Research on the Production of Pigments Based on Composite Pellets in the Recycling of Industrial Waste

Abstract

1. Introduction

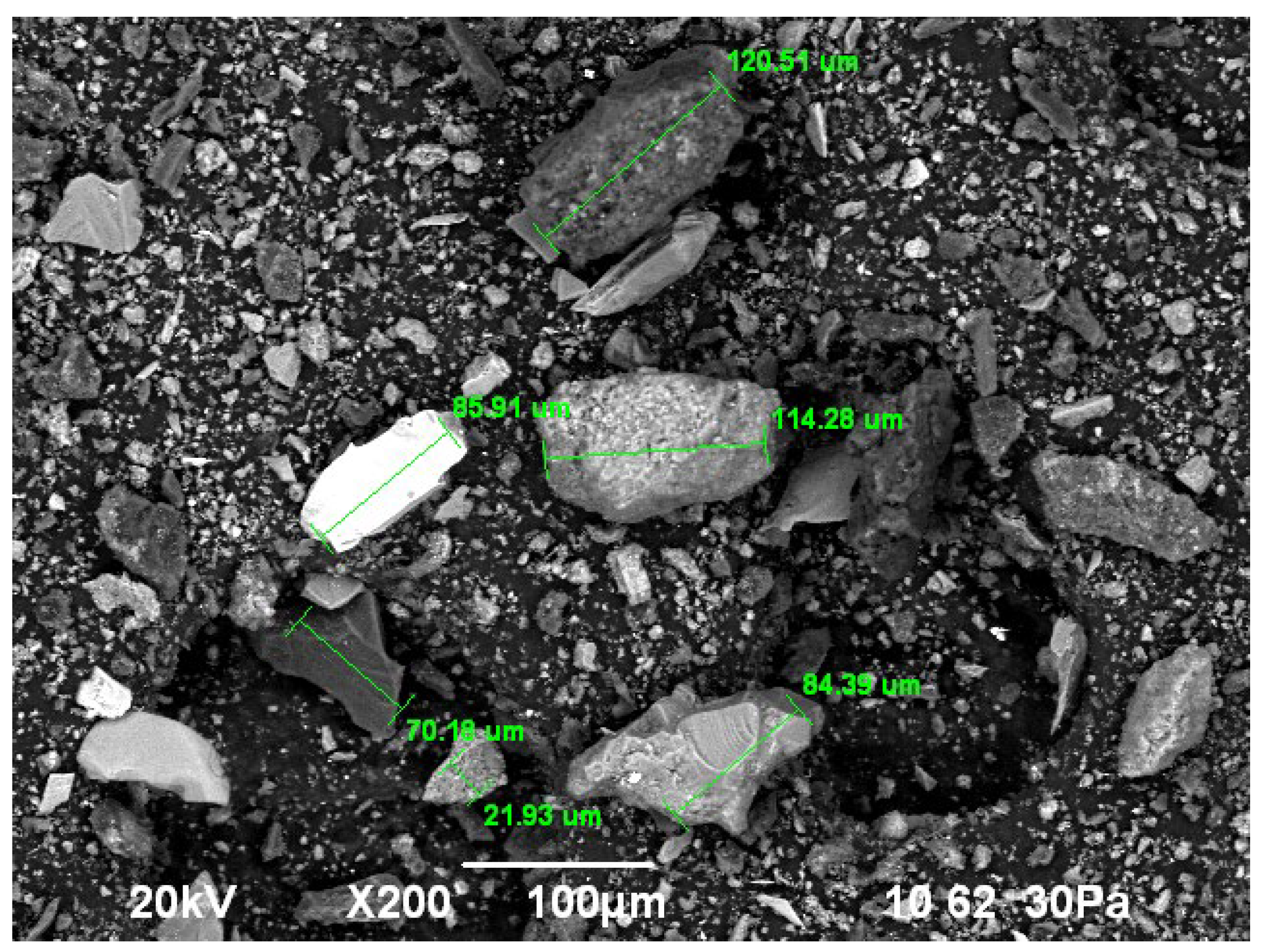

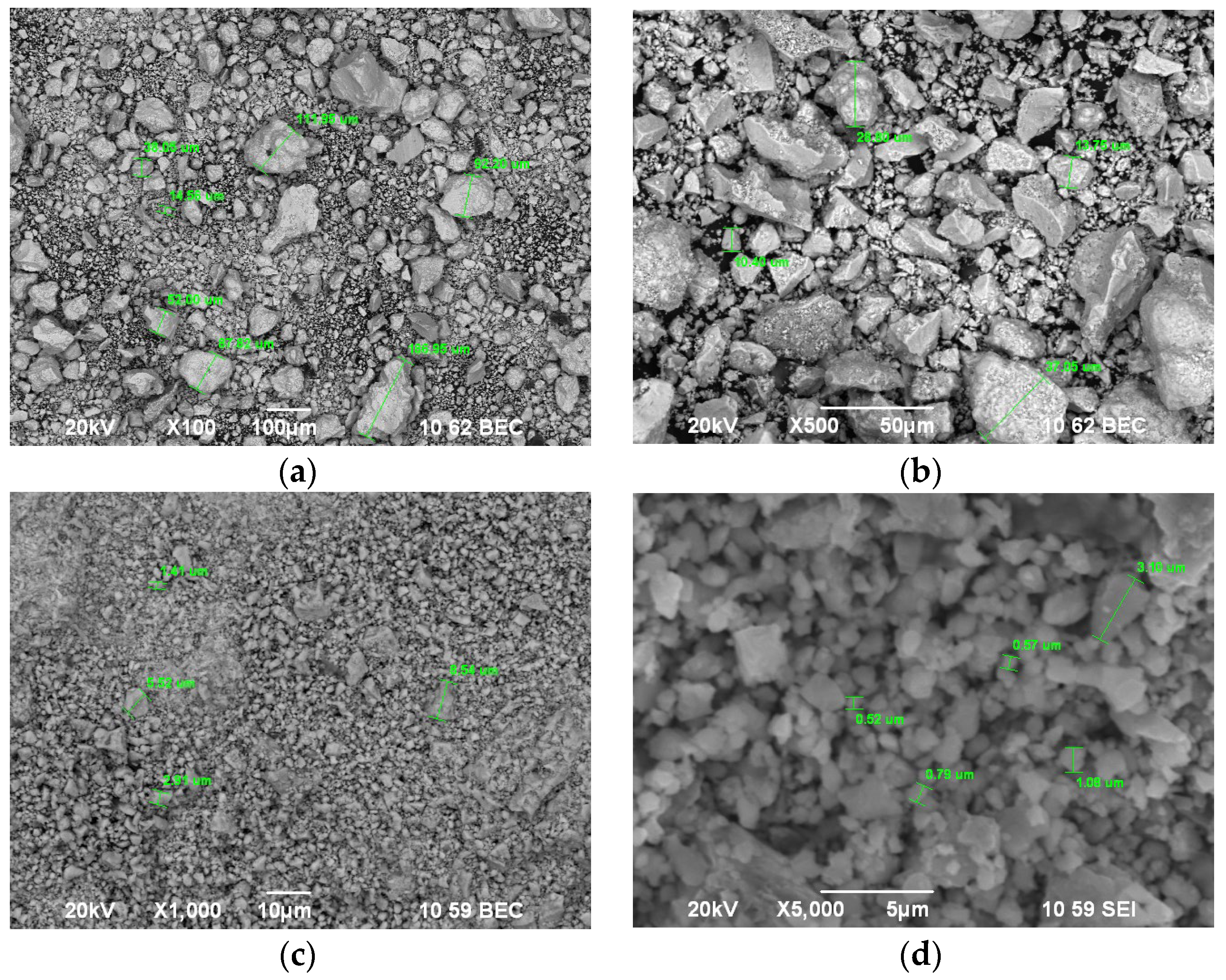

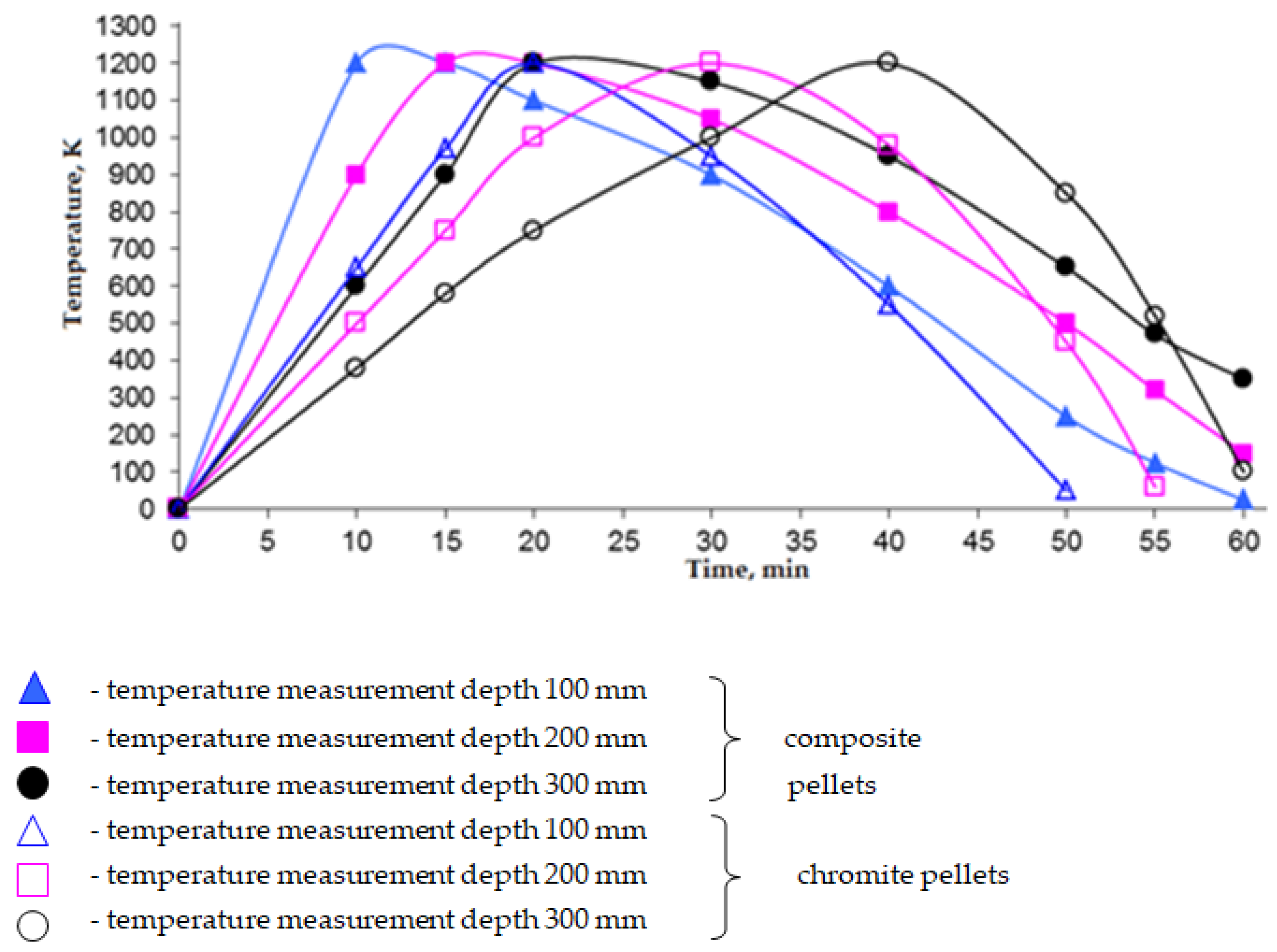

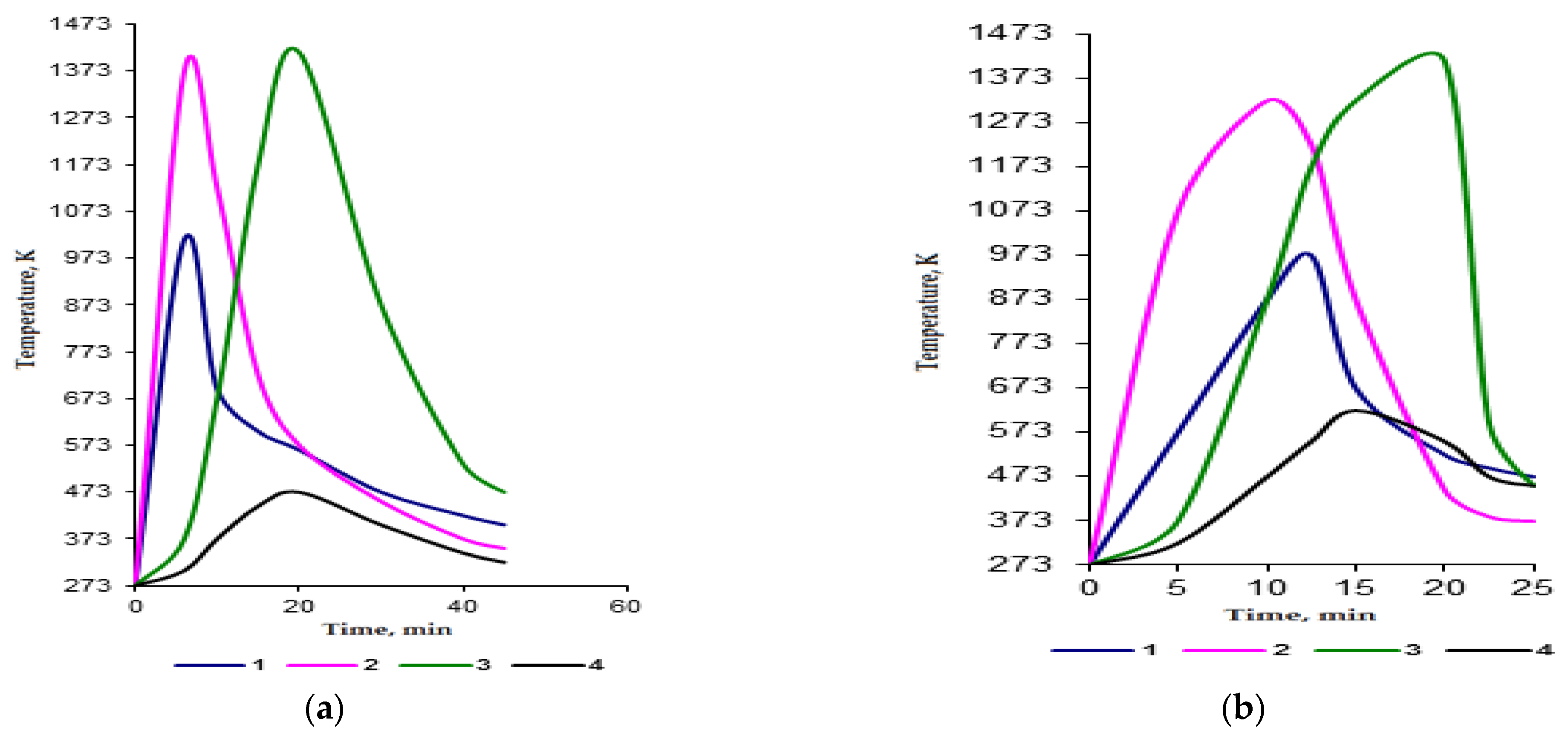

2. Materials and Methods

- -

- Chromite ores of class 0–10 mm—1.8–1.9 g/cm3;

- -

- Internal overburden rocks—1.2–1.3 g/cm3;

- -

- Aspiration dust (from Aktobe ferroalloy plant)—1.1–1.2 g/cm3.

2.1. Instrumental Research Methods

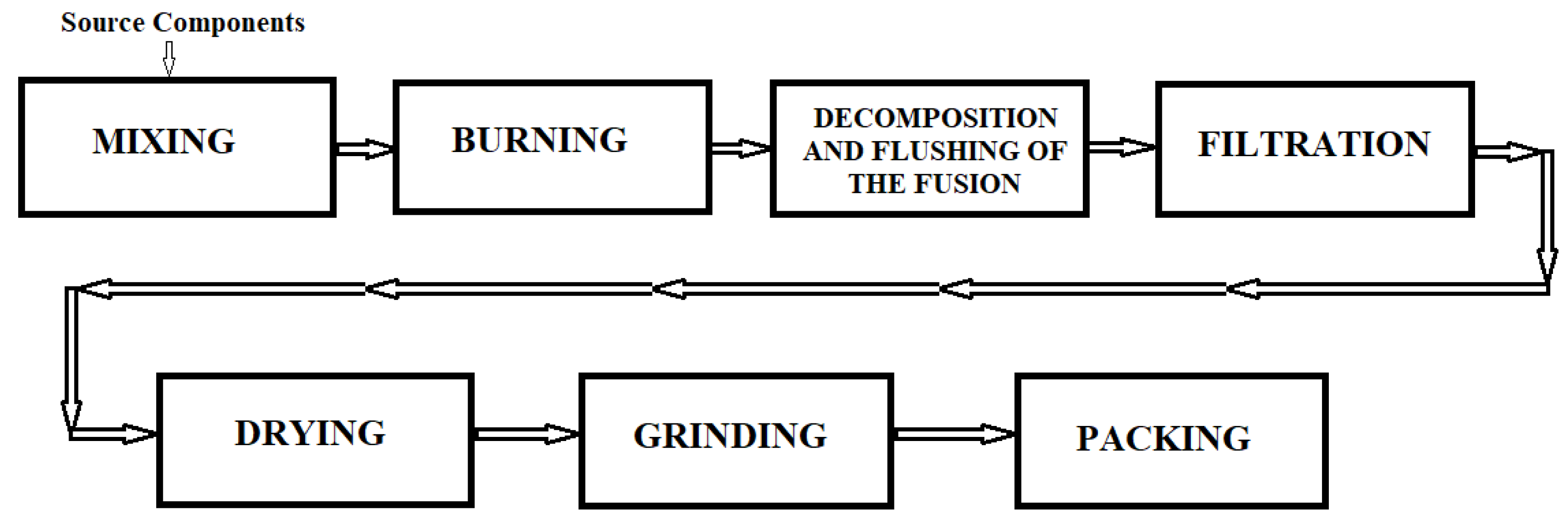

2.2. Methodology of the Experiment

3. Results and Discussion

4. Conclusions

- -

- Industrial waste, such as substandard chromite ores and overburden and aspiration dust, according to their physicochemical characteristics, can act as a secondary mineral raw material for the formation of a raw mixture in the form of composite pellets with subsequent production of a pigment-dye;

- -

- Composite pellets can be obtained from industrial waste, in particular, raw granules with a pellet moisture content of 10–15% with a compressive strength of 2.3–3.2 kg/pellet, as well as calcined pellets with a compressive strength of 150–200 kg/pellet containing 49.7% chromium oxide and less than 1.0% carbon in its composition;

- -

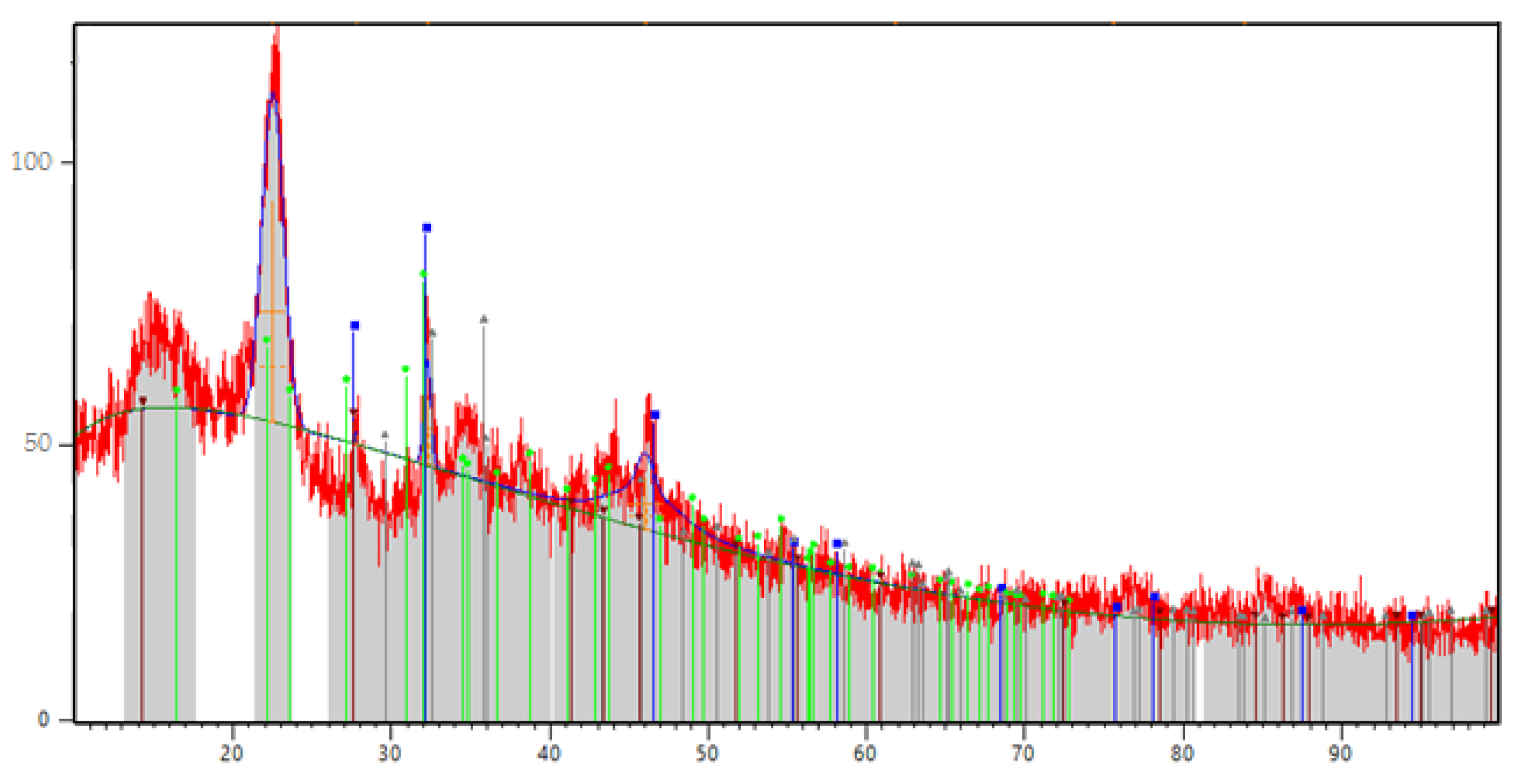

- The resulting chromite pigment is a modification of chromium oxohydroxide with the formula γ-CrOOH with a density of 3.4 kg/m3 and has an emerald green color and a hiding power of 38–42 g/m2;

- -

- The synthesized light green chromite pigment based on Cr3+ oxides with brightness exceeding foreign samples, when tested as a dye, showed that, unlike the traditionally obtained Cr2O3, it retains its color tone in a tinting medium and gives a pleasant emerald green color.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- American Chamber of Commerce in Kazakhstan. Analysis of Deviations of Kazakhstan’s Environmental Payments Systems from OECD-Country Standards, and Recommendations for Reforms, 9 April 2018; American Chamber of Commerce in Kazakhstan: Astana, Kazakhstan, 2018. [Google Scholar]

- Petrova, N.P. Solving the environmental problems of the region: A path to sustainable development. Bulletin of Russian Universities. Mathematics 2013, 18, 529–533. [Google Scholar]

- Tastanov, Y.; Serzhanova, N.; Ultarakova, A.; Sadykov, N.; Yerzhanova, Z.; Tastanova, A. Recycling of Chrome-Containing Waste from a Mining and Processing Plant to Produce Industrial Products. Processes 2023, 11, 1659. [Google Scholar] [CrossRef]

- Donayev, A.; Kolesnikov, A.; Shapalov, S.; Sapargaliyeva, B.; Ivakhniyuk, G. Studies of waste from the mining and metallurgical industry, with the determination of its impact on the life of the population. News Natl. Acad. Sci. Repub. Kazakhstan Ser. Geol. Tech. Sci. 2022, 4, 55–68. [Google Scholar] [CrossRef]

- Zhantasov, K.T.; Myrkhalykov, Z.U.; Turakulov, B.B.; Zhantasov, M.K.; Kocherov, E.N.; Zhantasova, D.M. Improvement of a Preparation Process of Chromite Raw Material Used for Ferroalloys and Pigments Manufacture. Eurasian Chem. Technol. J. 2015, 17, 251–260. [Google Scholar] [CrossRef]

- Marciano, C. Participatory Design and Public Policies: The Case of the General Regional Waste Plan in Valle d’Aosta (Italy). Waste 2023, 1, 468–481. [Google Scholar] [CrossRef]

- Splinter, K.; Moszyński, D.; Lendzion-Bieluń, Z. Microwave-Reactor-Based Preparation of Red Iron Oxide Pigment from Waste Iron Sulfate. Materials 2023, 16, 3242. [Google Scholar] [CrossRef]

- Kriznar, A.; Ager, F.; Macías, L.R.; Ortega Feliu, I.; Tubío, B.G.; Respaldiza, M.Á. Pigments and Inks Applied in Juan Vespucci’s Portolan Chart (1520). Colorants 2022, 1, 411–423. [Google Scholar] [CrossRef]

- Shoppert, A.; Valeev, D.; Diallo, M.M.; Loginova, I.; Beavogui, M.C.; Rakhmonov, A.; Ovchenkov, Y.; Pankratov, D. High-Iron Bauxite Residue (Red Mud) Valorization Using Hydrochemical Conversion of Goethite to Magnetite. Materials 2022, 15, 8423. [Google Scholar] [CrossRef]

- Gilshtein, E.; Pfeiffer, S.; Siegrist, S.; Vlnieska, V.; Graule, T.; Romanyuk, Y.E. Photonic Sintering of Oxide Ceramic Films: Effect of Colored FexOy Nanoparticle Pigments. Ceramics 2022, 5, 351–361. [Google Scholar] [CrossRef]

- Pugacheva, T.A.; Malkov, G.V.; Ilyin, A.A.; Indeikin, E.A.; Kurbatov, V.G. Core/Shell Pigments with Polyaniline Shell: Optical and Physical–Technical Properties. Polymers 2022, 14, 2005. [Google Scholar] [CrossRef]

- Volokitina, I.E. Structure and mechanical properties of aluminum alloy 2024 after cryogenic cooling during ECAP. J. Chem. Technol. Metall. 2020, 55, 580–585. [Google Scholar]

- Volokitina, I. Effect of Cryogenic Cooling After Ecap on Mechanical Properties of Aluminum Alloy D16. Met. Sci. Heat Treat. 2019, 61, 234–238. [Google Scholar] [CrossRef]

- Volokitina, I. Evolution of the Microstructure and Mechanical Properties of Copper under ECAP with Intense Cooling. Met. Sci. Heat Treat. 2020, 62, 253–258. [Google Scholar] [CrossRef]

- Felhősi, I.; Molnárné Nagy, L.; Horváth, S.; Pozman, T.; Bognár, J.; Szabó, T.; Keresztes, Z. Corrosion Protection and Heat Resistance of Paints for Outdoor Use. Materials 2023, 16, 2753. [Google Scholar] [CrossRef]

- Tatíčková, Z.; Kudláček, J.; Zoubek, M.; Kuchař, J. Behaviour of Thermochromic Coatings under Thermal Exposure. Coatings 2023, 13, 642. [Google Scholar] [CrossRef]

- Zhanikulov, N.N.; Khudyakova, T.M.; Taimasov, B.T.; Sarsenbayev, B.K.; Dauletiarov, M.S.; Kolesnikov, A.S.; Karshygayev, R.O. Receiving Portland Cement from Technogenic Raw Materials of South Kazakhstan. Eurasian Chem.-Technol. J. 2019, 21, 333–340. [Google Scholar] [CrossRef]

- Liu, K.; Chen, F.; Guo, Y.; Liu, Y.; Wang, S.; Yang, L. Influence of Basicity and Calcium-Containing Substances on the Consolidation Mechanism of Fluxed Iron Ore Pellets. Metals 2022, 12, 1057. [Google Scholar] [CrossRef]

- Volokitin, A.; Naizabekov, A.; Volokitina, I.; Kolesnikov, A. Changes in Microstructure and Properties of Austenitic Steel AISi 316 During High-Pressure Torsion. J. Chem. Technol. Metallur. 2022, 57, 809–815. [Google Scholar]

- Saveliev, D.E.; Makatov, D.K.; Vishnevskiy, A.V.; Gataullin, R.A. Accessory Minerals in the Chromitite Ores of Dzharlybutak Ore Group of Kempirsai Massif (Southern Urals, Kazakhstan): Clues for Ore Genesis. Minerals 2023, 13, 263. [Google Scholar] [CrossRef]

- Garuti, G.; Pushkarev, E.V.; Gottman, I.A.; Zaccarini, F. Chromite-PGM Mineralization in the Lherzolite Mantle Tectonite of the Kraka Ophiolite Complex (Southern Urals, Russia). Minerals 2021, 11, 1287. [Google Scholar] [CrossRef]

- Xiang, Y.; Zhang, Q.; Wang, D.; Wu, S. Mining Investment Risk Assessment for Nations along the Belt and Road Initiative. Land 2022, 11, 1287. [Google Scholar] [CrossRef]

- Zhantasov, K.; Zhantasov, M.; Turakulov, B.; Kocherov, Y. Beneficiation of off-grade chromite ore for production of inorganic substances. Eur. Int. J. Sci. Technol. 2013, 2, 35–40. [Google Scholar]

- Pownceby, M.I.; McCallum, D.A.; Bruckard, W.J. Automated and Quantitative Mineralogy Applied to Chromite Ore Characterization and Beneficiation. Minerals 2023, 13, 440. [Google Scholar] [CrossRef]

- Smailov, B.M.; Zharkinbekov, M.A.; Tuleshova, K.T.; Issabayev, N.N.; Tleuov, A.S.; Beisenbayev, O.K.; Esirkepova, M.M.; Azimov, A.M. Kinetic research and mathematical planning on the obtaining of potassium humate from brown coal of the Lenger deposit. Rasayan J. Chem. 2021, 14, 1899–1905. [Google Scholar] [CrossRef]

- Ismailov, B.; Zakirov, B.; Kadirbayeva, A.; Koshkarbayeva, S.; Smailov, B.; Azimov, A.; Issabayev, N. Methods for Obtaining Phosphorus-Containing Fertilizers Based on Industrial Waste. Inorganics 2023, 11, 224. [Google Scholar] [CrossRef]

- Nguyen, T.T.P.; Nguyen, V.T.; Hoang, N.; Hoang, V.D.; Luu, X.D.; Le, T.M.H.; Nguyen, T.H.; Hoang, N.B.; Tran, T.K.N.; Chu, M.N. Studies on Red Mud Material to Use for Combustion of Vietnam Pulverized Coal. Inorganics 2022, 10, 58. [Google Scholar] [CrossRef]

- Thabit, Q.; Nassour, A.; Nelles, M. Facts and Figures on Aspects of Waste Management in Middle East and North Africa Region. Waste 2023, 1, 52–80. [Google Scholar] [CrossRef]

- Rakhimova, G.; Stolboushkin, A.; Vyshar, O.; Stanevich, V.; Rakhimov, M.; Kozlov, P. Strong Structure Formation of Ceramic Composites Based on Coal Mining Overburden Rocks. J. Compos. Sci. 2023, 7, 209. [Google Scholar] [CrossRef]

- Roine, A.; Outokumpu, H.S.C. Chemistry for Windows. Chemical Reaction and EguilibriumLoftware with Extensive Thermochemical Datebase; Outokumpu Resaerch OY: Pori, Finland, 2020. [Google Scholar]

- Kolesnikova, O.; Syrlybekkyzy, S.; Fediuk, R.; Yerzhanov, A.; Nadirov, R.; Utelbayeva, A.; Agabekova, A.; Latypova, M.; Chepelyan, L.; Volokitina, I.; et al. Thermodynamic Simulation of Environmental and Population Protection by Utilization of Technogenic Tailings of Enrichment. Materials 2022, 15, 6980. [Google Scholar] [CrossRef] [PubMed]

- Naizabekov, A.B.; Kolesnikov, A.S.; Latypova, M.A.; Fedorova, T.D.; Mamitova, A.D. Current Trends to Obtain Metals and Alloys with Ultrafine-Grained Structure. Prog. Phys. Met. 2022, 23, 629–657. [Google Scholar]

- Kolesnikov, A.S.; Zhanikulov, N.N.; Syrlybekkyzy, S.; Kolesnikova, O.G.; Shal, A.L. Utilization of Waste from the Enrichment of Non-Ferrous Metal Ores as Secondary Mineral Raw Materials in the Production of Cement Clinker. Ecol. Ind. Russ. 2023, 27, 19–23. [Google Scholar] [CrossRef]

- Abbazov, I.; Kaldybaev, R.; Bektureyeva, G.; Kerimbekova, Z.; Yeshzhanov, A.; Botabaev, N.; Kaldybayeva, G.; Kenzhibayeva, G.; Izteuov, G.; Kolesnikov, A. Theoretical Researching of Particle Movement in Cleaning Zone of Dust-Arrester. Pol. J. Environ. Stud. 2023, 32, 1–8. [Google Scholar] [CrossRef]

- Kolesnikova, O.; Vasilyeva, N.; Kolesnikov, A.; Zolkin, A. Optimization of raw mix using technogenic waste to produce cement clinker. MIAB. Min. Inf. Anal. Bull. 2022, 60, 103–115. [Google Scholar] [CrossRef]

- De Azevedo, A.R.G.; Marvila, M.T.; Antunes, M.L.P.; Rangel, E.C.; Fediuk, R. Technological Perspective for Use the Natural Pineapple Fiber in Mortar to Repair Structures. Waste Biomass Valorization 2021, 12, 5131–5145. [Google Scholar] [CrossRef]

- Fediuk, R.; Amran, M.; Vatin, N.; Vasilev, Y.; Lesovik, V.; Ozbakkaloglu, T. Acoustic Properties of Innovative Concretes: A Review. Materials 2021, 14, 398. [Google Scholar] [CrossRef]

- Abid, S.R.; Gunasekaran, M.; Ali, S.H.; Kadhum, A.L.; Al-Gasham, T.S.; Fediuk, R.; Vatin, N.; Karelina, M. Impact Performance of Steel Fiber-Reinforced Self Compacting Concrete against Repeated Drop Weight Impact. Crystals 2021, 11, 91. [Google Scholar] [CrossRef]

- Amran, M.; Fediuk, R.; Murali, G.; Vatin, N.; Karelina, M.; Ozbakkaloglu, T.; Krishna, R.S.; Kumar, S.A.; Kumar, D.S.; Mishar, J. Rice Husk Ash-Based Concrete Composites: A Critical Review of Their Properties and Applications. Crystals 2021, 11, 168. [Google Scholar] [CrossRef]

- Fediuk, R. High-strength fibrous concrete of Russian Far East natural materials. IOP Conf. Ser. Mater. Sci. Eng. 2016, 116, 012020. [Google Scholar] [CrossRef]

- Rajendran, P.; Rathinasabapathy, R.; Chandra Kishore, S.; Bellucci, S. Computational-Simulation-Based Behavioral Analysis of Chemical Compounds. J. Compos. Sci. 2023, 7, 196. [Google Scholar] [CrossRef]

- Zhantasov, K.T.; Myrhalykov, Z.U.; Turakulov, B.B.; Erubai, A.; Dosaliev, K. The possibility of obtaining sintered pellets for the production of textile pigments and intermediate products from industrial waste. ResearchGate 2015, 359, 115–117. [Google Scholar]

- Cardinale, A.M.; Carbone, C.; Molinari, S.; Salviulo, G.; Ardini, F. MgAl-NO3 LDH: Adsorption Isotherms and Multivariate Optimization for Cr(VI) Removal. Chemistry 2023, 5, 633–645. [Google Scholar] [CrossRef]

- Kydyralyeva, A.S.; Beisenbayev, O.K.; Ortaev, A.E.; Smailov, B.M.; Nadyrov, K.S.; Issa, A.B.; Ibadullaev, A.S. Technology for the production of composite polymer materials based on recycled polypropylene and polyethylene terephthalate with the addition of modified sodium montmorillonite. Rasayan J. Chem. 2023, 15, 319–324. [Google Scholar] [CrossRef]

- Festa, G.; Scatigno, C.; Armetta, F.; Saladino, M.L.; Ciaramitaro, V.; Nardo, V.M.; Ponterio, R.C. Chemometric Tools to Point Out Benchmarks and Chromophores in Pigments through Spectroscopic Data Analyses. Molecules 2022, 27, 163. [Google Scholar] [CrossRef] [PubMed]

- Aso, S.; Onoda, H. Synthesis of Cobalt-Substituted Manganese Phosphate Purple Pigments. Materials 2023, 16, 4132. [Google Scholar] [CrossRef] [PubMed]

- Gao, L.; Li, B. The Effects of Surfactant and Metal Ions on the Stability and Rheological Properties of Nanoemulsions Loaded with Gardenia Yellow Pigment. Appl. Nano 2023, 4, 61–74. [Google Scholar] [CrossRef]

- Skopintseva, O.V.; Ganova, S.D.; Buzin, A.A.; Fedotova, V.P. Measures to reduce dusting during loading and transportation of solid mineral resources. Gorn. Zhurnal 2019, 12, 76–79. [Google Scholar] [CrossRef]

- Douzapau, M.; Roy Chowdhury, S.; Singh, S.; Ibukun, O.J.; Haldar, D. Stimuli-Responsive Designer Supramolecular Polymer Gel. Chemistry 2023, 5, 691–702. [Google Scholar] [CrossRef]

- Chung, C.-C.; Hwang, J.-J. Porous Diatomaceous Earth/Nano-Zinc Oxide Composites: Preparation and Antimicrobial Applications. J. Compos. Sci. 2023, 7, 204. [Google Scholar] [CrossRef]

- Taits, E.M.; Andreeva, I.A. Methods of Analysis and Testing of Coals; Nedra: Moscow, Russia, 1983; 301p. [Google Scholar]

- Zhirov, D.K. Development of a technique for determining the index of grinding of materials in centrifugal-impact mills. Chem. Phys. Mesoscopy 2016, 18, 49–60. [Google Scholar]

- GOST 15137-77; Iron and Manganese Ores, Agglomerates and Pellets. Determination of Tumbler Strength. All-Russian Classifier of Standards: Moscow, Russia, 1994.

- Zhantasov, K.T.; Myrhalykov, Z.U.; Moldabekov, S.M.; Turakulov, B.B.; Minakovsky, A.F.; Suleymenov, B.U. Agronomical field testing of new kinds of multicomponent mineral fertilizers. Eurasian Chem.-Technol. J. 2015, 17, 79–86. [Google Scholar] [CrossRef]

- Chekhomova, L.F. Synthesis and Modification of Chromium Oxides and Abrasive and Pigment Materials Based on Them. Ph.D. Thesis, Higher Attestation Commission of the Russian Federation, Yekaterinburg, Russia, 1999. [Google Scholar]

- Smailov, B.M.; Aravind, U.K.; Zakirov, B.S.; Azimov, A.M.; Tleuov, A.S.; Beisenbayev, O.K.; Aimenov, Z.T.; Issabayev, N.N. Technology for obtaining chelated organomineral microfertilizers based on humate-containing components. Rasayan J. Chem. 2023, 16, 428–433. [Google Scholar] [CrossRef]

- Lin, S.-K. Publisher’s Note to Launch Colorants—A Scientific Journal of Dyes, Pigments and Color Chemistry. Colorants 2022, 1, 3–4. [Google Scholar] [CrossRef]

- Kulikova, E.Y.; Balovtsev, S.V.; Skopintseva, O.V. Complex estimation of geotechnical risks in mine and underground construction. Sustain. Dev. Mt. Territories. 2023, 15, 7–16. [Google Scholar] [CrossRef]

- Zhangabay, N.; Sapargaliyeva, B.; Utelbayeva, A.; Yermakhanov, M.; Mussayeva, S. Experimental Analysis of the Stress State of a Prestressed Cylindrical Shell with Various Structural Parameters. Materials 2022, 15, 4996. [Google Scholar] [CrossRef] [PubMed]

- Volokitina, I.; Siziakova, E.; Fediuk, R.; Kolesnikov, A. Development of a Thermomechanical Treatment Mode for Stainless-Steel Rings. Materials 2022, 15, 4930. [Google Scholar] [CrossRef]

- Filin, A.E.; Kurnosov, I.Y.; Kolesnikova, L.A.; Ovchinnikova, T.I.; Kolesnikov, A.S. Description of the methodology for conducting an experiment on dust deposition of mining and metallurgical production. Ugol 2022, 9, 67–72. [Google Scholar] [CrossRef]

- Kulikova, A.A.; Kovaleva, A.M. Use of tailings of enrichment for laying of the developed space of mines. MIAB. Min. Inf. Anal. Bull. 2021, 2, 144–154. [Google Scholar] [CrossRef]

| Material | Content of Material of Class (mm) in % | ||||

|---|---|---|---|---|---|

| +10 | 5–10 | 3–5 | 1–3 | 0–1 | |

| Substandard chromite ore | 4.4 | 18.8 | 43.2 | 11.8 | 22.8 |

| Internal overburden rocks | - | 7.8 | 21.7 | 22.9 | 47.6 |

| Aspiration dust | - | - | - | 3.4 | 96.6 |

| Material | Content Of Components, in % Mass | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Cr2O3 | CaO | MgO | SiO2 | Fe2O3 | SO3total | Al2O3 | C | Moisture | |

| Substandard chromite ore | 38.9 | 0.26 | 19.27 | 22.78 | 10.11 | 0.02 | 6.76 | - | 1.9 |

| Internal overburden rocks | - | 5.1 | 2.3 | 32.7 | 9.9 | 1.8 | 12.8 | 35.4 | - |

| Aspiration dust | 44.5 | 0.15 | 0.15 | 10.84 | 11.18 | 0.018 | 7.67 | - | 1.6 |

| Material | Pellets, Firing Temperature, K | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Raw Materials | 1073 | 1173 | 1273 | 1373 | ||||||

| Cr2O3 | C | Cr2O3 | C | Cr2O3 | C | Cr2O3 | C | Cr2O3 | C | |

| Purely chromite | 20.9 | absent | 21.2 | absent | 21.8 | absent | 22.4 | absent | 22.6 | absent |

| Chromite with 5% of internal overburden rock | 19.8 | 4.3 | 21.1 | 2.2 | 22.0 | 2.0 | 22.2 | 2.0 | 22.2. | 1.9 |

| Chromite with 7.5% of internal overburden rock | 19.4 | 6.0 | 21.2 | 3.0 | 21.8 | 2.9 | 22.1 | 2.6 | 22.2 | 2.6 |

| Chromite with 10% of internal overburden rock | 18.9 | 8.6 | 21.3 | 4.0 | 21.6 | 3.9 | 22.2 | 3.6 | 22.2 | 3.5 |

| Material | Strength of Pellets In Compression of Fractions, mm | By GOST 15137-77 | ||||

|---|---|---|---|---|---|---|

| 20 | 18 | 16 | 14 | to shock, | abrasion, | |

| %+5 mm%−0.5 mm | ||||||

| Raw | 23 | 24 | 20 | 20 | - | - |

| Calcined without a bed during 25 min | 1490 | 2040 | 1620 | 1290 | 93 | 5 |

| Calcined on a bed of pellets during 45 min | 1900 | 2470 | 2240 | 1610 | 94 | 4 |

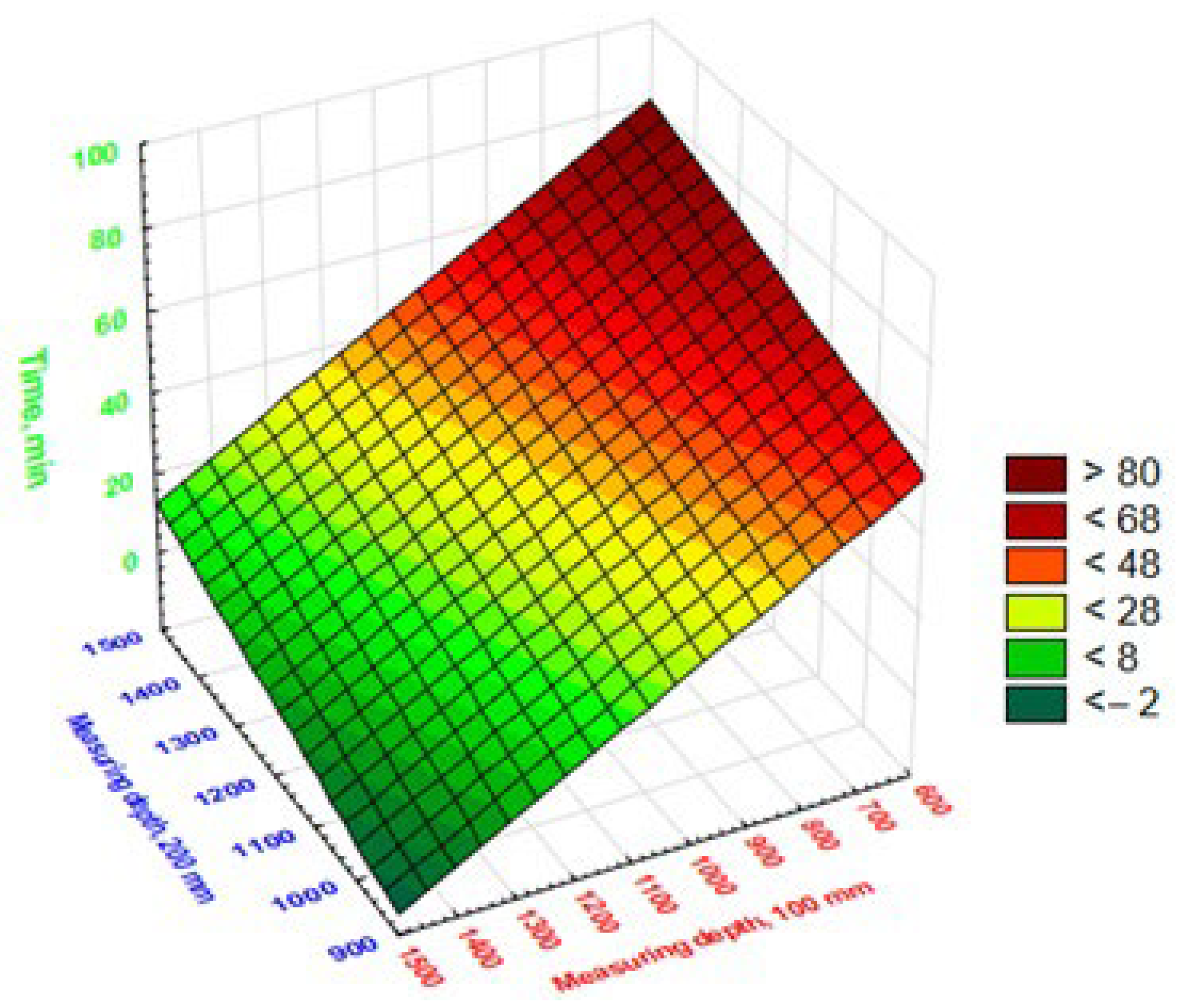

| Name | Temperature Measurement Depth (mm) | |||

|---|---|---|---|---|

| Time, min | 100 | 200 | 300 | |

| Chromite pellets containing carbon and aspiration dust | Temperature, K | |||

| 15 | 1427 | 1427 | 1173 | |

| 20 | 1327 | 1427 | 1473 | |

| 25 | 1293 | 1403 | 1473 | |

| 30 | 1173 | 1323 | 1423 | |

| 35 | 1033 | 1213 | 1343 | |

| 40 | 873 | 1073 | 1223 | |

| 45 | 723 | 928 | 1098 | |

| Sample Number | Content of Components, in % Mass | |||||||

|---|---|---|---|---|---|---|---|---|

| Cr2O3CaOMgO | SiO2 | Fe2O3 | SO3totalCfree | CO2 | ||||

| 1 | 49.9 | 0.56 | 14.0 | 27.23 | 7.91 | 0.07 | 0.77 | <0.1 |

| 2 | 49.4 | 0.60 | 14.0 | 27.4 | 7.82 | 0.06 | 0.62 | <0.1 |

| 3 | 49.7 | 0.60 | 14.1 | 28.0 | 6.61 | 0.05 | 0.84 | <0.1 |

| 4 | 49.8 | 0.55 | 13.85 | 28.6 | 6.12 | 0.55 | 0.93 | <0.1 |

| Average | 49.7 | 0.50 | 13.98 | 27.8 | 7.12 | 0.57 | 0.79 | <0.1 |

| Requirements of Technical Specification 20.12.24-335-35749547-2020 | ||

|---|---|---|

| Indicators | Norm | Obtained Sample |

| Mass fraction of the main substance in terms of CrOOH∙H2O, % not less than | 88 | 91 ± 1 |

| Mass fraction of water and volatile substances, % no more | 9 | 7.5 ± 1 |

| pH of water extract | 6.5–8.5 | 7.3 ± 0.5 |

| Mass fraction of substances soluble in water, % no more | 1.0 | 0.35 ± 0.1 |

| Hiding property, g/m, no more | 50 | 38 ± 1 |

| Residue on sieve No. 0063 after wet screening, % no more | 0.06 | 0.05 ± 0.01 |

| Composition, Mass. % | Hiding Property, g/m2 | Color Characteristics | |||||||

|---|---|---|---|---|---|---|---|---|---|

| CrOOH·H2O Substances | Water Soluble | H2O | X | Y | Z | λ, nmP, % | |||

| 94 | 0.3 | 2.2 | 38 | 14 | 22 | 21 | 496 | 33 | |

| 95 | 0.3 | 3.1 | 37 | 15 | 18 | 18 | 502 | 31 | |

| 92 | 0.6 | 6.2 | 39 | 16 | 22 | 22 | 501 | 31 | |

| 95 | 0.4 | 6.1 | 37 | 17 | 23 | 23 | 501 | 28 | |

| 94 | 0.4 | 5.6 | 39 | 12 | 19 | 18 | 497 | 36 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Turakulov, B.; Zhantasov, K.; Kolesnikov, A.; Smailov, B.; Liseitsev, Y. Research on the Production of Pigments Based on Composite Pellets in the Recycling of Industrial Waste. J. Compos. Sci. 2023, 7, 289. https://doi.org/10.3390/jcs7070289

Turakulov B, Zhantasov K, Kolesnikov A, Smailov B, Liseitsev Y. Research on the Production of Pigments Based on Composite Pellets in the Recycling of Industrial Waste. Journal of Composites Science. 2023; 7(7):289. https://doi.org/10.3390/jcs7070289

Chicago/Turabian StyleTurakulov, Bakhriddin, Kurmanbek Zhantasov, Alexandr Kolesnikov, Bakyt Smailov, and Yury Liseitsev. 2023. "Research on the Production of Pigments Based on Composite Pellets in the Recycling of Industrial Waste" Journal of Composites Science 7, no. 7: 289. https://doi.org/10.3390/jcs7070289

APA StyleTurakulov, B., Zhantasov, K., Kolesnikov, A., Smailov, B., & Liseitsev, Y. (2023). Research on the Production of Pigments Based on Composite Pellets in the Recycling of Industrial Waste. Journal of Composites Science, 7(7), 289. https://doi.org/10.3390/jcs7070289