Optimization of Metakaolin-Based Geopolymer Composite for Repair Application

Abstract

1. Introduction

2. Experimental Program

2.1. Materials

2.2. Mixture Proportions

2.3. Samples Preparation

2.4. Test Methods

3. Results and Discussion

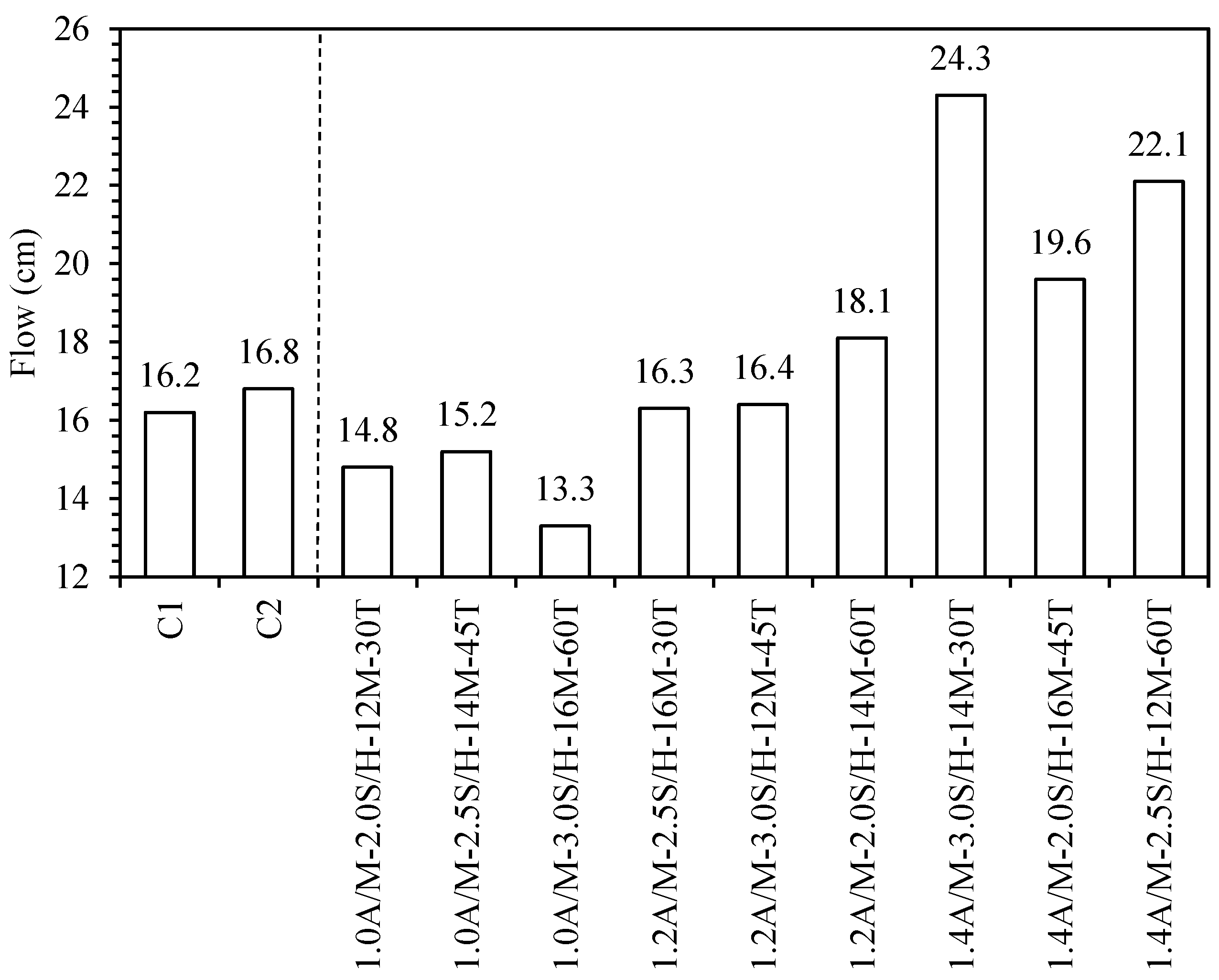

3.1. Flowability

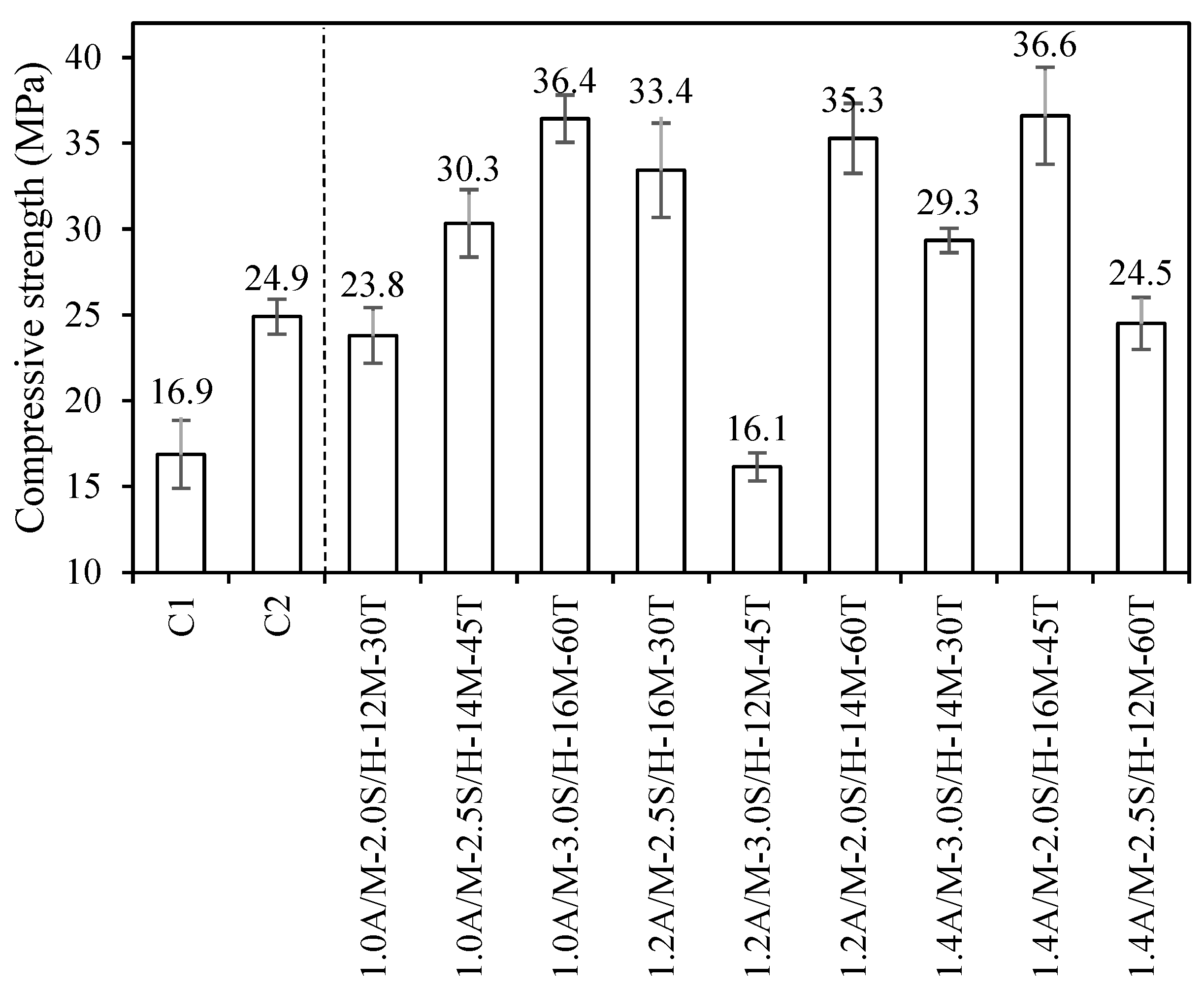

3.2. Compressive Strength

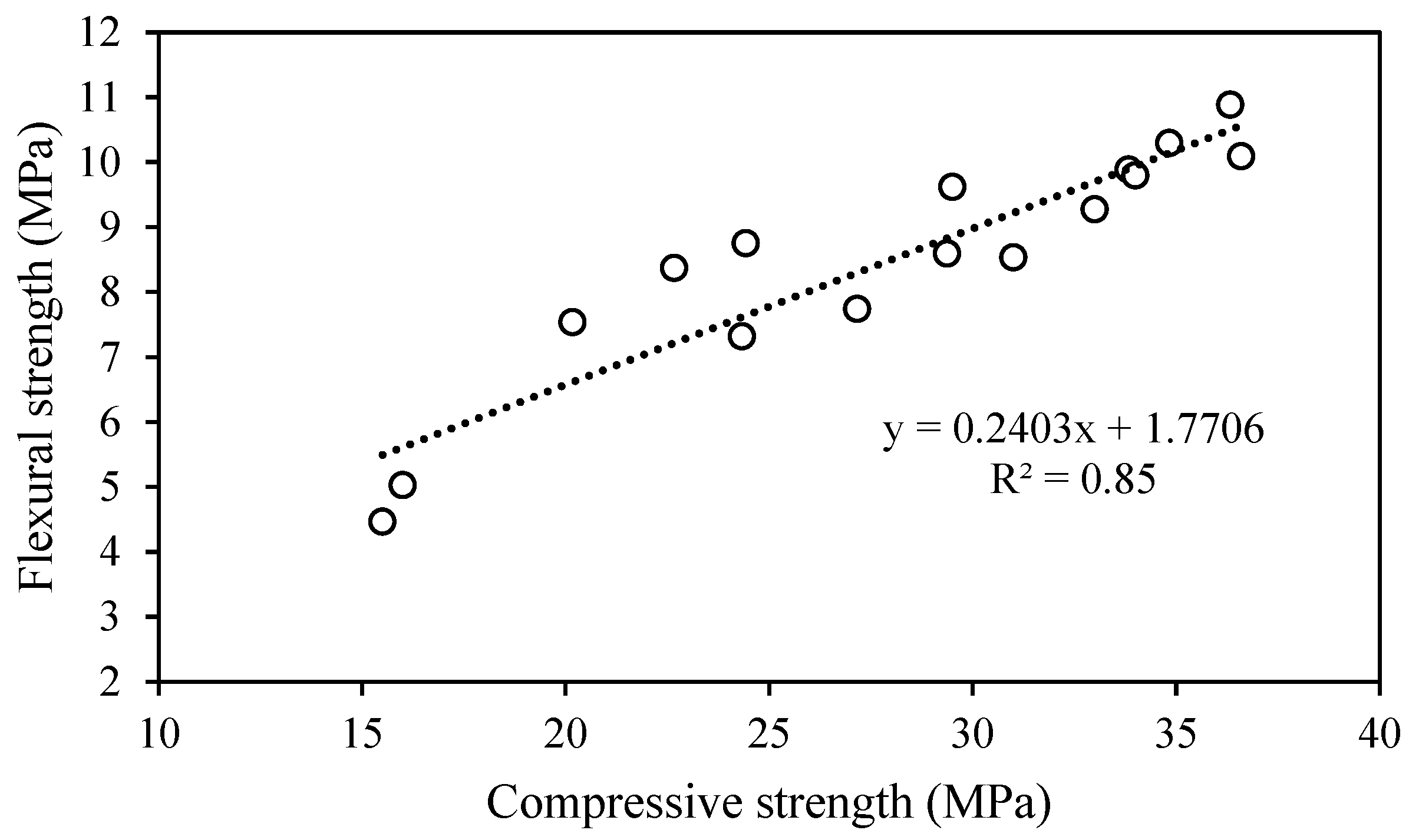

3.3. Flexural and Splitting Tensile Strengths

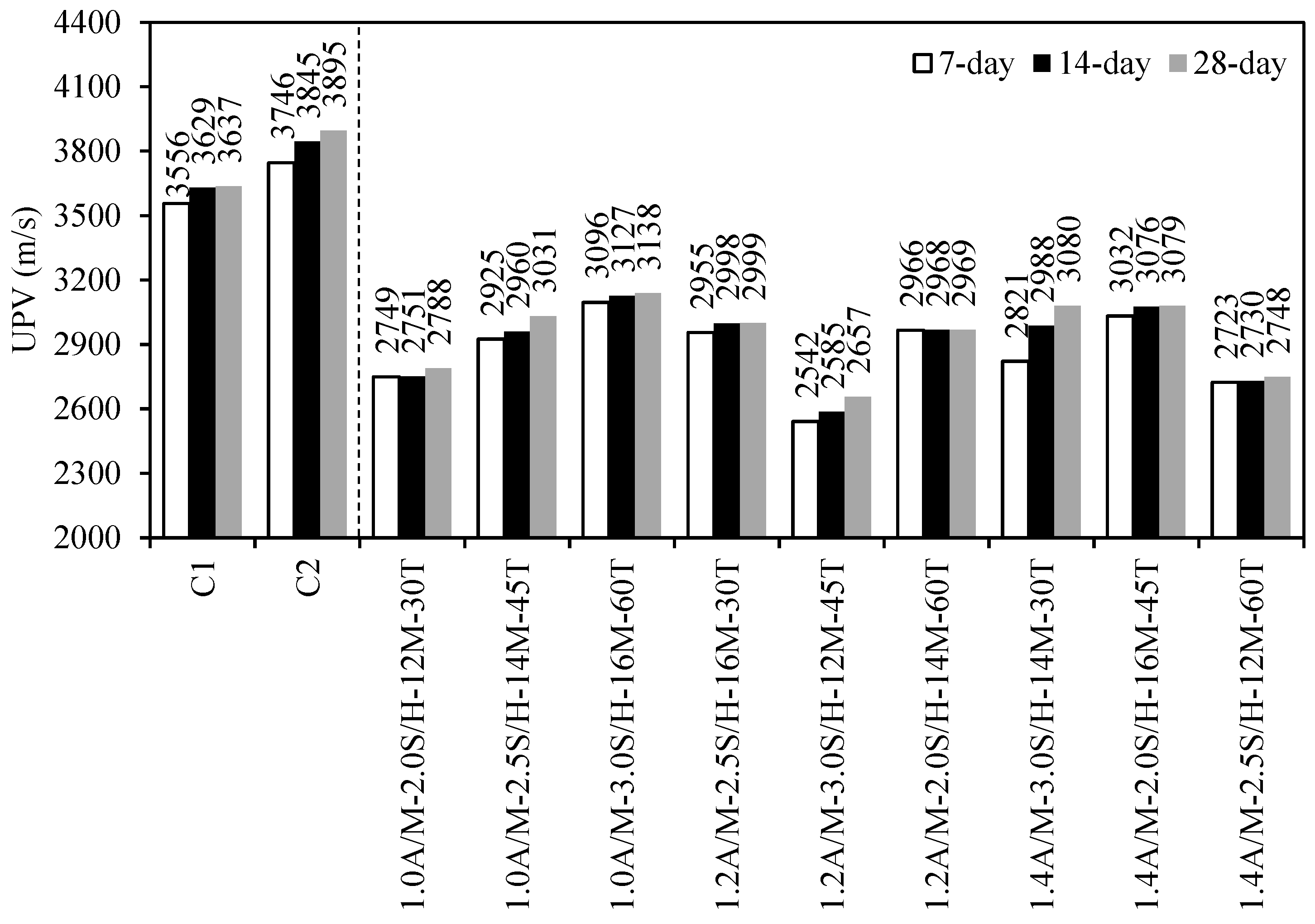

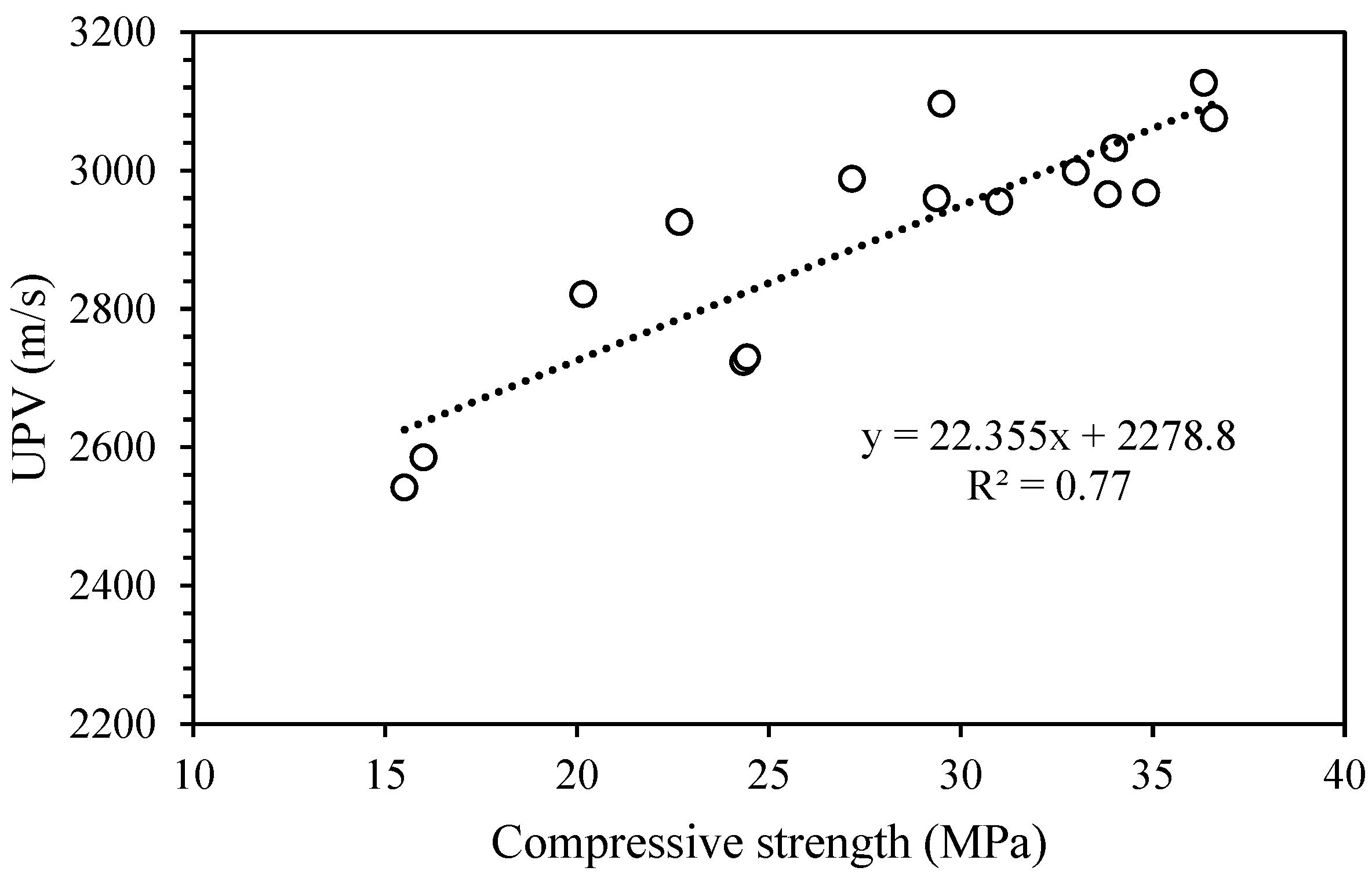

3.4. UPV

4. Optimization of GP Mixtures

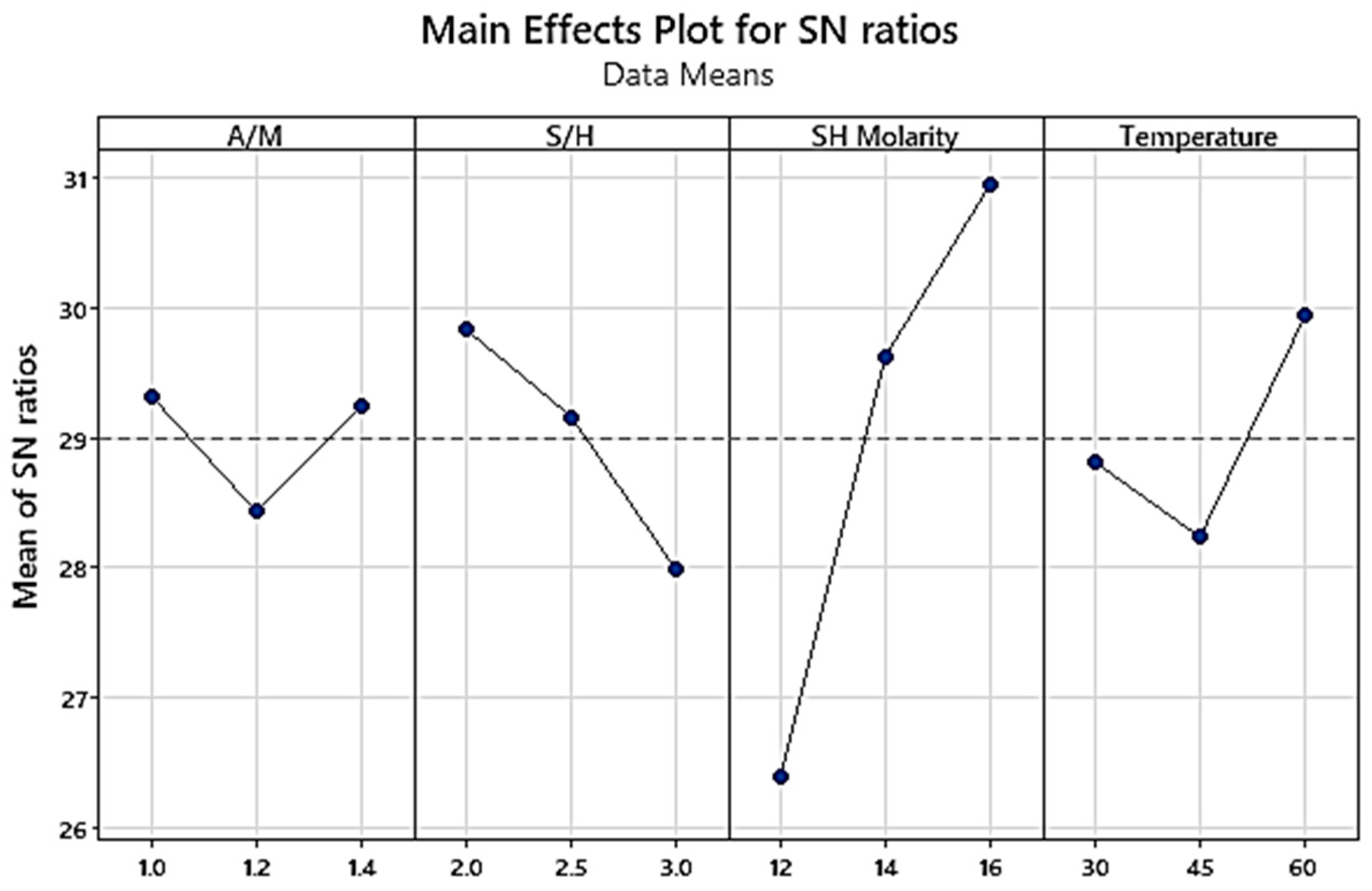

4.1. Taguchi Approach

4.2. Analysis of Variance

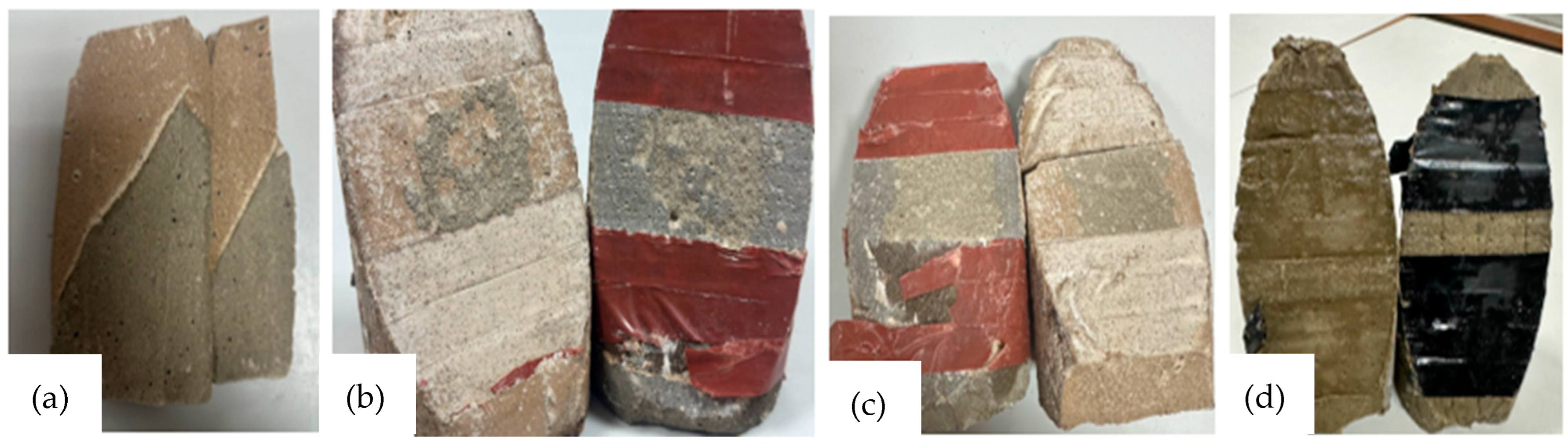

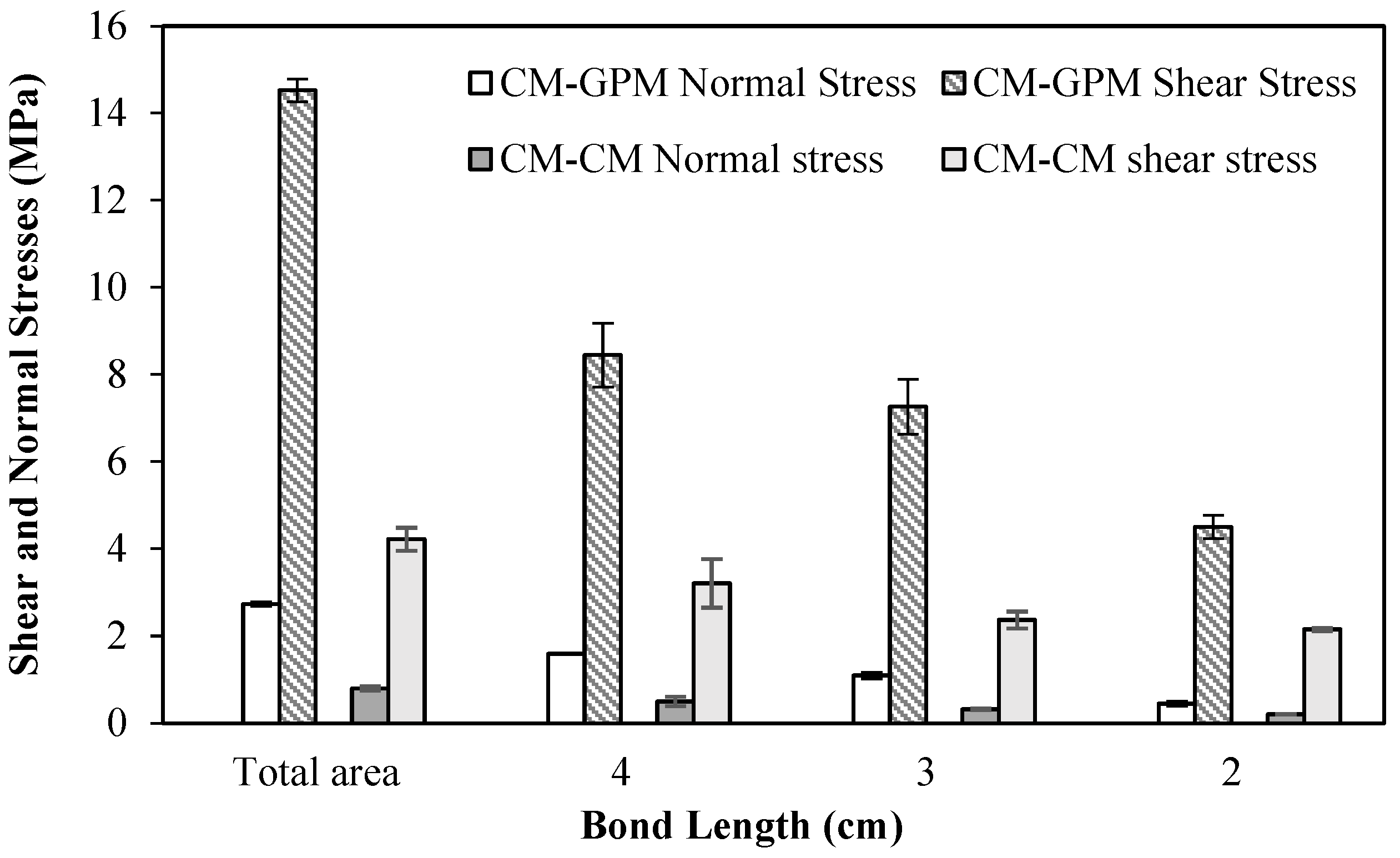

4.3. Validation of the Optimum Mix—Bond Strength Testing

5. Conclusions

- The flowability of the GP mixtures was found to increase with a higher alkaline activator-to-metakaolin ratio (A/M). ANOVA analysis confirmed that A/M had the most pronounced effect on workability, whereas the impact of other parameters was statistically insignificant.

- The compressive strength of MK-based geopolymer mortars surpassed 30 MPa when the A/M ratio, S/H ratio, SH molarity, and curing temperature were within the ranges of 1.0–1.4, 2.0–3.0, 14–16 M, and 45–60 °C, respectively. These conditions demonstrate the suitability of such combinations for targeted repair applications, particularly when compared to conventional cement-based mortars.

- The results for flexural strength, splitting tensile strength, and ultrasonic pulse velocity (UPV) aligned with those of compressive strength. Mixtures produced with higher A/M ratios and elevated curing temperatures exhibited enhanced performance, likely due to a more compact and refined matrix structure.

- The ANOVA results confirmed that A/M ratio and SH molarity were the most significant parameters affecting the mechanical behavior of the GP mixtures. Conversely, the SS/SH ratio and curing temperature showed comparatively lower influence on strength development within the tested range.

- The Taguchi method revealed that a GP mix with an A/M ratio of 1.4, SS/SH ratio of 2, sodium hydroxide molarity of 16, and a curing temperature of 60 °C delivered optimal performance. This optimized mix achieved compressive strengths of 39.9 MPa at 7 days and 41.0 MPa at 14 days, matching the strength levels of the cement-based reference mortar, even though it contained less binder (377–427 kg/m3 for the geopolymer compared to 464 kg/m3 for cement).

- GP mortars demonstrated superior bond strength compared to traditional cement-based composites. This can be attributed to the enhanced chemical bonding and denser matrix provided by the geopolymer structure, which improves the interfacial adhesion between layers or substrates.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Pérez-Lombard, L.; Ortiz, J.; Pout, C. A review on buildings energy consumption information. Energy Build. 2007, 40, 394–398. [Google Scholar] [CrossRef]

- Antunes, M.; Santos, R.L.; Pereira, J.; Rocha, P.; Horta, R.B.; Colaço, R. Alternative Clinker Technologies for reducing carbon emissions in cement industry: A Critical review. Materials 2021, 15, 209. [Google Scholar] [CrossRef]

- Nasser Eddine, Z.; Barraj, F.; Khatib, J.; Elkordi, A. From Waste to Resource: Utilizing Municipal Solid Waste Incineration Bottom Ash and Recycled Rubber in Pervious Concrete Pavement. Innov. Infrastruct. Solut. 2023, 8, 319. [Google Scholar] [CrossRef]

- El Mir, A.; Nehme, S.G. Effect of Air Entraining Admixture on the Properties of Self-Compacting Concrete Incorporating Supplementary Cementitious Materials. Pollack Period. 2017, 12, 85–98. [Google Scholar] [CrossRef]

- Barraj, F.; Jahami, A.; Hatoum, A.; Ghanoum, M. 3—Geopolymers and Alkali-Activated Materials in Pervious Concrete. In Woodhead Publishing Series in Civil and Structural Engineering; El-Hassan, H., Hamouda, M., Eds.; Woodhead Publishing: Cambridge, UK, 2025; pp. 35–75. ISBN 978-0-443-21704-3. [Google Scholar]

- Altameemi, S.; Adeleke, B.O.; Kinuthia, J.M.; Oti, J. Understanding the Effect of Waiting for the Dissolution of Sodium Hydroxide in Geopolymer Concrete Mixes. Materials 2025, 18, 849. [Google Scholar] [CrossRef]

- Duxson, P.; Fernández-Jiménez, A.; Provis, J.L.; Lukey, G.C.; Palomo, A.; Van Deventer, J.S.J. Geopolymer technology: The current state of the art. J. Mater. Sci. 2006, 42, 2917–2933. [Google Scholar] [CrossRef]

- Skane, R.; Schneider, P.A.; Jones, F.; van Riessen, A.; Jamieson, E.; Sun, X.; Rickard, W.D. Predicting the Stability of Geopolymer Activator Solutions for Optimised Synthesis through Thermodynamic Modelling. Chem. Eng. J. 2025, 515, 163543. [Google Scholar] [CrossRef]

- Albidah, A.; Alghannam, M.; Abbas, H.; Almusallam, T.; Al-Salloum, Y. Characteristics of metakaolin-based geopolymer concrete for different mix design parameters. J. Mater. Res. Technol. 2020, 10, 84–98. [Google Scholar] [CrossRef]

- Shilar, F.A.; Ganachari, S.V.; Patil, V.B.; Khan, T.M.Y.; Javed, S.; Baig, R.U. Optimization of alkaline activator on the strength properties of geopolymer concrete. Polymers 2022, 14, 2434. [Google Scholar] [CrossRef] [PubMed]

- Dandachy, M.E.E.; Hassoun, L.; El-Mir, A.; Khatib, J.M. Effect of elevated temperatures on compressive strength, ultrasonic pulse velocity, and transfer properties of Metakaolin-Based geopolymer mortars. Buildings 2024, 14, 2126. [Google Scholar] [CrossRef]

- Mahendra, K.; Narasimhan, M.C. One part alkali-activated materials for construction—A review. Mater. Today Proc. 2023, 93, 182–188. [Google Scholar] [CrossRef]

- Hachem, A.A.; Khatib, J.M.; El Dandachy, M.E. Assessment of interfacial mortar-mortar bond and pure shear strength of metakaolin-based geopolymer. Int. J. Build. Pathol. Adapt. 2025, 43, 732–748. [Google Scholar] [CrossRef]

- Abadel, A.A.; Albidah, A.S.; Altheeb, A.H.; Alrshoudi, F.A.; Abbas, H.; Al-Salloum, Y.A. Effect of molar ratios on strength, microstructure & embodied energy of metakaolin geopolymer. Adv. Concr. Constr. 2021, 11, 127. [Google Scholar] [CrossRef]

- Siciliano, U.C.; Zhao, J.; Trindade, A.C.C.; Liebscher, M.; Mechtcherine, V.; De Andrade Silva, F. Influence of curing temperature and pressure on the mechanical and microstructural development of metakaolin-based geopolymers. Constr. Build. Mater. 2024, 424, 135852. [Google Scholar] [CrossRef]

- Nath, P.; Sarker, P.K. Effect of GGBFS on setting, workability and early strength properties of fly ash geopolymer concrete cured in ambient condition. Constr. Build. Mater. 2014, 66, 163–171. [Google Scholar] [CrossRef]

- Dave, S.V.; Bhogayata, A.; Arora, N.K. Mix design optimization for fresh, strength and durability properties of ambient cured alkali activated composite by Taguchi method. Constr. Build. Mater. 2021, 284, 122822. [Google Scholar] [CrossRef]

- Dai, S.; Wang, H.; An, S.; Yuan, L. Mechanical properties and microstructural characterization of metakaolin geopolymers based on orthogonal tests. Materials 2022, 15, 2957. [Google Scholar] [CrossRef]

- Vora, P.R.; Dave, U.V. Parametric studies on compressive strength of geopolymer concrete. Procedia Eng. 2013, 51, 210–219. [Google Scholar] [CrossRef]

- Mo, B.; Zhu, H.; Cui, X.; He, Y.; Gong, S. Effect of curing temperature on geopolymerization of metakaolin-based geopolymers. Appl. Clay Sci. 2014, 99, 144–148. [Google Scholar] [CrossRef]

- DeSilva, P.; Sagoe-Crenstil, K.; Sirivivatnanon, V. Kinetics of geopolymerization: Role of Al2O3 and SiO2. Cem. Concr. Res. 2007, 37, 512–518. [Google Scholar] [CrossRef]

- Rovnaník, P. Effect of curing temperature on the development of hard structure of metakaolin-based geopolymer. Constr. Build. Mater. 2010, 24, 1176–1183. [Google Scholar] [CrossRef]

- Khale, D.; Chaudhary, R. Mechanism of geopolymerization and factors influencing its development: A review. J. Mater. Sci. 2007, 42, 729–746. [Google Scholar] [CrossRef]

- Perera, D.S.; Uchida, O.; Vance, E.R.; Finnie, K.S. Influence of curing schedule on the integrity of geopolymers. J. Mater. Sci. 2007, 42, 3099–3106. [Google Scholar] [CrossRef]

- Provis, J.L.; Van Deventer, J.S. Geopolymerisation kinetics. 1. In situ energy-dispersive X-ray diffractometry. Chem. Eng. Sci. 2007, 62, 2309–2317. [Google Scholar] [CrossRef]

- ASTM C33/C33M-18; Standard Specification for Concrete Aggregates. ASTM International: West Conshohocken, PA, USA, 2018. [CrossRef]

- Bawab, J.; El-Hassan, H.; El-Dieb, A.; Khatib, J. Effect of Mix Design Parameters on the Properties of Cementitious Composites Incorporating Volcanic Ash and Dune Sand. Dev. Built Environ. 2023, 16, 100258. [Google Scholar] [CrossRef]

- Bawab, J.; El-Hassan, H.; El-Dieb, A.; Khatib, J. Synergetic Impact of Volcanic Ash and Calcium Carbide Residue on the Properties and Microstructure of Cementitious Composites. Constr. Build. Mater. 2024, 439, 137390. [Google Scholar] [CrossRef]

- El-Mir, A.; Fayad, E.; Assaad, J.J.; El-Hassan, H. Multi-Response Optimization of Semi-Lightweight Concrete Incorporating Expanded Polystyrene Beads. Sustainability 2023, 15, 8757. [Google Scholar] [CrossRef]

- El-Mir, A.; Fayad, T.; Assaad, J.J.; El Dandachy, M.E.; Khatib, J.; El-Hassan, H. Multi-Criteria Optimization of SBR-Modified Mortar Incorporating Polyethylene Terephthalate Waste. Case Stud. Constr. Mater. 2024, 20, e03295. [Google Scholar] [CrossRef]

- ASTM C1437-20; Standard Test Method for Flow of Hydraulic Cement Mortar. ASTM International: West Conshohocken, PA, USA, 2020. [CrossRef]

- ASTM C109/C109M-21; Standard Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2-in. or [50-mm] Cube Specimens). ASTM International: West Conshohocken, PA, USA, 2021. [CrossRef]

- ASTM C293/C293M-16; Standard Test Method for Flexural Strength of Concrete (Using Simple Beam with Center-Point Loading). ASTM International: West Conshohocken, PA, USA, 2016. [CrossRef]

- ASTM C496/C496M-17; Standard Test Method for Splitting Tensile Strength of Cylindrical Concrete Specimens. ASTM International: West Conshohocken, PA, USA, 2017. [CrossRef]

- ASTM C597-16; Standard Test Method for Pulse Velocity Through Concrete. ASTM International: West Conshohocken, PA, USA, 2016. [CrossRef]

- Momayez, A.; Ehsani, M.R.; Ramezanianpour, A.A.; Rajaie, H. Comparison of Methods for Evaluating Bond Strength between Concrete Substrate and Repair Materials. Cem. Concr. Res. 2005, 35, 748–757. [Google Scholar] [CrossRef]

- Muñoz, M.A.C.; Harris, D.K.; Ahlborn, T.M.; Froster, D.C. Bond Performance between Ultrahigh-Performance Concrete and Normal-Strength Concrete. J. Mater. Civ. Eng. 2014, 26, 4014031. [Google Scholar] [CrossRef]

- El-Hassan, H.; El-Mir, A.; El-Maaddawy, T. 7—The Effect of Curing Regimes on Fiber-Reinforced Alkali-Activated Composites; Çevik, A., Niş, A., Eds.; Elsevier: Amsterdam, The Netherlands, 2023; pp. 161–189. ISBN 978-0-443-15301-3. [Google Scholar]

- Najm, O.; El-Hassan, H.; El-Dieb, A. Optimization of Alkali-Activated Ladle Slag Composites Mix Design Using Taguchi-Based TOPSIS Method. Constr. Build. Mater. 2022, 327, 126946. [Google Scholar] [CrossRef]

- Najm, O.; El-Hassan, H.; El-Dieb, A. Optimization of Alkali-Activated Ladle Slag-Fly Ash Composites Using a Taguchi-TOPSIS Hybrid Algorithm. Clean. Eng. Technol. 2024, 23, 100836. [Google Scholar] [CrossRef]

- Hwalla, J.; El-Hassan, H.; El-Mir, A.; Assaad, J.J.; El-Maaddawy, T. Development of Geopolymer and Cement-Based Shotcrete Mortar: Impact of Mix Design Parameters and Spraying Process. Constr. Build. Mater. 2024, 449, 138457. [Google Scholar] [CrossRef]

- Hwalla, J.; El-Mir, A.; El-Hassan, H.; El-Dieb, A. Taguchi Method for Optimizing Alkali-Activated Mortar Mixtures Using Waste Perlite Powder and Granulated Blast Furnace Slag BT—International RILEM Conference on Synergising Expertise towards Sustainability and Robustness of Cement-Based Materials and Concrete Structures; Jędrzejewska, A., Kanavaris, F., Azenha, M., Benboudjema, F., Schlicke, D., Eds.; Springer Nature Switzerland: Cham, Switzerland, 2023; pp. 362–373. [Google Scholar]

- Farhan, N.A.; Sheikh, M.N.; Hadi, M.N.S. Investigation of Engineering Properties of Normal and High Strength Fly Ash Based Geopolymer and Alkali-Activated Slag Concrete Compared to Ordinary Portland Cement Concrete. Constr. Build. Mater. 2019, 196, 26–42. [Google Scholar] [CrossRef]

- Fang, G.; Ho, W.K.; Tu, W.; Zhang, M. Workability and Mechanical Properties of Alkali-Activated Fly Ash-Slag Concrete Cured at Ambient Temperature. Constr. Build. Mater. 2018, 172, 476–487. [Google Scholar] [CrossRef]

- Dehnavi, A.; Rajabi, M.; Bavarsiha, F. The effect of temperature, time of curing and Na2O/SiO2 molar ratio on mechanical and chemical properties of geopolymer cement. Metall. Mater. Eng. 2020, 27, 213–226. [Google Scholar] [CrossRef]

- El-Mir, A.; Tannouri, P.; Assaad, J.J.; Nasr, D.; Ghannoum, M.; Barraj, F.; El-Hassan, H. Performance Optimization of SBR-Modified Pervious Composite Incorporating Recycled Concrete Aggregates. J. Compos. Sci. 2025, 9, 372. [Google Scholar] [CrossRef]

- Duxson, P.; Mallicoat, S.; Lukey, G.; Kriven, W.; Van Deventer, J. The effect of alkali and Si/Al ratio on the development of mechanical properties of metakaolin-based geopolymers. Colloids Surf. A Physicochem. Eng. Asp. 2006, 292, 8–20. [Google Scholar] [CrossRef]

- Abbas, R.; Khereby, M.A.; Ghorab, H.Y.; Elkhoshkhany, N. Preparation of geopolymer concrete using Egyptian kaolin clay and the study of its environmental effects and economic cost. Clean Technol. Environ. Policy 2020, 22, 669–687. [Google Scholar] [CrossRef]

- Enoh, M.K.E.; Ushie, D.O. Effect of sodium silicate to hydroxide ratio and sodium hydroxide Concentration on the Physico-Mechanical Properties of Geopolymer Binders. East Afr. J. Eng. 2023, 6, 113–121. [Google Scholar] [CrossRef]

- van Tonder, P. Tensile and Shear Response of Concrete with Nano-Materials. Steps Civil Constr. Environ. Eng. 2024, 2, 1–6. [Google Scholar] [CrossRef]

| Al2O3 | NaOH | SiO2 | Na2O | K2O | Fe2O3 | TiO2 | MgO | CaO | LOI | Density | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Cement | 4.3 | - | 21.4 | 0.52 | - | 3.1 | - | 2.7 | 62.9 | 1.84 | 3.15 |

| MK | 38.5 | - | 58.7 | - | 0.85 | 0.72 | 0.5 | 0.38 | 0.2 | 1.67 | 2.6 |

| Parameters, P | Levels | ||

|---|---|---|---|

| 1 | 2 | 3 | |

| P1: A/M, by mass | 1 | 1.2 | 1.4 |

| P2: S/H, by mass | 2 | 2.5 | 3 |

| P3: SH molarity | 12 | 14 | 16 |

| P4: Curing temperature | 30 | 45 | 60 |

| Mix ID | Mix Codification * | A/M | S/H | SH Molarity | Temperature (°C) |

|---|---|---|---|---|---|

| G1 | 1.0A/M-2.0S/H-12M-30T | 1 | 2 | 12 | 30 |

| G2 | 1.0A/M-2.5S/H-14M-45T | 1 | 2.5 | 14 | 45 |

| G3 | 1.0A/M-3.0S/H-16M-60T | 1 | 3 | 16 | 60 |

| G4 | 1.2A/M-2.5S/H-16M-30T | 1.2 | 2.5 | 16 | 30 |

| G5 | 1.2A/M-3.0S/H-12M-45T | 1.2 | 3 | 12 | 45 |

| G6 | 1.2A/M-2.0S/H-14M-60T | 1.2 | 2 | 14 | 60 |

| G7 | 1.4A/M-3.0S/H-14M-30T | 1.4 | 3 | 14 | 30 |

| G8 | 1.4A/M-2.0S/H-16M-45T | 1.4 | 2 | 16 | 45 |

| G9 | 1.4A/M-2.5S/H-12M-60T | 1.4 | 2.5 | 12 | 60 |

| Mix ID | Compressive Strength (MPa) | Increase in Strength | |||||

|---|---|---|---|---|---|---|---|

| 7-Day | 14-Day | 28-Day | 56-Day | 7–14 Days (%) | 7–28 Days (%) | 7–56 Days (%) | |

| C1 | 13.7 | 15.2 | 16.9 | 17.3 | 10.7 | 23.0 | 26.1 |

| C2 | 19.7 | 22.2 | 24.9 | 26.8 | 12.7 | 26.6 | 36.2 |

| 1.0A/M-2.0S/H-12M-30T | 22.8 | 23.4 | 23.8 | 24.0 | 2.5 | 4.2 | 5.1 |

| 1.0A/M-2.5S/H-14M-45T | 22.7 | 29.4 | 30.3 | 30.5 | 29.6 | 33.8 | 34.6 |

| 1.0A/M-3.0S/H-16M-60T | 29.5 | 36.3 | 36.4 | 36.5 | 23.2 | 23.5 | 23.7 |

| 1.2A/M-2.5S/H-16M-30T | 31.0 | 33.0 | 33.4 | 33.5 | 6.5 | 7.8 | 8.1 |

| 1.2A/M-3.0S/H-12M-45T | 15.5 | 16.0 | 16.1 | 16.2 | 3.2 | 4.1 | 4.5 |

| 1.2A/M-2.0S/H-14M-60T | 33.8 | 34.8 | 35.3 | 35.5 | 3.0 | 4.3 | 4.9 |

| 1.4A/M-3.0S/H-14M-30T | 20.2 | 27.2 | 29.3 | 29.6 | 34.7 | 45.5 | 46.8 |

| 1.4A/M-2.0S/H-16M-45T | 34.0 | 36.6 | 36.6 | 36.6 | 7.6 | 7.6 | 7.6 |

| 1.4A/M-2.5S/H-12M-60T | 24.3 | 24.4 | 24.5 | 24.5 | 0.4 | 0.7 | 0.7 |

| Property | Contribution (%) | |||

|---|---|---|---|---|

| A/M | S/H | SH Molarity | Temperature | |

| Flow | 87 | 0.1 | 11.1 | 1.8 |

| Compressive strength | 3.3 | 11.9 | 74.6 | 10.2 |

| Flexural strength | 6.2 | 14.9 | 51.7 | 27.2 |

| Splitting tensile strength | 0.9 | 5.7 | 76.3 | 17.1 |

| UPV | 6.3 | 1.0 | 89.8 | 2.9 |

| Results | Min (Mix G5) | Max (Mix G3) | C2 | Optimum GP |

|---|---|---|---|---|

| 7-day fc (MPa) | 15.5 | 29.5 | 19.7 | 39.9 |

| 14-day fc (MPa) | 16.0 | 36.3 | 22.2 | 41.0 |

| 7-day fr (MPa) | 4.5 | 9.6 | 6.2 | 9.3 |

| 14-day fr (MPa) | 5.0 | 10.9 | 7.3 | 10.8 |

| 7-day fs (MPa) | 3.6 | 5.5 | 5.8 | 8.0 |

| 14-day fs (MPa) | 4.1 | 9.0 | 7.4 | 10.0 |

| 7-day UPV (m/s) | 2542 | 3096 | 3746 | 2994.3 |

| 14-day UPV (m/s) | 2585 | 3126 | 3845 | 3025.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hawa, L.; El-Mir, A.; Khatib, J.; Nasr, D.; Assaad, J.; Elkordi, A.; Ezzedine El Dandachy, M. Optimization of Metakaolin-Based Geopolymer Composite for Repair Application. J. Compos. Sci. 2025, 9, 527. https://doi.org/10.3390/jcs9100527

Hawa L, El-Mir A, Khatib J, Nasr D, Assaad J, Elkordi A, Ezzedine El Dandachy M. Optimization of Metakaolin-Based Geopolymer Composite for Repair Application. Journal of Composites Science. 2025; 9(10):527. https://doi.org/10.3390/jcs9100527

Chicago/Turabian StyleHawa, Layal, Abdulkader El-Mir, Jamal Khatib, Dana Nasr, Joseph Assaad, Adel Elkordi, and Mohamad Ezzedine El Dandachy. 2025. "Optimization of Metakaolin-Based Geopolymer Composite for Repair Application" Journal of Composites Science 9, no. 10: 527. https://doi.org/10.3390/jcs9100527

APA StyleHawa, L., El-Mir, A., Khatib, J., Nasr, D., Assaad, J., Elkordi, A., & Ezzedine El Dandachy, M. (2025). Optimization of Metakaolin-Based Geopolymer Composite for Repair Application. Journal of Composites Science, 9(10), 527. https://doi.org/10.3390/jcs9100527