1. Introduction

In a context increasingly defined by highly efficient manufacturing processes and a growing emphasis on material savings aimed at minimizing the environmental impact of human activity on the planet, the main limitations in modern production are no longer imposed by manufacturing capabilities. Thanks to recent advancements in additive manufacturing (AM) technologies, it is now possible to produce complex geometries that would be otherwise unfeasible through conventional manufacturing techniques such as subtractive or formative methods [

1].

Moreover, one of the key benefits associated with additive production techniques lies in the vast array of advanced materials available on the market [

2,

3]. Among these, particular attention has been given to polymer matrix composites reinforced with carbon fibers, which offer an exceptional combination of mechanical performance and low weight, ideal for aerospace applications [

4,

5] where a high strength-to-weight ratio is a key parameter.

In this framework, the generative design (GD) process represents a powerful and innovative design approach. As a matter of fact, by employing algorithms to explore multiple alternatives, generative design generates optimized structural configurations based on predefined objective functions [

6].

Generative design integrates engineering constraints and performance requirements directly by simulating the mechanisms of natural evolution, enabling the generation of numerous design solutions that are both structurally robust and innovative [

7].

GD tools are able to simultaneously analyze a wide range of design contexts including different load cases and constraints, reducing the need for manual adjustment and computational recalculations related to the multiple load conditions and design constraints [

8].

Unlike traditional topological optimization, which typically involves only removing material from a predefined volume to meet structural requirements [

9,

10], the generative design process employs a network of interconnected algorithms that dynamically redefine the design space. These algorithms take into account not only the structural performance, but also the constraints related to manufacturing processes such as build orientation in additive manufacturing processes, overhang angle, and others [

11].

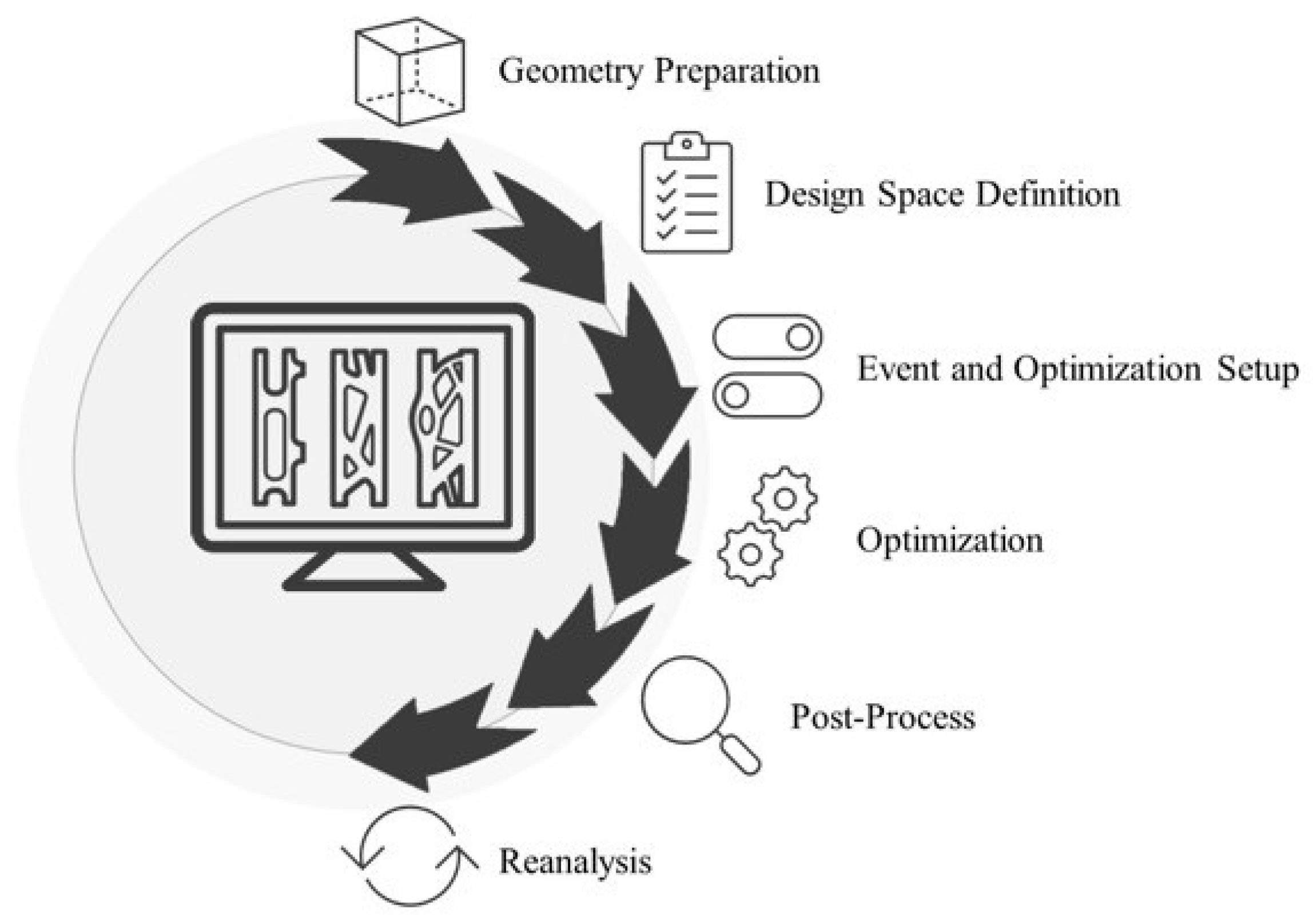

1.1. The Generative Design Process Workflow

The generative design process bases its entire methodology on a well-defined and structured workflow, according to [

12,

13,

14], as depicted in

Figure 1.

As shown in

Figure 1, the GD process starts with the

Geometry Preparation phase where the external boundaries of the model are defined [

15]. The primary focus at this stage is on accurately delineating the external limits of the structure to ensure feasibility and coherence with the overall function of the entire geometric model.

The second stage is the

Design Space Definition, in which the designer explicitly delineates the regions of the model to be optimized while distinguishing them from those that must remain unchanged due to functional, structural, or assembly constraints. The correct design space identification can alleviate the choice overload created by working with a large set of alternatives [

16]. Furthermore, the designer must anticipate and incorporate potential access zones such as regions required for maintenance, fastener placement, or connectivity to other systems. These considerations are key to ensuring the practicality and manufacturability of the final design.

The subsequent stage is the Event and Optimization Setup phase, where the user has to define all loading conditions and boundary constraints. Many advanced generative design software platforms allow for the creation and management of multiple load cases that can be evaluated simultaneously, enabling the generation of design solutions that maintain structural integrity under varying and often competing mechanical conditions.

Additionally, during this phase, the user must specify critical optimization parameters that include mesh fidelity, material properties, manufacturing methods, build orientation, which directly affects both surface roughness and structural strength [

17], and minimum or maximum feature sizes.

At the conclusion of the

Optimization Cycle, in the

Post-Processing Phase, raw algorithm-generated geometries are translated into manufacturable models [

18] that are then verified through finite element analysis (FEA) to validate its performance under the prescribed conditions.

If the final design meets the predefined performance and feasibility criteria, the process can be considered complete. However, should the outcome prove unsatisfactory, the user can iterate the process either by modifying the

Optimization Setup parameters or by using the post-processed candidate geometry as a new starting point for the

Geometry Preparation phase, highlighting the inherently iterative character of the generative design process [

19].

1.2. The Generative Design Process in Literature

A comprehensive review of contemporary literature reveals that the implementation of generative design methodologies in the aerospace field is well-established and has been investigated under a variety of perspectives.

Many available contributions can be classified into two principal research directions. On the one hand, several studies have addressed the development of structural aerospace components, such as bracket [

20,

21], frames [

22,

23], and load-bearing elements [

24], where GD is primarily employed to achieve lightweight yet mechanically efficient solutions. On the other hand, a significant portion of the literature has focused on the aerodynamic optimization of lifting surfaces, with generative design methods applied to the external shaping of wings to improve aerodynamic performance and efficiency [

25,

26].

Further research efforts can be identified in the field of mass reduction in lifting surfaces. Nevertheless, such investigations typically rely on topology optimization techniques rather than on generative design methodology. For example, in [

27], weight optimization of the VT in-board box structure through the linear static stress analysis approach was conducted, achieving a 3.8% decrement in the weight of the vertical tail structure.

While topology optimization has proven effective in reducing weight while maintaining structural integrity, it remains a fundamentally different approach, as it does not fully exploit the potential of generative algorithms to create entirely new structural concepts based on specified design requirements and allowing for a greater weight reduction.

In this context, the present study positions itself as an alternative contribution to state-of-the-art. Unlike many existing works, this research does not attempt to modify or re-optimize the external aerodynamic configuration of the wing. Instead, starting from a predefined and immutable aerodynamic shape, we generate an internal structural architecture that allows for significant mass reduction without compromising the functional requirements of the component. The novelty of this work lies precisely in the application of the generative design process to the creation of the entire internal structure of the wing, thereby advancing the current understanding of how such methods can be leveraged not only for individual components or aerodynamic surfaces, but for the holistic design of load-bearing aerospace structures.

1.3. The Generative Design Methods

The generative design process is a sophisticated AI-driven approach that profoundly alters traditional design and production processes. As an AI-driven approach, generative design employs different algorithms and to resolution methods explore multiple alternatives [

6].

The GD method can be classified in different categories based on resolution methodology:

Parametric CAD-based search strategy: Represents a designer-cantered methodology that operates without externally imposed limitations such as safeguard algorithms that restrict the emergence of specific geometries or inhibit substantial material removal. This method uses genetic algorithms and is entirely CAD based [

19,

28].

A fundamental limitation of this strategy is that a single iteration cannot be considered exhaustive since the resulting solution is strictly determined by the initial geometry. Therefore, to enable a comprehensive exploration of the design space, it becomes necessary to introduce multiple initial models (genotypes) to allow for the generation of a diverse set of candidate solutions that can subsequently be compared to identify the most suitable design alternative.

Evolutionary algorithm-based strategy: Represents a generative design technique that randomly generates sub-populations to obtain distinct designs in constrained and unconstrained design spaces within pre-design design constraints [

29,

30]. The evolutionary algorithm-based strategy also includes a space-filling based strategy to generate optimal design alternatives starting only from boundary conditions and interfaces regions [

31].

This kind of GD strategy uses teaching—learning algorithms [

30].

Iterated local search-based strategy: Represents a sampling-based technique aimed at exploring design alternatives derived from a constrained CAD model. The method is trial driven, whereby each trial produces a single design candidate. Among the generated alternatives, the selection of the most promising solution is carried out based on a dual criterion: the minimization of cost and compliance with feasibility constraints [

32,

33].

Grammar shape search-based strategy: Represents a support for designers in design exploration during the conceptual design stage. Specifically, shape grammar generates design variations by applying predefined sets of shape rules. The resulting forms emerge from finite arrangements of geometric elements, where each element may be repeatedly employed to produce novel configurations [

34,

35].

Topology optimization tool-based strategy: Represents a generative design tool based on topology optimization to explore various shapes. This method is based on the minimization of stiffness while fixing the volume minimization of weight under stress or the displacement constraint by using genetic algorithms [

36].

The method performs mesh refinement while improving accuracy in the definition of the optimal shape boundary [

37,

38].

Similar to the CAD-based search strategy, the principal limitation of this method lies in its strong dependence on the initial geometry.

1.4. Research Aim

The present research employs the topology optimization tool-based strategy methodology for the structural redesign of aerospace components, with a specific focus on the tailplane of an unmanned aerial vehicle (UAV), initially conceived as a conventional metallic structure. The baseline design for the genetic algorithm was defined as a solid volume derived from the external surface of the tailplane, and to overcome the inherent limitations of the methodology, three alternative initial configurations were devised.

By employing design for additive manufacturing (DfAM) strategies grounded in generative design principles, the objective of this study was to fully leverage the potential of Carbon PA, a high-performance polymer reinforced with 15% chopped carbon fiber.

The goal was to completely replace the aluminum alloy traditionally employed for vertical tail structures and create a structural component that radically departs from traditional aerospace design paradigms, achieving a significant weight reduction and maintaining the required mechanical properties.

In this context, the integration of generative design and additive manufacturing represents an area of growing interest in the advanced design of complex and lightweight components. A crucial aspect is the possibility of producing and testing the solutions generated by the GD process to validate the results experimentally, in addition to numerically, as obtained from the solver. Several studies have addressed this objective, such as the work conducted by Darsin et al. [

39], in which GD was applied to the development of a UAV frame, leading to design solutions that were subsequently analyzed in detail with respect to stress distribution for different materials including fiber-reinforced polymers. The experimental results validated the effectiveness of the process, highlighting the ability of generative design to produce lightweight yet mechanically efficient structures.

Further contributions in the literature [

40] support these findings, demonstrating that the generative design approach can adapt in a versatile manner to various types of materials applicable to additive manufacturing. This has enabled the development of structures validated both numerically, through FEM analyses, and experimentally, through the physical fabrication of components and their subsequent mechanical testing. The presented research begins with a detailed description of the baseline metallic configuration, then, the selected fiber-reinforced material is described.

Subsequently, the complete methodology used for setting up the generative design analysis is described.

In the Results section, the configurations obtained at the end of the process are presented, after which the post-processing phase and subsequent numerical reanalysis are detailed.

Finally, the last section presents the obtained results and includes a feasibility study for the additive manufacturing of sections of the generated components.

Thanks to the combination of fiber-reinforced polymers and generative design process, a significant mass reduction, up to 71.2% compared with a metallic design, was obtained.

2. Methods

2.1. Metal Benchmark Configuration

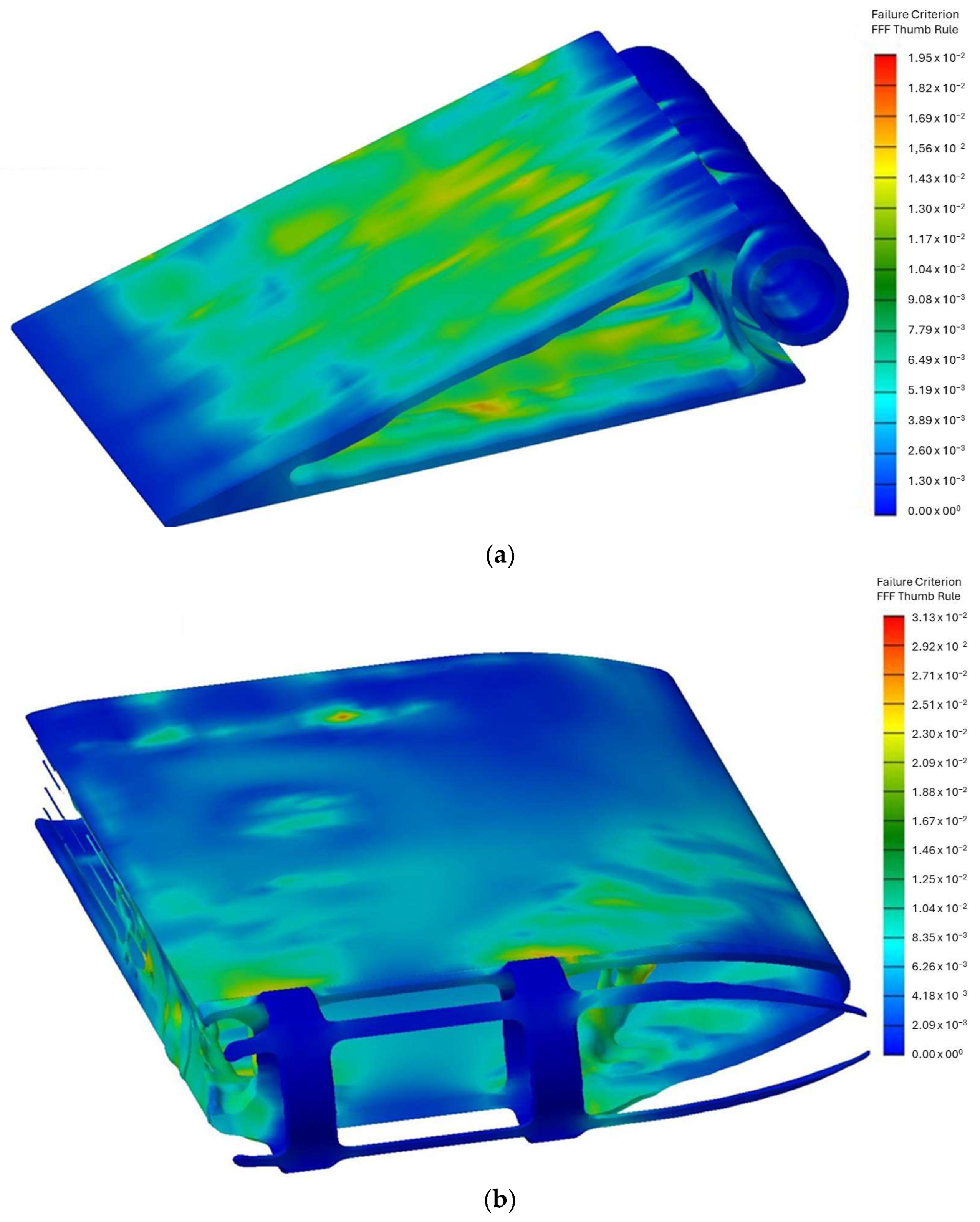

The initial reference of the UAV’s vertical tail consisted of a classical aeronautical structure including ribs, spars, and collaborating skin. The skin was fixed to ribs through rivets, and the entire vertical tail was fixed to the main structure by means of bushings, as shown in

Figure 2 [

41].

The benchmark structure was defined according to typical aeronautical design standards for metal structures, and the requirements set out in Appendix A of the CS-VLA regulations were taken into account when assessing its mechanical performance [

42]. These regulations require that each component must be capable of withstanding two primary loading scenarios corresponding to symmetrical and asymmetrical flight conditions.

Based on the wing area and prescribed load factor, the resulting load to be applied to the vertical tail resulted in 178 N. According to regulatory guidelines, the calculated force must be applied at 25% of the aerodynamic chord for the asymmetrical loading condition, and at 54.5% of the aerodynamic chord for the symmetrical loading condition, as shown in

Figure 3.

Therefore, a finite element model of the benchmark structure was developed in the Abaqus environment, considering a combination of steel and aluminum components. In detail, steel was used for load-bearing components like ribs and spars, while aluminum was adopted for the skin. Subsequently, preliminary numerical analyses were performed to evaluate the stress distribution and deformation of the vertical tail structure when subjected to normative-based prescribed loading conditions.

Combining results from both the asymmetrical and symmetrical loading conditions, a maximum stress value equal to 31.65 MPa and a maximum tip displacement equal to 0.60 mm were recorded. This condition ensured a 10.81 safety factor value. As expected, the numerical results given in

Figure 4 highlighted the capability of the reference metal configuration of the vertical tail to withstand the prescribed acting loads. Indeed, the main aim of the analyses was to establish a reference of the mechanical performance to support future redesigns of the structure using different design approaches, manufacturing methods, and materials. Moreover, the structure’s mass was also evaluated as an additional reference parameter for subsequent configurations. According to the prescribed material distribution, the reference structure had a mass of 2.75 kg.

2.2. Generative Design Process: Setting up the Analytical Process

This section provides a detailed description of the entire process for configuring the analysis parameters, from geometry preparation to the completion of the optimization parameter setup.

2.2.1. Geometry Preparation

The metal-based benchmark structure served as the reference for initiating the generative design process, allowing for the definition of the initial design space. In this specific case, the most critical constraint related to the preservation of external geometry. Indeed, any modification of the outer surface would result in a significant variation in aerodynamic performance. Consequently, the external surface was defined as a non-design space in order to keep it unaltered throughout the process.

The initial design volume was obtained by extruding a NACA 0015 airfoil in the spanwise direction for 380 mm. Subsequently, a cylindrical component was introduced at the root to secure the connection between the vertical tail and its supporting structure. The complete geometrical configuration is given in

Figure 5.

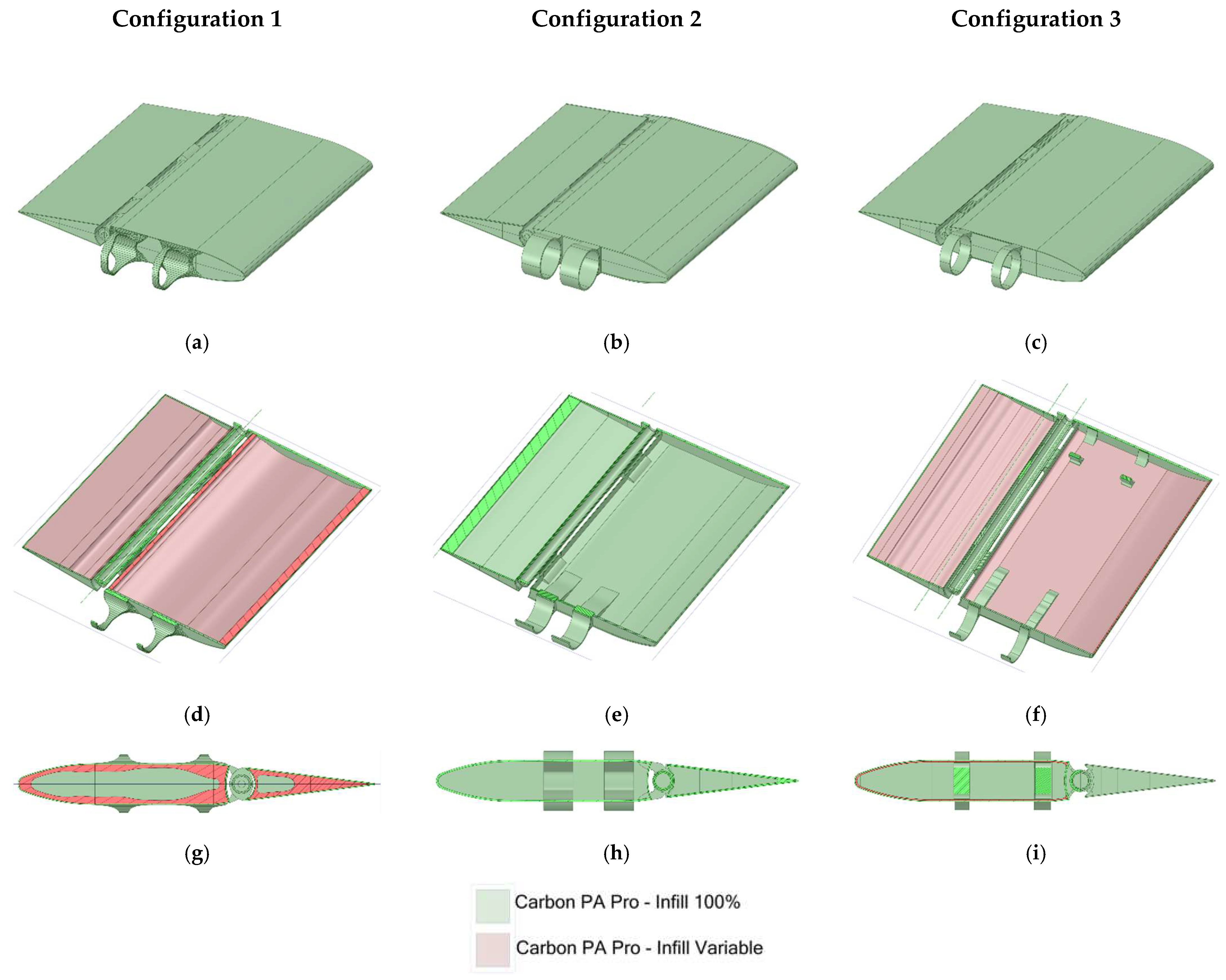

2.2.2. Design Space Definition

Once the initial geometry was prepared, the design space was defined. In the generative design process, a proper identification of design and non-design space regions is required as well as the application of all relevant constraints and external loads acting on the structure.

For the vertical tail structure, three different types of design space regions were adopted, differing in terms of thickness assigned to the non-design space regions. These configurations are shown in

Figure 6.

Figure 6 presents the three different approaches to the design space definition adopted as input for the generative design process. Specifically,

Figure 6a illustrates the strategy in which a 2.5 mm-thick non-design space was imposed for skin definition. This condition can be interpreted as enforcing a minimum skin thickness equal to 2.5 mm.

This choice lies in the need to ensure sufficient material for the manufacturing phase, thereby enabling the inclusion of an internal infill structure aimed at reducing the overall mass of the vertical tail.

The second configuration, in

Figure 6b, is characterized by a 1.5 mm thickness for the external surface. In this case, the use of internal infill was deliberately excluded, granting the algorithm more freedom to explore material reduction strategies.

Moreover, the third approach, depicted in

Figure 6c,d, is characterized by a 2.0 mm non-design space thickness. This intermediate value was selected to allow the algorithm the flexibility to converge toward either a thicker or thinner structural configuration. Additionally, in order to reduce computational complexity and facilitate a more targeted analysis, the rudder and wing-box regions were analyzed separately.

Additionally, a further set of non-design space regions was applied to two critical areas: the connection between the vertical tail and its supporting structure, and the rudder actuation interface. The former region was defined as a circular zone that was excluded from the generative design process, while the latter was entirely excluded from all analyses. Nonetheless, this component, depicted in

Figure 7, remained geometrically present in all configurations, as it serves a fundamental role in maintaining the mechanical connection between the main structure and the rudder.

According to the purpose of defining a metal reference structure, the same set of boundary conditions and mechanical constraints were applied in all configurations with a different design space definition.

Finally, the non-design space zones were deliberately selected to ensure the invariance of the aerodynamic characteristics of the vertical tail. Although the entire structure is intended to be manufactured in a composite material for additive manufacturing, the possibility of developing a hybrid metal–composite structure remains open. In this way, it is possible to enhance a solution that could combine the advantages of both material classes while simultaneously mitigating their respective drawbacks. In this scenario, the joining between the metal and composite could be achieved through thermoplastic adhesives, benefiting from the numerous advantages of adhesive bonding, in combination with surface texturing of the metal. Furthermore, should a hybrid metal–composite configuration be pursued, the process could be further improved by following the procedure proposed in [

43], where an optimization strategy for the design and manufacturing of hybrid metal–composite structures, capable of reducing the time required for a successful design process, was developed.

2.2.3. Event and Optimization Setup

Before starting the generative design process, it is essential to define the main optimization parameters that allow the GD algorithm to generate the optimal shape. Among all the optimization parameters available, the minimum safety factor value represents a key constraint. Specifically, lower values offer the algorithm greater design freedom, but may lead to a less resistant structure, while higher values allow for stiffer and heavier structures.

In this study, a safety factor of 3.0 was adopted for Configurations 1 and 2, which is exactly twice the minimum value of 1.5 established by the CS-VLA aeronautical regulation [

42]. This choice was motivated by the intention to account for potential additional loads not explicitly addressed by the regulations, thereby ensuring a higher margin of structural robustness. Conversely, for Configuration 3, the safety factor was set to the minimum value of 1.5 prescribed by the standard, with the aim of providing the software with greater exploration and freedom for lightweight structural solutions.

This adjustment reflects a trade-off between structural performance and the potential for mass reduction.

Another fundamental aspect in the generative design approach is represented by the support reduction strategy. However, this strategy was not adopted in this work as a proper orientation of the component on the build platform able to minimize the supports was established. Consequently, the implementation of any support optimization technique would have proven ineffective and could have even hindered the performance of the GD algorithm.

Finally, the complexity factor is defined as a key parameter that controls the refinement level of the mesh, which is crucial since the entire generative design process is strongly mesh-dependent. Adjusting this parameter directly affects the outcome: lower values produce coarser and more approximate geometries, generally easier to manufacture, while higher values generate finer details that may result in overly complex outputs, often beyond current manufacturing capabilities. For this reason, in the three different configurations analyzed, the complexity factor was varied in order to assess its influence on the results.

Table 1 summarizes the optimization parameter setup used in the generation of the three different configurations of the vertical tail.

The final step before starting the optimization process involves the application of boundary conditions. One of the key advantages of generative design software is its ability to evaluate multiple load cases simultaneously, allowing for the creation of geometries that are both flexible and capable of guaranteeing adequate mechanical performance under varying conditions.

In this work, only two loading conditions were considered, according to specifications of the CS-VLA regulations. Specifically, the two load cases, referred to as Event 1 and Event 2, are depicted in

Figure 8.

In Event 1, a force of 178 N was applied at 54.5% of the chord length, while the same force was applied at 25% of the chord length in Event 2. Both load cases assumed a fully fixed constraint at the interface between the vertical tail and its supporting structure, replicating a fixed boundary condition.

2.3. Carbon PA PRO Mechanical and Physical Properties

Starting from the metal materials adopted in the reference structure, the Carbon PA technopolymer was selected for the design of alternative configurations aimed at manufacturability through FFF additive processes as part of a metal replacement strategy.

This process goes beyond a simple material substitution and requires a substantial and appropriate structural redesign in order to fully exploit the potential of additive manufacturing and high-performance polymers.

The primary goal is to achieve a lighter structure with equivalent mechanical performance, generating positive effects on the overall aircraft efficiency in terms of fuel consumption and emissions. Carbon PA, or carbon polyamide (PA), is a nylon-based polymer reinforced with 15% chopped carbon fiber by weight, manufactured by Roboze S.p.A. (Bari, Italy).

The purpose of adding 15% chopped carbon fiber is to create a composite material with enhanced mechanical properties such as strength, stiffness, and thermal resistance. This material has been specifically engineered—from the selection of the polyamide matrix to the length and type of short fiber—in order to achieve mechanical properties suitable for replacing aluminum alloys. As such, Carbon PA is among the most promising candidates for use in metal replacement applications.

Finally, Carbon PA was modeled as an isotropic material by considering the mechanical and physical properties described in

Table 2 and

Table 3 [

44]. This assumption is justified by the low percentage of fiber reinforcement [

45] and by experimental studies [

46] showing that within the elastic region, the FEA simulation of FDM parts yields equivalent mean values of the mechanical properties.

Otherwise, traditional composites are typically modeled numerically using the following methodologies [

47,

48,

49].

Table 2.

Carbon PA PRO mechanical properties [

45].

Table 2.

Carbon PA PRO mechanical properties [

45].

| Properties | Operating

Conditions | Units | Value | Test Method |

|---|

| Tensile strength | 25 °C | MPa | 171 | ASTM D638, type IV [50] |

| Young modulus | 25 °C | GPa | 13.1 | ASTM D638, type IV |

| Elongation at maximum load | 25 °C | % | 1.58 | ASTM D638, type IV |

Table 3.

Carbon PA PRO physical properties [

45].

Table 3.

Carbon PA PRO physical properties [

45].

| Properties | Operating

Conditions | Units | Value | Test Method |

|---|

| Specific gravity | - | g/cm3 | 1.232 | ISO 1183-1 [51] |

| Glass transition temperature | 20 °C/min heating and cooling rate, in air | °C | 13.1 | ISO 11357-2 DSC [52] |

| Crystallization temperature | 20 °C/min heating and cooling rate, in air | °C | 1.58 | ISO 11357-3 DSC [53] |

| Melting temperature | 20 °C/min heating and cooling rate, in air | °C | | ISO 11357-3 DSC |

| Reinforcing phase | - | % | 15 | - |

3. Results

3.1. Optimization Results

The generative design process applied to Configuration 1 resulted in an optimized structure with a mass equal to 2.52 kg and a design as given in

Figure 9. At first glance, such a result in terms of design features may appear unsatisfactory. However, it is important to emphasize a key aspect of the adopted design strategy: the intentional use of increased wall thicknesses to enable the introduction of an internal infill structure during the post-processing phase. Thereby, a significant reduction in mass can be achieved while preserving the geometrical and structural integrity of the component. The benefits of this approach and the resulting improvements in weight efficiency are discussed in detail in the following section.

Moreover,

Figure 9 shows the Von Mises stress evaluated for Configuration 1; here, it is possible to observe how the more stressed zone was the bushings. This aspect is directly related to their thin shape.

The results obtained from Configuration 2, depicted in

Figure 10, were fully consistent with the expectations according to the initial setup of the optimization parameters. This configuration is characterized by an extremely thin external skin, with a thickness equal to 1.72 mm. As expected, a reduced wall thickness prevents the implementation of any internal infill structure during the additive manufacturing process.

This configuration demonstrates a promising potential and is characterized by a mass equal to 0.98 kg. This represents a significant reduction compared with more conservative configurations.

Figure 10 shows the tensional contour plot for Configuration 2; here the stress peak is located on the skin. Bushings are now thicker, and the stress is well-distributed.

Finally,

Figure 11 shows the results related to Configuration 3. In this case, it is possible to observe how the skin thickness was greater than that of Configuration 2 and lower than that of Configuration 1. The 2.2 mm thickness for skin was enough to allow for the inclusion of an internal infill structure, which contributed to the reduction in the overall mass of the component while maintaining an acceptable structural performance. The final mass was equal to 0.967 kg.

Figure 11 shows a well-distributed stress on the entire structure, reducing or eliminating concentrated tensions, leading to a more efficient structure.

As a summary,

Table 4 presents a comparison of masses resulting from the generative design process. Notably, all configurations already exhibited a lower mass compared with the metal benchmark. However, a further mass reduction is expected to be achieved during the post-processing phase, where additional optimizations and structural refinements are implemented.

3.2. Post-Processing

The generative design process enabled the evaluation of three different configuration types. However, the obtained results represent only conceptual designs and are not directly suitable for structural analysis or manufacturing. Consequently, the post-processing phase is required to refine and provide a clean geometry suitable for both finite element analyses and additive manufacturing processes.

Figure 12 illustrates the outcome of the post-processing phase. As previously discussed, the raw geometry generated by the generative design process required several modifications to ensure the proper functionality of the structure. Specifically, for each configuration, essential elements were added, such as closing ribs for both the rudder and the wing-box, in order to ensure aerodynamic efficiency. Additionally, internal structures were simplified to facilitate both numerical analyses and manufacturability.

Focusing on Configuration 1, shown in

Figure 12a, the final design at the end of the GD process presented a closed-shell structure. However, the cross-section’s analysis along the XY-plane (

Figure 12d) highlighted the potential use of an internal infill structure given the high safety factor values obtained during the preliminary simulations in Apex GD. This design choice enabled a well-balanced compromise between mass reduction and mechanical performance while preserving the overall structural integrity.

As anticipated during the definition of the boundary conditions, Configuration 1 was considered as the most conservative design. In contrast, Configuration 2, shown in

Figure 12h, exhibited a significantly slenderer geometry, with such a reduced thickness geometry that excludes any internal infill usage.

Nevertheless, also in this case, the internal structures were substantially simplified. All internal elements were removed, as the high safety factor associated with the configuration allowed for further structural refinement without compromising the mechanical performance. Since these internal features were essentially unstressed under the applied load conditions, their removal was considered appropriate, with no significant impact on the overall structural integrity.

Finally, the third configuration, shown in

Figure 12i, proved to be an intermediate solution between the others. In this case, it was possible to introduce an internal infill, albeit with a relatively thin thickness. This design choice contributed to an increase in structural stiffness, striking a balance between mass reduction and mechanical performance. Moreover, as suggested by the generative design software, the terminal support structures were retained in the final configuration as they were considered essential for ensuring the overall stability of the component.

Table 5 shows the mass summary of all the proposed configurations. In detail, Configuration 3 with 30% infill seemed to be the best candidate in terms of low-weight characteristics. Accordingly, FEA analyses were performed to re-evaluate the mechanical performances of the explored configurations, and the results are given in the next section.

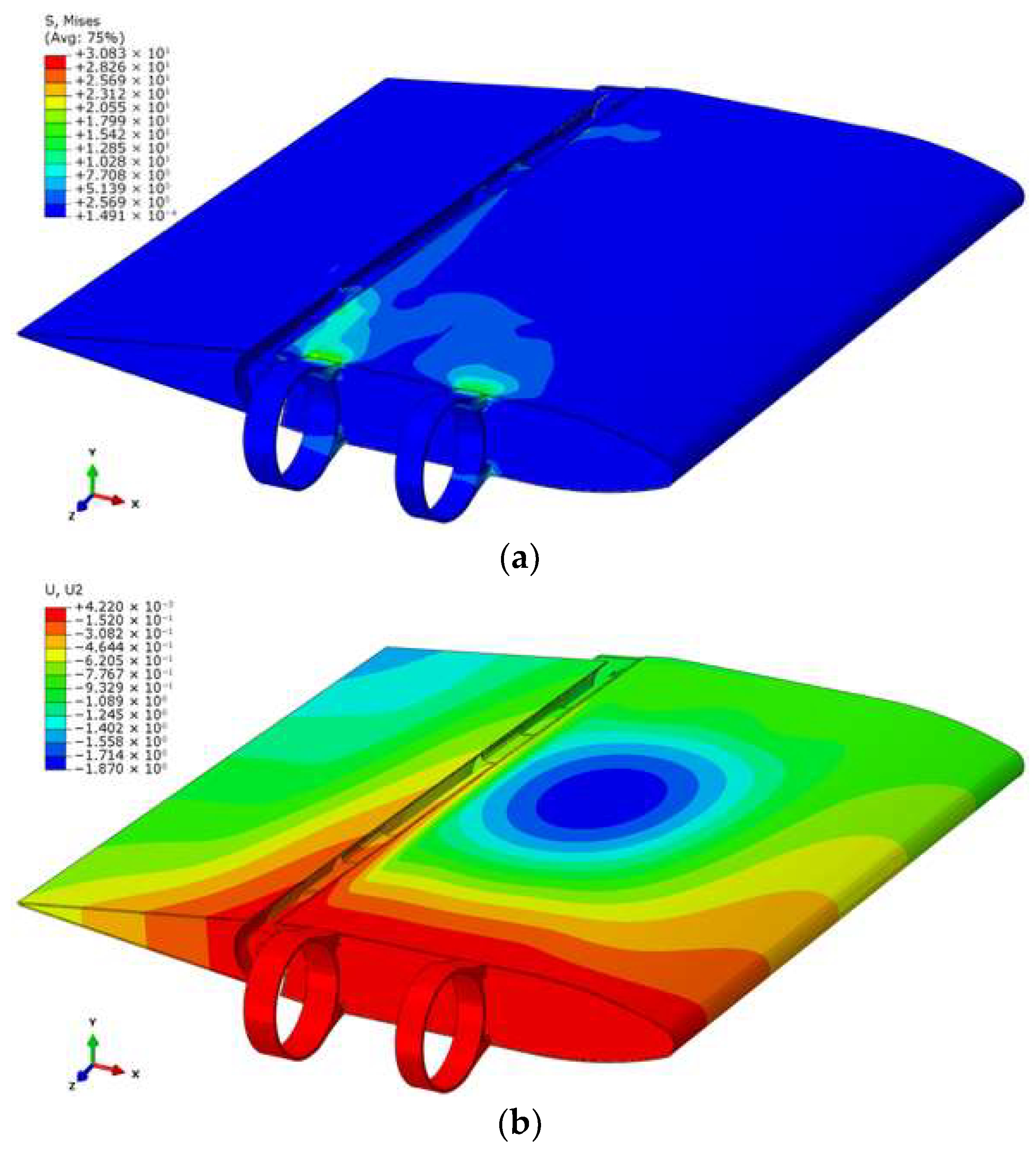

3.3. Reanalysis

To accurately capture the physical behavior of the structures through numerical simulations, the Abaqus finite element software was used. The numerical linear static analysis was performed using the implicit solution algorithm. 3D elements were employed to discretize all of the components, as depicted in

Figure 13 for Configuration 1. The same discretization approach was considered for all configurations.

Specifically, 8-node linear brick elements with a reduced-integration (named C3D8R) scheme were adopted for most components, ensuring reliable stress distribution and numerical stability [

54]. However, components with greater geometric complexity made it necessary to use tetrahedral elements (named C3D10R). An average element size equal to 4 mm was adopted for elements, resulting in a total mesh size of about 150,000 elements.

After the mesh definition, the contact conditions were specified. In the present case, “tie” contacts were introduced between the skin and internal structure and between the bushings and wing-box and rudder, since all of these components will be manufactured as a single integrated element. Moreover, to simulate the locked controls condition, tie contact was also used for the connection between the bushings and roller. After that, the boundary conditions were defined; according to CS-VLA regulations, the resulting load must be applied at 25% of the aerodynamic chord for the asymmetrical loading condition, and at 54.5% of the aerodynamic chord for the symmetrical loading condition, while the external bushings are fixed.

3.4. Reanalysis Results

Contour plots of the Von Mises stress state and displacement in the direction of the applied load for all of the analyzed configurations are reported in the following figures. Particularly, only the most critical loading conditions for each case are presented.

For Configuration 1 in

Figure 14, the most severe condition occurred when the load was applied at 25% of the chord length and when the internal volume was configurated with a 10% internal infill density. The entire structure was characterized by low stress distribution, as shown in

Figure 14a, and the maximum stress of 47.87 MPa ensured a 3.57 safety factor value. The maximum displacement, according to

Figure 14b, was observed at the tip of the structure, reaching a peak of 0.64 mm.

Regarding Configuration 2, the most critical load condition corresponded to force applied at 54.5% of the chord length. In this case, the maximum stress value was equal to 19.00 MPa, as depicted in

Figure 15a, and 39.6% lower than that in Configuration 1, ensuring a safety factor value equal to 9.0.

In this case, the maximum deflection occurred at the center of the wing-box, as shown in

Figure 15b, but the value was negligible from a structural standpoint, reaching only 1.27 mm, which did not compromise the component’s performance. The maximum displacement recorded at the tip resulted in being equal to 0.52 mm.

Finally, Configuration 3 exhibited a stress and displacement distribution very similar to that of Configuration 2. As a matter of fact, in this case, the maximum stress value was equal to 30.83 MPa when the load was applied at 54.5% of the chordwise length, as depicted in

Figure 16, ensuring a safety factor value equal to 5.54.

In this case, the higher peak values of stress and displacement compared with Configuration 2 still resulted in being well below the material’s allowable limits, ensuring structural safety. At the same time, this configuration allowed for a further mass reduction compared with Configuration 2, confirming its effectiveness as a lightweight design solution.

4. Discussion

The use of the fiber-reinforced technopolymer Carbon PA, in conjunction with the DfAM approach based on generative design principles, enabled a substantial reduction in the initial mass of the metallic benchmark component, as evidenced by the data presented in

Table 6 and

Table 7.

Starting from an initial mass of 2.75 kg, the iterative design and optimization process allowed for the development of several optimized configurations, with a variable mass reduction up to 71.2%. An interesting focus can be placed on Configuration 3—100%, which allowed for a 42.5% mass reduction under the assumption of 100% internal infill.

Subsequently, by further leveraging the intrinsic advantages offered by additive manufacturing technologies, it was possible to achieve an even lighter configuration with a final mass of 0.793 kg. This represents a total mass reduction of 71.2% compared with the original benchmark.

Finally, the substantial reduction in mass achieved through this approach will not only contribute to a significant decrease in material waste during production but also lead to a notable reduction in fuel consumption during flight operations. These improvements translate into a dual environmental benefit: lowering both the demand for raw materials and the carbon footprint associated with fuel usage.

Such outcomes underscore the potential of combining advanced polymeric materials with generative design and additive manufacturing to promote more sustainable practices in aerospace engineering and beyond.