G. Investigation of Moisture Sensitivity of Hot Mix Asphalt Concrete. Ph.D. Thesis, Asphalt Technology Program, Morgantown, WV, USA, 2006. [Google Scholar]

- Solaimanian, M.; Harvey, J.; Tahmoressi, M.; Tandon, V. Test methods to predict moisture sensitivity of hot-mix asphalt pavements. In Proceedings of the Transportation Research Board National Seminar, San Diego, CA, USA, 4–6 February 2003; pp. 77–110. [Google Scholar]

- Almaali, Y.A. Enhancing the Indirect Tensile Strength of Thin Hot Mix Asphalt Overlay by Utilizing Waste Materials. Libr. Prog.-Libr. Sci. Inf. Technol. Comput. 2024, 44, 239. [Google Scholar]

- Preciado, J.; Arguelles, G.M.; Dugarte, M.; Bonicelli, A.; Cantero, J.; Vega, D.; Barros, Y. Improving mechanical properties of hot mix asphalt using fibres and polymers in developing countries. IOP Conf. Ser. Mater. Sci. Eng. 2017, 245, 022013. [Google Scholar] [CrossRef]

- Islam, M.R.; Hossain, M.I.; Tarefder, R.A. A study of asphalt aging using Indirect Tensile Strength test. Constr. Build. Mater. 2015, 95, 218–223. [Google Scholar] [CrossRef]

- Navarro, F.M.; Gámez, M.C.R. Influence of crumb rubber on the indirect tensile strength and stiffness modulus of hot bituminous mixes. J. Mater. Civ. Eng. 2012, 24, 715–724. [Google Scholar] [CrossRef]

- The State Corporation for Roads and Bridges. Standard Specifications for Roads and Bridges, Section R/9, Hot-Mix Asphaltic Concrete Pavement; The State Corporation for Roads and Bridges, Ministry of Housing and Construction: Baghdad, Iraq, 2003.

- Choudhary, J.; Kumar, B.; Gupta, A. Utilization of solid waste materials as alternative fillers in asphalt mixes: A review. Constr. Build. Mater. 2020, 234, 117271. [Google Scholar] [CrossRef]

- Choudhary, J.; Kumar, B.; Gupta, A. Effect of filler on the bitumen-aggregate adhesion in asphalt mix. Int. J. Pavement Eng. 2018, 21, 1482–1490. [Google Scholar] [CrossRef]

- Xu, P.; Chen, Z.; Cai, J.; Pei, J.; Gao, J.; Zhang, J.; Zhang, J. The effect of retreated coal wastes as filler on the performance of asphalt mastics and mixtures. Constr. Build. Mater. 2019, 203, 9–17. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).