Investigation of Particleboard Production from Durian Husk and Bamboo Waste

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Response Surface Methodology and Central Composite Design

2.3. Particleboard Manufacturing

2.4. Chemical Analysis of Durian Husks

2.5. Testing of Bio-Based Particleboards

3. Results and Discussion

3.1. Chemical Analysis Result of Durian Husks

3.2. Physical and Mechanical Properties of Investigated Bio-Based Particleboard

3.3. Effects of DHR and UFR on TS, MOR, and IB of Bio-Based Particleboard

3.3.1. Effect of DHR and UFR on TS of Bio-Based Particleboard

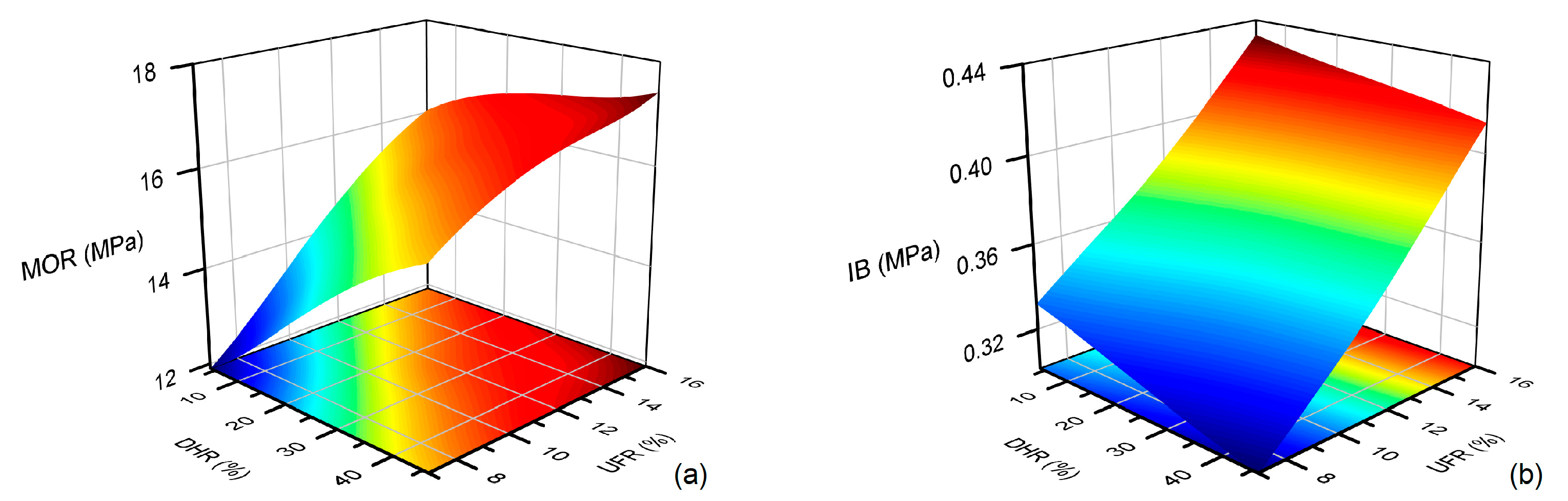

3.3.2. Effects of DHR and UFR on MOR and IB of Bio-Based Particleboard

3.4. Regression Analysis and Model Adequacy

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| CCD | Central composite design |

| DHR | Durian husk ratio |

| IB | Internal bond strength |

| MOR | Modulus of rupture |

| R² | Coefficient of determination |

| RSM | Response surface methodology |

| TAPPI | Technical Association of the Pulp and Paper Industry |

| TS | Thickness swelling |

| UF | Urea formaldehyde |

| UFR | Urea formaldehyde resin ratio |

References

- Okeke, F.O.; Ahmed, A.; Imam, A.; Hassanin, H. Study on Agricultural Waste Utilization in Sustainable Particleboard Production. E3S Web Conf. 2024, 563, 02007. [Google Scholar] [CrossRef]

- Mirindi, D. A Review of Particleboard Development and Performance Using Non-Toxic and Biodegradable Adhesives. Int. J. Eng. Trends Technol. 2024, 72, 252–260. [Google Scholar] [CrossRef]

- Lee, S.H.; Lum, W.C.; Boon, J.G.; Kristak, L.; Antov, P.; Pędzik, M.; Rogoziński, T.; Taghiyari, H.R.; Lubis, M.A.R.; Fatriasari, W.; et al. Particleboard from Agricultural Biomass and Recycled Wood Waste: A Review. J. Mater. Res. Technol. 2022, 20, 4630–4658. [Google Scholar] [CrossRef]

- Tarigan, F.O.; Hakim, L.; Purwoko, A.; Sucipto, T.; Nasution, H.; Fatriasari, W.; Lubis, M.A.R.; Sutiawan, J.; Bakhsi, M.I.; Kim, N.-H.; et al. Development and Characterization of Novel Hybrid Particleboard Made from Several Non-Wood Lignocellulosic Materials. Polymers 2025, 17, 512. [Google Scholar] [CrossRef] [PubMed]

- Chandroji Rao, K.M.; Sheshagiri, M.B.; Ramamoorthy, R.V.; Amran, M.; Nandanwar, A.; Vijayakumar, P.; Avudaiappan, S.; Guindos, P. Effect of Density on Acoustic and Thermal Properties of Low-Density Particle Boards Made from Agro-Residues: Towards Sustainable Material Solutions. BioResources 2024, 20, 601–624. [Google Scholar] [CrossRef]

- Calvez, I.; Garcia, R.; Koubaa, A.; Landry, V.; Cloutier, A. Recent Advances in Bio-Based Adhesives and Formaldehyde-Free Technologies for Wood-Based Panel Manufacturing. Curr. For. Rep. 2024, 10, 386–400. [Google Scholar] [CrossRef] [PubMed]

- Saropas, N.; Huijisut, P.; Noratad, S.; Supansomboon, S.; Wanakamol, P.; Supansomboon, S. Mechanical and Physical Properties of Binderless Particleboard from Rice Straw and Banana Pseudostem. Curr. Appl. Sci. Technol. 2024, 25, e0262175. [Google Scholar] [CrossRef]

- Kelkar, B.U.; Shukla, S.R.; Nagraik, P.; Paul, B.N. Structural Bamboo Composites: A Review of Processing, Factors Affecting Properties and Recent Advances. Adv. Bamboo Sci. 2023, 3, 100026. [Google Scholar] [CrossRef]

- Yen, T.-M.; Lee, J.-S. Comparing Aboveground Carbon Sequestration between Moso Bamboo (Phyllostachys heterocycla) and China Fir (Cunninghamia lanceolata) Forests Based on the Allometric Model. For. Ecol. Manag. 2011, 261, 995–1002. [Google Scholar] [CrossRef]

- Kuehl, Y. Resources, Yield, and Volume of Bamboos. In Bamboo; Liese, W., Köhl, M., Eds.; Springer International Publishing: Cham, Switzerland, 2015; pp. 91–111. ISBN 978-3-319-14132-9. [Google Scholar]

- Liese, W.; Welling, J.; Tang, T.K.H. Utilization of Bamboo. In Bamboo; Liese, W., Köhl, M., Eds.; Springer International Publishing: Cham, Switzerland, 2015; pp. 299–346. ISBN 978-3-319-14132-9. [Google Scholar]

- Laemlaksakul, V.; Kaewkuekool, S. Laminated Bamboo Materials for Furniture—A Systematic Approach to Innovative Product Design. WSEAS Trans. Adv. Eng. Educ. 2006, 3, 424–430. [Google Scholar]

- Widyorini, R. Evaluation of Physical and Mechanical Properties of Particleboard Made from Petung Bamboo Using Sucrose-Based Adhesive. BioResources 2020, 15, 5072–5086. [Google Scholar] [CrossRef]

- Durian Global Trade Overview 2023; FAO: Rome, Italy, 2023; p. 10.

- BPS—Statistics Indonesia Production of Fruits, 2021–2023. Available online: https://www.bps.go.id/en/statistics-table/2/NjIjMg==/production-of-fruits.html (accessed on 15 December 2024).

- Vietnam National Statistics Office’s Website Press Release Socio-Economic Situation in the Fourth Quarter and 2023. Available online: https://www.gso.gov.vn/en/data-and-statistics/2024/02/socio-economic-situation-in-the-fourth-quarter-and-2023/ (accessed on 15 December 2024).

- Walderich, A. Production Volume of Durians in Thailand in 2023, by Region. Available online: https://www.statista.com/statistics/1319755/thailand-durian-production-by-region/ (accessed on 15 December 2024).

- Siddharta, A. Production Volume of Durians in Malaysia from 2014 to 2023. Available online: https://www.statista.com/statistics/1000876/malaysia-durian-production/ (accessed on 15 December 2024).

- Balita, C. Production Volume of Durian in the Philippines from 2012 to 2023. Available online: https://www.statista.com/statistics/1289632/production-of-durian-philippines/ (accessed on 15 December 2024).

- Vietnam Durian Export Research Report 2024–2033; China Research and Intelligence: Shanghai, China, 2024; p. 80.

- Vietnam National Statistics Office’s Website Press Release Socio-Economic Situation in the Fourth Quarter and 2024. Available online: https://www.gso.gov.vn/en/highlight/2025/02/socio-economic-situation-in-the-fourth-quarter-and-2024/ (accessed on 15 January 2025).

- Gorade, H. Fresh Durian Market Demand, Size, Share, Trends, Forecast—2035; Market Research Future: Pune, India, 2025; p. 100. [Google Scholar]

- Khaksar, G.; Kasemcholathan, S.; Sirikantaramas, S. Durian (Durio zibethinus L.): Nutritional Composition, Pharmacological Implications, Value-Added Products, and Omics-Based Investigations. Horticulturae 2024, 10, 342. [Google Scholar] [CrossRef]

- Payus, C.M.; Refdin, M.A.; Zahari, N.Z.; Rimba, A.B.; Geetha, M.; Saroj, C.; Gasparatos, A.; Fukushi, K.; Alvin Oliver, P. Durian Husk Wastes as Low-Cost Adsorbent for Physical Pollutants Removal: Groundwater Supply. Mater. Today Proc. 2021, 42, 80–87. [Google Scholar] [CrossRef]

- Tan, C.-H.; Ishak, W.R.W.; Easa, A.M.; Hii, C.-L.; Chuo, K.M.J.; How, Y.-H.; Pui, L.-P. From Waste to Wealth: A Review on Valorisation of Durian Waste as Functional Food Ingredient. J. Food Meas. Charact. 2023, 17, 6222–6235. [Google Scholar] [CrossRef]

- Wai, W.W.; Alkarkhi, A.F.M.; Easa, A.M. Effect of Extraction Conditions on Yield and Degree of Esterification of Durian Rind Pectin: An Experimental Design. Food Bioprod. Process. 2010, 88, 209–214. [Google Scholar] [CrossRef]

- Gamay, R.A.J.; Botecario, P.M.N.; Sanchez, P.D.C.; Alvarado, M.C. Durian (Durio zibenthinus) Waste: A Promising Resource for Food and Diverse Applications—A Comprehensive Review. Food Prod. Process. Nutr. 2024, 6, 27. [Google Scholar] [CrossRef]

- Tang, T.K.H.; Nguyen, D.L. Investigation on Producing Single-Layer Particleboard from Bamboo Waste and Cocoa Pod Husks. J. For. Sci. Technol. 2020, 136–141. [Google Scholar]

- Tang, T.K.H.; Nguyen, D.L.; Ho, T.T.D. Optimum Condition of Manufacturing Hybrid Particleboard from Mixture of Cocoa Pod Husk and Bamboo Particles. J. Agric. Dev. 2019, 18, 10–15. [Google Scholar] [CrossRef]

- Widyorini, R.; Aini, E.N.; Lubis, Y.S.; Dewi, G.K. Water Resistance Ability and Mechanical Strength of Eco-Friendly Particleboard Made from Bamboo Waste and Maltodextrin-Based Adhesive. Drv. Ind. 2025, 76, 3–12. [Google Scholar] [CrossRef]

- Zddin, Z.; Risby, M.S. Durian Husk as Potential Source for Particleboard Industry. AIP Conf. Proc. 2010, 1217, 546–553. [Google Scholar] [CrossRef]

- Tang, T.K.H.; Nguyen, N.Q. Mechanical and physical properties of particleboards made from durian husk and rubberwood. J. For. Sci. Technol. 2025, 14, 160–167. [Google Scholar] [CrossRef]

- Humaira Alias, A.; Zainudin, E.S.; Mohd Norizan, M.N.; Rushdan, A.I. Development and Characterisation of Biocomposite Insulator Board from Durian Skin Fibres. Pertanika J. Sci. Technol. 2023, 31, 59–85. [Google Scholar] [CrossRef]

- TAPPI T 264 Cm-22; Preparation of Wood for Chemical Analysis. Technical Association of the Pulp and Paper Industry: Norcross, GA, USA, 2022.

- Browning, B.L. Methods of Wood Chemistry; Wiley-Interscience: New York, NY, USA, 1967; Volume 2. [Google Scholar]

- TAPPI T 222 Om-21; Acid-Insoluble Lignin in Wood and Pulp. Technical Association of the Pulp and Paper Industry: Norcross, GA, USA, 2021.

- BS EN 317:1993; Particleboards and Fibreboards—Determination of Swelling in Thickness After Immersion in Water. British Standards Institution: London, UK, 1993.

- BS EN 310:1993; Wood-Based Panels—Determination of Modulus of Elasticity in Bending and of Bending Strength. British Standards Institution: London, UK, 1993.

- BS EN 319:1993; Particleboards and Fibreboards—Determination of Tensile Strength Perpendicular to the Plane of the Board. British Standards Institution: London, UK, 1993.

- BS EN 312:2010; Particleboards—Specifications. British Standards Institution: London, UK, 2010.

- Khedari, J.; Nankongnab, N.; Hirunlabh, J.; Teekasap, S. New Low-Cost Insulation Particleboards from Mixture of Durian Peel and Coconut Coir. Build. Environ. 2004, 39, 59–65. [Google Scholar] [CrossRef]

- Jha, K.; Yahya, E.B.; Bairwan, R.D.; Sabri, M.; Abdul Khalil, H.P.S.; Ahmad, M.I.; Surya, I. Eco-Friendly Approach for Carboxymethyl Cellulose Isolation from Durian Peel Waste and Aerogel Scaffold Preparation. Nano-Struct. Nano-Objects 2024, 40, 101345. [Google Scholar] [CrossRef]

- Liese, W.; Tang, T.K.H. Properties of the Bamboo Culm. In Bamboo; Liese, W., Köhl, M., Eds.; Springer International Publishing: Cham, Switzerland, 2015; pp. 227–256. ISBN 978-3-319-14132-9. [Google Scholar]

- Chaowana, P.; Barbu, M.C. Bamboo: Potential Material for Biocomposites. In Lignocellulosic Fibre and Biomass-Based Composite Materials; Elsevier: Amsterdam, The Netherlands, 2017; pp. 259–289. ISBN 978-0-08-100959-8. [Google Scholar]

- Mai, C.; Zhang, K. Wood Chemistry. In Springer Handbook of Wood Science and Technology; Niemz, P., Teischinger, A., Sandberg, D., Eds.; Springer International Publishing: Cham, Switzerland, 2023; pp. 179–279. ISBN 978-3-030-81314-7. [Google Scholar]

- Niemz, P.; Mai, C.; Schmitt, U. Introduction to Wood Science. In Springer Handbook of Wood Science and Technology; Niemz, P., Teischinger, A., Sandberg, D., Eds.; Springer International Publishing: Cham, Switzerland, 2023; pp. 25–40. ISBN 978-3-030-81314-7. [Google Scholar]

- Klímek, P.; Meinlschmidt, P.; Wimmer, R.; Plinke, B.; Schirp, A. Using Sunflower (Helianthus annuus L.), Topinambour (Helianthus tuberosus L.) and Cup-Plant (Silphium perfoliatum L.) Stalks as Alternative Raw Materials for Particleboards. Ind. Crops Prod. 2016, 92, 157–164. [Google Scholar] [CrossRef]

- Bardak, S.; Nemli, G.; Tiryaki, S. The Influence of Raw Material Growth Region, Anatomical Structure and Chemical Composition of Wood on the Quality Properties of Particleboards. Maderas Cienc. Tecnol. 2017, 19, 363–372. [Google Scholar] [CrossRef]

- Boon, J.G.; Hashim, R.; Sulaiman, O.; Sugimoto, T.; Sato, M.; Salim, N.; Amini, M.H.M.; Nor Izaida, I.; Sitti Fatimah, M.R. Importance of Lignin on the Properties of Binderless Particleboard Made from Oil Palm Trunk. J. Eng. Appl. Sci. 2017, 12, 33–40. [Google Scholar]

- Liang, J.; Wu, J.; Xu, J. Low-Formaldehyde Emission Composite Particleboard Manufactured from Waste Chestnut Bur. J. Wood Sci. 2021, 67, 21. [Google Scholar] [CrossRef]

- Vitrone, F.; Ramos, D.; Ferrando, F.; Salvadó, J. Binderless Fiberboards for Sustainable Construction. Materials, Production Methods and Applications. J. Build. Eng. 2021, 44, 102625. [Google Scholar] [CrossRef]

- Hubbe, M.A.; Pizzi, A.; Zhang, H.; Halis, R. Critical Links Governing Performance of Self-Binding and Natural Binders for Hot-Pressed Reconstituted Lignocellulosic Board without Added Formaldehyde: A Review. BioResources 2017, 13, 2049–2115. [Google Scholar] [CrossRef]

- Iswanto, A.H.; Aritonang, W.; Azhar, I.; Supriyanto; Fatriasari, W. The Physical, Mechanical and Durability Properties of Sorghum Bagasse Particleboard by Layering Surface Treatment. J. Indian Acad. Wood Sci. 2017, 14, 1–8. [Google Scholar] [CrossRef]

| Factors | Ranges of Actual and Coded Values | ||||

|---|---|---|---|---|---|

| −α | −1 | 0 | +1 | +α | |

| Durian husk ratio (DHR, %) | 4 | 10 | 25 | 40 | 46 |

| UF resin ratio (UFR, %) | 7 | 8 | 11.5 | 15 | 16 |

| Component | Durian Husk in This Study | Durian Husk [41,42] | Bamboo [43,44] |

|---|---|---|---|

| Holocellulose | 72.84 (0.89) | 65.3–73.54 | 62.5–79.9 |

| Lignin | 15.92 (0.56) | 15.45–18.7 | 20.5–32.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tang, T.K.H.; Nguyen, N.Q. Investigation of Particleboard Production from Durian Husk and Bamboo Waste. J. Compos. Sci. 2025, 9, 276. https://doi.org/10.3390/jcs9060276

Tang TKH, Nguyen NQ. Investigation of Particleboard Production from Durian Husk and Bamboo Waste. Journal of Composites Science. 2025; 9(6):276. https://doi.org/10.3390/jcs9060276

Chicago/Turabian StyleTang, Thi Kim Hong, and Nhat Quang Nguyen. 2025. "Investigation of Particleboard Production from Durian Husk and Bamboo Waste" Journal of Composites Science 9, no. 6: 276. https://doi.org/10.3390/jcs9060276

APA StyleTang, T. K. H., & Nguyen, N. Q. (2025). Investigation of Particleboard Production from Durian Husk and Bamboo Waste. Journal of Composites Science, 9(6), 276. https://doi.org/10.3390/jcs9060276