Coconut Coir Fiber Composites for Sustainable Architecture: A Comprehensive Review of Properties, Processing, and Applications

Abstract

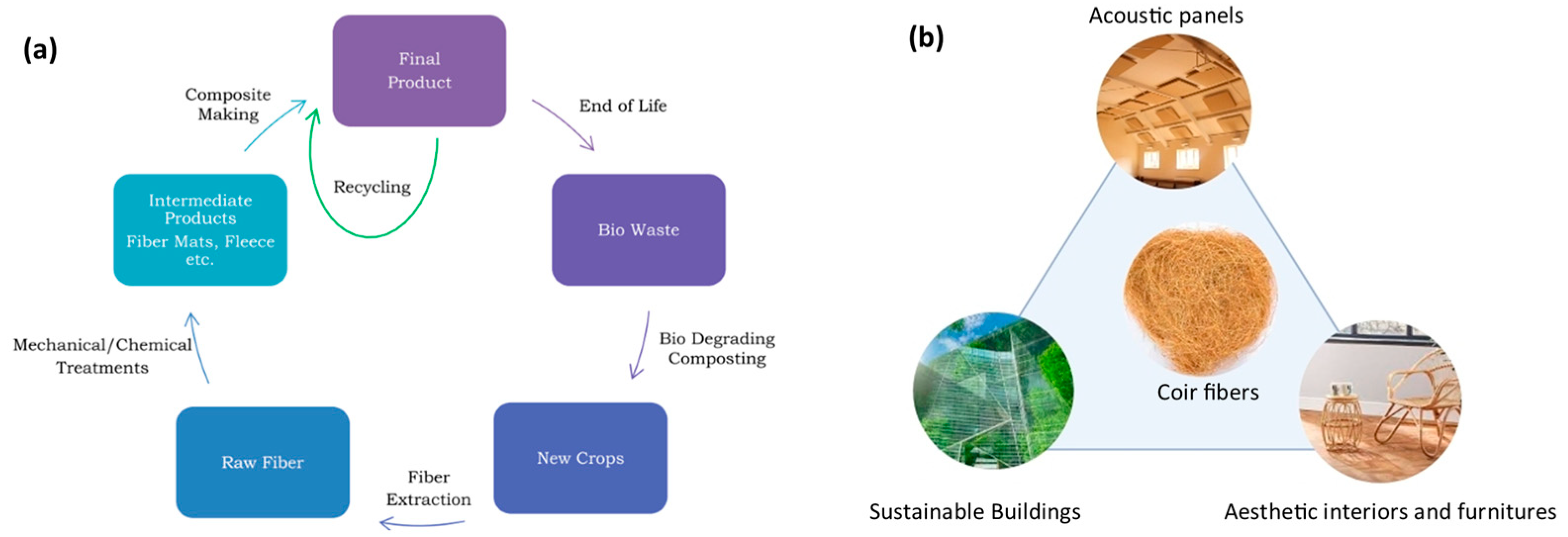

1. Introduction

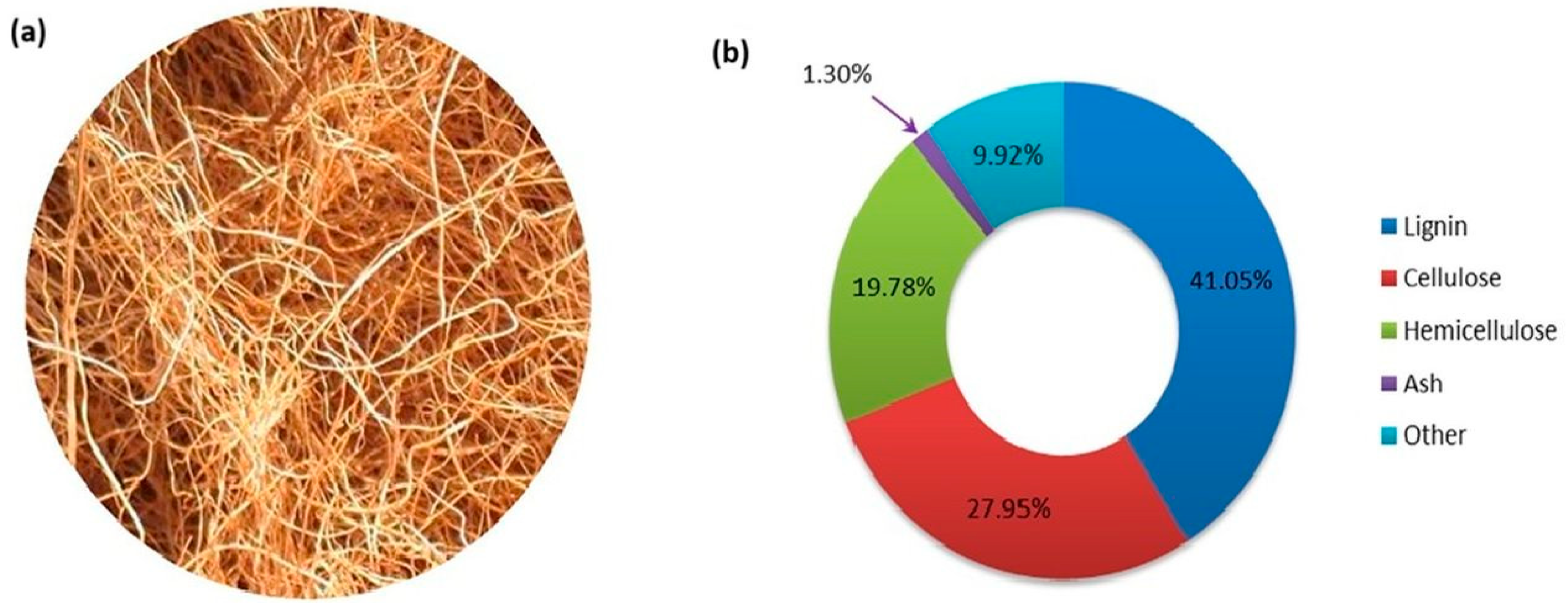

2. Properties of Coconut Coir

2.1. Physical and Chemical Properties

2.2. Mechanical Properties

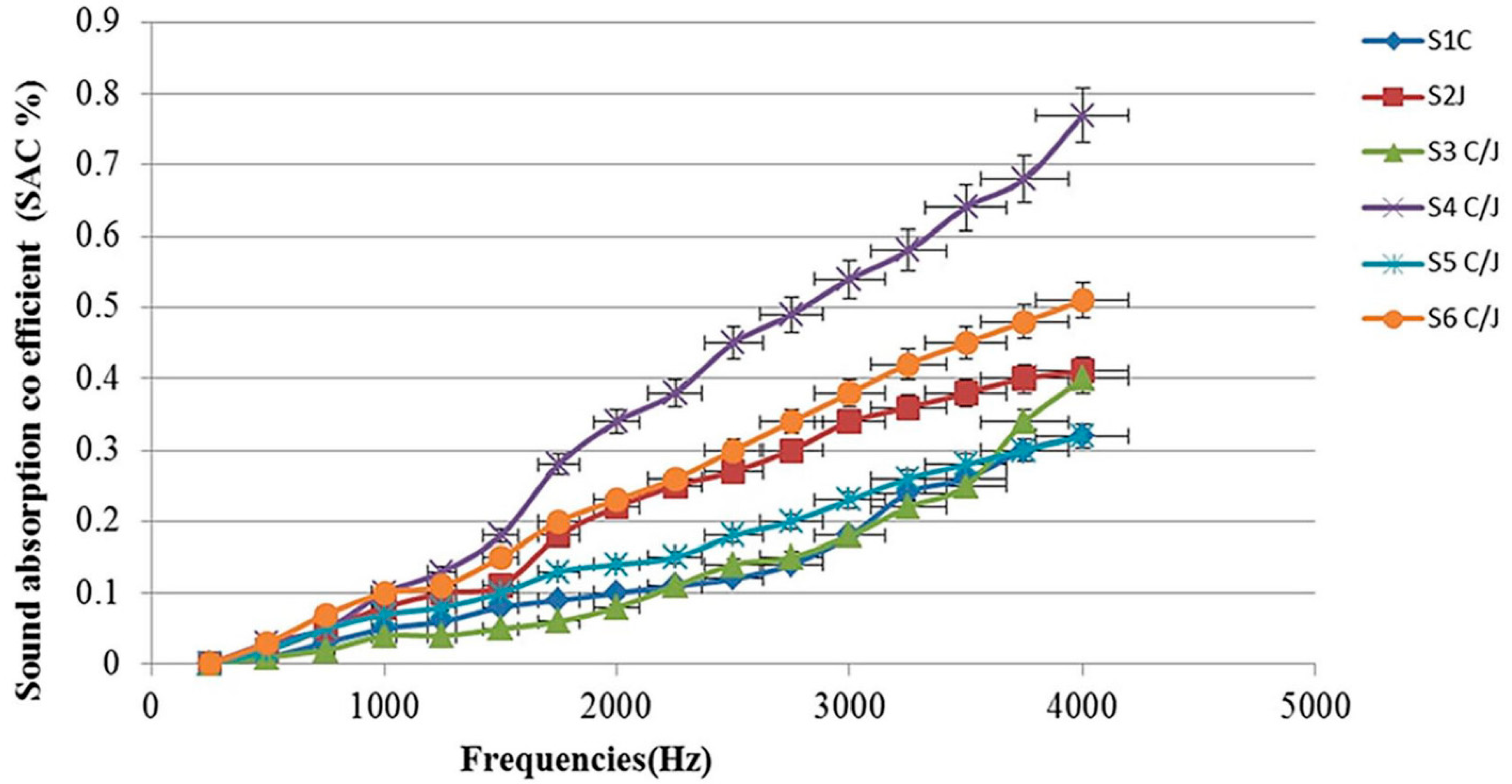

2.3. Thermal and Acoustic Properties

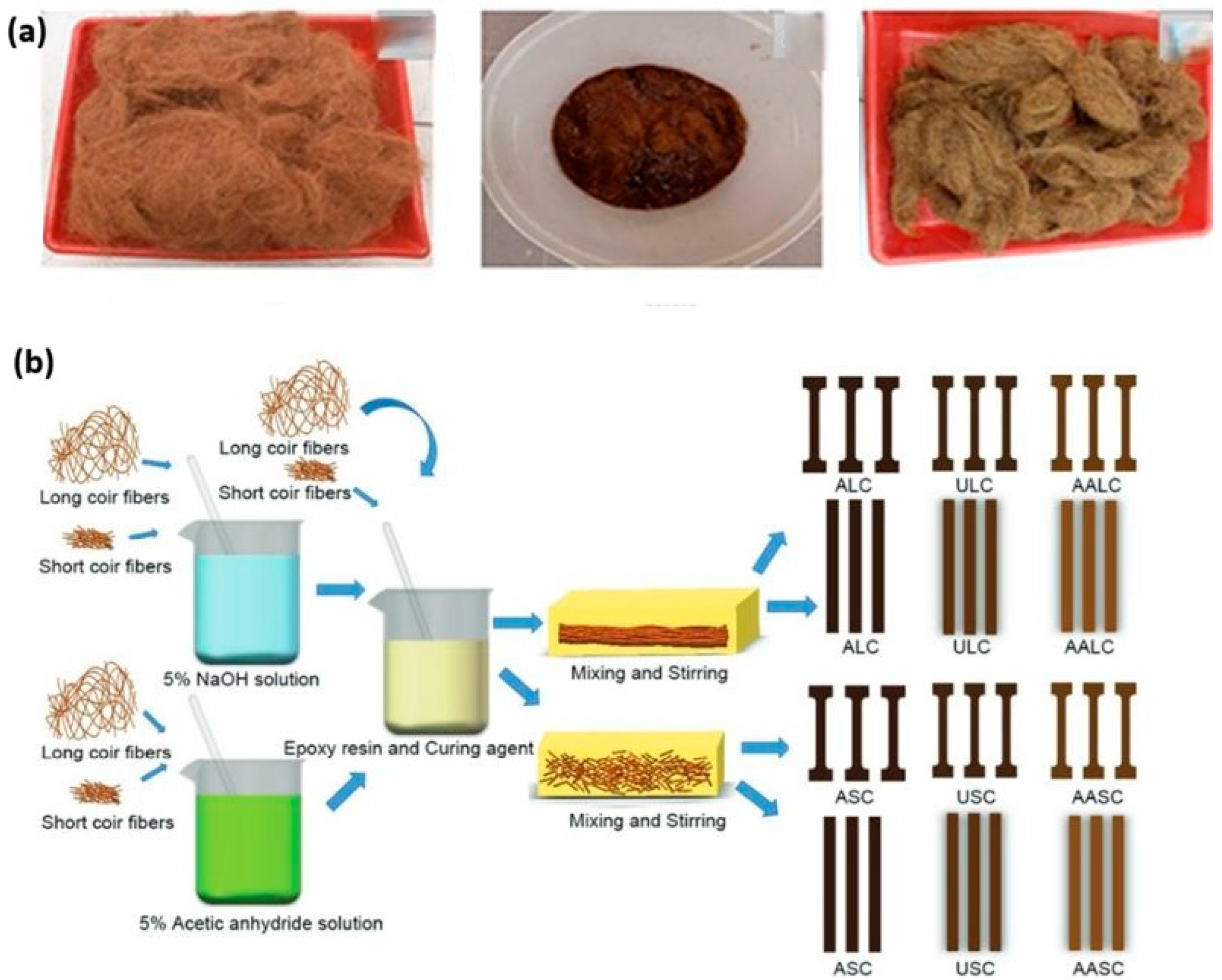

3. Production of Coconut Coir-Based Composites

3.1. Source of Coconut Coir

| Rank | Country | Production (metric tons) | Global Share (%) |

|---|---|---|---|

| 1 | India | 586,686 | 44.00% |

| 2 | Sri Lanka | 161,791 | 27.10% |

| 3 | Vietnam | 390,541 | 11.20% |

| 4 | Philippines | 60,983 | 4.80% |

| 5 | Indonesia | 52,932 | 4.10% |

| 6 | Thailand | 64,098 | 1.30% |

| 7 | Malaysia | 12,361 | 1.00% |

| 8 | Mexico | 11,981 | 0.90% |

| 9 | Guyana | 9583 | 0.80% |

| 10 | Bangladesh | 5072 | 0.40% |

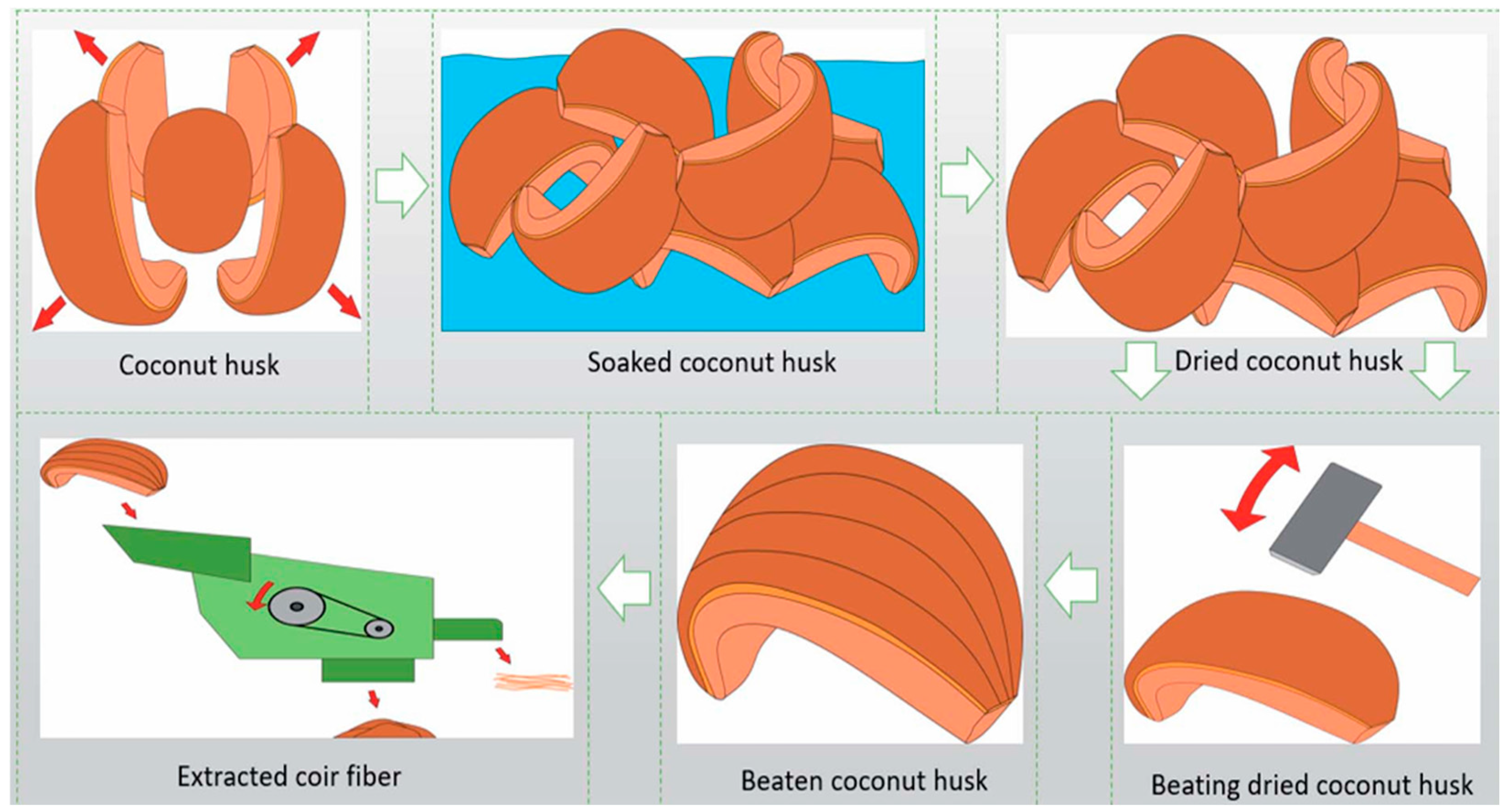

3.2. Fibre Extraction and Processing

3.3. Fabrication Techniques—Coir Reinforced Composites

3.4. Selection of Matrix Materials

3.5. Binder Materials

4. Architectural Applications

4.1. Structural Components

4.2. Interior Applications

4.3. Thermal and Acoustic Insulation

4.4. Biophilic Applications

5. Challenges and Limitations

5.1. Moisture Sensitivity

5.2. Consistency in Quality

5.3. Cost and Scalability

5.4. Flammability Properties

6. Future Prospects

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| CF | Coconut Fibers |

| NFRC | Natural Fiber Reinforced Composites |

| MOE | Modulus of elasticity |

| MOR | Modulus of rupture |

| FL | fiber length |

| FVF | Fiber Volume Fraction |

| CS | compressive strength |

| FTIR | Fourier Transform Infrared Spectroscopy |

| XRD | X-Ray Diffraction |

| CBPB | Cement Bonded Particle Boards |

| TGA | thermogravimetric analysis |

| DTG | Derivative Thermogravimetric Analysis |

| PP | Polypropylene |

| LCF | Long Coir Fibers |

| CFC | Coir Fibrous Chips |

| MUF | Melamine-Urea-Formaldehyde |

| UF | Urea-Formaldehyde |

| PF | Phenol-Formaldehyde |

| RTM | Resin Transfer Molding |

| IC | Isocyanate |

| GGBS | Ground Granulated Blast Furnace Slag |

| BST | Bio-based Sustainable Binder Type |

| VOC | Volatile Organic Compounds |

| LEED | Leadership in Energy and Environmental Design |

| BREEAM | Building Research Establishment Environmental Assessment Method |

| DSC | Differential Scanning Calorimetry |

| FR | Fire Retardant |

References

- Al Faruque, A.; Bilisik, K. Plant-Based Natural Fibre Reinforced Composites: A Review on Fabrication, Properties and Applications. Coatings 2020, 10, 973. [Google Scholar] [CrossRef]

- Adeniyi, A.G.; Onifade, D.V.; Ighalo, J.O.; Adeoye, A.S. A review of coir fiber reinforced polymer composites. Compos. Part B 2019, 176, 107305. [Google Scholar] [CrossRef]

- Seki, Y.; Selli, F.; Erdoğan, Ü.H.; Atagür, M.; Seydibeyoğlu, M.Ö. A review on alternative raw materials for sustainable production: Novel plant fibers. Cellulose 2022, 29, 4877–4918. [Google Scholar] [CrossRef]

- Väisänen, T.; Das, O.; Tomppo, L. A review on new bio-based constituents for natural fiber-polymer composites. J. Clean. Prod. 2017, 149, 582–596. [Google Scholar] [CrossRef]

- Elfaleh, I.; Abbassi, F.; Habibi, M.; Ahmad, F.; Guedri, M.; Nasri, M.; Garnier, C. A comprehensive review of natural fibers and their composites: An eco-friendly alternative to conventional materials. Results Eng. 2023, 19, 101271. [Google Scholar] [CrossRef]

- Suriani, M.J.; Ilyas, R.A.; Zuhri, M.Y.M.; Khalina, A.; Sultan, M.T.H.; Sapuan, S.M.; Ruzaidi, C.M.; Wan, F.N.; Zulkifli, F.; Harussani, M.M.; et al. Critical Review of Natural Fiber Reinforced Hybrid Composites: Processing, Properties, Applications and Cost. Polymers 2021, 13, 3514. [Google Scholar] [CrossRef] [PubMed]

- Sultana Mir, S.; Hasan, M.; Hasan, S.M.N.; Hossain, M.J.; Nafsin, N. Effect of chemical treatment on the properties of coir fiber reinforced polypropylene and polyethylene composites. Polym. Compos. 2017, 38, 1259–1265. [Google Scholar] [CrossRef]

- Mahmud, S.; Hasan, K.M.F.; Jahid, M.A.; Mohiuddin, K.; Zhang, R.; Zhu, J. Comprehensive Review on Plant Fiber-Reinforced Polymeric Biocomposites. J. Mater. Sci. 2021, 56, 7231–7264. [Google Scholar] [CrossRef]

- Maiti, S.; Islam, R.; Uddin, M.A.; Afroj, S.; Eichhorn, S.J.; Karim, N. Sustainable Fiber-Reinforced Composites: A Review. Adv. Sustain. Syst. 2022, 6, 2200258. [Google Scholar] [CrossRef]

- Hasan, K.M.F.; Horváth, P.G.; Alpár, T. Lignocellulosic Fiber Cement Compatibility: A State of the Art Review. J. Nat. Fibers 2022, 19, 5409–5434. [Google Scholar] [CrossRef]

- Hasan, K.M.F.; Horváth, P.G.; Bak, M.; Alpár, T. A state-of-the-art review on coir fiber-reinforced biocomposites. RSC Adv. 2021, 11, 10548–10571. [Google Scholar] [CrossRef]

- Ru, S.; Yang, R.; Yang, S.; Zhao, C. Effects of Physical and Mechanical Properties of Coir Fiber and Reinforced Epoxy Composites Treated with Acetic Anhydride and Alkali Effects of Physical and Mechanical Properties of Coir Fiber and Alkali. J. Nat. Fibers 2023, 20, 2285819. [Google Scholar] [CrossRef]

- Ichim, M.; Stelea, L.; Filip, I.; Lisa, G.; Muresan, E.I. Thermal and Mechanical Characterization of Coir Fibre–Reinforced Polypropylene Biocomposites. Crystals 2022, 12, 1249. [Google Scholar] [CrossRef]

- Viswanathan, R. Mechanical properties of coir pith particle board. Bioresour. Technol. 1999, 67, 93–95. [Google Scholar] [CrossRef]

- Kiran, M.C.; Mamatha, B.S.; Anand, N.; Prakash, V.; Murthy, N. Efficiency of Coir Particle Board for Acoustic & Thermal Applications. Open J. Acoust. 2019, 9, 39–47. [Google Scholar] [CrossRef]

- van Dam, J.E.G.; van den Oever, M.J.A.; Keijsers, E.R.P. Production process for high density high performance binderless boards from whole coconut husk. Ind. Crops Prod. 2004, 20, 97–101. [Google Scholar] [CrossRef]

- Aggarwal, L.K. Studies on cement-bonded coir fibre boards. Cem. Concr. Compos. 1992, 14, 63–69. [Google Scholar] [CrossRef]

- Goyat, V.; Ghangas, G.; Sirohi, S.; Kumar, A.; Nain, J. A review on mechanical properties of coir based composites. Mater. Today Proc. 2022, 62, 1738–1745. [Google Scholar] [CrossRef]

- Ikubanni, P.P.; Adeleke, A.A.; Adekanye, T.A.; Aladegboye, O.J.; Agboola, O.O.; Ogunsemi, B.T. Particleboard from biomass wastes: A review of production techniques, properties, and future trends. Res. Eng. Struct. Mater. 2024, 11, 713–740. [Google Scholar] [CrossRef]

- Nazi Mwambegu, M.; Gnanamoorthy, R. Water absorption in alkaline-treated coir pith—For use as reinforcement material in polymer matrix composites. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Mishra, L.; Basu, G. Coconut fibre: Its structure, properties and applications. In Handbook of Natural Fibres, 2nd ed.; Elsevier Inc.: Amsterdam, The Netherlands, 2020; Volume 1, pp. 231–255. [Google Scholar] [CrossRef]

- Morandim-Giannetti, A.A.; Agnelli, J.A.M.; Lanças, B.Z.; Magnabosco, R.; Casarin, S.A.; Bettini, S.H.P. Lignin as additive in polypropylene/coir composites: Thermal, mechanical and morphological properties. Carbohydr. Polym. 2012, 87, 2563–2568. [Google Scholar] [CrossRef]

- Ashok, A.; Senthilkumar, K.; Jayanarayanan, K.; Mini, K.M. Sustainable development of cement-bonded particle boards using coir fiber edge trims and grain granulated blast furnace slag (GGBS): Mechanical, thermal, and economic evaluations. Innov. Infrastruct. Solut. 2025, 10, 301. [Google Scholar] [CrossRef]

- Guruswamy, K.P.; Thambiannan, S.; Anthonysamy, A.; Jalgaonkar, K.; Dukare, A.S.; Pandiselvam, R.; Jha, N. Coir fibre-reinforced concrete for enhanced compressive strength and sustainability in construction applications. Heliyon 2024, 10, e39773. [Google Scholar] [CrossRef]

- Charles, G.; Ponganesh, S.P. Effect of Using Coconut Fibre by Manufacturingeco Friendly Bricks (Blocks); Sathyabama Institute of Science and Technology: Chennai, India, 2022. [Google Scholar]

- Musyarofah, L.; Sujito, S.; Hidayah, E.; Supriyanto, E. Effect of alkalization on mechanical properties of green composites reinforced with cellulose from coir fiber. Acad. Open 2020, 2242, 020016. [Google Scholar] [CrossRef]

- Siakeng, R.; Jawaid, M.; Ariffin, H.; Salit, M.S. Effects of Surface Treatments on Tensile, Thermal and Fibre-matrix Bond Strength of Coir and Pineapple Leaf Fibres with Poly Lactic Acid. J. Bionic Eng. 2018, 15, 1035–1046. [Google Scholar] [CrossRef]

- dos Santos, J.C.; Siqueira, R.L.; Vieira, L.M.G.; Freire, R.T.S.; Mano, V.; Panzera, T.H. Effects of sodium carbonate on the performance of epoxy and polyester coir-reinforced composites. Polym. Test. 2018, 67, 533–544. [Google Scholar] [CrossRef]

- Kabir, M.M.; Wang, H.; Lau, K.T.; Cardona, F. Chemical treatments on plant-based natural fibre reinforced polymer composites: An overview. Compos. Part B Eng. 2012, 43, 2883–2892. [Google Scholar] [CrossRef]

- Dong, Y.; Ghataura, A.; Takagi, H.; Haroosh, H.J.; Nakagaito, A.N.; Lau, K.-T. Polylactic acid (PLA) biocomposites reinforced with coir fibres: Evaluation of mechanical performance and multifunctional properties. Compos. Part A Appl. Sci. Manuf. 2014, 63, 76–84. [Google Scholar] [CrossRef]

- Rosa, M.F.; Chiou, B.; Medeiros, E.S.; Wood, D.F.; Williams, T.G.; Mattoso, L.H.C.; Orts, W.J.; Imam, S.H. Effect of fiber treatments on tensile and thermal properties of starch/ethylene vinyl alcohol copolymers/coir biocomposites. Bioresour. Technol. 2009, 100, 5196–5202. [Google Scholar] [CrossRef]

- Singh, Y.; Singh, J.; Sharma, S.; Lam, T.-D.; Nguyen, D.-N. Fabrication and characterization of coir/carbon-fiber reinforced epoxy based hybrid composite for helmet shells and sports-good applications: Influence of fiber surface modifications on the mechanical, thermal and morphological properties. J. Mater. Res. Technol. 2020, 9, 15593–15603. [Google Scholar] [CrossRef]

- Quiñones-Bolaños, E.; Gómez-Oviedo, M.; Mouthon-Bello, J.; Sierra-Vitola, L.; Berardi, U.; Bustillo-Lecompte, C. Potential use of coconut fibre modified mortars to enhance thermal comfort in low-income housing. J. Environ. Manag. 2021, 277, 111503. [Google Scholar] [CrossRef] [PubMed]

- Krishnasamy, B.; Shanmugam, N.; Subramanian, A.; Selvaraj, S.K.; Sakthivel, S.; Guru, R.; Admassu, Y. Sound-absorbing and thermal insulating properties of natural coir/jute hybrid composites for functional materials. J. Eng. Fiber. Fabr. 2024, 19, 15589250241270522. [Google Scholar] [CrossRef]

- Parikh, H.H.; Rana, H.; Raj, A.; Gbadeyan, O.J. Acoustic performance of coir fi ber-reinforced starch-based bio composites. Compos. Adv. Mater. 2025, 34, 26349833251339768. [Google Scholar] [CrossRef]

- Singh, V.K.; Mukhopadhyay, S. Banana fibre-based structures for acoustic insulation and absorption. J. Ind. Text. 2022, 51, 1355–1375. [Google Scholar] [CrossRef]

- Mohammed, L.; Ansari, M.N.M.; Pua, G.; Jawaid, M.; Islam, M.S. A Review on Natural Fiber Reinforced Polymer Composite and Its Applications. Int. J. Polym. Sci. 2015, 2015, 243947. [Google Scholar] [CrossRef]

- Yu, C. Natural Textile Fibres: Vegetable Fibres. In Textiles and Fashion; Elsevier: Amsterdam, The Netherlands, 2015; pp. 29–56. [Google Scholar] [CrossRef]

- Zakriya, G.M.; Ramakrishnan, G. Insulation and mechanical properties of jute and hollow conjugated polyester reinforced nonwoven composite. Energy Build. 2018, 158, 1544–1552. [Google Scholar] [CrossRef]

- Li, X.; Tabil, L.G.; Oguocha, I.N.; Panigrahi, S. Thermal diffusivity, thermal conductivity, and specific heat of flax fiber–HDPE biocomposites at processing temperatures. Compos. Sci. Technol. 2008, 68, 1753–1758. [Google Scholar] [CrossRef]

- Zhang, D.; Zhou, X.; Gao, Y.; Lyu, L. Structural Characteristics and Sound Absorption Properties of Waste Hemp Fiber. Coatings 2022, 12, 1907. [Google Scholar] [CrossRef]

- Huang, C.; Lin, J.; Lou, C.; Tsai, Y. The Efficacy of Coconut Fibers on the Sound-Absorbing and Thermal-Insulating Nonwoven Composite Board. Fibers Polym. 2013, 14, 1378–1385. [Google Scholar] [CrossRef]

- Stelte, W.; Reddy, N.; Barsberg, S.; Sanadi, A.R. Coir from coconut processing waste as a raw material for applications beyond traditional uses. BioResources 2022, 18, 2187–2212. [Google Scholar] [CrossRef]

- Verma, D.; Gope, P.C. The use of coir/coconut fibers as reinforcements in composites. In Biofiber Reinforcements in Composite Materials; Elsevier: Amsterdam, The Netherlands, 2015; pp. 285–319. [Google Scholar] [CrossRef]

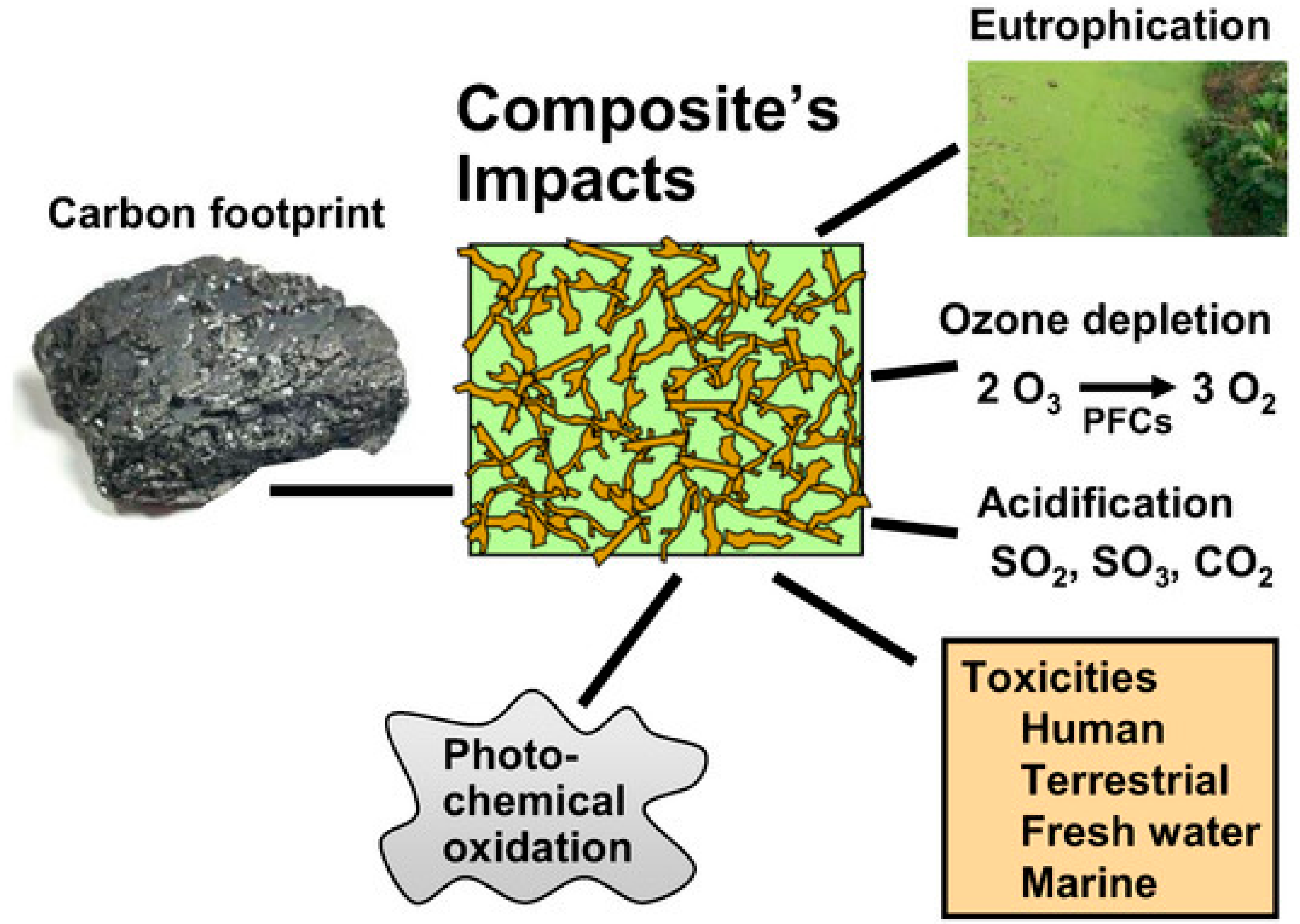

- Das, S.C.; La Rosa, A.D.; Grammatikos, S.A. Life cycle assessment of plant fibers and their composites. In Plant Fibers, Their Composites, and Applications; Elsevier: Amsterdam, The Netherlands, 2022; pp. 457–484. [Google Scholar] [CrossRef]

- RoLanka International, Inc. An Abundant Natural Fiber Resource to Save the Earth, Its Waters and Wetlands Coir (Coconut Fiber). 1994. Available online: https://rolanka.com/wp-content/uploads/2023/07/Coir-natural-by-product.pdf (accessed on 10 August 2025).

- Sanjay, M.R.; Siengchin, S.; Parameswaranpillai, J.; Jawaid, M.; Iulian, C.; Khan, A. A comprehensive review of techniques for natural fi bers as reinforcement in composites: Preparation, processing and characterization. Carbohydr. Polym. 2019, 207, 108–121. [Google Scholar] [CrossRef]

- Prabakaran. Sourcing Coconut Coir Products for Your Business: Types, Applications, and Export Potential. 2025. Available online: https://www.greglo.com/coconut-coir-products-sourcing-guide/ (accessed on 10 August 2025).

- Manoharan, S.D.K.S. Applications of coir fibres in automotive industry. Int. J. Innov. Res. Multidiscip. Educ. 2025, 10, 83–87. [Google Scholar] [CrossRef]

- Karthikeyan, A.; Kalpana, A. Effect of Fiber Length and NaOH Treatment on the Flexural Behavior of Coir Fiber Reinforced Epoxy Composite. J. Nat. Fibers 2022, 19, 15202–15212. [Google Scholar] [CrossRef]

- Thema, J.; Mdungazi, M.; Maluleke, K. The effect of varying coconut coir substrates and loam soil on the physiology, and biochemical constituents of tomato (Solanum lycopersicum var. esculentum) grown under greenhouse environment. Discov. Sustain. 2025, 6, 143. [Google Scholar] [CrossRef]

- Pawar, S. Global Coco Coir Market Size, Share, and Trends Analysis Report—Industry Overview and Forecast to 2032. Available online: https://www.databridgemarketresearch.com/reports/global-coco-coir-market#:~:text=CocoCoirMarketSize*Theglobal,coirinhorticulture%2Cagriculture%2Candindustrialsectors (accessed on 10 August 2025).

- Coir Production in 2020. Available online: https://www.fao.org/faostat/en/#data/QCL (accessed on 10 August 2025).

- Coir Board of India. Available online: http://coirboard.gov.in/?page_id=271 (accessed on 10 August 2025).

- Hubbe, M.A. Sustainable Composites: A Review with Critical Questions to Guide Future Initiatives. Sustainability 2023, 15, 11088. [Google Scholar] [CrossRef]

- Coir or Coconut Fiber—The Natural, Seed Fibre. Available online: https://www.textileschool.com/212/coir-or-coconut-fiber-the-natural-seed-fiber/ (accessed on 10 August 2025).

- Karthikeyan, A.; Balamurugan, K.; Kalpana, A. The effect of sodium hydroxide treatment and fiber length on the tensile property of coir fiber-reinforced epoxy composites. Sci. Eng. Compos. Mater. 2014, 21, 315–321. [Google Scholar] [CrossRef]

- Fiore, V.; Scalici, T.; Nicoletti, F.; Vitale, G.; Prestipino, M.; Valenza, A. A new eco-friendly chemical treatment of natural fibres: Effect of sodium bicarbonate on properties of sisal fibre and its epoxy composites. Compos. Part B Eng. 2016, 85, 150–160. [Google Scholar] [CrossRef]

- Viswanathan, R.; Gothandapani, L. Optimum Process Variables for the Production of Coir Pith Particle Board. J. Agric. Eng. Res. 1999, 74, 331–337. [Google Scholar] [CrossRef]

- Hasan, K.M.F.; Horváth, P.G.; Kóczán, Z.; Alpár, T. Thermo-mechanical properties of pretreated coir fiber and fibrous chips reinforced multilayered composites. Sci. Rep. 2021, 11, 3618. [Google Scholar] [CrossRef]

- Hasan, M.; Hoque, M.E.; Mir, S.S.; Saba, N.; Sapuan, S.M. Manufacturing of Coir Fibre-Reinforced Polymer Composites by Hot Compression Technique. In Manufacturing of Natural Fibre Reinforced Polymer Composites; Springer International Publishing: Cham, Switzerland, 2015; pp. 309–330. [Google Scholar] [CrossRef]

- Shravan Kumar, N.; Buddi, T.; Anitha Lakshmi, A.; Durga Rajesh, K.V. Synthesis and evaluation of mechanical properties for coconut fiber composites-A review. Mater. Today Proc. 2021, 44, 2482–2487. [Google Scholar] [CrossRef]

- Silva, G.G.; De Souza, D.A.; Machado, J.C.; Hourston, D.J. Mechanical and Thermal Characterization of Native Brazilian Coir Fiber. J. Appl. Polym. Sci. 2000, 76, 1197–1206. [Google Scholar] [CrossRef]

- Geethamma, V.G.; Kalaprasad, G.; Groeninckx, G.; Thomas, S. Dynamic mechanical behavior of short coir fiber reinforced natural rubber composites. Compos. Part A Appl. Sci. Manuf. 2005, 36, 1499–1506. [Google Scholar] [CrossRef]

- Nam, T.H.; Ogihara, S.; Tung, N.H.; Kobayashi, S. Effect of alkali treatment on interfacial and mechanical properties of coir fiber reinforced poly(butylene succinate) biodegradable composites. Compos. Part B Eng. 2011, 42, 1648–1656. [Google Scholar] [CrossRef]

- Verma, D.; Gope, P.C.; Shandilya, A.; Gupta, A.; Maheshwari, M.K. Coir Fibre Reinforcement and Application in Polymer Composites: A Review. J. Mater. Environ. Sci 2013, 4, 263–276. [Google Scholar]

- Khedari, J.; Charoenvai, S.; Hirunlabh, J. New insulating particleboards from durian peel and coconut coir. Build. Environ. 2003, 38, 435–441. [Google Scholar] [CrossRef]

- Zaia, U.J.; Cortez-Barbosa, J.; Morales, E.A.M.; Lahr, F.A.R.; Fátima Do Nascimento, M.; De Araujo, V.A. Production of Particleboards with Bamboo (Dendrocalamus giganteus) Reinforcement. BioResources 2015, 10, 1424–1433. [Google Scholar] [CrossRef]

- Ngadiman, N.; Kaamin, M.; Abd Kadir, A.; Sahat, S.; Zaini, A.; Nor Zentan, S.R.; Ahmad, N.A.; Wan Amran, W.H.A. Panel Board from Coconut Fibre and Pet Bottle. E3S Web Conf. 2018, 34, 01014. [Google Scholar] [CrossRef]

- Mahzan, S.; Hatta, M.; Imran Ghazali, M.; Mohideen Shahul Hameed, R.; Mahzan, S.; Ahmad Zaidi, A.; Hatta, M.; Ghazali, M.; Rasool Mohideen, S. Study on Sound Absorption Properties of Coconut Coir Fibre Reinforced Composite with Added Recycled Rubber. Int. J. Integr. Eng. 2010, 2, 29–34. [Google Scholar]

- Lim, J.X.; Ong, T.K.; Ng, C.K.; Chua, I.W.; Lee, Y.B.; Yap, Z.Y.; Bakar, R.A. Development of Particleboard from Green Coconut Waste. J. Phys. Conf. Ser. 2021, 2120, 012034. [Google Scholar] [CrossRef]

- Ramachandran, R.A.; Balqis, K. 16. Coconut Husk Particleboard Fyp Report. 2022. Available online: http://repository.psa.edu.my/bitstream/123456789/4452/1/16 (accessed on 10 August 2025).

- Mesquita, R.G.d.A.; Marconcini, J.M.; Sanadi, A.R.; César, A.A.d.S.; Tonoli, G.H.D.; Venås, T.M.; Mendes, L.M. Coir and Sisal Fibers as Fillers in the Production of Eucalyptus Medium Density Particleboards—MDP. Mater. Res. 2016, 19, 1429–1436. [Google Scholar] [CrossRef]

- Geethamma, V.G.; Joseph, R.; Thomas, S. Short coir fiber-reinforced natural rubber composites: Effects of fiber length, orientation, and alkali treatment. J. Appl. Polym. Sci. 1995, 55, 583–594. [Google Scholar] [CrossRef]

- Khedari, J.; Nankongnab, N.; Hirunlabh, J.; Teekasap, S. New low-cost insulation particleboards from mixture of durian peel and coconut coir. Build. Environ. 2004, 39, 59–65. [Google Scholar] [CrossRef]

- Arrohman, S.; Mustofa, A.S.H.; Ariawan, D.; Diharjo, K. Characteristics of mechanical properties of coir-fibre/rubber composite. J. Phys. Conf. Ser. 2020, 1511, 012065. [Google Scholar] [CrossRef]

- Das, S.C. Sustainable Green Composites From Flax Fiber Reinforced Biopolymer Matrices. In Encyclopedia of Green Materials; Springer Nature: Singapore, 2023; pp. 1–13. [Google Scholar] [CrossRef]

- Ferreira, F.; Pinheiro, I.; de Souza, S.; Mei, L.; Lona, L. Polymer Composites Reinforced with Natural Fibers and Nanocellulose in the Automotive Industry: A Short Review. J. Compos. Sci. 2019, 3, 51. [Google Scholar] [CrossRef]

- Das, S.C.; La Rosa, A.D.; Goutianos, S.; Grammatikos, S.A. Flax fibers, their composites and application. In Plant Fibers, their Composites, and Applications; Elsevier: Amsterdam, The Netherlands, 2022; pp. 209–232. [Google Scholar] [CrossRef]

- Ramamoorthy, S.K.; Skrifvars, M.; Persson, A.; Persson, A. A Review of Natural Fibers Used in Biocomposites: Plant, Animal and Regenerated Cellulose Fibers A Review of Natural Fibers Used in Biocomposites: Plant, Animal and Regenerated Cellulose Fibers. Polym. Rev. 2015, 55, 107–162. [Google Scholar] [CrossRef]

- Araújo Junior, C.P.; Coaquira, C.A.C.; Mattos, A.L.A.; de Souza Filho, M.d.S.M.; Feitosa, J.P.d.A.; de Morais, J.P.S.; de Freitas Rosa, M. Binderless Fiberboards Made from Unripe Coconut Husks. Waste Biomass Valorization 2018, 9, 2245–2254. [Google Scholar] [CrossRef]

- Arifuzzaman Khan, G.M.; Alam Shams, M.S.; Kabir, M.R.; Gafur, M.A.; Terano, M.; Alam, M.S. Influence of chemical treatment on the properties of banana stem fiber and banana stem fiber/coir hybrid fiber reinforced maleic anhydride grafted polypropylene/low-density polyethylene composites. J. Appl. Polym. Sci. 2013, 128, 1020–1029. [Google Scholar] [CrossRef]

- Monteiro, S.N.; Terrones, L.A.H.; D’Almeida, J.R.M. Mechanical performance of coir fiber/polyester composites. Polym. Test. 2008, 27, 591–595. [Google Scholar] [CrossRef]

- Ali, M. Coconut fibre: A versatile material and its applications in engineering. J. Civ. Eng. Constr. Technol. 2011, 2, 189–197. [Google Scholar]

- Ali, M.; Liu, A.; Sou, H.; Chouw, N. Mechanical and dynamic properties of coconut fibre reinforced concrete. Constr. Build. Mater. 2012, 30, 814–825. [Google Scholar] [CrossRef]

- Naveen, P.N.E.; Prasad, R.V. Evaluation of mechanical properties of coconut coir/bamboo fiber reinforced polymer matrix composites. Sci. Eng. 2013, 3, 15–22. [Google Scholar]

- Böger, T.; Bianchi, S.; Salzer, C.; Pichelin, F. Binderless boards made of milled coconut husk: An analysis of the technical feasibility and process restraints. Int. Wood Prod. J. 2018, 9, 3–8. [Google Scholar] [CrossRef]

- Ayrilmis, N.; Jarusombuti, S.; Fueangvivat, V.; Bauchongkol, P.; White, R.H. Coir fiber reinforced polypropylene composite panel for automotive interior applications. Fibers Polym. 2011, 12, 919–926. [Google Scholar] [CrossRef]

- Mudassar, A.; Han-Yong, J. Generation, Development and Modifications of Natural Fibers; IntechOpen: London, UK, 2020. [Google Scholar] [CrossRef]

- Swayam, R.; Sahoo, S.P.; Nayak, M.; Sahoo, A.; Khuntia, T. Design and analysis of coir fibre reinforced polypropylene based internal car door panel. Mater. Today Proc. 2023, 74, 1057–1062. [Google Scholar] [CrossRef]

- Kriti, P.M.S.; Tarlochan, K. Recent developments in natural fibre polymer composite materials for interior design applications: An overview from acoustic perspective. Int. J. Interact. Des. Manuf. 2025, 19, 1563–1589. [Google Scholar] [CrossRef]

- Mukhopadhyay, S.; Annamalai, D.; Srikanta, R. Coir Fiber for Heat Insulation. J. Nat. Fibers 2011, 8, 48–58. [Google Scholar] [CrossRef]

- Panyakaew, S.; Fotios, S. New thermal insulation boards made from coconut husk and bagasse. Energy Build. 2011, 43, 1732–1739. [Google Scholar] [CrossRef]

- Andiç-Çakir, Ö.; Sarikanat, M.; Tüfekçi, H.B.; Demirci, C.; Erdoğan, Ü.H. Physical and mechanical properties of randomly oriented coir fiber–cementitious composites. Compos. Part B Eng. 2014, 61, 49–54. [Google Scholar] [CrossRef]

- Mahmud, M.A.; Abir, N.; Anannya, F.R.; Nabi Khan, A.; Rahman, A.N.M.M.; Jamine, N. Coir fiber as thermal insulator and its performance as reinforcing material in biocomposite production. Heliyon 2023, 9, e15597. [Google Scholar] [CrossRef]

- Hasan, K.M.F.; György, P.; Zsófia, H.; Duong, K.; Anh, H.; Miklós, L.; László, B. Novel insulation panels development from multilayered coir short and long fiber reinforced phenol formaldehyde polymeric biocomposites. J. Polym. Res. 2021, 28, 467. [Google Scholar] [CrossRef]

- Figueiredo, A.; Vela, G.; Ascensão, G.; Vettorazzi, E.; Vicente, R.; Oliveira, M. Development of an innovative biocomposite using coconut fibres and bio-based binder for thermal and acoustic aplications in buildings. J. Clean. Prod. 2025, 491, 144834. [Google Scholar] [CrossRef]

- Sindhu, K.; Joseph, K.; Joseph, J.M.; Mathew, T.V. Degradation Studies of Coir Fiber/Polyester and Glass Fiber/Polyester Composites under Different Conditions. J. Reinf. Plast. Compos. 2007, 26, 1571–1585. [Google Scholar] [CrossRef]

- Boonyaroj, V.; Srijab, M.; Thiangsagul, M.; Larpsongserm, M. Plywood Production from Coconut Coir Fiber and Water Hyacinth. Appl. Mech. Mater. 2017, 866, 212–215. [Google Scholar] [CrossRef]

- Shrivastava, R.; Telang, A.; Rana, R.; Purohit, R. Mechanical Properties of Coir/G Lass Fiber Epoxy Resin Hybrid Composite. Mater. Today Proc. 2017, 4, 3477–3483. [Google Scholar] [CrossRef]

- Khuntia, T.; Biswas, S. An investigation on the flammability and dynamic mechanical behavior of coir fibers reinforced polymer composites. J. Ind. Text. 2022, 51, 1616–1640. [Google Scholar] [CrossRef]

- Rejeesh, C.R.; Saju, K.K. Methods and materials for reducing flammability behaviour of coir fibre based Composite Boards: A Review. Mater. Today Proc. 2017, 4, 9399–9407. [Google Scholar] [CrossRef]

- Paramanandham, J.; Ross, P.R.; Abbiramy, K.S.; Muthulingam, M. Studies on the moisture retention capacity of coir pith, as a function of time. Int. J. ChemTech Res. 2014, 6, 5049–5052. [Google Scholar]

| Category | Properties | Coconut Coir | Jute | Sisal | Hemp | Flax | Reference |

|---|---|---|---|---|---|---|---|

| Physical | Density (g/cm3) | 1.1–1.5 | 1.46 | 1.33 | 1.48 | 1.4 | [11,37,38] |

| Moisture content (%) | 9–11 | 12 | 11 | 9 | 7 | ||

| Fiber length | 15–35 cm | 750–1500 | 800–1200 | 700–900 | 2500 (long hemp) | ||

| Chemical | Lignin (wt%) | 40–50 | 12–13 | 9.9 | 10 | 2.2 | [37] |

| Hemicellulose (wt%) | 15–20 | 14–20 | 12 | 15 | 18.6–20.6 | ||

| Cellulose (wt%) | 27–45 | 61–71 | 65 | 68 | 71 | ||

| Mechanical | Tensile Strength (MPa) | 220 | 400–800 | 600–700 | 550–900 | 88–1500 | |

| Youngs Modulus (GPa) | 2–8 | 10–30 | 38 | 70 | 60–80 | ||

| Elongation at break (%) | 15–25 | 1.8 | 2–3 | 1.6 | 1.2–1.6 | ||

| Thermal and acoustic properties | Thermal Conductivity (W/(m·K)) | 0.04–0.1 | 0.036 | 0.038 | 0.028–0.110 | 0.033–0.12 | [13,34,39,40,41,42] |

| Onset degradation temperature (°C) | 200 | 240–270 | 200–275 | 150–207 | 250–270 | ||

| Sound absorption coefficient (NRC) | 0.8 | 0.9 | 0.4–0.7 | 0.9 | 0.5–0.8 |

| Composite System | Matrix/Polymer | Tensile Strength (MPa) | Flexural Strength (MPa) | Notable Observations | Reference |

|---|---|---|---|---|---|

| Coir/Polypropylene (PP) | PP | 25–32 | 38–50 | Alkali/chemical treatment improves interfacial adhesion and strength | [7,71] |

| Coir/Polyethylene (PE) | PE | 22–28 | 35–45 | Surface modification enhances dispersion and mechanical stability | [7] |

| Coir/Poly(butylene succinate) (PBS) | PBS (biodegradable) | 20–30 | 30–42 | Alkali treatment significantly improves tensile and flexural strength | [62] |

| Coir/Polylactic Acid (PLA) | PLA | 38–52 | 65–80 | Exhibits good tensile and thermal stability; multifunctional properties highlighted | [30,72] |

| Coir/Epoxy (with hybrid glass fiber) | Epoxy | 45–60 | 70–95 | Hybridization with glass fiber shows synergistic improvement in flexural performance | [73] |

| Coir/Polyester | UPR | 30–45 | 50–65 | General literature consensus shows moderate strength; dependent on fiber treatment | [59] |

| Coir/Polymer composites (general fabrication) | PP/PE (various) | – | – | Hot compression molding shown to produce uniform dispersion & improved bonding | [58] |

| Coir/rubber | rubber | 2.509 | 29–300 | Coir improves post-cracking toughness and flexural performance | [74,76] |

| Coir/Glass | 37 | 63 | The optimal composition was 10 wt% coir at 15 mm fiber length, showing the best tensile and flexural strength, while 20 mm fibers enhanced hardness but reduced strength. | [37] |

| Matrix/Binder Type | Type | Material Used | Key Insights | Applications | Reference |

|---|---|---|---|---|---|

| Urea-formaldehyde (UF) | Synthetic | Coir fibers, durian peels | Good bonding, cost-effective; density impacts thermal/acoustic insulation | Particleboards, acoustic/thermal panels | [15,67,75] |

| Phenol-formaldehyde (PF) | Synthetic | – | Superior strength, dimensional stability, better than UF | High-performance boards | [59] |

| Natural rubber | Natural | – | Improved fiber-matrix adhesion; elastic and eco-friendly | General coir composites | [74] |

| Polyurethane (castor oil-based) | Bio-based | – | Meets mechanical standards; sustainable with low VOC | Eco-friendly composite boards | [68] |

| Bst20 (green binder) | Bio-based | – | High MOR (11.61 MPa), water resistance; greener than UF | Sustainable fiberboards | [71] |

| Coconut husk with resin (varied %) | Composite | Coconut husk | Resin % affects sound absorption; tunable acoustic properties | Sound-absorbing boards | [72] |

| Binderless (natural lignin) | Binder less | White coir/Whole husks | Thermosetting lignin acts as a natural binder, eco-friendly, but has lower durability | Low-cost, simple composite boards | [16,68] |

| Cement | Inorganic | – | High durability, load-bearing, water-resistant | Construction-grade boards | [17] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nissar, M.; N., C.K.; Birjerane, Y.A.; Patil, S.; Shetty, S.; Das, A. Coconut Coir Fiber Composites for Sustainable Architecture: A Comprehensive Review of Properties, Processing, and Applications. J. Compos. Sci. 2025, 9, 516. https://doi.org/10.3390/jcs9100516

Nissar M, N. CK, Birjerane YA, Patil S, Shetty S, Das A. Coconut Coir Fiber Composites for Sustainable Architecture: A Comprehensive Review of Properties, Processing, and Applications. Journal of Composites Science. 2025; 9(10):516. https://doi.org/10.3390/jcs9100516

Chicago/Turabian StyleNissar, Mohammed, Chethan K. N., Yashaswini Anantsagar Birjerane, Shantharam Patil, Sawan Shetty, and Animita Das. 2025. "Coconut Coir Fiber Composites for Sustainable Architecture: A Comprehensive Review of Properties, Processing, and Applications" Journal of Composites Science 9, no. 10: 516. https://doi.org/10.3390/jcs9100516

APA StyleNissar, M., N., C. K., Birjerane, Y. A., Patil, S., Shetty, S., & Das, A. (2025). Coconut Coir Fiber Composites for Sustainable Architecture: A Comprehensive Review of Properties, Processing, and Applications. Journal of Composites Science, 9(10), 516. https://doi.org/10.3390/jcs9100516