High-Temperature Polyimide Composites—A Review on Polyimide Types, Manufacturing, and Mechanical and Thermal Behavior

Abstract

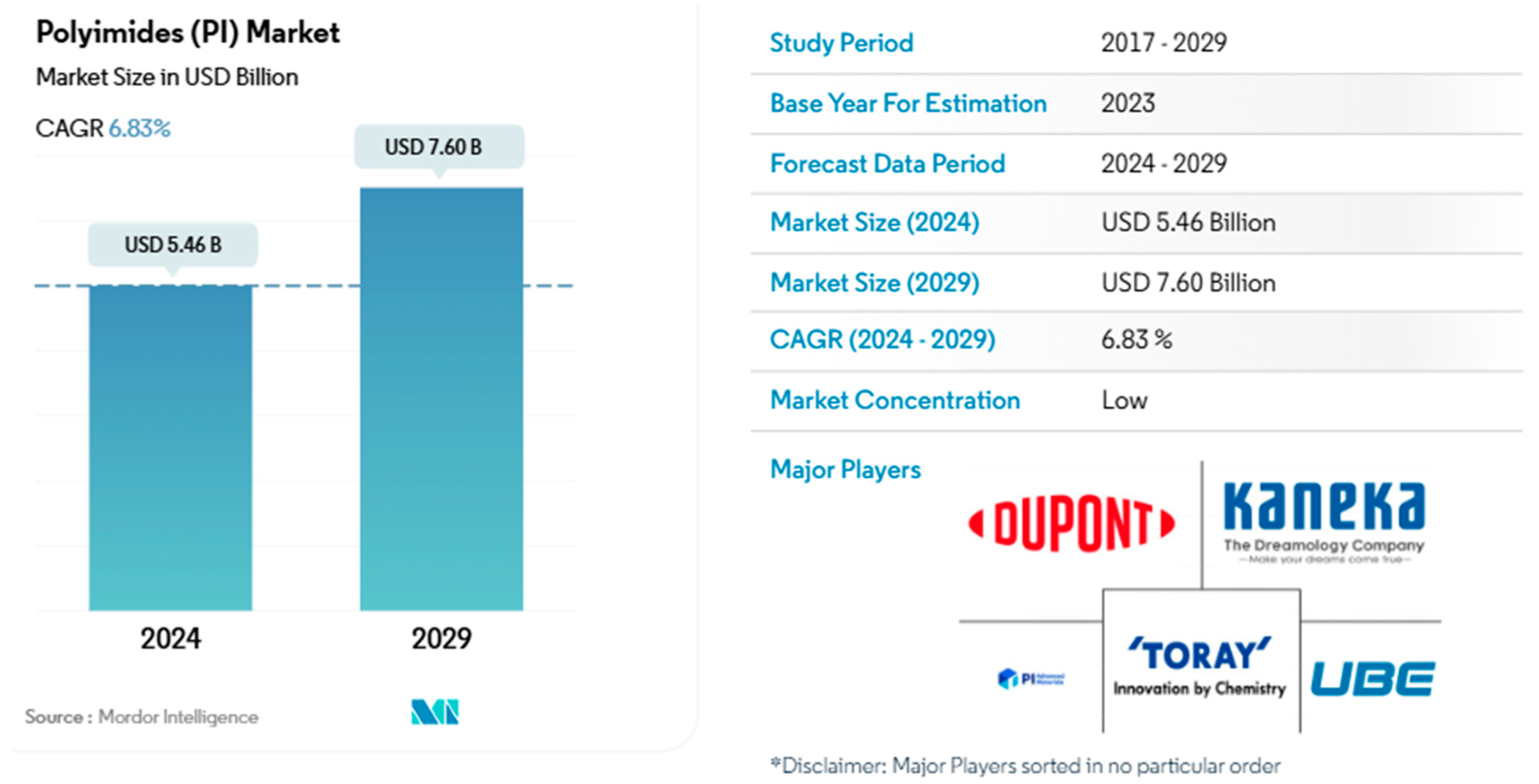

1. Introduction

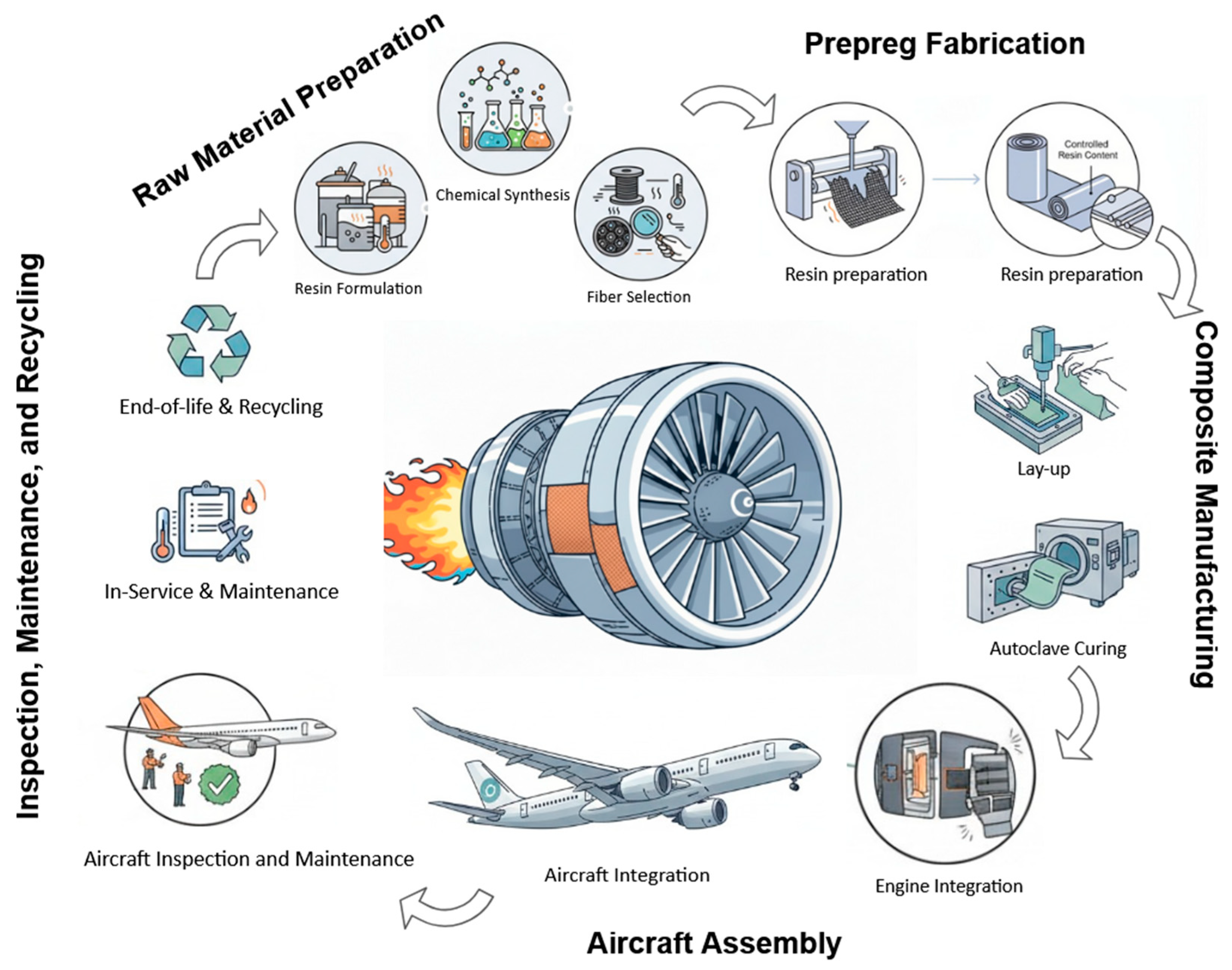

2. Types of Polyimides

2.1. Composition and Properties

Chemical Structure

2.2. Polymerization Techniques

2.3. Structural Modifications

2.4. Influence of Fluorinated Groups

3. Manufacturing Processes

4. Mechanical and Thermal Behavior

5. Discussion, Summary, and Outlook

Author Contributions

Funding

Conflicts of Interest

References

- Continuous Lower Energy, Emissions and Noise (CLEEN) Program Benefits 2022. Available online: https://www.faa.gov/sites/faa.gov/files/2022-07/eeSC-Mar2020-CLEENBenefitsSummary.pdf (accessed on 20 March 2025).

- Daghigh, V.; Belk, D.M.; Nikbin, K. Development and validation of finite element models for buckling of open-hole fiber-reinforced composites at ambient and cryogenic temperatures. Phys. Scr. 2023, 98, 025702. [Google Scholar] [CrossRef]

- Norris, G. Pratt & Whitney Lays Out Next-Gen GTF Roadmap 2022. Available online: https://aviationweek.com/shownews/farnborough-airshow/pratt-whitney-lays-out-next-gen-gtf-roadmap (accessed on 27 July 2025).

- Daghigh, V.; Khalili, S.M.R.; Eslami Farsani, R. Creep behavior of basalt fiber-metal laminate composites. Compos. Part B Eng. 2016, 91, 275–282. [Google Scholar] [CrossRef]

- Daghigh, V.; Daghigh, H.; Keller, M.W. Uncertainty-Based Design: Finite Element and Explainable Machine Learning Modeling of Carbon–Carbon Composites for Ultra-High Temperature Solar Receivers. J. Compos. Sci. 2025, 9, 100. [Google Scholar] [CrossRef]

- Zuzelski, M.; Laporte-Azcué, M.; Cordeiro, J.; Dhakal, S.; Daghigh, V.; Keller, M.; Ramsurn, H.; Otanicar, T. Design of a novel carbon/carbon composite microvascular solar receiver. Sol. Energy 2023, 262, 111794. [Google Scholar] [CrossRef]

- Daghigh, V. Mechanical Behavior of Basalt Fiber-Reinforced and Basalt Fiber Metal Laminate Composites Under Tensile, Bending, Charpy Impact and Creep Loads; IAU: Tehran, Iran, 2010; Available online: https://www.researchgate.net/publication/335173233_Mechanical_behavior_of_basalt_fiber-reinforced_and_basalt_fiber_metal_laminate_composites_under_tensile_bending_Charpy_impact_and_creep_loads (accessed on 27 July 2025).

- Khalili, S.M.R.; Daghigh, V.; Eslami Farsani, R. Mechanical behavior of basalt fiber-reinforced and basalt fiber metal laminate composites under tensile and bending loads. J. Reinf. Plast. Compos. 2011, 30, 647–659. [Google Scholar] [CrossRef]

- Farsani, R.E.; Khalili, S.; Daghigh, V. Charpy impact response of basalt fiber reinforced epoxy and basalt fiber metal laminate composites: Experimental study. Int. J. Damage Mech. 2014, 23, 729–744. [Google Scholar] [CrossRef]

- Behnia, S.; Daghigh, V.; Nikbin, K.; Fereidoon, A.; Ghorbani, J. Influence of Stacking Sequence and Notch Angle on the Charpy Impact Behavior of Hybrid Composites. Mech. Compos. Mater. 2016, 52, 489–496. [Google Scholar] [CrossRef]

- Lu, Z.; Xian, G.; Rashid, K. Creep Behavior of Resin Matrix and Basalt Fiber Reinforced Polymer (BFRP) Plate at Elevated Temperatures. J. Compos. Sci. 2017, 1, 1–17. [Google Scholar] [CrossRef]

- Farsani, E.; Seyed, M.R.K.; Vahid, D.; Reza, F.R.; Khalili, S.; Daghigh, V.; Fazaeli, R. Creep behavior of basalt and glass fiber reinforced epoxy composites. J. Mech. Res. Appl. JMRA 2011, 3, 29–36. Available online: https://www.researchgate.net/publication/267723175_Creep_Behavior_of_Basalt_and_Glass_Fiber_Reinforced_Epoxy_Composites (accessed on 27 July 2025).

- Ghorbani, J.; Daghigh, V.; Rahmati, S.; Mahdian, M.; Daghigh, H. Creep behavior of latania natural fiber-reinforced epoxy composites at elevated temperatures. Polym. Compos. 2021, 42, 3089–3097. [Google Scholar] [CrossRef]

- McKeen, L. The Effect of Sterilization on Plastics and Elastomers; Elsevier: Amsterdam, The Netherlands, 2012; pp. 169–182. [Google Scholar] [CrossRef]

- Greene, J.P. Automotive Plastics and Composites; Elsevier: Amsterdam, The Netherlands, 2021; pp. 175–190. [Google Scholar] [CrossRef]

- Materials and Coatings, Durable Polyimide Aerogels (LEW-TOPS-133) Stronger and Flexible, Polyimide Aerogels Provide Insulation and Structural Support. NASA Technol Transf PROGRAM n.d. Available online: https://technology.nasa.gov/patent/LEW-TOPS-133 (accessed on 12 July 2025).

- Nikolaevich Yastrebinsky, R.; Viktorovna Yastrebinskaya, A.; Ivanovich Gorodov, A.; Vladislavovna Akimenko, A. Polymer Boron-Containing Composite for Protecting Astronauts of Manned Orbital Stations from Secondary Neutron Radiation. J. Compos. Sci. 2024, 8, 1–15. [Google Scholar] [CrossRef]

- Fernberg, P.; Gong, G.; Mannberg, P.; Tsampas, S. Development of novel high Tg polyimide-based composites. Part I: RTM processing properties. J. Compos. Mater. 2018, 52, 253–260. [Google Scholar] [CrossRef]

- Yang, S.-Y.; Ji, M. Polyimide Matrices for Carbon Fiber Composites. In Advanced Polyimide Materials; Elsevier: Amsterdam, The Netherlands, 2018; pp. 93–136. [Google Scholar] [CrossRef]

- Li, Y.; Pan, W.; Zhang, F.; Leng, J. Shape memory polyimide composites with high storage modulus and high glass transition temperature. J. Intell. Mater. Syst. Struct. 2022, 33, 1762–1772. [Google Scholar] [CrossRef]

- Ball, G., III. High Temperature Polyimide Foams for Shuttle Upper Surface Thermal Insulation; NASA: Washington, DC, USA, 1974.

- Dan Rusu, R.J.M.; Abadie, M. New High-Performance Materials: Bio-Based, Eco-Friendly Polyimides. In Polyimide for Electronic and Electrical Engineering Applications; Diaham, S., Ed.; IntechOpen: London, UK, 2021. [Google Scholar] [CrossRef]

- Tserpes, K.; Sioutis, I. Advances in Composite Materials for Space Applications: A Comprehensive Literature Review. Aerospace 2025, 12, 215. [Google Scholar] [CrossRef]

- Polyimides (PI) Market Size & Share Analysis-Growth Trends & Forecasts Up to 2029. 2025. Available online: https://www.mordorintelligence.com/industry-reports/polyimides-market (accessed on 27 July 2025).

- Wu, Z.; Dong, J.; Teng, C.; Li, X.; Zhao, X.; Qin, X.; Ji, C.; Zhang, Q. Polyimide-based composites reinforced by carbon nanotube-grafted carbon fiber for improved thermal conductivity and mechanical property. Compos. Commun. 2023, 39, 101543. [Google Scholar] [CrossRef]

- Ji, X.; Ren, P.; Liu, H.; Shi, Y.; Yan, Y.; Wang, J. High-Temperature Tribological Behavior of Polyimide Composites with Dual-Phase MoS2/MXene Lubricants: A Synergistic Effect Analysis. J. Compos. Sci. 2025, 9, 373. [Google Scholar] [CrossRef]

- Akram, S.; Castellon, J.; Agnel, S.; Habas, J.-P. Synthesis Process Optimization of Polyimide Nanocomposite Multilayer Films, Their Dielectric Properties, and Modeling. In Polyimide for Electronic and Electrical Engineering Applications; Diaham, S., Ed.; IntechOpen: London, UK, 2021. [Google Scholar] [CrossRef]

- Serafini, T.T. PMR Polyimide Composites for Aerospace Applications; NASA Lewis Research Center: Cleveland, OH, USA, 1982. Available online: https://ntrs.nasa.gov/citations/19830007093?utm= (accessed on 27 July 2025).

- Chen, W.; Liu, H.; Hu, H.; Du, T.; Cui, T.; Tan, W.; Min, Y.; Liu, Y. Thermoplastic polyimide with high glass transition temperature enabled by N-butyl-N-phenylaniline groups. Polymer 2025, 335, 128769. [Google Scholar] [CrossRef]

- Wilson, D. PMR-15 processing, properties and problems—A review. Br. Polym. J. 1988, 20, 405–416. [Google Scholar] [CrossRef]

- St. Clair, A.K.; St. Clair, T.L. LARC-TPI: A Multi-Purpose Thermoplastic Polyimide 1982. Available online: https://ntrs.nasa.gov/citations/19820025654 (accessed on 22 February 2025).

- Yang, S.-Y.; Yuan, L.-L. Advanced Polyimide Films. In Advanced Polyimide Materials; Elsevier: Amsterdam, The Netherlands, 2018; pp. 1–66. [Google Scholar] [CrossRef]

- Kapton® Polyimide Films n.d. Available online: https://www.dupont.com/electronics-industrial/kapton-polyimide-film.html (accessed on 27 July 2025).

- Robinson, G.W. High Temperature Chemical Degradation of PMR-15 Polymer Resins. Master’s Thesis, Air Force Institute of Technology, Dayton, OH, USA, 2005. [Google Scholar]

- Zhuang, Y.; Seong, J.G.; Lee, Y.M. Polyimides containing aliphatic/alicyclic segments in the main chains. Prog. Polym. Sci. 2019, 92, 35–88. [Google Scholar] [CrossRef]

- Takizawa, K.; Asai, S.; Ando, S. Temperature dependence of electric conduction in polyimides with main chain triphenylamine structures. Polym. J. 2014, 46, 201–206. [Google Scholar] [CrossRef]

- Jiang, X.; Bin, Y.; Matsuo, M. Electrical and mechanical properties of polyimide–carbon nanotubes composites fabricated by in situ polymerization. Polymer 2005, 46, 7418–7424. [Google Scholar] [CrossRef]

- History of Polyimides n.d. Available online: https://kapton-tapes.com/history-of-polyimides/ (accessed on 27 July 2025).

- Technical Data Sheet Polyimide (PI) n.d. Available online: https://laminatedplastics.com/polyimide.pdf (accessed on 27 July 2025).

- Chisca, S.; Sava, I.; Musteata, V.-E.; Bruma, M. Dielectric and conduction properties of polyimide films. In Proceedings of the International Semiconductor. Conference, Sinaia, Romania, 17–19 October 2011; pp. 253–256. [Google Scholar] [CrossRef]

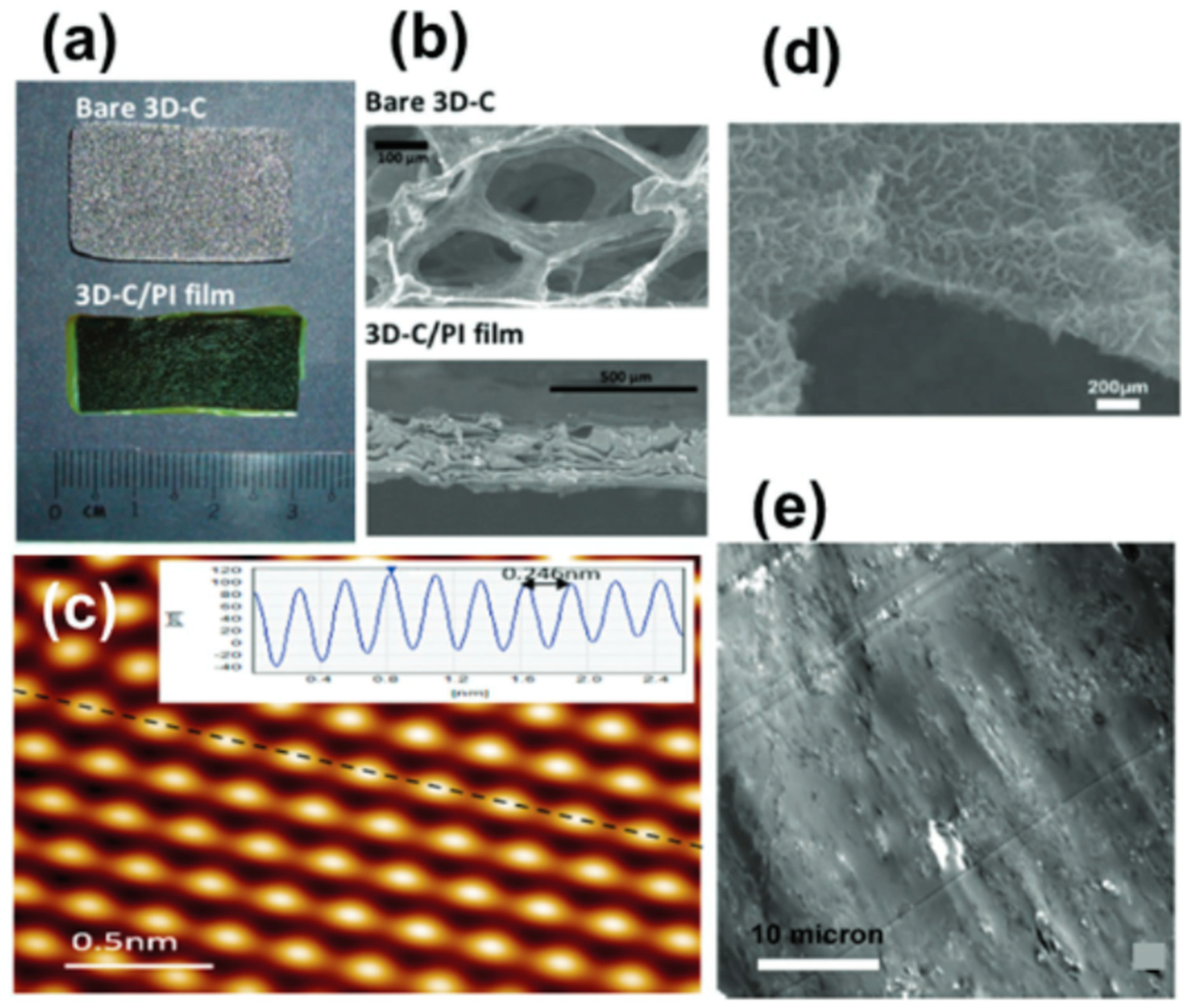

- Loeblein, M.; Bolker, A.; Tsang, S.H.; Atar, N.; Uzan-Saguy, C.; Verker, R.; Gouzman, I.; Grossman, E.; Teo, E.H.T. 3D Graphene-Infused Polyimide with Enhanced Electrothermal Performance for Long-Term Flexible Space Applications. Small 2015, 11, 6425–6434. [Google Scholar] [CrossRef] [PubMed]

- Gouzman, I.; Grossman, E.; Verker, R.; Atar, N.; Bolker, A.; Eliaz, N. Advances in Polyimide-Based Materials for Space Applications. Adv. Mater. 2019, 31, 1807738. [Google Scholar] [CrossRef]

- Dai, W.; Yu, J.; Liu, Z.; Wang, Y.; Song, Y.; Lyu, J.; Bai, H.; Nishimura, K.; Jiang, N. Enhanced thermal conductivity and retained electrical insulation for polyimide composites with SiC nanowires grown on graphene hybrid fillers. Compos. Part Appl. Sci. Manuf. 2015, 76, 73–81. [Google Scholar] [CrossRef]

- Dai, W.; Yu, J.; Wang, Y.; Song, Y.; Alam, F.E.; Nishimura, K.; Lin, C.-T.; Jiang, N. Enhanced thermal conductivity for polyimide composites with a three-dimensional silicon carbide nanowire@graphene sheets filler. J. Mater. Chem. A 2015, 3, 4884–4891. [Google Scholar] [CrossRef]

- Yan, W.; Zhang, Y.; Sun, H.; Liu, S.; Chi, Z.; Chen, X.; Xu, J. Polyimide nanocomposites with boron nitride-coated multi-walled carbon nanotubes for enhanced thermal conductivity and electrical insulation. J. Mater. Chem. A 2014, 2, 20958–20965. [Google Scholar] [CrossRef]

- Dong, L.; Lan, S.; Yang, J.; Chi, X. Plasma chemical reaction for nitric oxide and sulfur dioxide removal in corona discharge reactor. In Proceedings of the 2003 Annual Report Conference on Electrical Insulation and Dielectric Phenomena, Albuquerque, NM, USA, 19–22 October 2003; pp. 440–443. [Google Scholar]

- Li, T.-L.; Hsu, S.L.-C. Enhanced Thermal Conductivity of Polyimide Films via a Hybrid of Micro- and Nano-Sized Boron Nitride. J. Phys. Chem. B 2010, 114, 6825–6829. [Google Scholar] [CrossRef]

- Murakami, T.; Ebisawa, K.; Miyao, K.; Ando, S. Enhanced Thermal Conductivity in Polyimide/Silver Particle Composite Films Based on Spontaneous Formation of Thermal Conductive Paths. J. Photopolym. Sci. Technol. 2014, 27, 187–191. [Google Scholar] [CrossRef][Green Version]

- Wang, T.; Wang, M.; Fu, L.; Duan, Z.; Chen, Y.; Hou, X.; Wu, Y.; Li, S.; Guo, L.; Kang, R.; et al. Enhanced Thermal Conductivity of Polyimide Composites with Boron Nitride Nanosheets. Sci. Rep. 2018, 8, 1557. Available online: https://www.nature.com/articles/s41598-018-19945-3 (accessed on 27 July 2025). [CrossRef] [PubMed]

- Xie, S.-H.; Zhu, B.-K.; Li, J.-B.; Wei, X.-Z.; Xu, Z.-K. Preparation and properties of polyimide/aluminum nitride composites. Polym. Test. 2004, 23, 797–801. [Google Scholar] [CrossRef]

- Meng, Y.; Wu, H.; Zhang, Y.; Wei, Z. A flexible electrode based on a three-dimensional graphene network-supported polyimide for lithium-ion batteries. J. Mater. Chem. A 2014, 2, 10842–10846. [Google Scholar] [CrossRef]

- Yoonessi, M.; Gaier, J.R.; Sahimi, M.; Daulton, T.L.; Kaner, R.B.; Meador, M.A. Fabrication of Graphene–Polyimide Nanocomposites with Superior Electrical Conductivity. ACS Appl. Mater. Interfaces 2017, 9, 43230–43238. [Google Scholar] [CrossRef]

- Brink, M.H.; Brandom, D.K.; Wilkes, G.L.; McGrath, J.E. Synthesis and characterization of a novel ‘3F’-based fluorinated monomer for fluorine-containing polyimides. Polymer 1994, 35, 5018–5023. [Google Scholar] [CrossRef]

- Liaw, D.-J.; Wang, K.-L.; Huang, Y.-C.; Lee, K.-R.; Lai, J.-Y.; Ha, C.-S. Advanced polyimide materials: Syntheses, physical properties and applications. Prog. Polym. Sci. 2012, 37, 907–974. [Google Scholar] [CrossRef]

- Li, H.; Wang, X.; Gong, Y.; Zhao, H.; Liu, Z.; Tao, L.; Dastan, D.; Ma, K.; Hu, Z.; Sun, M. APDS modified several bisphenol A polyimides with low dielectric constant under high frequency. J. Polym. Res. 2023, 30, 407. [Google Scholar] [CrossRef]

- Selladurai, M.; Sundararajan, P.R.; Sarojadevi, M. Synthesis, thermal and mechanical properties of modified PMR/carbon fiber composites. Chem. Eng. J. 2012, 203, 333–347. [Google Scholar] [CrossRef]

- Hasegawa, M.; Fujii, M.; Ishii, J.; Yamaguchi, S.; Takezawa, E.; Kagayama, T.; Ishikawa, A. Colorless polyimides derived from 1S,2S,4R,5R-cyclohexanetetracarboxylic dianhydride, self-orientation behavior during solution casting, and their optoelectronic applications. Polymer 2014, 55, 4693–4708. [Google Scholar] [CrossRef]

- Mavukkandy, M.O.; McBride, S.A.; Warsinger, D.M.; Dizge, N.; Hasan, S.W.; Arafat, H.A. Thin film deposition techniques for polymeric membranes—A review. J. Membr. Sci. 2020, 610, 118258. [Google Scholar] [CrossRef]

- Blizard, K.G.; Haghighat, R.R. Processing and properties of polyimide melt blends containing a thermotropic liquid crystalline polymer. Polym. Eng. Sci. 1993, 33, 799–807. [Google Scholar] [CrossRef]

- Verma, D.; Goh, K.L. Functionalized Graphene-Based Nanocomposites for Energy Applications. In Functionalized Graphene Nanocomposites and Their Derivatives; Elsevier: Amsterdam, The Netherlands, 2019; pp. 219–243. [Google Scholar] [CrossRef]

- Chuang, K.C. Manufacturing of Thermoset Polyimide Composites by Laser Sintering 2019. Available online: https://ntrs.nasa.gov/citations/20240007068 (accessed on 27 July 2025).

- Sroog, C.E. Polyimides. Prog. Polym. Sci. 1991, 16, 561–694. [Google Scholar] [CrossRef]

- Polyimides: Fundamentals and Applications; CRC Press: Boca Raton, FL, USA, 2018. [CrossRef]

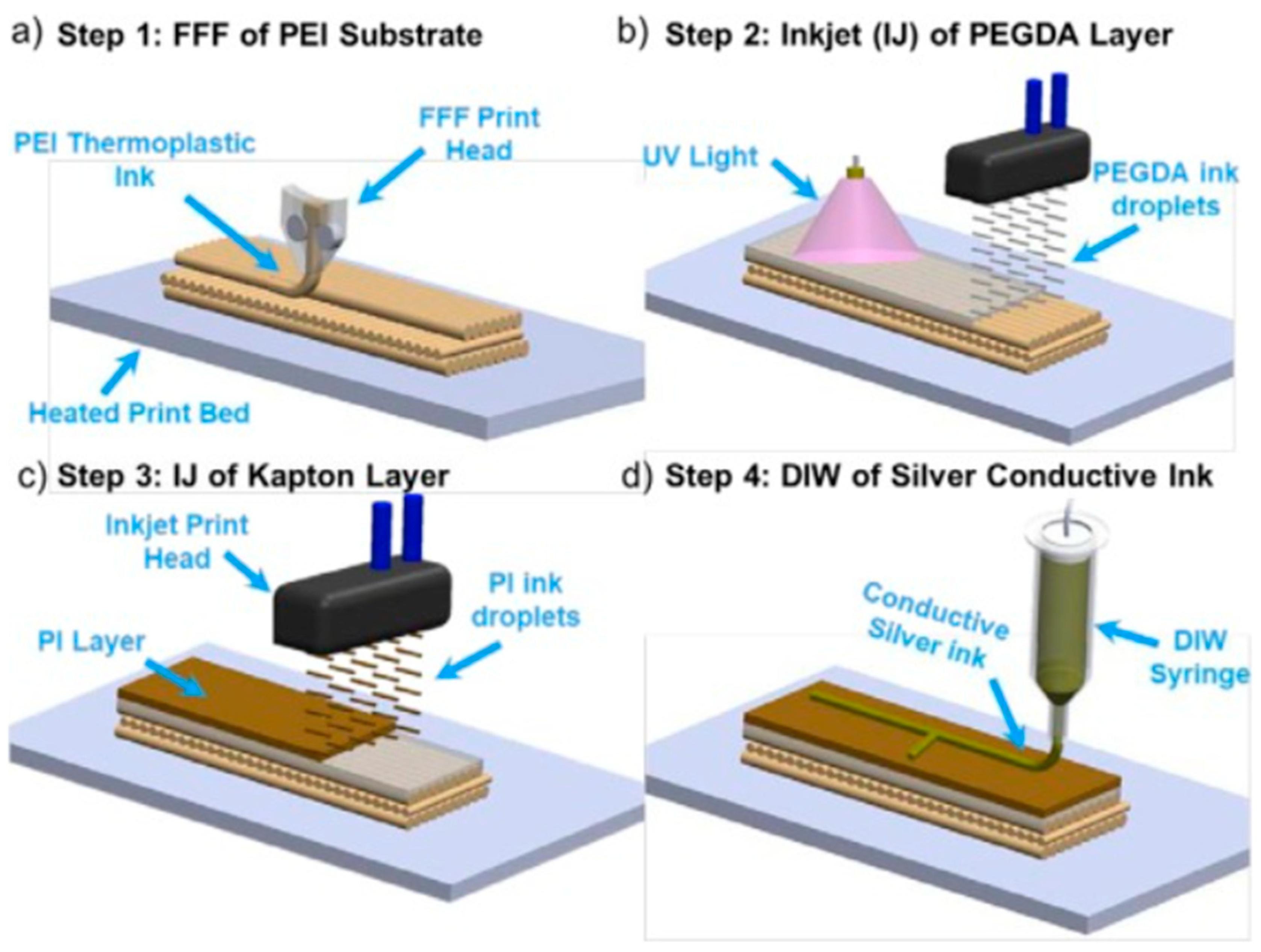

- Roach, D.J.; Roberts, C.; Wong, J.; Kuang, X.; Kovitz, J.; Zhang, Q.; Spence, T.G.; Qi, H.J. Surface modification of fused filament fabrication (FFF) 3D printed substrates by inkjet printing polyimide for printed electronics. Addit. Manuf. 2020, 36, 101544. [Google Scholar] [CrossRef]

- Lakkala, P.; Munnangi, S.R.; Bandari, S.; Repka, M. Additive manufacturing technologies with emphasis on stereolithography 3D printing in pharmaceutical and medical applications: A review. Int. J. Pharm. X 2023, 5, 100159. [Google Scholar] [CrossRef]

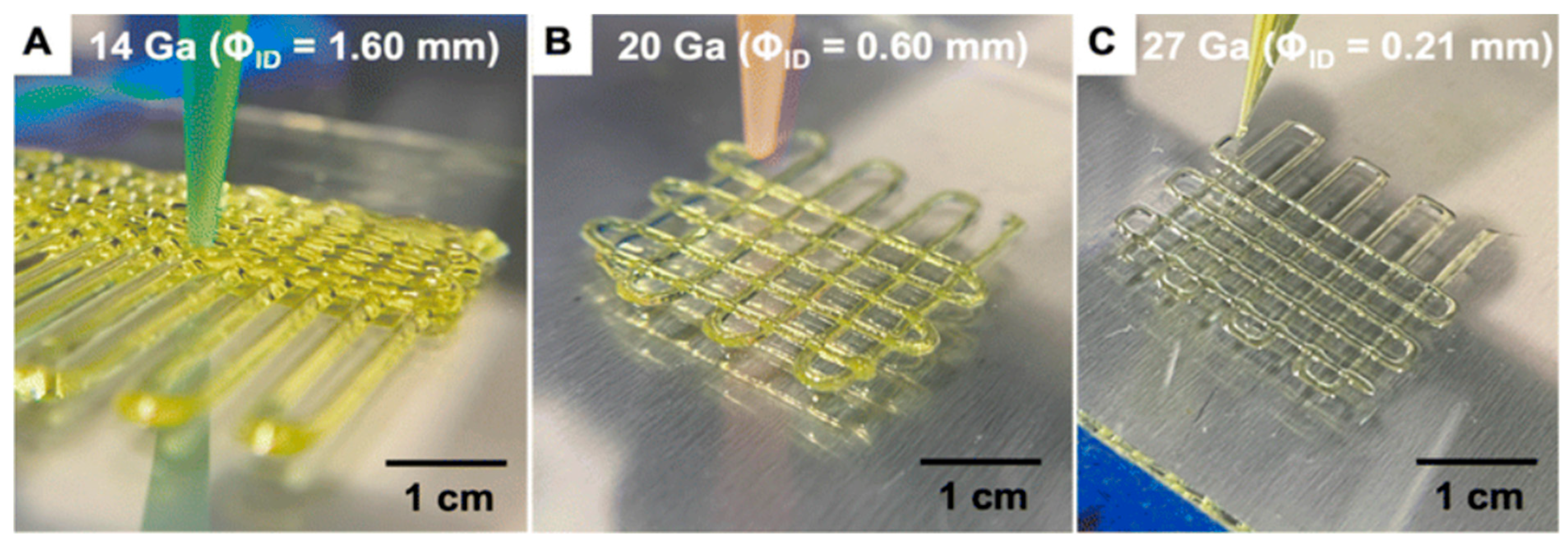

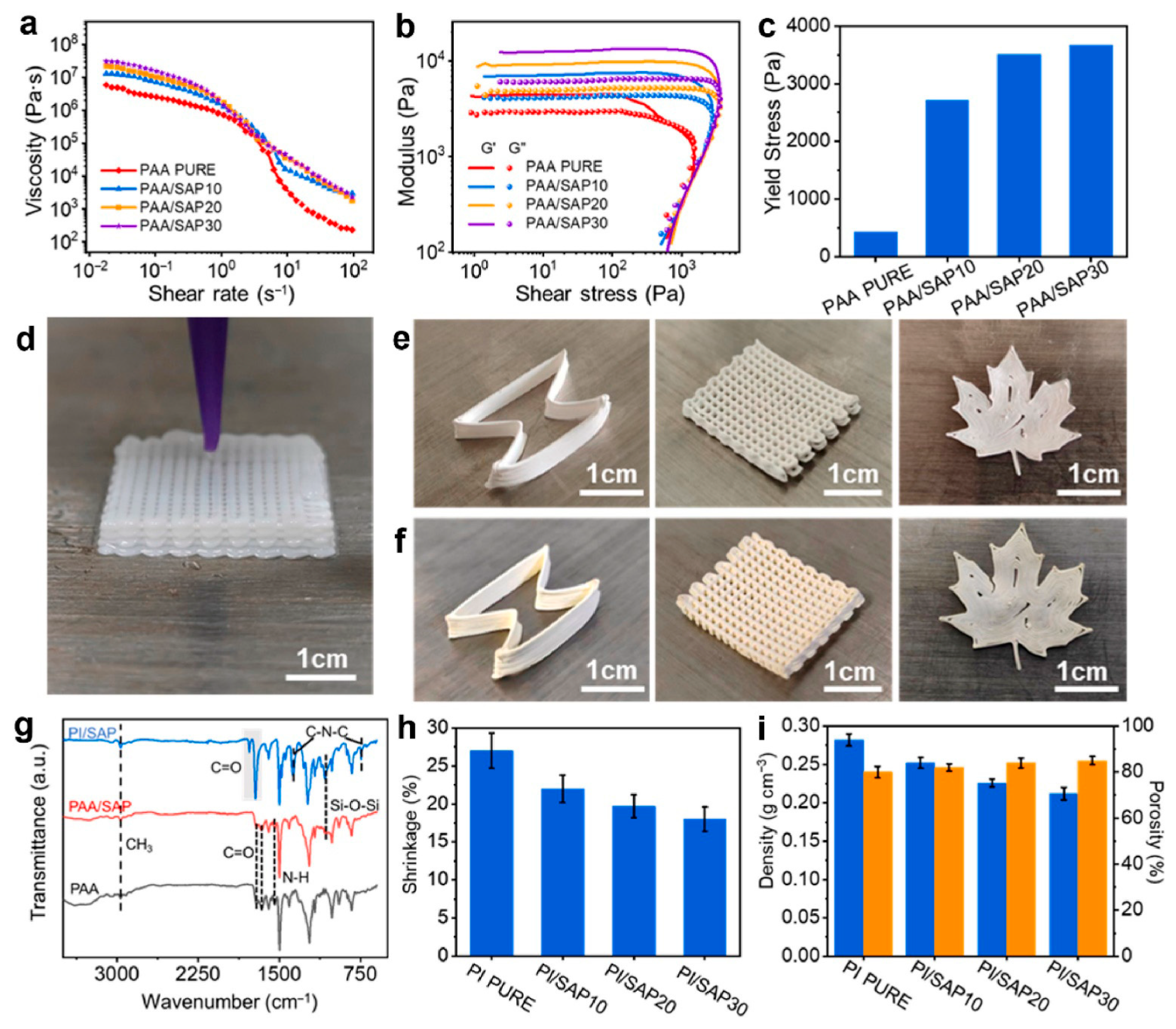

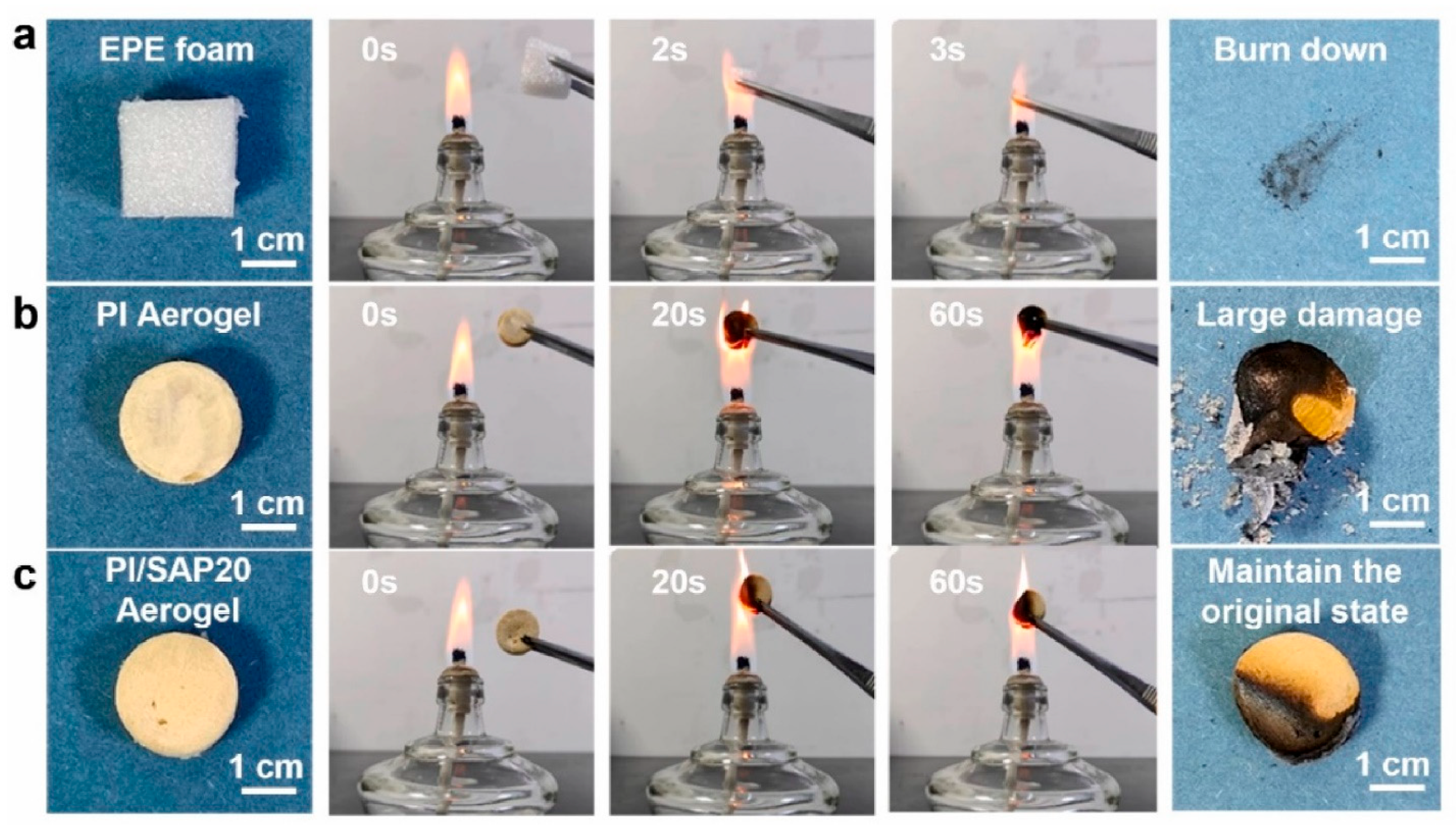

- Cipriani, C.E.; Dornbusch, D.A.; Vivod, S.L.; Pentzer, E.B. Direct ink writing of polyimide aerogels for battery thermal mitigation. RSC Appl. Polym. 2024, 2, 71–86. [Google Scholar] [CrossRef]

- Pelanconi, M.; Colombo, P.; Ortona, A. Additive manufacturing of silicon carbide by selective laser sintering of PA12 powders and polymer infiltration and pyrolysis. J. Eur. Ceram. Soc. 2021, 41, 5056–5065. [Google Scholar] [CrossRef]

- Hsiao, S.-H.; Chen, W.-T. Syntheses and Properties of Aromatic Polyimides Based on 1,1-Bis[4-(4-aminophenoxy)phenyl]-1-phenyl-2,2,2-trifluoroethane and 1,1-Bis[4-(4-aminophenoxy)phenyl]-1-phenylethane. J. Polym. Res. 2003, 10, 95–103. [Google Scholar] [CrossRef]

- Zhang, H.-Y.; Yuan, L.-L.; Hong, W.-J.; Yang, S.-Y. Improved Melt Processabilities of Thermosetting Polyimide Matrix Resins for High Temperature Carbon Fiber Composite Applications. Polymers 2022, 14, 965. [Google Scholar] [CrossRef]

- Dong, Z.; Feng, T.; Zheng, C.; Li, G.; Liu, F.; Qiu, X. Mechanical properties of polyimide/multi-walled carbon nanotube composite fibers. Chin. J. Polym. Sci. 2016, 34, 1386–1395. [Google Scholar] [CrossRef]

- Daghigh, V.; Lacy, T.E.; Daghigh, H.; Gu, G.; Baghaei, K.T.; Horstemeyer, M.F.; Pittman, C.U. Heat deflection temperatures of bio-nano-composites using experiments and machine learning predictions. Mater. Today Commun. 2020, 22, 100789. [Google Scholar] [CrossRef]

- Daghigh, V.; Lacy, T.E.; Daghigh, H.; Gu, G.; Baghaei, K.T.; Horstemeyer, M.F.; Pittman, C.U. Machine learning predictions on fracture toughness of multiscale bio-nano-composites. J. Reinf. Plast. Compos. 2020, 39, 587–598. [Google Scholar] [CrossRef]

- Daghigh, V. Mechanical and Thermal Behavior of Multiscale Bi-Nano-Composites Using Experiments and Machine Learning Predictions. Ph.D. Thesis, Mississippi State University, Starkville, MS, USA, 2020. [Google Scholar]

- Nasihatgozar, M.; Daghigh, V.; Lacy, T.E.; Daghigh, H.; Nikbin, K.; Simoneau, A. Mechanical characterization of novel latania natural fiber reinforced PP/EPDM composites. Polym. Test. 2016, 56, 321–328. [Google Scholar] [CrossRef]

- Daghigh, V.; Lacy, T.E.; Pittman, C.U.; Daghigh, H. Influence of maleated polypropylene coupling agent on mechanical and thermal behavior of latania fiber-reinforced PP/EPDM composites. Polym. Compos. 2018, 39, E1751–E1759. [Google Scholar] [CrossRef]

- Panin, S.V.; Bogdanov, A.A.; Eremin, A.V.; Buslovich, D.G.; Burkov, M.V. Creep Behavior of Particulate Polyimide and Polyetherimide Based Composites Under Fatigue. Russ. Phys. J. 2023, 66, 372–377. [Google Scholar] [CrossRef]

- Chuang, K. Development of DMBZ-15 High-Glass-Transition-Temperature Polyimides as PMR-15 Replacements Given R&D 100 Award; NASA Glenn Research Center: Cleveland, OH, USA, 2003.

- Tsuji, L.; McManus, H.; Bowles, K. Mechanical Properties of Degraded PMR-15 Resin. In Time Dependent and Nonlinear Effects in Polymers and Composites; ASTM International: West Conshohocken, PA, USA, 2000; pp. 3–17. [Google Scholar] [CrossRef]

- Service, T.H. Creep rupture of a phenolic-alumina particulate composite. J. Mater. Sci. 1993, 28, 6087–6090. [Google Scholar] [CrossRef]

- Hinkley, J.A.; Mings, S.L. Fracture Toughness of Polyimide Film; NASA Langley Research Center: Hampton, VA, USA, 2013. Available online: https://ntrs.nasa.gov/citations/19900016814 (accessed on 27 July 2025).

- Wu, T.; Ganobjak, M.; Siqueira, G.; Zeng, Z.; Li, M.; Filimonova, E.; Saghamanesh, S.; Bonnin, A.; Sivaraman, D.; Yip, J.; et al. 3D Printed Polyimide Nanocomposite Aerogels for Electromagnetic Interference Shielding and Thermal Management. Adv. Mater. Technol. 2023, 8, 2202155. [Google Scholar] [CrossRef]

- Fu, Z.; Yu, D.; Xue, T.; Zhang, X.; Fan, W. 3D printed polyimide-based composite aerogels with shape memory and thermal insulation properties. Compos. Commun. 2025, 56, 102335. [Google Scholar] [CrossRef]

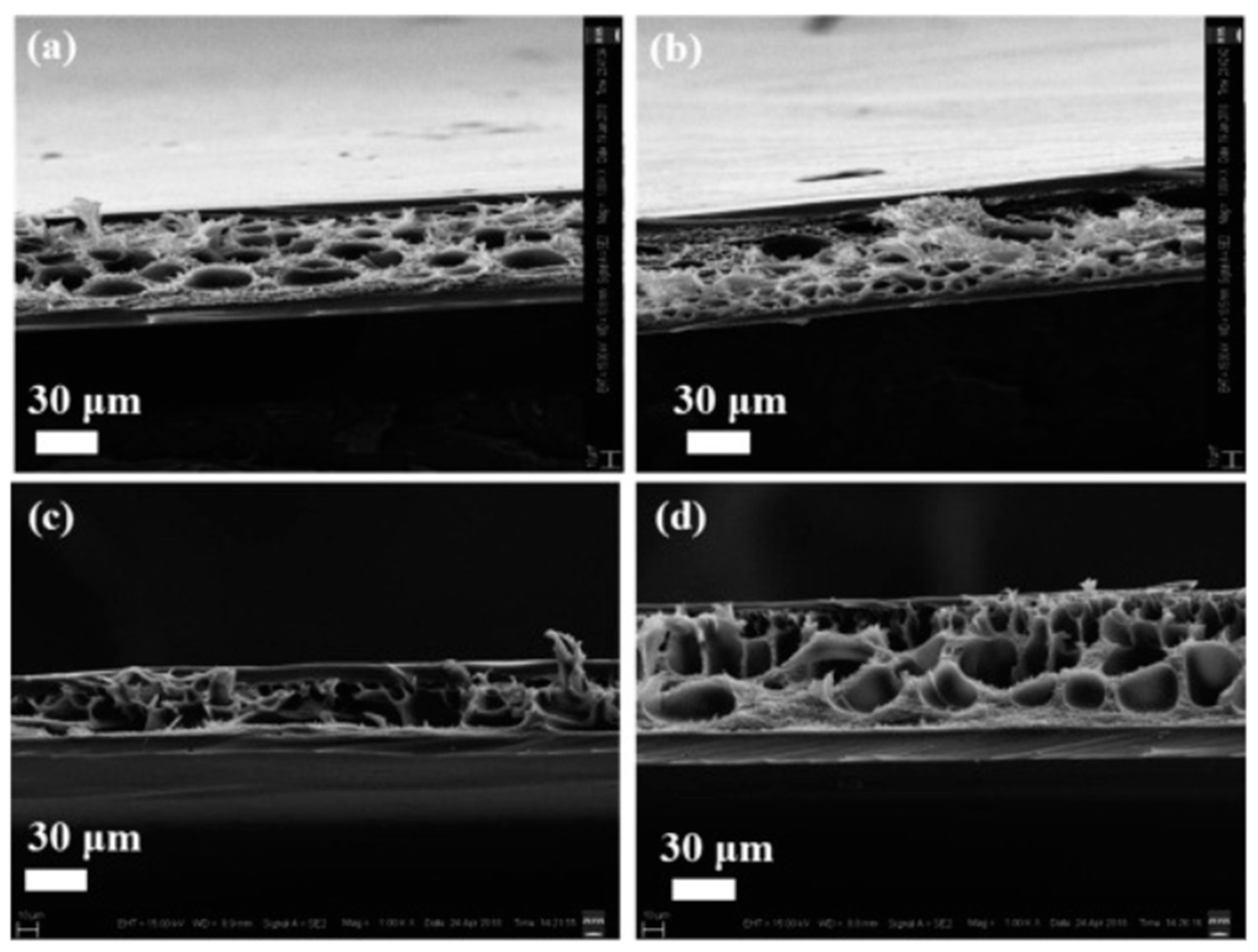

- Zhang, P.; Zhang, K.; Chen, X.; Dou, S.; Zhao, J.; Li, Y. Mechanical, dielectric and thermal properties of polyimide films with sandwich structure. Compos. Struct. 2021, 261, 113305. [Google Scholar] [CrossRef]

| Type of Polyimide | Description | Examples | Properties | Applications |

|---|---|---|---|---|

| Thermosetting Polyimides | Cure irreversibly to form a highly cross-linked network. They require controlled curing processes and do not melt upon reheating. | PMR-15 | Exceptional thermal stability, chemical resistance, and mechanical strength. They maintain structural integrity in extreme environments. | High-temperature structural components in aerospace, military, and other demanding environments. |

| Thermoplastic Polyimides | They can be remelted and reprocessed using conventional melt techniques. Their formulation allows for recyclability and ease of processing compared to their thermosetting counterparts. | LARC-TPI | Excellent thermal and mechanical performance, with added benefits of reworkability and recyclability. | Electronic packaging and high-performance components where reshaping, reworking, or recycling is advantageous. |

| Polyimide Films | Produced as thin, flexible sheets rather than bulk materials. They are engineered for applications that demand both flexibility and high thermal resistance. | Kapton | High dielectric strength, impressive thermal stability, and mechanical flexibility, combined with lightweight properties. | Flexible electronics, insulation, and applications in aerospace and military sectors that require conformable, lightweight materials. |

| Filler | Thermal Conductivity (W m−1 K−1) | |||

|---|---|---|---|---|

| wt% | vol% | Neat PI | Filled PI | |

| Sic nanowires on graphene [41,42] | 7 | 0.25 | 0.577 | |

| 11 | 0.25 | 2.63 | ||

| MWCNTs [42,43,44] | 3 | 0.18 | 0.25 | |

| BN-c-MWCNTs [42,45] | 3 | 0.18 | 0.38 | |

| AlN [46] | 9 | 0.225 | 0.675 | |

| BN [42,47] | 30 | 0.18 | 1.2 | |

| Silver particles [42,48] | 45 | 0.2 | 15 | |

| BNNS [49] | 7 | 0.25 | 2.95 (in-plane TC) | |

| Aluminum nitride nanoparticles [42,50] | 30 | 0.22 | 0.6 | |

| 3D-C [41,42] | 0.35 | 0.3 | 0.15 | 1.7 |

| Manufacturing Method | Description | Applications | Notes |

|---|---|---|---|

| Film Casting/Solvent Casting | Polyamic acid is cast onto a substrate and thermally imidized into a film | Kapton® films, electronics insulation | Precise thickness control, used for flexible films |

| Molding and Sintering | Thermoplastic polyimides are molded, then sintered at high temperatures | Structural parts (e.g., Torlon®) | Suitable for melt-processable polyimides |

| Solution Processing/Coating | Precursor solution is spin- or dip-coated, followed by thermal curing | Flexible PCBs, insulating layers | Ideal for thin films and coatings in electronics |

| Machining from Stock Shapes | Rods, blocks, or sheets are machined using CNC or conventional techniques | Precision parts, custom shapes | Allows high-dimensional accuracy; subtractive process |

| Laminating and Bonding | Polyimide films are bonded with other materials in layered configurations | Multilayer electronics, composites | Enables integration of different functional materials |

| Additive Manufacturing (AM) | 3D printing using thermoplastic or reactive polyimide materials | Prototyping, complex geometries, custom parts | Emerging; includes FFF, SLA, DIW, and SLS; not yet widely adopted |

| Material Type | Tensile Strength (MPa) | Elongation at Break (%) | Tensile Modulus (GPa) | Flexural Strength (MPa) | Flexural Modulus (GPa) |

|---|---|---|---|---|---|

| Neat PI | 94–120 | 7–15 | 1.85–2.18 | - | - |

| CF-PI | - | - | - | 1552 | 119 |

| CNT-PI | 1400 | 14.3 | - | - | - |

| Polymer Type | Max Service Temp. | Creep Resistance at Elevated Temperature | Notes |

|---|---|---|---|

| Neat Polyimide | Up to 260 °C | Excellent | Low creep rates even at high temperatures; suitable for demanding applications. |

| Polyimide Composites | Up to 260 °C | Excellent | Reinforcement with materials like carbon fibers enhances creep resistance. |

| Epoxy Resin | Up to 120 °C | Moderate | Higher creep rates at elevated temperatures; commonly used for adhesive properties. |

| Polyester Resin | Up to 100 °C | Moderate | Higher creep rates compared to polyimides; limited use in high-temperature applications. |

| Phenolic Resin | Up to 150 °C | Good | Maintains mechanical properties up to approximately 150 °C; performance diminishes at higher temperatures. |

| Material | Thickness (µm) | Number of Tests | Kc (MPa m0.5) |

|---|---|---|---|

| LARC-TPI | 25 | 12 | 1.98 ± 0.37 |

| LARC-TPI | 45 | 16 | 2.79 ± 0.37 |

| Polyamidie-imide | 16 | 16 | 4.28 ± 0.26 |

| Kapton | 25 | 37 | 1.65 ± 0.14 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Daghigh, V.; Daghigh, H.; Harrison, R. High-Temperature Polyimide Composites—A Review on Polyimide Types, Manufacturing, and Mechanical and Thermal Behavior. J. Compos. Sci. 2025, 9, 526. https://doi.org/10.3390/jcs9100526

Daghigh V, Daghigh H, Harrison R. High-Temperature Polyimide Composites—A Review on Polyimide Types, Manufacturing, and Mechanical and Thermal Behavior. Journal of Composites Science. 2025; 9(10):526. https://doi.org/10.3390/jcs9100526

Chicago/Turabian StyleDaghigh, Vahid, Hamid Daghigh, and Roger Harrison. 2025. "High-Temperature Polyimide Composites—A Review on Polyimide Types, Manufacturing, and Mechanical and Thermal Behavior" Journal of Composites Science 9, no. 10: 526. https://doi.org/10.3390/jcs9100526

APA StyleDaghigh, V., Daghigh, H., & Harrison, R. (2025). High-Temperature Polyimide Composites—A Review on Polyimide Types, Manufacturing, and Mechanical and Thermal Behavior. Journal of Composites Science, 9(10), 526. https://doi.org/10.3390/jcs9100526