Development of Carbide-Reinforced Al-7075 Multi-Layered Composites via Friction Stir Additive Manufacturing

Abstract

1. Introduction

| Base Alloy | Reinforcement | Microstructure (Uniform) | Microhardness (Uniform) | In Process Cooling | Tool Wear | PWHT | Reference |

|---|---|---|---|---|---|---|---|

| Al-6061-T6 | × | × | × | × | × | × | [10] |

| Al-6061-T6 | × | × | × | × | × | × | [11] |

| Al-6061-T6/ Al-7075-T6 | × | × | × | × | × | × | [12,25] |

| Al-6061-T6/ Al-5083-O/ Al-7075-T6 | × | × | × | × | × | × | [13] |

| Al-7075-O | × | × | × | × | × | × | [14] |

| Al-7N01-T4 | × | × | × | × | × | √ | [15] |

| Al-7075-T6 | × | × | × | × | × | × | [16] |

| Al-7075-T6 | × | × | × | × | × | × | [17] |

| Al-7075-T6 | × | × | × | × | × | √ | [18] |

| Al-7075-T6 | × | √ | √ | √ | × | √ | [19] |

| Al-7N01-T4 | × | √ | √ | √ | × | √ | [26] |

| Al-7075-T6 | × | √ | √ | √ | × | × | [27] |

| Al6061-T6 | SiC | × | × | × | √ | × | [20] |

| Al6061-T6 | TiC, GS | × | × | × | × | × | [21] |

| Al-5059-O | SiC | × | × | × | × | × | [22] |

| Al-7075-T6 | ZrO2/G | × | × | × | × | × | [23] |

| Al-7075-T6 | ZrO2/Gr | × | × | × | × | × | [24] |

2. Materials and Methods

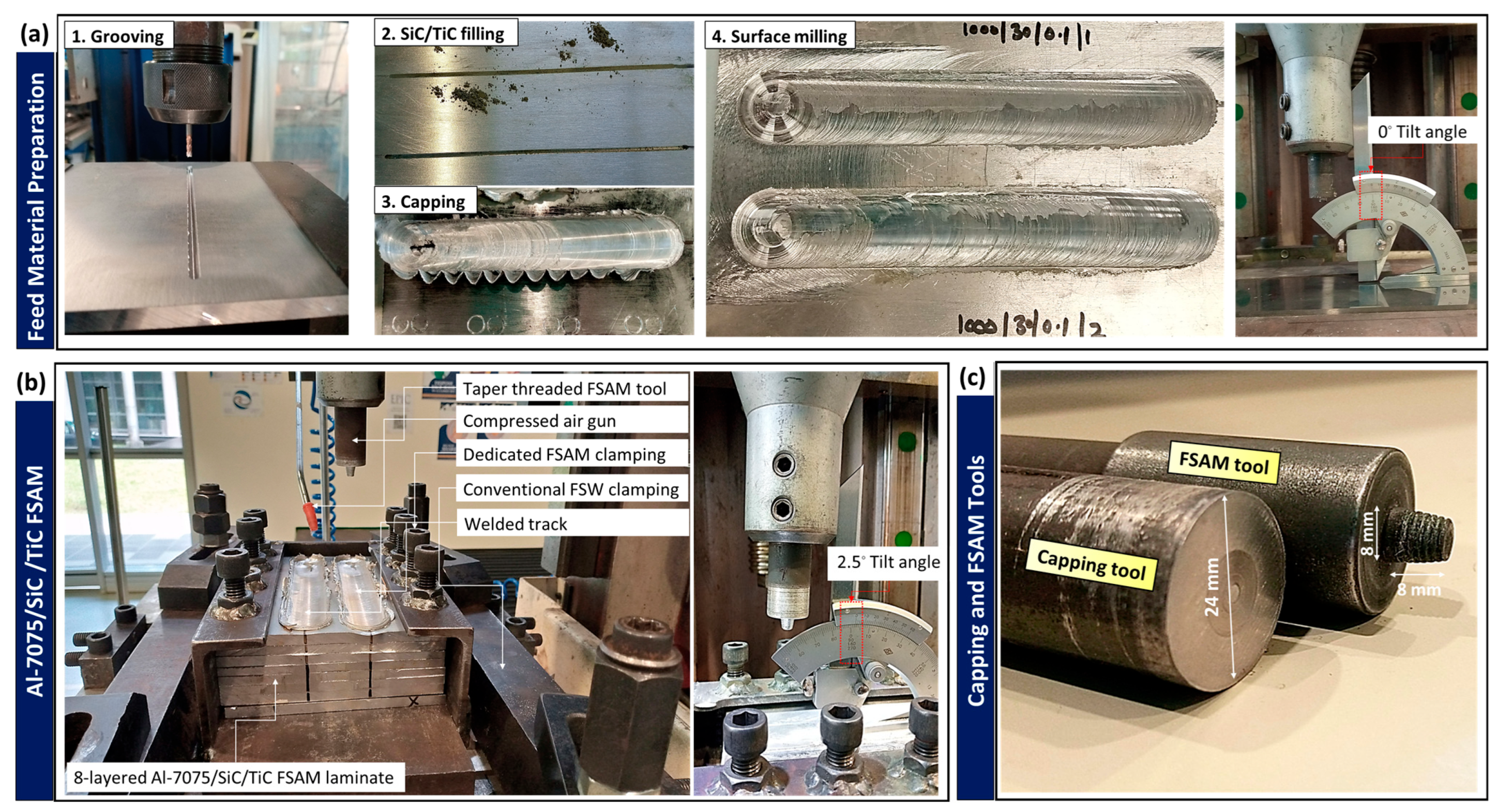

2.1. Feed Material Preparation and FSAM

2.2. Sample Preparation and PWHT

2.3. Microstructure and Mechanical Testing

3. Results and Discussion

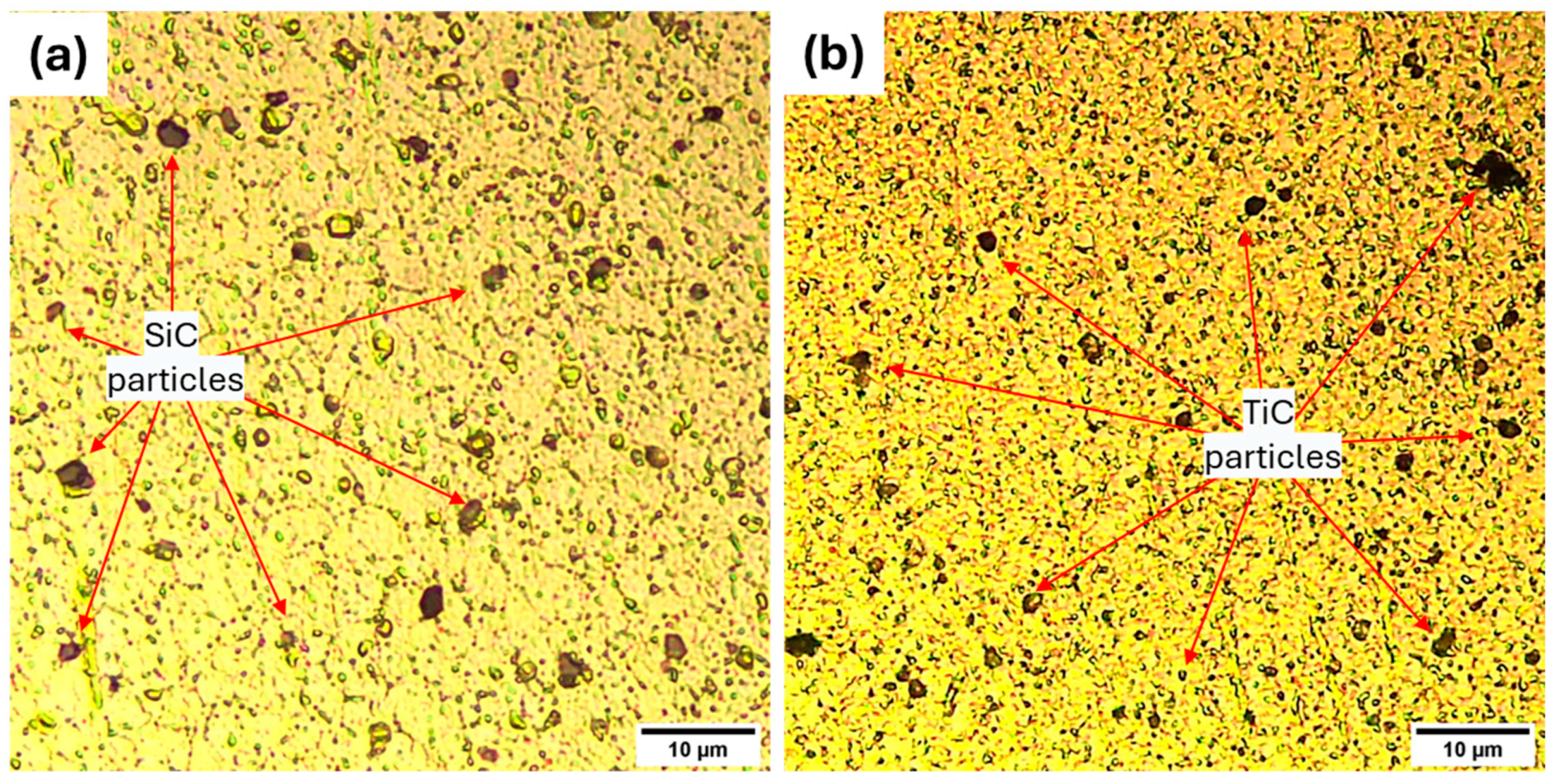

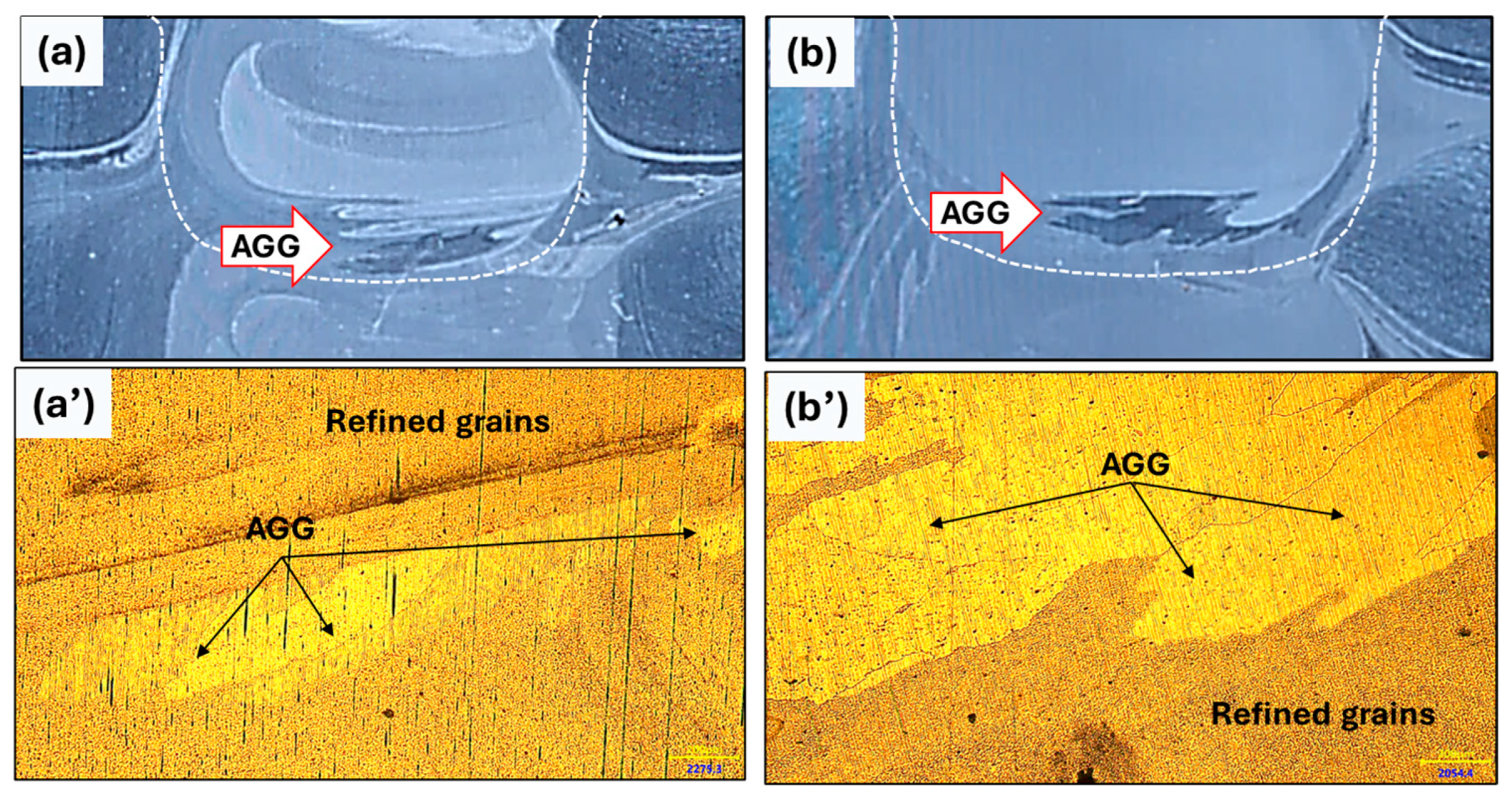

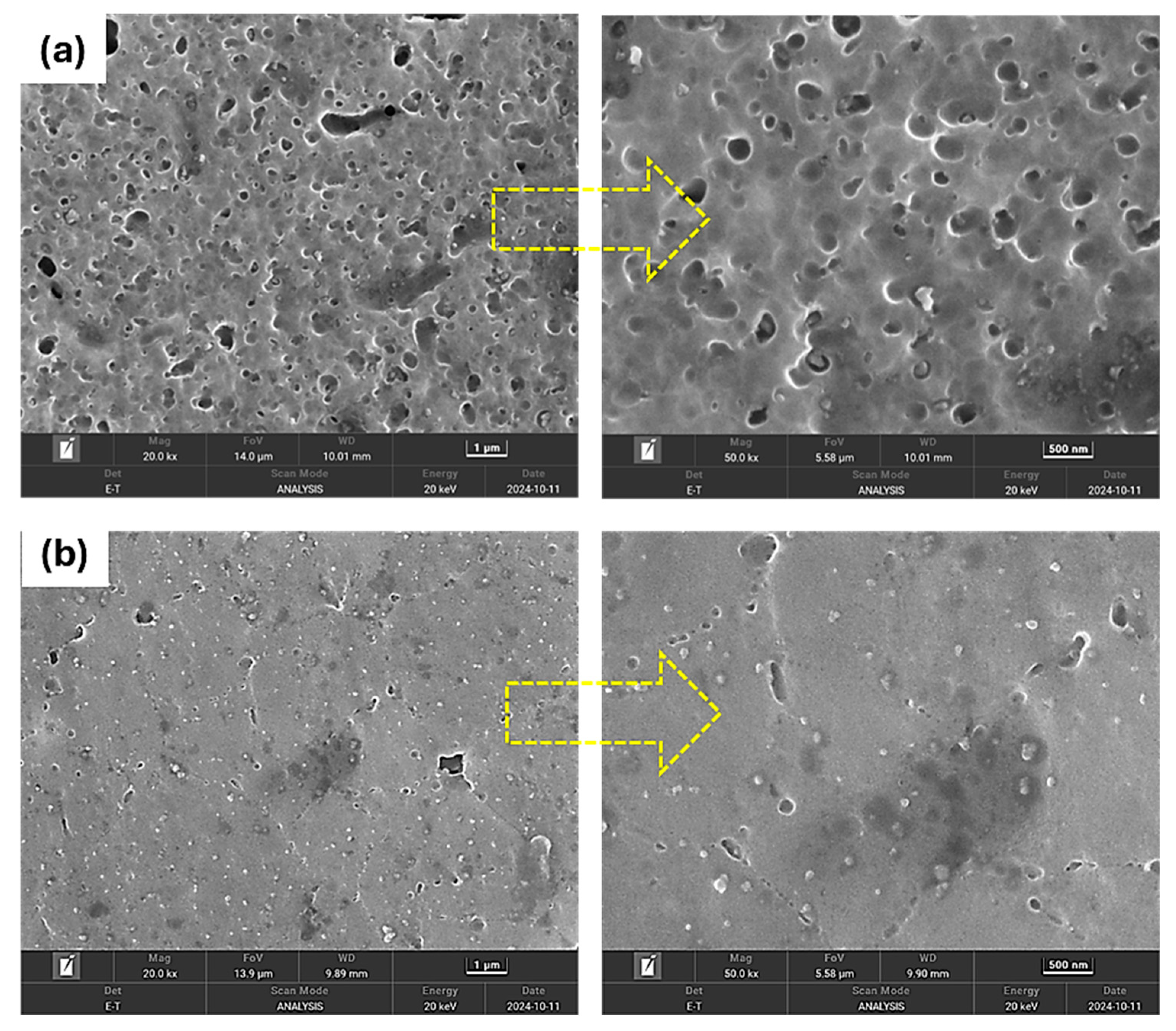

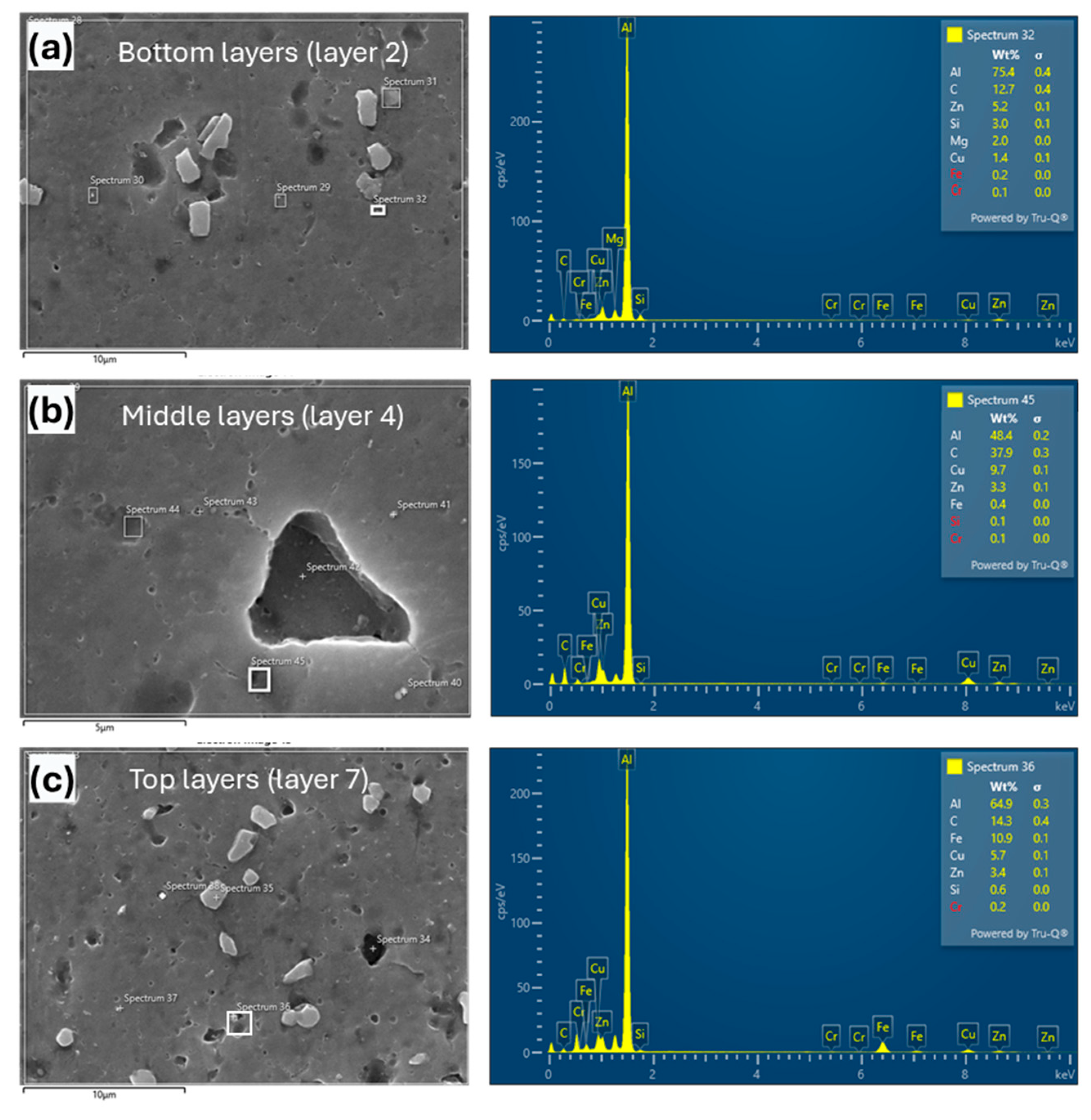

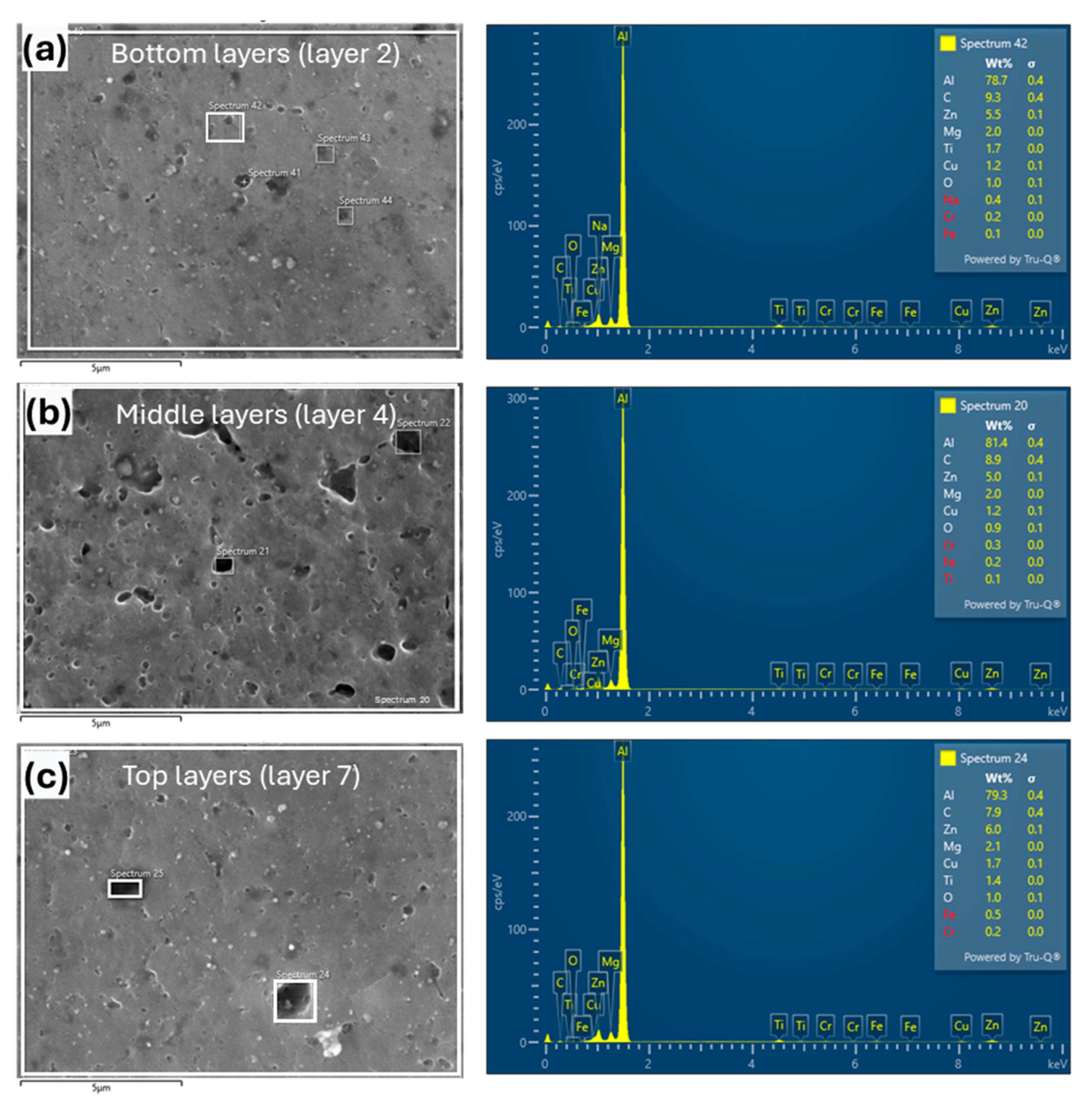

3.1. Microstructure

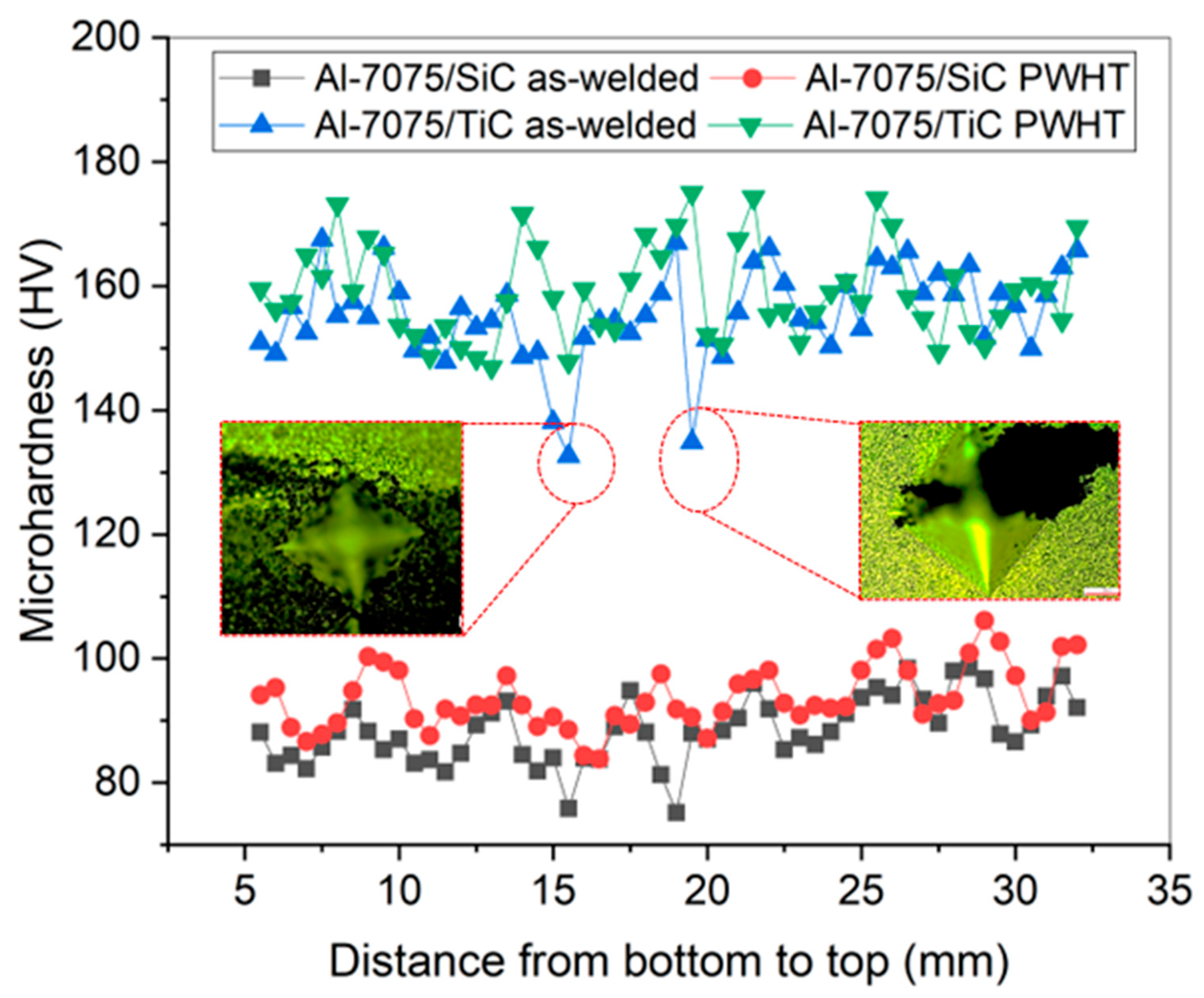

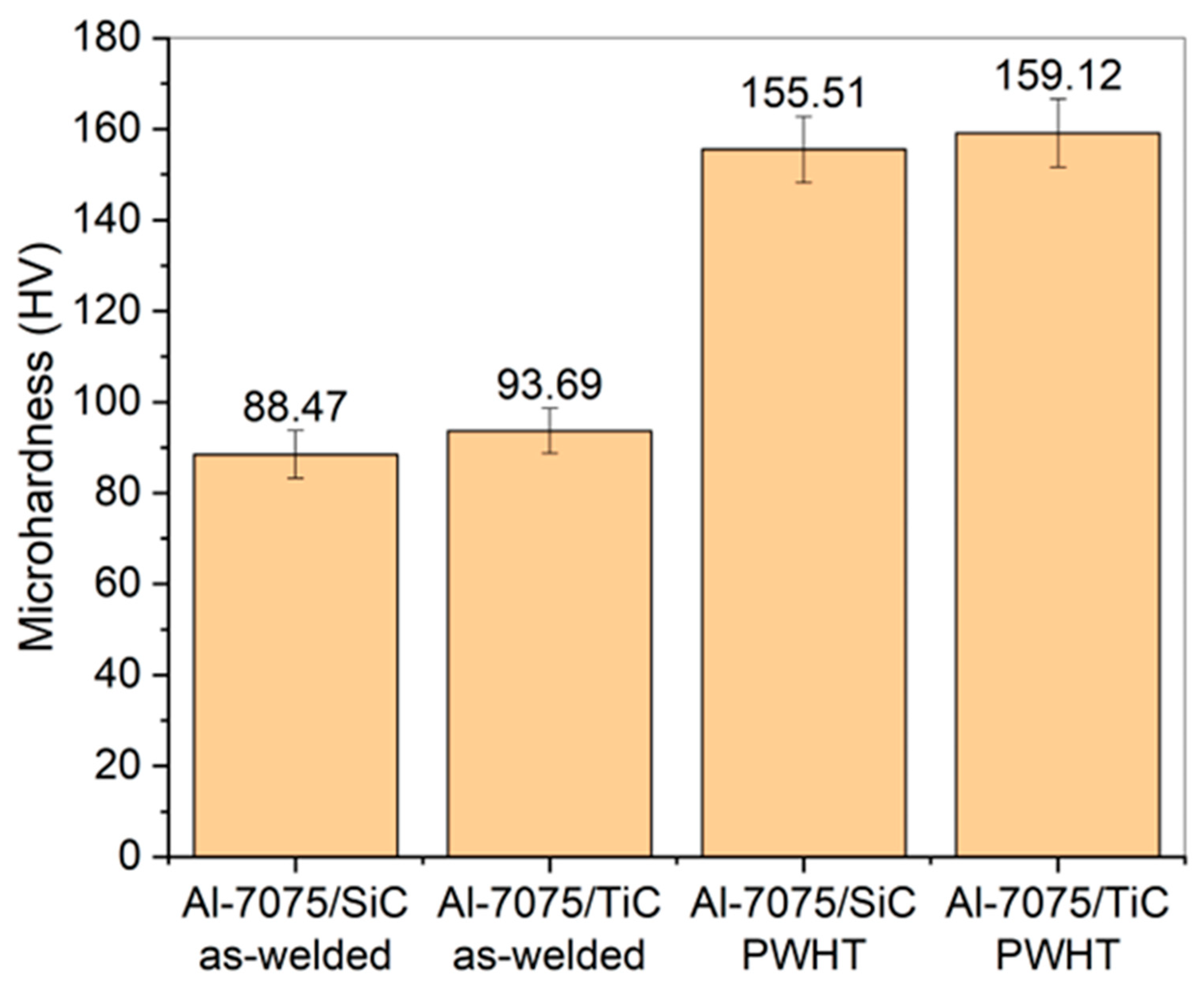

3.2. Microhardness

3.3. Tensile Properties

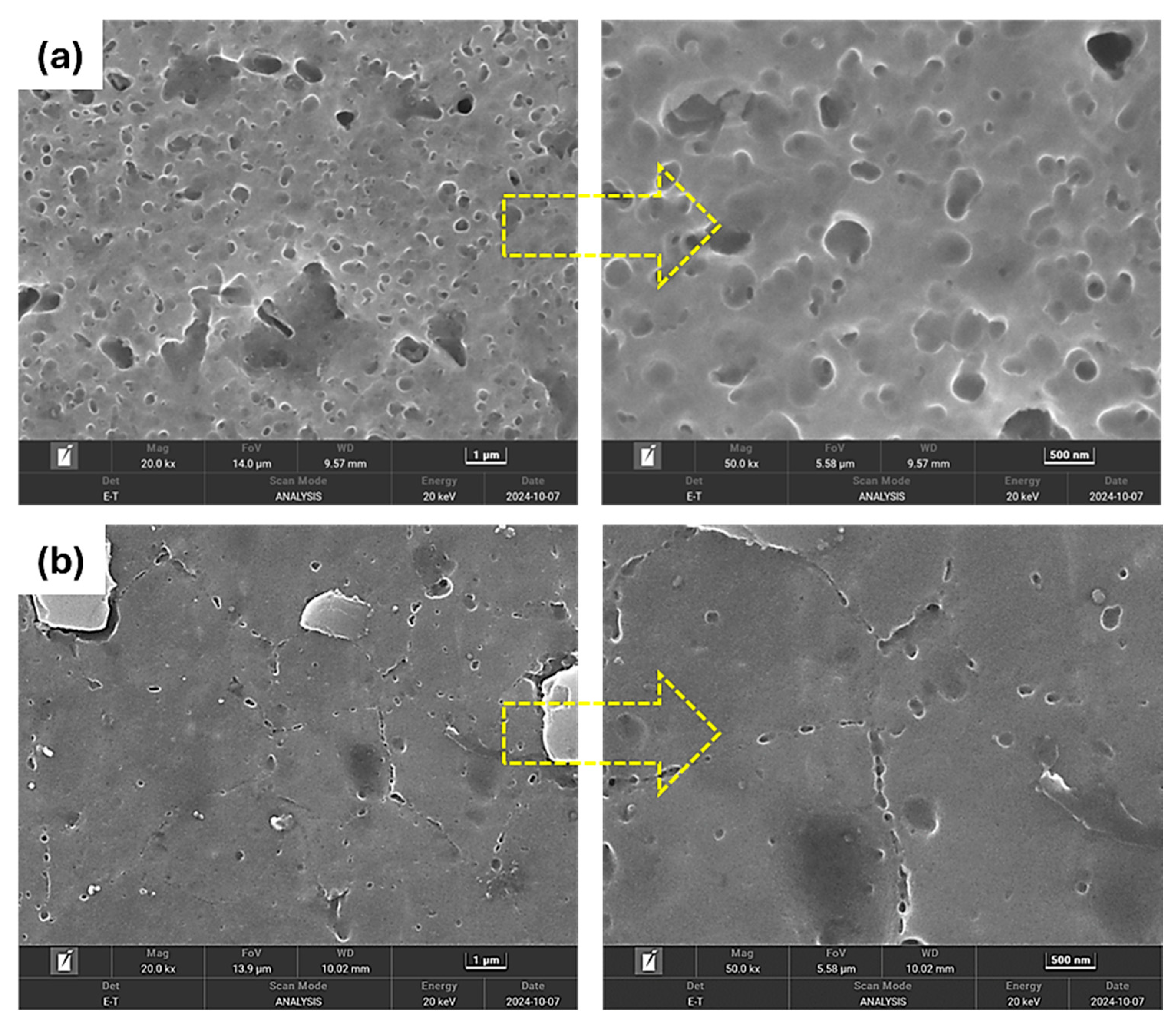

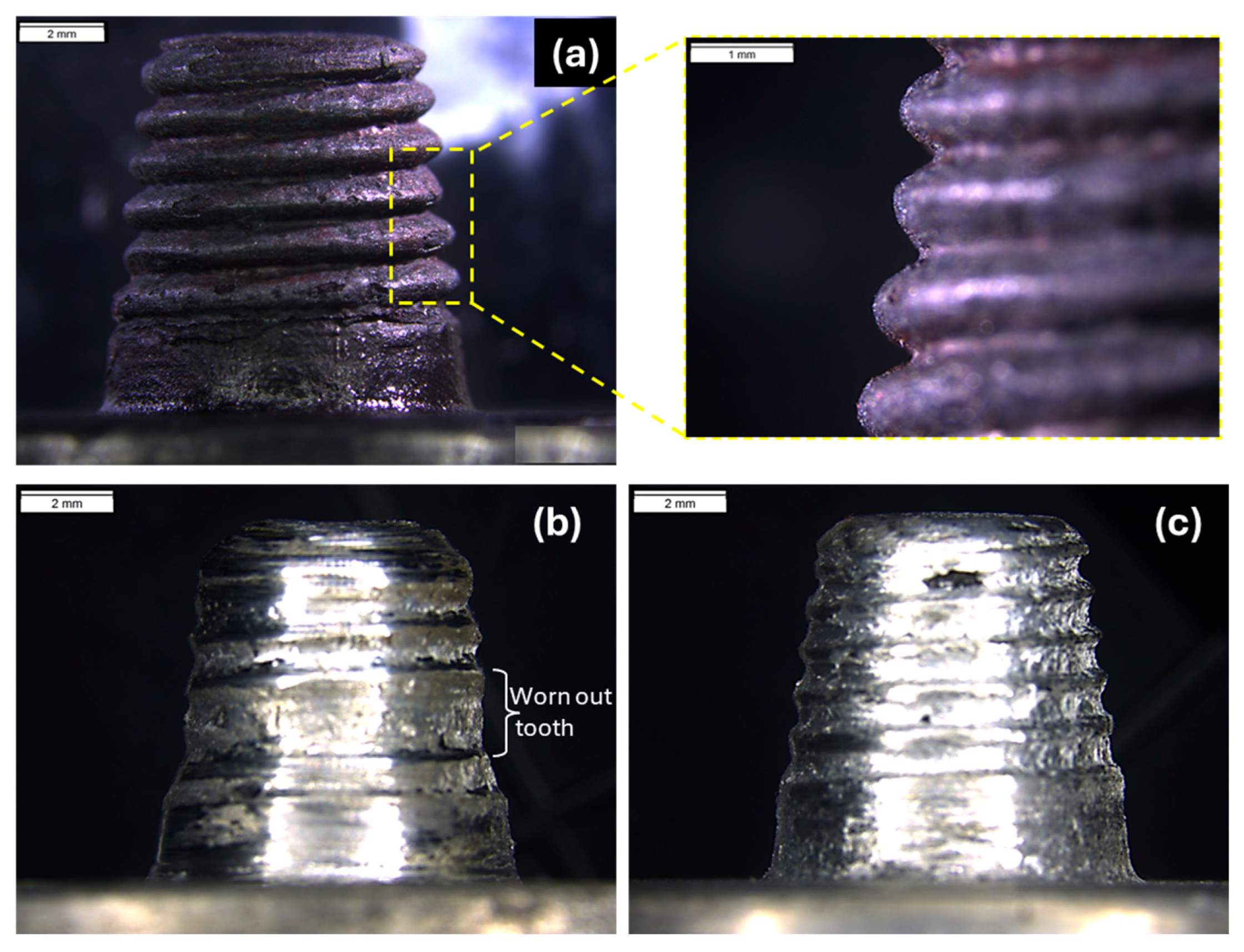

3.4. Tool Wear Analysis

4. Conclusions

- Microstructural characterization revealed defect-free composites with uniformly distributed reinforcements and fine equiaxed grains generated through DRX; however, slight particle agglomeration was noted near the bottom of the PDZ.

- Reinforcement with TiC led to a significantly refined grain structure under both as-welded and PWHT conditions, achieving a minimum grain size of 1.25 µm and nearly a 95% reduction relative to the BM.

- Composites containing TiC displayed enhanced mechanical properties, recording a peak microhardness of 159.12 HV, tensile strength of 313.46 MPa, and elongation of 11.14%, outperforming those reinforced with SiC.

- Tool wear analysis indicated that SiC reinforcement induced greater tool degradation (1.17% weight loss), while TiC resulted in lower wear (0.54%), contributing to improved tool stability. These findings highlight the suitability of TiC for multi-layer FSAM applications, enhancing tool life, process consistency, and overall cost-efficiency for industrial implementation.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kvvssn, V.; Butt, M.M.; Laieghi, H.; Uddin, Z.; Salamci, E.; Kim, D.B.; Kizil, H. Recent Progress in Additive Manufacturing of 7XXX Aluminum Alloys; Springer: London, UK, 2025; Volume 137, ISBN 0123456789. [Google Scholar]

- Janga, V.S.R.; Awang, M.; Sallih, N.; Lemma, T.A. Thermo-Mechanical and Material Flow Characteristics of Tool Sequencing Dynamics in Refill FSSW of Thin Alclad AA7075-T6 Sheets: Numerical Analysis Using Meshless Smoothed-Particle Hydrodynamics Method. J. Adv. Join. Process. 2025, 11, 100285. [Google Scholar] [CrossRef]

- Oropeza, D.; Hofmann, D.C.; Williams, K.; Firdosy, S.; Bordeenithikasem, P.; Sokoluk, M.; Liese, M.; Liu, J.; Li, X. Welding and Additive Manufacturing with Nanoparticle-Enhanced Aluminum 7075 Wire. J. Alloys Compd. 2020, 834, 154987. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Zhu, H.; Qi, T.; Hu, Z.; Zeng, X. Selective Laser Melting of High Strength Al-Cu-Mg Alloys: Processing, Microstructure and Mechanical Properties. Mater. Sci. Eng. A 2016, 656, 47–54. [Google Scholar] [CrossRef]

- White, D. Object Consolidation Employing Friction Joining. US6457629B1, 1 October 2002. [Google Scholar]

- Palanivel, S.; Mishra, R.S. Building without Melting: A Short Review of Friction-Based Additive Manufacturing Techniques. Int. J. Addit. Subtractive Mater. Manuf. 2017, 1, 82–103. [Google Scholar] [CrossRef]

- Baumann, J.A. Production of Energy Efficient Preform Structures (PEEPS); DE-EE0003483; The Boeing Company: Crystal City, VA, USA, 2012. [Google Scholar]

- Lequeu, P.; Muzzolini, R.; Ehrstrom, J.C.; Bron, F.; Maziarz, R. High-Performance Friction Stir Welded Structures Using Advanced Alloys. In Proceedings of the Aeromat Conference, Seattle, WA, USA, 15–18 May 2006. [Google Scholar]

- Hassan, A.; Pedapati, S.R.; Awang, M.; Soomro, I.A. A Comprehensive Review of Friction Stir Additive Manufacturing (FSAM) of Non-Ferrous Alloys. Materials 2023, 16, 2723. [Google Scholar] [CrossRef]

- Choudhury, S.; Acharya, U.; Sethi, D.; Roy, J.; Roy, B.S. Synergic Enhancement of Ductility and Toughness in Friction Stir Additively Fabricated AA6061-T6 Build. J. Adhes. Sci. Technol. 2024, 38, 3092–3118. [Google Scholar] [CrossRef]

- Zhang, Y.; Guan, X.; Wang, L.; Wang, X.; Zhan, X. The Microstructure Diversity in Different Areas of the Ring-Route Al 6061-T6 Additive Zone by Friction Stir Additive Manufacturing. Int. J. Adv. Manuf. Technol. 2023, 128, 4857–4871. [Google Scholar] [CrossRef]

- Venkit, H.; Selvaraj, S.K. Novel Technique for Design and Manufacture of Alternating Gradient Composite Structure of Aluminum Alloys Using Solid. Materials 2022, 15, 7369. [Google Scholar] [CrossRef]

- Jha, K.K.; Imam, M. Microstructure Evolution and Local Mechanical Properties of Friction Stir Additively Manufactured (FSAM) AA5083/AA6061/AA7075 Gradient Composite. Mater. Sci. Eng. A 2024, 903, 146668. [Google Scholar] [CrossRef]

- Yuqing, M.; Liming, K.; Chunping, H.; Fencheng, L.; Qiang, L. Formation Characteristic, Microstructure, and Mechanical Performances of Aluminum-Based Components by Friction Stir Additive Manufacturing. Int. J. Adv. Manuf. Technol. 2016, 83, 1637–1647. [Google Scholar] [CrossRef]

- He, C.; Li, Y.; Zhang, Z.; Wei, J.; Zhao, X. Investigation on Microstructural Evolution and Property Variation along Building Direction in Friction Stir Additive Manufactured Al–Zn–Mg Alloy. Mater. Sci. Eng. A 2020, 777, 139035. [Google Scholar] [CrossRef]

- Hassan, A.; Awang, M.; Pedapati, S.R.; Altaf, K.; Marode, R.V.; Ahmed, S.W. Experimental Investigation on Tool Pin Profile for Defect-Free Multi-Layered Laminates Using Friction Stir Additive Manufacturing. Results Eng. 2023, 20, 101516. [Google Scholar] [CrossRef]

- Hassan, A.; Awang, M.; Rao Pedapati, S.; Altaf, K.; Ahmed, N.; Marode, R.V.; Ahmed, S.W.; Soomro, I.A. Investigation on Surface Hardness and Microstructure Evolution in AA 7075-T651 Multi-Layered Laminate Fabricated Through Friction Stir Additive Manufacturing. Iran. J. Mater. Sci. Eng. 2023, 20, 1–12. [Google Scholar] [CrossRef]

- Liu, J.; Miao, Y.; Wu, R.; Wei, C.; Zhao, Y.; Wu, Y.; Deng, Q. Effect of Heat Treatment on Microstructure, Mechanical Properties and Corrosion Resistance of 7075 Aluminum Alloys Fabricated by Improved Friction Stir Additive Manufacturing. J. Alloys Compd. 2024, 1007, 176512. [Google Scholar] [CrossRef]

- Hassan, A.; Altaf, K.; Ahmed, N.; Pedapati, S.R.; Marode, R.V. Enhancing Microhardness and Tensile Strength of In-Process Cooled Al-7075-T651 FSAM Laminates without Compromising Ductility through PWHT. J. Adv. Join. Process. 2025, 11, 100304. [Google Scholar] [CrossRef]

- Choudhury, S.; Das, R.; Sethi, D.; Roy, J.; Roy, B.S. Critical Assessment 43: Microstructural and Mechanical Properties of Friction Stir Additively Fabricated SiC-Reinforced AA6061 Build. Mater. Sci. Technol. 2023, 39, 3090–3110. [Google Scholar] [CrossRef]

- Maurya, M.; Kumar, S.; Maurya, A. Friction Stir Additive Manufactured AA 6061/TiC/GS Composite: Assessment of Microstructural and Mechanical Properties. Phys. Scr. 2024, 99, 075939. [Google Scholar] [CrossRef]

- Srivastava, M.; Rathee, S. Microstructural and Microhardness Study on Fabrication of Al 5059/SiC Composite Component via a Novel Route of Friction Stir Additive Manufacturing. Mater. Today Proc. 2020, 39, 1775–1780. [Google Scholar] [CrossRef]

- Kumar, A.; Kumar, Y.; Maji, K.; Kumar, S. Investigation on Fractographic and Microstructure Evolution in AA7075/ZrO2/G Multilayer Laminated Composite Fabricated Using Friction Stir Additive Manufacturing Process. J. Mater. Eng. Perform. 2024, 34, 17542–17550. [Google Scholar] [CrossRef]

- Kumar, A.; Kumar, Y.; Maji, K. Advancement and Mechanical Performance of Friction Stir Additive Manufactured Al7075/ZrO 2 /Gr Composite. Rapid Prototyp. J. 2025, 31, 1461–1472. [Google Scholar] [CrossRef]

- Kumaran Selvaraj, S.; Manoj, A.L.; Mathew, A.B.; Govind, A.V.; Sundaramali, G.; Chadha, U.; Vajipeyajula, B.; Patterson, A.E. Parameter Optimization for Dissimilar Aluminum Alloys Joined Using Friction Stir Additive Manufacturing: A Screening Study. Eng. Rep. 2025, 7, 1–10. [Google Scholar] [CrossRef]

- He, C.; Li, Y.; Wei, J.; Zhang, Z.; Tian, N.; Qin, G.; Zhao, X. Enhancing the Mechanical Performance of Al–Zn–Mg Alloy Builds Fabricated via Underwater Friction Stir Additive Manufacturing and Post-Processing Aging. J. Mater. Sci. Technol. 2022, 108, 26–36. [Google Scholar] [CrossRef]

- Hassan, A.; Altaf, K.; Awang, M.; Pedapati, S.R.; Ahmed, N.; Marode, R.V. Multi-Objective Optimization of Friction Stir Additively Manufactured Al-7075 Multi-Layered Laminates. J. Alloys Compd. 2024, 993, 174659. [Google Scholar] [CrossRef]

- Duan, Y.; Dang, Y.; Yi, S.; Cao, X.; Cao, Y.; Chen, Z. Microstructure and Properties of SiC Particle Reinforced AA7075 Composites by Friction Stir Processing. J. Mater. Res. Technol. 2025, 34, 1349–1361. [Google Scholar] [CrossRef]

- Patil, N.A.; Pedapati, S.R.; Mamat, O.B.; Syah Lubis, A.M.H. Optimization of Friction Stir Process Parameters for Enhancement in Surface Properties of Al 7075-SiC/Gr Hybrid Surface Composites. Coatings 2019, 9, 830. [Google Scholar] [CrossRef]

- Vasava, A.; Singh, D. Influence of Various Tool Shoulder Design on Hybrid Surface Composite of AA7075-T651/SiC/Graphene through Friction Stir Processing. Can. Metall. Q. 2023, 63, 1–19. [Google Scholar] [CrossRef]

- Murthy, V.; Kumar, D.S.; Saju, K.K.; Rajaprakash, B.M.; Rajashekar, R. Optimization of Friction Stir Processing Parameters for Manufacturing Silicon Carbide Reinforced Aluminum 7075-T651 Surface Composite. Mater. Today Proc. 2019, 18, 4549–4555. [Google Scholar] [CrossRef]

- Kumar, A.; Kumar, V. Fabrication and Optimization of AA7075-7%SiC Surface Composites Using RSM Technique via Friction Stir Processing. J. Alloy. Metall. Syst. 2023, 3, 100022. [Google Scholar] [CrossRef]

- Ande, R.; Gulati, P.; Shukla, D.K.; Dhingra, H. Microstructural and Wear Characteristics of Friction Stir Processed Al-7075/SiC Reinforced Aluminium Composite. Mater. Today Proc. 2019, 18, 4092–4101. [Google Scholar] [CrossRef]

- Kumar, S.; Kumar, A.; Vanitha, C. Corrosion Behaviour of Al 7075 /TiC Composites Processed through Friction Stir Processing. Mater. Today Proc. 2019, 15, 21–29. [Google Scholar] [CrossRef]

- Sundaramoorthy, S.; Gopalan, R.; Thulasiram, R. Microstructural Characterization, Tribological and Corrosion Behavior of AA7075 -TiC Composites. China Foundry 2024, 21, 334–342. [Google Scholar] [CrossRef]

- Kesharwani, R.; Jha, K.K.; Imam, M.; Sarkar, C.; Barsoum, I. Comparison of Microstructural, Texture and Mechanical Properties of SiC and Zn Particle Reinforced FSW 6061-T6 Aluminium Alloy. J. Mater. Res. Technol. 2023, 26, 3301–3321. [Google Scholar] [CrossRef]

- Patil, N.A.; Pedapati, S.R.; Mamat, O.B.; Hidayat Syah Lubis, A.M. Effect of SiC/Fly Ash Reinforcement on Surface Properties of Aluminum 7075 Hybrid Composites. Coatings 2020, 10, 541. [Google Scholar] [CrossRef]

- Patil, N.A.; Pedapati, S.R.; Mamat, O.; Lubis, A.M.H.S. Morphological Characterization, Statistical Modeling and Wear Behavior of AA7075-Titanium Carbide-Graphite Surface Composites via Friction Stir Processing. J. Mater. Res. Technol. 2021, 11, 2160–2180. [Google Scholar] [CrossRef]

- Bayazid, S.M.; Farhangi, H.; Asgharzadeh, H.; Radan, L.; Ghahramani, A.; Mirhaji, A. Effect of Cyclic Solution Treatment on Microstructure and Mechanical Properties of Friction Stir Welded 7075 Al Alloy. Mater. Sci. Eng. A 2016, 649, 293–300. [Google Scholar] [CrossRef]

- Gao, Z.B.; Ma, W.; Deng, X.Z. Analysis of the Ground Rib Axial Profile of the Spiral Guid Roller. Appl. Mech. Mater. 2013, 385–386, 216–219. [Google Scholar] [CrossRef]

- Hassan, K.A.A.; Norman, A.F.; Price, D.A.; Prangnell, P.B. Stability of Nugget Zone Grain Structures in High Strength Al-Alloy Friction Stir Welds during Solution Treatment. Acta Mater. 2003, 51, 1923–1936. [Google Scholar] [CrossRef]

- Panwariya, C.; Dwivedi, D.K. Mechanistic Insights into Abnormal Grain Growth Suppression in Friction Stir Welded 7075-T651 Aluminum Alloys through Variation in Tool Rotational Speed. Mater. Today Commun. 2024, 40, 110133. [Google Scholar] [CrossRef]

- Rana, R.; Karmakar, A.; Karunakar, D.B. Effect of Tool Travel Rate on Microstructure Evolution and Mechanical Properties of Dissimilar Friction Stir Welded Joints of AA7075 and AA6061 Aluminium Alloys. J. Mater. Eng. Perform. 2023, 33, 10835–10852. [Google Scholar] [CrossRef]

- Chen, Y.; Ding, H.; Li, J.; Cai, Z.; Zhao, J.; Yang, W. Influence of Multi-Pass Friction Stir Processing on the Microstructure and Mechanical Properties of Al-5083 Alloy. Mater. Sci. Eng. A 2016, 650, 281–289. [Google Scholar] [CrossRef]

- Dong, B.; Cai, X.; Lin, S.; Li, X.; Fan, C.; Yang, C.; Sun, H. Wire Arc Additive Manufacturing of Al-Zn-Mg-Cu Alloy: Microstructures and Mechanical Properties. Addit. Manuf. 2020, 36, 101447. [Google Scholar] [CrossRef]

- Patel, S.K.; Singh, V.P.; Roy, B.S.; Kuriachen, B. Recent Research Progresses in Al-7075 Based in-Situ Surface Composite Fabrication through Friction Stir Processing: A Review. Mater. Sci. Eng. B 2020, 262, 114708. [Google Scholar] [CrossRef]

- Slack, G.A. Thermal Conductivity of Pure and Impure Silicon, Silicon Carbide, and Diamond. J. Appl. Phys. 1964, 35, 3460–3466. [Google Scholar] [CrossRef]

- Zhang, M.; Tan, Z.; Huang, Y.; Huang, Z.; Liu, X.; Zhang, K. Preparation and Interfacial Microstructure of High Thermal Conductivity Diamond/SiC Composites. Ceram. Int. 2024, 50, 23754–23762. [Google Scholar] [CrossRef]

- Román-Manso, B.; Chevillotte, Y.; Osendi, M.I.; Belmonte, M.; Miranzo, P. Thermal Conductivity of Silicon Carbide Composites with Highly Oriented Graphene Nanoplatelets. J. Eur. Ceram. Soc. 2016, 36, 3987–3993. [Google Scholar] [CrossRef]

- Li, J.; Zhang, H.; Zhang, Y.; Che, Z.; Wang, X. Microstructure and Thermal Conductivity of Cu/Diamond Composites with Ti-Coated Diamond Particles Produced by Gas Pressure Infiltration. J. Alloys Compd. 2015, 647, 941–946. [Google Scholar] [CrossRef]

- Mao, Y.; Ke, L.; Liu, F.; Liu, Q.; Huang, C.; Xing, L. Effect of Tool Pin Eccentricity on Microstructure and Mechanical Properties in Friction Stir Welded 7075 Aluminum Alloy Thick Plate. Mater. Des. 2014, 62, 334–343. [Google Scholar] [CrossRef]

- Li, Y.; He, C.; Wei, J.; Zhang, Z.; Tian, N.; Qin, G.; Zhao, X. Effect of Post-Fabricated Aging on Microstructure and Mechanical Properties in Underwater Friction Stir Additive Manufacturing of Al–Zn–Mg–Cu Alloy. Materials 2022, 15, 3368. [Google Scholar] [CrossRef] [PubMed]

- Bagheri, E.; Adibi, N.; Ding, H.; Chen, Y.; Guo, S. Mechanical and Corrosion Properties of Al2O3/7075 Aluminum Matrix Composites Prepared by Additive Friction Stir Deposition. Prog. Addit. Manuf. 2025, 10, 6167–6181. [Google Scholar] [CrossRef]

- Zhang, Z.; Wan, L.; Wen, Q.; Shi, Y.; Feng, Z. Wire-Based Friction Stir Additive Manufacturing of TiC Reinforced Al-Cu-Mg Composite: Particle Refinement and Dispersion. Compos. Part A 2025, 196, 109009. [Google Scholar] [CrossRef]

- Lian, X.; Xu, W.; Zhang, P.; Wang, W.; Xie, L.; Chen, X. Design and Mechanical Properties of SiC Reinforced Gd2O3/6061Al Neutron Shielding Composites. Ceram. Int. 2023, 49, 27707–27715. [Google Scholar] [CrossRef]

- Guo, X.; Niu, Y.; Huang, L.; Ji, H.; Zheng, X. Microstructure and Tribological Property of TiC-Mo Composite Coating Prepared by Vacuum Plasma Spraying. J. Therm. Spray Technol. 2012, 21, 1083–1090. [Google Scholar] [CrossRef]

- Radhika, N.; Raghu, R. Prediction of Mechanical Properties and Modeling on Sliding Wear Behavior of LM25/TiC Composite Using Response Surface Methodology. Part. Sci. Technol. 2018, 36, 104–111. [Google Scholar] [CrossRef]

- Molla Ramezani, N.; Davoodi, B.; Aberoumand, M.; Rezaee Hajideh, M. Assessment of Tool Wear and Mechanical Properties of Al 7075 Nanocomposite in Friction Stir Processing (FSP). J. Braz. Soc. Mech. Sci. Eng. 2019, 41, 1–14. [Google Scholar] [CrossRef]

| Tool parameters | Pin geometry | Taper-threaded |

| Shoulder geometry | Flat | |

| Pin length | 8 mm | |

| Pin diameter (root/tip) | 8 mm/6 mm | |

| Shoulder diameter | 24 mm | |

| Tool material | H13 steel | |

| Machine parameters | Tool rotation speed (TRS) | 1000 rpm (counterclockwise) |

| Tool transverse speed (TTS) | 20 mm/min | |

| Downward force | 5 kN | |

| Plunge depth | 0.3 mm | |

| Tool tilt angle | 2.5° | |

| Number of passes | 2 | |

| Cooling environment | Forced cooling through compressed air | |

| Reinforcement | Nano particles | SiC, TiC |

| Incorporation method | Groove method |

| Tool Dimensions | Pin Root Diameter (mm) | Pin Tip Diameter (mm) | Pin Length (mm) | Tool Weight (grams) | Weight Loss (%) |

|---|---|---|---|---|---|

| Before FSAM (new unused tool) | 8 | 6 | 8 | 230.5 | - |

| After FSAM (Al-7075/SiC) | 7.89 | 4.75 | 7.82 | 227.8 | 1.17 |

| After FSAM (Al-7075/TiC) | 7.97 | 5.4 | 7.98 | 229.25 | 0.54 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hassan, A.; Altaf, K.; Ismail, M.C.; Pedapati, S.R.; Marode, R.V.; Soomro, I.A.; Ahmed, N. Development of Carbide-Reinforced Al-7075 Multi-Layered Composites via Friction Stir Additive Manufacturing. J. Compos. Sci. 2025, 9, 568. https://doi.org/10.3390/jcs9100568

Hassan A, Altaf K, Ismail MC, Pedapati SR, Marode RV, Soomro IA, Ahmed N. Development of Carbide-Reinforced Al-7075 Multi-Layered Composites via Friction Stir Additive Manufacturing. Journal of Composites Science. 2025; 9(10):568. https://doi.org/10.3390/jcs9100568

Chicago/Turabian StyleHassan, Adeel, Khurram Altaf, Mokhtar Che Ismail, Srinivasa Rao Pedapati, Roshan Vijay Marode, Imtiaz Ali Soomro, and Naveed Ahmed. 2025. "Development of Carbide-Reinforced Al-7075 Multi-Layered Composites via Friction Stir Additive Manufacturing" Journal of Composites Science 9, no. 10: 568. https://doi.org/10.3390/jcs9100568

APA StyleHassan, A., Altaf, K., Ismail, M. C., Pedapati, S. R., Marode, R. V., Soomro, I. A., & Ahmed, N. (2025). Development of Carbide-Reinforced Al-7075 Multi-Layered Composites via Friction Stir Additive Manufacturing. Journal of Composites Science, 9(10), 568. https://doi.org/10.3390/jcs9100568