Enhanced Fire Resistance and Mechanical Properties of Epoxy and Epoxy-Based Fiber-Reinforced Composites with Hexachlorocyclotriphosphazene Modification

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Tensile Tests of the Epoxy Filled with HCTP

2.2.2. Vertical Burn Tests of the Epoxy and Epoxy-Based FRC Filled with HCTP

2.2.3. Three-Point Bending Tests of FRC

2.2.4. Interlaminar Fracture Toughness Tests of FRC

3. Results

3.1. Tensile Properties

3.2. Vertical Burn Tests for the Epoxy and Epoxy-Based FRCs

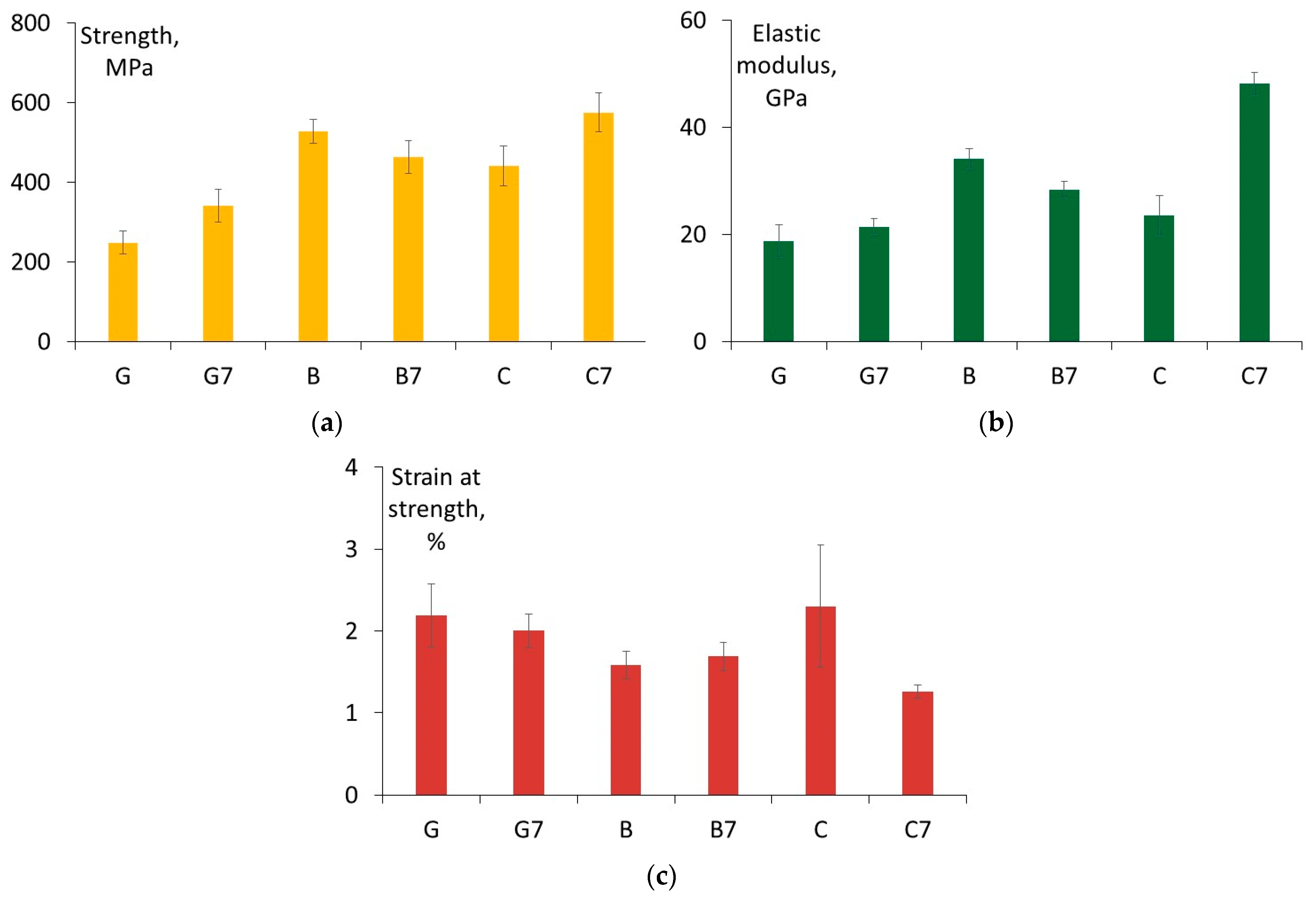

3.3. Flexural Properties of Neat and HCTP-Modified FRCs

3.4. Mode I Interlaminar Fracture Toughness Tests of the Neat and HCTP-Modified FRCs

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Lv, Y.F.; Thomas, W.; Chalk, R.; Singamneni, S. Flame retardant polymeric materials for additive manufacturing. Mater. Today Proc. 2020, 33, 5720–5724. [Google Scholar] [CrossRef]

- Glaskova-Kuzmina, T.; Dejus, D.; Jātnieks, J.; Kruuv, P.-P.; Lancere, L.; Kobenko, S.; Sarakovskis, A.; Zolotarjovs, A. Flame-retardant and tensile properties of the polyamide-12 processed by selective laser sintering. J. Compos. Sci. 2022, 6, 185. [Google Scholar] [CrossRef]

- Seraji, S.M.; Gan, H.; Swan, S.R.; Varley, R.J. Phosphazene as an effective flame retardant for rapid curing epoxy resins. React. Funct. Polym. 2021, 164, 104910. [Google Scholar] [CrossRef]

- Chai, M. Flammability Performance of Bio-Derived COMPOSITE Materials for Aircraft Interiors. Ph.D. Thesis, The University of Aukland, Auckland, New Zealand, 2014. [Google Scholar]

- Kim, N.K.; Dutta, S.; Bhattacharyya, D. A review of flammability of natural fibre reinforced polymeric composites. Compos. Sci. Technol. 2018, 162, 64–78. [Google Scholar] [CrossRef]

- Shi, X.-H.; Li, X.-L.; Li, Y.-M.; Li, Z.; Wang, D.Y. Flame-retardant strategy and mechanism of fiber reinforced polymeric composite: A review. Compos. B Eng. 2022, 233, 109663. [Google Scholar] [CrossRef]

- Dasari, A.; Yu, Z.-Z.; Cai, G.-P.; Mai, Y.-W. Recent developments in the fire retardancy of polymeric materials. Prog. Polym. Sci. 2013, 38, 1357–1387. [Google Scholar] [CrossRef]

- Suihkonen, R.; Nevalainen, K.; Orell, O.; Honkanen, M.; Tang, L.; Zhang, H.; Zhang, Z.; Vuorinen, J. Performance of epoxy filled with nano- and micro-sized magnesium hydroxide. J. Mater Sci. 2012, 47, 1480–1488. [Google Scholar] [CrossRef]

- Tarasov, I.V.; Oboishchikova, A.V.; Borisov, R.S.; Kireev, V.V.; Sirotin, I.S. Phosphazene-containing epoxy resins based on bisphenol F with enhanced heat resistance and mechanical properties: Synthesis and properties. Polymers 2022, 14, 4547. [Google Scholar] [CrossRef]

- Yang, G.; Wu, W.-H.; Wang, Y.-H.; Jiao, Y.-H.; Lu, L.-Y.; Qu, H.-Q.; Qin, X.-Y. Synthesis of a novel phosphazene-based flame retardant with active amine groups and its application in reducing the fire hazard of epoxy resin. J. Hazard. Mater. 2019, 366, 78–87. [Google Scholar] [CrossRef]

- Huo, S.; Song, P.; Yu, B.; Ran, S.; Chevali, V.S.; Liu, L. Phosphorus-containing flame retardant epoxy thermosets: Recent advances and future perspectives. Prog. Polym. Sci. 2021, 114, 101366. [Google Scholar] [CrossRef]

- Yang, S.; Wang, J.; Huo, S.; Wang, J.; Tang, Y. Synthesis of a phosphorus/nitrogen-containing compound based on maleimide and cyclotriphosphazene and its flame-retardant mechanism on epoxy resin. Polym. Degrad. Stab. 2016, 126, 9–16. [Google Scholar] [CrossRef]

- Gaifutdinov, A.M.; Andrianova, K.A.; Amirova, L.M.; Milyukov, V.A.; Zagidullin, A.A.; Amirov, R.R. Low-flammability carbon fiber reinforced composites based on low-viscosity phosphorus-containing epoxy binders for transfer molding methods. Mater. Today Commun 2024, 40, 109340. [Google Scholar] [CrossRef]

- Patel, P.; Hull, T.R.; Lyon, R.E.; Stoliarov, S.I.; Walters, R.N.; Crowley, S.; Safronava, N. Investigation of the thermal decomposition and flammability of PEEK and its carbon and glass-fibre composites. Polym. Degrad. Stab. 2011, 96, 12–22. [Google Scholar] [CrossRef]

- Chen, D.; Sun, G.; Meng, M.; Jin, X.; Li, Q. Flexural performance and cost efficiency of carbon/basalt/glass hybrid FRP composite laminates. Thin. Wall. Struct. 2019, 142, 516–531. [Google Scholar] [CrossRef]

- Asadi, A.; Baaij, F.; Mainka, H.; Rademacher, M.; Thompson, J.; Kalaitzidou, K. Basalt fibers as a sustainable and cost-effective alternative to glass fibers in sheet molding compound (SMC). Compos. B Eng. 2017, 123, 210–218. [Google Scholar] [CrossRef]

- López de Vergara, U.; Sarrionandia, M.; Gondra, K.; Aurrekoetxea, J. Impact behaviour of basalt fibre reinforced furan composites cured under microwave and thermal conditions. Compos. B Eng. 2014, 66, 156–161. [Google Scholar] [CrossRef]

- Diniță, A.; Ripeanu, R.G.; Ilincă, C.N.; Cursaru, D.; Matei, D.; Naim, R.I.; Tănase, M.; Portoacă, A.I. Advancements in Fiber-Reinforced Polymer Composites: A Comprehensive Analysis. Polymers 2024, 16, 2. [Google Scholar] [CrossRef] [PubMed]

- Lopresto, V.; Leone, C.; De Iorio, I. Mechanical characterization of basalt fibre reinforced plastic. Compos. B Eng. 2011, 42, 717–723. [Google Scholar] [CrossRef]

- Balaji, K.V.; Shirvanimoghaddam, K.; Rajan, G.S.; Ellis, A.V.; Naebe, M. Surface treatment of basalt fiber for use in automotive composites. Mater. Today Chem. 2020, 17, 100334. [Google Scholar] [CrossRef]

- Landucci, G.; Rossi, F.; Nicolella, C.; Zanelli, S. Design and testing of innovative materials for passive fire protection. Fire Safety J. 2009, 44, 1103–1109. [Google Scholar] [CrossRef]

- Mouritz, A.P.; Mathys, Z.; Gibson, A.G. Heat release of polymer composites in fire. Compos. A Appl. Sci. Manuf. 2006, 37, 1040–1054. [Google Scholar] [CrossRef]

- Bhat, T.; Chevali, V.; Liu, X.; Feih, S.; Mouritz, A. Fire structural resistance of basalt fibre composite. Compos. A Appl. Sci. Manuf. 2015, 71, 107–115. [Google Scholar] [CrossRef]

- Dhand, V.; Mittal, G.; Rhee, K.Y.; Park, S.-J.; Hui, D. A short review on basalt fiber reinforced polymer composites. Compos. B Eng. 2015, 73, 166–180. [Google Scholar] [CrossRef]

- Epoxy Resin EpikoteMGS LR 285, Hexion. Available online: https://www.havel-composites.com/en/products/epoxy-resin-l-285-mgs-7-2575 (accessed on 17 June 2024).

- Hardener Epikure MGS LH 285, Hexion. Available online: https://www.r-g.de/en/art/110119 (accessed on 17 June 2024).

- BAS UNI 350. Basaltex. Available online: https://www.basaltex.com/products/multi-axial-fabrics (accessed on 17 June 2024).

- Glass Fabric AEROGLASS 390 g/m2 Twill 2/2, Havel. Available online: https://www.havel-composites.com/en/products/glass-fabric-aeroglass-390g-m2-twill-2-2-2508-9478 (accessed on 17 June 2024).

- ECC. Carbon Fabric (Style 442-5 Aero, Twill Weave). Available online: https://www.r-g.de/en/art/190225 (accessed on 17 June 2024).

- ISO 527-1:2019; Plastics—Determination of Tensile Properties. Part 1: General Principles. International Organization for Standardization: Geneva, Switzerland, 2019. Available online: https://www.iso.org/standard/75824.html (accessed on 18 June 2024).

- ASTM D3801; Standard Test Method for Measuring the Comparative Burning Characteristics of Solid Plastics in a Vertical Position. ASTM International: West Conshohocken, PA, USA, 2020. Available online: https://www.astm.org/d3801-20a.html (accessed on 17 June 2024).

- ASTM D790; Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials. ASTM International: West Conshohocken, PA, USA, 2017. Available online: https://www.astm.org/d0790-17.html (accessed on 17 June 2024).

- Glaskova-Kuzmina, T.; Aniskevich, A.; Papanicolaou, G.; Portan, D.; Zotti, A.; Borriello, A.; Zarrelli, M. Hydrothermal aging of an epoxy resin filled with carbon nanofillers. Polymers 2020, 12, 1153. [Google Scholar] [CrossRef] [PubMed]

- Glaskova-Kuzmina, T.; Zotti, A.; Borriello, A.; Zarrelli, M.; Aniskevich, A. Basalt fibre composite with carbon nanomodified epoxy matrix under hydrothermal ageing. Polymers 2021, 13, 532. [Google Scholar] [CrossRef] [PubMed]

- ASTM D5528; Standard Test Method for Mode I Interlaminar Fracture Toughness of Unidirectional Fiber-Reinforced Polymer Matrix Composites. ASTM International: West Conshohocken, PA, USA, 2022. Available online: https://www.astm.org/d5528-13.html (accessed on 17 June 2024).

- Glaskova-Kuzmina, T.; Stankevics, L.; Tarasovs, S.; Sevcenko, J.; Špaček, V.; Sarakovskis, A.; Zolotarjovs, A.; Shmits, K.; Aniskevich, A. Effect of core-shell rubber nanoparticles on the mechanical properties of epoxy and epoxy-based CFR. Materials 2022, 15, 7502. [Google Scholar] [CrossRef] [PubMed]

- Kim, Y.-H.; Baek, J.J.; Chang, K.C.; Lim, H.S.; Choi, M.-S.; Koh, W.-G.; Shin, G. Influence of Thiol-Functionalized Polysilsesquioxane/Phosphorus Flame-Retardant Blends on the Flammability and Thermal, Mechanical, and Volatile Organic Compound (VOC) Emission Properties of Epoxy Resins. Polymers 2024, 16, 842. [Google Scholar] [CrossRef] [PubMed]

- Niu, M.; Zhang, Z.; Wei, Z.; Wang, W. Effect of a Novel Flame Retardant on the Mechanical, Thermal and Combustion Properties of Poly(Lactic Acid). Polymers 2020, 12, 2407. [Google Scholar] [CrossRef]

- Liu, Q.; Wang, D.; Li, Z.; Li, Z.; Peng, X.; Liu, C.; Zhang, Y.; Zheng, P. Recent Developments in the Flame-Retardant System of Epoxy Resin. Materials 2020, 13, 2145. [Google Scholar] [CrossRef]

- Toldy, A.; Szolnoki, B.; Marosi, G. Flame retardancy of fibre-reinforced epoxy resin composites for aerospace applications. Polym. Degrad. Stab. 2011, 96, 371–376. [Google Scholar] [CrossRef]

- Parveez, B.; Kittur, M.I.; Badruddin, I.A.; Kamangar, S.; Hussien, M.; Umarfarooq, M.A. Scientific Advancements in Composite Materials for Aircraft Applications: A Review. Polymers 2022, 14, 5007. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Glaskova-Kuzmina, T.; Vidinejevs, S.; Volodins, O.; Sevcenko, J.; Aniskevich, A.; Špaček, V.; Raškinis, D.; Vogonis, G. Enhanced Fire Resistance and Mechanical Properties of Epoxy and Epoxy-Based Fiber-Reinforced Composites with Hexachlorocyclotriphosphazene Modification. J. Compos. Sci. 2024, 8, 290. https://doi.org/10.3390/jcs8080290

Glaskova-Kuzmina T, Vidinejevs S, Volodins O, Sevcenko J, Aniskevich A, Špaček V, Raškinis D, Vogonis G. Enhanced Fire Resistance and Mechanical Properties of Epoxy and Epoxy-Based Fiber-Reinforced Composites with Hexachlorocyclotriphosphazene Modification. Journal of Composites Science. 2024; 8(8):290. https://doi.org/10.3390/jcs8080290

Chicago/Turabian StyleGlaskova-Kuzmina, Tatjana, Sergejs Vidinejevs, Olegs Volodins, Jevgenijs Sevcenko, Andrey Aniskevich, Vladimir Špaček, Dalius Raškinis, and Gediminas Vogonis. 2024. "Enhanced Fire Resistance and Mechanical Properties of Epoxy and Epoxy-Based Fiber-Reinforced Composites with Hexachlorocyclotriphosphazene Modification" Journal of Composites Science 8, no. 8: 290. https://doi.org/10.3390/jcs8080290

APA StyleGlaskova-Kuzmina, T., Vidinejevs, S., Volodins, O., Sevcenko, J., Aniskevich, A., Špaček, V., Raškinis, D., & Vogonis, G. (2024). Enhanced Fire Resistance and Mechanical Properties of Epoxy and Epoxy-Based Fiber-Reinforced Composites with Hexachlorocyclotriphosphazene Modification. Journal of Composites Science, 8(8), 290. https://doi.org/10.3390/jcs8080290