Investigation of Particleboard Production from Durian Husk and Bamboo Waste

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Response Surface Methodology and Central Composite Design

2.3. Particleboard Manufacturing

2.4. Chemical Analysis of Durian Husks

2.5. Testing of Bio-Based Particleboards

3. Results and Discussion

3.1. Chemical Analysis Result of Durian Husks

3.2. Physical and Mechanical Properties of Investigated Bio-Based Particleboard

3.3. Effects of DHR and UFR on TS, MOR, and IB of Bio-Based Particleboard

3.3.1. Effect of DHR and UFR on TS of Bio-Based Particleboard

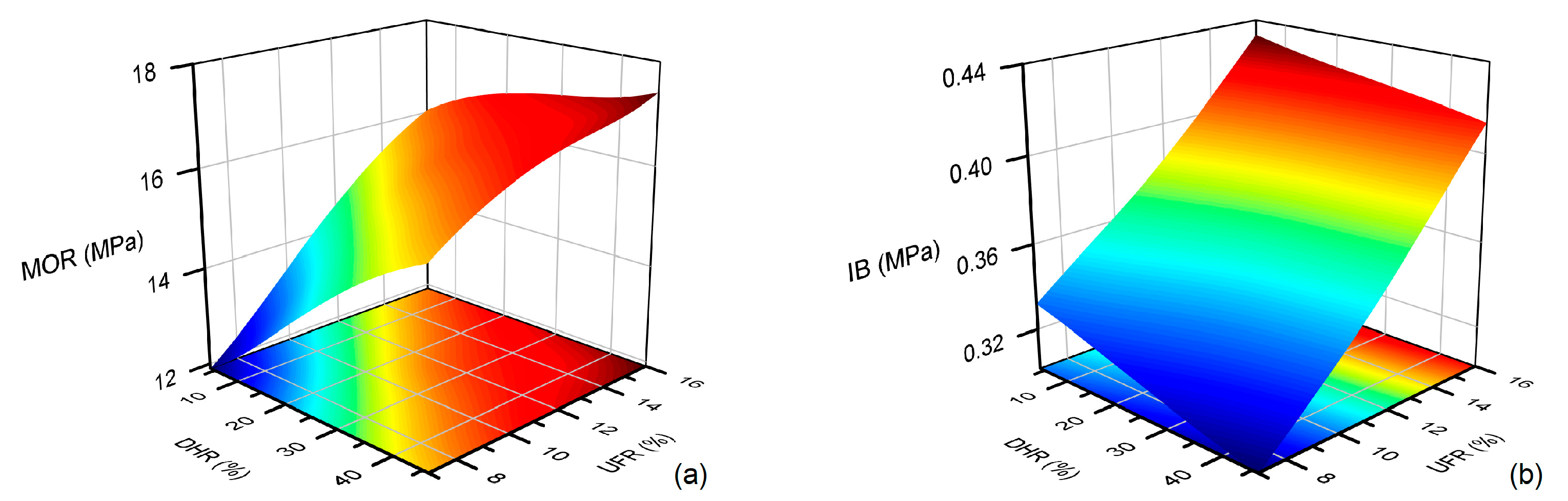

3.3.2. Effects of DHR and UFR on MOR and IB of Bio-Based Particleboard

3.4. Regression Analysis and Model Adequacy

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| CCD | Central composite design |

| DHR | Durian husk ratio |

| IB | Internal bond strength |

| MOR | Modulus of rupture |

| R² | Coefficient of determination |

| RSM | Response surface methodology |

| TAPPI | Technical Association of the Pulp and Paper Industry |

| TS | Thickness swelling |

| UF | Urea formaldehyde |

| UFR | Urea formaldehyde resin ratio |

References

- Okeke, F.O.; Ahmed, A.; Imam, A.; Hassanin, H. Study on Agricultural Waste Utilization in Sustainable Particleboard Production. E3S Web Conf. 2024, 563, 02007. [Google Scholar] [CrossRef]

- Mirindi, D. A Review of Particleboard Development and Performance Using Non-Toxic and Biodegradable Adhesives. Int. J. Eng. Trends Technol. 2024, 72, 252–260. [Google Scholar] [CrossRef]

- Lee, S.H.; Lum, W.C.; Boon, J.G.; Kristak, L.; Antov, P.; Pędzik, M.; Rogoziński, T.; Taghiyari, H.R.; Lubis, M.A.R.; Fatriasari, W.; et al. Particleboard from Agricultural Biomass and Recycled Wood Waste: A Review. J. Mater. Res. Technol. 2022, 20, 4630–4658. [Google Scholar] [CrossRef]

- Tarigan, F.O.; Hakim, L.; Purwoko, A.; Sucipto, T.; Nasution, H.; Fatriasari, W.; Lubis, M.A.R.; Sutiawan, J.; Bakhsi, M.I.; Kim, N.-H.; et al. Development and Characterization of Novel Hybrid Particleboard Made from Several Non-Wood Lignocellulosic Materials. Polymers 2025, 17, 512. [Google Scholar] [CrossRef] [PubMed]

- Chandroji Rao, K.M.; Sheshagiri, M.B.; Ramamoorthy, R.V.; Amran, M.; Nandanwar, A.; Vijayakumar, P.; Avudaiappan, S.; Guindos, P. Effect of Density on Acoustic and Thermal Properties of Low-Density Particle Boards Made from Agro-Residues: Towards Sustainable Material Solutions. BioResources 2024, 20, 601–624. [Google Scholar] [CrossRef]

- Calvez, I.; Garcia, R.; Koubaa, A.; Landry, V.; Cloutier, A. Recent Advances in Bio-Based Adhesives and Formaldehyde-Free Technologies for Wood-Based Panel Manufacturing. Curr. For. Rep. 2024, 10, 386–400. [Google Scholar] [CrossRef] [PubMed]

- Saropas, N.; Huijisut, P.; Noratad, S.; Supansomboon, S.; Wanakamol, P.; Supansomboon, S. Mechanical and Physical Properties of Binderless Particleboard from Rice Straw and Banana Pseudostem. Curr. Appl. Sci. Technol. 2024, 25, e0262175. [Google Scholar] [CrossRef]

- Kelkar, B.U.; Shukla, S.R.; Nagraik, P.; Paul, B.N. Structural Bamboo Composites: A Review of Processing, Factors Affecting Properties and Recent Advances. Adv. Bamboo Sci. 2023, 3, 100026. [Google Scholar] [CrossRef]

- Yen, T.-M.; Lee, J.-S. Comparing Aboveground Carbon Sequestration between Moso Bamboo (Phyllostachys heterocycla) and China Fir (Cunninghamia lanceolata) Forests Based on the Allometric Model. For. Ecol. Manag. 2011, 261, 995–1002. [Google Scholar] [CrossRef]

- Kuehl, Y. Resources, Yield, and Volume of Bamboos. In Bamboo; Liese, W., Köhl, M., Eds.; Springer International Publishing: Cham, Switzerland, 2015; pp. 91–111. ISBN 978-3-319-14132-9. [Google Scholar]

- Liese, W.; Welling, J.; Tang, T.K.H. Utilization of Bamboo. In Bamboo; Liese, W., Köhl, M., Eds.; Springer International Publishing: Cham, Switzerland, 2015; pp. 299–346. ISBN 978-3-319-14132-9. [Google Scholar]

- Laemlaksakul, V.; Kaewkuekool, S. Laminated Bamboo Materials for Furniture—A Systematic Approach to Innovative Product Design. WSEAS Trans. Adv. Eng. Educ. 2006, 3, 424–430. [Google Scholar]

- Widyorini, R. Evaluation of Physical and Mechanical Properties of Particleboard Made from Petung Bamboo Using Sucrose-Based Adhesive. BioResources 2020, 15, 5072–5086. [Google Scholar] [CrossRef]

- Durian Global Trade Overview 2023; FAO: Rome, Italy, 2023; p. 10.

- BPS—Statistics Indonesia Production of Fruits, 2021–2023. Available online: https://www.bps.go.id/en/statistics-table/2/NjIjMg==/production-of-fruits.html (accessed on 15 December 2024).

- Vietnam National Statistics Office’s Website Press Release Socio-Economic Situation in the Fourth Quarter and 2023. Available online: https://www.gso.gov.vn/en/data-and-statistics/2024/02/socio-economic-situation-in-the-fourth-quarter-and-2023/ (accessed on 15 December 2024).

- Walderich, A. Production Volume of Durians in Thailand in 2023, by Region. Available online: https://www.statista.com/statistics/1319755/thailand-durian-production-by-region/ (accessed on 15 December 2024).

- Siddharta, A. Production Volume of Durians in Malaysia from 2014 to 2023. Available online: https://www.statista.com/statistics/1000876/malaysia-durian-production/ (accessed on 15 December 2024).

- Balita, C. Production Volume of Durian in the Philippines from 2012 to 2023. Available online: https://www.statista.com/statistics/1289632/production-of-durian-philippines/ (accessed on 15 December 2024).

- Vietnam Durian Export Research Report 2024–2033; China Research and Intelligence: Shanghai, China, 2024; p. 80.

- Vietnam National Statistics Office’s Website Press Release Socio-Economic Situation in the Fourth Quarter and 2024. Available online: https://www.gso.gov.vn/en/highlight/2025/02/socio-economic-situation-in-the-fourth-quarter-and-2024/ (accessed on 15 January 2025).

- Gorade, H. Fresh Durian Market Demand, Size, Share, Trends, Forecast—2035; Market Research Future: Pune, India, 2025; p. 100. [Google Scholar]

- Khaksar, G.; Kasemcholathan, S.; Sirikantaramas, S. Durian (Durio zibethinus L.): Nutritional Composition, Pharmacological Implications, Value-Added Products, and Omics-Based Investigations. Horticulturae 2024, 10, 342. [Google Scholar] [CrossRef]

- Payus, C.M.; Refdin, M.A.; Zahari, N.Z.; Rimba, A.B.; Geetha, M.; Saroj, C.; Gasparatos, A.; Fukushi, K.; Alvin Oliver, P. Durian Husk Wastes as Low-Cost Adsorbent for Physical Pollutants Removal: Groundwater Supply. Mater. Today Proc. 2021, 42, 80–87. [Google Scholar] [CrossRef]

- Tan, C.-H.; Ishak, W.R.W.; Easa, A.M.; Hii, C.-L.; Chuo, K.M.J.; How, Y.-H.; Pui, L.-P. From Waste to Wealth: A Review on Valorisation of Durian Waste as Functional Food Ingredient. J. Food Meas. Charact. 2023, 17, 6222–6235. [Google Scholar] [CrossRef]

- Wai, W.W.; Alkarkhi, A.F.M.; Easa, A.M. Effect of Extraction Conditions on Yield and Degree of Esterification of Durian Rind Pectin: An Experimental Design. Food Bioprod. Process. 2010, 88, 209–214. [Google Scholar] [CrossRef]

- Gamay, R.A.J.; Botecario, P.M.N.; Sanchez, P.D.C.; Alvarado, M.C. Durian (Durio zibenthinus) Waste: A Promising Resource for Food and Diverse Applications—A Comprehensive Review. Food Prod. Process. Nutr. 2024, 6, 27. [Google Scholar] [CrossRef]

- Tang, T.K.H.; Nguyen, D.L. Investigation on Producing Single-Layer Particleboard from Bamboo Waste and Cocoa Pod Husks. J. For. Sci. Technol. 2020, 136–141. [Google Scholar]

- Tang, T.K.H.; Nguyen, D.L.; Ho, T.T.D. Optimum Condition of Manufacturing Hybrid Particleboard from Mixture of Cocoa Pod Husk and Bamboo Particles. J. Agric. Dev. 2019, 18, 10–15. [Google Scholar] [CrossRef]

- Widyorini, R.; Aini, E.N.; Lubis, Y.S.; Dewi, G.K. Water Resistance Ability and Mechanical Strength of Eco-Friendly Particleboard Made from Bamboo Waste and Maltodextrin-Based Adhesive. Drv. Ind. 2025, 76, 3–12. [Google Scholar] [CrossRef]

- Zddin, Z.; Risby, M.S. Durian Husk as Potential Source for Particleboard Industry. AIP Conf. Proc. 2010, 1217, 546–553. [Google Scholar] [CrossRef]

- Tang, T.K.H.; Nguyen, N.Q. Mechanical and physical properties of particleboards made from durian husk and rubberwood. J. For. Sci. Technol. 2025, 14, 160–167. [Google Scholar] [CrossRef]

- Humaira Alias, A.; Zainudin, E.S.; Mohd Norizan, M.N.; Rushdan, A.I. Development and Characterisation of Biocomposite Insulator Board from Durian Skin Fibres. Pertanika J. Sci. Technol. 2023, 31, 59–85. [Google Scholar] [CrossRef]

- TAPPI T 264 Cm-22; Preparation of Wood for Chemical Analysis. Technical Association of the Pulp and Paper Industry: Norcross, GA, USA, 2022.

- Browning, B.L. Methods of Wood Chemistry; Wiley-Interscience: New York, NY, USA, 1967; Volume 2. [Google Scholar]

- TAPPI T 222 Om-21; Acid-Insoluble Lignin in Wood and Pulp. Technical Association of the Pulp and Paper Industry: Norcross, GA, USA, 2021.

- BS EN 317:1993; Particleboards and Fibreboards—Determination of Swelling in Thickness After Immersion in Water. British Standards Institution: London, UK, 1993.

- BS EN 310:1993; Wood-Based Panels—Determination of Modulus of Elasticity in Bending and of Bending Strength. British Standards Institution: London, UK, 1993.

- BS EN 319:1993; Particleboards and Fibreboards—Determination of Tensile Strength Perpendicular to the Plane of the Board. British Standards Institution: London, UK, 1993.

- BS EN 312:2010; Particleboards—Specifications. British Standards Institution: London, UK, 2010.

- Khedari, J.; Nankongnab, N.; Hirunlabh, J.; Teekasap, S. New Low-Cost Insulation Particleboards from Mixture of Durian Peel and Coconut Coir. Build. Environ. 2004, 39, 59–65. [Google Scholar] [CrossRef]

- Jha, K.; Yahya, E.B.; Bairwan, R.D.; Sabri, M.; Abdul Khalil, H.P.S.; Ahmad, M.I.; Surya, I. Eco-Friendly Approach for Carboxymethyl Cellulose Isolation from Durian Peel Waste and Aerogel Scaffold Preparation. Nano-Struct. Nano-Objects 2024, 40, 101345. [Google Scholar] [CrossRef]

- Liese, W.; Tang, T.K.H. Properties of the Bamboo Culm. In Bamboo; Liese, W., Köhl, M., Eds.; Springer International Publishing: Cham, Switzerland, 2015; pp. 227–256. ISBN 978-3-319-14132-9. [Google Scholar]

- Chaowana, P.; Barbu, M.C. Bamboo: Potential Material for Biocomposites. In Lignocellulosic Fibre and Biomass-Based Composite Materials; Elsevier: Amsterdam, The Netherlands, 2017; pp. 259–289. ISBN 978-0-08-100959-8. [Google Scholar]

- Mai, C.; Zhang, K. Wood Chemistry. In Springer Handbook of Wood Science and Technology; Niemz, P., Teischinger, A., Sandberg, D., Eds.; Springer International Publishing: Cham, Switzerland, 2023; pp. 179–279. ISBN 978-3-030-81314-7. [Google Scholar]

- Niemz, P.; Mai, C.; Schmitt, U. Introduction to Wood Science. In Springer Handbook of Wood Science and Technology; Niemz, P., Teischinger, A., Sandberg, D., Eds.; Springer International Publishing: Cham, Switzerland, 2023; pp. 25–40. ISBN 978-3-030-81314-7. [Google Scholar]

- Klímek, P.; Meinlschmidt, P.; Wimmer, R.; Plinke, B.; Schirp, A. Using Sunflower (Helianthus annuus L.), Topinambour (Helianthus tuberosus L.) and Cup-Plant (Silphium perfoliatum L.) Stalks as Alternative Raw Materials for Particleboards. Ind. Crops Prod. 2016, 92, 157–164. [Google Scholar] [CrossRef]

- Bardak, S.; Nemli, G.; Tiryaki, S. The Influence of Raw Material Growth Region, Anatomical Structure and Chemical Composition of Wood on the Quality Properties of Particleboards. Maderas Cienc. Tecnol. 2017, 19, 363–372. [Google Scholar] [CrossRef]

- Boon, J.G.; Hashim, R.; Sulaiman, O.; Sugimoto, T.; Sato, M.; Salim, N.; Amini, M.H.M.; Nor Izaida, I.; Sitti Fatimah, M.R. Importance of Lignin on the Properties of Binderless Particleboard Made from Oil Palm Trunk. J. Eng. Appl. Sci. 2017, 12, 33–40. [Google Scholar]

- Liang, J.; Wu, J.; Xu, J. Low-Formaldehyde Emission Composite Particleboard Manufactured from Waste Chestnut Bur. J. Wood Sci. 2021, 67, 21. [Google Scholar] [CrossRef]

- Vitrone, F.; Ramos, D.; Ferrando, F.; Salvadó, J. Binderless Fiberboards for Sustainable Construction. Materials, Production Methods and Applications. J. Build. Eng. 2021, 44, 102625. [Google Scholar] [CrossRef]

- Hubbe, M.A.; Pizzi, A.; Zhang, H.; Halis, R. Critical Links Governing Performance of Self-Binding and Natural Binders for Hot-Pressed Reconstituted Lignocellulosic Board without Added Formaldehyde: A Review. BioResources 2017, 13, 2049–2115. [Google Scholar] [CrossRef]

- Iswanto, A.H.; Aritonang, W.; Azhar, I.; Supriyanto; Fatriasari, W. The Physical, Mechanical and Durability Properties of Sorghum Bagasse Particleboard by Layering Surface Treatment. J. Indian Acad. Wood Sci. 2017, 14, 1–8. [Google Scholar] [CrossRef]

| Factors | Ranges of Actual and Coded Values | ||||

|---|---|---|---|---|---|

| −α | −1 | 0 | +1 | +α | |

| Durian husk ratio (DHR, %) | 4 | 10 | 25 | 40 | 46 |

| UF resin ratio (UFR, %) | 7 | 8 | 11.5 | 15 | 16 |

| Component | Durian Husk in This Study | Durian Husk [41,42] | Bamboo [43,44] |

|---|---|---|---|

| Holocellulose | 72.84 (0.89) | 65.3–73.54 | 62.5–79.9 |

| Lignin | 15.92 (0.56) | 15.45–18.7 | 20.5–32.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tang, T.K.H.; Nguyen, N.Q. Investigation of Particleboard Production from Durian Husk and Bamboo Waste. J. Compos. Sci. 2025, 9, 276. https://doi.org/10.3390/jcs9060276

Tang TKH, Nguyen NQ. Investigation of Particleboard Production from Durian Husk and Bamboo Waste. Journal of Composites Science. 2025; 9(6):276. https://doi.org/10.3390/jcs9060276

Chicago/Turabian StyleTang, Thi Kim Hong, and Nhat Quang Nguyen. 2025. "Investigation of Particleboard Production from Durian Husk and Bamboo Waste" Journal of Composites Science 9, no. 6: 276. https://doi.org/10.3390/jcs9060276

APA StyleTang, T. K. H., & Nguyen, N. Q. (2025). Investigation of Particleboard Production from Durian Husk and Bamboo Waste. Journal of Composites Science, 9(6), 276. https://doi.org/10.3390/jcs9060276