Computational Approach for Optimizing Resin Flow Behavior in Resin Transfer Molding with Variations in Injection Pressure, Fiber Permeability, and Resin Sorption

Abstract

1. Introduction

2. Background Study

2.1. RTM and Radial Flow Behavior

2.2. The Role of Resin Properties in RTM

2.3. Effect of Resin Sorption on Flow Dynamics

3. Materials and Method

3.1. Materials

3.1.1. Resin System

3.1.2. Fibrous Reinforcement

3.1.3. Resin Injection Process

3.2. Numerical Modeling Approach and Governing Equations for Radial Resin Injection in RTM

3.2.1. Mass Conservation Equation

3.2.2. Darcy’s Law for Fluid Flow in Porous Media

3.2.3. Incorporation of Resin Sorption Effects

3.2.4. Solution of Governing Equations

Pressure Distribution

Velocity of Resin Flow

Flow-Front Position over Time

Total Resin Volume Injected Considering Radial Flow Dynamics

Analytical Estimation of Mold Filling Time Based on Permeability and Pressure Gradients

3.2.5. Theoretical Case

Pressure Field

Velocity Field

Flow-Front Position

3.2.6. Experimental Case

Injection Pressure as a Function of Time

4. Results and Discussion

4.1. Derivation of Mass Conservation Equation

4.1.1. Darcy’s Law for Radial Resin Flow

4.1.2. Derivation of Pressure Distribution

4.1.3. Radial Velocity of Resin

4.1.4. Derivation of Flow-Front Position over Time

4.1.5. Total Resin Volume Injected Based on Flow Front Advancement

4.1.6. Integral Formulation for Injection Time Considering Logarithmic Flow Behavior

4.1.7. Validation Equations

4.2. Pressure Distribution and Flow-Front Propagation

4.3. Flow-Front Progression and Its Dependence on Injection Pressure and Radius

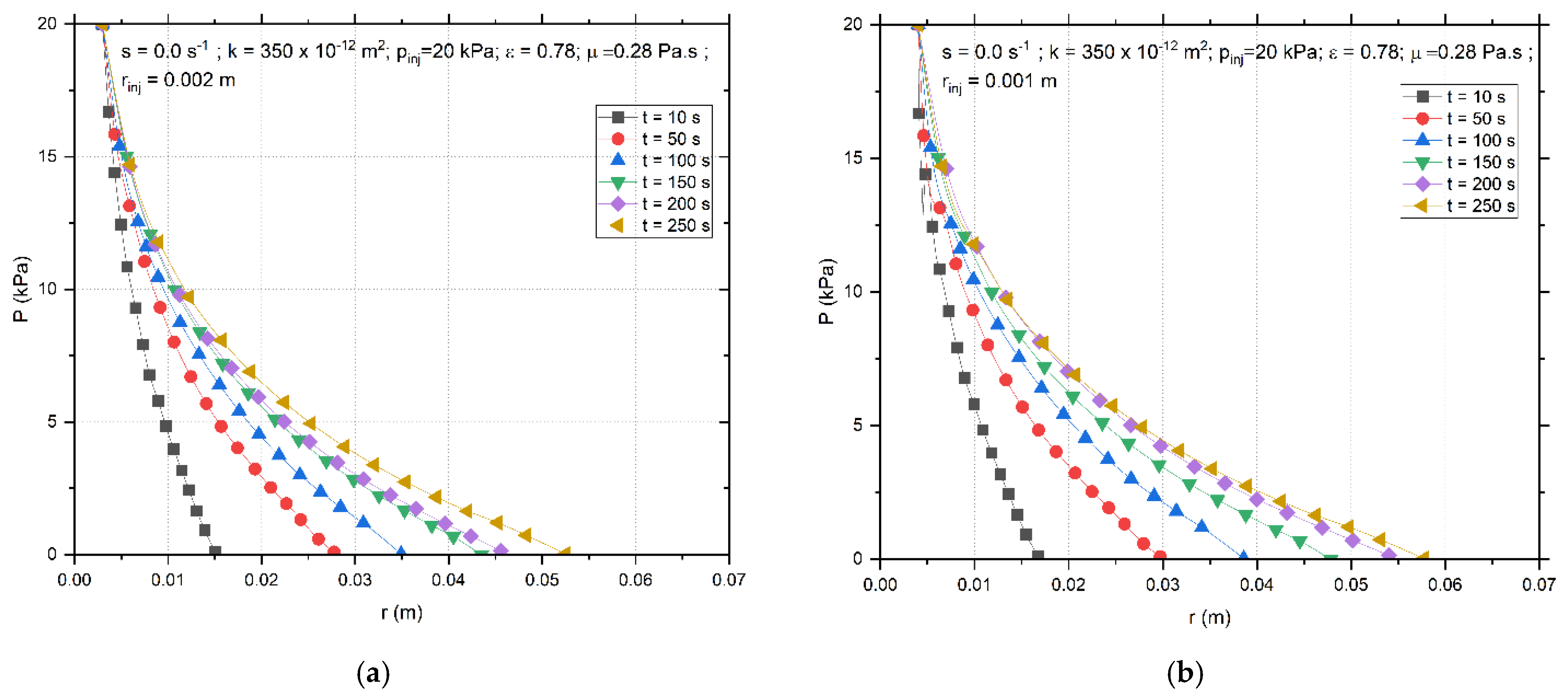

4.4. Transient Pressure Behavior for Different Injection Radii and Impact of Injection Radius on Flow Front and Velocity

4.5. Impact of Permeability on Pressure, Flow Front, and Velocity

4.6. Effect of Sorption on Pressure Distribution, Flow-Front Progression, and Velocity Evolution

4.7. Impact of Porosity on Pressure Distribution, Flow-Front Progression, and Velocity Evolution

4.8. Effect of Resin Viscosity on Pressure Distribution, Flow-Front Progression, and Velocity Evolution

5. Conclusions

- Injection Pressure Influence:

- Higher injection pressure (15 kPa to 25 kPa) significantly accelerates resin infiltration.

- At 250 s, the flow front reached 0.056 m at 15 kPa, 0.062 m at 20 kPa, and 0.068 m at 25 kPa, confirming the enhanced penetration at higher pressures.

- A 30% increase in the infiltration depth was observed as the pressure increased from 15 kPa to 25 kPa.

- Effect of Injection Radius:

- A larger injection radius (0.001 m to 0.003 m) improved radial flow.

- The flow-front position increased by ~20% at 250 s, demonstrating that a larger injection area enhanced the uniform resin distribution.

- The velocity decay was sharper for smaller injection radii, leading to a higher resistance and slower filling times.

- Permeability and Resin Sorption Effects:

- A 100× reduction in permeability (from 350 × 10−12 m2 to 0.035 × 10−12 m2) caused a 75% decrease in the resin infiltration rate, confirming the crucial role of permeability in the mold filling efficiency.

- Increased resin sorption rates (5 × 10−4 s−1 to 10 × 10−4 s−1) led to reduced infiltration depth and delayed pressure stabilization, highlighting the necessity for optimizing fiber–resin interactions.

- Impact of Porosity Variation:

- Decreasing the porosity (ε = 0.78, ε = 0.58) resulted in a 15% reduction in the flow-front position at 250 s.

- Lower porosity increased flow resistance, reducing resin mobility and extending injection time.

- Influence of Resin Viscosity:

- Higher viscosity (0.28 Pa·s and 0.48 Pa·s) led to longer filling times and higher pressure retentions near the injection site.

- The infiltration depth at 250 s was reduced by ~18%, confirming that viscosity significantly affects the flow-front advancement.

- Validation and Predictive Accuracy

- A direct numerical–experimental comparison revealed a relative error below 5% for key parameters, including the flow-front position, resin velocity, and total injected resin volume.

- The developed numerical model accurately predicted the pressure evolution, velocity trends, and resin infiltration depth, and aligned well with the experimental findings.

- Implications and Future Work

- The findings confirm that optimizing the injection pressure, fiber permeability, and porosity can significantly enhance the mold filling efficiency and reduce void formation.

- The integration of machine learning algorithms can further refine predictive modeling and real-time process control in RTM.

- Future studies will focus on extending the model to multi-inlet RTM processes, incorporating fiber compaction effects, and improving the sustainability of bio-based resin systems.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Diniță, A.; Ripeanu, R.G.; Ilincă, C.N.; Cursaru, D.; Matei, D.; Naim, R.I.; Tănase, M.; Portoacă, A.I. Advancements in Fiber-Reinforced Polymer Composites: A Comprehensive Analysis. Polymers 2023, 16, 2. [Google Scholar] [CrossRef] [PubMed]

- Karim, M.A.; Abdullah, M.Z.; Deifalla, A.F.; Azab, M.; Waqar, A. An assessment of the processing parameters and application of fibre-reinforced polymers (FRPs) in the petroleum and natural gas industries: A review. Results Eng. 2023, 18, 101091. [Google Scholar] [CrossRef]

- Choi, J.Y.; Jeon, J.H.; Lyu, J.H.; Park, J.; Kim, G.Y.; Chey, S.Y.; Quan, Y.-J.; Bhandari, B.; Prusty, B.G.; Ahn, S.-H. Current Applications and Development of Composite Manufacturing Processes for Future Mobility. Int. J. Precis. Eng. Manuf. Technol. 2023, 10, 269–291. [Google Scholar] [CrossRef]

- Mengesha, G. Advances in Composite Structures: A Systematic Review of Design, Performance, and Sustainability Trends. Compos. Mater. 2025, 9, 1–17. [Google Scholar] [CrossRef]

- Teixidó, H.; Staal, J.; Caglar, B.; Michaud, V. Capillary Effects in Fiber Reinforced Polymer Composite Processing: A Review. Front. Mater. 2022, 9, 809226. [Google Scholar] [CrossRef]

- Giavaras, A.; Boateng, E. Transient filling modelling at meso-level for RTM process using a single phase LSM. Int. J. Mater. Form. 2015, 8, 197–210. [Google Scholar] [CrossRef]

- Oliveira, J.S.; Carvalho, L.H.; Delgado, J.M.P.Q.; Lima, A.G.B.; Pereira, A.S.; Franco, C.M.R.; Chaves, F.S. Applying Resin Radial Injection for Manufacturing Fiber-Reinforced Polymer Composite: Advanced Mathematical Modeling and Simulation. Polymers 2024, 16, 3525. [Google Scholar] [CrossRef]

- Nascimento Santos, M.J.; Delgado, J.M.P.Q.; Barbosa de Lima, A.G.; Oliveira, I.R. Liquid Injection Molding Process in the Manufacturing of Fibrous Composite Materials: Theory, Advanced Modeling and Engineering Applications; Springer: Cham, Switzerland, 2018; pp. 251–272. [Google Scholar] [CrossRef]

- Habibi, M.; Ruiz, É.; Lebrun, G.; Laperrière, L. Effect of surface density and fiber length on the porosity and permeability of nonwoven flax reinforcement. Text. Res. J. 2018, 88, 1776–1787. [Google Scholar] [CrossRef]

- Mehdikhani, M.; Gorbatikh, L.; Verpoest, I.; Lomov, S. V Voids in fiber-reinforced polymer composites: A review on their formation, characteristics, and effects on mechanical performance. J. Compos. Mater. 2019, 53, 1579–1669. [Google Scholar] [CrossRef]

- Facciotto, S.; Simacek, P.; Advani, S.G.; Pickett, A.; Middendorf, P. Modeling formation and evolution of voids in unsaturated dual scale preforms in Resin Transfer Molding processes. Compos. Part A Appl. Sci. Manuf. 2023, 173, 107675. [Google Scholar] [CrossRef]

- Kang, J.; Wang, M. Flow behavior prediction at free-fibrous interface. Int. J. Heat Mass Transf. 2024, 228, 125621. [Google Scholar] [CrossRef]

- Kumar, S.; Samal, S.K.; Mohanty, S.; Nayak, S.K. Recent Development of Biobased Epoxy Resins: A Review. Polym. Plast. Technol. Eng. 2018, 57, 133–155. [Google Scholar] [CrossRef]

- Hiremath, P.; Ranjan, R.; DeSouza, V.; Bhat, R.; Patil, S.; Maddodi, B.; Shivamurthy, B.; Perez, T.C.; Naik, N. Enhanced Wear Resistance in Carbon Nanotube-Filled Bio-Epoxy Composites: A Comprehensive Analysis via Scanning Electron Microscopy and Atomic Force Microscopy. J. Compos. Sci. 2023, 7, 478. [Google Scholar] [CrossRef]

- Haresamudram, H.; Essa, I.; Plötz, T. Assessing the State of Self-Supervised Human Activity Recognition Using Wearables. Proc. ACM Interact. Mob. Wearable Ubiquitous Technol. 2022, 6, 1–47. [Google Scholar] [CrossRef]

- Klose, L.; Meyer-Heydecke, N.; Wongwattanarat, S.; Chow, J.; Pérez García, P.; Carré, C.; Streit, W.; Antranikian, G.; Romero, A.M.; Liese, A. Towards Sustainable Recycling of Epoxy-Based Polymers: Approaches and Challenges of Epoxy Biodegradation. Polymers 2023, 15, 2653. [Google Scholar] [CrossRef]

- Rojtman, E.; Denis, M.; Sirvent, C.; Lapinte, V.; Caillol, S.; Briou, B. Polyols from cashew nut shell liquid (CNSL): Corner-stone building blocks for cutting-edge bio-based additives and polymers. Polym. Chem. 2024, 15, 4375–4415. [Google Scholar] [CrossRef]

- Bobade, S.K.; Paluvai, N.R.; Mohanty, S.; Nayak, S.K. Bio-Based Thermosetting Resins for Future Generation: A Review. Polym. Plast. Technol. Eng. 2016, 55, 1863–1896. [Google Scholar] [CrossRef]

- Delgado, J.M.P.Q.; Barbosa de Lima, A.G.; do Nascimento Santos, M.J. Transport Phenomena in Liquid Composite Molding Processes; Springer International Publishing: Cham, Switzerland, 2019. [Google Scholar] [CrossRef]

- Ali, M.A.; Umer, R.; Khan, K.A.; Cantwell, W.J. Application of X-ray computed tomography for the virtual permeability prediction of fiber reinforcements for liquid composite molding processes: A review. Compos. Sci. Technol. 2019, 184, 107828. [Google Scholar] [CrossRef]

- Gomez, C.; Salvatori, D.; Caglar, B.; Trigueira, R.; Orange, G.; Michaud, V. Resin Transfer molding of High-Fluidity Polyamide-6 with modified Glass-Fabric preforms. Compos. Part A Appl. Sci. Manuf. 2021, 147, 106448. [Google Scholar] [CrossRef]

- Bodaghi, M.; Lomov, S.V.; Simacek, P.; Correia, N.C.; Advani, S.G. On the variability of permeability induced by reinforcement distortions and dual scale flow in liquid composite moulding: A review. Compos. Part A Appl. Sci. Manuf. 2019, 120, 188–210. [Google Scholar] [CrossRef]

- Wen Goh, K.; Algot, K.K.; Laxmaiah, G.; Babu, P.R.; Vodnala, V.P.; Zainul, R. Experimental analysis, simulation, and evaluation of process parameters of GFRP composites produced through resin transfer molding. Adv. Manuf. Polym. Compos. Sci. 2025, 11, 2441629. [Google Scholar] [CrossRef]

- Simacek, P.; Advani, S.G. Resin flow modeling in compliant porous media: An efficient approach for liquid composite molding. Int. J. Mater. Form. 2018, 11, 503–515. [Google Scholar] [CrossRef]

- El Moumen, A.; Saouab, A.; Imad, A.; Kanit, T. Towards a numerical modeling of the coupling between RTM process and induced mechanical properties for rigid particle-filled composites. Int. J. Adv. Manuf. Technol. 2023, 125, 1251–1270. [Google Scholar] [CrossRef]

- Peng, Y.; Li, M.; Yang, X. Void formation and suppression in CFRP laminate using newly designed ultrasonic vibration assisted RTM technique. Compos. Struct. 2024, 329, 117796. [Google Scholar] [CrossRef]

- Natarajan, B. Processing-structure-mechanical property relationships in direct formed carbon nanotube articles and their composites: A review. Compos. Sci. Technol. 2022, 225, 109501. [Google Scholar] [CrossRef]

- Yang, J.; Bai, Y.; Sun, J.; Lv, K.; Lang, Y. Recent advances of thermosetting resin and its application prospect in oil and gas drilling and production engineering. Geoenergy Sci. Eng. 2023, 230, 212222. [Google Scholar] [CrossRef]

- Mustapha, R.; Rahmat, A.R.; Abdul Majid, R.; Mustapha, S.N.H. Vegetable oil-based epoxy resins and their composites with bio-based hardener: A short review. Polym. Technol. Mater. 2019, 58, 1311–1326. [Google Scholar] [CrossRef]

- Devansh; Patil, P.; Pinjari, D.V. Oil-based epoxy and their composites: A sustainable alternative to traditional epoxy. J. Appl. Polym. Sci. 2024, 141, e55560. [Google Scholar] [CrossRef]

- Zhao, F.; Liu, X.; Zhao, J.; Feng, T.; Guo, W. Plant fiber-reinforced composites based on injection molding process: Manufacturing, service life, and remanufacturing. Polym. Compos. 2024, 45, 4876–4899. [Google Scholar] [CrossRef]

- Wang, X.; Xue, F.; Gu, X.; Xia, X. Simulation of Frost-Heave Failure of Air-Entrained Concrete Based on Thermal–Hydraulic–Mechanical Coupling Model. Materials 2024, 17, 3727. [Google Scholar] [CrossRef]

- Rudawska, A.; Szabelski, J.; Miturska-Barańska, I.; Doluk, E. Biological Reinforcement of Epoxies as Structural Adhesives. In Structural Adhesives; Wiley: Hoboken, NJ, USA, 2023; pp. 31–104. [Google Scholar] [CrossRef]

- Oya, Y.; Matsumiya, T.; Ito, A.; Matsuzaki, R.; Okabe, T. Gate optimization for resin transfer molding in dual-scale porous media: Numerical simulation and experiment measurement. J. Compos. Mater. 2020, 54, 2131–2145. [Google Scholar] [CrossRef]

- Zhao, C.; Yang, B.; Wang, S.; Ma, C.; Wang, S.; Bi, F. Three-Dimensional Numerical Simulation of Meso-Scale-Void Formation during the Mold-Filling Process of LCM. Appl. Compos. Mater. 2019, 26, 1121–1137. [Google Scholar] [CrossRef]

- Huang, Z.M.; Lee, S.Y.; Kim, H.M.; Youn, J.R.; Song, Y.S. Three-dimensional numerical simulation for resin transfer molding of automotive wheel. Korea-Aust. Rheol. J. 2019, 31, 141–147. [Google Scholar] [CrossRef]

- Sandberg, M.; Yuksel, O.; Baran, I.; Hattel, J.H.; Spangenberg, J. Numerical and experimental analysis of resin-flow, heat-transfer, and cure in a resin-injection pultrusion process. Compos. Part A Appl. Sci. Manuf. 2021, 143, 106231. [Google Scholar] [CrossRef]

- Baum, M.; Anders, D.; Reinicke, T. Approaches for Numerical Modeling and Simulation of the Filling Phase in Injection Molding: A Review. Polymers 2023, 15, 4220. [Google Scholar] [CrossRef] [PubMed]

- do Nascimento Santos, M.J.; de Oliveira Neto, G.L.; Carmo de Lima, A.R.; de Oliveira, N.G.N.; Pereira de Farias, R.; Pereira Ramos, R.; de Lima, A.G.B. Resin Radial and Isothermal Infiltration in Fibrous Media: A New Mathematical Formulation. Defect Diffus. Forum 2020, 400, 123–134. [Google Scholar] [CrossRef]

- Shevtsov, S.; Zhilyaev, I.; Chang, S.-H.; Wu, J.-K.; Huang, J.-P.; Snezhina, N. Experimental and Numerical Study of Vacuum Resin Infusion for Thin-Walled Composite Parts. Appl. Sci. 2020, 10, 1485. [Google Scholar] [CrossRef]

- Asiliskender, A.; Peiró, J.; Lee, K.-Y.; Parlamas, A.; Falzon, B.; Kazancı, Z. Predicting filling efficiency of composite resin injection repair. Compos. Part A Appl. Sci. Manuf. 2023, 174, 107708. [Google Scholar] [CrossRef]

- Dammann, C.; Mahnken, R. Simulation of a resin transfer molding process using a phase field approach within the theory of porous media. Compos. Part A Appl. Sci. Manuf. 2019, 120, 147–160. [Google Scholar] [CrossRef]

- Lionetto, F.; Moscatello, A.; Totaro, G.; Raffone, M.; Maffezzoli, A. Experimental and Numerical Study of Vacuum Resin Infusion of Stiffened Carbon Fiber Reinforced Panels. Materials 2020, 13, 4800. [Google Scholar] [CrossRef]

- Magalhães, G.M.C.; Fragassa, C.; Lemos, R.d.L.; Isoldi, L.A.; Amico, S.C.; Rocha, L.A.O.; Souza, J.A.; dos Santos, E.D. Numerical Analysis of the Influence of Empty Channels Design on Performance of Resin Flow in a Porous Plate. Appl. Sci. 2020, 10, 4054. [Google Scholar] [CrossRef]

- Bernard, M.; Zamora, M.; Géraud, Y.; Boudon, G. Transport properties of pyroclastic rocks from Montagne Pelée volcano (Martinique, Lesser Antilles). J. Geophys. Res. Solid Earth 2007, 112. [Google Scholar] [CrossRef]

- Laadel, N.-E.; El Mansori, M.; Kang, N.; Marlin, S.; Boussant-Roux, Y. Permeation barriers for hydrogen embrittlement prevention in metals—A review on mechanisms, materials suitability and efficiency. Int. J. Hydrogen Energy 2022, 47, 32707–32731. [Google Scholar] [CrossRef]

- Hu, F.; La Scala, J.J.; Yadav, S.K.; Throckmorton, J.; Palmese, G.R. Epoxidized soybean oil modified using fatty acids as tougheners for thermosetting epoxy resins: Part 2—Effect of curing agent and epoxy molecular weight. J. Appl. Polym. Sci. 2021, 138, 50579. [Google Scholar] [CrossRef]

- Yadav, S.K.; Hu, F.; La Scala, J.J.; Palmese, G.R. Toughening Anhydride-Cured Epoxy Resins Using Fatty Alkyl-Anhydride-Grafted Epoxidized Soybean Oil. ACS Omega 2018, 3, 2641–2651. [Google Scholar] [CrossRef] [PubMed]

- Leclerc, J.S.; Ruiz, E. Porosity reduction using optimized flow velocity in Resin Transfer Molding. Compos. Part A Appl. Sci. Manuf. 2008, 39, 1859–1868. [Google Scholar] [CrossRef]

- Matsuzaki, R.; Seto, D.; Todoroki, A.; Mizutani, Y. In situ void content measurements during resin transfer molding. Adv. Compos. Mater. 2013, 22, 239–254. [Google Scholar] [CrossRef]

| Parameter | FormuLITE |

|---|---|

| Calculated bio-content | 36.6 |

| Mix ratio by weight | 100:30 |

| Mix ratio by volume | 100:36 |

| Mix viscosity at 25 °C (cPs) | 700 |

| Mix viscosity at 40 °C (cPs) | 242 |

| Pot life at 25 °C (min) | 105 |

| Pot life at 40 °C (min) | 57 |

| Tg (°C) | 92 |

| Tensile strength (MPa) | 62 |

| Tensile modulus (MPa) | 2615 |

| Elongation at Fmax (%)/Elongation at break (%) | 4.8/6.4 |

| Flexural strength (MPa) | 92 |

| Flexural modulus (MPa) | 2262 |

| Parameter | Experimental Value | Numerical Prediction | Relative Error (%) |

|---|---|---|---|

| Injection Pressure (Pa) | 20,000 | 20,000 | 0 |

| Flow-Front Position at 250 s (m) | 0.058 | 0.056 | 3.45 |

| Resin Velocity at 10 s (m/s) | 0.0075 | 0.0072 | 4 |

| Total Resin Volume Injected (m3) | 0.0005 | 0.00048 | 4 |

| Injection Time for Full Mold Filling (s) | 240 | 235 | 2.08 |

| Condition | Parameter | ε (-) | k (×10−12 m2) | S (×10−4 s−1) | µ (Pa·s) | Pinj (kPa) | rinj (m) | Pff (Pa) |

|---|---|---|---|---|---|---|---|---|

| 1 | Base Case | 0.78 | 350 | 0 | 0.28 | 15 | 0.003 | 0 |

| 2 | Higher Injection Pressure | 0.78 | 350 | 0 | 0.28 | 20 | 0.003 | 0 |

| 3 | Maximum Injection Pressure | 0.78 | 350 | 0 | 0.28 | 25 | 0.003 | 0 |

| 4 | Reduced Injection Radius | 0.78 | 350 | 0 | 0.28 | 20 | 0.002 | 0 |

| 5 | Smallest Injection Radius | 0.78 | 350 | 0 | 0.28 | 20 | 0.001 | 0 |

| 6 | Reduced Permeability | 0.78 | 3.5 | 0 | 0.28 | 20 | 0.003 | 0 |

| 7 | Minimal Permeability | 0.78 | 0.035 | 0 | 0.28 | 20 | 0.003 | 0 |

| 8 | Sorption Effect Introduced | 0.78 | 350 | 5 | 0.28 | 20 | 0.003 | 0 |

| 9 | Increased Sorption | 0.78 | 350 | 10 | 0.28 | 20 | 0.003 | 0 |

| 10 | Reduced Porosity | 0.68 | 350 | 0 | 0.28 | 20 | 0.003 | 0 |

| 11 | Minimum Porosity | 0.58 | 350 | 0 | 0.28 | 20 | 0.003 | 0 |

| 12 | Higher Resin Viscosity | 0.78 | 350 | 0 | 0.38 | 20 | 0.003 | 0 |

| 13 | Maximum Resin Viscosity | 0.78 | 350 | 0 | 0.48 | 20 | 0.003 | 0 |

| Condition | Parameter | ε (-) | k (×10−12 m2) | S (×10−4 s−1) | µ (Pa·s) | Pinj (kPa) | rinj (m) | rff at 10 s (m) | rff at 50 s (m) | rff at 100 s (m) | rff at 150 s (m) | rff at 200 s (m) | rff at 2500 s (m) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | Base Case | 0.78 | 350 | 0 | 0.28 | 15 | 0.003 | 0.015 | 0.030 | 0.037 | 0.045 | 0.051 | 0.056 |

| 2 | Higher Injection Pressure | 0.78 | 350 | 0 | 0.28 | 20 | 0.003 | 0.016 | 0.033 | 0.041 | 0.051 | 0.057 | 0.062 |

| 3 | Maximum Injection Pressure | 0.78 | 350 | 0 | 0.28 | 25 | 0.003 | 0.018 | 0.034 | 0.045 | 0.055 | 0.062 | 0.068 |

| 4 | Reduced Injection Radius | 0.78 | 350 | 0 | 0.28 | 20 | 0.002 | 0.013 | 0.026 | 0.032 | 0.039 | 0.044 | 0.048 |

| 5 | Smallest Injection Radius | 0.78 | 350 | 0 | 0.28 | 20 | 0.001 | 0.014 | 0.028 | 0.036 | 0.044 | 0.049 | 0.053 |

| 6 | Reduced Permeability | 0.78 | 3.5 | 0 | 0.28 | 20 | 0.003 | 0.002 | 0.003 | 0.004 | 0.005 | 0.005 | 0.006 |

| 7 | Minimal Permeability | 0.78 | 0.035 | 0 | 0.28 | 20 | 0.003 | 0.004 | 0.007 | 0.009 | 0.011 | 0.013 | 0.014 |

| 8 | Sorption Effect Introduced | 0.78 | 350 | 5 | 0.28 | 20 | 0.003 | 0.016 | 0.031 | 0.039 | 0.047 | 0.053 | 0.058 |

| 9 | Increased Sorption | 0.78 | 350 | 10 | 0.28 | 20 | 0.003 | 0.016 | 0.032 | 0.040 | 0.049 | 0.055 | 0.060 |

| 10 | Reduced Porosity | 0.68 | 350 | 0 | 0.28 | 20 | 0.003 | 0.016 | 0.033 | 0.041 | 0.051 | 0.057 | 0.062 |

| 11 | Minimum Porosity | 0.58 | 350 | 0 | 0.28 | 20 | 0.003 | 0.018 | 0.034 | 0.045 | 0.055 | 0.062 | 0.068 |

| 12 | Higher Resin Viscosity | 0.78 | 350 | 0 | 0.38 | 20 | 0.003 | 0.016 | 0.031 | 0.039 | 0.047 | 0.053 | 0.058 |

| 13 | Maximum Resin Viscosity | 0.78 | 350 | 0 | 0.48 | 20 | 0.003 | 0.016 | 0.033 | 0.041 | 0.051 | 0.057 | 0.062 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hiremath, P.; Ambiger, K.D.; Jayashree, P.K.; Heckadka, S.S.; Deepak, G.D.; Murthy, B.R.N.; Kowshik, S.; Naik, N. Computational Approach for Optimizing Resin Flow Behavior in Resin Transfer Molding with Variations in Injection Pressure, Fiber Permeability, and Resin Sorption. J. Compos. Sci. 2025, 9, 129. https://doi.org/10.3390/jcs9030129

Hiremath P, Ambiger KD, Jayashree PK, Heckadka SS, Deepak GD, Murthy BRN, Kowshik S, Naik N. Computational Approach for Optimizing Resin Flow Behavior in Resin Transfer Molding with Variations in Injection Pressure, Fiber Permeability, and Resin Sorption. Journal of Composites Science. 2025; 9(3):129. https://doi.org/10.3390/jcs9030129

Chicago/Turabian StyleHiremath, Pavan, Krishnamurthy D. Ambiger, P. K. Jayashree, Srinivas Shenoy Heckadka, G. Divya Deepak, B. R. N. Murthy, Suhas Kowshik, and Nithesh Naik. 2025. "Computational Approach for Optimizing Resin Flow Behavior in Resin Transfer Molding with Variations in Injection Pressure, Fiber Permeability, and Resin Sorption" Journal of Composites Science 9, no. 3: 129. https://doi.org/10.3390/jcs9030129

APA StyleHiremath, P., Ambiger, K. D., Jayashree, P. K., Heckadka, S. S., Deepak, G. D., Murthy, B. R. N., Kowshik, S., & Naik, N. (2025). Computational Approach for Optimizing Resin Flow Behavior in Resin Transfer Molding with Variations in Injection Pressure, Fiber Permeability, and Resin Sorption. Journal of Composites Science, 9(3), 129. https://doi.org/10.3390/jcs9030129