Sustainable Composites from Sugarcane Bagasse Fibers and Bio-Based Epoxy with Insights into Wear Performance, Thermal Stability, and Machine Learning Predictive Modeling

Abstract

1. Introduction

1.1. Sugarcane Bagasse Fiber

1.2. Bio-Based Epoxy

1.3. Synergistic Potential of Sugarcane Bagasse Fibers and Bio-Based Epoxy

2. Materials and Methods

2.1. Chemical Treatment of Bagasse Fibers

2.1.1. Potassium Permanganate (KMnO4) Treatment

2.1.2. Benzene Sulfonyl Chloride (C6H5SO2Cl) Treatment

2.1.3. Ethylene Dichloride Treatment

2.2. Material Characterization

3. Results and Discussion

3.1. FTIR Analysis

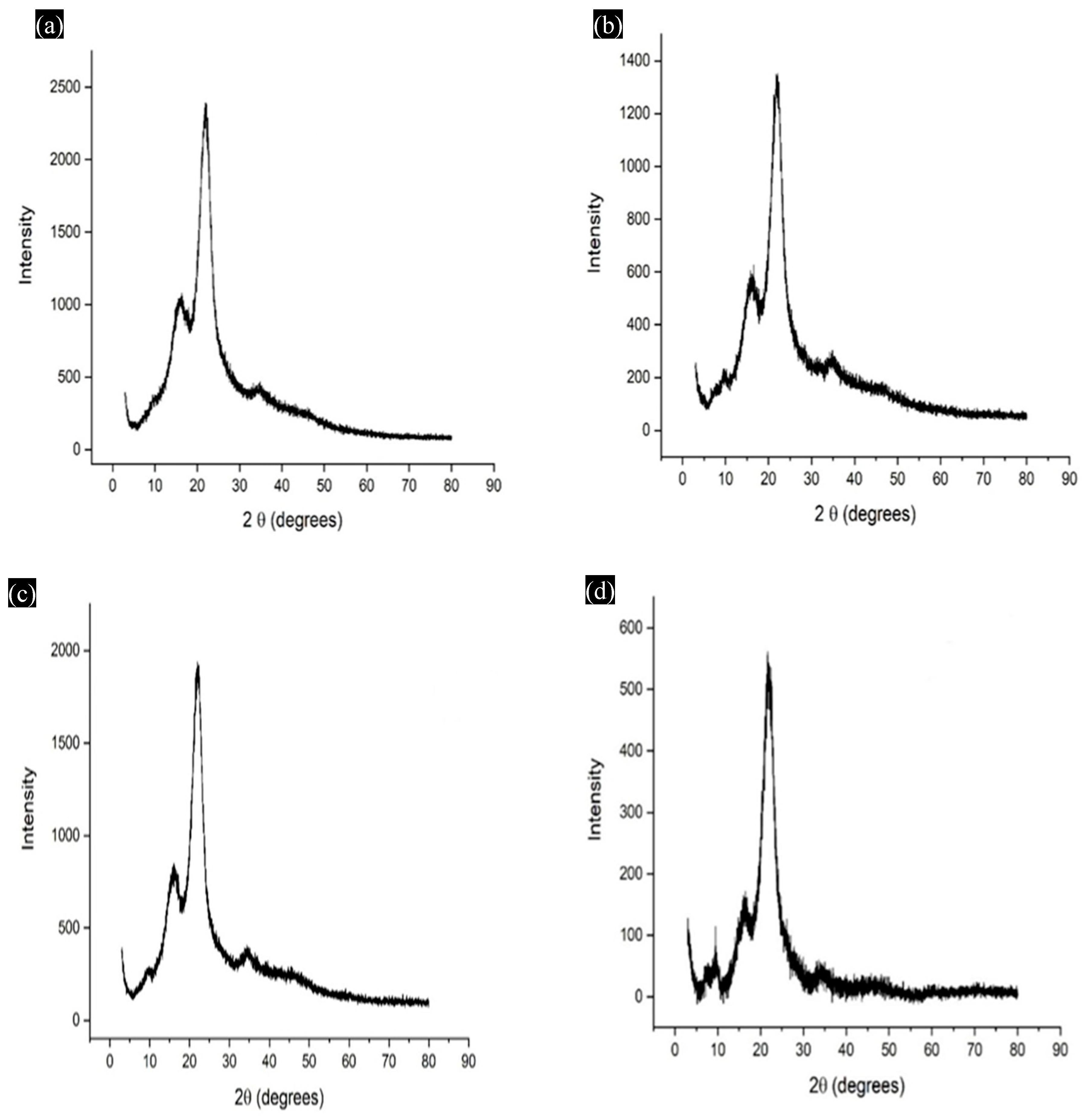

3.2. XRD Analysis

3.3. SEM Analysis

3.4. Thermogravimetric Analysis (TGA)

3.5. Experimental Design and Analysis of Wear Testing Using Taguchi Method

3.6. Machine Learning Insights into Wear Performance and Predictive Modeling

4. Conclusions

4.1. Wear Resistance

- Fiber treatment emerged as the most influential factor in determining wear resistance, contributing 90.86% to the variation, as confirmed by the ANOVA results. Among the treatments, ethylene dichloride-treated fibers exhibited the lowest wear rate (0.245 mg/m), which was attributed to their optimized surface modification that enhanced fiber–matrix bonding.

- The raw fibers demonstrated the highest wear rate (0.382 mg/m), underscoring the impact of poor interfacial adhesion and untreated surfaces.

- Lubrication type is ranked as the second most significant factor, with hybrid and grease lubricants effectively reducing wear through protective barriers.

4.2. Thermal Stability

- TGA analysis revealed improved thermal stability across treated fibers, with ethylene dichloride-treated fibers exhibiting the highest thermal onset temperature (T20% at 260 °C) and moderate char yield (1.3 mg). This balance reflects the removal of amorphous components and enhanced hydrophobicity, which correlates with superior wear performance.

- KMnO4-treated fibers demonstrated moderate stability (T20% at 250 °C, char yield of 1.2 mg), while benzene sulfonyl chloride treatments (10% and 20%) optimized hydrophobicity and matrix compatibility but showed reduced thermal stability at higher concentrations.

4.3. Crystallinity Index

- The XRD results demonstrated that alkali pre-treatment led to the highest crystallinity index (62%), promoting interfacial bonding. However, the reduced crystallinity in the KMnO3 and ethylene dichloride treatments (50.5% and 40.6%, respectively) was counterbalanced by the improved surface reactivity and chemical modifications, resulting in enhanced wear resistance.

4.4. Machine Learning Insights

- The Random Forest model effectively predicted wear rates with high accuracy, confirming that fiber treatment was the dominant variable influencing wear. Minimal deviations at higher wear rates suggest areas for model refinement, such as feature interactions and dataset expansion.

4.5. Practical Implications

- The synergy between sugarcane bagasse fibers and bio-based epoxy produced composites with superior thermal stability, mechanical performance, and wear resistance. The environmental benefits, including reduced CO2 emissions (50%) and weight reduction (35% in automotive applications), further validate their potential for sustainable industrial use.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mtibe, A.; Motloung, M.P.; Bandyopadhyay, J.; Ray, S.S. Synthetic Biopolymers and Their Composites: Advantages and Limitations—An Overview. Macromol. Rapid Commun. 2021, 42, 2100130. [Google Scholar] [CrossRef] [PubMed]

- Malek, N.S.A.; Omar, H.; Rosman, N.; Hajar, N.; Aizamddin, M.F.; Bonnia, N.N.; Khusaimi, Z.; Mahmood, M.R.; Asli, N.A. Tailoring Synergistic Polylactic Acid–Based Nanocomposites for Sustainable Antimicrobial Fruit Packaging. Packag. Technol. Sci. 2025, 38, 163–192. [Google Scholar] [CrossRef]

- Righetti, G.I.C.; Faedi, F.; Famulari, A. Embracing Sustainability: The World of Bio-Based Polymers in a Mini Review. Polymers 2024, 16, 950. [Google Scholar] [CrossRef]

- Oh, E.; Zúniga, M.M.G.; Nguyen, T.B.; Kim, B.-H.; Tien, T.T.; Suhr, J. Sustainable green composite materials in the next-generation mobility industry: Review and prospective. Adv. Compos. Mater. 2024, 33, 1368–1419. [Google Scholar] [CrossRef]

- Zheng, Y.; Liao, J.; Fang, Y.; Gui, R.; Hou, Y.; Zhang, M.; Dong, Y.; Zheng, Q.; Luan, P.; Chen, X. Innovative fabrication of eco-friendly bio-based foam from sugarcane bagasse and sodium alginate with enhanced properties and sustainable applications for plastic replacement. Int. J. Biol. Macromol. 2024, 282, 137464. [Google Scholar] [CrossRef] [PubMed]

- Tang, Y.; He, Y.; Tan, J.; Wang, T.; Cui, X. Green fabrication of glueless biocomposites with bagasse and intrinsic lignin to prepare high-conductive monolithic biochar. Int. J. Biol. Macromol. 2025, 305, 141334. [Google Scholar] [CrossRef]

- Maiti, S.; Islam, M.R.; Uddin, M.A.; Afroj, S.; Eichhorn, S.J.; Karim, N. Sustainable Fiber-Reinforced Composites: A Review. Adv. Sustain. Syst. 2022, 6, 2200258. [Google Scholar] [CrossRef]

- Palanisamy, S.; Vijayananth, K.; Murugesan, T.M.; Palaniappan, M.; Santulli, C. The prospects of natural fiber composites: A brief review. Int. J. Lightweight Mater. Manuf. 2024, 7, 496–506. [Google Scholar] [CrossRef]

- Thapliyal, D.; Verma, S.; Sen, P.; Kumar, R.; Thakur, A.; Tiwari, A.K.; Singh, D.; Verros, G.D.; Arya, R.K. Natural Fibers Composites: Origin, Importance, Consumption Pattern, and Challenges. J. Compos. Sci. 2023, 7, 506. [Google Scholar] [CrossRef]

- Sathish, M.; Radhika, N.; Venuvanka, N.; Rajeshkumar, L. A review on sustainable properties of plant fiber-reinforced polymer composites: Characteristics and properties. Polym. Int. 2024, 73, 887–943. [Google Scholar] [CrossRef]

- Ghernaout, D.; Belaadi, A.; Boumaaza, M.; Chai, B.X.; Jawaid, M.; Abdullah, M.M.; Krishnasamy, P.; Al-Khawlani, A. Effects of incorporating cellulose fibers from Yucca treculeana L. on the thermal characteristics of green composites based on high-density poly-ethylene: An eco-friendly material for cleaner production. J. Mater. Res. Technol. 2024, 31, 787–798. [Google Scholar] [CrossRef]

- Najafi, H.; Sani, A.G.; Sobati, M.A. A comparative evaluation on the physicochemical properties of sugarcane residues for thermal conversion processes. Ind. Crops Prod. 2023, 202, 117112. [Google Scholar] [CrossRef]

- Prabhu, R.; Ganesh, S.; Mahesha, G.; Bhat, K.S. Physicochemical characteristics of chemically treated bagasse fibers. Cogent Eng. 2022, 9, 2014025. [Google Scholar] [CrossRef]

- Dhali, K.; Ghasemlou, M.; Daver, F.; Cass, P.; Adhikari, B. A review of nanocellulose as a new material towards environmental sustainability. Sci. Total Environ. 2021, 775, 145871. [Google Scholar] [CrossRef]

- Mohammadinejad, R.; Maleki, H.; Larrañeta, E.; Fajardo, A.R.; Nik, A.B.; Shavandi, A.; Sheikhi, A.; Ghorbanpour, M.; Farokhi, M.; Govindh, P.; et al. Status and future scope of plant-based green hydrogels in biomedical engineering. Appl. Mater. Today 2019, 16, 213–246. [Google Scholar] [CrossRef]

- Qaseem, M.F.; Shaheen, H.; Wu, A.-M. Cell wall hemicellulose for sustainable industrial utilization. Renew. Sustain. Energy Rev. 2021, 144, 110996. [Google Scholar] [CrossRef]

- Balk, M.; Sofia, P.; Neffe, A.T.; Tirelli, N. Lignin, the Lignification Process, and Advanced, Lignin-Based Materials. Int. J. Mol. Sci. 2023, 24, 11668. [Google Scholar] [CrossRef]

- Mubarak, A.A.; Ilyas, R.A.; Nordin, A.H.; Ngadi, N.; Alkbir, M.F.M. Recent developments in sugarcane bagasse fibre-based adsorbent and their potential industrial applications: A review. Int. J. Biol. Macromol. 2024, 277, 134165. [Google Scholar] [CrossRef]

- Bartos, A.; Utomo, B.P.; Kanyar, B.; Anggono, J.; Soetaredjo, F.E.; Móczó, J.; Pukánszky, B. Reinforcement of polypropylene with alkali-treated sugarcane bagasse fibers: Mechanism and consequences. Compos. Sci. Technol. 2020, 200, 108428. [Google Scholar] [CrossRef]

- Nurazzi, N.M.; Asyraf, M.R.M.; Rayung, M.; Norrrahim, M.N.F.; Shazleen, S.S.; Rani, M.S.A.; Shafi, A.R.; Aisyah, H.A.; Radzi, M.H.M.; Sabaruddin, F.A.; et al. Thermogravimetric Analysis Properties of Cellulosic Natural Fiber Polymer Composites: A Review on Influence of Chemical Treatments. Polymers 2021, 13, 2710. [Google Scholar] [CrossRef]

- Mohammed, M.; Rahman, R.; Mohammed, A.M.; Adam, T.; Betar, B.O.; Osman, A.F.; Dahham, O.S. Surface treatment to improve water repellence and compatibility of natural fiber with polymer matrix: Recent advancement. Polym. Test. 2022, 115, 107707. [Google Scholar] [CrossRef]

- Dhakal, H.N.; Khan, S.H.; Alnaser, I.A.; Karim, M.R.; Saifullah, A.; Zhang, Z. Potential of Date Palm Fibers (DPFs) as a Sustainable Reinforcement for Bio-Composites and its Property Enhancement for Key Applications: A Review. Macromol. Mater. Eng. 2024, 309, 2400081. [Google Scholar] [CrossRef]

- Verma, D.; Okhawilai, M.; Goh, K.L.; Sharma, M. Thermomechanical Analyses of Alkali-Treated Coconut Husk-Bagasse Fiber-Calcium Carbonate Hybrid Composites. Sustainability 2023, 15, 1686. [Google Scholar] [CrossRef]

- Suryawanshi, A.; Mestry, O.; Patil, S. Characterization & tribological performance of graphene reinforced bagasse ash epoxy composite using Taguchi technique. Mater. Today Proc. 2024, in press. [Google Scholar] [CrossRef]

- Ranakoti, L.; Gangil, B.; Rajesh, P.K.; Singh, T.; Sharma, S.; Li, C.; Ilyas, R.; Mahmoud, O. Effect of surface treatment and fiber loading on the physical, mechanical, sliding wear, and morphological characteristics of tasar silk fiber waste-epoxy composites for multifaceted biomedical and engineering applications: Fabrication and characterizations. J. Mater. Res. Technol. 2022, 19, 2863–2876. [Google Scholar] [CrossRef]

- Carvalho, D.; Ferreira, N.; França, B.; Marques, R.; Silva, M.; Silva, S.; Silva, E.; Macário, D.; Barroso, L.; Silva, C.J.; et al. Advancing sustainability in the automotive industry: Bioprepregs and fully bio-based composites. Compos. Part C Open Access 2024, 14, 100459. [Google Scholar] [CrossRef]

- Rangappa, S.M.; Siengchin, S.; Parameswaranpillai, J.; Jawaid, M.; Ozbakkaloglu, T. Lignocellulosic fiber reinforced composites: Progress, performance, properties, applications, and future perspectives. Polym. Compos. 2022, 43, 645–691. [Google Scholar] [CrossRef]

- Kumar, D.K.M.; Udaiyakumar, K.C. Investigation on mechanical properties of sugarcane bagasse ash reinforced with incorporation of HDPE—Montmorillonite composite materials. Mater Today Proc. 2021, 45, 6123–6127. [Google Scholar] [CrossRef]

- Matykiewicz, D.; Barczewski, M.; Mousa, M.S.; Sanjay, M.R.; Siengchin, S. Impact Strength of Hybrid Epoxy–Basalt Composites Modified with Mineral and Natural Fillers. ChemEngineering 2021, 5, 56. [Google Scholar] [CrossRef]

- Malik, M.; Bhattacharyya, S.K.; Barai, S.V. Thermal and mechanical properties of concrete and its constituents at elevated temperatures: A review. Constr. Build. Mater. 2021, 270, 121398. [Google Scholar] [CrossRef]

- Naik, N.; Shivamurthy, B.; Thimmappa, B.H.S.; Guo, Z.; Bhat, R. Bio-Based Epoxies: Mechanical Characterization and Their Applicability in the Development of Eco-Friendly Composites. J. Compos. Sci. 2022, 6, 294. [Google Scholar] [CrossRef]

- Hiremath, P.; Ranjan, R.; DeSouza, V.; Bhat, R.; Patil, S.; Maddodi, B.; Shivamurthy, B.; Perez, T.C.; Naik, N. Enhanced Wear Resistance in Carbon Nanotube-Filled Bio-Epoxy Composites: A Comprehensive Analysis via Scanning Electron Microscopy and Atomic Force Microscopy. J. Compos. Sci. 2023, 7, 478. [Google Scholar] [CrossRef]

- Mohammed, M.; Oleiwi, J.K.; Mohammed, A.M.; Jawad, A.J.M.; Osman, A.F.; Adam, T.; Betar, B.O.; Gopinath, S.C.; Dahham, O.S.; Jaafar, M. Comprehensive insights on mechanical attributes of natural-synthetic fibres in polymer composites. J. Mater. Res. Technol. 2023, 25, 4960–4988. [Google Scholar] [CrossRef]

- Andrew, J.J.; Dhakal, H.N. Sustainable biobased composites for advanced applications: Recent trends and future opportunities–A critical review. Compos. Part. C Open Access 2022, 7, 100220. [Google Scholar] [CrossRef]

- Capretti, M.; Giammaria, V.; Santulli, C.; Boria, S.; Del Bianco, G. Use of Bio-Epoxies and Their Effect on the Performance of Polymer Composites: A Critical Review. Polymers 2023, 15, 4733. [Google Scholar] [CrossRef]

- Di Matteo, P.; Iadarola, A.; Ciardiello, R.; Paolino, D.S.; Gazza, F.; Lambertini, V.G.; Brunella, V. Cross-Linking Reaction of Bio-Based Epoxy Systems: An Investigation into Cure Kinetics. Polymers 2024, 16, 2499. [Google Scholar] [CrossRef]

- Yadav, R.; Singh, M.; Shekhawat, D.; Lee, S.-Y.; Park, S.-J. The role of fillers to enhance the mechanical, thermal, and wear characteristics of polymer composite materials: A review. Compos. Part A Appl. Sci. Manuf. 2023, 175, 107775. [Google Scholar] [CrossRef]

- Devendrappa, S.K.; Puttegowda, M.; Nagaraju, S.B. Enhancing wear resistance, mechanical properties of composite materials through sisal and glass fiber reinforcement with epoxy resin and graphite filler. J. Indian Chem. Soc. 2024, 101, 101349. [Google Scholar] [CrossRef]

- Sakib, M.N.; Kabir, G.; Ali, S.M. A life cycle analysis approach to evaluate sustainable strategies in the furniture manufacturing industry. Sci. Total Environ. 2024, 907, 167611. [Google Scholar] [CrossRef]

- Arslan, M.; Yılmaz, M.N.; Günay, K.; Ünlü, N. Removing selenite ions (SeO32−) from aqueous solutions by 4-vinyl pyridine monomer grafted poly(ethylene terephthalate) fibers and an estimation of its adsorption mechanism over pH dependency of the adsorption. Polym. Bull. 2023, 80, 3135–3152. [Google Scholar] [CrossRef]

- Noaman, A.; Ebrahiem, E.; Abdelrahman, M.; Abdel-Halim, M. The Effect of Fiber-Adhesive Composite on Bond Strength of Plastic Plates-Part III: The Effect of pH on Mechanical Behavior and Mechanical Properties. J. Adv. Eng. Trends 2023, 42, 257–270. [Google Scholar] [CrossRef]

- Nguyen, N.-H.; Abellán-García, J.; Lee, S.; Nguyen, T.-K.; Vo, T.P. Simultaneous prediction the strain and energy absorption capacity of ultra-high performance fiber reinforced concretes by using multi-output regression model. Constr. Build. Mater. 2023, 384, 131418. [Google Scholar] [CrossRef]

- Sathiyamurthy, S.; Saravanakumar, S.; Vinoth, V. Enhancing tribological performance of hybrid fiber-reinforced composites through machine learning and response surface methodology. J. Reinf. Plast. Compos. 2024. [Google Scholar] [CrossRef]

- Kumari, P.; Toshniwal, D. Extreme gradient boosting and deep neural network based ensemble learning approach to forecast hourly solar irradiance. J. Clean. Prod. 2021, 279, 123285. [Google Scholar] [CrossRef]

- Natras, R.; Soja, B.; Schmidt, M. Ensemble Machine Learning of Random Forest, AdaBoost and XGBoost for Vertical Total Electron Content Forecasting. Remote Sens. 2022, 14, 3547. [Google Scholar] [CrossRef]

| Sample | Crystallinity Index |

|---|---|

| Raw untreated fiber | 59% |

| Pre-treated fiber | 62% |

| KMnO4-Soaked fiber | 50.5% |

| KMnO4-refluxed fiber | 46% |

| 10% Benzene sulphonyl chloride treated | 48.5% |

| 20% Benzene sulphonyl chloride treated | 42.5% |

| Ethylene dichloride-treated fiber | 40.6% |

| Parameter | FormuLITE |

|---|---|

| Calculated bio-content | 36.6 |

| Mix ratio by weight | 100:30 |

| Mix ratio by volume | 100:36 |

| Mix viscosity at 25 °C (cPs) | 700 |

| Mix viscosity at 40 °C (cPs) | 242 |

| Pot life at 25 °C (min) | 105 |

| Pot life at 40 °C (min) | 57 |

| Tg (°C) | 92 |

| Tensile strength (MPa) | 62 |

| Tensile modulus (MPa) | 2615 |

| Elongation at Fmax (%)/Elongation at break (%) | 4.8/6.4 |

| Flexural strength (MPa) | 92 |

| Flexural modulus (MPa) | 2262 |

| Fibers | T20% (°C) | T(max) (°C) | Sample Weight at 800 °C (mg) | Yc (Char Yield, mg) |

|---|---|---|---|---|

| Raw Fiber | 210 | 400 | 4.2 | 0.5 |

| Pre-Treated Fiber | 235 | 510 | 3.8 | 0.7 |

| KMnO4-Soaked Fiber | 250 | 480 | 3.5 | 0.75 |

| KMnO4-Refluxed Fiber | 245 | 460 | 5.7 | 1.2 |

| 10% C6H5SO2Cl-Treated Fiber | 155 | 490 | 5.4 | 1.1 |

| 20% C6H5SO2Cl-Treated Fiber | 140 | 470 | 4.6 | 1.25 |

| Ethylene Dichloride-Treated Fiber | 260 | 430 | 5.2 | 1.3 |

| Load (N) | Sliding Speed (m/s) | Fiber Treatment | Lubrication Type | Sliding Distance (m) | Wear Rate (mg/m) | Friction Coefficient (µ) |

|---|---|---|---|---|---|---|

| 10 | 0.5 | Raw | Dry | 100 | 0.055 | 0.6 |

| 10 | 1 | Pre | Water | 200 | 0.05 | 0.55 |

| 10 | 1.5 | KMn | Oil | 300 | 0.045 | 0.5 |

| 10 | 2 | Benz | Grease | 400 | 0.04 | 0.45 |

| 10 | 2.5 | Ethy | Hybrid | 500 | 0.035 | 0.4 |

| 20 | 0.5 | Pre | Oil | 400 | 0.05 | 0.55 |

| 20 | 1 | KMn | Grease | 500 | 0.045 | 0.5 |

| 20 | 1.5 | Benz | Hybrid | 100 | 0.04 | 0.45 |

| 20 | 2 | Ethy | Dry | 200 | 0.035 | 0.4 |

| 20 | 2.5 | Raw | Water | 300 | 0.06 | 0.65 |

| 30 | 0.5 | KMn | Hybrid | 200 | 0.045 | 0.5 |

| 30 | 1 | Benz | Dry | 300 | 0.04 | 0.45 |

| 30 | 1.5 | Ethy | Water | 400 | 0.035 | 0.4 |

| 30 | 2 | Raw | Oil | 500 | 0.065 | 0.7 |

| 30 | 2.5 | Pre | Grease | 100 | 0.05 | 0.55 |

| 40 | 0.5 | Benz | Water | 500 | 0.04 | 0.45 |

| 40 | 1 | Ethy | Oil | 100 | 0.035 | 0.4 |

| 40 | 1.5 | Raw | Grease | 200 | 0.07 | 0.75 |

| 40 | 2 | Pre | Hybrid | 300 | 0.055 | 0.6 |

| 40 | 2.5 | KMn | Dry | 400 | 0.045 | 0.5 |

| 50 | 0.5 | Ethy | Grease | 300 | 0.035 | 0.4 |

| 50 | 1 | Raw | Hybrid | 400 | 0.075 | 0.8 |

| 50 | 1.5 | Pre | Dry | 500 | 0.05 | 0.55 |

| 50 | 2 | KMn | Water | 100 | 0.045 | 0.5 |

| 50 | 2.5 | Benz | Oil | 200 | 0.04 | 0.45 |

| Level | Load (N) | Sliding Speed (m/s) | Fiber Treatment | Lubrication Type | Sliding Distance (m) |

|---|---|---|---|---|---|

| 1 | −1.446 | −1.446 | −1.462 | −1.446 | −1.446 |

| 2 | −1.444 | −1.439 | −1.486 | −1.440 | −1.440 |

| 3 | −1.442 | −1.440 | −1.443 | −1.436 | −1.441 |

| 4 | −1.438 | −1.439 | −1.424 | −1.442 | −1.439 |

| 5 | −1.439 | −1.444 | −1.394 | −1.444 | −1.442 |

| Delta | 0.008 | 0.007 | 0.093 | 0.010 | 0.007 |

| Rank | 3 | 4.5 | 1 | 2 | 4.5 |

| Level | Load (N) | Sliding Speed (m/s) | Fiber Treatment | Lubrication Type | Sliding Distance (m) |

|---|---|---|---|---|---|

| 1 | 0.2725 | 0.2725 | 0.2450 | 0.2725 | 0.2725 |

| 2 | 0.2780 | 0.2945 | 0.2175 | 0.2890 | 0.2890 |

| 3 | 0.2835 | 0.2890 | 0.2725 | 0.3000 | 0.2835 |

| 4 | 0.2945 | 0.2890 | 0.3055 | 0.2835 | 0.2945 |

| 5 | 0.2945 | 0.2780 | 0.3825 | 0.2780 | 0.2835 |

| Delta | 0.0220 | 0.0220 | 0.1650 | 0.0275 | 0.0220 |

| Rank | 4 | 4 | 1 | 2 | 4 |

| Source | DF | Seq SS | Contribution | Adj SS | Adj MS | F-Value | p-Value |

|---|---|---|---|---|---|---|---|

| Fiber Treatment | 4 | 0.002684 | 90.86% | 0.002684 | 0.000671 | 54.78 | 0.000 |

| Lubrication Type | 4 | 0.000074 | 2.51% | 0.000074 | 0.000019 | 1.51 | 0.246 |

| Error | 16 | 0.000196 | 6.64% | 0.000196 | 0.000012 | ||

| Total | 24 | 0.002954 | 100.00% |

| Term | Coef | SE Coef | 95% CI | T-Value | p-Value | VIF |

|---|---|---|---|---|---|---|

| Constant | 0.047200 | 0.000700 | (0.045716, 0.048684) | 67.43 | 0.000 | |

| Fiber Treatment | ||||||

| Benz | −0.00720 | 0.00140 | (−0.01017, −0.00423) | −5.14 | 0.000 | 1.60 |

| Ethy | −0.01220 | 0.00140 | (−0.01517, −0.00923) | −8.71 | 0.000 | 1.60 |

| KMn | −0.00220 | 0.00140 | (−0.00517, 0.00077) | −1.57 | 0.136 | 1.60 |

| Pre | 0.00380 | 0.00140 | (0.00083, 0.00677) | 2.71 | 0.015 | 1.60 |

| Lubrication Type | ||||||

| Dry | −0.00220 | 0.00140 | (−0.00517, 0.00077) | −1.57 | 0.136 | 1.60 |

| Grease | 0.00080 | 0.00140 | (−0.00217, 0.00377) | 0.57 | 0.576 | 1.60 |

| Hybrid | 0.00280 | 0.00140 | (−0.00017, 0.00577) | 2.00 | 0.063 | 1.60 |

| Oil | −0.00020 | 0.00140 | (−0.00317, 0.00277) | −0.14 | 0.888 | 1.60 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Samanth, M.; Hiremath, P.; Deepak, G.D.; Naik, N.; H S, A.; Heckadka, S.S.; Shivamurthy, R.C. Sustainable Composites from Sugarcane Bagasse Fibers and Bio-Based Epoxy with Insights into Wear Performance, Thermal Stability, and Machine Learning Predictive Modeling. J. Compos. Sci. 2025, 9, 124. https://doi.org/10.3390/jcs9030124

Samanth M, Hiremath P, Deepak GD, Naik N, H S A, Heckadka SS, Shivamurthy RC. Sustainable Composites from Sugarcane Bagasse Fibers and Bio-Based Epoxy with Insights into Wear Performance, Thermal Stability, and Machine Learning Predictive Modeling. Journal of Composites Science. 2025; 9(3):124. https://doi.org/10.3390/jcs9030124

Chicago/Turabian StyleSamanth, Mahima, Pavan Hiremath, G. Divya Deepak, Nithesh Naik, Arunkumar H S, Srinivas Shenoy Heckadka, and R. C. Shivamurthy. 2025. "Sustainable Composites from Sugarcane Bagasse Fibers and Bio-Based Epoxy with Insights into Wear Performance, Thermal Stability, and Machine Learning Predictive Modeling" Journal of Composites Science 9, no. 3: 124. https://doi.org/10.3390/jcs9030124

APA StyleSamanth, M., Hiremath, P., Deepak, G. D., Naik, N., H S, A., Heckadka, S. S., & Shivamurthy, R. C. (2025). Sustainable Composites from Sugarcane Bagasse Fibers and Bio-Based Epoxy with Insights into Wear Performance, Thermal Stability, and Machine Learning Predictive Modeling. Journal of Composites Science, 9(3), 124. https://doi.org/10.3390/jcs9030124