Abstract

Fused Deposition Modeling (FDM) has evolved from a rapid prototyping technique to an established manufacturing process for various industrial applications, including aerospace, robotics, biomedical engineering, and food production. Despite its versatility, the surface quality and dimensional accuracy of FDM-printed parts remain significant challenges, limiting their applicability in high-performance and precision-driven industries. Some of the primary limitations of FDM are volumetric error, shape deviation, and surface roughness, which directly affect the mechanical properties and functional performance of printed components. Post-processing techniques are available to mitigate these problems. Among the available post-processing techniques, CNC machining has emerged as a viable solution for improving the surface finish and dimensional precision of FDM parts. The integration of subtractive CNC machining with additive FDM printing enables the development of hybrid manufacturing strategies, leveraging the design freedom of 3D printing while ensuring superior surface quality. This paper presents a comprehensive review of recent studies on CNC post-processing of FDM-printed parts, analyzing its impact on surface roughness, dimensional accuracy, and material properties. Additionally, key process parameters influencing the effectiveness of CNC machining are discussed.

1. Introduction

Additive manufacturing (AM) has recently gained a key role in production engineering as it keeps the promise of overcoming the design constraints of traditional manufacturing processes (e.g., CNC milling and turning), enabling the creation of intricately shaped parts at a cost-effective rate and, at once, diminishing scrap production [1,2].

Producing an object through additive manufacturing is a multi-step process, starting from a three-dimensional (3D) virtual model of the part geometry. Generated in a Computer-Aided Design (CAD) environment or using a Reverse Engineering approach, the 3D model is then divided into 2D triangular sections, and the related information is written on an International Standard for the Exchange of Product (STEP) model data or an informal Standard Tessellation Language (STL) format [2]. Subsequently, this data is transferred into a Computer-Aided Manufacturing (CAM) environment to set the process parameters (e.g., part orientation, support generation, and infill density) and slice the model into finite thickness layers to generate the optimum tool path. Based on this process data, a 3D object is created by selectively layering a blended material. Thus, additive manufacturing only requires the knowledge of the part geometry but not its detailed analysis to identify the needed fixtures and the machining sequence, which makes AM the primary choice when dealing with frequent design changes, high design complexity, and low production volumes [2,3,4].

In the past decade, several AM techniques have been developed, including Stereo-Lithography (SLA), Direct Metal Deposition (DMD), Selective Laser Sintering (SLS), Ink Jet Modeling (IJM), and Fused Deposition Modeling (FDM). The proposed techniques differ in both the employed material (e.g., liquid resins, plastic filaments, and metal powders) and the methodology used to layer it (e.g., fusion, binding, and powders or resin solidification), which influence the product surface quality and dimensional accuracy, and building speed [5,6].

Fused Deposition Modeling (FDM), also named Fused Filament Fabrication (FFF), is among the most widely adopted Additive Manufacturing techniques due to its simplicity and cost-effectiveness. Fused Deposition Modeling relies upon a layer-by-layer printing process that makes the bonding between adjacent layers (namely, the interlayer bonding) inherently weaker than the bonding within the material itself (i.e., intralayer bonding). Since the resulting material anisotropy and the poor mechanical properties may significantly question the application of 3D-printed components in load-bearing applications, several studies focused on determining their constitutive equations [7,8,9]. Meanwhile, numerous parametric studies aimed at characterizing their mechanical performance (e.g., tensile and flexural strength, Young’s modulus and ultimate elongation) showing that they highly depend on the selected printing parameters, such as building orientation, raster angle, infill density, feed rate, layer thickness, and nozzle temperature [10,11,12,13,14,15,16,17]. Therefore, a proper selection of these parameters may help to produce parts and components with the desired mechanical properties, even if some inherent limitations cannot be completely overcome.

Besides the mechanical properties, pre-processing (e.g., slicing and path-planning) and printing variables also affect the dimensional accuracy of FDM parts [18,19,20,21,22] and the surface quality [17,22,23]. In this perspective, the staircase pattern characterizing the surface of 3D-printed parts represents an inherent issue that, induced by the layer-by-layer printing process, significantly affects its surface roughness and, thus, its functionality. On the other hand, volumetric error and shape deviation mainly govern the form of an FDM-printed component and its ability to pair with other functional parts in complex structures and bear service loads.

Therefore, although enabling intricate designs, FDM typically results in poor surface finishing and low dimensional accuracy, preventing its adoption from industrial-scale manufacturing. As an attempt to address these shortcomings, different post-printing solutions have been applied, including post-printing heat treatments [24,25], hot cutter machining [26], acetone vapor bath [27,28,29], laser and CNC milling. Among them, CNC machining is a well-established manufacturing process ensuring incredibly low surface roughness, whose evolution may be accurately predicted based on the selected process parameters (especially feed rate, cutting speed, and tool geometry), tight dimensional tolerances, and high repeatability [30]. Moreover, CNC machining enables the development of novel hybrid strategies combining the AM ability to produce complex shaped geometries with the improved surface quality and dimensional accuracy ensured by the existing CNC machines [31]. From this perspective, this review attempts to bridge the knowledge gap between additive manufacturing and post-processing strategies to increase the surface quality and dimensional accuracy of FDM-printed parts, with a specific focus on CNC machining. Despite the widespread use of FDM in rapid prototyping and end-use applications, the poor surface finish and geometric deviations of printed components keep on limiting their adoption in industrial applications where tight dimensional tolerance have to be fulfilled. By consolidating the current research on machining strategies, tool wear, cooling methods, and hybrid manufacturing systems, this review provides a foundational understanding for researchers and practitioners seeking to enhance the functional performance of FDM parts using CNC machining.

2. Fused Deposition Modeling Process

Proposed and patented to S.S. Crump, establisher of Stratasys Ltd. (Eden Prairie, MN, USA) in 1992 [32], Fused Deposition Modeling (FDM) is an extrusion-based additive manufacturing process in which a semi-molten thermoplastic filament is deposed layer-by-layer to create a 3D part.

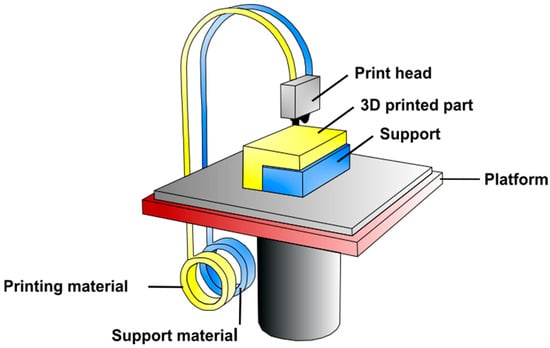

The raw thermoplastic filament, whose diameter generally varies in the range of 1.75–2.85 mm, is unwound from a spool and fed into the printer head using a gear-driven or pinch-roller feed mechanism. The printer head generally combines diverse components (Figure 1): a motor to provide the power to move and heat the filament, and an aluminum heater block combined with a temperature sensor (e.g., a thermistor), a hot reservoir, and a nozzle for material extrusion and deposition. This complex system, generally referred to as extruder, also encompasses an integrated cooling system to ensure thermal stability and, at once, prevent the filament from breakage. Thus, the thermoplastic filament is first heated up to its melting temperature (typically ranging from 180 °C to 500 °C) and then extruded onto the build platform (also named print bed) to which it adheres and starts cooling down, bonding to adjacent and underlying layers to form a three-dimensional object.

Figure 1.

Fused Deposition Modeling (FDM): process scheme (adapted from [33]).

The build platform consists of a thick plate of rigid material (e.g., borosilicate glass or aluminum) that serves as the substrate for material deposition. In order to increase the overall quality of the FDM-printed parts, printing beds are generally heated. In fact, reducing the thermal gradient between the extruded material and the printing bed lowers the occurrence of inherent issues, especially delamination and warping. Warping is a typical FDM issue that arises from a combination of thermal shrinkage and thermal gradient, which induce residual stresses that accumulate during cooling and eventually lead to part deformation and corner detachment or peel [34].

The extrusion and deposition sequence are controlled by a G-code file, which contains the selected process parameters, and the optimum tool path associated with the designed model. In this perspective, the key process parameters were proven to be the layer thickness (i.e., the printing vertical resolution), the extrusion temperature governing the melt flow and inter-layer adhesion, the nozzle geometry that controls the shape and the size of the extruded filament, the nozzle velocity that affects filament deposition (thus, dimensional accuracy), and the infill pattern and raster angles, which play a major role in determining the printed material meso-structure, anisotropy, and mechanical properties [16,17,35,36].

Although FDM offers numerous advantages, particularly, low material waste, cost efficiency, complex geometries, and frequent design changes, it also presents certain limitations described in the next paragraph.

3. Limitations of Fused Deposition Modeling in Industrial Applications

Fused Deposition Modeling (FDM) has expanded beyond its initial use in rapid prototyping and is now employed to manufacture production-grade parts in diverse industrial applications, including the production of tooling components, robotics and aerospace [37,38], food production [39], medicine, and biomedical engineering [40,41]. Nonetheless, the poor surface quality and the low dimensional accuracy of the FDM-printed parts may significantly impact the product characteristics (i.e., form, dimensional tolerances, and functionality) and, thus, represent one of the major limitations of the FDM process [42]. Therefore, this section presents a review of studies addressing these issues: volumetric error (VE), shape deviation and finishing tolerances, and surface roughness.

3.1. Volumetric Error (VE)

In additive manufacturing, objects are fabricated by approximating a given design through layers stacked one on the other along the printing direction. During the pre-processing stage, the design 3D solid model is converted into unordered triangular surfaces (i.e., tessellation). Thus, the accuracy of its representation depends on the selected tolerances, generally expressed as the maximum distance between the CAD surface and the vector representing one of the triangle sides (i.e., chordal error, Figure 2). As a rule of thumb, increasing the tessellation density, i.e., the number of triangles used to discretize the original surface, results in higher computational costs and, at once, lower chordal error. Nonetheless, even at high tessellation densities, chordal error cannot be completely avoided, which leads to discrepancies between the design volume and the volume of the printed object. In order to evaluate and minimize the volumetric error and the corresponding surface approximation, several studies focused on this issue. For instance, Masood et al. introduced an approach to calculate the volumetric error in simple geometries (e.g., cubes, cylinders, spheres) [43], which was subsequently extended to more complex shapes [44]. Later on, Navangul and coworkers developed the Vertex Translation Algorithm, an iterative approach that translates the vertices of the discretizing triangles with maximum chordal error to their corresponding design points, thereby generating new facets [45]. Similarly, Zha and Anand proposed the Surface-based Modification Algorithm that selectively and adaptively modifies the tessellated surface to enhance dimensional accuracy [46].

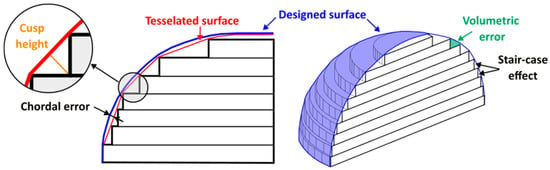

Figure 2.

Dimensional issues of the Fused Deposition Modeling (FDM) process: stair-case affect, cusp height, chordal error, and volumetric error.

Alongside volumetric error, cusp height is an inherent artifact arising from the layer-by-layer printing process, defined as the maximum deviation between the CAD geometry and the FDM-printed surface. Studies [47,48] showed that cusp height, which depends on build orientation and layer thickness, significantly contribute to the volumetric error in fabricated parts.

3.2. Stair-Case Effect, Shape Deviation, and Dimensional Tolerances

In the FDM printing process, slicing is the most critical step as it generates both the printing contour and the associated tool path. The defined contour is then extruded layer-by-layer to build the part. However, since the layer generation relies upon a vertical extrusion process, the outer boundaries of the printed surface inevitably deviate from the original tessellated geometry. As a result, geometrical and dimensional deviations arise. Commonly known as shape deviation and stair-case effect (Figure 2), these phenomena are particularly evident when printing complex and curvilinear surfaces and lead to poor surface finish and low dimensional accuracy. Thus, achieving the desired accuracy and surface quality requires post-processing operations.

In order to control the dimensional accuracy and reduce the stair-case effect, adaptative slicing represents a viable solution in which the layer thickness is evaluated and adjusted according to the designed model surface geometry to fulfill the desired dimensional tolerance. In this perspective, adaptative slicing procedures selectively reduce the slice thickness of regions characterized by high curvature and severe sidewall slope. Thus, over uniform slicing, adaptative slicing keeps the promise of reducing built time and, to a certain extent, the stair-case effect, which directly results in increased dimensional accuracy and surface quality. Based on the parameter chosen to represent the desired dimensional tolerance, adaptative slicing procedures may be distinguished into approaches based on changes in the area of adjacent layers (i.e., the layer thickness is adjusted when the ratio of adjacent layers areas exceeds a threshold level) [49], approaches based on the curvature (i.e., the layer thickness is selectively adapted when the curvature of the designed surface becomes large) [50], and approaches relying upon the cusp height [51].

Cusp height, a concept that was first proposed by Dolenc et al. [52], is defined as the maximum distance between the layered printed surface and the designed surface due to the staircase effect (Figure 2). Because it depends on the layer thickness and the angle between the normal vector and the slice plane, cusp height provides a quantitative estimation of the dimensional accuracy of the FDM-printed part, making it one of the most effective parameters for adaptive slicing. Pandey et al. [53] published a comprehensive review of the existing slicing techniques. The amount of collected data demonstrates that adaptive slicing significantly improves the surface quality of FDM-printed parts, as well as their dimensional accuracy, which is essential to ensuring product function and overall quality. Nonetheless, when higher dimensional tolerances and surface quality are needed, these pre-processing approaches have to be combined with post-processing strategies. Among them, CNC machining keeps the promise of achieving high repeatability, incredibly low surface roughness and, at once, tight dimensional tolerances.

3.3. Surface Roughness

Volumetric error and shape deviation equally contribute to surface irregularities, which ultimately lead to high surface roughness. An extensive research effort has been devoted to evaluating the surface roughness of FDM-printed parts, revealing its significant dependence on process parameters [54]. For example, Barrios and Romero performed an orthogonal experiment design to identify the printing parameters with the highest influence on surface roughness and, thus, assessed the primary role of flow rate and print acceleration [55]. Similarly, Kadhum et al. focused on the effect of the infill pattern, showing that the optimal infill pattern varies for different polymers [17]. In particular, the quarter cubic pattern was found to minimize the surface roughness of PETG parts, while cross and concentric patterns were the optimum infill pattern when considering PLA and PLA+, respectively. In [22], Vidakis et al. present a more comprehensive analysis, where the authors combined a variance analysis (ANOVA) with a reduced-quadratic regression model to investigate the influence of six key printing parameters (namely, layer thickness, infill density, bed temperature, raster deposition angle, printing speed, and nozzle temperature) on porosity, dimensional accuracy, and surface quality of FDM-printed parts.

Among the printing parameters, layer thickness and build orientation were found to play a major role in influencing surface roughness. From this perspective, Kattethota and Henderson developed a theoretical approach correlating the inclination angle of a surface with the build direction [56]. The obtained results demonstrate that increasing layer thickness leads to higher surface roughness. Similarly, shallow angles between the printed surface and the build direction correspond to lower surface quality.

Relatively few studies focused on modeling the surface roughness in FDM processes. A first attempt was made by Reeves et al. who proposed and validated an analytical model to describe the surface roughness of layer-manufactured parts by accounting for several process parameters (namely, surface angle, layer thickness, and layer profile) [57]. Similarly, Pandey et al. developed a semi-empirical model to predict the surface roughness of FDM-printed components [26]. By approximating the layer edge profile as a parabolic curve, this model manages to assess the surface roughness with an extremely high confidence level. More recently, Ahn at al. proposed an equation to describe the continuous roughness distribution by calculating the surface roughness for all surface angles. Their innovative approach integrates actual surface roughness measurements with interpolation data, offering comprehensive predictive capabilities [58].

4. CNC Machining

Post-processing strategies are aimed at increasing the surface quality and dimensional accuracy of FDM-printed parts. These improvements are particularly relevant given the inherent limitations of the FDM process—such as the previously mentioned volumetric errors, shape deviations, and surface roughness—which CNC machining can effectively mitigate. However, most of the available literature on CNC machining of FDM parts focuses primarily on milling operations and surface quality enhancement, especially the reduction in surface roughness. However, compared to conventional thermoplastic machining, the post-processing of FDM-printed parts through CNC machining introduces unique challenges, mainly due to the weak interlayer bonding, the inherent anisotropy, and porosity of additively manufactured parts [59]. Unlike injection-molded or extruded thermoplastics, FDM-printed parts exhibit directional mechanical properties, residual stresses, and surface irregularities caused by stair-stepping effects [60]. These characteristics make FDM-printed parts highly susceptible to delamination, dimensional inaccuracies, and unpredictable machining behavior. Consequently, CNC machining of FDM components requires an adaptive approach in which the process parameters (encompassing cutting speed, feed rate, depth of cut, and tool selection) must be optimized to prevent excessive heat buildup, material tearing, or interlayer delamination [61] (Figure 3).

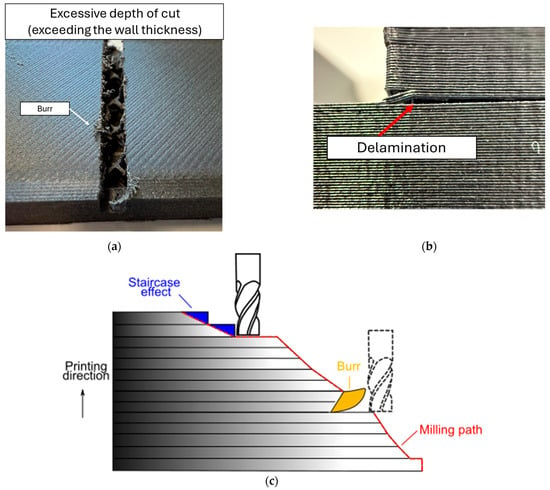

Figure 3.

Typical defects after CNC machining of FDM parts: (a) excessive depth of cut can reveal the infill pattern below [source: authors experimentation]; (b) delamination of layers [source: authors experimentation]; (c) schematic representation of the milling process of FDM parts (adapted from [61]).

According to Del Sol et al. [62] down milling generally provided a better surface finishing (i.e., lower ) than up milling, as the tool’s cutting action pushed down on the filaments, reducing delamination. It also showed greater consistency in smoothing FDM surface grooves. Up milling occasionally yielded lower values, but this was only significant for smaller layer heights (0.15 mm); at larger heights (0.25 mm), results were more variable probably due to filament deposition defects.

Spindle speed, which is directly linked to cut speed, must be carefully calibrated to balance heat generation and cutting efficiency. Excessive speeds can induce thermal softening in thermoplastics [63] (e.g., PLA and ABS), leading to deformation. On the other hand, insufficient speeds may accelerate tool wear and, at once, increase cutting forces.

Similarly, selecting the proper feed rate represents a trade-off between productivity and surface quality. In fact, higher feed rates reduce cycle times but risk greater surface roughness due to the uneven material removal, which becomes particularly problematic when machining FDM parts with inappropriate layer adhesion. Conversely, lower feed rates correspond to superior surface finishes but increase machining time and promote localize heat accumulation, which poses challenges for low-melting-temperature polymers. Depth of cut () introduces additional issues to this balance, as aggressive cutting depths risk delaminating weakly bonded FDM layers, especially those with low infill densities or not proper build orientations. Therefore, shallow, multi-pass strategies are generally preferred to address this shortcoming and, at once, mitigate stress concentrations, even if they demand precise toolpath planning to maintain machining efficiency [64].

FDM printing parameters directly influence the effectiveness of CNC milling in improving surface quality and machinability. For example, the build orientation highly affects both the as-printed and the post-machined surface roughness [65]. When maintaining constant CNC parameters, the lowest roughness is achieved with horizontally printed parts (0°), while vertically printed samples (90°), even if improved, still exhibit high residual roughness compared to horizontal orientations.

Layer thickness also influences the CNC post-processing requirements in hybrid manufacturing. In fact, with increasing layer thickness (e.g., over 0.3 mm), the number and the severity of the induced surface irregularities increase. As a result, deeper CNC cuts have to be used, even if tool wear and compromised final surface finishes may arise. Conversely, thinner layers (e.g., 0.1 mm) produce smoother surfaces and, thus, require minimal material removal during machining. Tomal et al. [66] demonstrated that combining FDM with abrasive milling on a single platform significantly improved dimensional accuracy (by 71–99%) and surface finish (by up to 91.3% roughness reduction). Their study confirmed that printing layer thickness significantly affected the final roughness, with roughness values decreasing proportionally to layer thickness reduction.

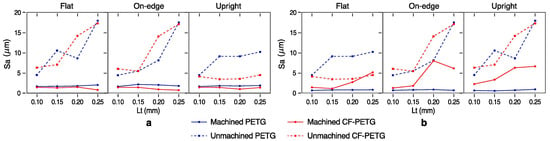

Figure 4 shows the effect of layer thickness () on surface roughness () for both machined and unmachined PETG and CF-PETG specimens, analyzed across three build orientations: flat, on-edge, and upright. According to Vallejo et al. machined specimens (solid lines) show consistently lower values across all values and build orientations, demonstrating the effectiveness of the machining process in improving surface texture. However, for samples with higher (especially 0.20–0.25 mm), peripheral milling operations led to an increase in roughness, particularly in CF-reinforced PETG.

Figure 4.

Surface roughness (Sa) as a function of layer thickness (Lt) for PETG and CF-PETG specimens in three build orientations: flat, on-edge, and upright. (a) Comparison of machined and unmachined PETG; (b) comparison of machined and unmachined CF-PETG [67].

Another critical factor influencing CNC performance is infill density and structure [17]. Low infill percentages (typically <50%) create internal voids, making the part more prone to vibrating and undergoing deformation under machining forces, which may lead to dimensional inaccuracies. In contrast, high infill densities provide a solid base that allows for finer finishing passes and reduced chatter during cutting, which results in enhanced machining stability and surface quality.

Moreover, the nozzle temperature during printing process affects material bonding strength, which in turn, impacts CNC machinability. Mani et al. [68] assessed the effect of the nozzle temperature on PLA FDM-printed parts, highlighting that lower nozzle temperatures (180–200 °C) produce weaker interlayer adhesion, increasing the risk of delamination and chipping during machining, whereas higher temperatures (210–220 °C) enhance superior bonding, resulting in a more uniform and stable material structure that facilitates CNC milling.

Hybrid manufacturing systems offer several key benefits by combining FDM with CNC machining on the same platform. Accordingly to Lee et al. [69], this approach combines the design flexibility of additive manufacturing with the dimensional accuracy and surface finish of subtractive processes, effectively overcoming traditional FDM. The development of their five-axis machine allows support-free fabrication of overhang features, reducing material waste and minimizing post-processing efforts. Additionally, the hybrid system’s capabilities extend to functional material integration, such as embedding different materials (e.g., aluminum reinforcements) within the polymer matrix to improve structural stiffness and thermal stability. In this regard, according to the authors, combining the use of thicker layers with the precision and accuracy of conventional CNC finishing allows for an optimal balance between production efficiency and the desired surface quality, resulting in a reduced total production time compared to using FDM alone with very thin layers.

4.1. Cutting Speed (Vt)

Among the critical machining parameters, cutting speed directly affects material removal rate, thermal effects, and surface quality. Conventionally expressed in meters per minute (m/min) or millimeters per minute (mm/min), cutting speed is defined as the linear velocity at which the tool cutting edge moves relative to the workpiece surface during machining. However, most of the revised papers do not refer to cutting speed but only to the rotational speed (normally measured in rpm). Cutting speed can be expressed as a function of the rotational speed according to Equation (1):

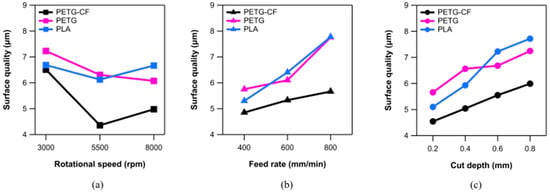

where D indicates the cutting tool diameter (in mm). When machining homogeneous thermoplastics, higher spindle speeds generally result in improved surface quality, finer chips, and reduced tool marks. However, due to their layered structure, anisotropy, and inherent porosity, FDM-printed materials exhibit a significantly different response. In fact, excessive speeds may induce localized heating, causing interlayer weakening, delamination, and geometric distortion. In this perspective, the published studies provide somewhat conflicting indications on the optimal cutting speed. As an example, Ferreira et al. [70] found that, when dry milling of FDM-printed polyamide 12 (PA12) parts, the minimum surface roughness parts was achieved at intermediate cutting speeds (i.e., 100–300 m/min). However, El Mehtedi et al. [59] investigated the effect of the cutting speed on several polymers and reported different results: approximately 5500 rpm (mid-range of 3000–8000 rpm using a 6 mm tool) produced the best results for PLA and CF-PETG when using lubricant, while PETG required higher speeds (8000 rpm) for optimal machining. On the other hand, Guo et al. [71] did not find a great change in roughness in the studied range of cutting speed for PEEK and CF-PEEK. Moreover, at high cutting speeds, friction and heat generation increase, inducing specific surface features, such as local defects, voids, and uneven surfaces, when considering CF/PEEK composites. In fact, the inclusion of fiber reinforcement results in increased material brittleness and, at once, promotes the formation of voids and cavities. These two effects degrade the surface quality, especially when machining parameters deviated from their optimal values.

4.2. Feed Rate (Vf)

Defined as the linear velocity at which the cutting tool advances through the material, the feed rate determines the material removal rate and, thus, significantly influences machining efficiency. A well-optimized feed rate ensures dimensional accuracy and, at once, may prevent the onset of machining-induced surface defects.

Pămărac and Petruse [72] analyzed the face and contour milling of ABS and PLA components at different combinations of feed rates and tool geometries. Their study revealed that for PLA-printed parts, surface roughness improves at higher feed rates, whereas for ABS-printed parts, the lowest roughness is achieved at lower feed rates when using pressurized air for cooling. Conversely, El Mehtedi et al. [59] found that a lower feed rate improves surface roughness in 3D-printed PLA when using mineral oil-in-water emulsion as a cutting fluid. Similar results were observed for PETG and CF-PETG samples.

Ferreira et al. [70] investigated the effect of several machining parameters on the surface roughness of machined PA12 and CF-PA12. By performing an ANOVA analysis, the authors pointed out that feed rate () plays a primary role in determining the FDM-printed part surface quality. In particular, lower feed rates (0.01 mm/tooth) resulted in the lowest roughness, whereas higher feed rates (0.07 mm/tooth) reduced machining time but led to increased roughness and higher cutting forces. Given these results, the optimal feed rates depend on the material and lubrication conditions.

Moreover, when machining thermoplastic materials, exceeding the glass transition temperature can significantly impact surface quality, dimensional accuracy, and tool life. In fact, if the temperature increases beyond this threshold level, the polymer stiffness reduces and deformation arises, resulting in smearing, which deteriorates the surface finish. For example, PLA, whose glass transition temperature is relatively low (~60 °C), is highly susceptible to softening and melting, which leads the cutting tool to bond to the work piece surface and thus, to worsen its roughness.

In addition to surface quality issues, machining at temperatures above the glass transition temperature may induce dimensional inaccuracy. In fact, as its temperature increases, the workpiece undergoes deformation and thermal distortion with a consequent loss of tolerances and warpage. Similarly, due to excessive heat, smearing may occur causing polymers to soften and adhere to the tool or the machined surface rather than forming clean chips. Due to their low thermal conductivity, thermoplastics easily reach their glass transition temperature, leading to surface degradation and reduced dimensional accuracy. Furthermore, excessive heat can lead to built-up edge (BUE) formation, where softened material sticks to the tool, reducing cutting efficiency, accelerating tool wear, and clogging the tool flutes, which increases friction and cutting forces. To prevent these issues, proper machining strategies must be applied. First, cooling methods help remove chips and increase heat dissipation, maintaining the temperature below the glass transition temperature. Second, optimizing cutting parameters is essential for reducing roughness. If no lubrication is available, higher feed rates may help to minimize heat accumulation and, thus, improve the surface roughness. Finally, tool selection and coatings play a vital role in controlling heat generation; for example, sharp carbide tools reduce frictional heating.

4.3. Depth of Cut ()

Depth of cut is a crucial factor influencing material removal rate, cutting forces, and stress distribution. Unlike solid thermoplastics, as already mentioned, FDM-printed materials contain structural defects, voids, and interlayer adhesion inconsistencies, which makes them highly susceptible to delamination and geometric warping, especially when at high depths of cut. In this perspective, for low-infill pattern, depth of cut should be set lower than the wall thickness, although low depth of cut may be insufficient to eliminate the staircase effects. Therefore, the cutting depth must be selected within a narrow range so as to ensuring effective removal of surface imperfections without exposing internal defects [42]. In fact, it should be higher than the initial total roughness to remove the original surface morphology generated by the 3D printing process. On the other hand, it must not exceed the upper limit determined by underlying voids and internal defects within the material (Figure 3c).

El Mehtedi et al. [59] performed an experimental campaign to assess the effect depth of cut on the surface roughness (Figure 5) and burr formations of different materials (PLA, PET, and CF-PETG). Using different depths of cut for roughing and finishing passes to achieve improved surface quality, the authors found that that a relatively low depth of cut (0.2 mm) reduces surface roughness, while a higher depth of cut tends to minimize burr formation. However, too small depth of cut generally fails to remove the staircase effect [42], while an excessively large depth of cut increases cutting forces, potentially reducing surface quality due to the relatively low stiffness of polymers. Similarly, Guo et al. [71] found that for unreinforced PEEK samples, the optimal depth of cut () was 0.1 mm, beyond which roughness increased. In contrast, for CF-PEEK, they identified an optimal ap of approximately 0.2 mm, with surface roughness increasing at both lower and higher depths of cut. For the PA12 polymer [70], the lowest roughness was found at the lowest level of the studied range (0.6 to 1.0 mm).

Figure 5.

Main effects plot of surface roughness (Sa) as a function of (a) rotational speed, (b) feed rate, and (c) depth of cut [59].

4.4. Tool Geometry and Tool Wear

Tool geometry and material selection are critical for managing cutting forces, minimizing tool wear, and optimizing surface finish. The inherent presence of microstructural inconsistencies within the FDM-printed parts influences the formation of chip formation, as well as the tool engagement. However, since most of the existing literature provides either incomplete or not explicit indications on the geometries of the employed tool, establishing standardized recommendations is cumbersome. Nonetheless, a few key considerations can be drawn.

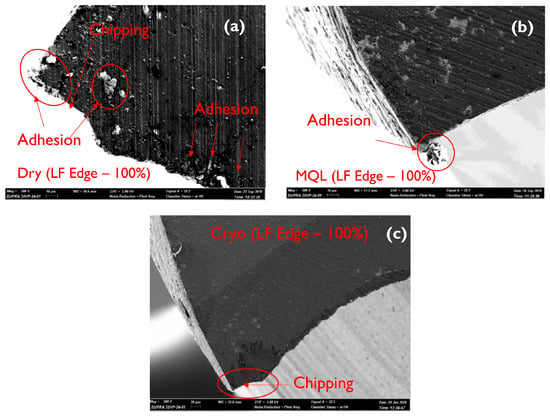

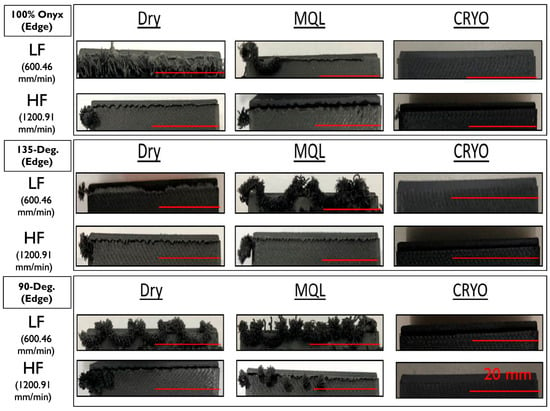

When machining FDM-printed parts, tool wear occurs, although its progression and severity depend on material properties, cutting conditions, and cooling strategies (Figure 6). Cococetta et al. [73,74] assessed the effects of machining process parameters and cooling/lubricating conditions on the cutting forces and tool wear occurring in milling of 3D printed thermoplastic CFRP composites, highlighting the primary role of abrasion, adhesion, and chipping. Abrasive wear was shown to occur along the cutting edges due to constant friction between the tool and the work piece material. In particular, the authors found that flank wear was prevalent in dry machining of CFRPs, as the abrasive carbon fibers eroded the tool coating, exposing the tungsten carbide base. However, the presence of carbon fiber generally reduces both the energy consumption of the process and the cutting forces during machining operations [67]. This may be due to the self-lubricating effect of carbon fibers [75].

Figure 6.

Tool wear during edge milling of nylon with chopped carbon fiber at low feed rate under different cooling conditions: (a) dry, (b) MQL, and (c) cryogenic [74].

Adhesive wear results from the relative motion between two sliding surfaces (i.e., the work piece and the tool surface). In fact, due to the pressure between the two surface contacting asperities, high temperatures and plastic deformation arise, forming adhesive bonds. Therefore, material transfer occurs from the softer (i.e., the workpiece surface) to the harder surface (i.e., the tool). The relative sliding between contacting surfaces causes the breakage of these highly localized adhesive joints, resulting in material being removed from the tool. Minimum Quantity Lubrication (MQL) was shown to reduce adhesion wear, minimizing direct tool-workpiece contact and, thus, preventing excessive material buildup on the tool. Chipping arises from mechanical instability and vibrations occurring either in the CNC machine or the workpiece. Thus, high feed rates promote chipping initiation, as impact forces applied to the tool during machining operation increase. Chipping was mainly observed at the tool tip and cutting edges and reduced by cryogenic cooling. In fact, cryogenic cooling lowers tool temperatures and hardens the composite surface.

4.5. Lubrication and Cooling Strategies

Cooling and lubrication are essential for heat dissipation, chip evacuation, and tool life. However, in FDM-printed parts, excessive cooling may induce thermal contraction, the onset of delaminations between layers, and dimensional distortions. As an example, Ferreira et al. (2020) [70] observed that dry machining of unreinforced and fiber-reinforced PA12 composites promotes tool wear, highlighting the need for lubrication when machining high-performance polymers. The study revealed that cutting forces increased when face milling unreinforced PA12, which results in more severe tool wear. This evidence may be attributed to the lubricating effect of carbon fibers, which may act as solid lubricant (analogous to graphite) in machining applications and, thus, reduce cutting forces. As stated above, Cococcetta et al. [73,74] demonstrated that cryogenic machining reduced burr formation in CFRPs by 90%, significantly improving surface finish. MQL (Minimum Quantity Lubrication) improved both surface roughness and tool wear in carbon fiber composites, though it was less effective than cryogenic cooling. Hence, the existing literature indicates that cryogenic cooling is among the most effective methods for heat dissipation during machining operations, especially when milling high-performance polymers. Nonetheless, its high operational costs and technical complexity limit its widespread adoption in general machining operations. Therefore, when milling standard thermoplastics (e.g., PLA and ABS), air cooling or conventional lubricants are widely preferred, as they keep the promise of reducing operational costs and, at once, ensure adequate thermal management. It has also to be noted that although generally less effective than lubricated strategies, dry milling may still significantly improve the surface quality of an FDM-printed part, provided that milling parameters are carefully selected. Table 1 shows a summary of what has just been discussed.

Table 1.

Lubrication and cooling strategies performances for FDM parts.

Moreover, a critical consideration across all materials is to avoid exceeding their softening point, particularly the glass transition temperature. Maintaining temperature below these thresholds prevents thermal distortion and ensures optimal dimensional accuracy and surface finish.

4.6. Dimensional Accuracy and Tolerance Improvements

Beyond improving surface roughness, CNC machining also enhances dimensional accuracy, making FDM-printed parts suitable for applications requiring tight tolerances.

Amanullah et al. [76] investigated a hybrid manufacturing system integrating FDM and CNC milling in a single platform. The study demonstrated that CNC machining improved dimensional accuracy by reducing shape deviations by over 70% compared to as-printed FDM parts. The integration of IR sensors in their hybrid machine further enhanced alignment precision, effectively minimizing dimensional discrepancies that typically arise when transferring parts between separate additive and subtractive manufacturing setups.

Bruni et al. [77] further examined the role of CNC machining in improving the dimensional accuracy of FDM-printed ABS parts (Figure 7). Their research showed that milling operations nearly eliminated stair-stepping effects and reduced waviness deviations, improving the profile shape of the specimens. This confirms that CNC machining is a viable solution for achieving precision in additively manufactured components.

Figure 7.

Profile shape before (a) and after (b) machining [77].

Kamer and Uzay [78] focused on the mechanical performance of PLA parts that underwent CNC machining. Their results indicated that CNC-milled edges resulted in more consistent tensile properties outcomes, with elongation at break increasing by 13.45% and 33.55% for parts printed with 1.75 mm and 2.85 mm diameter PLA filaments, respectively. This suggests that CNC machining not only enhances surface quality but also the material mechanical properties as it removes surface irregularities.

In general, only simple geometries were studied in the literature. To enable the fabrication of complex geometries in dual-composite FDM structures, such as the CCF/PA–SCF/PA lattice [79], several machining considerations must be addressed. The heterogeneity of materials with differing stiffness and thermal expansion coefficients requires the careful selection of cutting parameters to avoid issues like delamination, chipping, or uneven surface finish. Cutting parameters must be optimized to avoid defects like delamination and uneven surfaces. The high abrasiveness of carbon fiber composites demands wear-resistant tools and advanced cooling methods. Thin-walled lattice features require low-force strategies and specialized fixturing to prevent deformation. Thermal and mechanical control is essential to maintain the part’s dimensional stability and functionality.

4.7. Burr Formation

While CNC machining improves surface quality and dimensional accuracy, it also presents challenges when it comes to burr formation. Burr formation is a significant issue, as it negatively impacts both dimensional accuracy and surface quality. Burrs are undesirable material projections that remain attached to the machined surface after cutting. Their formation is influenced by cutting speed, feed rate, tool geometry, material properties, and cooling/lubrication conditions.

El Mehtedi et al. [59,80] systematically investigated burr formation during milling of 3D-printed PLA, PETG, and CF-PETG parts using lubricant. While each material has its own characteristics in all cases, they found that optimal roughness and minimal burr height required different machining parameters. Specifically, the best surface roughness () was achieved at low feed rates and low depth of cut, whereas the lowest burr height was obtained at high feed rates combined with a high depth of cut of the studied range. This suggests a trade-off between surface roughness improvement and burr formation, requiring careful process parameter selection.

According to [73], burrs predominantly form on the down-milling side due to insufficient shearing action of the cutting tool. In dry milling conditions, while the up-milling side benefits from clean tool shearing action, the down-milling side experiences material deformation that promotes burr adhesion to the workpiece. Cryogenic machining significantly reduces burr formation, nearly eliminating it. Below its glass transition point, the polymer matrix altered its behavior from ductile to brittle, thereby reducing burr formation during milling. Minimum quantity lubrication (MQL) was observed to be more effective than dry machining (Figure 8), as it reduced the degree of burr formation, though it did not entirely eliminate it [74]. Table 2 provides a summary of all the reviewed papers on CNC machining of FDM-printed parts.

Figure 8.

Burr formation under different lubrication conditions: dry, MQL, and cryogenic [74].

Table 2.

Summary of CNC machining parameters for FDM-printed materials, highlighting the key results based on the reviewed studies.

5. Conclusions and Future Perspectives

CNC machining has demonstrated substantial potential as a post-processing strategy for enhancing the surface quality and dimensional accuracy of FDM-printed parts. Unlike in conventional metalworking, where CNC machining is the primary means of part production, in the context of FDM-printed parts (and similarly in metal additive manufacturing), CNC machining functions as a corrective process. Its role is not to create the geometry from raw stock, but rather to refine dimensional tolerances, correct surface irregularities, and ensure functional performance. This corrective function is particularly critical for ensuring the end-use viability of additively manufactured parts, especially in high-performance or precision-driven applications. However, achieving optimal outcomes requires careful tuning of process parameters to balance competing factors, such as surface roughness, dimensional tolerances, tool wear, and burr formation. The selection of cutting speed, feed rate, depth of cut, and cooling strategy must be tailored to both the printed material and its inherent microstructural characteristics, including anisotropy, porosity, and fiber reinforcement. The emergence of hybrid manufacturing systems, which synergistically combine additive and subtractive processes, presents significant opportunities for enhanced manufacturing efficiency and improved component performance. Particularly noteworthy are integrated hybrid platforms that perform both manufacturing operations in a single setup, offering distinct advantages through reduced alignment errors and increased process efficiency.

In summary, the main outcomes of this short review are as follows:

- Compared to unmachined FDM parts, CNC post-processing can reduce surface roughness (Sa), eliminate the stair-step effect, and enhance dimensional tolerances—especially when shallow cuts and appropriate cooling strategies are applied.

- Surface quality post-machining is strongly influenced by FDM parameters, such as layer thickness, build orientation, and infill density. For instance, horizontally printed parts and lower layer thicknesses typically result in smoother machined surfaces even in reinforced material with CF.

- Parameters like cutting speed, feed rate, and depth of cut must be adjusted according to the material and structure. Higher speeds and aggressive cuts can lead to delamination or burrs.

- Among cooling methods, cryogenic cooling yields the best results in terms of surface quality and minimal burr formation but is less accessible due to cost. Minimum Quantity Lubrication (MQL) provides a practical compromise, reducing tool wear and improving roughness compared to dry machining.

While significant progress has been made in understanding the role of CNC machining in improving FDM-printed part quality, it is important to acknowledge that this field of research is still in its early stages. This brief review highlights the considerable knowledge gaps that remain, particularly in areas, such as process standardization, toolpath optimization, and material-specific machining strategies. Much work remains to be done to fully understand and harness the potential of post-processing for FDM additive manufacturing. One of the main limitations of the reviewed studies lies in their predominant focus on simple geometries and single-material components, which do not fully reflect the complexity of real-world applications. To drive meaningful advancements in the field, future research should expand toward the investigation of complex geometries and multi-material FDM-printed structures, which pose unique challenges for CNC post-processing. Moreover, increasing the availability of open-access experimental datasets would significantly support the validation and benchmarking of future studies, particularly those involving new or advanced materials.

In this context, future research efforts should prioritize the following key areas:

- Development of a fully automated hybrid manufacturing system.

- Implementation of real-time process monitoring and adaptive control mechanisms.

- Application of artificial intelligence and machine learning techniques for process optimization and quality prediction in post-processing of additive manufactured components.

Beyond parameter optimization and hybrid systems, future research should also explore sustainable practices in CNC post-processing, investigate novel toolpaths and cutting strategies specifically tailored to the characteristics of FDM materials, and address the challenges of scaling hybrid manufacturing for medium to high-volume production.

Author Contributions

Conceptualization, M.C., G.L., M.E.M., P.B. and F.A.; writing—original draft preparation, M.C., G.L., M.E.M., P.B. and F.A.; writing—review and editing, M.C., G.L., M.E.M., P.B. and F.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The data presented in the paper are available upon request.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Wang, X.; Jiang, M.; Zhou, Z.; Gou, J.; Hui, D. 3D Printing of Polymer Matrix Composites: A Review and Prospective. Compos. Part B Eng. 2017, 110, 442–458. [Google Scholar] [CrossRef]

- Gibson, I.; Rosen, D.; Stucker, B.; Khorasani, M. Additive Manufacturing Technologies; Springer International Publishing: Cham, Switzerland, 2021; ISBN 978-3-030-56126-0. [Google Scholar]

- Abdulhameed, O.; Al-Ahmari, A.; Ameen, W.; Mian, S.H. Additive Manufacturing: Challenges, Trends, and Applications. Adv. Mech. Eng. 2019, 11, 1687814018822880. [Google Scholar] [CrossRef]

- Skylar-Scott, M.A.; Mueller, J.; Visser, C.W.; Lewis, J.A. Voxelated Soft Matter via Multimaterial Multinozzle 3D Printing. Nature 2019, 575, 330–335. [Google Scholar] [CrossRef] [PubMed]

- Hopkinson, N.; Hague, R.; Dickens, P. Rapid Manufacturing: An Industrial Revolution for the Digital Age; John Wiley & Sons: Hoboken, NJ, USA, 2006; ISBN 978-0-470-03286-2. [Google Scholar]

- Kafle, A.; Luis, E.; Silwal, R.; Pan, H.M.; Shrestha, P.L.; Bastola, A.K. 3D/4D Printing of Polymers: Fused Deposition Modelling (FDM), Selective Laser Sintering (SLS), and Stereolithography (SLA). Polymers 2021, 13, 3101. [Google Scholar] [CrossRef] [PubMed]

- Somireddy, M.; Czekanski, A.; Singh, C.V. Development of Constitutive Material Model of 3D Printed Structure via FDM. Mater. Today Commun. 2018, 15, 143–152. [Google Scholar] [CrossRef]

- Garzon-Hernandez, S.; Arias, A.; Garcia-Gonzalez, D. A Continuum Constitutive Model for FDM 3D Printed Thermoplastics. Compos. Part B Eng. 2020, 201, 108373. [Google Scholar] [CrossRef]

- Bandinelli, F.; Peroni, L.; Morena, A. Elasto-Plastic Mechanical Modeling of Fused Deposition 3D Printing Materials. Polymers 2023, 15, 234. [Google Scholar] [CrossRef]

- Mansour, M.; Tsongas, K.; Tzetzis, D.; Antoniadis, A. Mechanical and Dynamic Behavior of Fused Filament Fabrication 3D Printed Polyethylene Terephthalate Glycol Reinforced with Carbon Fibers. Polym. Plast. Technol. Eng. 2018, 57, 1715–1725. [Google Scholar] [CrossRef]

- Rodríguez-Panes, A.; Claver, J.; Camacho, A. The Influence of Manufacturing Parameters on the Mechanical Behaviour of PLA and ABS Pieces Manufactured by FDM: A Comparative Analysis. Materials 2018, 11, 1333. [Google Scholar] [CrossRef]

- Durgashyam, K.; Indra Reddy, M.; Balakrishna, A.; Satyanarayana, K. Experimental Investigation on Mechanical Properties of PETG Material Processed by Fused Deposition Modeling Method. Mater. Today Proc. 2019, 18, 2052–2059. [Google Scholar] [CrossRef]

- Guessasma, S.; Belhabib, S.; Nouri, H. Printability and Tensile Performance of 3D Printed Polyethylene Terephthalate Glycol Using Fused Deposition Modelling. Polymers 2019, 11, 1220. [Google Scholar] [CrossRef] [PubMed]

- Vinyas, M.; Athul, S.J.; Harursampath, D.; Nguyen Thoi, T. Mechanical Characterization of the Poly Lactic Acid (PLA) Composites Prepared through the Fused Deposition Modelling Process. Mater. Res. Express 2019, 6, 105359. [Google Scholar] [CrossRef]

- Selvam, A.; Mayilswamy, S.; Whenish, R.; Velu, R.; Subramanian, B. Preparation and Evaluation of the Tensile Characteristics of Carbon Fiber Rod Reinforced 3D Printed Thermoplastic Composites. J. Compos. Sci. 2020, 5, 8. [Google Scholar] [CrossRef]

- Gao, G.; Xu, F.; Xu, J.; Tang, G.; Liu, Z. A Survey of the Influence of Process Parameters on Mechanical Properties of Fused Deposition Modeling Parts. Micromachines 2022, 13, 553. [Google Scholar] [CrossRef] [PubMed]

- Kadhum, A.H.; Al-Zubaidi, S.; Abdulkareem, S.S. Effect of the Infill Patterns on the Mechanical and Surface Characteristics of 3D Printing of PLA, PLA+ and PETG Materials. ChemEngineering 2023, 7, 46. [Google Scholar] [CrossRef]

- Sood, A.K.; Ohdar, R.K.; Mahapatra, S.S. Improving Dimensional Accuracy of Fused Deposition Modelling Processed Part Using Grey Taguchi Method. Mater. Des. 2009, 30, 4243–4252. [Google Scholar] [CrossRef]

- Turner, B.N.; Gold, S.A. A Review of Melt Extrusion Additive Manufacturing Processes: II. Materials, Dimensional Accuracy, and Surface Roughness. Rapid Prototyp. J. 2015, 21, 250–261. [Google Scholar] [CrossRef]

- Livesu, M.; Ellero, S.; Martínez, J.; Lefebvre, S.; Attene, M. From 3D Models to 3D Prints: An Overview of the Processing Pipeline. Comput. Graph. Forum 2017, 36, 537–564. [Google Scholar] [CrossRef]

- Alexopoulou, V.E.; Christodoulou, I.T.; Markopoulos, A.P. Effect of Printing Speed and Layer Height on Geometrical Accuracy of FDM-Printed Resolution Holes of PETG Artifacts. Eng. Proc. 2022, 24, 11. [Google Scholar]

- Vidakis, N.; David, C.; Petousis, M.; Sagris, D.; Mountakis, N.; Moutsopoulou, A. The Effect of Six Key Process Control Parameters on the Surface Roughness, Dimensional Accuracy, and Porosity in Material Extrusion 3D Printing of Polylactic Acid: Prediction Models and Optimization Supported by Robust Design Analysis. Adv. Ind. Manuf. Eng. 2022, 5, 100104. [Google Scholar] [CrossRef]

- Kovan, V.; Tezel, T.; Topal, E.S.; Camurlu, H.E. Printing Parameters Effect on Surface Characteristics of 3D Printed PLA Materials. Mach. Technol. Mater. 2018, 12, 266–269. [Google Scholar]

- Bhandari, S.; Lopez-Anido, R.A.; Gardner, D.J. Enhancing the Interlayer Tensile Strength of 3D Printed Short Carbon Fiber Reinforced PETG and PLA Composites via Annealing. Addit. Manuf. 2019, 30, 100922. [Google Scholar] [CrossRef]

- Jayanth, N.; Jaswanthraj, K.; Sandeep, S.; Mallaya, N.H.; Siddharth, S.R. Effect of Heat Treatment on Mechanical Properties of 3D Printed PLA. J. Mech. Behav. Biomed. Mater. 2021, 123, 104764. [Google Scholar] [CrossRef]

- Pandey, P.M.; Reddy, N.V.; Dhande, S.G. Improvement of Surface Finish by Staircase Machining in Fused Deposition Modeling. J. Mater. Process. Technol. 2003, 132, 323–331. [Google Scholar] [CrossRef]

- Lalehpour, A.; Barari, A. Post Processing for Fused Deposition Modeling Parts with Acetone Vapour Bath. IFAC-Pap. 2016, 49, 42–48. [Google Scholar] [CrossRef]

- Lalehpour, A.; Janeteas, C.; Barari, A. Surface Roughness of FDM Parts after Post-Processing with Acetone Vapor Bath Smoothing Process. Int. J. Adv. Manuf. Technol. 2018, 95, 1505–1520. [Google Scholar] [CrossRef]

- Demircali, A.A.; Yilmaz, D.; Yilmaz, A.; Keskin, O.; Keshavarz, M.; Uvet, H. Enhancing Mechanical Properties and Surface Quality of FDM-Printed ABS: A Comprehensive Study on Cold Acetone Vapor Treatment. Int. J. Adv. Manuf. Technol. 2024, 130, 4027–4039. [Google Scholar] [CrossRef]

- Knight, W.A.; Boothroyd, G. Fundamentals of Metal Machining and Machine Tools, 3rd ed.; CRC Press: Boca Raton, FL, USA, 2019; ISBN 978-0-429-11424-3. [Google Scholar]

- Cortina, M.; Arrizubieta, J.I.; Ruiz, J.E.; Ukar, E.; Lamikiz, A. Latest Developments in Industrial Hybrid Machine Tools That Combine Additive and Subtractive Operations. Materials 2018, 11, 2583. [Google Scholar] [CrossRef]

- Crump, S.S.; Muir, A.E.-P.D. Creating Three-Dimensional Objects. 1992. Available online: https://patentimages.storage.googleapis.com/21/01/d3/69165ba25d15e0/US5121329.pdf (accessed on 3 June 2025).

- Kiński, W.; Pietkiewicz, P. The concept of the material supply system in 3D printer using a wear FDM material. Mechanik 2018, 7, 543–545. [Google Scholar] [CrossRef]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive Manufacturing (3D Printing): A Review of Materials, Methods, Applications and Challenges. Compos. Part B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Abeykoon, C.; Sri-Amphorn, P.; Fernando, A. Optimization of Fused Deposition Modeling Parameters for Improved PLA and ABS 3D Printed Structures. Int. J. Lightweight Mater. Manuf. 2020, 3, 284–297. [Google Scholar] [CrossRef]

- Hsueh, M.-H.; Lai, C.-J.; Chung, C.-F.; Wang, S.-H.; Huang, W.-C.; Pan, C.-Y.; Zeng, Y.-S.; Hsieh, C.-H. Effect of Printing Parameters on the Tensile Properties of 3D-Printed Polylactic Acid (PLA) Based on Fused Deposition Modeling. Polymers 2021, 13, 2387. [Google Scholar] [CrossRef] [PubMed]

- Murr, L.E. Frontiers of 3D Printing/Additive Manufacturing: From Human Organs to Aircraft Fabrication. J. Mater. Sci. Technol. 2016, 32, 987–995. [Google Scholar] [CrossRef]

- Klippstein, H.; Diaz De Cerio Sanchez, A.; Hassanin, H.; Zweiri, Y.; Seneviratne, L. Fused Deposition Modeling for Unmanned Aerial Vehicles (UAVs): A Review. Adv. Eng. Mater. 2018, 20, 1700552. [Google Scholar] [CrossRef]

- Lille, M.; Nurmela, A.; Nordlund, E.; Metsä-Kortelainen, S.; Sozer, N. Applicability of Protein and Fiber-Rich Food Materials in Extrusion-Based 3D Printing. J. Food Eng. 2018, 220, 20–27. [Google Scholar] [CrossRef]

- Bru, J.; Leite, M.; Ribeiro, A.; Reis, L.; Deus, A.; Fátima Vaz, M. Bioinspired Structures for Core Sandwich Composites Produced by Fused Deposition Modelling. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2020, 234, 379–393. [Google Scholar] [CrossRef]

- Jiang, G.; Yang, T.; Xu, J.; Tao, D.; Luo, C.; Wang, C.; Dong, Q.; Wang, Y. Investigation into Hydroxypropyl-Methylcellulose-Reinforced Polylactide Composites for Fused Deposition Modelling. Ind. Crops Prod. 2020, 146, 112174. [Google Scholar] [CrossRef]

- Boschetto, A.; Bottini, L.; Veniali, F. Finishing of Fused Deposition Modeling Parts by CNC Machining. Robot. Comput.-Integr. Manuf. 2016, 41, 92–101. [Google Scholar] [CrossRef]

- Masood, S.H.; Rattanawong, W.; Iovenitti, P. Part Build Orientations Based on Volumetric Error in Fused Deposition Modelling. Int. J. Adv. Manuf. Technol. 2000, 16, 162–168. [Google Scholar] [CrossRef]

- Masood, S.H.; Rattanawong, W.; Iovenitti, P. A Generic Algorithm for a Best Part Orientation System for Complex Parts in Rapid Prototyping. J. Mater. Process. Technol. 2003, 139, 110–116. [Google Scholar] [CrossRef]

- Navangul, G.; Paul, R.; Anand, S. Error Minimization in Layered Manufacturing Parts by Stereolithography File Modification Using a Vertex Translation Algorithm. J. Manuf. Sci. Eng. 2013, 135, 031006. [Google Scholar] [CrossRef]

- Zha, W.; Anand, S. Geometric Approaches to Input File Modification for Part Quality Improvement in Additive Manufacturing. J. Manuf. Process. 2015, 20, 465–477. [Google Scholar] [CrossRef]

- Taufik, M.; Jain, P.K. Volumetric Error Control in Layered Manufacturing. In International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Proceedings of the ASME 2015 International Design Engineering Technical Conferences & Computers and Information in Engineering Conference IDETC/CIE, Boston, MA, USA, 2–5 August 2015; American Society of Mechanical Engineers Digital Collection: New York, NY, USA, 2015. [Google Scholar]

- Taufik, M.; Jain, P. Surface Roughness Improvement Using Volumetric Error Control through Adaptive Slicing. Int. J. Rapid Manuf. 2017, 6, 279. [Google Scholar] [CrossRef]

- Zhao, Z.; Laperriere, L. Adaptive Direct Slicing of the Solid Model for Rapid Prototyping. Int. J. Prod. Res. 2000, 38, 69–83. [Google Scholar] [CrossRef]

- Sun, S.H.; Chiang, H.W.; Lee, M.I. Adaptive Direct Slicing of a Commercial CAD Model for Use in Rapid Prototyping. Int. J. Adv. Manuf. Technol. 2007, 34, 689–701. [Google Scholar] [CrossRef]

- Kulkarni, P.; Dutta, D. On the Integration of Layered Manufacturing and Material Removal Processes. J. Manuf. Sci. Eng. 1999, 122, 100–108. [Google Scholar] [CrossRef]

- Dolenc, A.; Mäkelä, I. Slicing Procedures for Layered Manufacturing Techniques. Comput. Aided Des. 1994, 26, 119–126. [Google Scholar] [CrossRef]

- Mohan Pandey, P.; Venkata Reddy, N.; Dhande, S.G. Slicing Procedures in Layered Manufacturing: A Review. Rapid Prototyp. J. 2003, 9, 274–288. [Google Scholar] [CrossRef]

- Wahab Hashmi, A.; Singh Mali, H.; Meena, A. Improving the Surface Characteristics of Additively Manufactured Parts: A Review. Mater. Today Proc. 2023, 81, 723–738. [Google Scholar] [CrossRef]

- Barrios, J.M.; Romero, P.E. Improvement of Surface Roughness and Hydrophobicity in PETG Parts Manufactured via Fused Deposition Modeling (FDM): An Application in 3D Printed Self–Cleaning Parts. Materials 2019, 12, 2499. [Google Scholar] [CrossRef]

- Kattethota, G.; Henderson, M. A Visual Tool to Improve Layered Manufacturing Part Quality; University of Texas Libraries: Austin, TX, USA, 1999. [Google Scholar]

- Reeves, P.E.; Cobb, R.C. Reducing the Surface Deviation of Stereolithography Using In-process Techniques. Rapid Prototyp. J. 1997, 3, 20–31. [Google Scholar] [CrossRef]

- Ahn, D.; Kim, H.; Lee, S. Surface Roughness Prediction Using Measured Data and Interpolation in Layered Manufacturing. J. Mater. Process. Technol. 2009, 209, 664–671. [Google Scholar] [CrossRef]

- El Mehtedi, M.; Buonadonna, P.; El Mohtadi, R.; Loi, G.; Aymerich, F.; Carta, M. Optimizing Milling Parameters for Enhanced Machinability of 3D-Printed Materials: An Analysis of PLA, PETG, and Carbon-Fiber-Reinforced PETG. JMMP 2024, 8, 131. [Google Scholar] [CrossRef]

- Elayeb, A.; Tlija, M.; Eltaief, A.; Louhichi, B.; Zemzemi, F. Minimizing Dimensional Defects in FFF Using a Novel Adaptive Slicing Method Based on Local Shape Complexity. J. Manuf. Mater. Process. 2024, 8, 59. [Google Scholar] [CrossRef]

- Zhou, H.; Cheng, X.; Jiang, X.; Zheng, G.; Zhang, J.; Li, Y.; Tang, M. Study of the Interlayer Bonding Strength for Combined 3D Printing and Milling of Polyetheretherketone. J. Appl. Polym. Sci. 2023, 140, e53773. [Google Scholar] [CrossRef]

- Del Sol, I.; Domínguez Calvo, Á.; Piñero, D.; Salguero, J.; Batista, M. Study of the FDM Parameters of the ABS Parts in the Surface Quality after Machining Operations. KEM 2019, 813, 203–208. [Google Scholar] [CrossRef]

- El Mehtedi, M.; Buonadonna, P.; El Mohtadi, R.; Aymerich, F.; Carta, M. Surface Quality Related to Machining Parameters in 3D-Printed PETG Components. Procedia Comput. Sci. 2024, 232, 1212–1221. [Google Scholar] [CrossRef]

- El Mehtedi, M.; Buonadonna, P.; Loi, G.; El Mohtadi, R.; Carta, M.; Aymerich, F. Surface Quality Related to Face Milling Parameters in 3D Printed Carbon Fiber-Reinforced PETG. J. Compos. Sci. 2024, 8, 128. [Google Scholar] [CrossRef]

- Lalegani Dezaki, M.; Mohd Ariffin, M.K.A.; Ismail, M.I.S. Effects of CNC Machining on Surface Roughness in Fused Deposition Modelling (FDM) Products. Materials 2020, 13, 2608. [Google Scholar] [CrossRef]

- Tomal, A.N.M.A.; Saleh, T.; Khan, M.R. Combination of Fused Deposition Modelling with Abrasive Milling for Attaining Higher Dimensional Accuracy and Better Surface Finish. IIUM Eng. J. 2018, 19, 221–231. [Google Scholar] [CrossRef]

- Vallejo, J.; García-Plaza, E.; Núñez, P.J.; Chacón, J.M.; Caminero, M.A.; Romero, A. Machinability Analysis of Carbon Fibre Reinforced PET-Glycol Composites Processed by Additive Manufacturing. Compos. Part A Appl. Sci. Manuf. 2023, 172, 107561. [Google Scholar] [CrossRef]

- Mani, M.; Karthikeyan, A.G.; Kalaiselvan, K.; Muthusamy, P.; Muruganandhan, P. Optimization of FDM 3-D Printer Process Parameters for Surface Roughness and Mechanical Properties Using PLA Material. Mater. Today Proc. 2022, 66, 1926–1931. [Google Scholar] [CrossRef]

- Lee, W.; Wei, C.; Chung, S.-C. Development of a Hybrid Rapid Prototyping System Using Low-Cost Fused Deposition Modeling and Five-Axis Machining. J. Mater. Process. Technol. 2014, 214, 2366–2374. [Google Scholar] [CrossRef]

- Ferreira, I.; Madureira, R.; Villa, S.; de Jesus, A.; Machado, M.; Alves, J.L. Machinability of PA12 and Short Fibre–Reinforced PA12 Materials Produced by Fused Filament Fabrication. Int. J. Adv. Manuf. Technol. 2020, 107, 885–903. [Google Scholar] [CrossRef]

- Guo, C.; Liu, X.; Liu, G. Surface Finishing of FDM-Fabricated Amorphous Polyetheretherketone and Its Carbon-Fiber-Reinforced Composite by Dry Milling. Polymers 2021, 13, 2175. [Google Scholar] [CrossRef]

- Pămărac, R.G.; Petruse, R.E. Study Regarding the Optimal Milling Parameters for Finishing 3D Printed Parts from ABS and PLA Materials. Acta Univ. Cibiniensis. Tech. Ser. 2018, 70, 66–72. [Google Scholar] [CrossRef]

- Cococcetta, N.M.; Pearl, D.; Jahan, M.P.; Ma, J. Investigating Surface Finish, Burr Formation, and Tool Wear during Machining of 3D Printed Carbon Fiber Reinforced Polymer Composite. J. Manuf. Process. 2020, 56, 1304–1316. [Google Scholar] [CrossRef]

- Cococcetta, N.; Jahan, M.P.; Schoop, J.; Ma, J.; Pearl, D.; Hassan, M. Post-Processing of 3D Printed Thermoplastic CFRP Composites Using Cryogenic Machining. J. Manuf. Process. 2021, 68, 332–346. [Google Scholar] [CrossRef]

- Giltrow, J.P.; Lancaster, J.K. Carbon-Fibre Reinforced Polymers as Self-Lubricating Materials. Proc. Inst. Mech. Eng. Conf. Proc. 1967, 182, 147–157. [Google Scholar] [CrossRef]

- Amanullah, A.N.M.; Murshiduzzaman; Saleh, T.; Khan, R. Design and Development of a Hybrid Machine Combining Rapid Prototyping and CNC Milling Operation. Procedia Eng. 2017, 184, 163–170. [Google Scholar] [CrossRef]

- Bruni, C.; Gianangeli, C.; Mancia, T.; Greco, L.; Pieralisi, M. Improving Dimensional and Surface Quality of Additive Manufactured Parts. J. Phys. Conf. Ser. 2020, 1507, 042003. [Google Scholar] [CrossRef]

- Kamer, M.S.; Uzay, Ç. Investigation of The Effect of CNC Milling Cutting Process on The Tensile Test of PLA Samples Produced Using Two Different 3D Printers with The FDM Method. Derg. Çukurova Üniversitesi Mühendislik Fakültesi Derg. 2024, 39, 599–608. [Google Scholar] [CrossRef]

- Chen, Y.; Ye, L.; Kinloch, A.J.; Zhang, Y.X. 3D Printed Carbon-Fibre Reinforced Composite Lattice Structures with Good Thermal-Dimensional Stability. Compos. Sci. Technol. 2022, 227, 109599. [Google Scholar] [CrossRef]

- El Mehtedi, M.; Buonadonna, P.; Carta, M.; El Mohtadi, R.; Marongiu, G.; Loi, G.; Aymerich, F. Effects of Milling Parameters on Roughness and Burr Formation in 3D-Printed PLA Components. Procedia Comput. Sci. 2023, 217, 1560–1569. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).