Non-Destructive Evaluation of Impact-Damaged Sandwich Composites: Influence of Fiber Type

Abstract

1. Introduction

2. Materials and Experimental Procedure

3. Results and Discussion

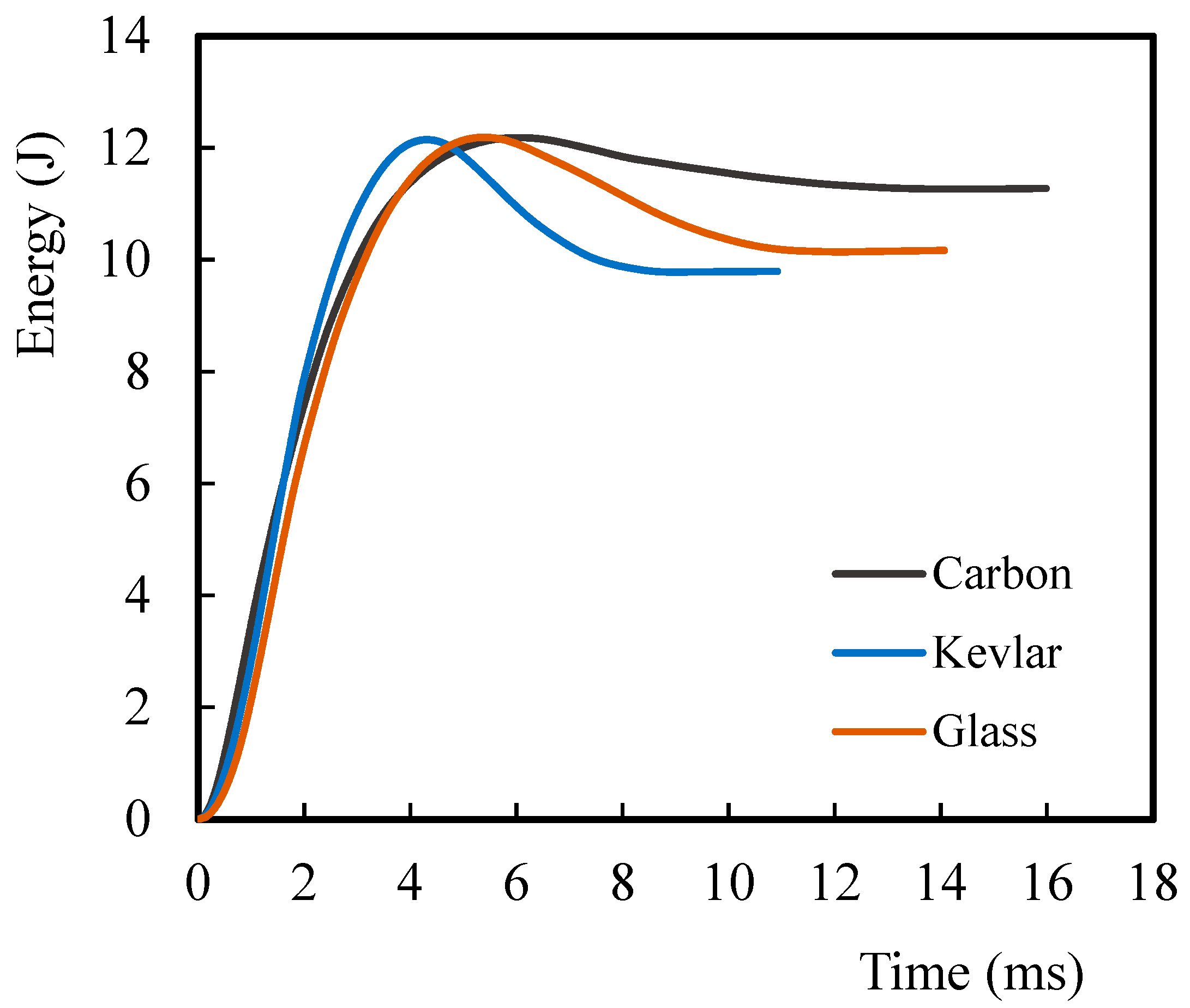

3.1. Impact Characterization

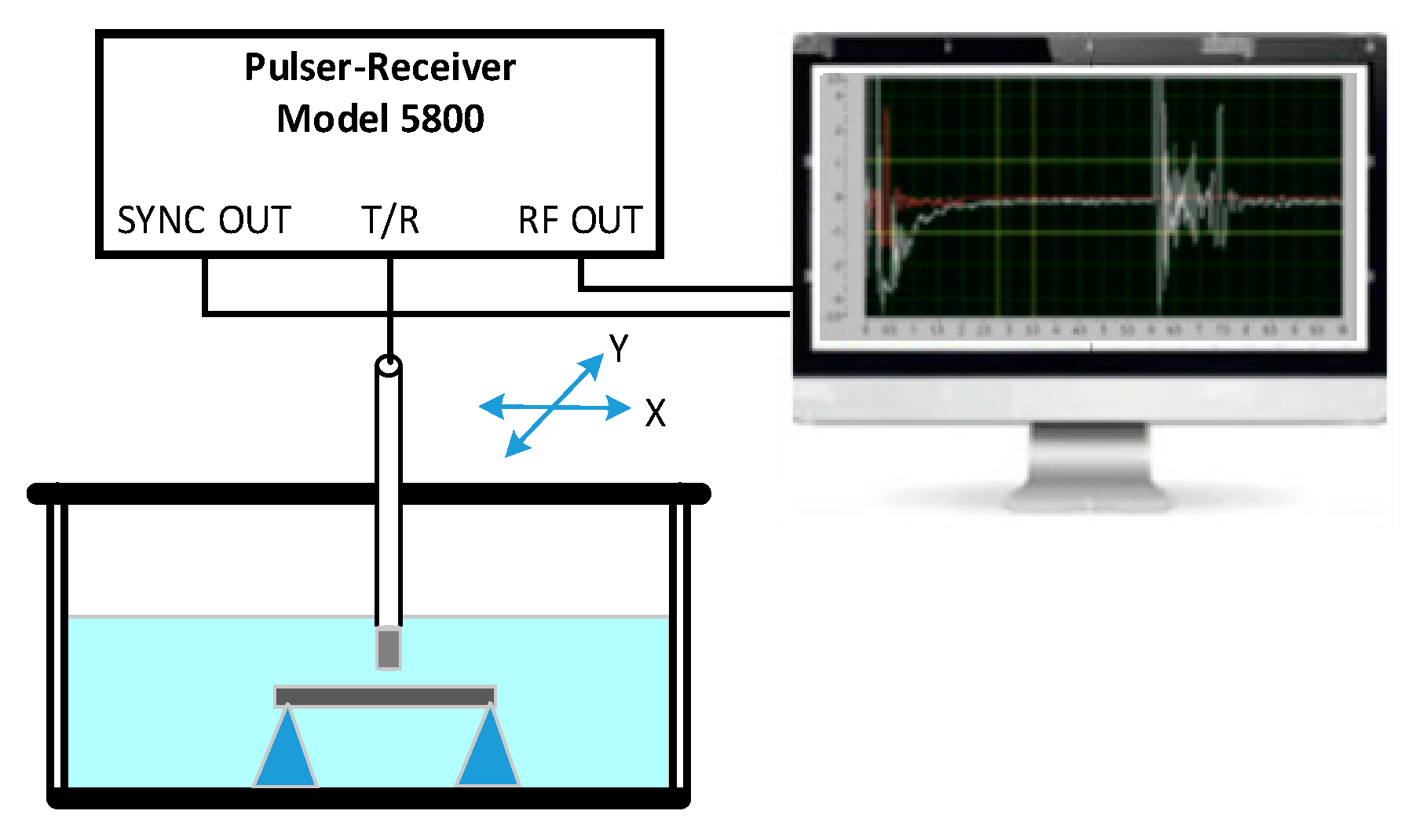

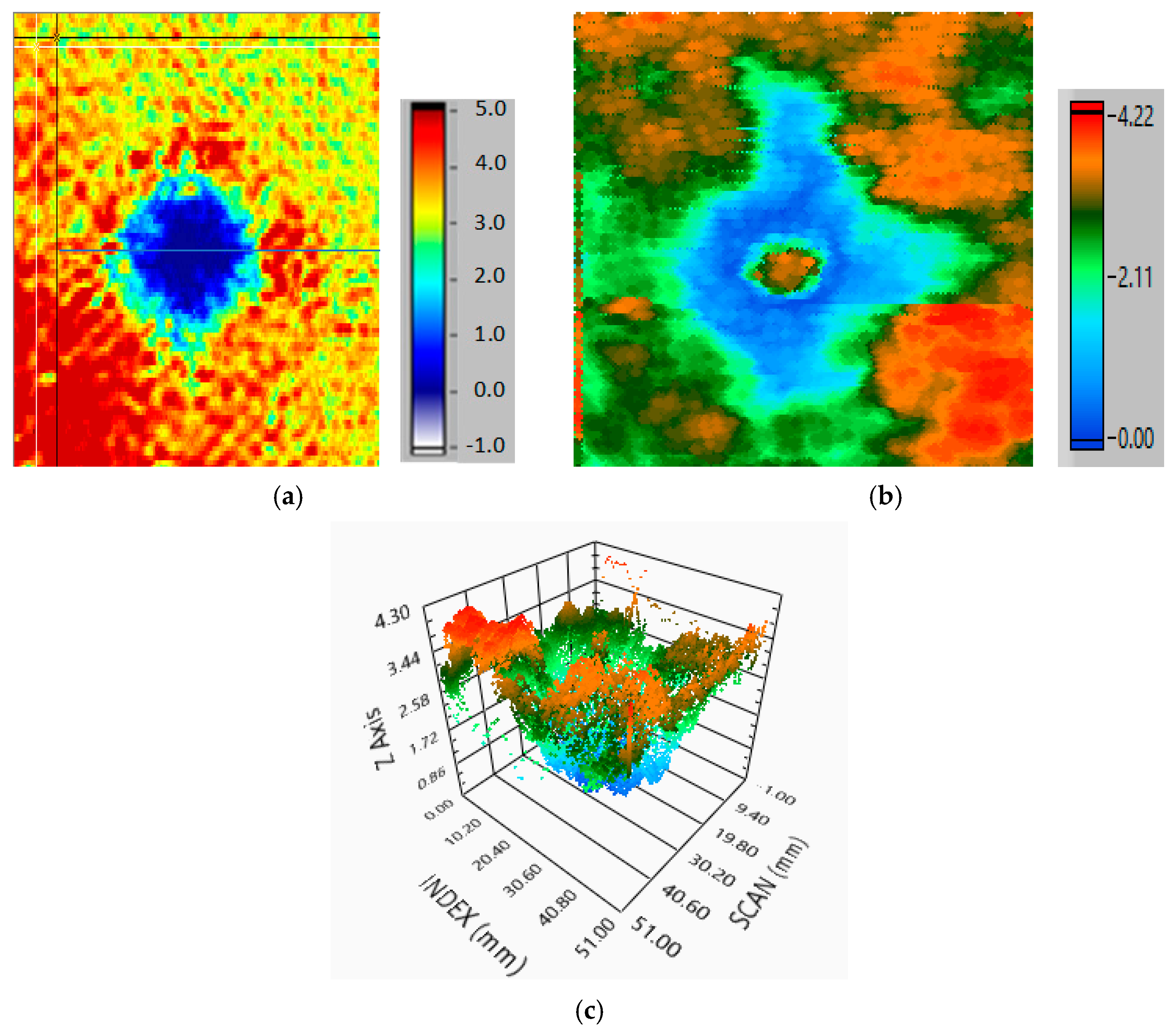

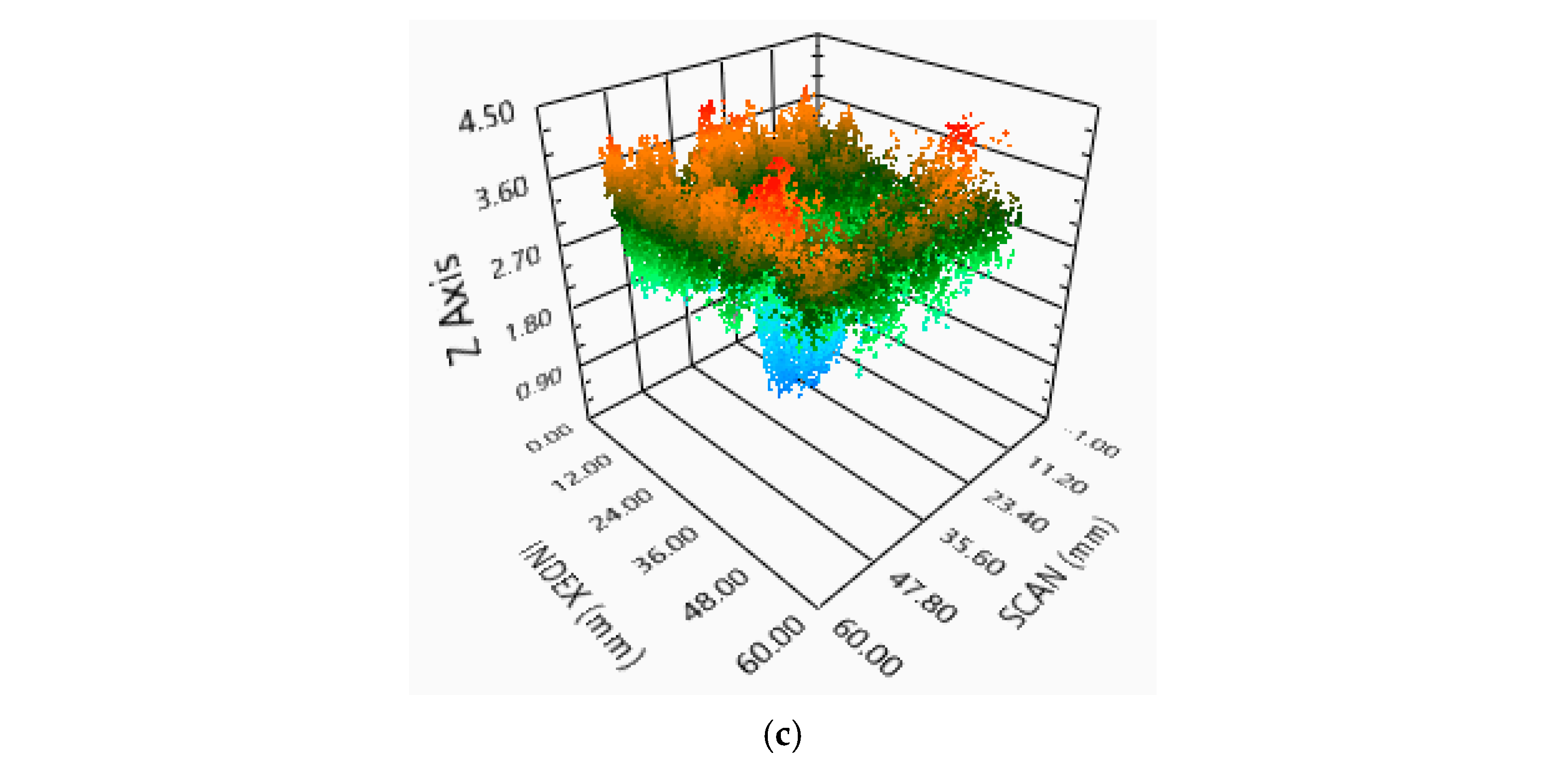

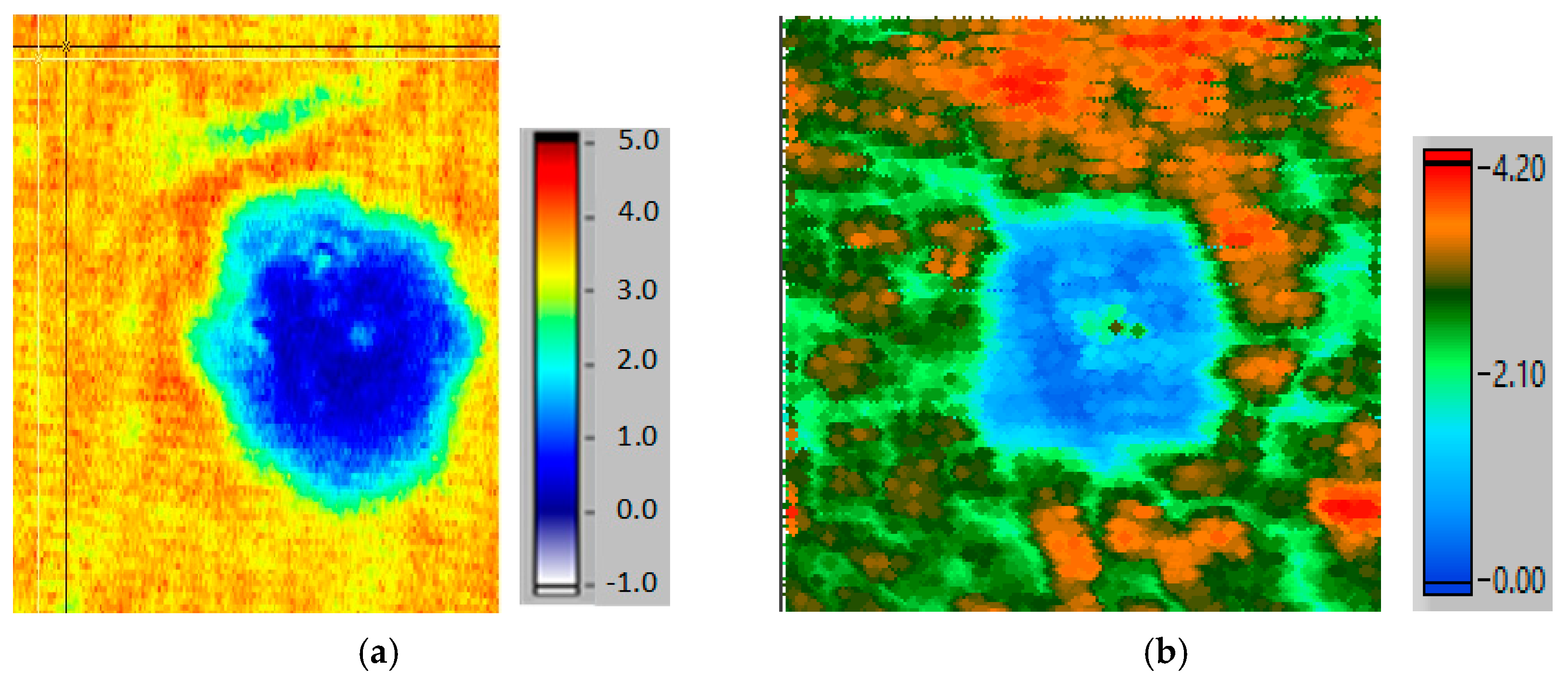

3.2. Ultrasonic C-Scan Inspection of Laminates

4. Conclusions

- Sandwich composites have a higher maximum load and elastic energy than single-fiber structures. In the case of the sandwich composites, the lowest impact force determined was 4221 N, while for the single fiber, the maximum value for the impact force was 2875 N, which means a difference of around 32%. Comparing the elastic energy, the sandwich composite with Kevlar in the core has the highest value (26.9%), around 24% higher than the single-Kevlar-fiber one.

- The lowest impact force is observed with carbon fibers in the case of single fibers, and for sandwich structures, the lowest impact force occurs when carbon fibers are used in the core. However, the sandwich composite with carbon in the core has a 46% higher impact force value than the single-carbon-fiber composite.

- The IBS derived from the load–displacement curves indicated that, for the sandwich configurations, a higher IBS value corresponds to a smaller damage size.

- Carbon fibers, being brittle, show very localized damage, which corresponds to a higher IBS.

- In the case of glass fibers with some ductility, several ramifications can be observed, which correspond to fragmentation, and hence a lower IBS.

- On the other hand, Kevlar fibers, which are more ductile, show a damage propagation mode between those of the other two types, as also observed for the IBS value.

- This finding was validated using the C-scan technique, particularly the immersion method. The GCG configuration demonstrated superior performance in mitigating damage compared to the other sandwich designs.

- The core is primarily responsible for the structural response in sandwich composites.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chen, S.; Hu, J.; Han, S.; Guo, Y.; Belzile, N.; Deng, T. A review on emerging composite materials for cesium adsorption and environmental remediation on the latest decade. Sep. Purif. Technol. 2020, 251, 117340. [Google Scholar] [CrossRef]

- Tornero, R.G. Composite materials are more present today than ever before in cars. Reinf. Plast. 2015, 59, 131. [Google Scholar] [CrossRef]

- Hsissou, R.; Seghiri, R.; Benzekri, Z. Miloudi Hilali, Mohamed Rafik, Ahmed Elharfi, Polymer composite materials: A comprehensive review. Compos. Struct. 2021, 262, 113640. [Google Scholar] [CrossRef]

- Parveez, B.; Kittur, M.I.; Badruddin, I.A.; Kamangar, S.; Hussien, M.; Umarfarooq, M.A. Scientific Advancements in Composite Materials for Aircraft Applications: A Review. Polymer 2022, 14, 5007. [Google Scholar] [CrossRef]

- Adams, R.D.; Cawley, P.D. A review of defects types and non-destructive testing techniques for composites and bonded joints. NDT Int. 1998, 21, 208–222. [Google Scholar]

- Amaro, A.M.; Reis, P.N.B.; de Moura, M.F.S.F.; Santos, J.B. Damage detection on laminated composite materials using several NDT techniques. Insight 2012, 54, 14–20. [Google Scholar] [CrossRef]

- Tabatabaeian, A.; Fotouhi, S.; Fotouhi, M. 2-Visual inspection of impact damage in composite materials. In Non-Destructive Testing of Impact Damage in Fiber-Reinforced Polymer Composites; Woodhead Publishing Series in Composites Science and Engineering; Woodhead Publishing: Sawston, UK, 2024; pp. 43–67. [Google Scholar] [CrossRef]

- Tabatabaeian, A.; Jerković, B.; Harrison, P.; Marchiori, E.; Fotouhi, M. Barely visible impact damage detection in composite structures using deep learning networks with varying complexities. Compos. Part B Eng. 2023, 264, 110907. [Google Scholar] [CrossRef]

- Davies, G.A.O.; Hitchings, D.; Zhou, G. Impact damage and residual strengths of woven fabric glass/polyester laminates. Compos. Part A Appl. Sci. Manuf. 1996, 27, 1147–1156. [Google Scholar] [CrossRef]

- de Moura, M.F.S.F.; Marques, A.T. Prediction of low velocity impact damage in carbon–epoxy laminates. Compos. Part A Appl. Sci. Manuf. 2002, 33, 361–368. [Google Scholar] [CrossRef]

- Amaro, A.M.; de Moura, M.F.S.F.; Reis, P.N.B. Residual strength after low velocity impact in carbon–epoxy laminates. Mater. Sci. Forum 2006, 514–516, 624–628. [Google Scholar] [CrossRef]

- Amaro, A.M.; Reis, P.N.B.; de Moura, M.F.S.F. Delamination effect on bending behaviour in carbon–epoxy composites. Strain 2011, 47, 203–208. [Google Scholar] [CrossRef]

- Reis, P.N.B.; Ferreira, J.A.M.; Antunes, F.V.; Richardson, M.O.W. Effect of interlayer delamination on mechanical behavior of carbon/epoxy laminates. J. Compos. Mater. 2009, 43, 2609–2621. [Google Scholar] [CrossRef]

- Baran, I.; Weijermar, W. Residual bending behaviour of sandwich composites after impact. J. Sandw. Struct. Mater. 2020, 22, 402–422. [Google Scholar] [CrossRef]

- Mallick, P.K. Fibre-Reinforced Composites Materials, Manufacturing and Design, 3rd ed.; Taylor & Francis Group: New York, NY, USA, 2007; p. 616. [Google Scholar]

- Chandrasekar, M.; Shahroze, R.M.; Ishak, M.R.; Saba, N.; Jawaid, M.; Senthilkumar, K.; Senthil Muthu Kumar, T.; Siengchin, S. Flax and sugar palm reinforced epoxy composites: Effect of hybridization on physical, mechanical, morphological and dynamic mechanical properties. Mater. Res. Express 2019, 6, 105331. [Google Scholar] [CrossRef]

- Hassan, M.Z.; Cantwell, W.J. The influence of core properties on the perforation resistance of sandwich structures—An experimental study. Compos. Part B Eng. 2012, 43, 3231–3238. [Google Scholar] [CrossRef]

- Hung, P.; Lau, K.; Cheng, L.; Leng, J.; Hui, D. Impact response of hybrid carbon/glass fibre reinforced polymer composites designed for engineering applications. Compos. Part B Eng. 2018, 133, 86–90. [Google Scholar] [CrossRef]

- Chen, D.; Luo, Q.; Meng, M.; Li, Q.; Sun, G. Low velocity impact behavior of interlayer hybrid composite laminates with carbon/glass/basalt fibres. Compos. Part B Eng. 2019, 176, 107191. [Google Scholar] [CrossRef]

- Cheon, J.; Lee, M.; Kim, M. Study on the stab resistance mechanism and performance of the carbon, glass and aramid fiber reinforced polymer and hybrid composites. Compos. Struct. 2020, 234, 111690. [Google Scholar] [CrossRef]

- Zhang, C.; Rao, Y.; Li, W. Low-velocity impact behavior of intralayer hybrid composites based on carbon and glass non-crimp fabric. Compos. Struct. 2020, 234, 111713. [Google Scholar] [CrossRef]

- Liu, H.; Falzon, B.G.; Tan, W. Experimental and numerical studies on the impact response of damage-tolerant hybrid unidirectional/woven carbon-fibre reinforced composite laminates. Compos. Part B Eng. 2020, 136B, 101–118. [Google Scholar] [CrossRef]

- Bian, T.; Lyu, Q.; Fan, X.; Zhang, X.; Li, X.; Guo, Z. Efects of Fiber Architectures on the Impact Resistance of Composite Laminates Under Low-Velocity Impact. Appl. Compos. Mater. 2022, 29, 1125–1145. [Google Scholar] [CrossRef]

- ASTM D 7136. ASTM International: West Conshohocken, PA, USA. 2020. Available online: https://www.astm.org/d7136_d7136m-15.html (accessed on 2 January 2025).

- Monjon, A.; Santos, P.; Valvez, S.; Reis, P.N.B. Hybridization effects on bending and interlaminar shear strength of composite laminates. Materials 2022, 14, 1302. [Google Scholar] [CrossRef] [PubMed]

- David-West, O.S.; Nash, D.H.; Banks, W.M. An experimental study of damage accumulation in balanced CFRP laminates due to repeated impact. Compos. Struct. 2008, 83, 247–258. [Google Scholar] [CrossRef]

- David-West, O.S.; Nash, D.H.; Banks, W.M. Low-velocity heavy mass impact response of singly curved composites. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2014, 228, 17–33. [Google Scholar] [CrossRef]

- Aslan, Z.; Karakuzu, R.; Okutan, B. The response of laminated composite plates under low-velocity impact loading. Compos. Struct. 2003, 59, 119–127. [Google Scholar] [CrossRef]

- Hosur, M.V.; Adbullah, M.; Jeelani, S. Studies on the low-velocity impact response of woven hybrid composites. Compos. Struct. 2005, 67, 253–262. [Google Scholar] [CrossRef]

- Iqbal, K.; Khan, S.-U.; Munir, A.; Kim, J.-K. Impact damage resistance of CFRP with nanoclay-filled epoxy matrix. Compos. Sci. Technol. 2009, 69, 1949–1957. [Google Scholar] [CrossRef]

- Amaro, A.M.; Reis, P.N.B.; Neto, M.A.; Louro, C. Effects of alkaline and acid solutions on glass/epoxy composites. Polym. Degrad. Stab. 2013, 98, 853–862. [Google Scholar] [CrossRef]

- Amaro, A.M.; Reis, P.N.B.; Neto, M.A. Experimental study of temperature effects on composite laminates subjected to multi-impacts. Compos. Part B Eng. 2016, 98, 23–29. [Google Scholar] [CrossRef]

- Khashaba, U.A. A comprehensive study of low-velocity impact behavior and damage evaluation of angle-ply thin woven GFRP composites under elevated temperatures. Compos. Sci. Technol. 2024, 252, 110608. [Google Scholar] [CrossRef]

- Newaz, G.M.; Walsh, D.J. Interrelationship of damage and strain in particulate composites. J. Comp. Mater. 1989, 23, 326e36. [Google Scholar] [CrossRef]

- Chow, C.L.; Wang, J. An anisotropic theory of elasticity for continuum damage mechanics. Int. J. Fract. 1987, 33, 3e16. [Google Scholar] [CrossRef]

- Morais, W.A.; Monteiro, S.N.; d’Almeida, J.R.M. Evaluation of repeated low energy impact damage in carbon-epoxy composite laminates. Compos. Struct. 2005, 67, 307e15. [Google Scholar] [CrossRef]

- Aktas, M.; Atas, C.; Icten, B.M.; Karakuzu, R. An experimental investigation of the impact response of composite laminates. Compos. Struct. 2009, 87, 307–313. [Google Scholar] [CrossRef]

| Stacking Sequence | Average Thickness (mm) |

|---|---|

| 12C | 2.1 |

| 12G | 1.8 |

| 12K | 2.1 |

| 4C + 4G + 4C | 2.7 |

| 4G + 4C + 4G | 2.8 |

| 4G + 4K + 4G | 2.7 |

| Composite | Maximum Load (N) | Maximum Displacement (mm) | Elastic Energy (%) |

|---|---|---|---|

| C | 2276 (76) | 7.5 (0.6) | 7.0 (0.6) |

| K | 2875 (56) | 6.2 (0.3) | 20.4 (1.7) |

| G | 2372 (79) | 7.6 (0.2) | 16.9 (1.4) |

| Composite | Maximum Load (N) | Maximum Displacement (mm) | Elastic Energy (%) |

|---|---|---|---|

| 4C + 4G + 4C | 4782 (217) | 3.8 (0.2) | 16.8 (1.5) |

| 4G + 4C + 4G | 4221 (192) | 4.4 (0.1) | 25.9 (2.1) |

| 4G + 4K + 4G | 4674 (369) | 4.3 (0.1) | 26.9 (2.6) |

| Damage Area (mm2) | Stacking Sequence | |||

| 4C + 4G + 4C | 4G + 4C + 4G | 4G + 4K + 4G | ||

| Air-Coupling C-Scan | 714.4 ± 32.1 | 184.8 ± 11.6 | 531.9 ± 31.8 | |

| Immersion C-Scan | 741.4 ± 42.2 | 201.8 ± 17.2 | 553.9 ± 32.4 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Santos, J.; Reis, P.N.B.; Santos, M.; Amaro, A.M. Non-Destructive Evaluation of Impact-Damaged Sandwich Composites: Influence of Fiber Type. J. Compos. Sci. 2025, 9, 86. https://doi.org/10.3390/jcs9020086

Santos J, Reis PNB, Santos M, Amaro AM. Non-Destructive Evaluation of Impact-Damaged Sandwich Composites: Influence of Fiber Type. Journal of Composites Science. 2025; 9(2):86. https://doi.org/10.3390/jcs9020086

Chicago/Turabian StyleSantos, Jaime, Paulo N. B. Reis, Mario Santos, and Ana M. Amaro. 2025. "Non-Destructive Evaluation of Impact-Damaged Sandwich Composites: Influence of Fiber Type" Journal of Composites Science 9, no. 2: 86. https://doi.org/10.3390/jcs9020086

APA StyleSantos, J., Reis, P. N. B., Santos, M., & Amaro, A. M. (2025). Non-Destructive Evaluation of Impact-Damaged Sandwich Composites: Influence of Fiber Type. Journal of Composites Science, 9(2), 86. https://doi.org/10.3390/jcs9020086