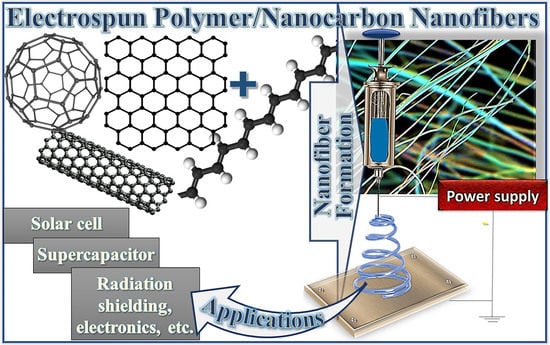

Electrospinning Processing of Polymer/Nanocarbon Nanocomposite Nanofibers—Design, Features, and Technical Compliances

Abstract

1. Introduction

2. Nanocarbon Nanofillers in Polymeric Nanocomposites

3. Nanofibers of Polymeric Nanocomposites

4. Electrospinning Technique for Nanofibers

5. Design and Characteristics of Electrospun Polymer/Nanocarbon Nanocomposite Nanofibers

6. Significance of Electrospun Polymer/Nanocarbon Nanocomposite Nanofibers

7. Future and Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Mobaraki, M.; Liu, M.; Masoud, A.-R.; Mills, D.K. Biomedical Applications of Blow-Spun Coatings, Mats, and Scaffolds—A Mini-Review. J. Compos. Sci. 2023, 7, 86. [Google Scholar] [CrossRef]

- Kausar, A.; Ahmad, I.; Maaza, M.; Eisa, M.; Bocchetta, P. Cutting-Edge Green Polymer/Nanocarbon Nanocomposite for Supercapacitor—State-of-the-Art. J. Compos. Sci. 2022, 6, 376. [Google Scholar] [CrossRef]

- Samir, Z.; Paleo, A.J.; Aribou, N.; Nioua, Y.; da Silva, J.O.; Cerqueira, M.F.; Moreira, J.A.; Achour, M.E. Dielectric Spectroscopy of Melt-Mixed Polypropylene and Pyrolytically Stripped Carbon Nanofiber Composites. J. Compos. Sci. 2022, 6, 368. [Google Scholar] [CrossRef]

- Pathak, A.K.; Yokozeki, T. Recycled Carbon Nanofiber-Polypropylene Nanocomposite: A Step towards Sustainable Structural Material Development. J. Compos. Sci. 2022, 6, 332. [Google Scholar] [CrossRef]

- Alegaonkar, A.P.; Alegaonkar, P.S. Nanocarbons: Preparation, Assessments, and Applications; CRC Press: Boca Raton, FL, USA, 2023. [Google Scholar]

- Kausar, A.; Bocchetta, P. Polymer/graphene nanocomposite membranes: Status and emerging prospects. J. Compos. Sci. 2022, 6, 76. [Google Scholar] [CrossRef]

- Al-Dhahebi, A.M.; Ling, J.; Krishnan, S.G.; Yousefzadeh, M.; Elumalai, N.K.; Saheed, M.S.M.; Ramakrishna, S.; Jose, R. Electrospinning research and products: The road and the way forward. Appl. Phys. Rev. 2022, 9, 011319. [Google Scholar] [CrossRef]

- Zhang, X.; Ru, Z.; Sun, Y.; Zhang, M.; Wang, J.; Ge, M.; Liu, H.; Wu, S.; Cao, C.; Ren, X. Recent advances in applications for air pollutants purification and perspectives of electrospun nanofibers. J. Clean. Prod. 2022, 378, 134567. [Google Scholar] [CrossRef]

- Bulut, U.; Sayin, V.O.; Altin, Y.; Cevher, S.C.; Cirpan, A.; Bedeloglu, A.C.; Soylemez, S. A flexible carbon nanofiber and conjugated polymer-based electrode for glucose sensing. Microchem. J. 2023, 184, 108148. [Google Scholar] [CrossRef]

- Nair, A.B.; Shamsudeen, S.P.; Joys, M.; Varghese, N. Future Perspectives of Polymer Supercapacitors for Advanced Energy Storage Applications. In Polymer Nanocomposites in Supercapacitors; CRC Press: Boca Raton, FL, USA, 2023; pp. 237–257. [Google Scholar]

- Kumar, V.; Alam, M.N.; Manikkavel, A.; Song, M.; Lee, D.-J.; Park, S.-S. Silicone rubber composites reinforced by carbon nanofillers and their hybrids for various applications: A review. Polymers 2021, 13, 2322. [Google Scholar] [CrossRef]

- Alatawna, A.; Birenboim, M.; Nadiv, R.; Buzaglo, M.; Peretz-Damari, S.; Peled, A.; Regev, O.; Sripada, R. The effect of compatibility and dimensionality of carbon nanofillers on cement composites. Constr. Build. Mater. 2020, 232, 117141. [Google Scholar] [CrossRef]

- Kausar, A. Nanocarbon in polymeric nanocomposite hydrogel—Design and multi-functional tendencies. Polym.-Plast. Technol. Mater. 2020, 59, 1505–1521. [Google Scholar] [CrossRef]

- Mas, B.; Fernández-Blázquez, J.P.; Duval, J.; Bunyan, H.; Vilatela, J.J. Thermoset curing through Joule heating of nanocarbons for composite manufacture, repair and soldering. Carbon 2013, 63, 523–529. [Google Scholar] [CrossRef]

- Choudhary, V.; Gupta, A. Polymer/carbon nanotube nanocomposites. Carbon Nanotub. Polym. Nanocomposites 2011, 2011, 65–90. [Google Scholar]

- Chu, C.-C.; White, K.L.; Liu, P.; Zhang, X.; Sue, H.-J. Electrical conductivity and thermal stability of polypropylene containing well-dispersed multi-walled carbon nanotubes disentangled with exfoliated nanoplatelets. Carbon 2012, 50, 4711–4721. [Google Scholar] [CrossRef]

- Al-Osaimi, J.; Alhosiny, N.; Badawi, A.; Abdallah, S. The effects of CNTs types on the structural and electrical properties of CNTs/PMMA nanocomposite films. Int. J. Eng. Technol. 2013, 13, 77–79. [Google Scholar]

- Nam, I.; Lee, H.-K.; Jang, J. Electromagnetic interference shielding/absorbing characteristics of CNT-embedded epoxy composites. Compos. Part A Appl. Sci. Manuf. 2011, 42, 1110–1118. [Google Scholar] [CrossRef]

- Guadagno, L.; Raimondo, M.; Vittoria, V.; Vertuccio, L.; Naddeo, C.; Russo, S.; De Vivo, B.; Lamberti, P.; Spinelli, G.; Tucci, V. Development of epoxy mixtures for application in aeronautics and aerospace. RSC Adv. 2014, 4, 15474–15488. [Google Scholar] [CrossRef]

- Amr, I.T.; Al-Amer, A.; Thomas, S.P.; Sougrat, R.; Atieh, M.A. Mechanical, rheological and thermal properties of polystyrene/1-octadecanol modified carbon nanotubes nanocomposites. Fuller. Nanotub. Carbon Nanostructures 2015, 23, 209–217. [Google Scholar] [CrossRef]

- Patton, S.T.; Frasca, A.J.; Hu, J.; Varshney, V.; Phillips, B.S.; Roy, A.K.; Voevodin, A.A. Multiphysics characterization of multi-walled carbon nanotube thermoplastic polyurethane polymer nanocomposites during compression. Carbon 2016, 98, 638–648. [Google Scholar] [CrossRef]

- Khan, N.I.; Halder, S.; Das, S.; Goyat, M.S. Graphitic nanoparticles functionalized with epoxy moiety for enhancing the mechanical performance of hybrid carbon fiber reinforced polymer laminated composites. Polym. Compos. 2021, 42, 678–692. [Google Scholar] [CrossRef]

- Khare, K.S.; Khabaz, F.; Khare, R. Effect of carbon nanotube functionalization on mechanical and thermal properties of cross-linked epoxy–carbon nanotube nanocomposites: Role of strengthening the interfacial interactions. ACS Appl. Mater. Interfaces 2014, 6, 6098–6110. [Google Scholar] [CrossRef] [PubMed]

- Cui, J.; Zhou, S. Facile fabrication of highly conductive polystyrene/nanocarbon composites with robust interconnected network via electrostatic attraction strategy. J. Mater. Chem. C 2018, 6, 550–557. [Google Scholar] [CrossRef]

- Lee, S.; Suh, D.; Kim, W.; Xu, C.; Kim, T.; Song, C.; Yoo, C.; Kim, Y.; Kim, J.; Baik, S. Carbon nanotube covalent bonding mediates extraordinary electron and phonon transports in soft epoxy matrix interface materials. Carbon 2020, 157, 12–21. [Google Scholar] [CrossRef]

- Guo, Y.; Ruan, K.; Shi, X.; Yang, X.; Gu, J. Factors affecting thermal conductivities of the polymers and polymer composites: A review. Compos. Sci. Technol. 2020, 193, 108134. [Google Scholar] [CrossRef]

- Xu, X.; Lv, H.; Zhang, M.; Wang, M.; Zhou, Y.; Liu, Y.; Yu, D.-G. Recent progress in electrospun nanofibers and their applications in heavy metal wastewater treatment. Front. Chem. Sci. Eng. 2023, 17, 249–275. [Google Scholar] [CrossRef]

- Maliszewska, I.; Czapka, T. Electrospun Polymer Nanofibers with Antimicrobial Activity. Polymers 2022, 14, 1661. [Google Scholar] [CrossRef]

- Ibrahim, H.M.; Klingner, A. A review on electrospun polymeric nanofibers: Production parameters and potential applications. Polym. Test. 2020, 90, 106647. [Google Scholar] [CrossRef]

- Shinde, S.S.; Kher, J.A. A review on polyaniline and its noble metal composites. Int. J. Innov. Res. Sci. Eng. Technol. 2014, 3, 16570–16576. [Google Scholar] [CrossRef]

- Aliheidari, N.; Aliahmad, N.; Agarwal, M.; Dalir, H. Electrospun Nanofibers for Label-Free Sensor Applications. Sensors 2019, 19, 3587. [Google Scholar] [CrossRef]

- Zhao, G.; Shi, L.; Yang, G.; Zhuang, X.; Cheng, B. 3D fibrous aerogels from 1D polymer nanofibers for energy and environmental applications. J. Mater. Chem. A 2023, 11, 512–547. [Google Scholar] [CrossRef]

- Chaudhari, S.; Sharma, Y.; Archana, P.S.; Jose, R.; Ramakrishna, S.; Mhaisalkar, S.; Srinivasan, M. Electrospun polyaniline nanofibers web electrodes for supercapacitors. J. Appl. Polym. Sci. 2013, 129, 1660–1668. [Google Scholar] [CrossRef]

- Mittal, V. Synthesis Techniques for Polymer Nanocomposites; John Wiley & Sons: Hoboken, NJ, USA, 2015. [Google Scholar]

- Sacco, L.N.; Vollebregt, S. Overview of Engineering Carbon Nanomaterials such as Carbon Nanotubes (CNTs), Carbon Nanofibers (CNFs), Graphene and Nanodiamonds and Other Carbon Allotropes inside Porous Anodic Alumina (PAA) Templates. Nanomaterials 2023, 13, 260. [Google Scholar] [CrossRef]

- Wang, C.; Wang, J.; Zeng, L.; Qiao, Z.; Liu, X.; Liu, H.; Zhang, J.; Ding, J. Fabrication of electrospun polymer nanofibers with diverse morphologies. Molecules 2019, 24, 834. [Google Scholar] [CrossRef]

- Ganguly, S. Preparation/processing of polymer-graphene composites by different techniques. In Polymer Nanocomposites Containing Graphene; Elsevier: Amsterdam, The Netherlands, 2022; pp. 45–74. [Google Scholar]

- Nemati, S.; Kim, S.-J.; Shin, Y.M.; Shin, H. Current progress in application of polymeric nanofibers to tissue engineering. Nano Converg. 2019, 6, 36. [Google Scholar] [CrossRef] [PubMed]

- Jeong, K.; Kim, D.H.; Chung, Y.S.; Hwang, S.K.; Hwang, H.Y.; Kim, S.S. Effect of processing parameters of the continuous wet spinning system on the crystal phase of PVDF fibers. J. Appl. Polym. Sci. 2018, 135, 45712. [Google Scholar] [CrossRef]

- Huang, T.; Marshall, L.R.; Armantrout, J.E.; Yembrick, S.; Dunn, W.H.; Oconnor, J.M.; Mueller, T.; Avgousti, M.; Wetzel, M.D. Production of Nanofibers by Melt Spinning. US8277711B2, 2 October 2012. [Google Scholar]

- Liu, R.; Xu, X.; Zhuang, X.; Cheng, B. Solution blowing of chitosan/PVA hydrogel nanofiber mats. Carbohydr. Polym. 2014, 101, 1116–1121. [Google Scholar] [CrossRef] [PubMed]

- Oliveira, J.E.; Mattoso, L.H.; Orts, W.J.; Medeiros, E.S. Structural and morphological characterization of micro and nanofibers produced by electrospinning and solution blow spinning: A comparative study. Adv. Mater. Sci. Eng. 2013, 2013, 409572. [Google Scholar] [CrossRef]

- Marjuban, S.M.H.; Rahman, M.; Duza, S.S.; Ahmed, M.B.; Patel, D.K.; Rahman, M.S.; Lozano, K. Recent Advances in Centrifugal Spinning and Their Applications in Tissue Engineering. Polymers 2023, 15, 1253. [Google Scholar] [CrossRef] [PubMed]

- Alsharif, A.M. Power law liquid jets’ trajectories and instability during centrifugal spinning. Alex. Eng. J. 2023, 68, 301–314. [Google Scholar] [CrossRef]

- Duan, Y.; Ding, Y.; Xu, Z.; Huang, Y.; Yin, Z. Helix electrohydrodynamic printing of highly aligned serpentine micro/nanofibers. Polymers 2017, 9, 434. [Google Scholar] [CrossRef]

- Zhang, Z.; He, H.; Fu, W.; Ji, D.; Ramakrishna, S. Electro-hydrodynamic direct-writing technology toward patterned ultra-thin fibers: Advances, materials and applications. Nano Today 2020, 35, 100942. [Google Scholar] [CrossRef]

- Yin, Z.; Huang, Y.; Duan, Y.; Zhang, H. Electrohydrodynamic Direct-Writing for Flexible Electronic Manufacturing; Springer: Berlin/Heidelberg, Germany, 2018. [Google Scholar]

- Mahmoudi, N.; Simchi, A. On the biological performance of graphene oxide-modified chitosan/polyvinyl pyrrolidone nanocomposite membranes: In vitro and in vivo effects of graphene oxide. Mater. Sci. Eng. C 2017, 70, 121–131. [Google Scholar] [CrossRef] [PubMed]

- Luraghi, A.; Peri, F.; Moroni, L. Electrospinning for drug delivery applications: A review. J. Control. Release 2021, 334, 463–484. [Google Scholar] [CrossRef]

- Yadav, T.C.; Srivastava, A.K.; Mishra, P.; Singh, D.; Raghuwanshi, N.; Singh, N.K.; Singh, A.K.; Tiwari, S.K.; Prasad, R.; Pruthi, V. Electrospinning: An efficient biopolymer-based micro-and nanofibers fabrication technique. In Next Generation Biomanufacturing Technologies; ACS Publications: Washington, DC, USA, 2019; pp. 209–241. [Google Scholar]

- Yu, D.-G.; Li, Q.; Song, W.; Xu, L.; Zhang, K.; Zhou, T. Advanced technique-based combination of innovation education and safety education in higher education. J. Chem. Educ. 2023, 100, 507–516. [Google Scholar] [CrossRef]

- Hosseini Ravandi, S.A.; Sadrjahani, M.; Valipouri, A.; Dabirian, F.; Ko, F.K. Recently developed electrospinning methods: A review. Text. Res. J. 2022, 92, 5130–5145. [Google Scholar] [CrossRef]

- Liu, Y.; Hao, M.; Zhou, C.; Yang, B.; Jiang, S.; Huang, J.; Chen, Z.; Liu, Y.; Ramakrishna, S. Scale-up strategies for electrospun nanofiber production. In Electrospun and Nanofibrous Membranes; Elsevier: Amsterdam, The Netherlands, 2023; pp. 205–266. [Google Scholar]

- Jiang, J.; Liu, Y.; Chen, J.; Wang, X.; Yu, Z.; Li, W.; Zheng, G. In-situ molding of micro three-dimensional columnar structure by electric-field-focused electrospinning. Mater. Today Commun. 2023, 35, 105589. [Google Scholar] [CrossRef]

- Yoon, J.; Yang, H.S.; Lee, B.S.; Yu, W.R. Recent progress in coaxial electrospinning: New parameters, various structures, and wide applications. Adv. Mater. 2018, 30, 1704765. [Google Scholar] [CrossRef]

- Reise, M.; Kranz, S.; Guellmar, A.; Wyrwa, R.; Rosenbaum, T.; Weisser, J.; Jurke, A.; Schnabelrauch, M.; Heyder, M.; Watts, D.C. Coaxial electrospun nanofibers as drug delivery system for local treatment of periodontitis. Dent. Mater. 2023, 39, 132–139. [Google Scholar] [CrossRef]

- Mostofizadeh, M.; Pitcher, M.L.; Sheikhi, A. Coaxial electrospinning. In Electrospun and Nanofibrous Membranes; Elsevier: Amsterdam, The Netherlands, 2023; pp. 105–126. [Google Scholar]

- Lee, B.-S.; Park, K.-M.; Yu, W.-R.; Youk, J.H. An effective method for manufacturing hollow carbon nanofibers and microstructural analysis. Macromol. Res. 2012, 20, 605–613. [Google Scholar] [CrossRef]

- Khalf, A.; Singarapu, K.; Madihally, S.V. Cellulose acetate core–shell structured electrospun fiber: Fabrication and characterization. Cellulose 2015, 22, 1389–1400. [Google Scholar] [CrossRef]

- McClellan, P.; Landis, W.J. Recent applications of coaxial and emulsion electrospinning methods in the field of tissue engineering. BioResearch Open Access 2016, 5, 212–227. [Google Scholar] [CrossRef] [PubMed]

- Klabukov, I.; Balyasin, M.; Krasilnikova, O.; Tenchurin, T.; Titov, A.; Krasheninnikov, M.; Mudryak, D.; Sulina, Y.; Shepelev, A.; Chvalun, S. Angiogenic Modification of Microfibrous Polycaprolactone by pCMV-VEGF165 Plasmid Promotes Local Vascular Growth after Implantation in Rats. Int. J. Mol. Sci. 2023, 24, 1399. [Google Scholar] [CrossRef] [PubMed]

- Tan, N.P.; Cabatingan, L.K.; Lim, K.J.A. Synthesis of TiO2 nanofiber by solution blow spinning (SBS) method. In Book Synthesis of TiO2 Nanofiber by Solution Blow Spinning (SBS) Method; Trans Tech Publications: Zurich, Switzerland, 2020; pp. 122–128. [Google Scholar]

- Sinha-Ray, S.; Sinha-Ray, S.; Yarin, A.L.; Pourdeyhimi, B. Theoretical and experimental investigation of physical mechanisms responsible for polymer nanofiber formation in solution blowing. Polymer 2015, 56, 452–463. [Google Scholar] [CrossRef]

- Medeiros, E.S.; Glenn, G.M.; Klamczynski, A.P.; Orts, W.J.; Mattoso, L.H. Solution blow spinning: A new method to produce micro and nanofibers from polymer solutions. J. Appl. Polym. Sci. 2009, 113, 2322–2330. [Google Scholar] [CrossRef]

- Xu, H.; Yagi, S.; Ashour, S.; Du, L.; Hoque, M.E.; Tan, L. A Review on Current Nanofiber Technologies: Electrospinning, Centrifugal Spinning, and Electro—Centrifugal Spinning. Macromol. Mater. Eng. 2023, 308, 2200502. [Google Scholar] [CrossRef]

- Ren, L.; Kotha, S.P. Centrifugal jet spinning for highly efficient and large-scale fabrication of barium titanate nanofibers. Mater. Lett. 2014, 117, 153–157. [Google Scholar] [CrossRef]

- Huang, Y.; Duan, Y.; Ding, Y.; Bu, N.; Pan, Y.; Lu, N.; Yin, Z. Versatile, kinetically controlled, high precision electrohydrodynamic writing of micro/nanofibers. Sci. Rep. 2014, 4, 5949. [Google Scholar] [CrossRef]

- He, X.; Gu, J.; Hao, Y.; Zheng, M.; Wang, L.; Yu, J.; Qin, X. Continuous manufacture of stretchable and integratable thermoelectric nanofiber yarn for human body energy harvesting and self-powered motion detection. Chem. Eng. J. 2022, 450, 137937. [Google Scholar] [CrossRef]

- Miyazawa, K.I. Synthesis and properties of fullerene nanowhiskers and fullerene nanotubes. J. Nanosci. Nanotechnol. 2009, 9, 41–50. [Google Scholar] [CrossRef]

- Yang, Y.; Juríček, M. Fullerene wires assembled inside carbon nanohoops. ChemPlusChem 2022, 87, e202100468. [Google Scholar] [CrossRef]

- Jamieson, F.C.; Domingo, E.B.; McCarthy-Ward, T.; Heeney, M.; Stingelin, N.; Durrant, J.R. Fullerene crystallisation as a key driver of charge separation in polymer/fullerene bulk heterojunction solar cells. Chem. Sci. 2012, 3, 485–492. [Google Scholar] [CrossRef]

- Insuasty, A.; Atienza, C.; López, J.L.; Martín, N. Supramolecular pentapeptide-based fullerene nanofibers: Effect of molecular chirality. Chem. Commun. 2015, 51, 10506–10509. [Google Scholar] [CrossRef] [PubMed]

- Kausar, A.; Ahmad, I.; Maaza, M.; Eisa, M.; Bocchetta, P. Polymer/Fullerene Nanocomposite for Optoelectronics—Moving toward Green Technology. J. Compos. Sci. 2022, 6, 393. [Google Scholar] [CrossRef]

- Kang, J.; Qin, K.; Zhang, H.; Hirata, A.; Wang, J.; Chen, M.; Zhao, N.; Sun, R.; Fujita, T.; Shi, C. Direct synthesis of fullerene-intercalated porous carbon nanofibers by chemical vapor deposition. Carbon 2012, 50, 5162–5166. [Google Scholar] [CrossRef]

- Pierini, F.; Lanzi, M.; Nakielski, P.; Pawłowska, S.; Urbanek, O.; Zembrzycki, K.; Kowalewski, T.A. Single-material organic solar cells based on electrospun fullerene-grafted polythiophene nanofibers. Macromolecules 2017, 50, 4972–4981. [Google Scholar] [CrossRef]

- Solanki, A.; Wu, B.; Salim, T.; Yeow, E.K.L.; Lam, Y.M.; Sum, T.C. Performance improvements in polymer nanofiber/fullerene solar cells with external electric field treatment. J. Phys. Chem. C 2014, 118, 11285–11291. [Google Scholar] [CrossRef]

- Jiang, Z.; Zhang, H.; Zhang, Z.; Murayama, H.; Okamoto, K. Improved bonding between PAN-based carbon fibers and fullerene-modified epoxy matrix. Compos. Part A Appl. Sci. Manuf. 2008, 39, 1762–1767. [Google Scholar] [CrossRef]

- Zhang, F.; Yang, K.; Liu, G.; Chen, Y.; Wang, M.; Li, S.; Li, R. Recent Advances on Graphene: Synthesis, Properties, and Applications. Compos. Part A Appl. Sci. Manuf. 2022, 160, 107051. [Google Scholar] [CrossRef]

- Chen, L.; Shen, Y.; Liu, Z.; Song, Q.; Jiang, Y. Experimental and modeling investigation on thermodynamic effect of graphene doped shape memory epoxy composites. Polymer 2022, 239, 124430. [Google Scholar] [CrossRef]

- Saud, S.N.; Bakhsheshi-Rad, H.; Yaghoubidoust, F.; Iqbal, N.; Hamzah, E.; Ooi, C.R. Corrosion and bioactivity performance of graphene oxide coating on TiNb shape memory alloys in simulated body fluid. Mater. Sci. Eng. C 2016, 68, 687–694. [Google Scholar] [CrossRef]

- Zhuang, Y.; Cao, X.; Zhang, J.; Ma, Y.; Shang, X.; Lu, J.; Yang, S.; Zheng, K.; Ma, Y. Monomer casting nylon/graphene nanocomposite with both improved thermal conductivity and mechanical performance. Compos. Part A Appl. Sci. Manuf. 2019, 120, 49–55. [Google Scholar] [CrossRef]

- Lee, J.-G.; Kim, D.-Y.; Mali, M.G.; Al-Deyab, S.S.; Swihart, M.T.; Yoon, S.S. Supersonically blown nylon-6 nanofibers entangled with graphene flakes for water purification. Nanoscale 2015, 7, 19027–19035. [Google Scholar] [CrossRef] [PubMed]

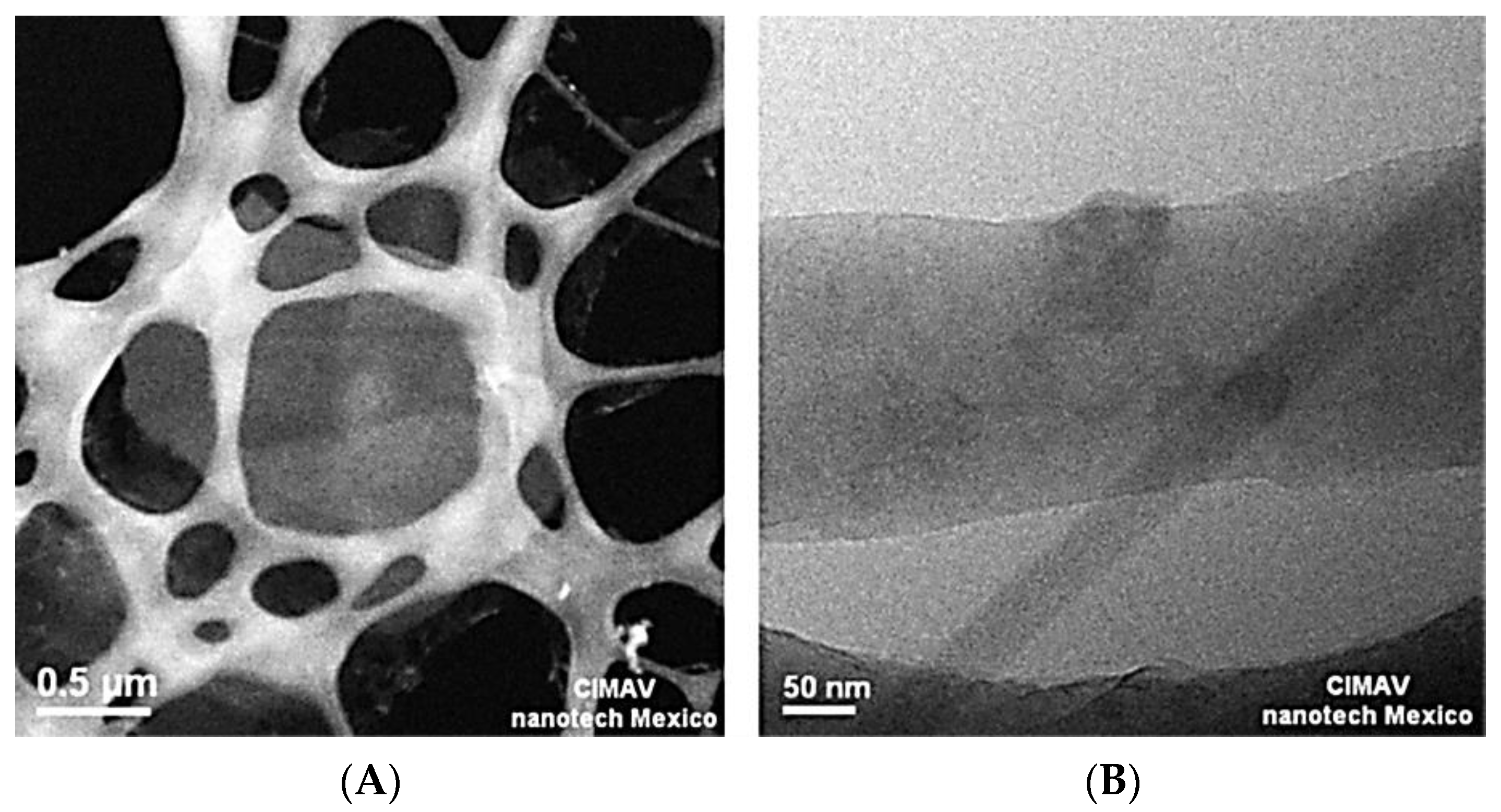

- Leyva-Porras, C.; Ornelas-Gutiérrez, C.; Miki-Yoshida, M.; Avila-Vega, Y.I.; Macossay, J.; Bonilla-Cruz, J. EELS analysis of Nylon 6 nanofibers reinforced with nitroxide-functionalized graphene oxide. Carbon 2014, 70, 164–172. [Google Scholar] [CrossRef]

- Maccaferri, E.; Mazzocchetti, L.; Benelli, T.; Zucchelli, A.; Giorgini, L. Morphology, thermal, mechanical properties and ageing of nylon 6, 6/graphene nanofibers as Nano2 materials. Compos. Part B Eng. 2019, 166, 120–129. [Google Scholar] [CrossRef]

- Weise, B.A.; Wirth, K.G.; Völkel, L.; Morgenstern, M.; Seide, G. Pilot-scale fabrication and analysis of graphene-nanocomposite fibers. Carbon 2019, 144, 351–361. [Google Scholar] [CrossRef]

- Afzal, H.M.; Shehzad, F.; Zubair, M.; Bakather, O.Y.; Al-Harthi, M.A. Influence of microwave irradiation on thermal properties of PVA and PVA/graphene nanocomposites. J. Therm. Anal. Calorim. 2020, 139, 353–365. [Google Scholar] [CrossRef]

- Bao, Q.; Zhang, H.; Yang, J.X.; Wang, S.; Tang, D.Y.; Jose, R.; Ramakrishna, S.; Lim, C.T.; Loh, K.P. Graphene–polymer nanofiber membrane for ultrafast photonics. Adv. Funct. Mater. 2010, 20, 782–791. [Google Scholar] [CrossRef]

- Abdah, M.A.A.M.; Zubair, N.A.; Azman, N.H.N.; Sulaiman, Y. Fabrication of PEDOT coated PVA-GO nanofiber for supercapacitor. Mater. Chem. Phys. 2017, 192, 161–169. [Google Scholar] [CrossRef]

- Barzegar, F.; Bello, A.; Fabiane, M.; Khamlich, S.; Momodu, D.; Taghizadeh, F.; Dangbegnon, J.; Manyala, N. Preparation and characterization of poly (vinyl alcohol)/graphene nanofibers synthesized by electrospinning. J. Phys. Chem. Solids 2015, 77, 139–145. [Google Scholar] [CrossRef]

- Dong, X.; Hu, M.; He, J.; Tian, Y.; Wang, H.-T. A new phase from compression of carbon nanotubes with anisotropic Dirac fermions. Sci. Rep. 2015, 5, 10713. [Google Scholar] [CrossRef]

- Iijima, S. Helical microtubules of graphitic carbon. Nature 1991, 354, 56–58. [Google Scholar] [CrossRef]

- Palser, A.H. Interlayer interactions in graphite and carbon nanotubes. Phys. Chem. Chem. Phys. 1999, 1, 4459–4464. [Google Scholar] [CrossRef]

- Liu, W.-W.; Chai, S.-P.; Mohamed, A.R.; Hashim, U. Synthesis and characterization of graphene and carbon nanotubes: A review on the past and recent developments. J. Ind. Eng. Chem. 2014, 20, 1171–1185. [Google Scholar] [CrossRef]

- Gupta, C.; Maheshwari, P.H.; Dhakate, S.R. Development of multiwalled carbon nanotubes platinum nanocomposite as efficient PEM fuel cell catalyst. Mater. Renew. Sustain. Energy 2016, 5, 2. [Google Scholar] [CrossRef]

- Fajardo-Diaz, J.L.; Morelos-Gomez, A.; Cruz-Silva, R.; Ishii, K.; Yasuike, T.; Kawakatsu, T.; Yamanaka, A.; Tejima, S.; Izu, K.; Saito, S. Low-pressure reverse osmosis membrane made of cellulose nanofiber and carbon nanotube polyamide nano-nanocomposite for high purity water production. Chem. Eng. J. 2022, 448, 137359. [Google Scholar] [CrossRef]

- Amer Flayeh, A.; Jawad Kadhim, H. Enhancing the physical properties of polystyrene nanofibers by adding multiwall carbon nanotubes and natural dye. Fuller. Nanotub. Carbon Nanostructures 2022, 30, 1090–1096. [Google Scholar] [CrossRef]

- Arjmandi, S.K.; Khademzadeh Yeganeh, J.; Zare, Y.; Rhee, K.Y. Development of Kovacs model for electrical conductivity of carbon nanofiber–polymer systems. Sci. Rep. 2023, 13, 7. [Google Scholar] [CrossRef]

- Kaynan, O.; Atescan, Y.; Ozden-Yenigun, E.; Cebeci, H. Mixed Mode delamination in carbon nanotube/nanofiber interlayered composites. Compos. Part B Eng. 2018, 154, 186–194. [Google Scholar] [CrossRef]

- Menzel, V.C.; Tudela, I. Additive manufacturing of polyaniline-based materials: An opportunity for new designs and applications in energy and biotechnology. Curr. Opin. Chem. Eng. 2022, 35, 100742. [Google Scholar] [CrossRef]

- Xu, D.; Xu, Q.; Wang, K.; Chen, J.; Chen, Z. Fabrication of free-standing hierarchical carbon nanofiber/graphene oxide/polyaniline films for supercapacitors. ACS Appl. Mater. Interfaces 2014, 6, 200–209. [Google Scholar] [CrossRef]

- Mao, L.; Zhang, K.; Chan, H.S.O.; Wu, J. Surfactant-stabilized graphene/polyaniline nanofiber composites for high performance supercapacitor electrode. J. Mater. Chem. 2012, 22, 80–85. [Google Scholar] [CrossRef]

- Noh, Y.J.; Joh, H.-I.; Yu, J.; Hwang, S.H.; Lee, S.; Lee, C.H.; Kim, S.Y.; Youn, J.R. Ultra-high dispersion of graphene in polymer composite via solvent free fabrication and functionalization. Sci. Rep. 2015, 5, 9141. [Google Scholar] [CrossRef] [PubMed]

- Liao, Y.; Zhang, C.; Zhang, Y.; Strong, V.; Tang, J.; Li, X.-G.; Kalantar-Zadeh, K.; Hoek, E.M.; Wang, K.L.; Kaner, R.B. Carbon nanotube/polyaniline composite nanofibers: Facile synthesis and chemosensors. Nano Lett. 2011, 11, 954–959. [Google Scholar] [CrossRef]

- Cheng, J.; Pu, H.; Du, J. A processing method with high efficiency for low density polyethylene nanofibers reinforced by aligned carbon nanotubes via nanolayer coextrusion. Polymer 2017, 111, 222–228. [Google Scholar] [CrossRef]

- Qiu, Q.; Chen, S.; Li, Y.; Yang, Y.; Zhang, H.; Quan, Z.; Qin, X.; Wang, R.; Yu, J. Functional nanofibers embedded into textiles for durable antibacterial properties. Chem. Eng. J. 2020, 384, 123241. [Google Scholar] [CrossRef]

- Pillai, R.R.; Thomas, V. Plasma Surface Engineering of Natural and Sustainable Polymeric Derivatives and Their Potential Applications. Polymers 2023, 15, 400. [Google Scholar] [CrossRef]

- Barzoki, P.K.; Latifi, M.; Rezadoust, A. The outstanding effect of nanomat geometry on the interlaminar fracture toughness behavior out of autoclave made glass/phenolic composites under mode-I loading. Eng. Fract. Mech. 2019, 205, 108–119. [Google Scholar] [CrossRef]

- Chung, J.; Kwak, S.-Y. Solvent-assisted heat treatment for enhanced chemical stability and mechanical strength of meta-aramid nanofibers. Eur. Polym. J. 2018, 107, 46–53. [Google Scholar] [CrossRef]

- Kumar, T.S.M.; Kumar, K.S.; Rajini, N.; Siengchin, S.; Ayrilmis, N.; Rajulu, A.V. A comprehensive review of electrospun nanofibers: Food and packaging perspective. Compos. Part B Eng. 2019, 175, 107074. [Google Scholar] [CrossRef]

- Akampumuza, O.; Gao, H.; Zhang, H.; Wu, D.; Qin, X.H. Raising nanofiber output: The progress, mechanisms, challenges, and reasons for the pursuit. Macromol. Mater. Eng. 2018, 303, 1700269. [Google Scholar] [CrossRef]

- Navaratnam, S.; Selvaranjan, K.; Jayasooriya, D.; Rajeev, P.; Sanjayan, J. Applications of natural and synthetic fiber reinforced polymer in infrastructure: A suitability assessment. J. Build. Eng. 2023, 66, 105835. [Google Scholar] [CrossRef]

- Adapa, S.K. Prospects of Natural Fiber-Reinforced Polymer Composites for Additive Manufacturing Applications: A Review. JOM 2023, 75, 920–940. [Google Scholar] [CrossRef]

- Kasgoz, A.; Akın, D.; Ayten, A.I.; Durmus, A. Effect of different types of carbon fillers on mechanical and rheological properties of cyclic olefin copolymer (COC) composites. Compos. Part B Eng. 2014, 66, 126–135. [Google Scholar] [CrossRef]

- Chen, J.; Gao, X.; Song, W. Effect of various carbon nanofillers and different filler aspect ratios on the thermal conductivity of epoxy matrix nanocomposites. Results Phys. 2019, 15, 102771. [Google Scholar] [CrossRef]

- Wypych, G. Functional Fillers: Chemical Composition, Morphology, Performance, Applications; Elsevier: Amsterdam, The Netherlands, 2023. [Google Scholar]

- Zahmatkeshan, M.; Adel, M.; Bahrami, S.; Esmaeili, F.; Rezayat, S.M.; Saeedi, Y.; Mehravi, B.; Jameie, S.B.; Ashtari, K. Polymer-based nanofibers: Preparation, fabrication, and applications. In Handbook of Nanofibers; Springer: Berlin/Heidelberg, Germany, 2019; pp. 215–261. [Google Scholar]

- Wang, P.; Lv, H.; Cao, X.; Liu, Y.; Yu, D.-G. Recent progress of the preparation and application of electrospun porous nanofibers. Polymers 2023, 15, 921. [Google Scholar] [CrossRef]

- Collins, S.D.; Ran, N.A.; Heiber, M.C.; Nguyen, T.Q. Small is powerful: Recent progress in solution-processed small molecule solar cells. Adv. Energy Mater. 2017, 7, 1602242. [Google Scholar] [CrossRef]

- Su, M.S.; Kuo, C.Y.; Yuan, M.C.; Jeng, U.S.; Su, C.J.; Wei, K.H. Improving device efficiency of polymer/fullerene bulk heterojunction solar cells through enhanced crystallinity and reduced grain boundaries induced by solvent additives. Adv. Mater. 2011, 23, 3315–3319. [Google Scholar] [CrossRef]

- Liao, H.-C.; Ho, C.-C.; Chang, C.-Y.; Jao, M.-H.; Darling, S.B.; Su, W.-F. Additives for morphology control in high-efficiency organic solar cells. Mater. Today 2013, 16, 326–336. [Google Scholar] [CrossRef]

- Moulé, A.J.; Meerholz, K. Controlling morphology in polymer–fullerene mixtures. Adv. Mater. 2008, 20, 240–245. [Google Scholar] [CrossRef]

- Howard, J.B.; Noh, S.; Beier, A.E.; Thompson, B.C. Fine tuning surface energy of poly (3-hexylthiophene) by heteroatom modification of the alkyl side chains. ACS Macro Lett. 2015, 4, 725–730. [Google Scholar] [CrossRef]

- Kurniawan, M.; Salim, T.; Tai, K.F.; Sun, S.; Sie, E.J.; Wu, X.; Yeow, E.K.L.; Huan, C.H.A.; Lam, Y.M.; Sum, T.C. Carrier dynamics in polymer nanofiber: Fullerene solar cells. J. Phys. Chem. C 2012, 116, 18015–18022. [Google Scholar] [CrossRef]

- Larcher, D.; Tarascon, J.-M. Towards greener and more sustainable batteries for electrical energy storage. Nat. Chem. 2015, 7, 19. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Wei, B. Supercapacitors based on nanostructured carbon. Nano Energy 2013, 2, 159–173. [Google Scholar] [CrossRef]

- Szubzda, B.; Szmaja, A.; Ozimek, M.; Mazurkiewicz, S. Polymer membranes as separators for supercapacitors. Appl. Phys. A 2014, 117, 1801–1809. [Google Scholar] [CrossRef]

- Wang, C.; Murugadoss, V.; Kong, J.; He, Z.; Mai, X.; Shao, Q.; Chen, Y.; Guo, L.; Liu, C.; Angaiah, S. Overview of carbon nanostructures and nanocomposites for electromagnetic wave shielding. Carbon 2018, 140, 696–733. [Google Scholar] [CrossRef]

- Yang, Z.; Hao, X.; Chen, S.; Ma, Z.; Wang, W.; Wang, C.; Yue, L.; Sun, H.; Shao, Q.; Murugadoss, V. Long-term antibacterial stable reduced graphene oxide nanocomposites loaded with cuprous oxide nanoparticles. J. Colloid Interface Sci. 2019, 533, 13–23. [Google Scholar] [CrossRef]

- Jiang, D.; Murugadoss, V.; Wang, Y.; Lin, J.; Ding, T.; Wang, Z.; Shao, Q.; Wang, C.; Liu, H.; Lu, N. Electromagnetic interference shielding polymers and nanocomposites-a review. Polym. Rev. 2019, 59, 280–337. [Google Scholar] [CrossRef]

- Shearer, C.J.; Cherevan, A.; Eder, D. Application and future challenges of functional nanocarbon hybrids. Adv. Mater. 2014, 26, 2295–2318. [Google Scholar] [CrossRef]

- Rose, A.; Prasad, K.G.; Sakthivel, T.; Gunasekaran, V.; Maiyalagan, T.; Vijayakumar, T. Electrochemical analysis of graphene oxide/polyaniline/polyvinyl alcohol composite nanofibers for supercapacitor applications. Appl. Surf. Sci. 2018, 449, 551–557. [Google Scholar] [CrossRef]

- Zhou, S.; Zhang, H.; Zhao, Q.; Wang, X.; Li, J.; Wang, F. Graphene-wrapped polyaniline nanofibers as electrode materials for organic supercapacitors. Carbon 2013, 52, 440–450. [Google Scholar] [CrossRef]

- Ehsani, A.; Heidari, A.A.; Shiri, H.M. Electrochemical pseudocapacitors based on ternary nanocomposite of conductive polymer/graphene/metal oxide: An introduction and review to it in recent studies. Chem. Rec. 2019, 19, 908–926. [Google Scholar] [CrossRef]

- Shin, M.K.; Lee, B.; Kim, S.H.; Lee, J.A.; Spinks, G.M.; Gambhir, S.; Wallace, G.G.; Kozlov, M.E.; Baughman, R.H.; Kim, S.J. Synergistic toughening of composite fibres by self-alignment of reduced graphene oxide and carbon nanotubes. Nat. Commun. 2012, 3, 650. [Google Scholar] [CrossRef] [PubMed]

- Kaczor-Urbanowicz, K.E.; Martín Carreras-Presas, C.; Kaczor, T.; Tu, M.; Wei, F.; Garcia—Godoy, F.; Wong, D.T. Emerging technologies for salivaomics in cancer detection. J. Cell. Mol. Med. 2017, 21, 640–647. [Google Scholar] [CrossRef] [PubMed]

- Glyva, V.; Kovalenko, V.; Levchenko, L.; Tykhenko, O. Research into protective properties of electromagnetic screens based on the metal-containing nanostructures. East. Eur. J. Adv. Technol. 2017, 12, 50–56. [Google Scholar] [CrossRef]

- Lu, T.; Gu, H.; Hu, Y.; Zhao, T.; Zhu, P.; Sun, R.; Wong, C.-P. Three Dimensional Copper Foam-Filled Elastic Conductive Composites with Simultaneously Enhanced Mechanical, Electrical, Thermal and Electromagnetic Interference (EMI) Shielding Properties. In Book Three Dimensional Copper Foam-Filled Elastic Conductive Composites with Simultaneously Enhanced Mechanical, Electrical, Thermal and Electromagnetic Interference (EMI) Shielding Properties; IEEE: Las Vegas, NV, USA, 2019; pp. 1916–1920. [Google Scholar]

- Qin, R.; Hu, M.; Zhang, N.; Guo, Z.; Yan, Z.; Li, J.; Liu, J.; Shan, G.; Yang, J. Flexible Fabrication of Flexible Electronics: A General Laser Ablation Strategy for Robust Large-Area Copper-Based Electronics. Adv. Electron. Mater. 2019, 5, 1900365. [Google Scholar] [CrossRef]

- Shahzad, F.; Alhabeb, M.; Hatter, C.B.; Anasori, B.; Hong, S.M.; Koo, C.M.; Gogotsi, Y. Electromagnetic interference shielding with 2D transition metal carbides (MXenes). Science 2016, 353, 1137–1140. [Google Scholar] [CrossRef]

- Ji, H.; Zhao, R.; Zhang, N.; Jin, C.; Lu, X.; Wang, C. Lightweight and flexible electrospun polymer nanofiber/metal nanoparticle hybrid membrane for high-performance electromagnetic interference shielding. NPG Asia Mater. 2018, 10, 749–760. [Google Scholar] [CrossRef]

- Kumar, S.; Purohit, R.; Malik, M. Properties and applications of polymer matrix nano composite materials. Mater. Today Proc. 2015, 2, 3704–3711. [Google Scholar] [CrossRef]

- Liu, F.; Dong, S.; Zhang, Z.; Dai, X.; Xin, Y.; Wang, X.; Liu, K.; Yuan, Z.; Zhang, J.; Chen, M. Polyaniline/MWCNT Nanocomposite as Sensor for Electroanalytical Determination of Phenol in Oil Field Wastewater. Int. J. Electrochem. Sci. 2019, 14, 9122–9131. [Google Scholar] [CrossRef]

- Joseph, N.; Varghese, J.; Sebastian, M.T. A facile formulation and excellent electromagnetic absorption of room temperature curable polyaniline nanofiber based inks. J. Mater. Chem. C 2016, 4, 999–1008. [Google Scholar] [CrossRef]

- Lyu, J.; Zhao, X.; Hou, X.; Zhang, Y.; Li, T.; Yan, Y. Electromagnetic interference shielding based on a high strength polyaniline-aramid nanocomposite. Compos. Sci. Technol. 2017, 149, 159–165. [Google Scholar] [CrossRef]

- Nakagaito, A.N.; Nogi, M.; Yano, H. Displays from transparent films of natural nanofibers. MRS Bull. 2010, 35, 214–218. [Google Scholar] [CrossRef]

- Andrady, A.L. Science and Technology of Polymer Nanofibers; John Wiley & Sons: Hoboken, NJ, USA, 2008. [Google Scholar]

- Mora-Boza, A.; López-Ruiz, E.; López-Donaire, M.L.; Jiménez, G.; Aguilar, M.R.; Marchal, J.A.; Pedraz, J.L.; Vázquez-Lasa, B.; Román, J.S.; Gálvez-Martín, P. Evaluation of Glycerylphytate Crosslinked Semi-and Interpenetrated Polymer Membranes of Hyaluronic Acid and Chitosan for Tissue Engineering. Polymers 2020, 12, 2661. [Google Scholar] [CrossRef]

- Morales-Zamudio, L.; Lozano, T.; Caballero-Briones, F.; Zamudio, M.A.; Angeles-San Martin, M.E.; de Lira-Gomez, P.; Martinez-Colunga, G.; Rodriguez-Gonzalez, F.; Neira, G.; Sanchez-Valdes, S. Structure and Mechanical Properties of Graphene Oxide-Reinforced Polycarbonate. Mater. Chem. Phys. 2020, 261, 124180. [Google Scholar] [CrossRef]

- Bonetti, L.; Fiorati, A.; Serafini, A.; Masotti, G.; Tana, F.; D’Agostino, A.; Draghi, L.; Altomare, L.; Chiesa, R.; Farè, S. Graphene nanoplatelets composite membranes for thermal comfort enhancement in performance textiles. J. Appl. Polym. Sci. 2020, 138, 49645. [Google Scholar] [CrossRef]

- Sierra-Solache, R.; Muro, C.; Maciel, A.; Illescas, J.; Díaz, M.; Carbajal-Franco, G.; Hernández, O. Water recovery from textile wastewater treatment by encapsulated cells of Phanerochaete chrysosporium and ultrafiltration system. Biologia 2020, 75, 1717–1729. [Google Scholar] [CrossRef]

- Othman, F.E.C.; Yusof, N.; Ismail, A.F. Activated-Carbon Nanofibers/Graphene Nanocomposites and Their Adsorption Performance Towards Carbon Dioxide. Chem. Eng. Technol. 2020, 43, 2023–2030. [Google Scholar] [CrossRef]

- Boroojeni, F.R.; Mashayekhan, S.; Abbaszadeh, H.-A.; Ansarizadeh, M.; Khoramgah, M.-S.; Movaghar, V.R. Bioinspired Nanofiber Scaffold for Differentiating Bone Marrow-Derived Neural Stem Cells to Oligodendrocyte-Like Cells: Design, Fabrication, and Characterization. Int. J. Nanomed. 2020, 15, 3903–3920. [Google Scholar] [CrossRef]

- Pinto, A.M.; Cabral, J.; Tanaka, D.A.P.; Mendes, A.M.; Magalhães, F.D. Effect of incorporation of graphene oxide and graphene nanoplatelets on mechanical and gas permeability properties of poly (lactic acid) films. Polym. Int. 2013, 62, 33–40. [Google Scholar] [CrossRef]

- Ferrari, A.C.; Bonaccorso, F.; Fal’Ko, V.; Novoselov, K.S.; Roche, S.; Bøggild, P.; Borini, S.; Koppens, F.H.; Palermo, V.; Pugno, N. Science and technology roadmap for graphene, related two-dimensional crystals, and hybrid systems. Nanoscale 2015, 7, 4598–4810. [Google Scholar] [CrossRef]

- Loukelis, K.; Helal, Z.A.; Mikos, A.G.; Chatzinikolaidou, M. Nanocomposite Bioprinting for Tissue Engineering Applications. Gels 2023, 9, 103. [Google Scholar] [CrossRef] [PubMed]

- Asadi, N.; Del Bakhshayesh, A.R.; Sadeghzadeh, H.; Asl, A.N.; Kaamyabi, S.; Akbarzadeh, A. Nanocomposite electrospun scaffold based on polyurethane/polycaprolactone incorporating gold nanoparticles and soybean oil for tissue engineering applications. J. Bionic Eng. 2023, 20, 1712–1722. [Google Scholar] [CrossRef]

- Goenka, S.; Sant, V.; Sant, S. Graphene-based nanomaterials for drug delivery and tissue engineering. J. Control. Release 2014, 173, 75–88. [Google Scholar] [CrossRef] [PubMed]

- Ali, E.A.; Abo-Salem, H.M.; Arafa, A.A.; Nada, A.A. Chitosan Schiff base electrospun fabrication and molecular docking assessment for nonleaching antibacterial nanocomposite production. Cellulose 2023, 30, 3505–3522. [Google Scholar] [CrossRef]

- Li, Y.; Chen, Y.; Wu, Q.; Huang, J.; Zhao, Y.; Li, Q.; Wang, S. Improved Hydrophobic, UV Barrier and Antibacterial Properties of Multifunctional PVA Nanocomposite Films Reinforced with Modified Lignin Contained Cellulose Nanofibers. Polymers 2022, 14, 1705. [Google Scholar] [CrossRef]

- Suja, P.; Reshmi, C.; Sagitha, P.; Sujith, A. Electrospun nanofibrous membranes for water purification. Polym. Rev. 2017, 57, 467–504. [Google Scholar] [CrossRef]

- Zhao, K.; Tian, X.; Xing, J.; Huang, N.; Zhang, H.; Zhao, H.; Wang, W. Tunable mechanical behavior of collagen-based films: A comparison of celluloses in different geometries. Int. J. Biol. Macromol. 2022, 214, 120–127. [Google Scholar] [CrossRef]

- Lee, J.B.; Jeong, S.I.; Bae, M.S.; Yang, D.H.; Heo, D.N.; Kim, C.H.; Alsberg, E.; Kwon, I.K. Highly porous electrospun nanofibers enhanced by ultrasonication for improved cellular infiltration. Tissue Eng. Part A 2011, 17, 2695–2702. [Google Scholar] [CrossRef]

- Menazea, A.; Ahmed, M. Wound healing activity of Chitosan/Polyvinyl Alcohol embedded by gold nanoparticles prepared by nanosecond laser ablation. J. Mol. Struct. 2020, 1217, 128401. [Google Scholar] [CrossRef]

- Mostafa, M.; Kandile, N.G.; Mahmoud, M.K.; Ibrahim, H.M. Synthesis and characterization of polystyrene with embedded silver nanoparticle nanofibers to utilize as antibacterial and wound healing biomaterial. Heliyon 2022, 8, e08772. [Google Scholar] [CrossRef]

- Min, T.; Zhou, L.; Sun, X.; Du, H.; Zhu, Z.; Wen, Y. Electrospun functional polymeric nanofibers for active food packaging: A review. Food Chem. 2022, 391, 133239. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kausar, A.; Ahmad, I. Electrospinning Processing of Polymer/Nanocarbon Nanocomposite Nanofibers—Design, Features, and Technical Compliances. J. Compos. Sci. 2023, 7, 290. https://doi.org/10.3390/jcs7070290

Kausar A, Ahmad I. Electrospinning Processing of Polymer/Nanocarbon Nanocomposite Nanofibers—Design, Features, and Technical Compliances. Journal of Composites Science. 2023; 7(7):290. https://doi.org/10.3390/jcs7070290

Chicago/Turabian StyleKausar, Ayesha, and Ishaq Ahmad. 2023. "Electrospinning Processing of Polymer/Nanocarbon Nanocomposite Nanofibers—Design, Features, and Technical Compliances" Journal of Composites Science 7, no. 7: 290. https://doi.org/10.3390/jcs7070290

APA StyleKausar, A., & Ahmad, I. (2023). Electrospinning Processing of Polymer/Nanocarbon Nanocomposite Nanofibers—Design, Features, and Technical Compliances. Journal of Composites Science, 7(7), 290. https://doi.org/10.3390/jcs7070290