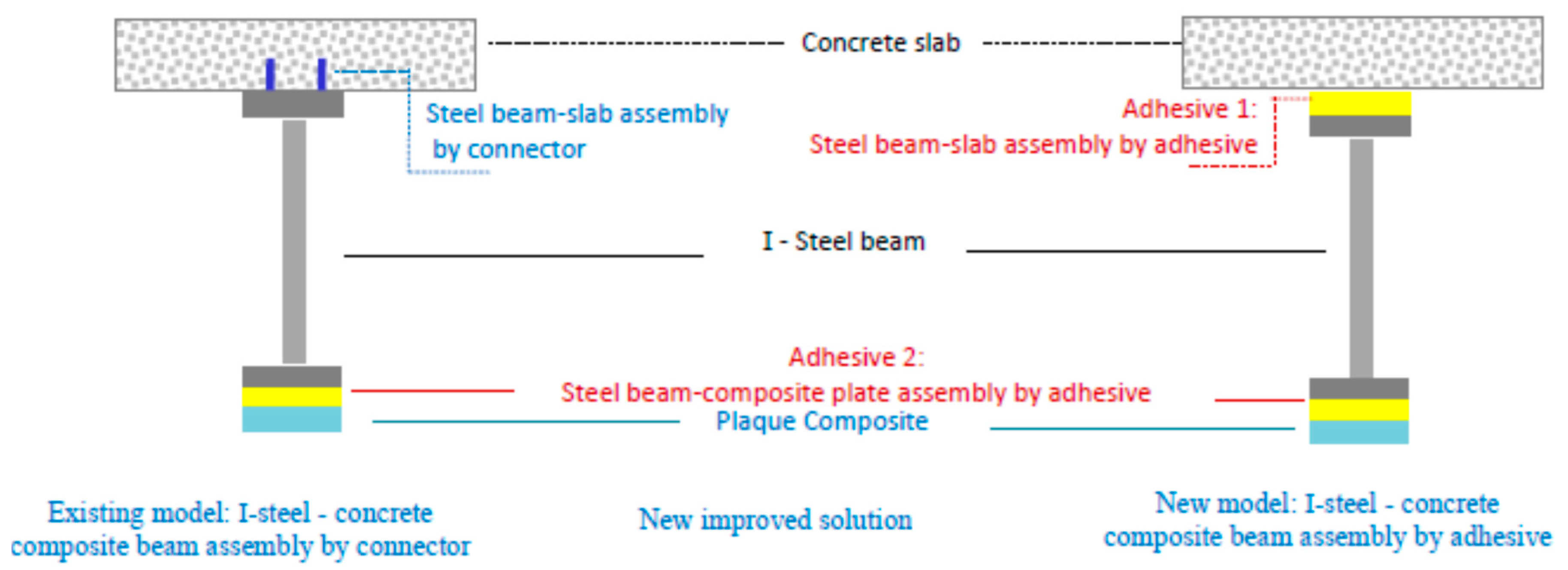

Analysis of Interface Sliding in a Composite I-Steel–Concrete Beam Reinforced by a Composite Material Plate: The Effect of Concrete–Steel Connection Modes

Abstract

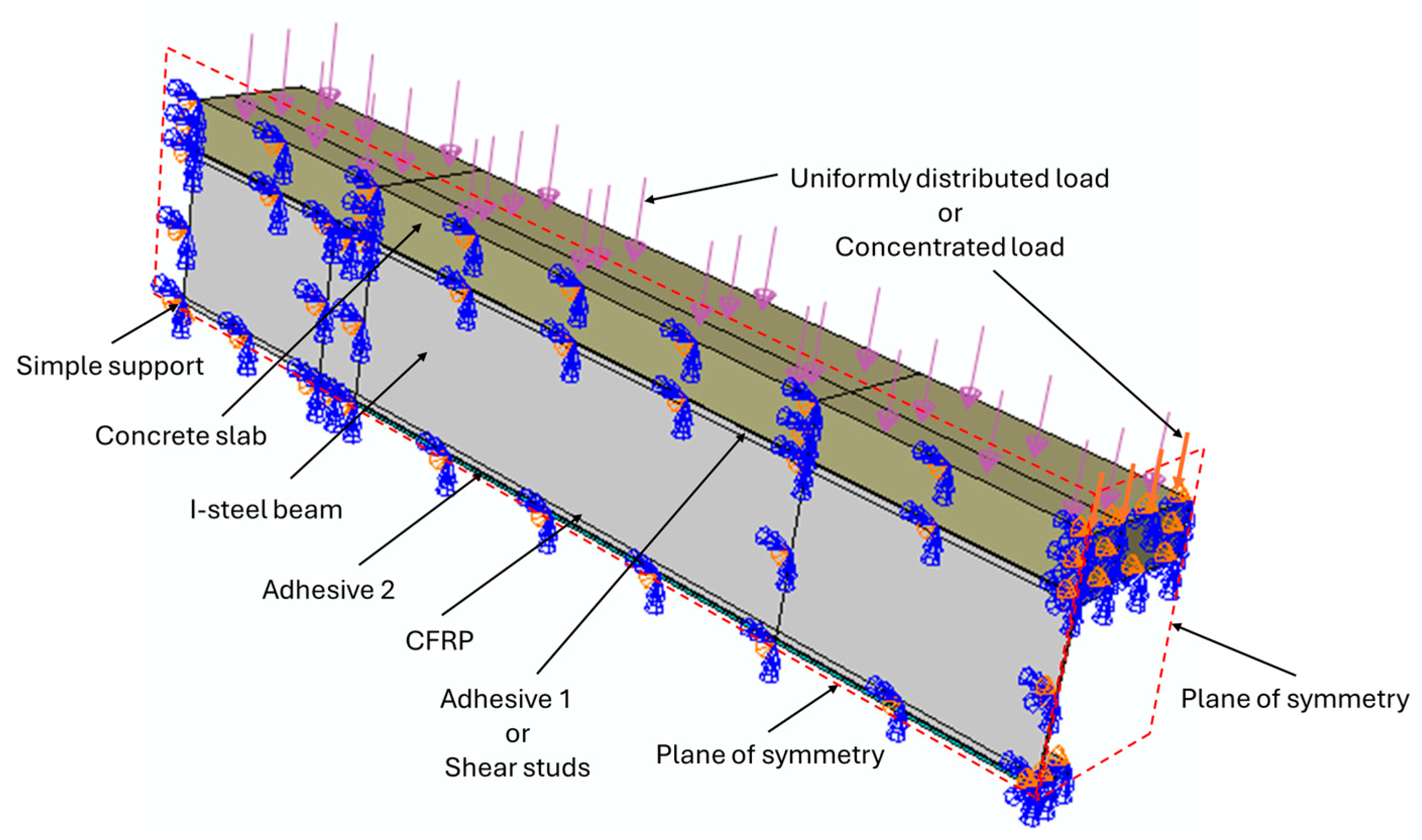

1. Introduction

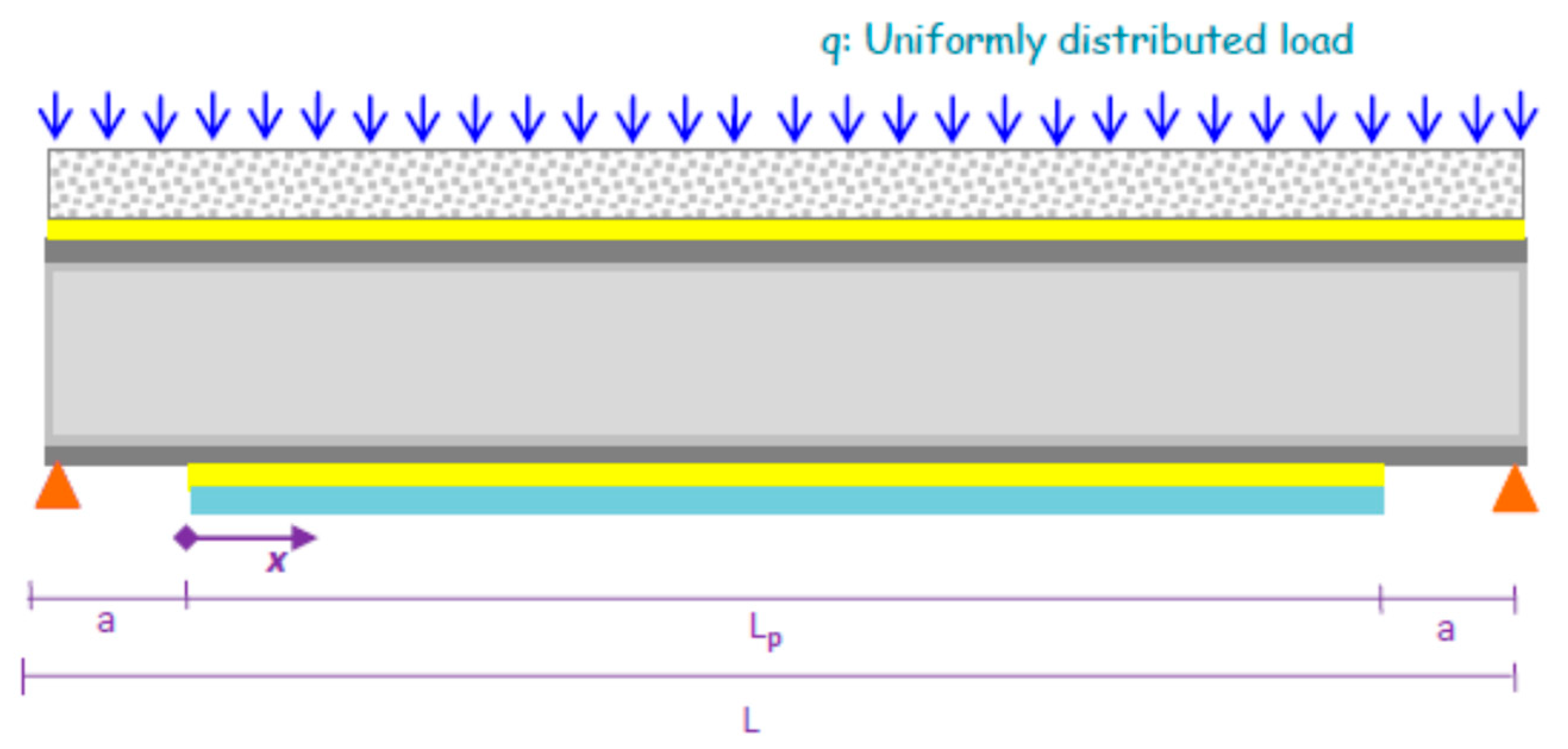

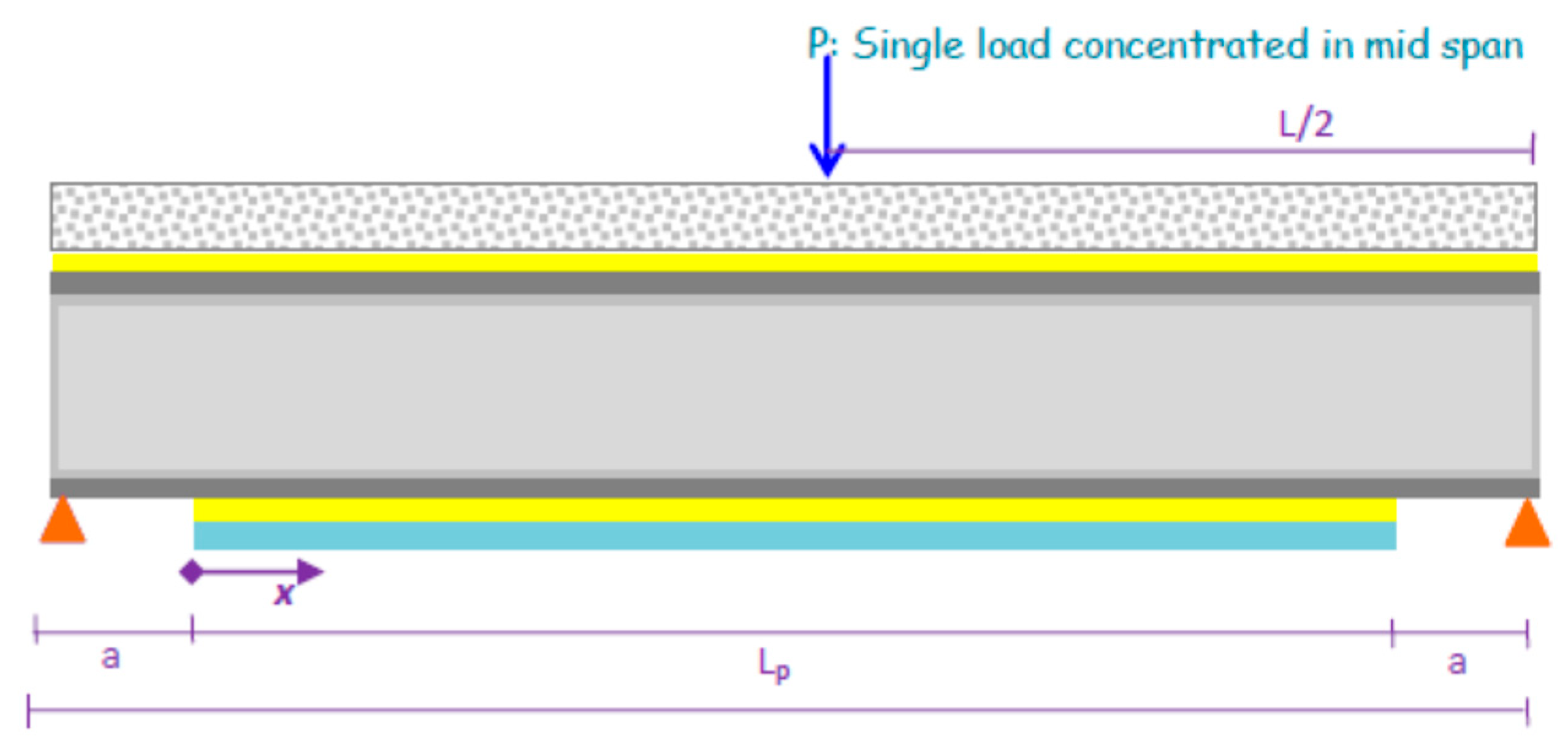

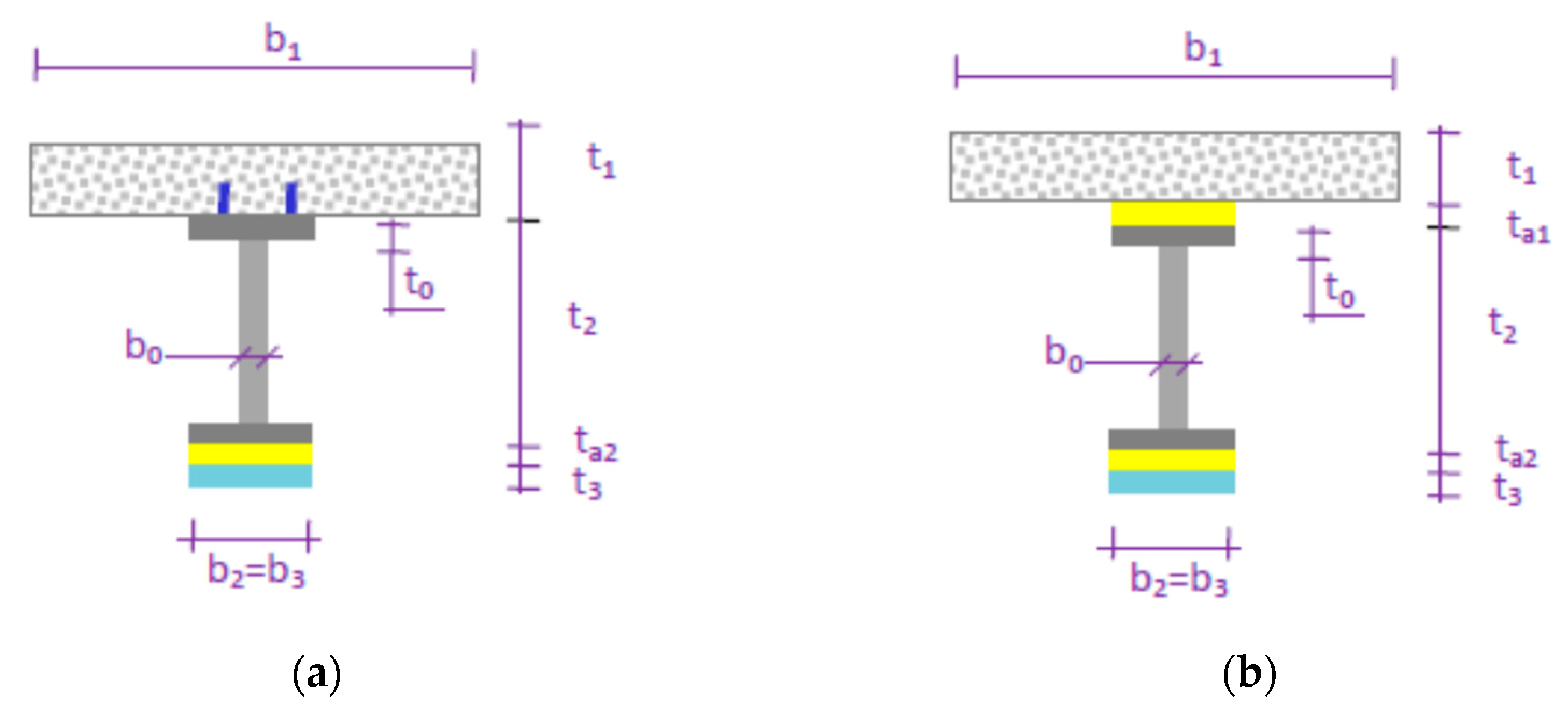

2. Solution Method

- -

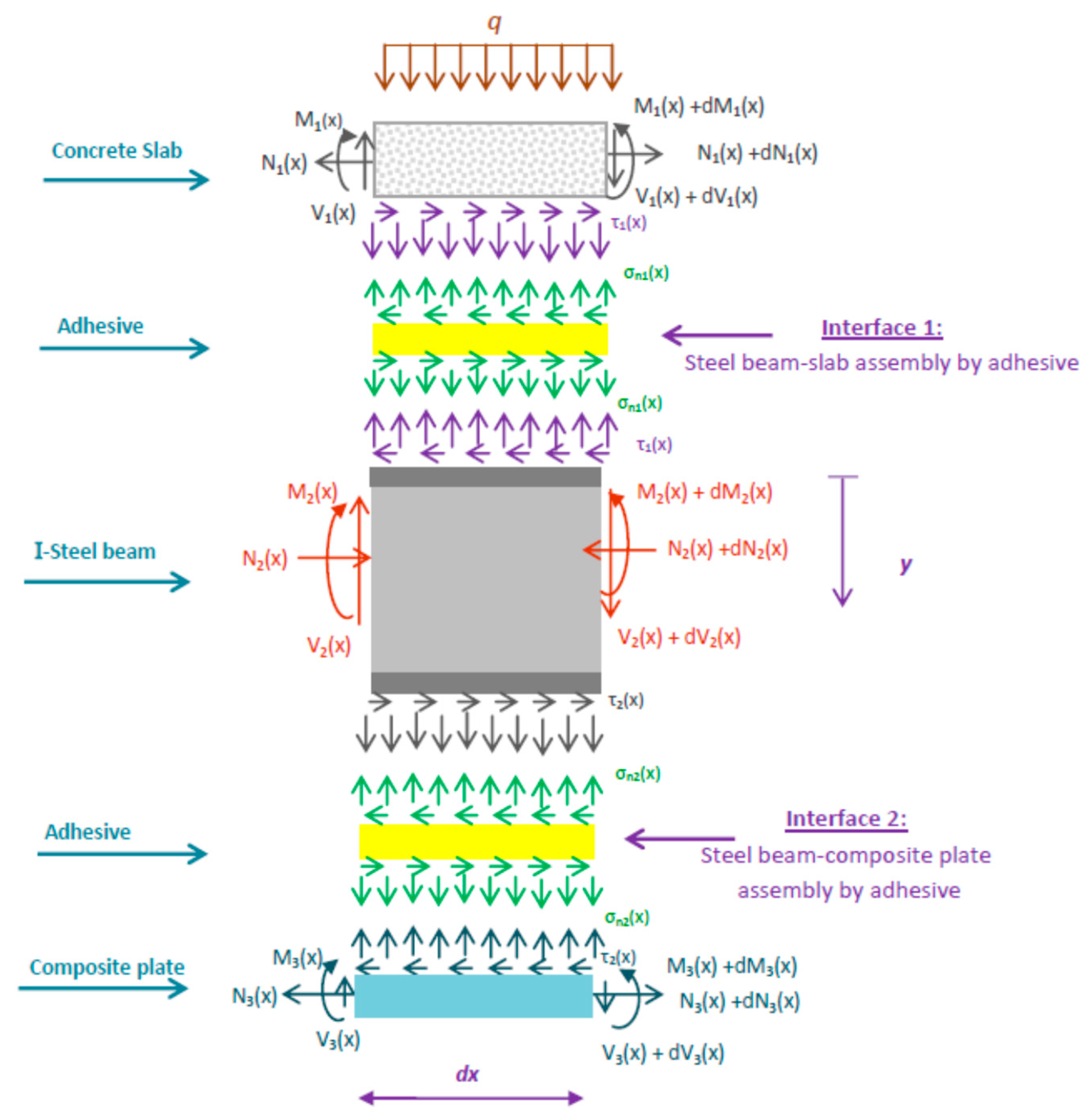

- The formulation of the underlying assumptions and development of the static equilibrium model for the composite system.

- -

- The derivation of internal force expressions within an infinitesimal beam element , facilitating the analysis of load transfer mechanisms across the steel–concrete interface.

- -

- The mathematical modeling of axial strain distributions in both the steel section and concrete slab, accounting for differential deformation under applied loads.

- -

- The determination of shear stress distributions along the interface, derived from relative displacements between the bonded materials.

- -

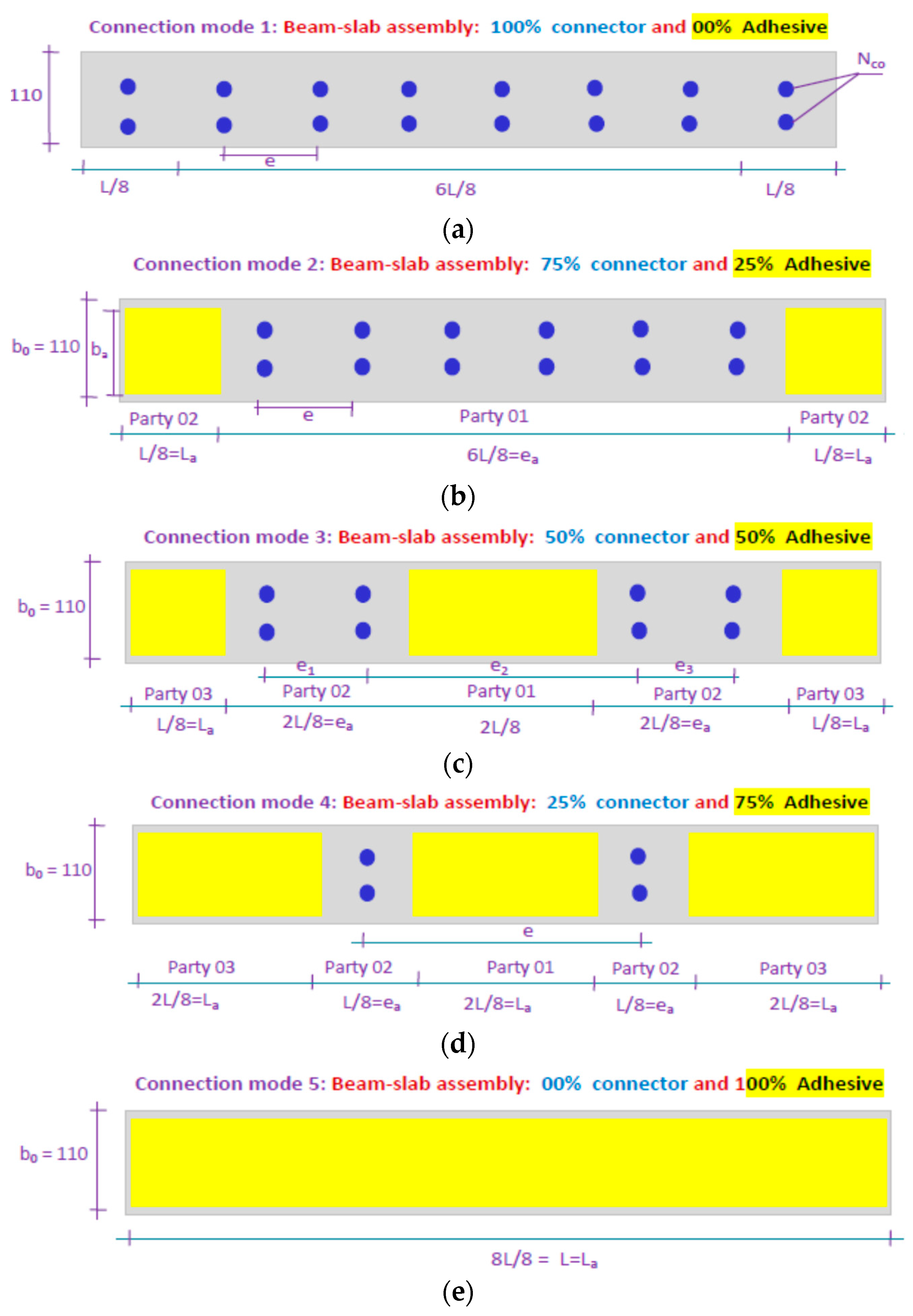

- The quantification of interfacial stresses and slip as functions of the connection strategy—whether through mechanical shear connectors, structural adhesive bonding, or a hybrid of both.

- -

- The development of a finite element simulation methodology to validate the analytical model and extend its applicability to various composite configurations and material systems.

2.1. Assumptions

- -

- The adhesive’s bending deformations are not considered.

- -

- The composite–steel bond interface (Interface 2) is secure, but there is a slip between the concrete slab and the steel beam (Interface 1).

- -

- The materials considered are linear and elastic.

- -

- The beam is supported and shallow, ensuring that plane sections remain planar during bending.

- -

- The adhesive layer’s stress remains constant through the thickness.

- -

- The shear stress analysis supposes equal curvatures between the beam and plate, but the peel stress solution does not. Loading causes vertical separation between the steel beam and composite plate, resulting in interfacial normal stress in the adhesive layer.

- -

- The parabolic shear stress distribution is assumed through the depth of both the composite steel–concrete beam and the connected plate.

2.2. Internal Forces in the Interfaces

- -

- Index “1” corresponds to the first adherent “concrete slab”.

- -

- Index “2” corresponds to the second adherent “steel beam”.

- -

- Index “3” corresponds to the third adherent “composite reinforcement plate”.

2.3. Longitudinal Strains

2.4. Shear Stresses

2.4.1. Case 1: Interface Shear Stress Distribution with Only Connectors or Adhesive

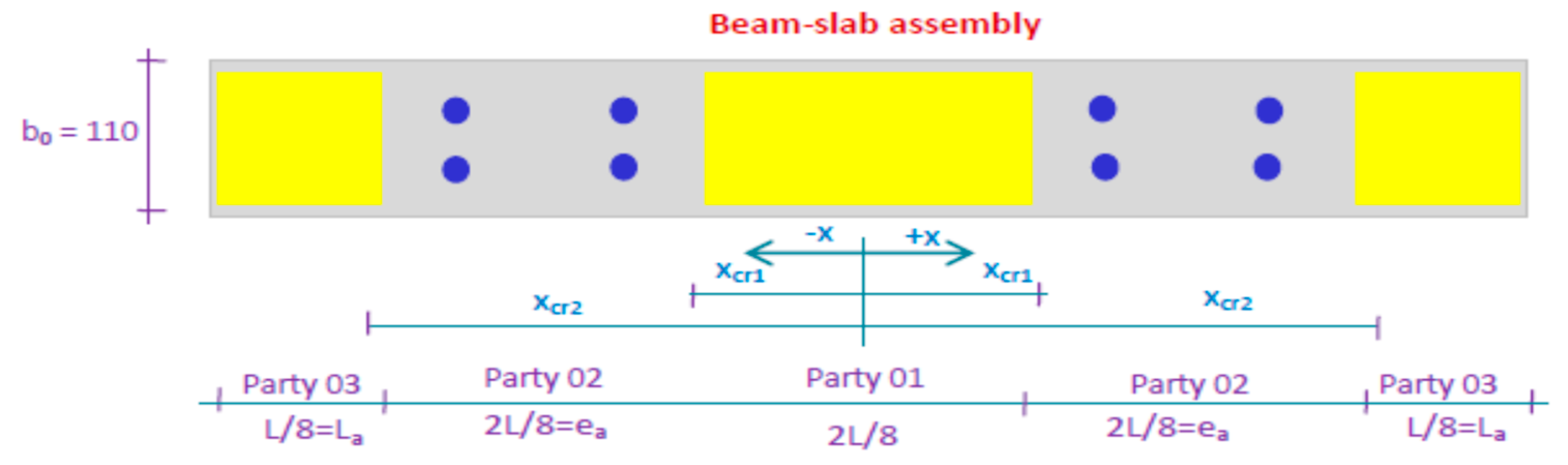

2.4.2. Case 2: Interface Shear Stress Distribution with Both Connectors and Adhesives

2.5. Finite Element Simulation Method

3. Results and Discussion

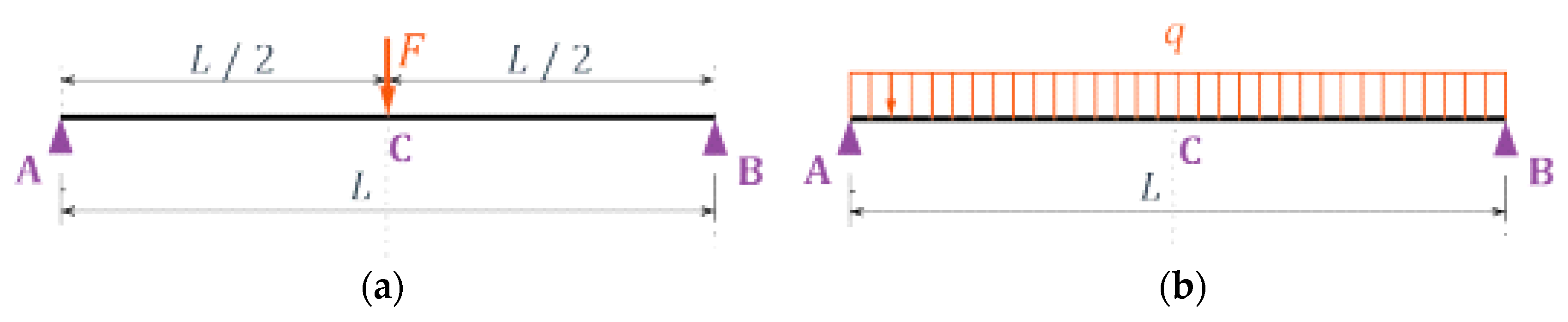

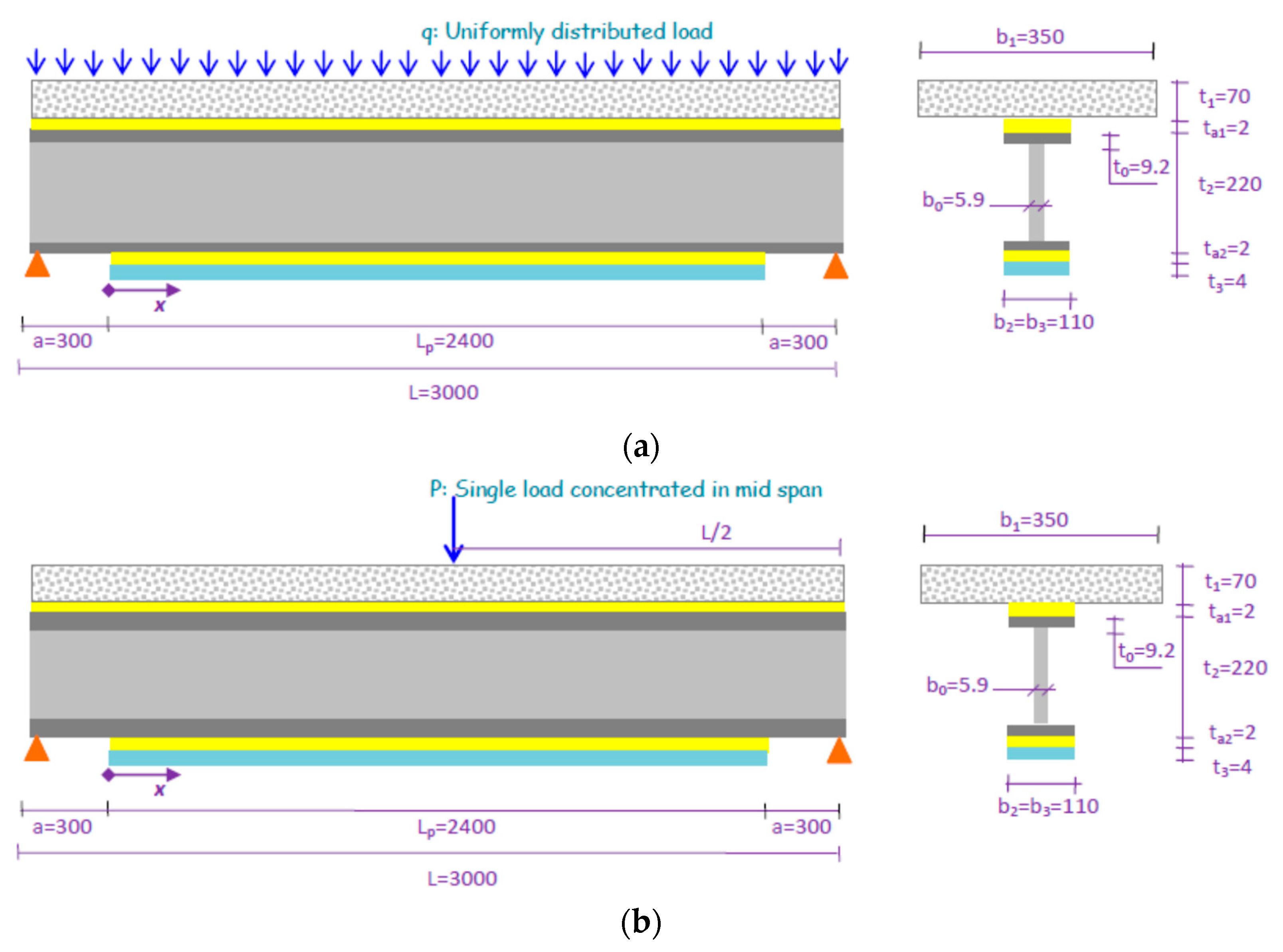

3.1. Material and Geometry Data

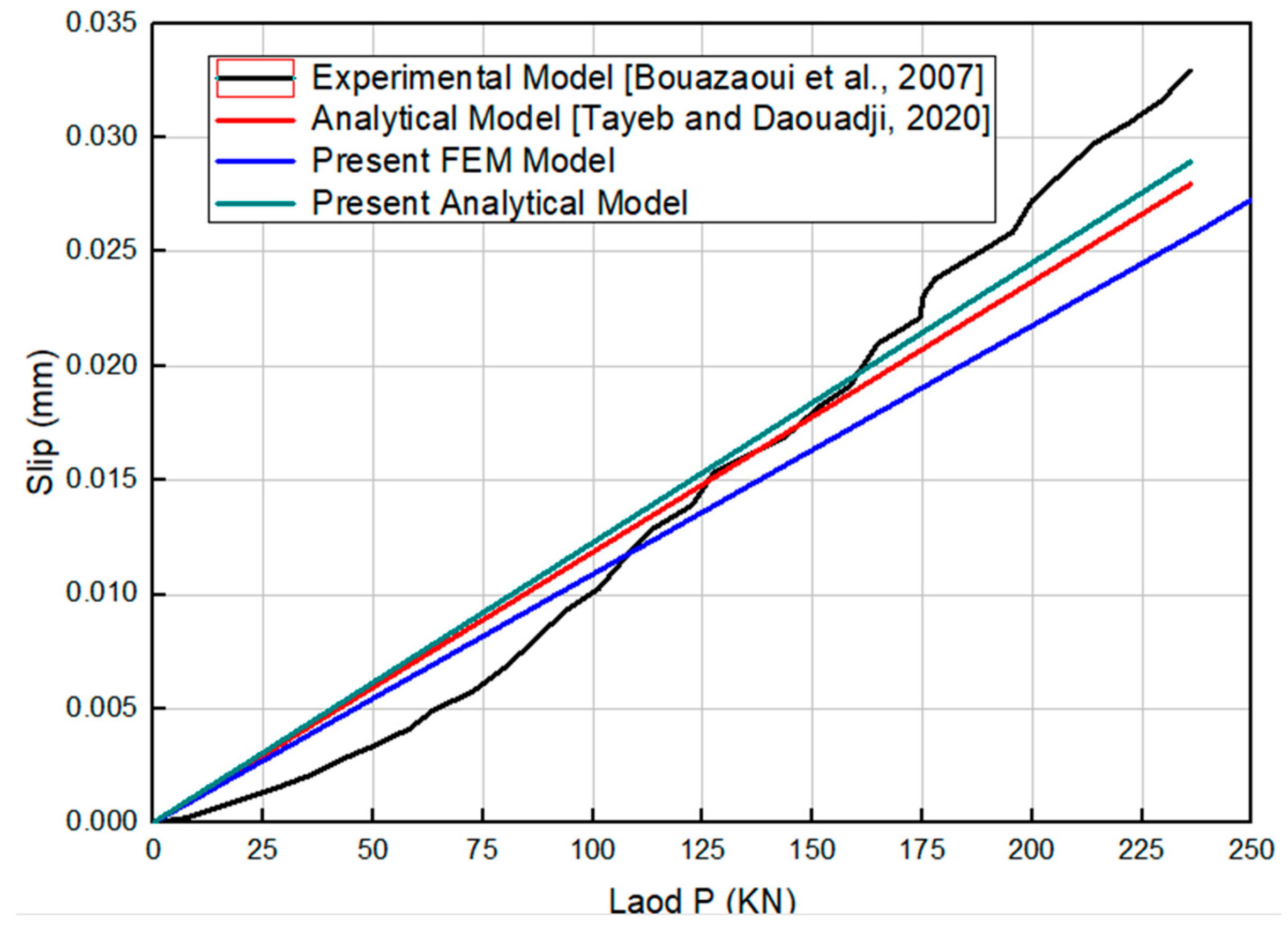

3.2. Validation of the Model by Comparison with Existing Solutions

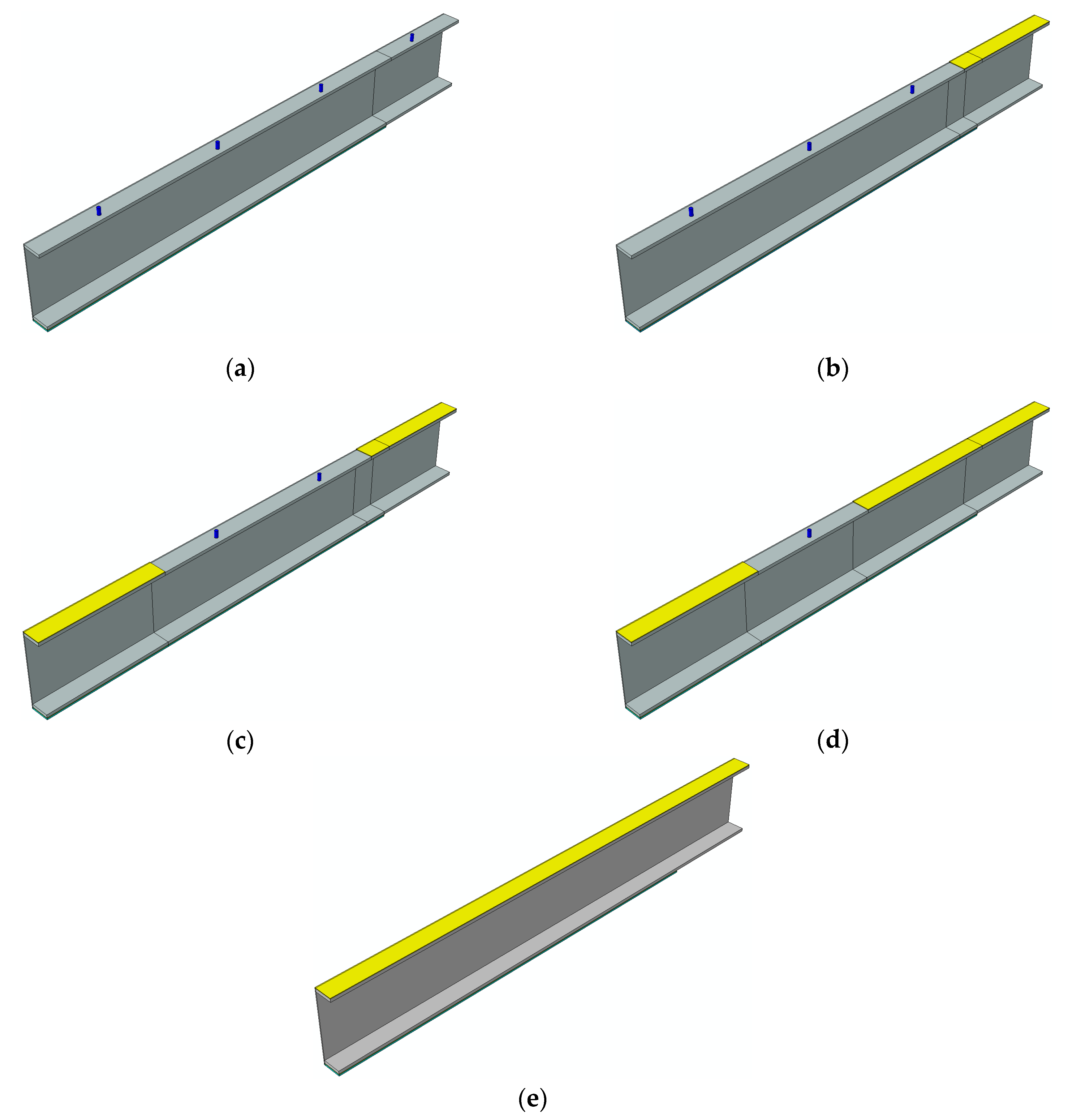

3.3. Finite Element Analysis Results for Hybrid Connection Modes

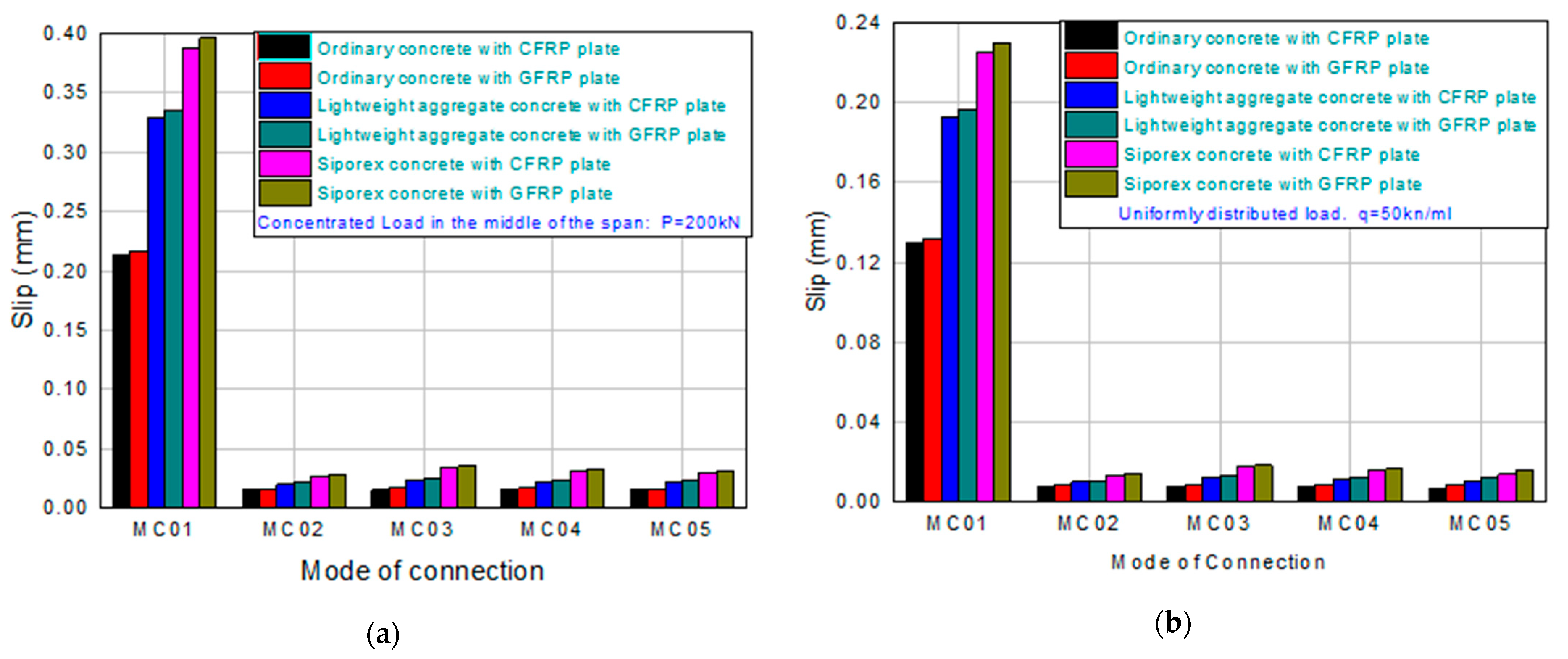

3.4. Comparison of Analytical Model with Finite Element (FEM) Results

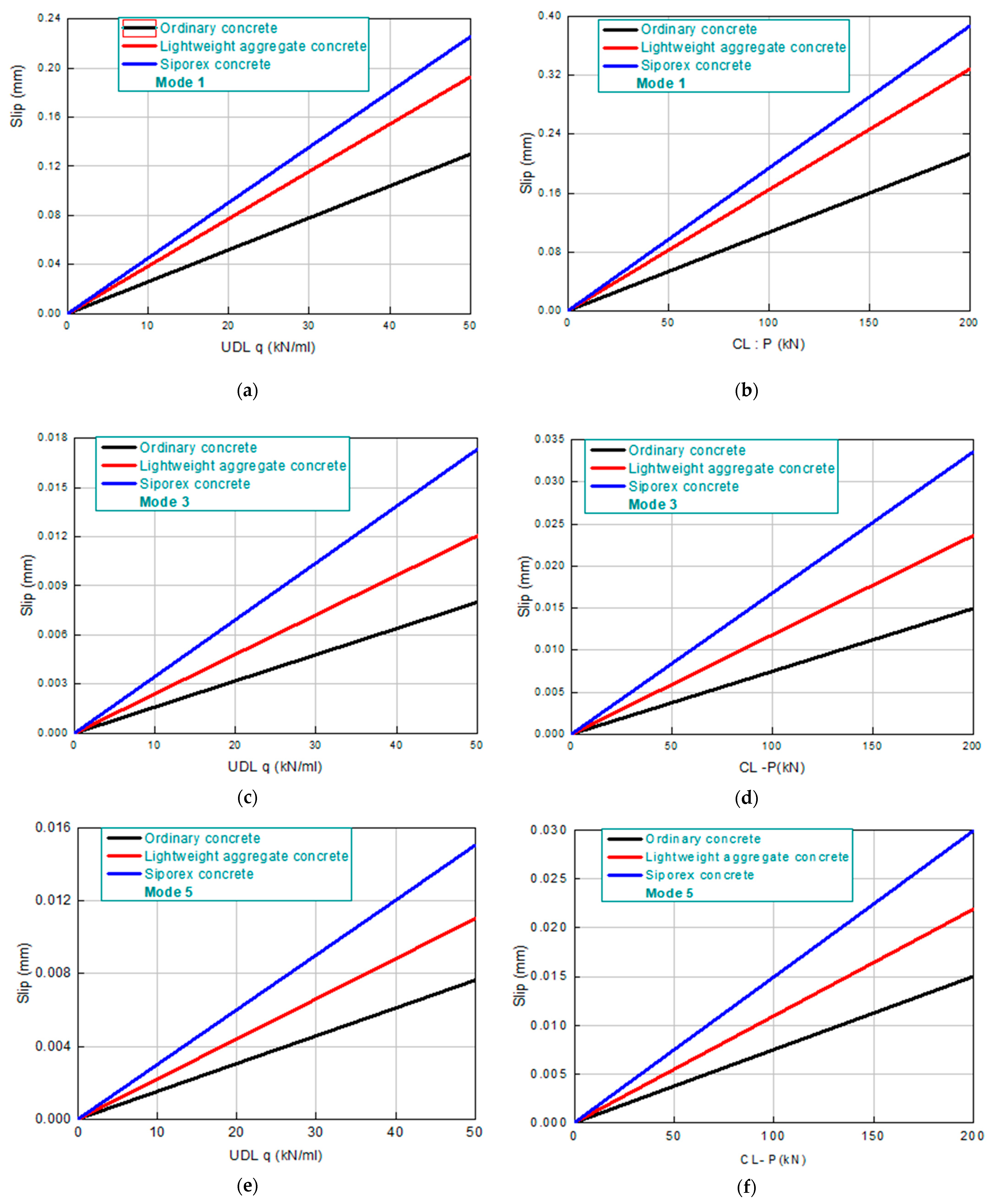

3.5. The Effect of the Type of the Composite Reinforcement and Connection Mode on the Interface Slippage

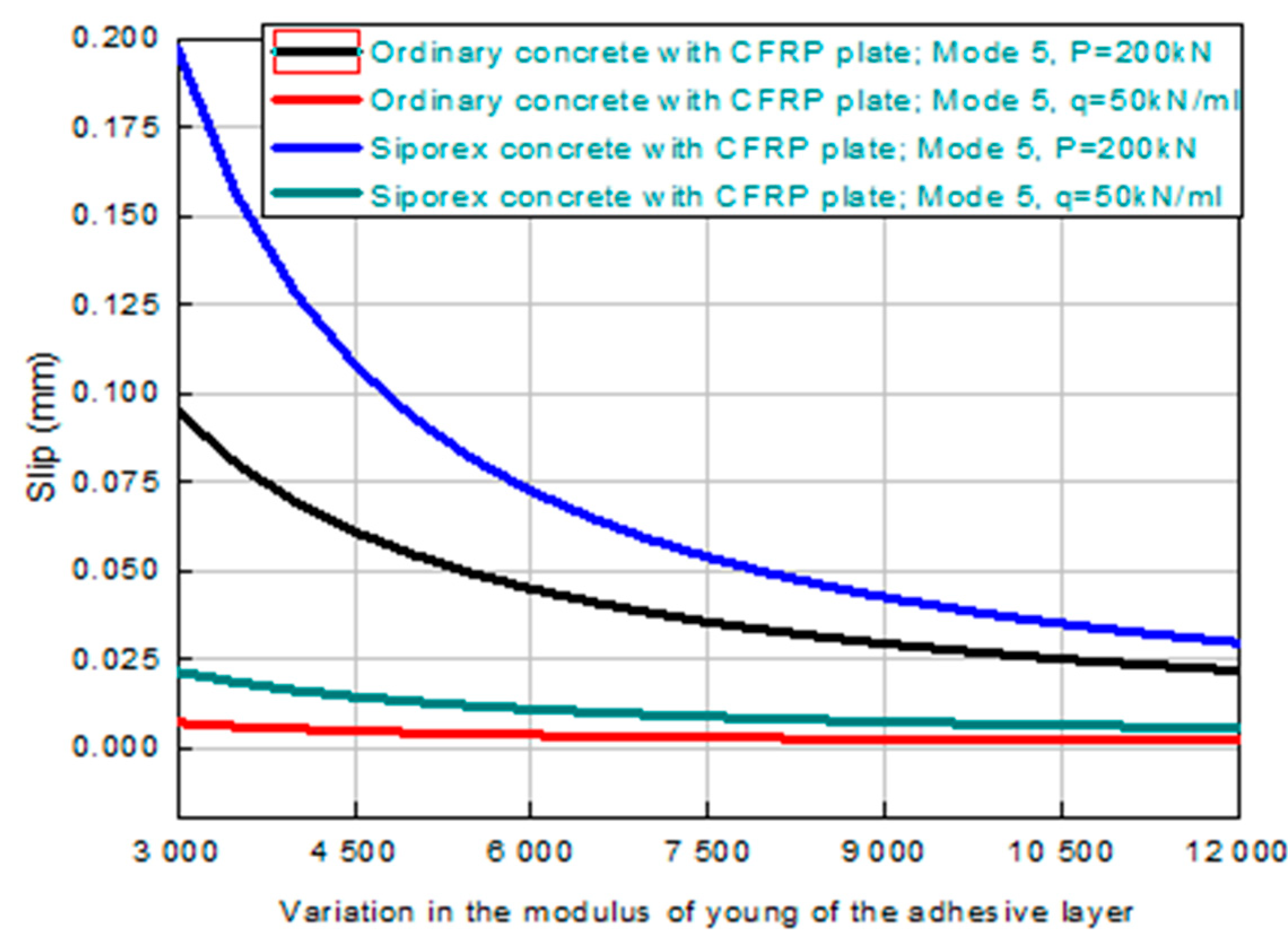

3.6. The Effect of Young’s Modulus for the Adhesive Layer on Interface Slippage

4. Conclusions

- -

- The degree of interaction between the steel and concrete, controlled by the shear stiffness of the interface, is critical to the performance of composite systems.

- -

- Adhesively bonded connections significantly reduce the interface slip compared to mechanical connectors. The adhesive-only configuration (mode 5) consistently showed the least slippage, while mechanical-only connections (mode 1) exhibited the highest slippage, highlighting the effectiveness of continuous bonding in improving stress transfer and reducing shear lag.

- -

- The proposed closed-form analytical model, based on the nonlinear beam theory, was validated against finite element simulations with discrepancies between 0.3% and 10.7%. The model accommodates various loading conditions and material properties, offering practical utility for structural design.

- -

- Parametric studies demonstrated that higher adhesive stiffness and CFRP reinforcement reduce interface slippage, especially in beams with low-stiffness concrete (e.g., Siporex), thereby improving composite action and load distribution.

- -

- The model provides a reliable framework for selecting adhesive properties and reinforcement types, making it a useful tool for the design and retrofitting of bonded composite structures, particularly in structural rehabilitation contexts.

- -

- The analytical model assumes ideal bonding conditions, and the adhesive layer’s stress remains constant throughout the thickness, which may not fully capture localized nonlinearities.

- -

- Long-term effects, such as creep, shrinkage, and environmental aging, were not considered.

- -

- This study is limited to static loading conditions and simply supported beam configurations.

- -

- Time-dependent and environmental effects, including temperature sensitivity, adhesive degradation, and durability under moisture.

- -

- Extended geometries and boundary conditions, including continuous spans, fixed supports, and different cross-section shapes.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Larrinaga, P.; Garmendia, L.; Piñero, I.; San-José, J.T. Flexural strengthening of low-grade reinforced concrete beams with compatible composite material: Steel Reinforced Grout (SRG). Constr. Build. Mater. 2020, 235, 117790. [Google Scholar] [CrossRef]

- Cai, M.; Li, W.; Wan, Z.; Sheng, J.; Tan, J.; Ma, C. Cracking control technique for continuous steel-concrete composite girders under negative bending moment. Arch. Civ. Eng. 2023, 69, 239–251. [Google Scholar] [CrossRef]

- Lin, W.; Lam, H.; Yoda, T. Experimental study on steel–concrete composite twin I-girder bridges. J. Bridge Eng. 2020, 25, 04019129. [Google Scholar] [CrossRef]

- Benrahou, K.H.; Ameur, M.; Tounsi, A.; Benyoucef, S.; Bedia, E.A. Influence of Adhesive Characteristics on the Interfacial Stress Concentrations in Externally FRP Plated Steel Beams. Compos. Interfaces 2010, 17, 283–300. [Google Scholar] [CrossRef]

- He, S.; Xu, Y.; Zhong, H.; Mosallam, A.S.; Chen, Z. Investigation on interfacial anti-sliding behavior of high strength steel-UHPC composite beams. Compos. Struct. 2023, 316, 117036. [Google Scholar] [CrossRef]

- Wang, Y.H.; Yu, J.; Liu, J.P.; Zhou, B.X.; Chen, Y.F. Experimental study on assembled monolithic steel-prestressed concrete composite beam in negative moment. J. Constr. Steel Res. 2020, 167, 105667. [Google Scholar] [CrossRef]

- Tounsi, A.; Daouadji, T.H.; Benyoucef, S. Interfacial stresses in FRP-plated RC beams: Effect of adherend shear deformations. Int. J. Adhes. Adhes. 2009, 29, 343–351. [Google Scholar] [CrossRef]

- Henriques, D.; Gonçalves, R.; Sousa, C.; Camotim, D. GBT-based time-dependent analysis of steel-concrete composite beams including shear lag and concrete cracking effects. Thin-Walled Struct. 2020, 150, 106706. [Google Scholar] [CrossRef]

- Tayeb, B.; Daouadji, T.H.; Abderezak, R.; Tounsi, A. Structural bonding for civil engineering structures: New model of composite I-steel-concrete beam strengthened with CFRP plate. Steel Compos. Struct. 2021, 41, 417–435. [Google Scholar] [CrossRef]

- Daouadji, T.H.; Abderezak, R.; Rabia, B. Analysis of mechanical performance of continuous steel beams with variable section bonded by a prestressed composite plate. Steel Compos. Struct. 2024, 50, 183–199. [Google Scholar] [CrossRef]

- Chergui, S.; Daouadji, T.H.; Hamrat, M.; Boulekbache, B.; Bougara, A.; Abbes, B.; Amziane, S. Interfacial stresses in damaged RC beams strengthened by externally bonded prestressed GFRP laminate plate: Analytical and numerical study. Adv. Mater. Res. 2019, 8, 197–217. [Google Scholar] [CrossRef]

- Rabia, B.; Abderezak, R.; Daouadji, T.H.; Abbes, B.; Belkacem, A.; Abbes, F. Analytical analysis of the interfacial shear stress in RC beams strengthened with prestressed exponentially-varying properties plate. Adv. Mater. Res. 2018, 7, 29. [Google Scholar] [CrossRef]

- Abderezak, R.; Rabia, B.; Daouadji, T.H.; Abbes, B.; Belkacem, A.; Abbes, F. Elastic analysis of interfacial stresses in prestressed PFGM-RC hybrid beams. Adv. Mater. Res. 2018, 7, 83. [Google Scholar] [CrossRef]

- Oehlers, D.J.; Coughlan, C.G. The shear stiffness of stud shear connections in composite beams. J. Constr. Steel Res. 1986, 6, 273–284. [Google Scholar] [CrossRef]

- Silva, A.R.; das Neves, F.D.A.; Junior, J.B.S. Optimization of partially connected composite beams using nonlinear programming. Structures 2020, 25, 743–759. [Google Scholar] [CrossRef]

- Lavall, A.C.C.; Silva, R.D.; Costa, R.S.; Fakury, R.H. Análise avançada de pórticos de aço conforme as prescrições da ABNT NBR 8800: 2008. Rev. Estrut. Aço 2013, 2, 146–165. [Google Scholar]

- Simulia. Abaqus Documentations; Dassault Systemes: Vélizy-Villacoublay, France, 2019. [Google Scholar]

- Tayeb, B.; Daouadji, T.H. Improved analytical solution for slip and interfacial stress in composite steel-concrete beam bonded with an adhesive. Adv. Mater. Res. 2020, 9, 133–153. [Google Scholar] [CrossRef]

- Bouazaoui, L.; Perrenot, G.; Delmas, Y.; Li, A. Experimental study of bonded steel concrete composite structures. J. Constr. Steel Res. 2007, 63, 1268–1278. [Google Scholar] [CrossRef]

- Souici, A.; Berthet, J.F.; Li, A.; Rahal, N. Behaviour of both mechanically connected and bonded steel–concrete composite beams. Eng. Struct. 2013, 49, 11–23. [Google Scholar] [CrossRef]

- Li, A.; Yurtdas, I.; Abbès, B. Creep in steel-concrete composite beams bonded by adhesive and connected by studs. Structures 2025, 74, 108560. [Google Scholar] [CrossRef]

| Materials | Young’s Modulus (MPa) | Poisson Ratio | |

|---|---|---|---|

| Concrete slab | Ordinary concrete | ||

| Siporex concrete | |||

| Lightweight aggregate concrete | |||

| Adhesives | Adhesive 1 (between concrete slab and steel beam) | ||

| Adhesive 2 (between steel beam and composite plate) | |||

| Composites | CFRP | ||

| GFRP | |||

| IPE 220 beam | Steel | ||

| Concrete | Solution | Mode 1 | Mode 2 | Mode 3 | Mode 4 | Mode 5 |

|---|---|---|---|---|---|---|

| Ordinary | FEM | 0.2129 | 0.0150 | 0.0149 | 0.0155 | 0.0150 |

| Analytical | 0.2091 | 0.0134 | 0.0143 | 0.0150 | 0.0146 | |

| Lightweight aggregate | FEM | 0.3286 | 0.0201 | 0.0236 | 0.0223 | 0.0219 |

| Analytical | 0.3230 | 0.0190 | 0.0213 | 0.0213 | 0.0211 | |

| Siporex | FEM | 0.3870 | 0.0268 | 0.0336 | 0.0310 | 0.0299 |

| Analytical | 0.3833 | 0.0262 | 0.0310 | 0.0304 | 0.0296 |

| Concrete | Solution | Mode 1 | Mode 2 | Mode 3 | Mode 4 | Mode 5 |

|---|---|---|---|---|---|---|

| Ordinary | FEM | 0.1298 | 0.0077 | 0.0080 | 0.0080 | 0.0070 |

| Analytical | 0.1294 | 0.0075 | 0.0078 | 0.0078 | 0.0063 | |

| Lightweight aggregate | FEM | 0.1926 | 0.0099 | 0.0120 | 0.0112 | 0.0100 |

| Analytical | 0.1904 | 0.0095 | 0.0119 | 0.0110 | 0.0099 | |

| Siporex | FEM | 0.2253 | 0.0131 | 0.0173 | 0.0155 | 0.0137 |

| Analytical | 0.2200 | 0.0129 | 0.0171 | 0.0153 | 0.0129 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Daouadji, T.H.; Abbès, B.; Bensatallah, T.; Abbès, F. Analysis of Interface Sliding in a Composite I-Steel–Concrete Beam Reinforced by a Composite Material Plate: The Effect of Concrete–Steel Connection Modes. J. Compos. Sci. 2025, 9, 273. https://doi.org/10.3390/jcs9060273

Daouadji TH, Abbès B, Bensatallah T, Abbès F. Analysis of Interface Sliding in a Composite I-Steel–Concrete Beam Reinforced by a Composite Material Plate: The Effect of Concrete–Steel Connection Modes. Journal of Composites Science. 2025; 9(6):273. https://doi.org/10.3390/jcs9060273

Chicago/Turabian StyleDaouadji, Tahar Hassaine, Boussad Abbès, Tayeb Bensatallah, and Fazilay Abbès. 2025. "Analysis of Interface Sliding in a Composite I-Steel–Concrete Beam Reinforced by a Composite Material Plate: The Effect of Concrete–Steel Connection Modes" Journal of Composites Science 9, no. 6: 273. https://doi.org/10.3390/jcs9060273

APA StyleDaouadji, T. H., Abbès, B., Bensatallah, T., & Abbès, F. (2025). Analysis of Interface Sliding in a Composite I-Steel–Concrete Beam Reinforced by a Composite Material Plate: The Effect of Concrete–Steel Connection Modes. Journal of Composites Science, 9(6), 273. https://doi.org/10.3390/jcs9060273