Assessment of Adhesion in Woven Fabric-Reinforced Laminates (FRLs) Using Novel Yarn Pullout in Laminate Test

Abstract

1. Introduction

2. Experimental Procedure

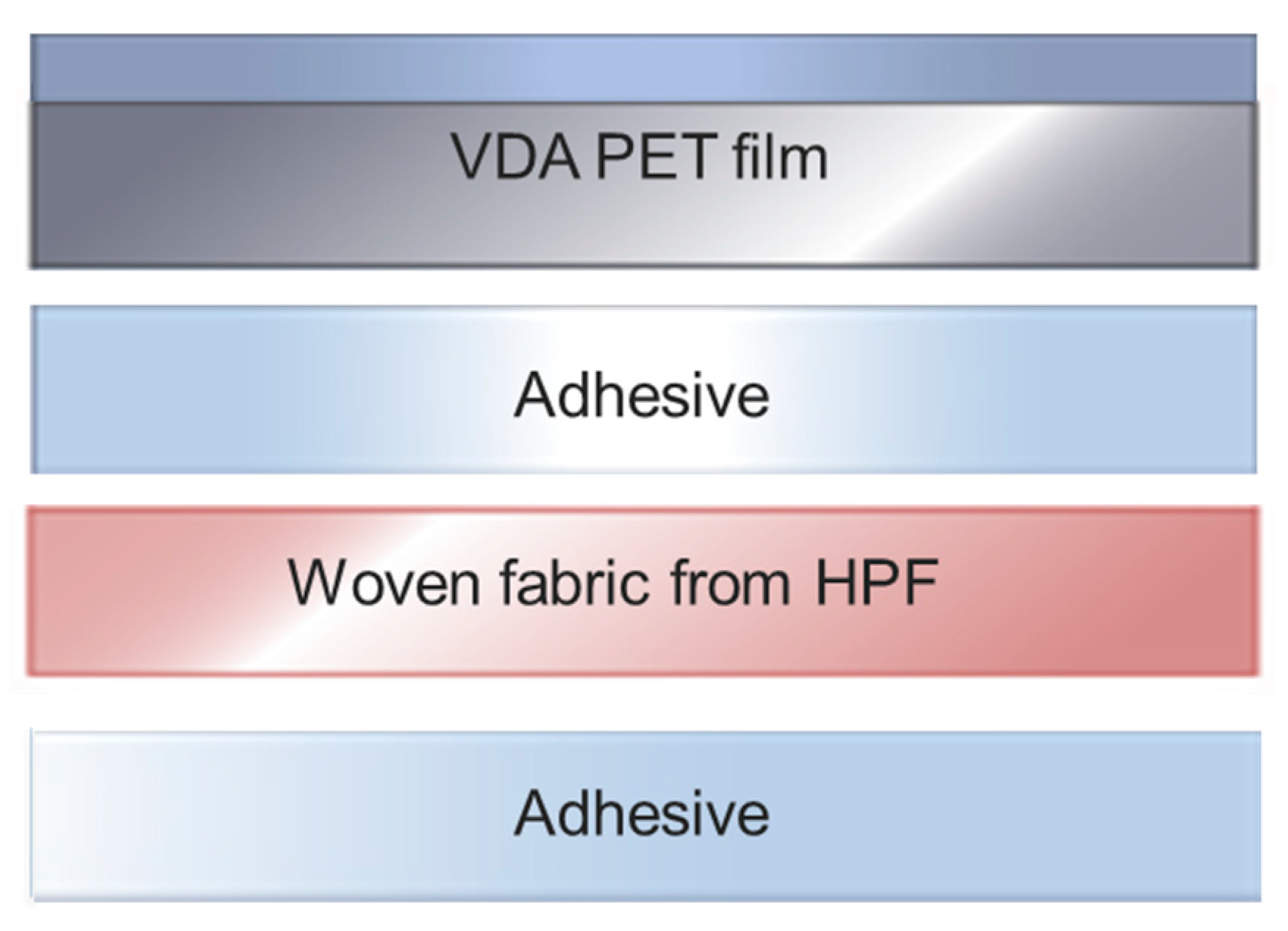

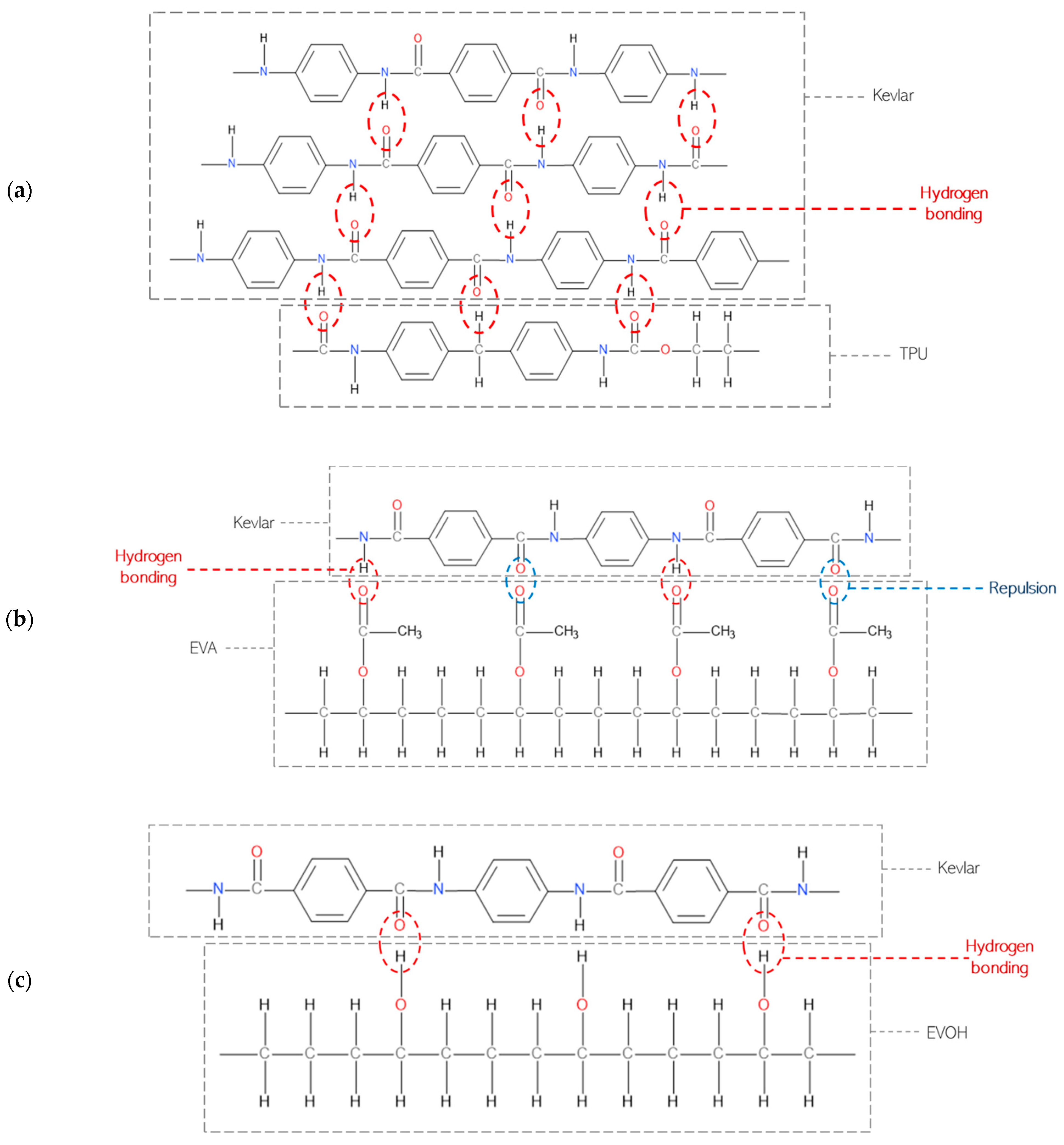

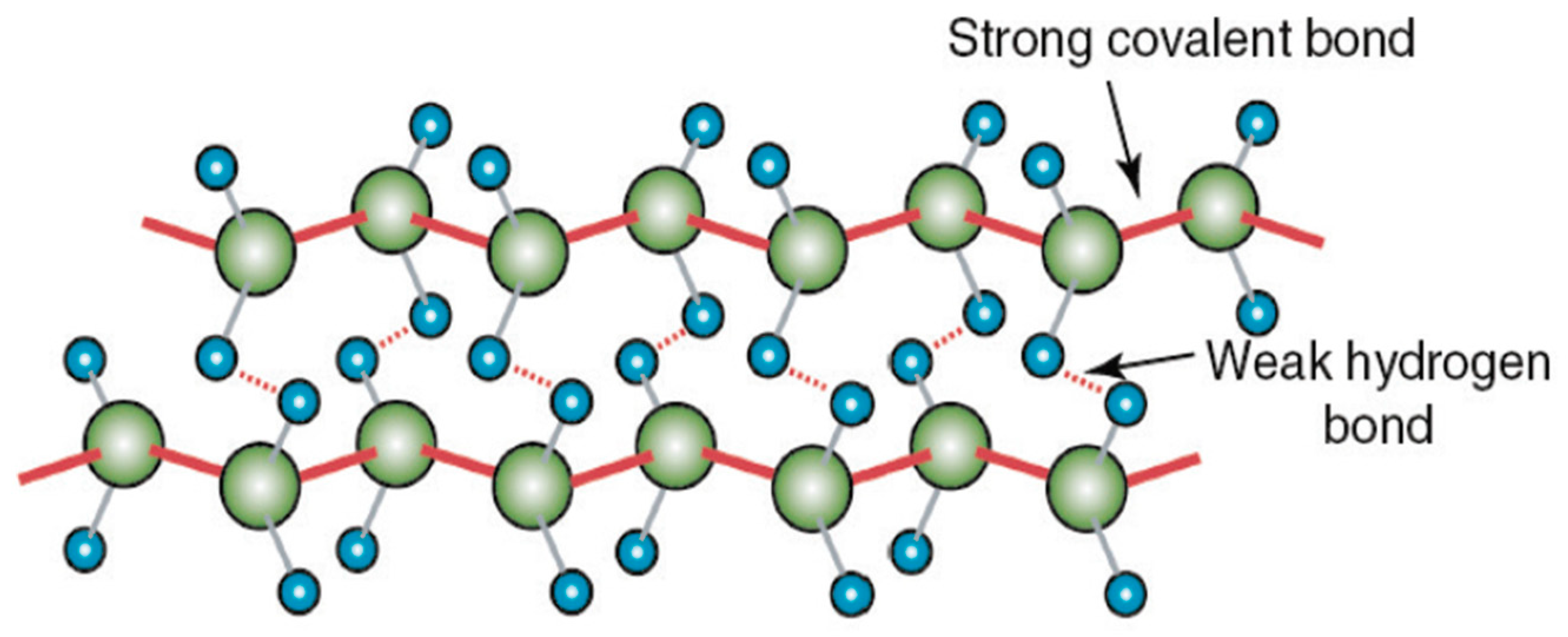

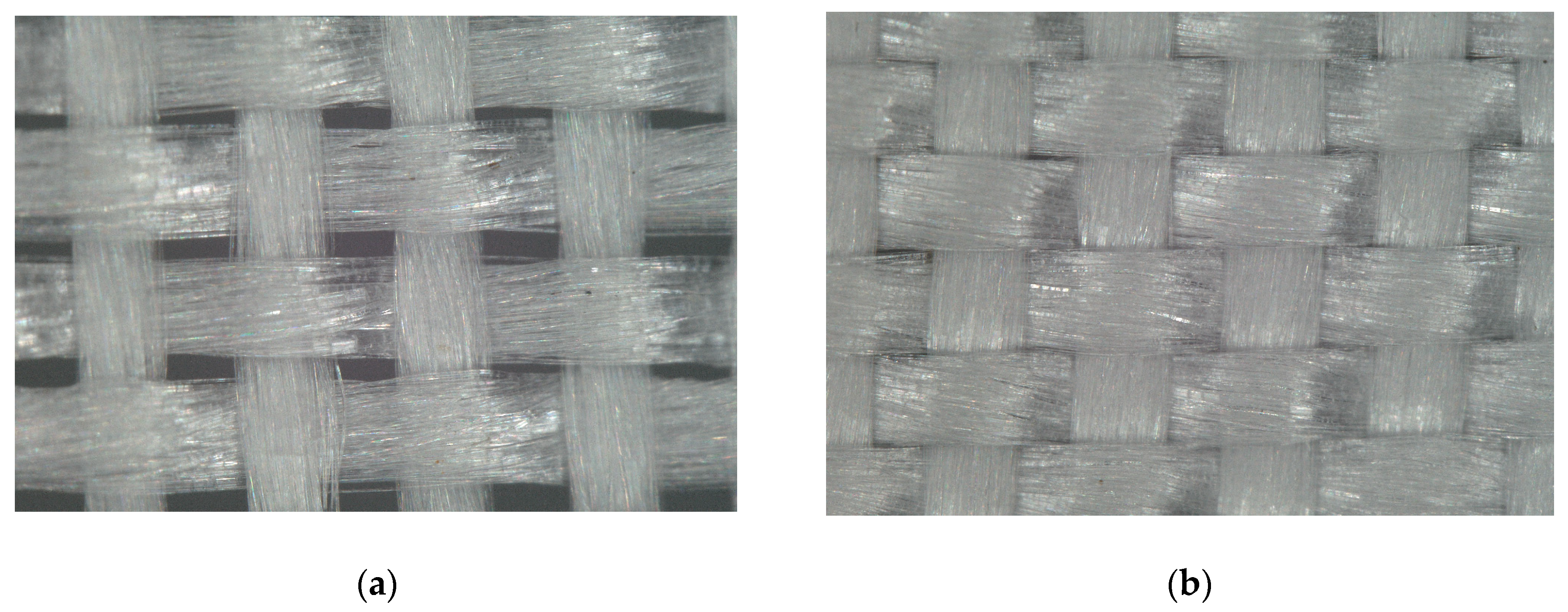

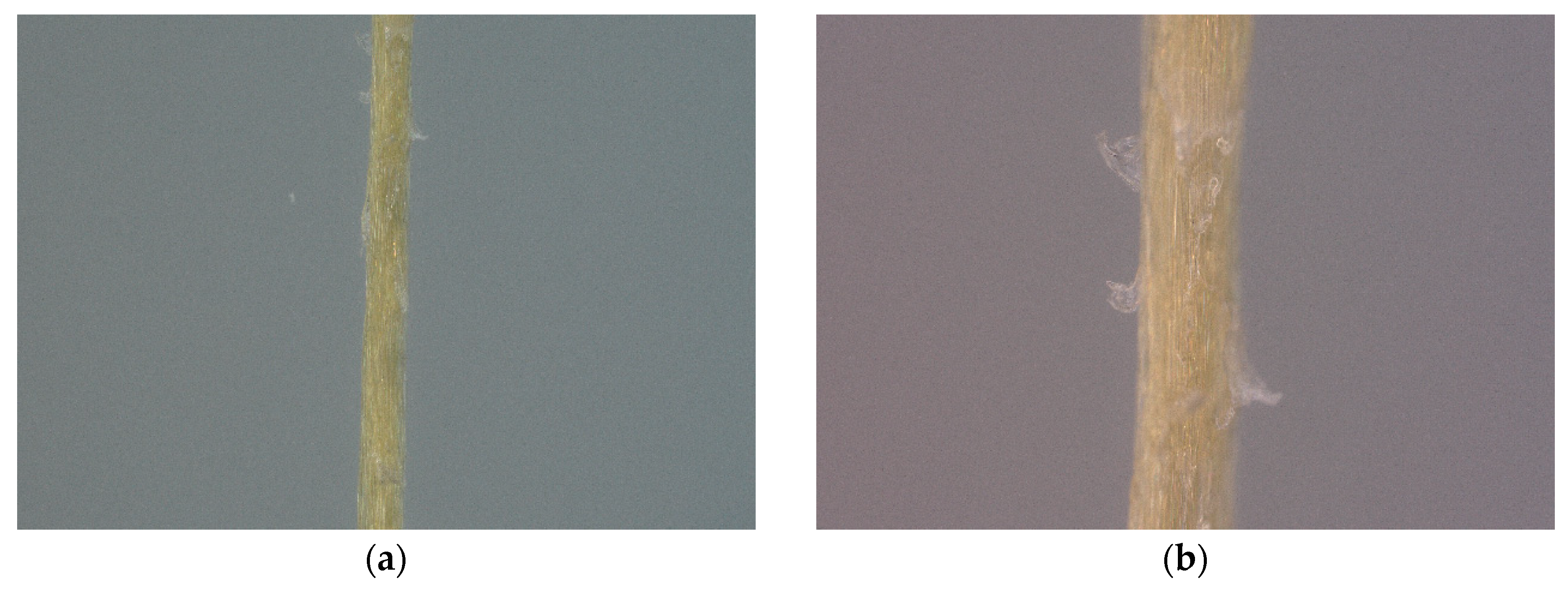

2.1. Materials

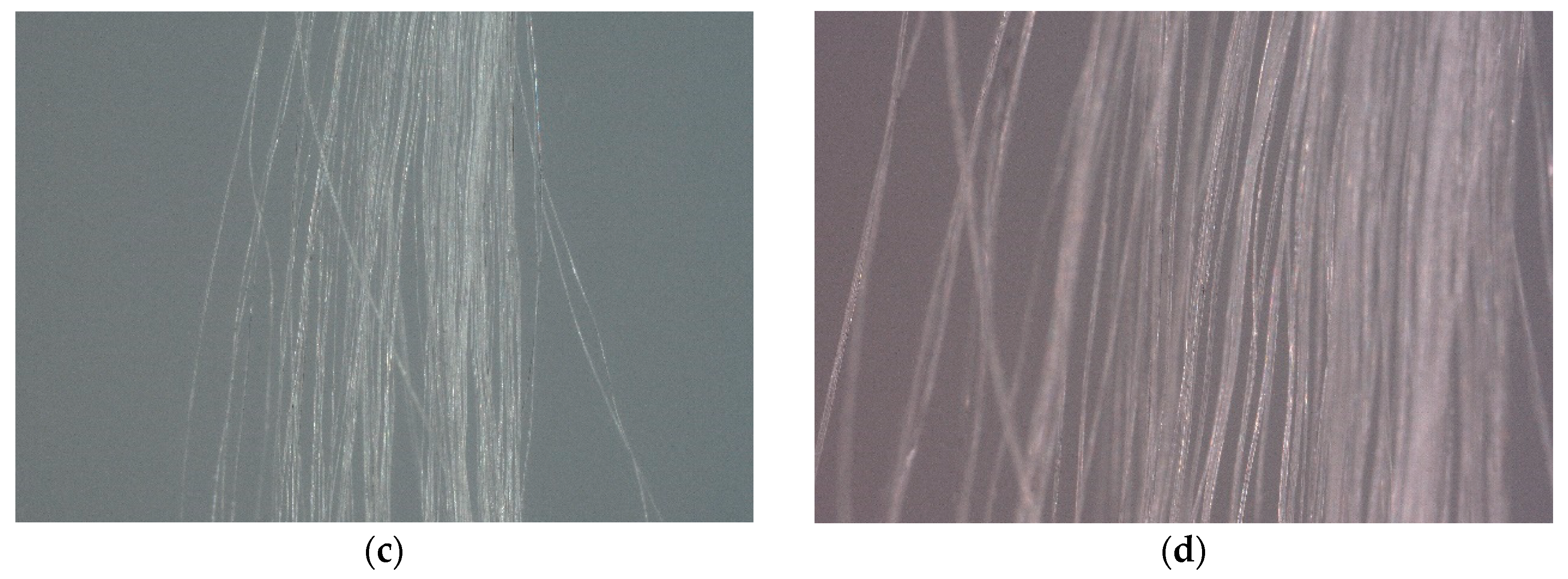

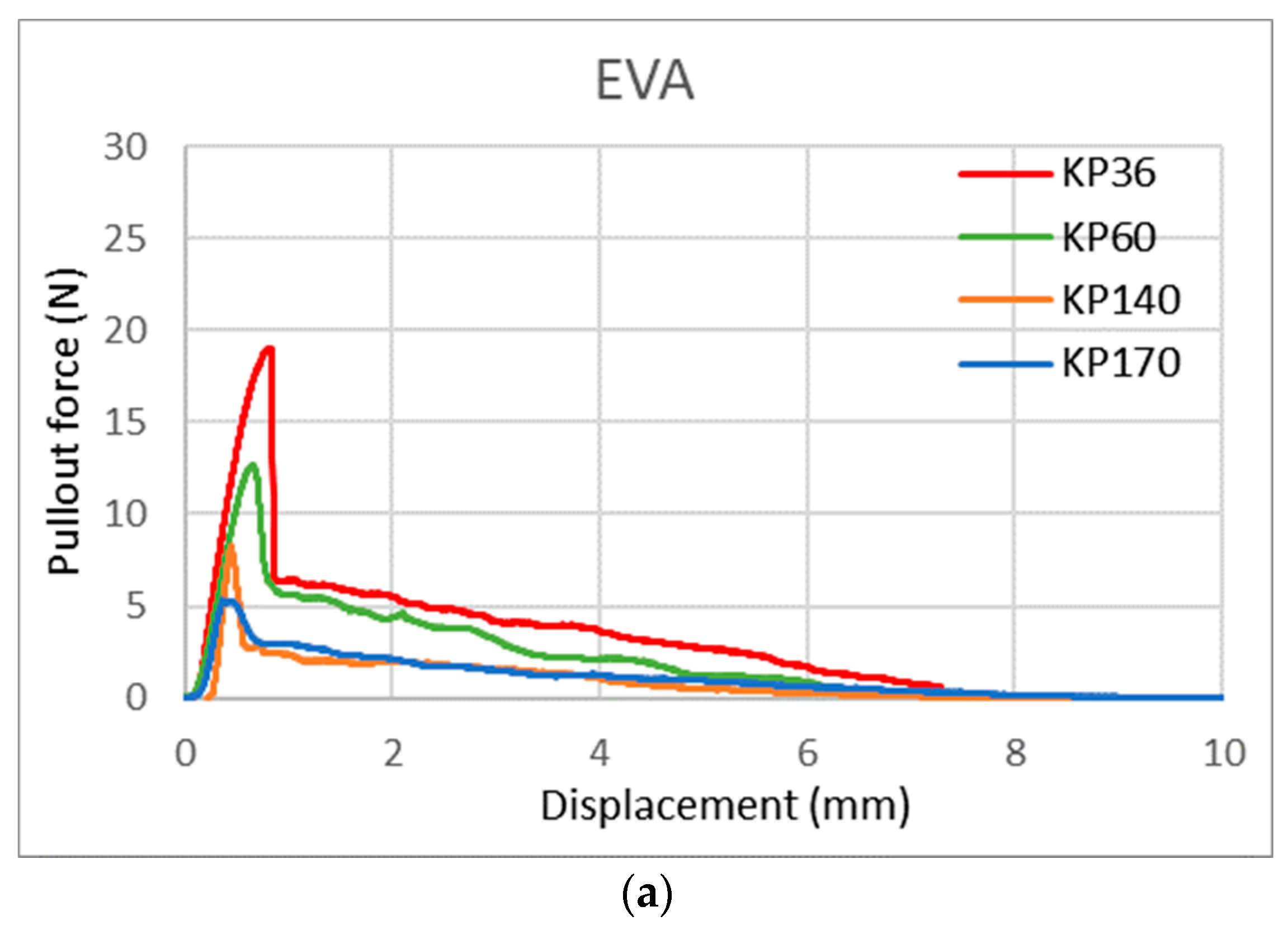

2.2. Fabric Structure Parameters

2.3. Laminates Formation

2.4. Testing and Characterization

3. Results and Discussions

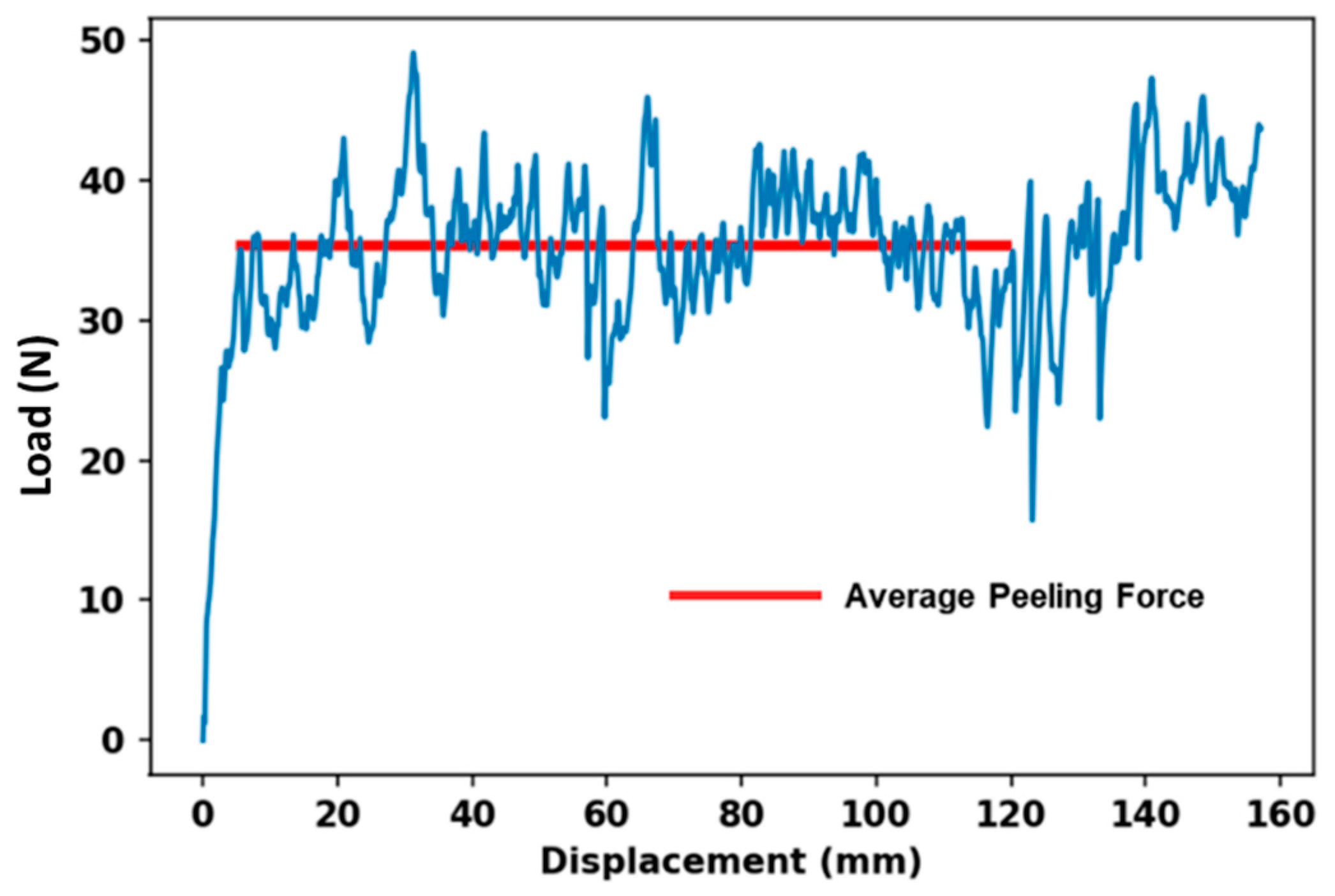

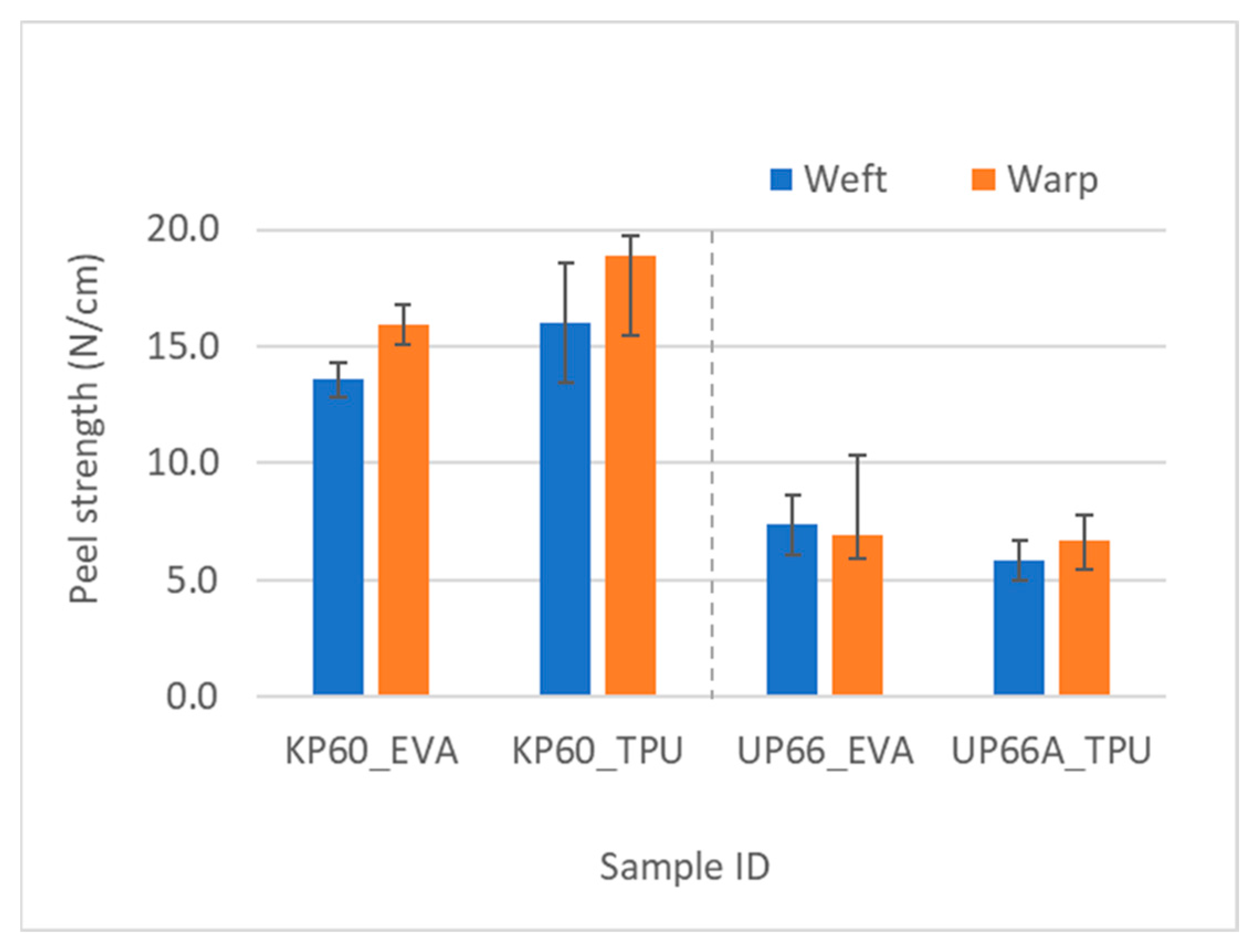

3.1. T-Peel Test

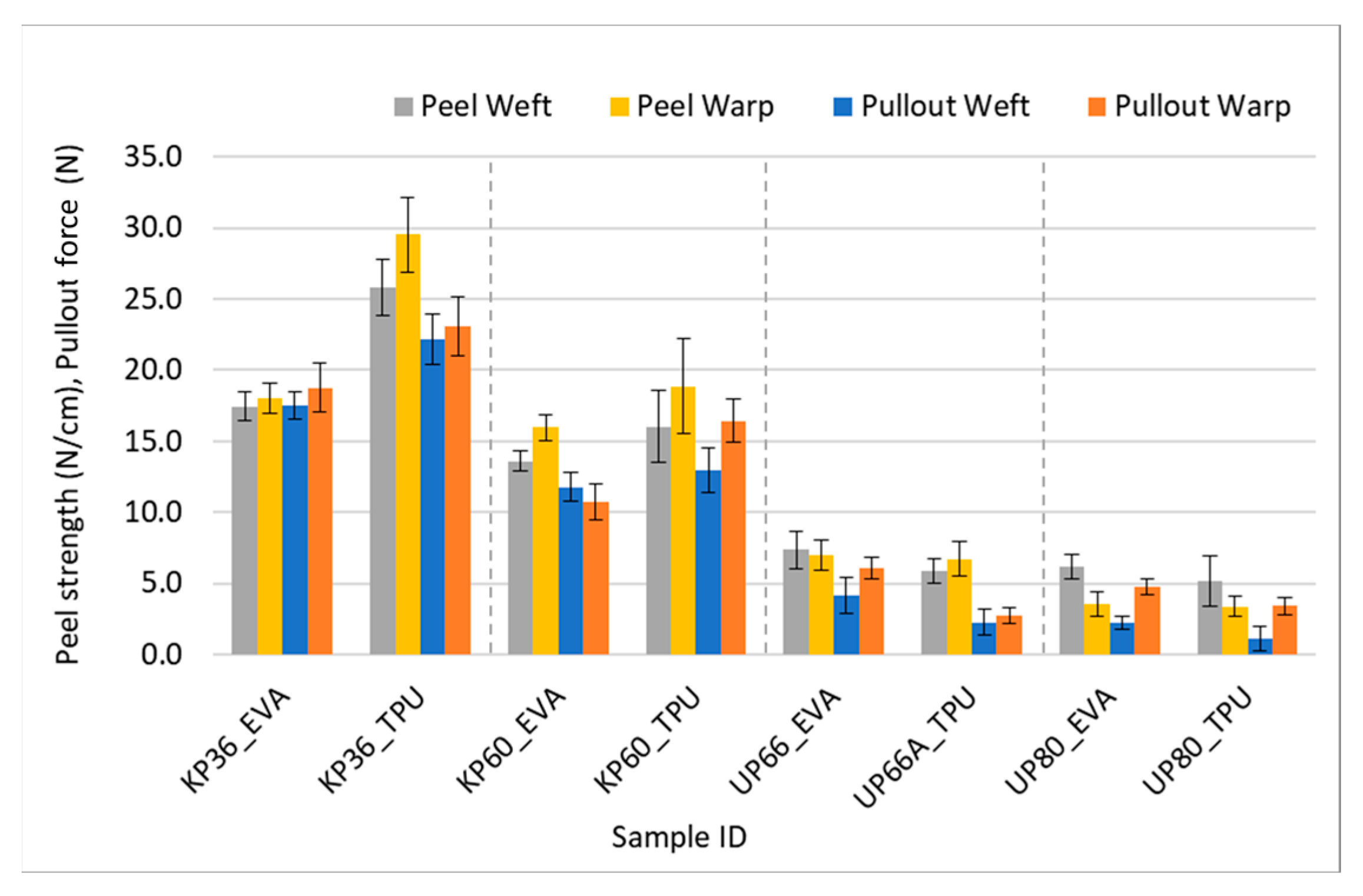

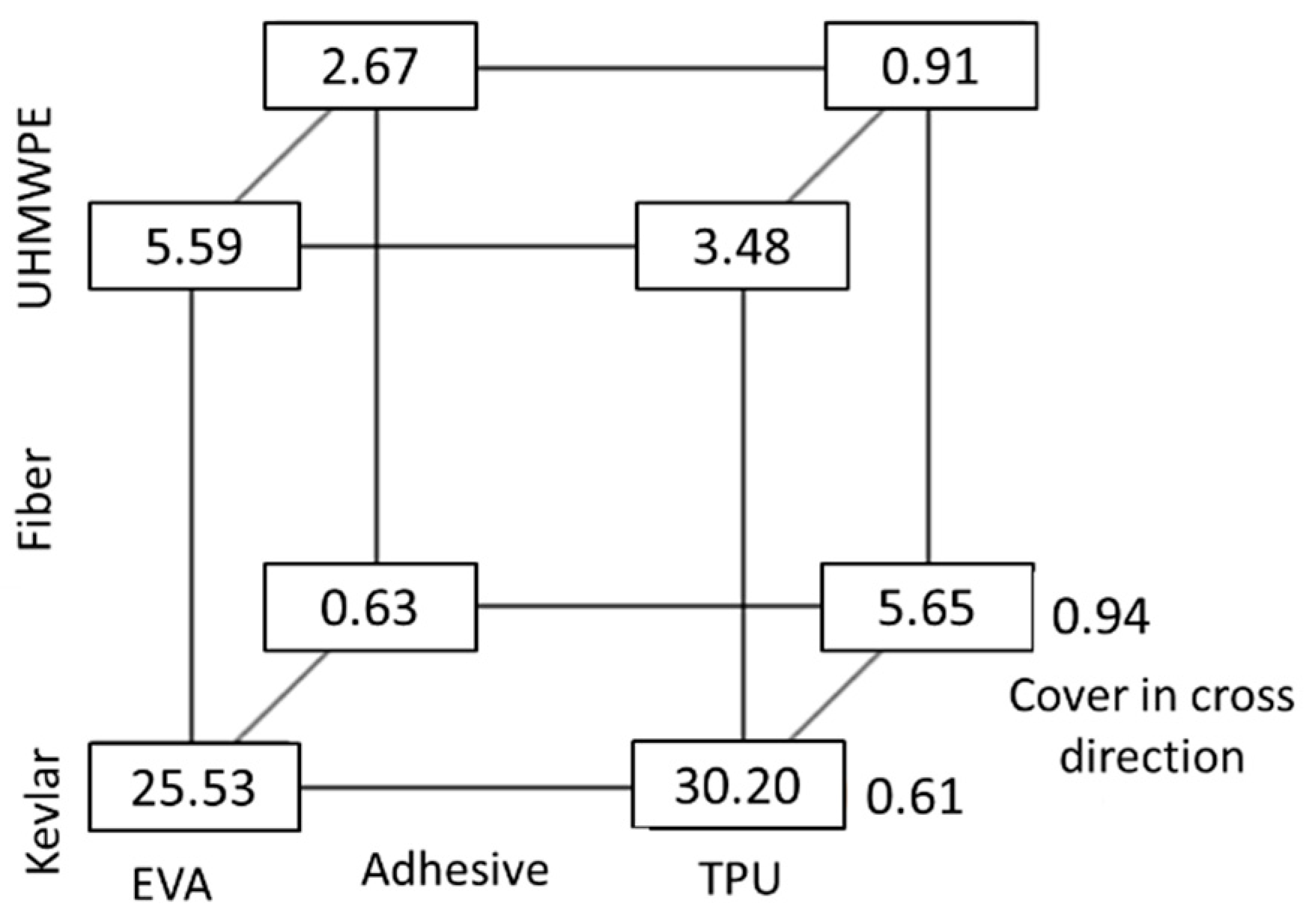

3.2. Correlation between Peel and Pullout in Laminate Test

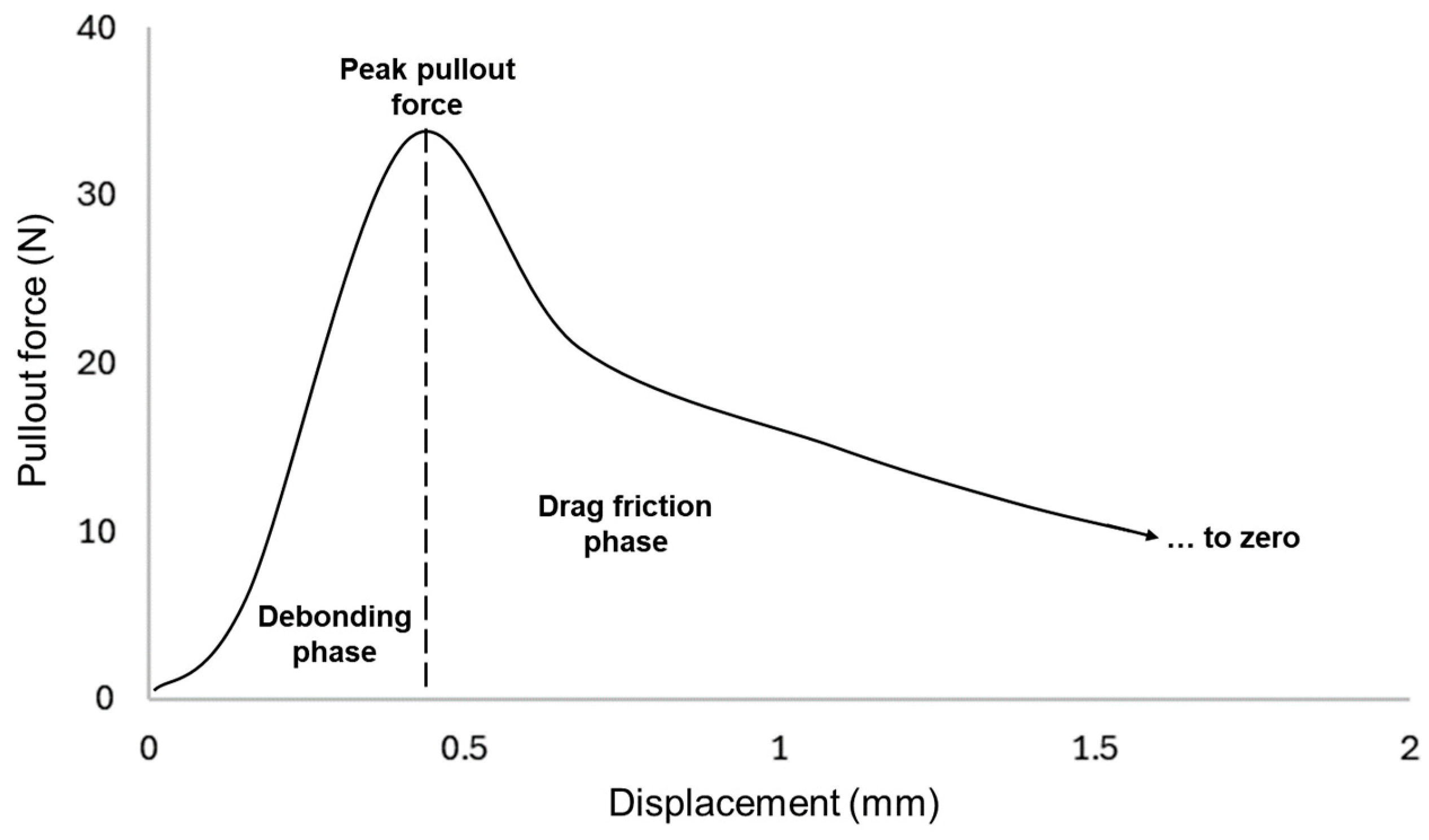

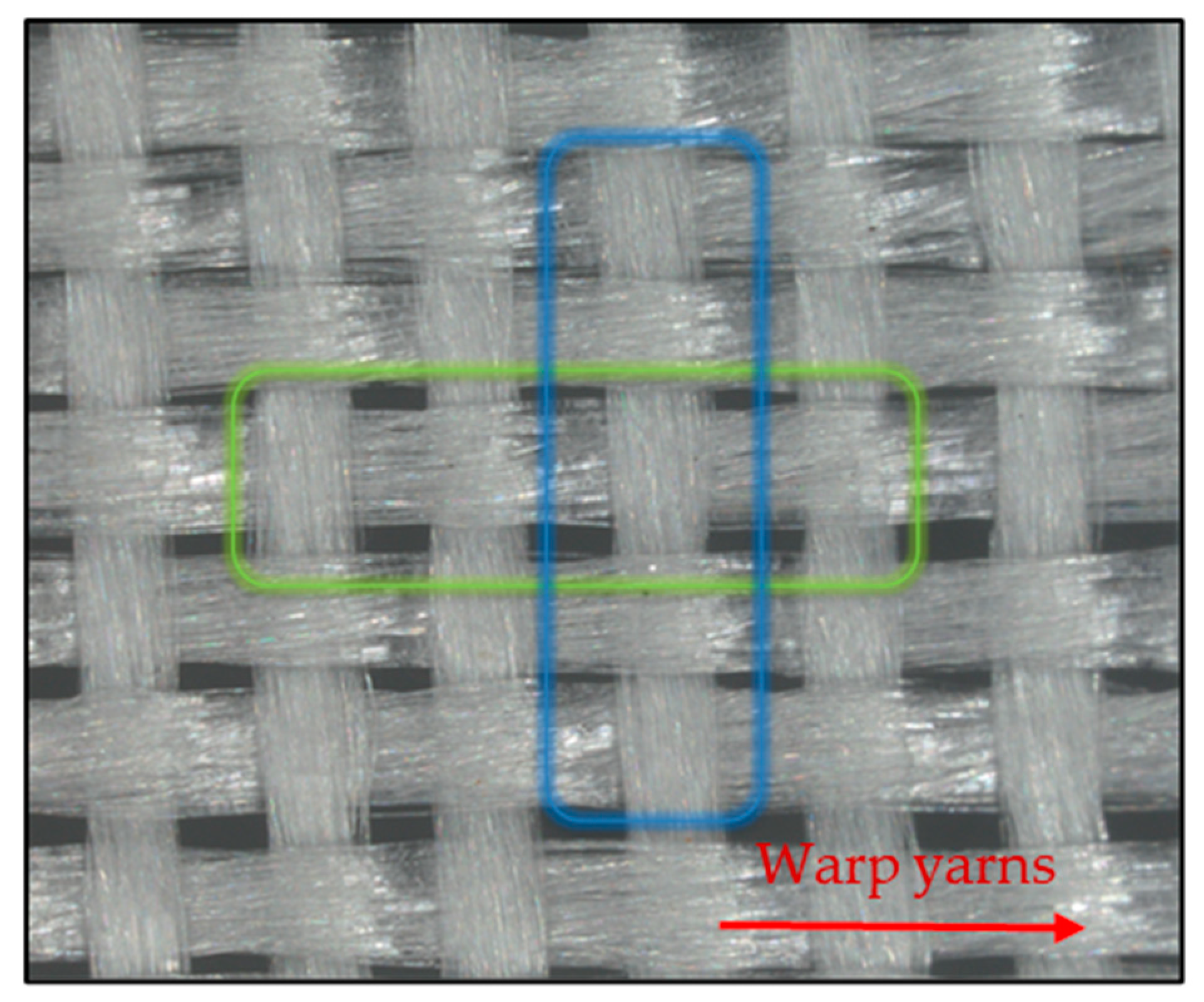

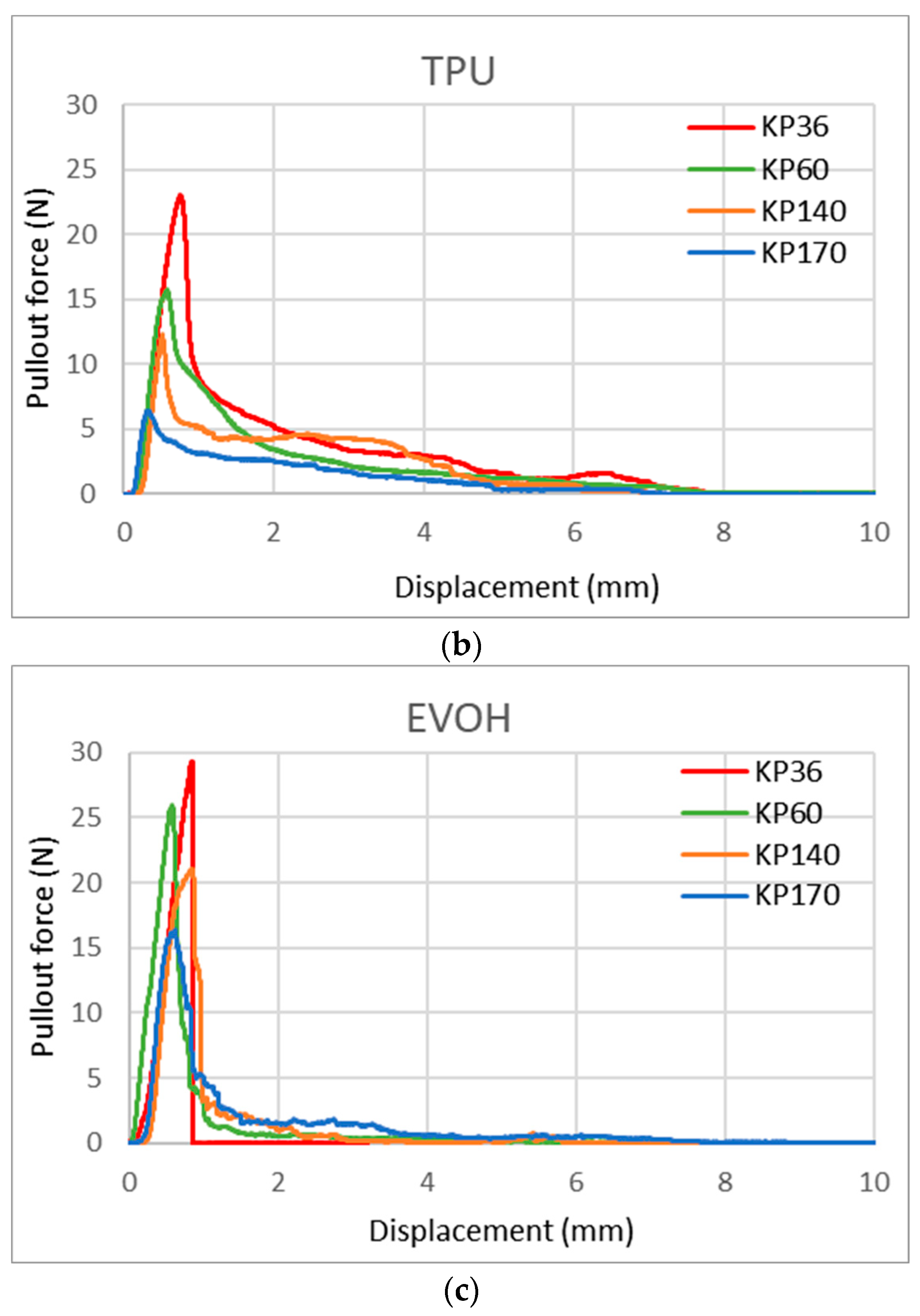

3.3. Yarn Pullout in FRL Test

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Litteken, D.A. Inflatable Technology: Using Flexible Materials to Make Large Structures. In Proceedings of the Electroactive Polymer Actuators and Devices (EAPAD) XXI, Denver, CO, USA, 4–7 March 2019. [Google Scholar] [CrossRef]

- Mandlekar, N.; Joshi, M.; Butola, B.S. A Review on Specialty Elastomers Based Potential Inflatable Structures and Applications. Adv. Ind. Eng. Polym. Res. 2022, 5, 33–45. [Google Scholar] [CrossRef]

- Abramowitch, A. The Advantages of Inflatable Structures. Giant Inflatables Industrial. Available online: https://www.industrysearch.com.au/the-advantages-of-inflatable-structures/f/19393 (accessed on 8 April 2022).

- Veldman, S.L.; Vermeeren, C.A.J.R. Inflatable Structures in Aerospace Engineering—An Overview. Compos. Mater. Struct. 2001, 468, 93. [Google Scholar]

- Li, A. Evaluation of Laminated Hull Material for High Altitude Airship. Ph.D. Thesis, North Carolina State University, Raleigh, NC, USA, 2018. [Google Scholar]

- Smith, M.; Rainwater, L. Applications of Scientific Ballooning Technology to High Altitude Airships. Aerosp. Res. Cent. 2012, 17–19. [Google Scholar] [CrossRef]

- Li, H.; Hu, Y.; Fu, X.; Zheng, X.; Liu, H.; Tao, J. Effect of Adhesive Quantity on Failure Behavior and Mechanical Properties of Fiber Metal Laminates Based on the Aluminum–Lithium Alloy. Compos. Struct. 2016, 152, 687–692. [Google Scholar] [CrossRef]

- Čuk, M.; Bizjak, M.; Kočevar, T.N. Influence of Simple and Double-Weave Structures on the Adhesive Properties of 3D Printed Fabrics. Polymers 2022, 14, 755. [Google Scholar] [CrossRef] [PubMed]

- Lin, M.-C.; Lou, C.-W.; Lin, J.-Y.; Lin, T.A.; Lin, J.-H. Mechanical Property Evaluations of Flexible Laminated Composites Reinforced by High-Performance Kevlar Filaments: Tensile Strength, Peel Load, and Static Puncture Resistance. Compos. Part B Eng. 2019, 166, 139–147. [Google Scholar] [CrossRef]

- Macchi, P.; Sironi, A. Chemical Bonding in Transition Metal Carbonyl Clusters: Complementary Analysis of Theoretical and Experimental Electron Densities. Coord. Chem. Rev. 2003, 238–239, 383–412. [Google Scholar] [CrossRef]

- Grabowski, S.J.; Leszczynski, J. Hydrogen Bonding—New Insights; Springer: Berlin/Heidelberg, Germany, 2006. [Google Scholar]

- Chowdhury, S.C.; Sockalingam, S.; Gillespie, J.W., Jr. Inter-molecular interactions in ultrahigh molecular weight polyethylene single crystals. Comput. Mater. Sci. 2020, 172, 109306. [Google Scholar] [CrossRef]

- Deshpande, V.S. Ultra-Strong Molecules, Ballistic Performance of Ultra-High Molecular Weight Polyethylene Composites. In High-Entropy Materials, Ultra-Strong Molecules, and Nanoelectronics; National Academies of Sciences, Engineering, and Medicine: Washington, DC, USA, 2019; pp. 3–4. [Google Scholar] [CrossRef]

- Abbott, S. Sticking Together: The Science of Adhesion; Royal Society of Chemistry: London, UK, 2020. [Google Scholar]

- Chhetri, S.; Bougherara, H. A comprehensive review on surface modification of UHMWPE fiber and interfacial properties. Compos. Part A Appl. Sci. Manuf. 2021, 140, 106146. [Google Scholar] [CrossRef]

- Galuszynski, S. Structure and Tightness of Woven Fabrics. Indian J. Text. Res. 1987, 12, 71–77. [Google Scholar] [CrossRef]

- Peirce, F.T. Geometry of Cloth Structure. Text. Res. J. 1937, 28, 45–96. [Google Scholar] [CrossRef]

- El Messiry, M.; Mito, A.-B.; Al-Oufy, A.; El-Tahan, E. Effect of Fabric Material and Tightness on the Mechanical Properties of Fabric–Cement Composites. Alex. Eng. J. 2014, 53, 785–801. [Google Scholar] [CrossRef]

- ASTM Standard D1876; Standard Test Method for Peel Resistance of Adhesives (T-Peel Test). ASTM International: West Conshohocken, PA, USA, 2016.

- Hussain, M.; Imad, A.; Saouab, A.; Kanit, T.; Nawab, Y.; Herbelot, C.; Kashif, M. Properties and Characterization of Novel 3D Jute Reinforced Natural Fibre Aluminium Laminates. J. Compos. Mater. 2020, 55, 1879–1891. [Google Scholar] [CrossRef]

- Broughton, W.R.; Mera, R.D.; Hinopoulos, G. Creep Testing of Adhesive Joints T-Peel Test; National Physical Laboratory: Teddington, UK, 1999. [Google Scholar]

- Dhaliwal, G.S.; Newaz, G.M. Effect of Resin Rich Veil Cloth Layers on the Uniaxial Tensile Behavior of Carbon Fiber Reinforced Fiber Metal Laminates. J. Compos. Sci. 2018, 2, 61. [Google Scholar] [CrossRef]

- Adekunle, F. Evaluation and Enhancement of Adhesion in Fiber-Reinforced Laminated Structures. Ph.D. Thesis, North Carolina State University, Raleigh, NC, USA, 2024. [Google Scholar]

- Nilakantan, G.; Gillespie, J.W., Jr. Yarn Pull-out Behavior of Plain Woven Kevlar Fabrics: Effect of Yarn Sizing, Pullout Rate, and Fabric Pre-Tension. Compos. Struct. 2013, 101, 215–224. [Google Scholar] [CrossRef]

| No. | Fiber Type | Fabric Areal Density (g/m2) | Woven Fabric ID | Yarn Linear Density (tex, g/km) | Fabric Count (ends/cm × picks/cm) |

|---|---|---|---|---|---|

| 1 | Kevlar | 36 | KP36 | 21.5 | 8 × 8 |

| 2 | Kevlar | 60 | KP60 | 21.5 | 13.5 × 13.5 |

| 3 | Kevlar | 140 | KP140 | 150 | 5.3 × 5.3 |

| 4 | Kevlar | 170 | KP170 | 127 | 6.5 × 6.5 |

| 5 | UHMWPE | 66 | UP66 | 24.5 | 15.7 × 11.8 |

| 6 | UHMWPE | 80 | UP80 | 24.5 | 19.7 × 13.8 |

| Sample ID | Cover Fabric | Cover Weft | Cover Warp |

|---|---|---|---|

| KP36 | 0.92 | 0.69 | 0.74 |

| KP60 | 0.97 | 0.84 | 0.84 |

| KP140 | 0.97 | 0.81 | 0.83 |

| KP170 | 0.98 | 0.85 | 0.88 |

| UP66 | 0.92 | 0.61 | 0.80 |

| UP80 | 0.98 | 0.66 | 0.94 |

| No. | Fiber Type | Fabric Areal Density (g/m2) | Yarn Linear Density (tex, g/km) | Fabric Count (ends/cm × picks/cm) | Adhesive | Laminate ID |

|---|---|---|---|---|---|---|

| 1 | Kevlar | 36 | 21.5 | 8 × 8 | EVOH | KP36_EVOH |

| 2 | EVA | KP36_EVA | ||||

| 3 | TPU | KP36_TPU | ||||

| 4 | Kevlar | 60 | 21.5 | 13.5 × 13.5 | EVOH | KP60_EVOH |

| 5 | EVA | KP60_EVA | ||||

| 6 | TPU | KP60_TPU | ||||

| 7 | Kevlar | 140 | 150 | 5.3 × 5.3 | EVOH | KP140_EVOH |

| 8 | EVA | KP140_EVA | ||||

| 9 | TPU | KP140_TPU | ||||

| 10 | Kevlar | 170 | 126.7 | 6.7 × 6.5 | EVOH | KP170_EVOH |

| 11 | EVA | KP170_EVA | ||||

| 12 | TPU | KP170_TPU | ||||

| 13 | UHMWPE | 66 | 24.5 | 15.7 × 11.8 | EVA | UP66_EVA |

| 14 | TPU | UP66_TPU | ||||

| 15 | UHMWPE | 80 | 24.5 | 19.7 × 13.8 | EVA | UP80_EVA |

| 16 | TPU | UP80_TPU |

| Sample ID | Weft | Warp |

|---|---|---|

| KP36_EVA | No difference | No difference |

| KP36_TPU | Ad to fab > Ad to film | Ad to fab > Ad to film |

| KP60_EVA | No difference | No difference |

| KP60_TPU | No difference | Ad to fab > Ad to film |

| KP140_EVA | No difference | No difference |

| KP140_TPU | Ad to fab > Ad to film | Ad to film > Ad to fab |

| KP170_EVA | Ad to fab > Ad to film | No difference |

| KP170_TPU | Ad to film > Ad to fab | Ad to film > Ad to fab |

| UP66_EVA | Ad to film > Ad to fab | No difference |

| UP66A_TPU | Ad to fab > Ad to film | Ad to fab > Ad to film |

| UP80_EVA | Ad to fab > Ad to film | Ad to fab > Ad to film |

| UP80_TPU | Ad to film > Ad to fab | Ad to fab > Ad to film |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Adekunle, F.; Li, A.; Vallabh, R.; Seyam, A.-F.M. Assessment of Adhesion in Woven Fabric-Reinforced Laminates (FRLs) Using Novel Yarn Pullout in Laminate Test. J. Compos. Sci. 2024, 8, 242. https://doi.org/10.3390/jcs8070242

Adekunle F, Li A, Vallabh R, Seyam A-FM. Assessment of Adhesion in Woven Fabric-Reinforced Laminates (FRLs) Using Novel Yarn Pullout in Laminate Test. Journal of Composites Science. 2024; 8(7):242. https://doi.org/10.3390/jcs8070242

Chicago/Turabian StyleAdekunle, Feyi, Ang Li, Rahul Vallabh, and Abdel-Fattah M. Seyam. 2024. "Assessment of Adhesion in Woven Fabric-Reinforced Laminates (FRLs) Using Novel Yarn Pullout in Laminate Test" Journal of Composites Science 8, no. 7: 242. https://doi.org/10.3390/jcs8070242

APA StyleAdekunle, F., Li, A., Vallabh, R., & Seyam, A.-F. M. (2024). Assessment of Adhesion in Woven Fabric-Reinforced Laminates (FRLs) Using Novel Yarn Pullout in Laminate Test. Journal of Composites Science, 8(7), 242. https://doi.org/10.3390/jcs8070242