There Are over 60 Ways to Produce Biocompatible Calcium Orthophosphate (CaPO4) Deposits on Various Substrates

Abstract

1. Introduction

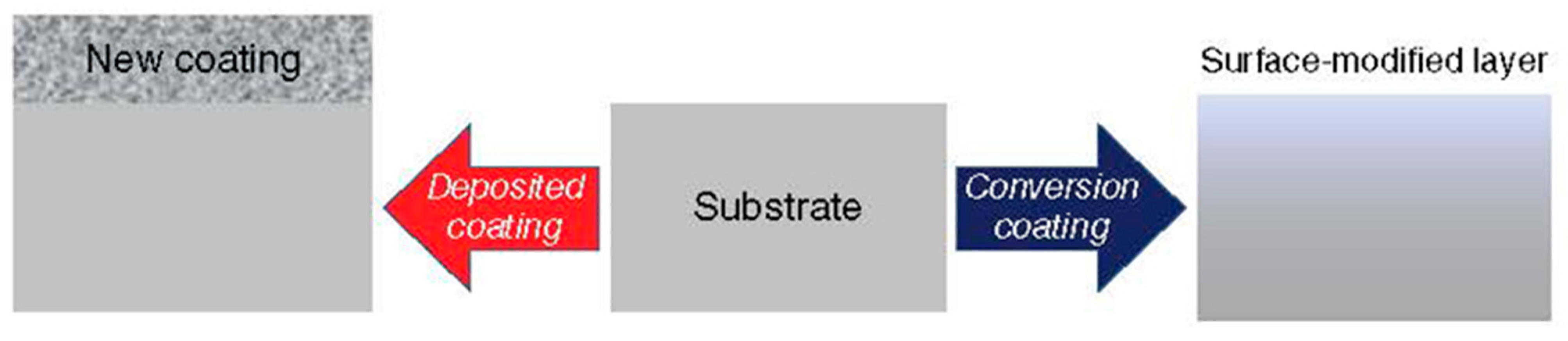

2. General Knowledge, Terminology and Definitions

- The kernel contains substances that are toxic, cause adverse or allergic reactions, or have a bitter or unpleasant odor;

- The coating protects the core material from its environment and increases its stability and shelf life;

- The coating improves mechanical integrity, which means that coated products are more resistant to misuse (e.g., wear and tear);

- Modification of the surface properties of the core, such as biocompatibility, light reflection, electrical conductivity, color, etc.;

- Decoration (in cases where the core alone is tasteless);

- The core contains material that can easily migrate and stain hands, clothes, etc.;

- Changing the release profile of active ingredients, such as pharmaceuticals, from the core.

3. Brief Knowledge on the Important Pre- and Post-Deposition Treatments

- Part 1.

- Methods to Produce Biocompatible CaPO4 Deposits

4. CaPO4 Deposited on Various Substrates

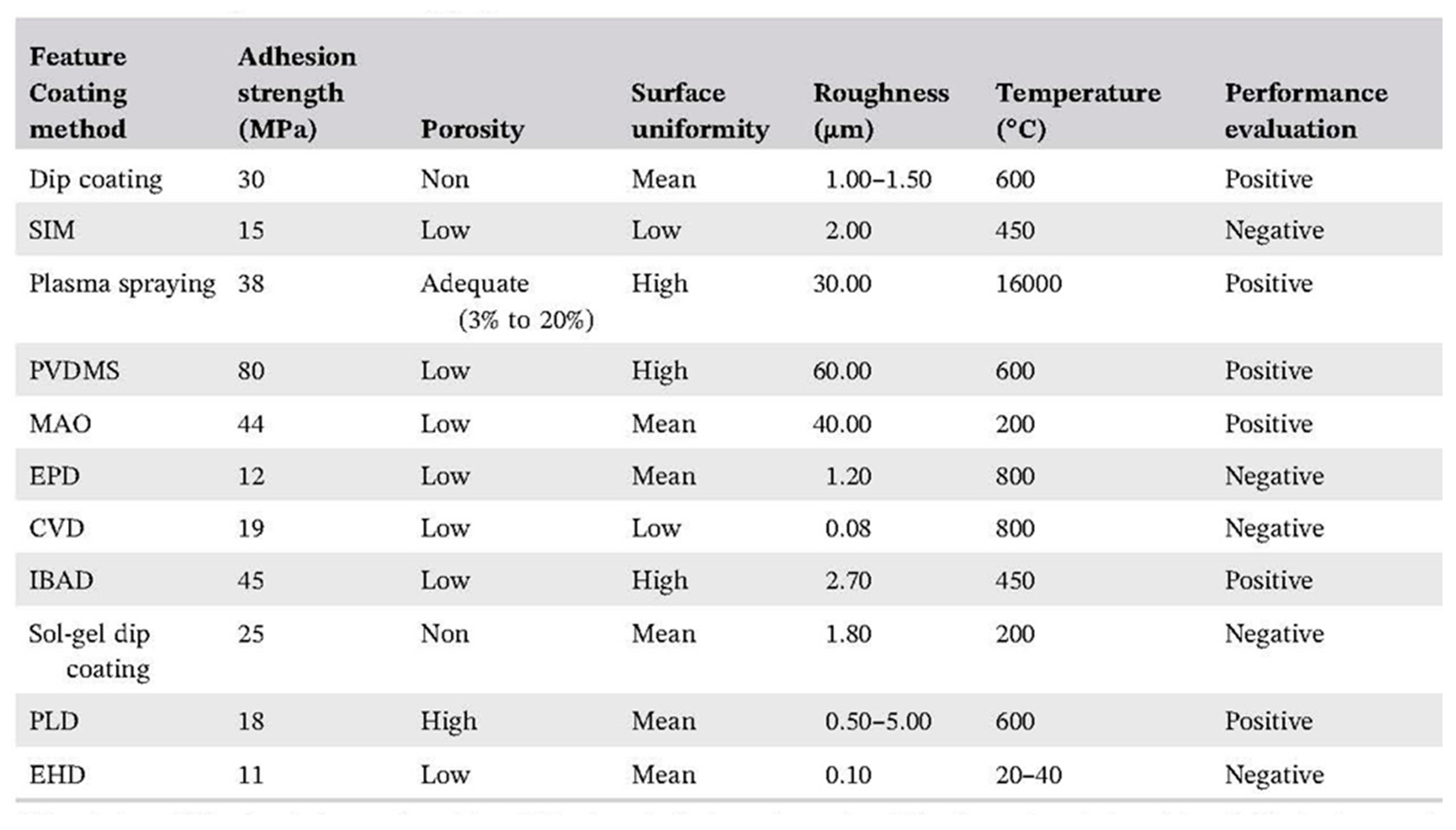

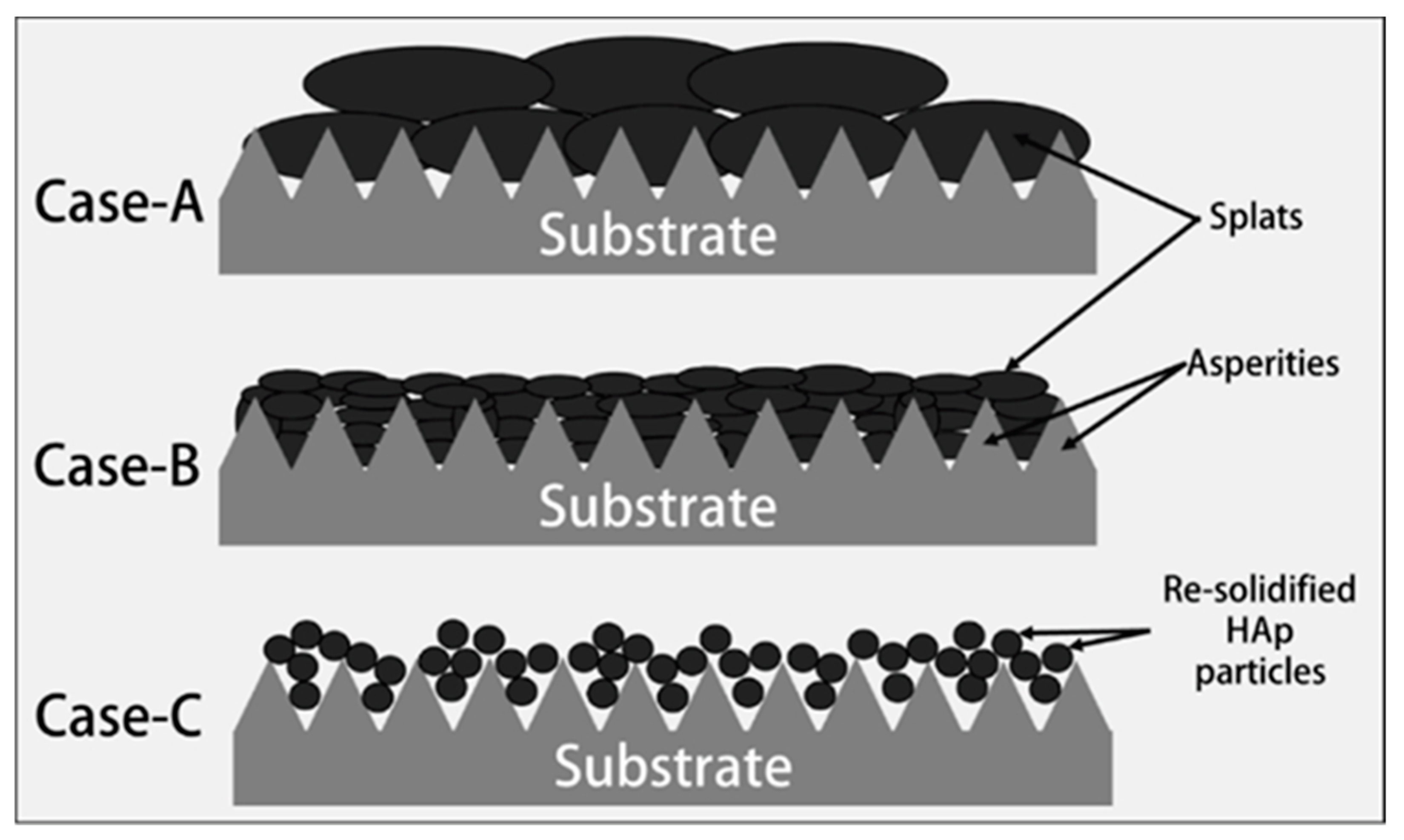

4.1. Thermal Spraying Deposition Techniques

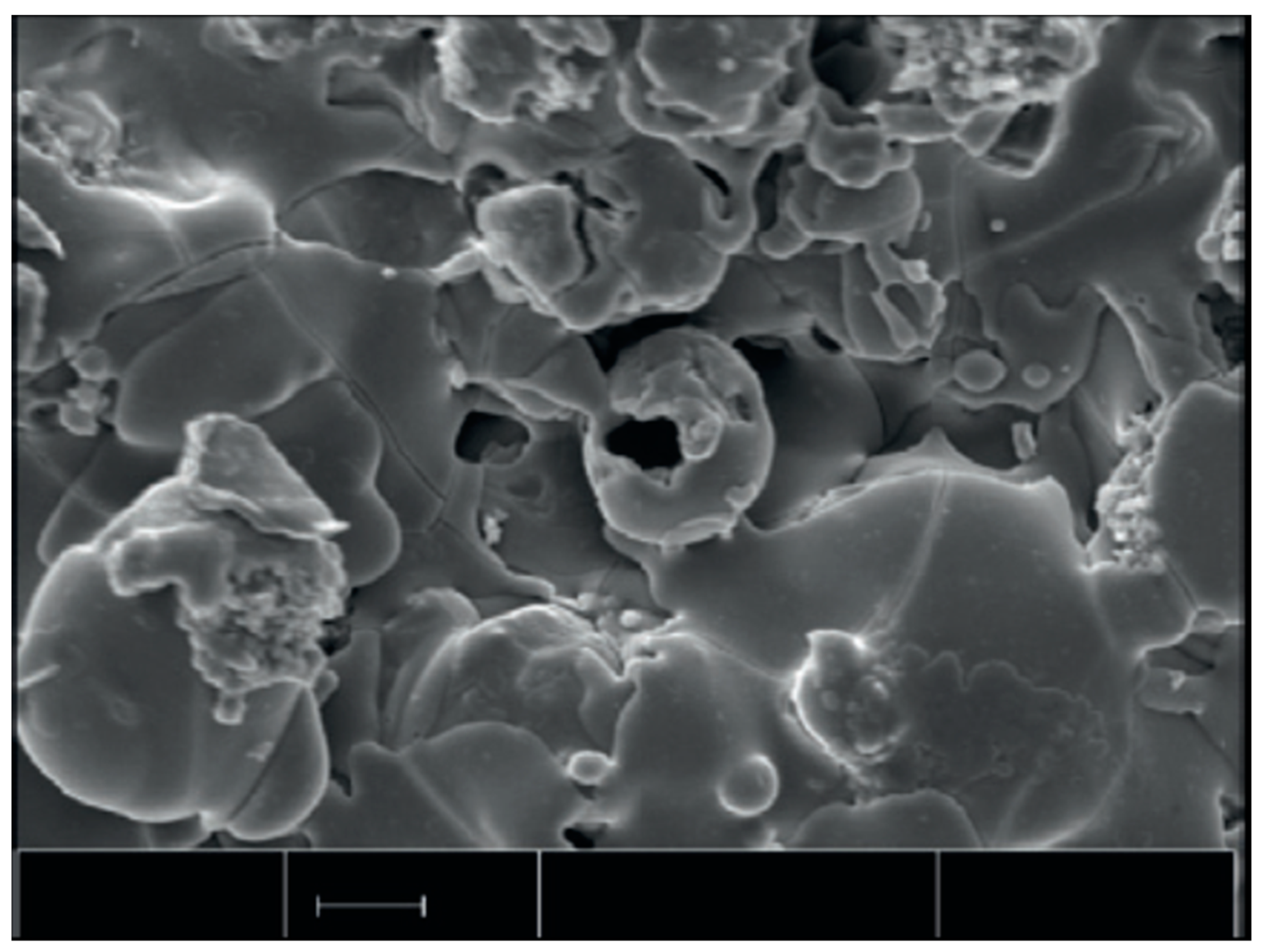

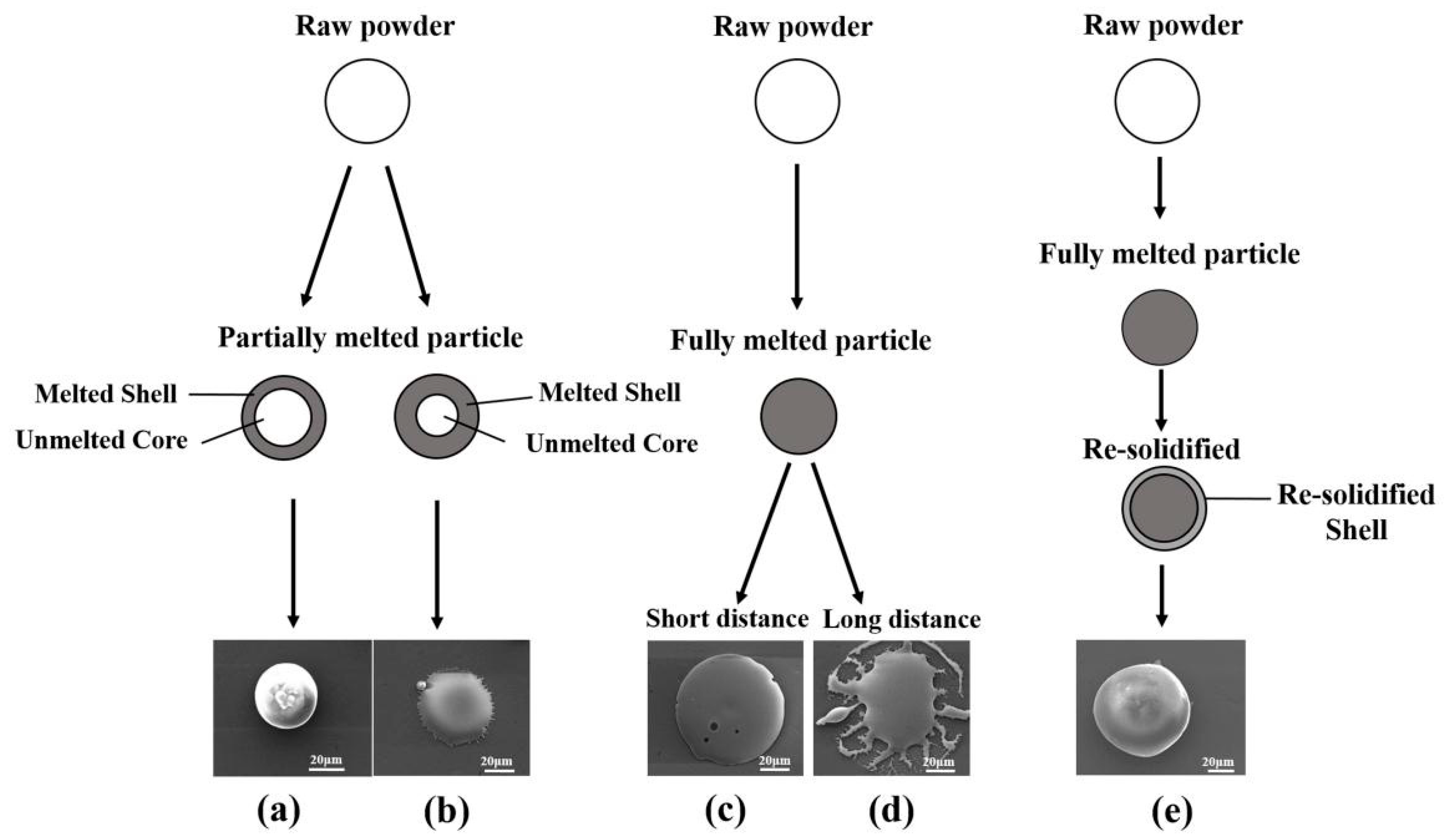

4.1.1. Plasma Spraying

4.1.2. High Velocity Oxy-Fuel (HVOF) Spraying

4.2. Vapor Deposition Techniques

4.2.1. Ion- and Electron-Beam Assisted (IBAD and EBAD) Depositions

4.2.2. Pulsed Laser Deposition (PLD)

4.2.3. Magnetron Sputtering

4.2.4. Electron-Cyclotron-Resonance (ECR) Plasma Sputtering

4.2.5. Metalorganic Chemical Vapor Deposition (MOCVD)

4.2.6. Molecular Precursor and Thermal Decomposition Techniques

4.3. Wet Techniques

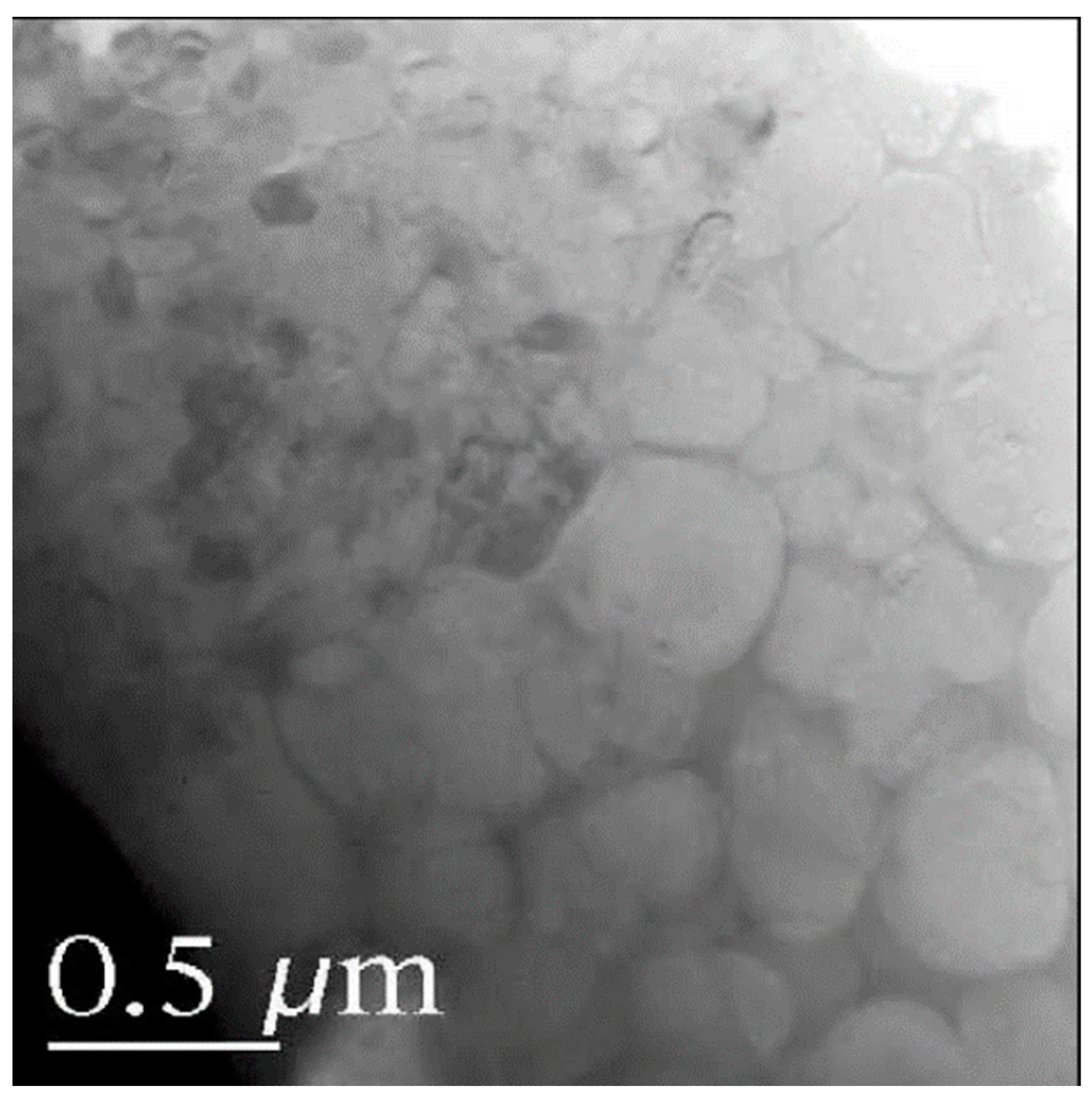

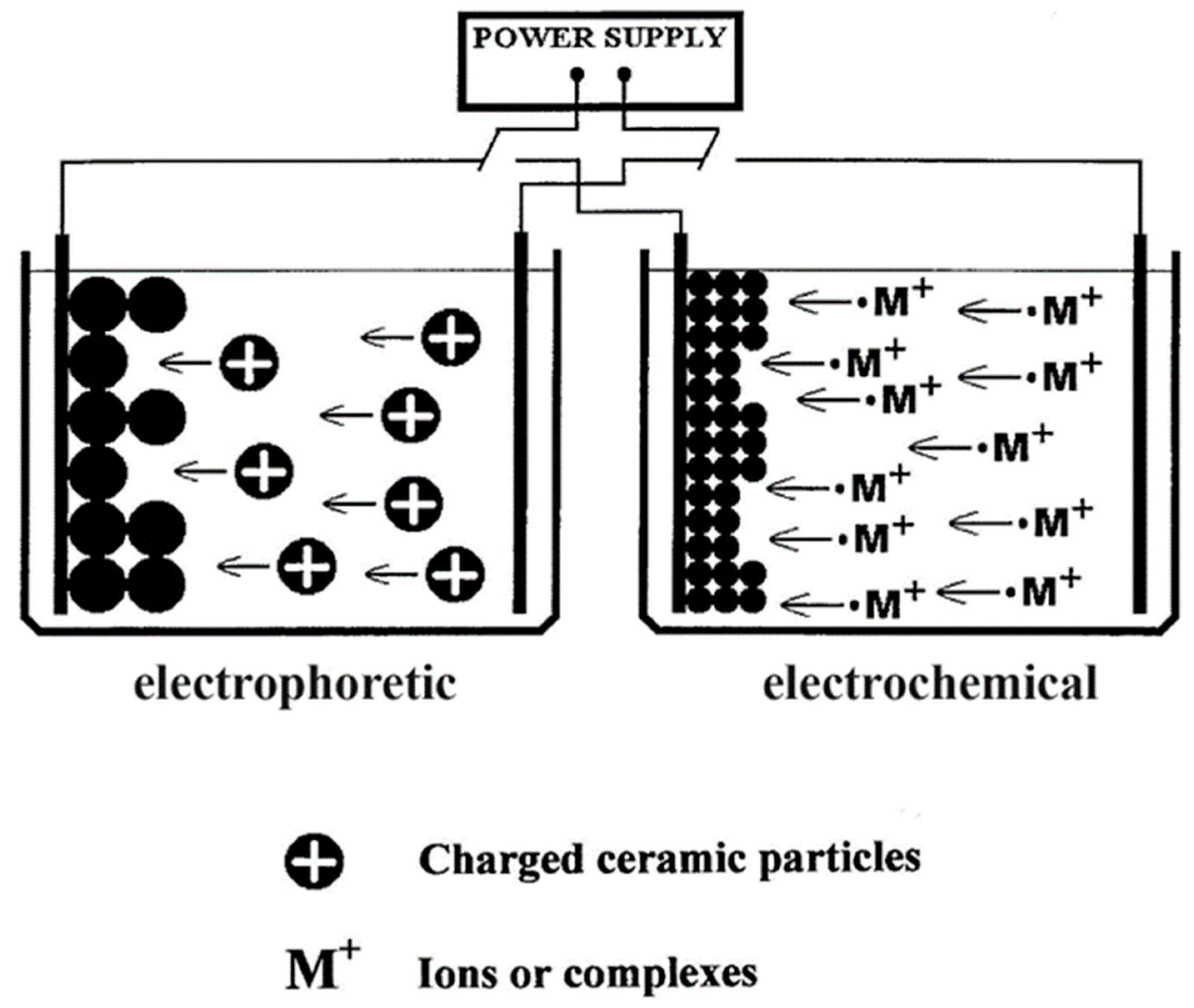

4.3.1. Electrophoretic Deposition (EPD)

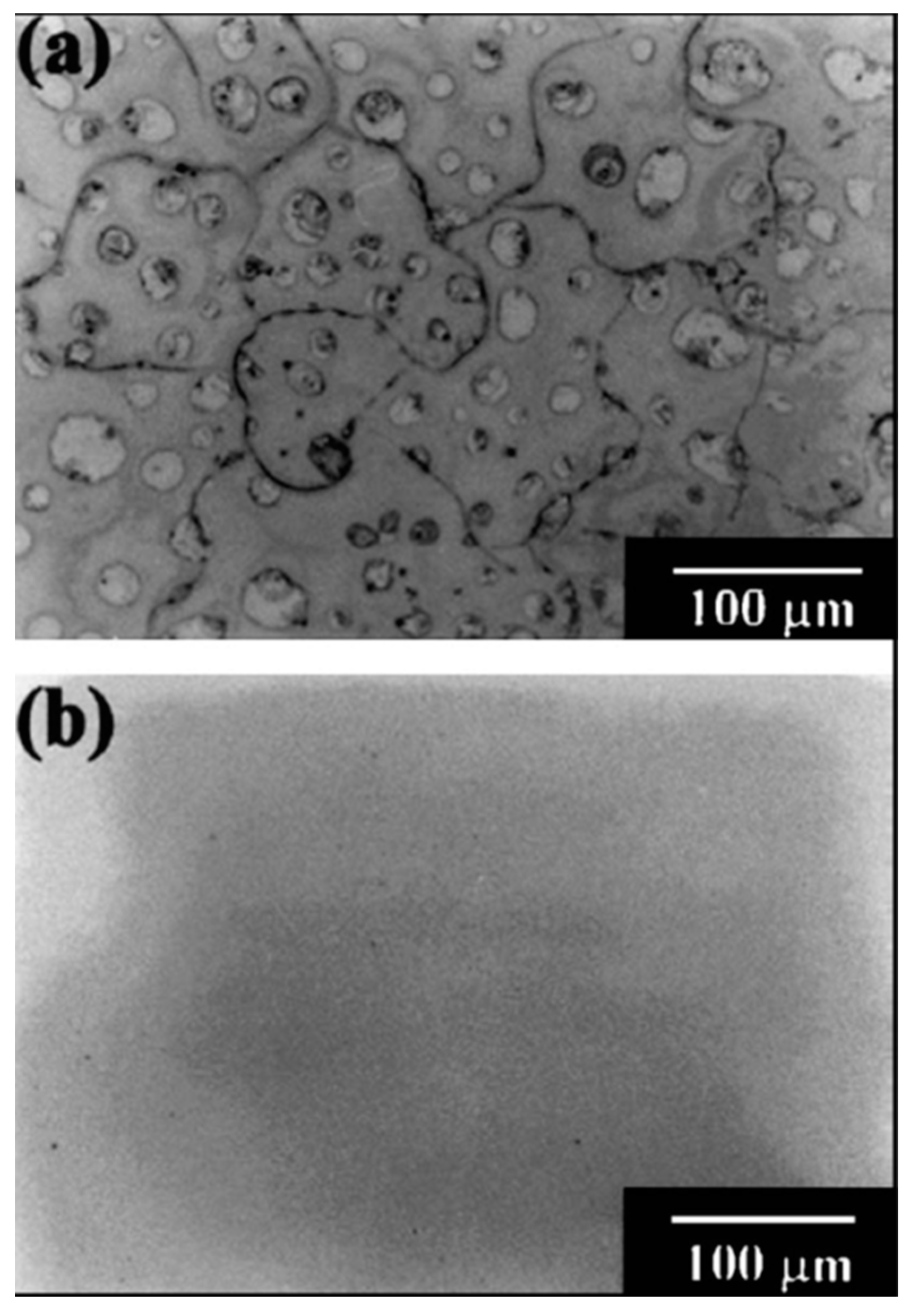

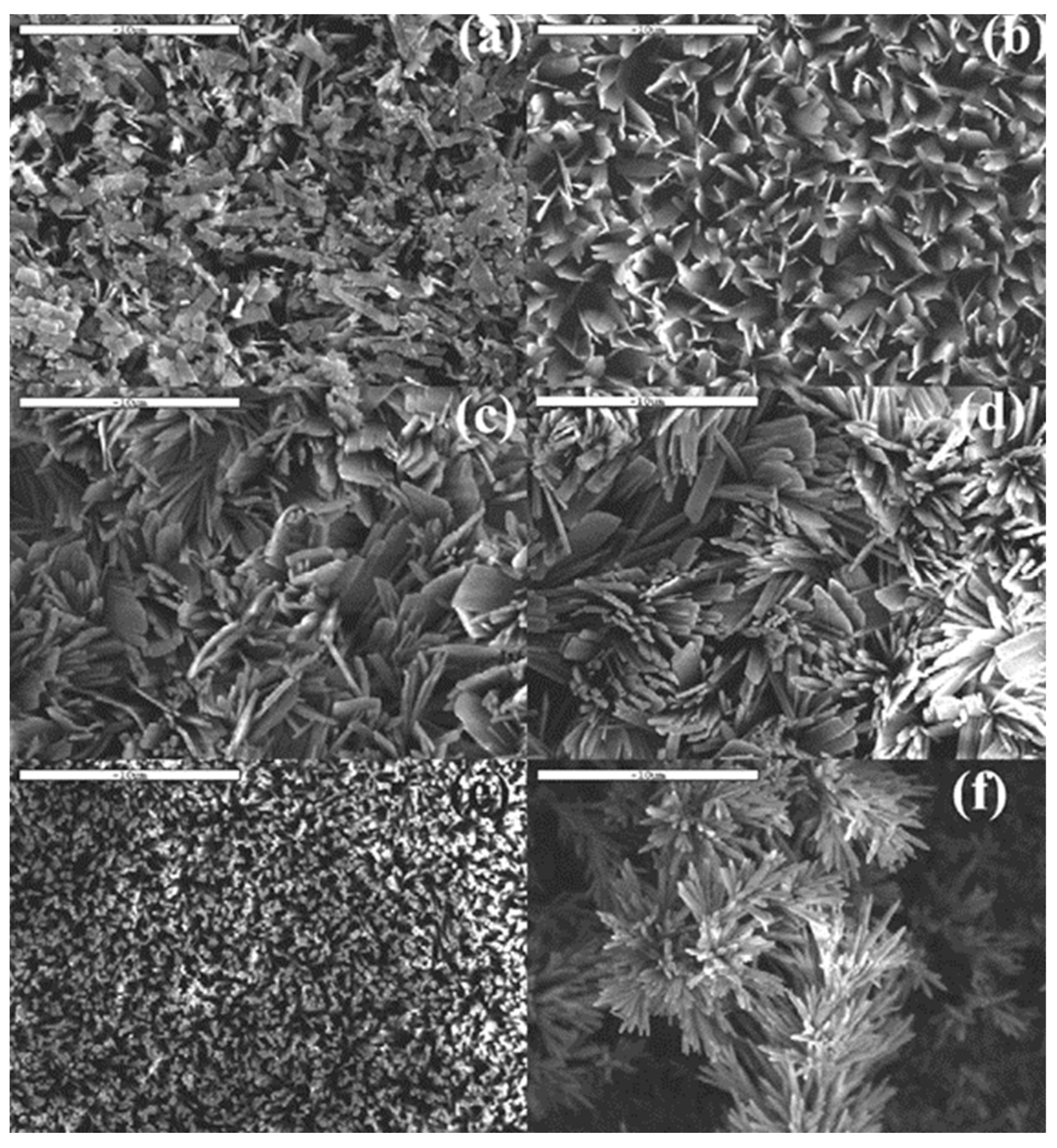

4.3.2. Electrochemical (ECD) or Cathodic Deposition

4.3.3. Sol–Gel Deposition

4.3.4. Wet-Chemical and Biomimetic Deposition Techniques

4.3.5. Dip Coating Technique

4.3.6. Spin Coating Technique

4.3.7. Hydrothermal Deposition Method

4.3.8. Thermal Substrate Deposition Technique

4.3.9. Alternate Soaking Deposition

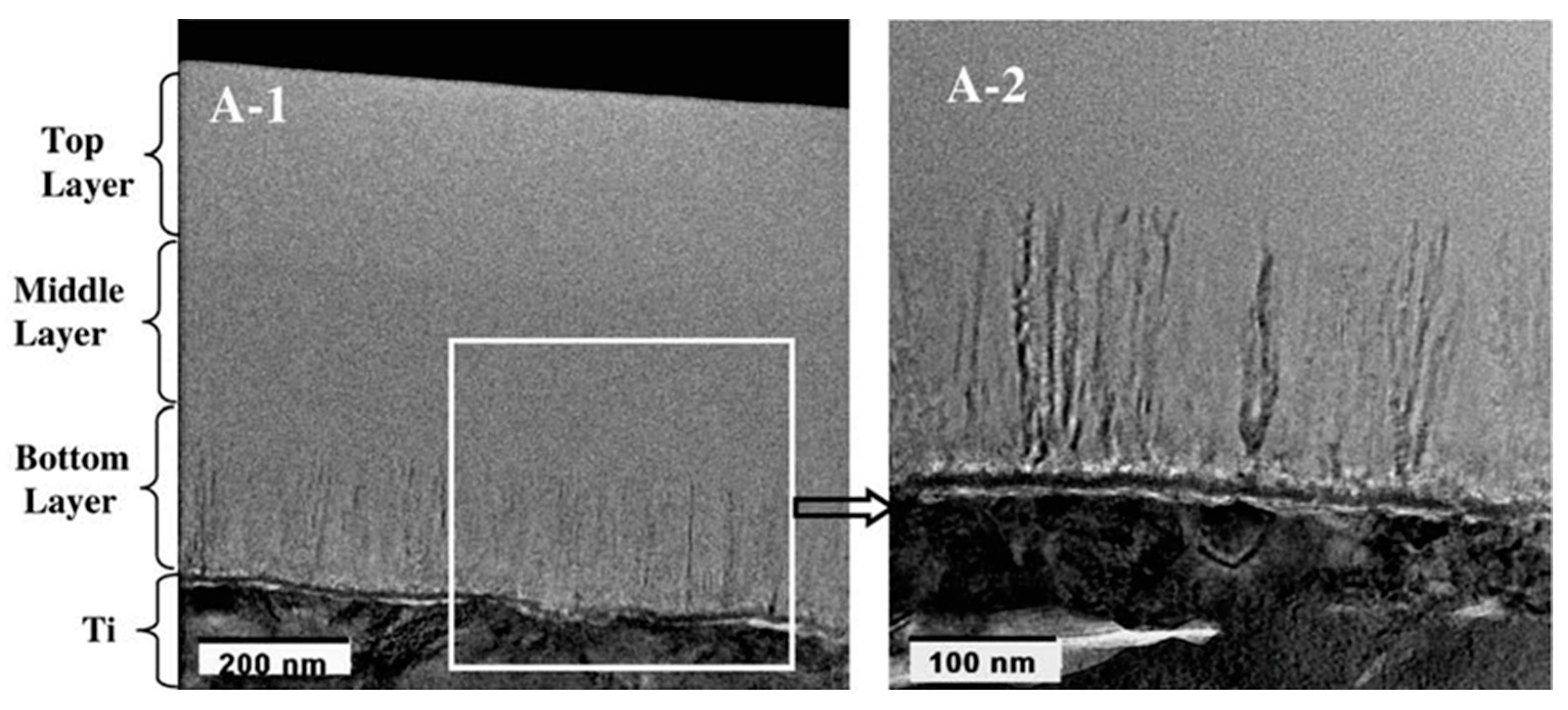

4.3.10. Micro-Arc Oxidation (MAO) Technique

4.4. Other CaPO4 Deposition Techniques: Miscellaneous

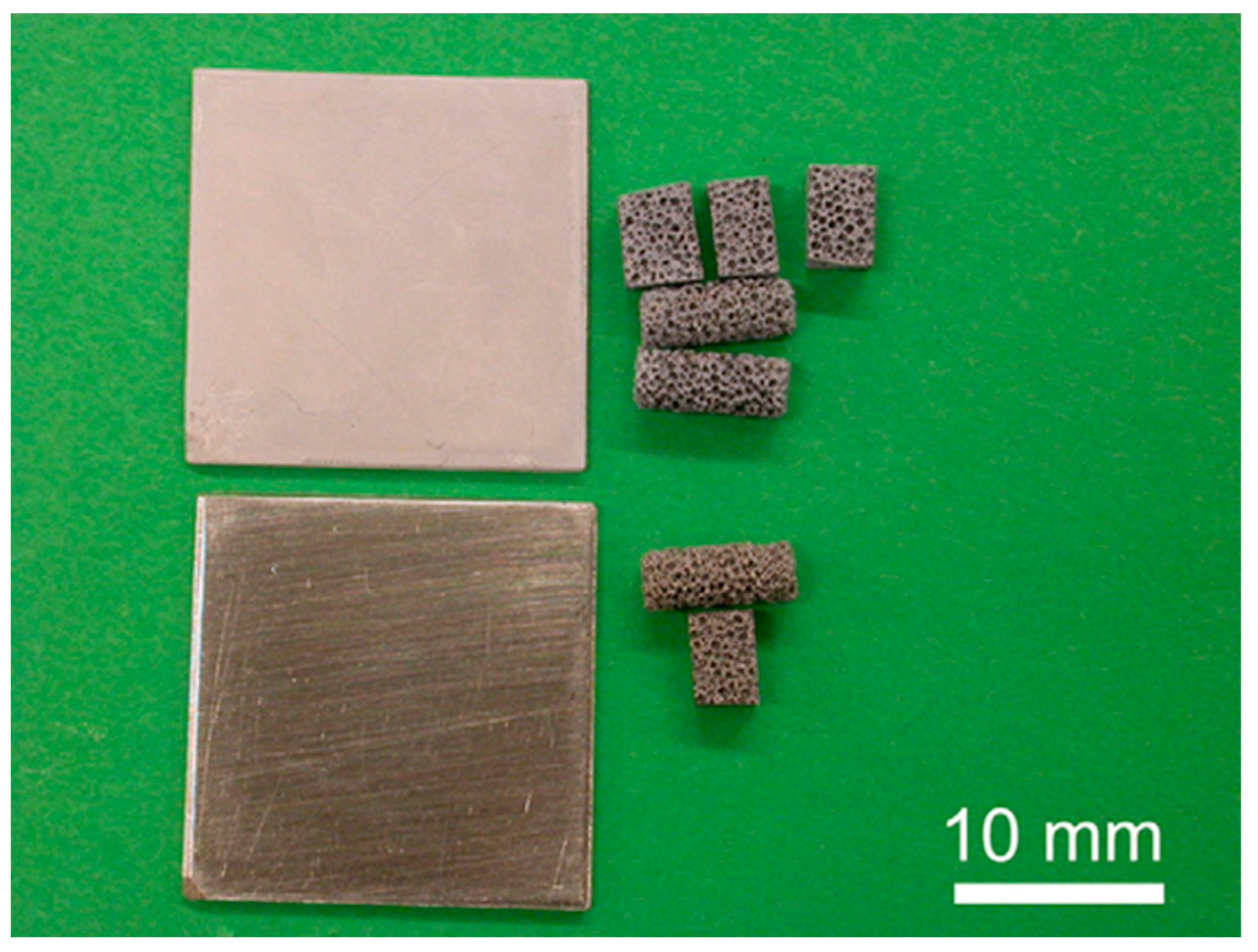

4.4.1. Hot Isostatic Pressing (HIP)

4.4.2. Implantation into the Surface of Superplastic Alloys

4.4.3. A Double Layered Capsule Hydrothermal Hot Pressing

4.4.4. Detonation Gun (D-Gun) Spraying

4.4.5. Aerosol–Gel Deposition

4.4.6. Aerosol Deposition (AD)

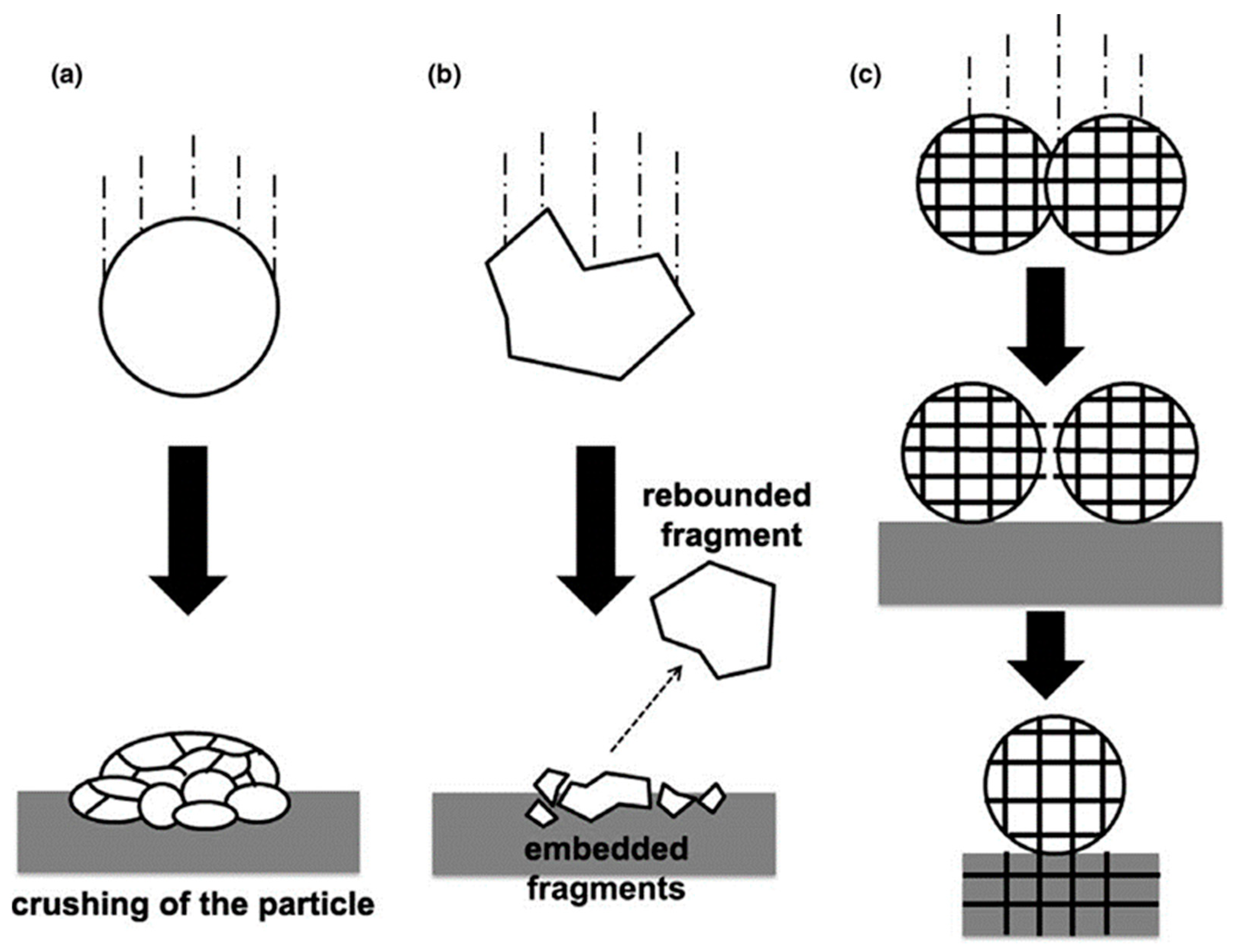

4.4.7. Cold Spraying (CS)

4.4.8. Blast Coating

4.4.9. Direct Laser Melting

4.4.10. Transmission Laser Coating

4.4.11. Laser Cladding

4.4.12. Laser-Engineered Net Shaping (LENS™)

4.4.13. Matrix Assisted Pulsed Laser Evaporation (MAPLE)

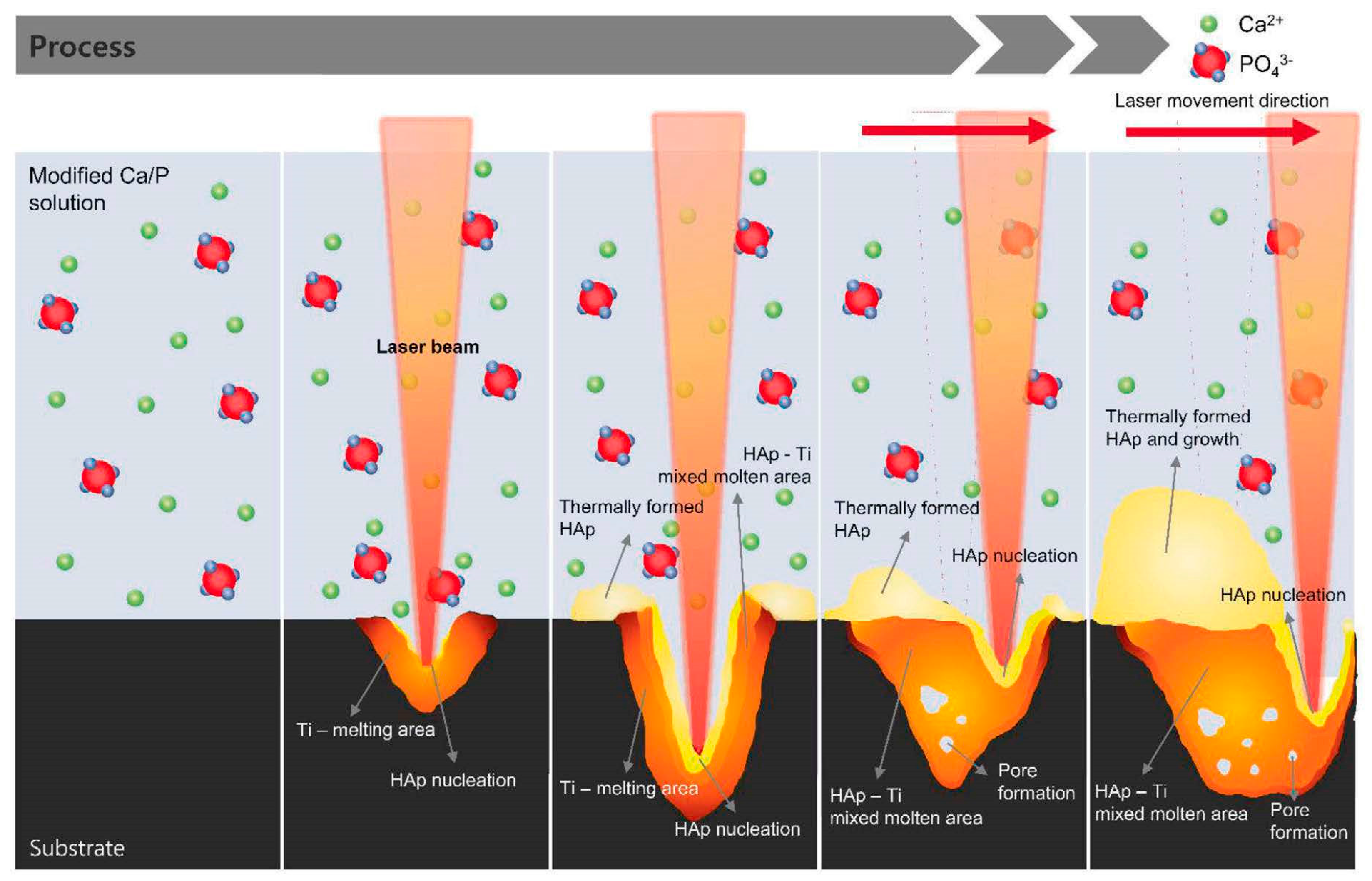

4.4.14. Liquid Phase Laser Deposition

4.4.15. Laser-Induced Forward Transfer with Optical Stamp (LIFTOP)

4.4.16. Laser-Induced Single-Step Coating (LISSC)

4.4.17. Electrostatic Spray Deposition (ESD) Technique

4.4.18. Spray Pyrolysis (Pyrosol) Technique

4.4.19. Polymeric Deposition Route

4.4.20. Atomic Layer Deposition (ALD)

4.4.21. Drop-On-Demand (DOD) Micro-Dispensing Technique

4.4.22. Vapor Diffusion Sitting Drop Micro-Method (VDSDM)

4.4.23. Mechanochemical Synthesis or Ball Impact Method

4.4.24. Mechanofusion

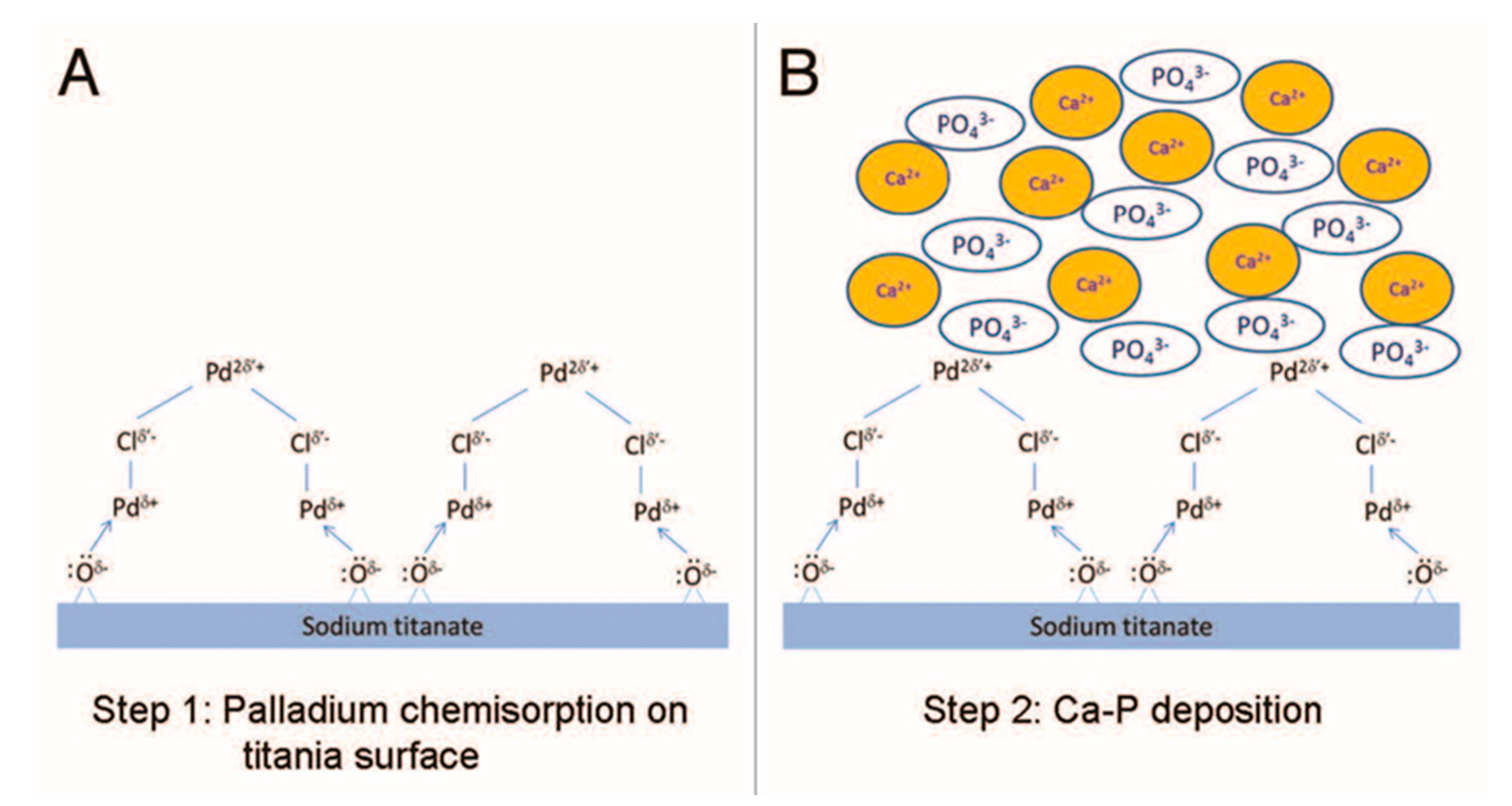

4.4.25. Autocatalytic Deposition

4.4.26. Galvanic Deposition

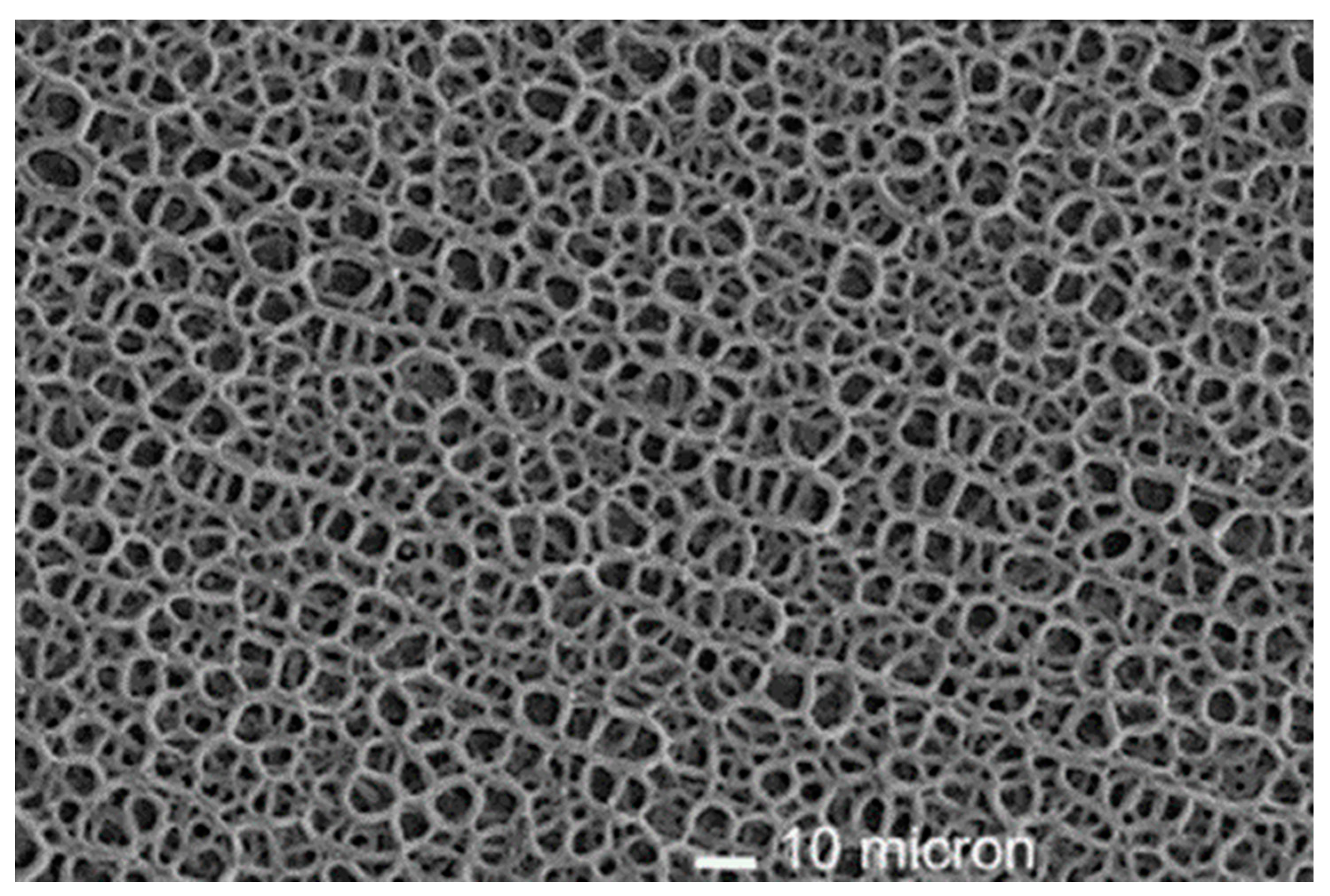

4.4.27. Anodization Technique

4.4.28. Simultaneous Precipitation and Electrodeposition

4.4.29. Electrical Stimulation

4.4.30. Cyclic Electrodeposition

4.4.31. Cyclic Spin Coating

4.4.32. Biomediated Deposition Technique (Biosynthesis)

4.4.33. Emulsion Route

4.4.34. Slurry Processing Technique

4.4.35. Slip Coating Technique

4.4.36. Deposition by Solvent Evaporation

4.4.37. Discrete Crystalline Deposition

4.4.38. Powder Mixed Electrical Discharge Machining (PMEDM)

4.4.39. Investment Casting

4.4.40. Brush Painting

4.4.41. Photocatalytic Deposition

4.4.42. Adsorption

4.4.43. Sonocoating

4.4.44. Ultrasonic Mechanical Coating and Armoring (UMCA)

4.4.45. Osteomimetic Deposition

4.4.46. Surface-Induced Mineralization (SIM)

4.4.47. Ionized Jet Deposition (IJD)

4.4.48. Undisclosed Proprietary Deposition Techniques

4.4.49. Additive Manufacturing Techniques

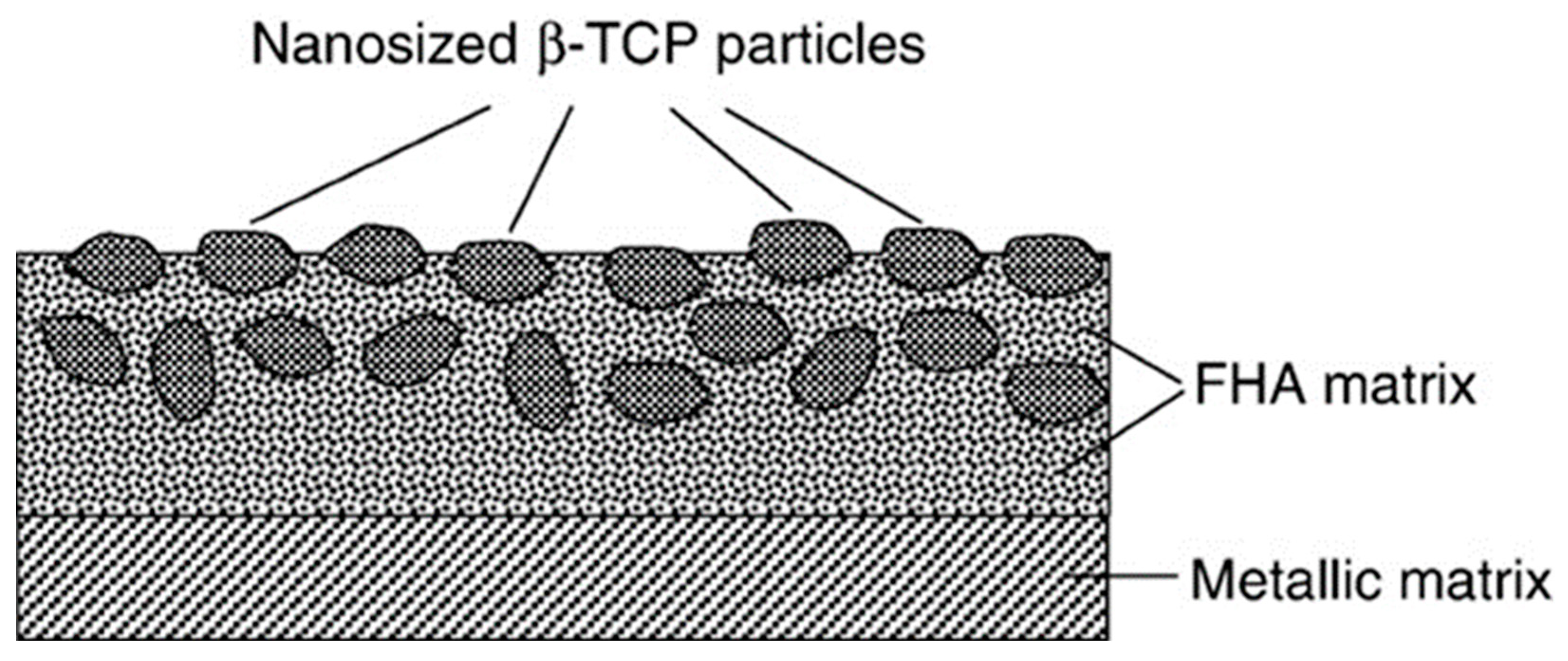

5. Deposition of Ion-Substituted CaPO4 and CaPO4-Containing Biocomposites

6. Conversion-Formed CaPO4 Deposits

- Part 2.

- Properties and Applications

7. A Brief Description of the Most Important Properties

7.1. Introduction

7.2. Elastic Modulus and Hardness

7.3. Fatigue Properties

7.4. Thickness

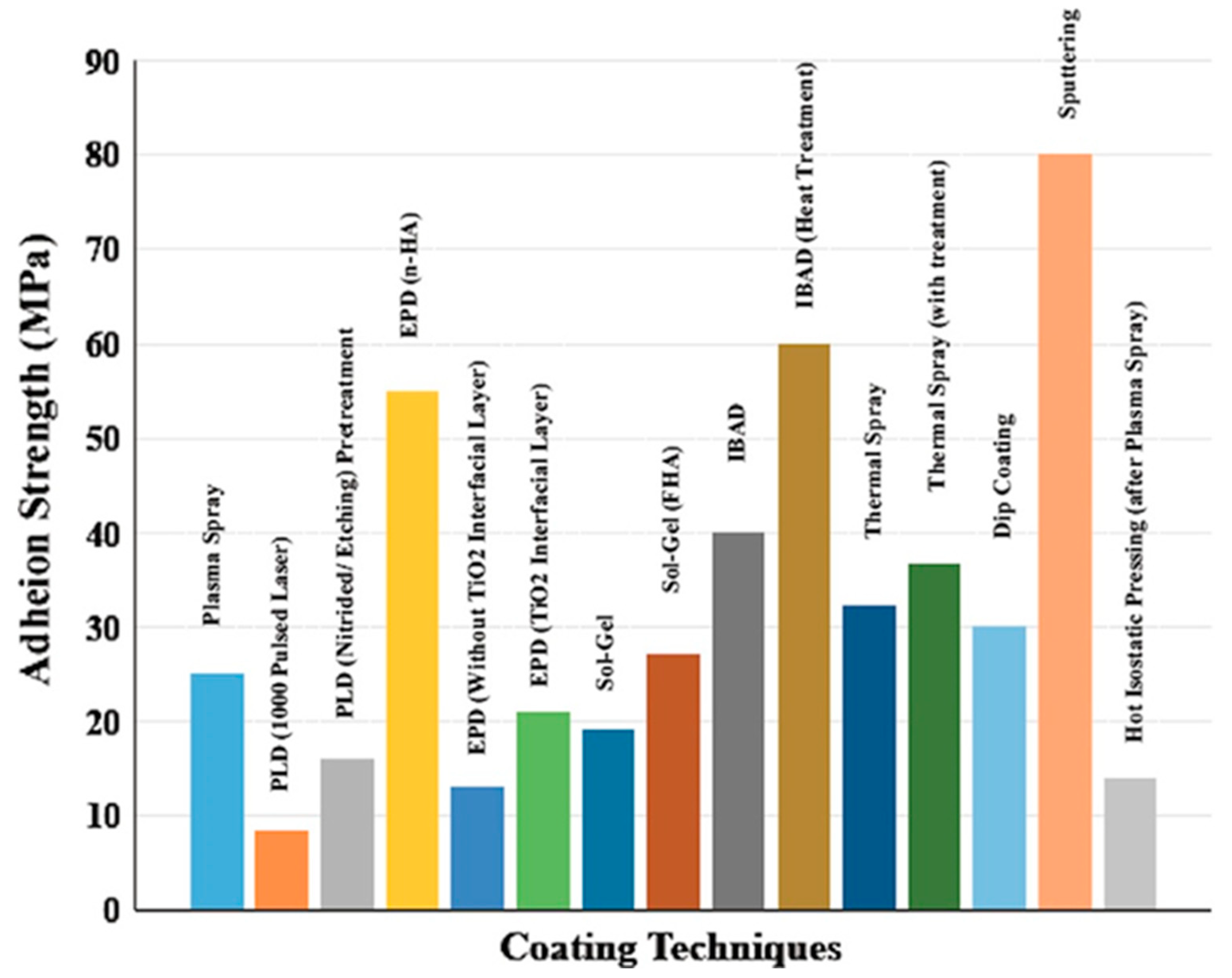

7.5. Adhesion and Cohesion

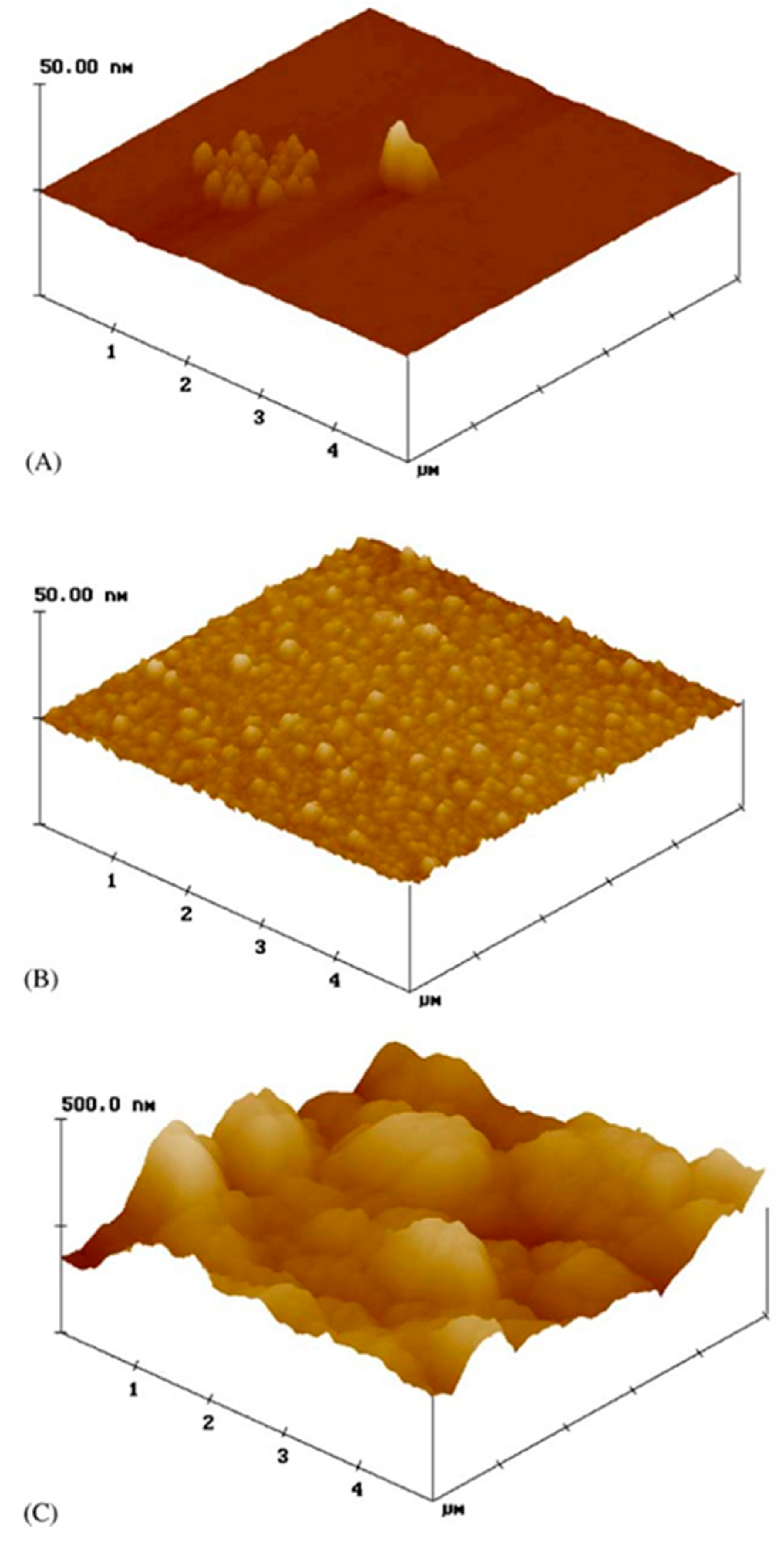

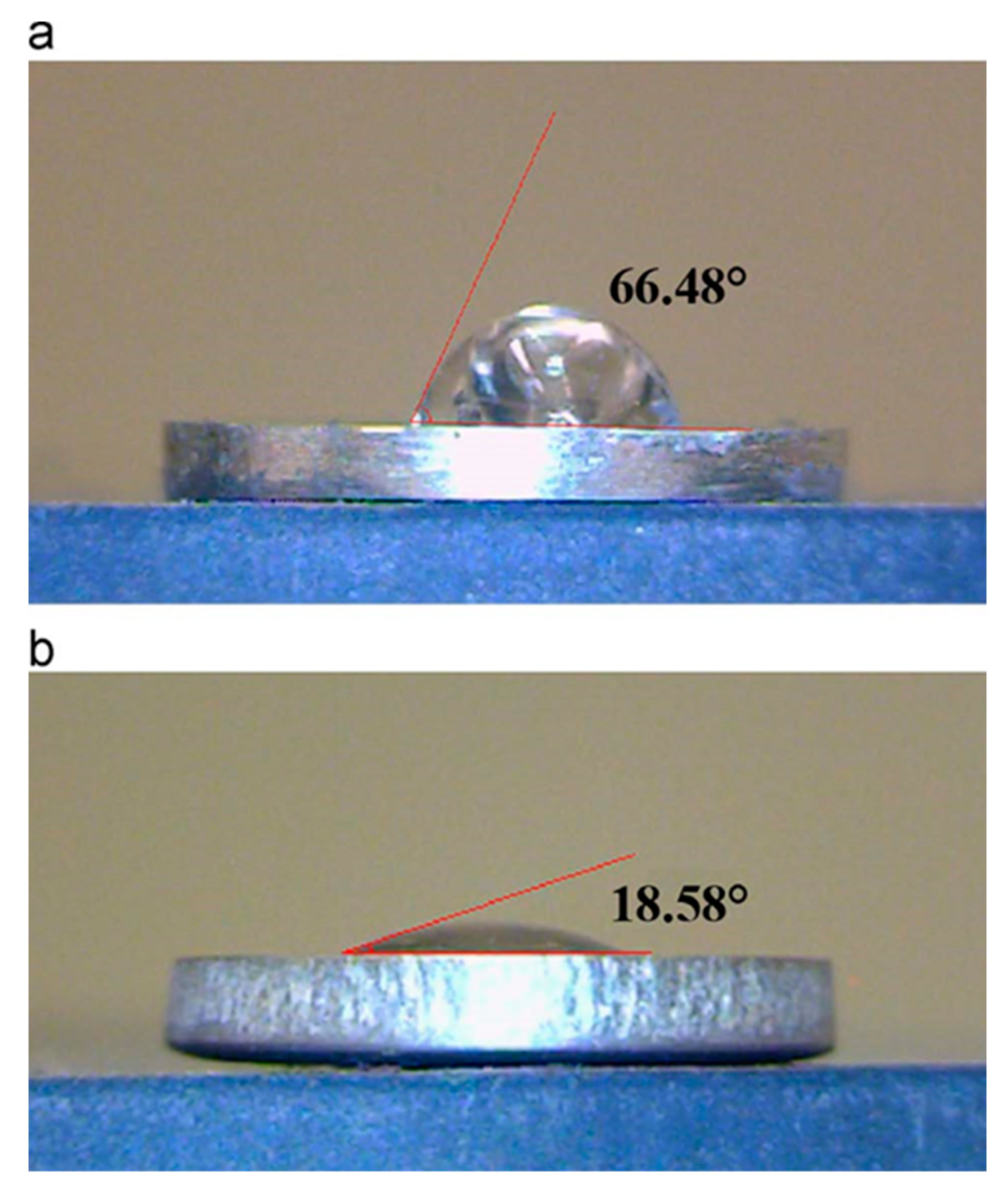

7.6. Surface Characteristics: Crystallinity, Morphology and Roughness

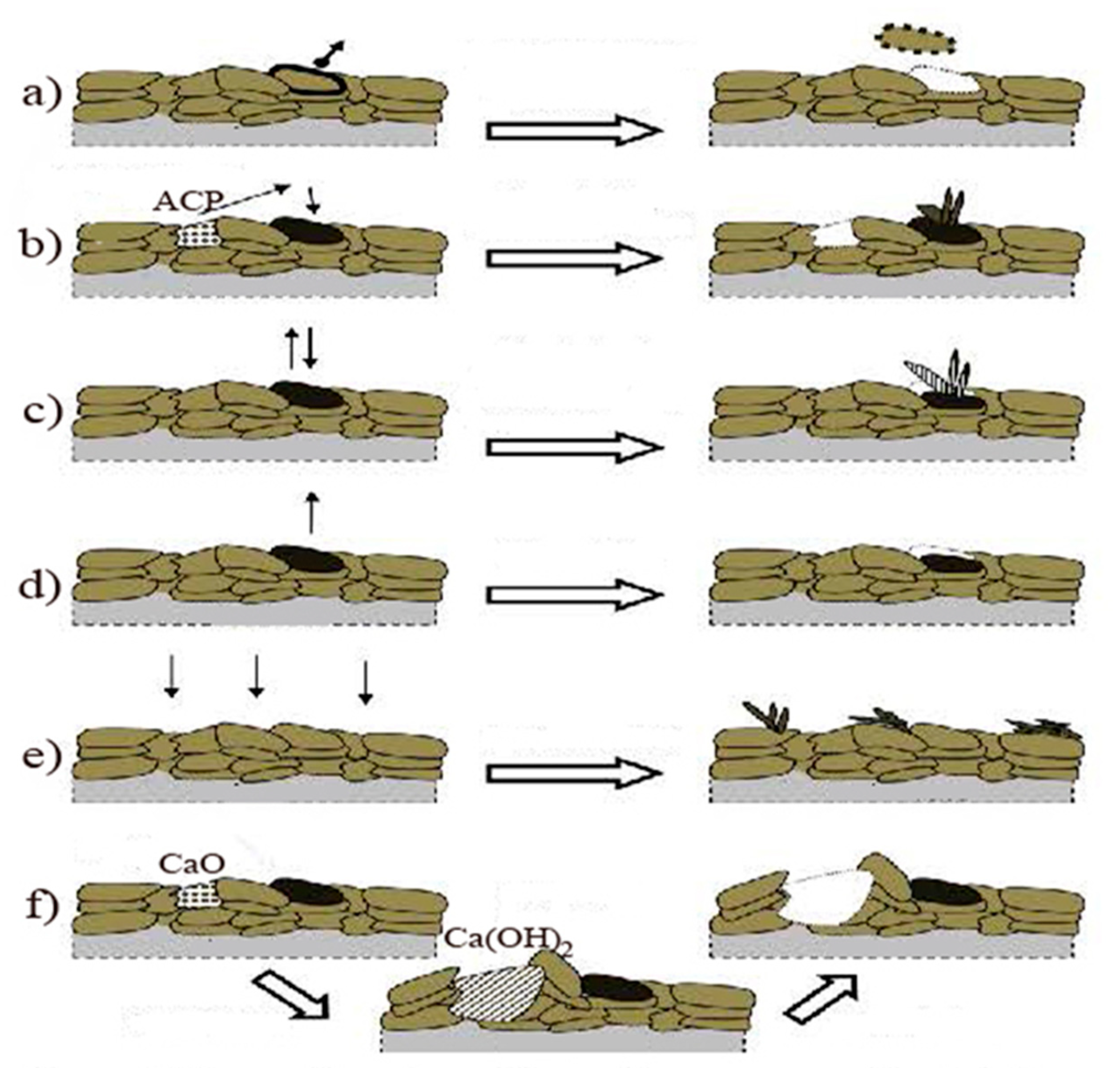

7.7. Biodegradation

7.8. Interaction with Cells and Tissue Responses

8. Biomedical Applications of CaPO4 Deposits

9. Future Directions

10. Conclusions

Funding

Data Availability Statement

Conflicts of Interest

References

- Available online: https://en.wikipedia.org/wiki/Surface_engineering (accessed on 20 April 2023).

- Biesiekierski, A.; Wang, J.; Gepreel, M.A.H.; Wen, C. A new look at biomedical Ti-based shape memory alloys. Acta Biomater. 2012, 8, 1661–1669. [Google Scholar] [CrossRef] [PubMed]

- Duan, K.; Wang, R. Surface modifications of bone implants through wet chemistry. J. Mater. Chem. 2006, 16, 2309–2321. [Google Scholar] [CrossRef]

- LeGeros, R.Z. Calcium Phosphates in Oral Biology and Medicine, Monographs in Oral Science; Myers, H.M., Ed.; Karger: Basel, Switzerland, 1991; Volume 15, 201p. [Google Scholar]

- Dorozhkin, S.V. Calcium Orthophosphates: Applications in Nature, Biology, and Medicine; Pan Stanford: Singapore, 2012; 854p. [Google Scholar]

- Dorozhkin, S.V. Calcium Orthophosphate-Based Bioceramics and Biocomposites; Wiley-VCH: Weinheim, Germany, 2016; 405p. [Google Scholar]

- Ong, J.L.; Chan, D.C.N. Hydroxyapatite and their use as coatings in dental implants: A review. Crit. Rev. Biomed. Eng. 1999, 28, 667–707. [Google Scholar] [CrossRef] [PubMed]

- de Groot, K.; Wolke, J.G.C.; Jansen, J.A. Calcium phosphate coatings for medical implants. Proc. Inst. Mech. Eng. Part H J. Eng. Med. 1998, 212, 137–147. [Google Scholar] [CrossRef]

- Onoki, T.; Hashida, T. New method for hydroxyapatite coating of titanium by the hydrothermal hot isostatic pressing technique. Surf. Coat. Tech. 2006, 200, 6801–6807. [Google Scholar] [CrossRef]

- Kobayashi, T.; Itoh, S.; Nakamura, S.; Nakamura, M.; Shinomiya, K.; Yamashita, K. Enhanced bone bonding of hydroxyapatite-coated titanium implants by electrical polarization. J. Biomed. Mater. Res. A 2007, 82A, 145–151. [Google Scholar] [CrossRef]

- Epinette, J.A.M.D.; Geesink, R.G.T. Hydroxyapatite Coated Hip and Knee Arthroplasty; Elsevier: Amsterdam, The Netherlands, 1995; 394p. [Google Scholar]

- Willmann, G. Coating of implants with hydroxyapatite–material connections between bone and metal. Adv. Eng. Mater. 1999, 1, 95–105. [Google Scholar] [CrossRef]

- Epinette, J.A.; Manley, M.T. (Eds.) Fifteen Years of Clinical Experience with Hydroxyapatite Coatings in Joint Arthroplasty; Springer: Paris, France, 2004; 452p. [Google Scholar]

- Habibovic, P.; Li, J.; van der Valk, C.M.; Meijer, G.; Layrolle, P.; van Blitterswijk, C.A.; de Groot, K. Biological performance of uncoated and octacalcium phosphate-coated Ti6Al4V. Biomaterials 2005, 26, 23–36. [Google Scholar] [CrossRef]

- Hahn, B.D.; Park, D.S.; Choi, J.J.; Ryu, J.; Yoon, W.H.; Kim, K.H.; Park, C.; Kim, H.E. Dense nanostructured hydroxyapatite coating on titanium by aerosol deposition. J. Am. Ceram. Soc. 2009, 92, 683–687. [Google Scholar] [CrossRef]

- Callahan, T.J.; Gantenberg, J.B.; Sands, B.E. Calcium phosphate (Ca-P) coating draft guidance for preparation of Food and Drug Administration (FDA) submissions for orthopedic and dental endosseous implants. In Characterization and Performance of Calcium Phosphate Coatings for Implants; Horowitz, E., Parr, J.E., Eds.; ASTM STP 1196: Philadelphia, PA, USA, 1994; pp. 185–197. [Google Scholar]

- Implants for Surgery: Coating for Hydroxyapatite Ceramics; ISO: Geneva, Switzerland, 1996; pp. 1–8.

- 510(K) Information Needed for Hydroxyapatite Coated Orthopedic Implants. March 10, 1995 (revised 2/20/97). Available online: http://www.fda.gov/MedicalDevices/DeviceRegulationandGuidance/GuidanceDocuments/ucm080224.htm (accessed on 20 April 2023).

- ISO 13779-2:2000; Implants for Surgery—Hydroxyapatite—Part 2: Coatings of Hydroxyapatite. ISO: Geneva, Switzerland, 2000. Available online: https://www.iso.org/standard/26841.html (accessed on 20 April 2023).

- ISO 13779-2:2008; Implants for Surgery—Hydroxyapatite—Part 2: Coatings of Hydroxyapatite. ISO: Geneva, Switzerland, 2008. Available online: https://www.iso.org/standard/43827.html (accessed on 20 April 2023).

- ISO 13779-2:2018; Implants for Surgery—Hydroxyapatite—Part 2: Thermally Sprayed Coatings of Hydroxyapatite. ISO: Geneva, Switzerland, 2018. Available online: https://www.iso.org/standard/64617.html (accessed on 20 April 2023).

- ISO 13779-4:2002; Implants for Surgery—Hydroxyapatite—Part 4: Determination of Coating Adhesion Strength. ISO: Geneva, Switzerland, 2002. Available online: https://www.iso.org/standard/30723.html (accessed on 20 April 2023).

- ISO 13779-4:2018; Implants for Surgery—Hydroxyapatite—Part 4: Determination of Coating Adhesion Strength. ISO: Geneva, Switzerland, 2002. Available online: https://www.iso.org/standard/64619.html (accessed on 20 April 2023).

- Available online: https://www.wikiwand.com/en/Coating (accessed on 20 April 2023).

- Ohring, M. Materials Science of Thin Films, 2nd ed.; Academic Press: San Diego, CA, USA, 2002; 794p. [Google Scholar]

- Kibardin, S.A.; Lazurkin, V.B. Thin-layer chromatography of proteins on plates coated with hydroxylapatite. Biochemistry 1965, 30, 483–487. [Google Scholar]

- McHugh, T.H. Protein-lipid interactions in edible films and coatings. Nahrung 2000, 44, 148–151. [Google Scholar] [CrossRef] [PubMed]

- Falguera, V.; Quintero, J.P.; Jiménez, A.; Muñoz, J.A.; Ibarz, A. Edible films and coatings: Structures, active functions and trends in their use. Trends Food Sci. Tech. 2011, 22, 292–303. [Google Scholar] [CrossRef]

- Cabañas, M.V. Bioceramic coatings for medical implants. In Bio-Ceramics with Clinical Applications; Vallet-Regí, M., Ed.; Wiley: Chichester, UK, 2014; pp. 249–289. [Google Scholar]

- Yang, Y.; Kim, K.H.; Ong, J.L. A review on calcium phosphate coatings produced using a sputtering process—An alternative to plasma spraying. Biomaterials 2005, 26, 327–337. [Google Scholar] [CrossRef]

- Narayanan, R.; Seshadri, S.K.; Kwon, T.Y.; Kim, K.H. Calcium phosphate-based coatings on titanium and its alloys. J. Biomed. Mater. Res. B Appl. Biomater. 2008, 85B, 279–299. [Google Scholar] [CrossRef]

- Narayanan, R.; Kim, K.H.; Rautray, T.R. Surface Modification of Titanium for Biomaterial Applications; Nova Science: Hauppauge, NY, USA, 2010; p. 352. [Google Scholar]

- Tsui, Y.C.; Doyle, C.; Clyne, T.W. Plasma sprayed hydroxyapatite coatings on titanium substrates: Part 1: Mechanical properties and residual stress levels. Biomaterials 1998, 19, 2015–2029. [Google Scholar] [CrossRef]

- Oyane, A.; Uchida, M.; Choong, C.; Triffitt, J.; Jones, J.; Ito, A. Simple surface modification of poly(ε-caprolactone) for apatite deposition from simulated body fluid. Biomaterials 2005, 26, 2407–2413. [Google Scholar] [CrossRef] [PubMed]

- Lakstein, D.; Kopelovitch, W.; Barkay, Z.; Bahaa, M.; Hendel, D.; Eliaz, N. Enhanced osseointegration of grit-blasted, NaOH-treated and electrochemically hydroxyapatite-coated Ti–6Al–4V implants in rabbits. Acta Biomater. 2009, 5, 2258–2269. [Google Scholar] [CrossRef] [PubMed]

- Eliaz, N.; Ritman-Hertz, O.; Aronov, D.; Weinberg, E.; Shenhar, Y.; Rosenman, G.; Weinreb, M.; Ron, E. The effect of surface treatments on the adhesion of electrochemically deposited hydroxyapatite coating to titanium and on its interaction with cells and bacteria. J. Mater. Sci. Mater. Med. 2011, 22, 1741–1752. [Google Scholar] [CrossRef]

- Pattanayak, D.K.; Yamaguchi, S.; Matsushita, T.; Nakamura, T.; Kokubo, T. Apatite-forming ability of titanium in terms of pH of the exposed solution. J. R. Soc. Interface 2012, 9, 2145–2155. [Google Scholar] [CrossRef]

- El-Rab, S.M.F.G.; Fadl-allah, S.A.; Montser, A.A. Improvement in antibacterial properties of Ti by electrodeposition of biomimetic Ca–P apatite coat on anodized titania. Appl. Surf. Sci. 2012, 261, 1–7. [Google Scholar] [CrossRef]

- Ajami, E.; Aguey-Zinsou, K.F. Calcium phosphate growth at electropolished titanium surfaces. J. Funct. Biomater. 2012, 3, 327–348. [Google Scholar] [CrossRef] [PubMed]

- Zhao, X.; Li, H.; Chen, M.; Li, K.; Wang, B.; Xu, Z.; Cao, S.; Zhang LDeng, H.; Lu, J. Strong-bonding calcium phosphate coatings on carbon/carbon composites by ultrasound-assisted anodic oxidation treatment and electrochemical deposition. Appl. Surf. Sci. 2012, 258, 5117–5125. [Google Scholar] [CrossRef]

- Ágreda, C.G.; Mendes, M.W.D.; Bressiani, J.C.; Bressiani, A.H.A. Apatite coating on titanium samples obtained by powder metallurgy. Adv. Sci. Technol. 2013, 86, 28–33. [Google Scholar]

- Xiao, X.; Yu, J.; Tang, H.; Mao, D.; Wang, C.; Liu, R. TiO2 nanotube arrays induced deposition of hydroxyapatite coating by hydrothermal treatment. Mater. Chem. Phys. 2013, 138, 695–702. [Google Scholar] [CrossRef]

- Dorozhkin, S.V. Calcium orthophosphate coatings on magnesium and its biodegradable alloys. Acta Biomater. 2014, 10, 2919–2934. [Google Scholar] [CrossRef]

- Lu, Y.P.; Xiao, G.Y.; Li, S.T.; Sun, R.X.; Li, M.S. Microstructural inhomogeneity in plasma-sprayed hydroxyapatite coatings and effect of post-heat treatment. Appl. Surf. Sci. 2006, 252, 2412–2421. [Google Scholar] [CrossRef]

- Khalili, V.; Naji, H. Developing a mechanochemical surface pretreatment to increase the adhesion strength of hydroxyapatite electrophoretic coating on the NiTi alloy as a bone implant. Surf. Coat. Tech. 2020, 397, 125985. [Google Scholar] [CrossRef]

- Mohammadi, Z.; Ziaei-Moayyed, A.A.; Mesgar, A.S.M. Adhesive and cohesive properties by indentation method of plasma-sprayed hydroxyapatite coatings. Appl. Surf. Sci. 2007, 253, 4960–4965. [Google Scholar] [CrossRef]

- Lu, Y.P.; Chen, Y.M.; Li, S.T.; Wang, J.H. Surface nanocrystallization of hydroxyapatite coating. Acta Biomater. 2008, 4, 1865–1872. [Google Scholar] [CrossRef]

- Zhang, X.; Xiao, G.Y.; Liu, B.; Jiang, C.C.; Li, N.B.; Lu, Y.P. The formation of hydroxyapatite layer onto hopeite coating on stainless steel substrate. Corr. Sci. 2016, 111, 216–229. [Google Scholar] [CrossRef]

- Leonor, I.B.; Reis, R.L. An innovative auto-catalytic deposition route to produce calcium-phosphate coatings on polymeric biomaterials. J. Mater. Sci. Mater. Med. 2003, 14, 435–441. [Google Scholar] [CrossRef]

- Bunker, B.C.; Rieke, P.C.; Tarasevich, B.J.; Campbell, A.A.; Fryxell, G.E.; Graff, G.L.; Song, L.; Liu, J.; Virden, J.W.; McVay, G.L. Ceramic thin-film formation on functionalized interfaces through biomimetic processing. Science 1994, 264, 48–55. [Google Scholar] [CrossRef]

- Zheng, Y.; Xiong, C.; Zhang, S.; Li, X.; Zhang, L. Bone-like apatite coating on functionalized poly(etheretherketone) surface via tailored silanization layers technique. Mater. Sci. Eng. C 2015, 55, 512–523. [Google Scholar] [CrossRef] [PubMed]

- Le, V.Q.; Pourroy, G.; Cochis, A.; Rimondini, L.; Abdel-Fattah, W.I.; Mohammed, H.I.; Carradò, A. Alternative technique for calcium phosphate coating on titanium alloy implants. Biomatter 2014, 4, e28534. [Google Scholar] [CrossRef] [PubMed]

- Hoppe, A.; Will, J.; Detsch, R.; Boccaccini, A.R.; Greil, P. Formation and in vitro biocompatibility of biomimetic hydroxyapatite coatings on chemically treated carbon substrates. J. Biomed. Mater. Res. A 2014, 102A, 193–203. [Google Scholar] [CrossRef]

- Tanahashi, M.; Yao, T.; Kokubo, T.; Minoda, M.; Miyamoto, T.; Nakamura, T.; Yamamuro, T. Apatite coated on organic polymers by biomimetic process: Improvement in its adhesion to substrate by NaOH treatment. J. Appl. Biomater. 1994, 5, 339–347. [Google Scholar] [CrossRef] [PubMed]

- Duan, K.; Tang, A.; Wang, R. Accelerating calcium phosphate growth on NaOH-treated poly-(lactic-co-glycolic acid) by evaporation-induced surface crystallization. Appl. Surf. Sci. 2008, 255, 2442–2448. [Google Scholar] [CrossRef]

- Okada, M.; Furuzono, T. Hydroxyapatite nanocrystal coating on biodegradable microspheres. Mater. Sci. Eng. B 2010, 173, 199–203. [Google Scholar] [CrossRef]

- Wu, M.; Wang, Q.; Liu, X.; Liu, H. Biomimetic synthesis and characterization of carbon nanofiber/hydroxyapatite composite scaffolds. Carbon 2013, 51, 335–345. [Google Scholar] [CrossRef]

- Peng, F.; Shaw, M.T.; Olson, J.R.; Wei, M. Influence of surface treatment and biomimetic hydroxyapatite coating on the mechanical properties of hydroxyapatite/poly(L-lactic acid) fibers. J. Biomater. Appl. 2013, 27, 641–649. [Google Scholar] [CrossRef]

- Hashizume, M.; Maeda, M.; Iijima, K. Biomimetic calcium phosphate coating on polyimide films by utilizing surface-selective hydrolysis treatments. J. Ceram. Soc. Jpn. 2013, 121, 816–818. [Google Scholar] [CrossRef]

- Kramer, E.; Kunkemoeller, B.; Wei, M. Evaluation of alkaline pre-treatment of PLLA fibers for biomimetic hydroxyapatite coating. Surf. Coat. Tech. 2014, 244, 23–28. [Google Scholar] [CrossRef]

- Rajesh, P.; Mohan, N.; Yokogawa, Y.; Varma, H. Pulsed laser deposition of hydroxyapatite on nanostructured titanium towards drug eluting implants. Mater. Sci. Eng. C 2013, 33, 2899–2904. [Google Scholar] [CrossRef] [PubMed]

- Riau, A.K.; Mondal, D.; Setiawan, M.; Palaniappan, A.; Yam, G.H.F.; Liedberg, B.; Venkatraman, S.S.; Mehta, J.S. Functionalization of the polymeric surface with bioceramic nanoparticles via a novel, nonthermal dip coating method. ACS Appl. Mater. Interfaces 2016, 8, 35565–35577. [Google Scholar] [CrossRef]

- Xiong, X.B.; Zeng, X.R.; Zou, C.L.; Zhou, J.Z. Strong bonding strength between HA and (NH4)2S2O8-treated carbon/carbon composite by hydrothermal treatment and induction heating. Acta Biomater. 2009, 5, 1785–1790. [Google Scholar] [PubMed]

- Mucalo, M.R.; Yokogawa, Y.; Toriyama, M.; Suzuki, T.; Kawamoto, Y.; Nagata, F.; Nishizawa, K. Growth of calcium phosphate on surface-modified cotton. J. Mater. Sci. Mater. Med. 1995, 6, 597–605. [Google Scholar] [CrossRef]

- Yokogawa, Y.; Paz Reyes, J.; Mucalo, M.R.; Toriyama, M.; Kawamoto, Y.; Suzuki, T.; Nishizawa, K.; Nagata, F.; Kamayama, T. Growth of calcium phosphate on phosphorylated chitin fibres. J. Mater. Sci. Mater. Med. 1997, 8, 407–412. [Google Scholar] [CrossRef]

- Li, K.; Wang, J.; Liu, X.; Xiong, X.; Liu, H. Biomimetic growth of hydroxyapatite on phosphorylated electrospun cellulose nanofibers. Carbohyd. Polym. 2012, 90, 1573–1581. [Google Scholar] [CrossRef]

- Tretinnikov, O.N.; Kato, K.; Ikada, Y. In vitro hydroxyapatite deposition onto a film surface-grated with organophosphate polymer. J. Biomed. Mater. Res. 1994, 28, 1365–1373. [Google Scholar] [CrossRef]

- Kim, H.M.; Uenoyama, M.; Kokubo, T.; Minoda, M.; Miyamoto, T.; Nakamura, T. Biomimetic apatite formation on polyethylene photografted with vinyltrimethoxysilane and hydrolyzed. Biomaterials 2001, 22, 2489–2494. [Google Scholar] [CrossRef]

- Wang, X.; Zhao, X.; Wang, W.; Zhang, J.; Zhang, L.; He, F.; Yang, J. Controllable preparation of a nano-hydroxyapatite coating on carbon fibers by electrochemical deposition and chemical treatment. Mater. Sci. Eng. C 2016, 63, 96–105. [Google Scholar] [CrossRef] [PubMed]

- Xiao, Y.; Gong, T.; Zhou, S. The functionalization of multi-walled carbon nanotubes by in situ deposition of hydroxyapatite. Biomaterials 2010, 31, 5182–5190. [Google Scholar] [CrossRef]

- Neelgund, G.M.; Oki, A.; Luo, Z. In situ deposition of hydroxyapatite on graphene nanosheets. Mater. Res. Bull. 2013, 48, 175–179. [Google Scholar] [CrossRef]

- Waterman, J.; Pietak, A.; Birbilis, N.; Woodfield, T.; Dias, G.; Staiger, M.P. Corrosion resistance of biomimetic calcium phosphate coatings on magnesium due to varying pretreatment time. Mater. Sci. Eng. B 2011, 176, 1756–1760. [Google Scholar] [CrossRef]

- Tanahashi, M.; Yao, T.; Kokubo, T.; Minoda, M.; Miyamoto, T.; Nakamura, T.; Yamamuro, T. Apatite coated on organic polymers by biomimetic process: Improvement in its adhesion to substrate by glow-discharge treatment. J. Biomed. Mater. Res. 1995, 29, 349–357. [Google Scholar] [CrossRef] [PubMed]

- Yabutsuka, T.; Fukushima, K.; Kidokoro, Y.; Matsunaga, T.; Takai, S.; Yao, T. Fabrication of bioactive fiber reinforced polyetheretherketone by the function of apatite nuclei. Key Eng. Mater. 2017, 720, 246–251. [Google Scholar] [CrossRef]

- Baker, K.C.; Drelich, J.; Miskioglu, I.; Israel, R.; Herkowitz, H.N. Effect of polyethylene pretreatments on the biomimetic deposition and adhesion of calcium phosphate films. Acta Biomater. 2007, 3, 391–401. [Google Scholar] [CrossRef] [PubMed]

- Liu, G.J.; Miyaji, F.; Kokubo, T.; Takadama, H.; Nakamura, T.; Murakami, A. Apatite-organic polymer composites prepared by a biomimetic process: Improvement in adhesion of the apatite layer to the substrate by ultraviolet irradiation. J. Mater. Sci. Mater. Med. 1998, 9, 285–290. [Google Scholar] [CrossRef]

- Suzuki, N.; Umeda, T.; Sumi, T.; Horikoshi, S.; Kuwahara, H.; Toyama, T.; Musha, Y.; Itatani, K. Rapid formation of hydroxyapatite layer on polyetheretherketone by vacuum ultraviolet irradiation and microwave heating techniques. J. Ceram. Soc. Jpn. 2016, 124, 49–54. [Google Scholar] [CrossRef]

- Gopi, D.; Sherif, E.S.M.; Rajeswari, D.; Kavitha, L.; Pramod, R.; Dwivedi, J.; Polaki, S.R. Evaluation of the mechanical and corrosion protection performance of electrodeposited hydroxyapatite on the high energy electron beam treated titanium alloy. J. Alloys Compd. 2014, 616, 498–504. [Google Scholar] [CrossRef]

- Gopi, D.; Karthika, A.; Rajeswari, D.; Kavitha, L.; Pramod, R.; Dwivedi, J. Investigation on corrosion protection and mechanical performance of minerals substituted hydroxyapatite coating on HELCDEB-treated titanium using pulsed electrodeposition method. RSC Adv. 2014, 4, 34751–34759. [Google Scholar] [CrossRef]

- Orii, Y.; Masumoto, H.; Honda, Y.; Anada, T.; Goto, T.; Sasaki, K.; Suzuki, O. Enhancement of octacalcium phosphate deposition on a titanium surface activated by electron cyclotron resonance plasma oxidation. J. Biomed. Mater. Res. B Appl. Biomater. 2010, 93B, 476–483. [Google Scholar] [CrossRef] [PubMed]

- Mutsuzaki, H.; Yokoyama, Y.; Ito, A.; Oyane, A. Formation of apatite coatings on an artificial ligament using a plasma- and precursor-assisted biomimetic process. Int. J. Mol. Sci. 2013, 14, 19155–19168. [Google Scholar] [CrossRef] [PubMed]

- Faria, D.; Henriques, B.; Souza, A.C.; Silva, F.S.; Carvalho, O. Laser-assisted production of HAp-coated zirconia structured surfaces for biomedical applications. J. Mech. Behav. Biomed. Mater. 2020, 112, 104049. [Google Scholar] [CrossRef]

- Roguska, A.; Hiromoto, S.; Yamamoto, A.; Woźniak, M.J.; Pisarek, M.; Lewandowska, M. Collagen immobilization on 316L stainless steel surface with cathodic deposition of calcium phosphate. Appl. Surf. Sci. 2011, 257, 5037–5045. [Google Scholar] [CrossRef]

- Jo, J.H.; Kang, B.G.; Shin, K.S.; Kim, H.E.; Hahn, B.D.; Park, D.S.; Koh, Y.H. Hydroxyapatite coating on magnesium with MgF₂ interlayer for enhanced corrosion resistance and biocompatibility. J. Mater. Sci. Mater. Med. 2011, 22, 2437–2447. [Google Scholar] [CrossRef]

- Chi, M.H.; Tsou, H.K.; Chung, C.J.; He, J.L. Biomimetic hydroxyapatite grown on biomedical polymer coated with titanium dioxide interlayer to assist osteocompatible performance. Thin Solid Films 2013, 549, 98–102. [Google Scholar] [CrossRef]

- Wu, J.; Hirata, I.; Zhao, X.; Gao, B.; Okazaki, M.; Kato, K. Influence of alkyl chain length on calcium phosphate deposition onto titanium surfaces modified with alkylphosphonic acid monolayers. J. Biomed. Mater. Res. A 2013, 101A, 2267–2272. [Google Scholar] [CrossRef] [PubMed]

- Zheng, Y.; Xiong, C.; Zhang, L. Formation of bone-like apatite on plasma-carboxylated poly(etheretherketone) surface. Mater. Lett. 2014, 126, 147–150. [Google Scholar] [CrossRef]

- Chen, W.; Long, T.; Guo, Y.J.; Zhu, Z.A.; Guo, Y.P. Hydrothermal synthesis of hydroxyapatite coatings with oriented nanorod arrays. RSC Adv. 2014, 4, 185–191. [Google Scholar] [CrossRef]

- Chen, W.; Tian, B.; Lei, Y.; Ke, Q.F.; Zhu, Z.A.; Guo, Y.P. Hydroxyapatite coatings with oriented nanoplate and nanorod arrays: Fabrication, morphology, cytocompatibility and osteogenic differentiation. Mater. Sci. Eng. C 2016, 67, 395–408. [Google Scholar] [CrossRef] [PubMed]

- Kizuki, T.; Matsushita, T.; Kokubo, T. Apatite-forming PEEK with TiO2 surface layer coating. J. Mater. Sci. Mater. Med. 2015, 26, 5359. [Google Scholar] [CrossRef] [PubMed]

- Sidane, D.; Chicot, D.; Yala, S.; Ziani, S.; Khireddine, H.; Iost, A.; Decoopman, X. Study of the mechanical behavior and corrosion resistance of hydroxyapatite sol-gel thin coatings on 316 L stainless steel pre-coated with titania film. Thin Solid Films 2015, 593, 71–80. [Google Scholar] [CrossRef]

- Ulasevich, S.A.; Poznyak, S.K.; Kulak, A.I.; Lisenkov, A.D.; Starykevich, M.; Skorb, E.V. Photocatalytic deposition of hydroxyapatite onto a titanium dioxide nanotubular layer with fine tuning of layer nanoarchitecture. Langmuir 2016, 32, 4016–4021. [Google Scholar] [CrossRef] [PubMed]

- Azem, F.A.; Birlik, I.; Braic, V.; Toparli, M.; Celik, E.; Parau, A.; Kiss, A.; Titorencu, I.; Vladescu, A. Effect of SiC interlayer between Ti6Al4V alloy and hydroxyapatite films. Proc. Inst. Mech. Eng. H 2015, 229, 307–318. [Google Scholar] [CrossRef] [PubMed]

- Cruz, M.A.E.; Ruiz, G.C.M.; Faria, A.N.; Zancanela, D.C.; Pereira, L.S.; Ciancaglini, P.; Ramos, A.P. Calcium carbonate hybrid coating promotes the formation of biomimetic hydroxyapatite on titanium surfaces. Appl. Surf. Sci. 2016, 370, 459–468. [Google Scholar] [CrossRef]

- Yang, Y.C.; Yang, C.Y. Mechanical and histological evaluation of a plasma sprayed hydroxyapatite coating on a titanium bond coat. Ceram. Int. 2013, 39, 6509–6516. [Google Scholar] [CrossRef]

- Sawaguchi, H.; Xu, J.; Kawai, T.; Mineta, T.; Nonomura, Y. Formation process of apatite layer on titanium-coated silicon wafer surfaces. J. Ceram. Soc. Jpn. 2016, 124, 753–756. [Google Scholar] [CrossRef]

- Strąkowska, P.; Beutner, R.; Gnyba, M.; Zielinski, A.; Scharnweber, D. Electrochemically assisted deposition of hydroxyapatite on Ti6Al4V substrates covered by CVD diamond films—coating characterization and first cell biological results. Mater. Sci. Eng. C 2016, 59, 624–635. [Google Scholar] [CrossRef]

- Lin, Z.; Zhou, D.; Zhou, J.; Huang, M.; Zhang, X. Construction of different morphology of calcium phosphate film on titanium base oxidation layer superhydrophobic-superhydrophilic pattern. Mater. Lett. 2016, 180, 309–312. [Google Scholar] [CrossRef]

- Oyane, A.; Kawashita, M.; Nakanishi, K.; Kokubo, T.; Minoda, M.; Miyamoto, T.; Nakamura, T. Bonelike apatite formation on ethylene-vinyl alcohol copolymer modified with silane coupling agent and calcium silicate solutions. Biomaterials 2003, 24, 1729–1735. [Google Scholar] [CrossRef]

- Shirosaki, Y.; Kubo, M.; Takashima, S.; Tsuru, K.; Hayakawa, S.; Osaka, A. In vitro apatite formation on organic polymers modified with a silane coupling reagent. J. R. Soc. Interface 2005, 22, 335–340. [Google Scholar] [CrossRef] [PubMed]

- Balas, F.; Kawashita, M.; Nakamura, T.; Kokubo, T. Formation of bone-like apatite on organic polymers treated with a silane-coupling agent and a titania solution. Biomaterials 2006, 27, 1704–1710. [Google Scholar] [CrossRef]

- Rakngarm, A.; Mutoh, Y. Characterization and fatigue damage of plasma sprayed HAp top coat with Ti and HAp/Ti bond coat layers on commercially pure titanium substrate. J. Mech. Behav. Biomed. Mater. 2009, 2, 444–453. [Google Scholar] [CrossRef] [PubMed]

- Laonapakul, T.; Otsuka, Y.; Nimkerdphol, A.R.; Mutoh, Y. Acoustic emission and fatigue damage induced in plasma-sprayed hydroxyapatite coating layers. J. Mech. Behav. Biomed. Mater. 2012, 8, 123–133. [Google Scholar] [CrossRef] [PubMed]

- Nimkerdphol, A.R.; Otsuka, Y.; Mutoh, Y. Effect of dissolution/precipitation on the residual stress redistribution of plasma-sprayed hydroxyapatite coating on titanium substrate in simulated body fluid (SBF). J. Mech. Behav. Biomed. Mater. 2014, 36, 98–108. [Google Scholar] [CrossRef]

- Kim, H.W.; Lee, S.Y.; Bae, C.J.; Noh, Y.J.; Kim, H.E.; Kim, H.M.; Ko, J.S. Porous ZrO2 bone scaffold coated with hydroxyapatite with fluorapatite intermediate layer. Biomaterials 2003, 24, 3277–3284. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.W.; Yoon, B.H.; Koh, Y.H.; Kim, H.E. Processing and performance of hydroxyapatite/fluorapatite double layer coating on zirconia by the powder slurry method. J. Am. Ceram. Soc. 2006, 89, 2466–2472. [Google Scholar] [CrossRef]

- Pham, M.T.; Reuther, H.; Matz, W.; Mueller, R.; Steiner, G.; Oswald, S.; Zyganov, I. Surface induced reactivity for titanium by ion implantation. J. Mater. Sci. Mater. Med. 2000, 11, 383–391. [Google Scholar] [CrossRef]

- Baumann, H.; Bethge, K.; Bilger, G.; Jones, D.; Symietz, I. Thin hydroxyapatite surface layers on titanium produced by ion implantation. Nucl. Instrum. Meth. B 2002, 196, 286–292. [Google Scholar] [CrossRef]

- Krupa, D.; Baszkiewicz, J.; Kozubowski, J.A.; Barcz, A.; Sobczak, J.W.; Biliński, A.; Lewandowska-Szumieł, M.; Rajchel, B. Effect of dual ion implantation of calcium and phosphorus on the properties of titanium. Biomaterials 2005, 26, 2847–2856. [Google Scholar] [CrossRef] [PubMed]

- Rautray, T.R.; Narayanan, R.; Kwon, T.Y.; Kim, K.H. Accelerator based synthesis of hydroxyapatite by MeV ion implantation. Thin Solid Films 2010, 518, 3160–3163. [Google Scholar] [CrossRef]

- Coreño-Alonsoa, J.; Coreño-Alonsob, O.; Martínez-Rosalesc, J.M. Apatite formation on alumina: The role of the initial adsorption of calcium and phosphate ions. Ceram. Int. 2014, 40, 4909–4915. [Google Scholar] [CrossRef]

- Ferraris, S.; Spriano, S.; Bianchi, C.L.; Cassinelli, C.; Vernè, E. Surface modification of Ti-6Al-4 V alloy for biomineralization and specific biological response: Part II, alkaline phosphatase grafting. J. Mater. Sci. Mater. Med. 2011, 22, 1835–1842. [Google Scholar] [CrossRef]

- Aminian, A.; Pardun, K.; Volkmann, E.; Li Destri, G.; Marletta, G.; Treccani, L.; Rezwan, K. Enzyme-assisted calcium phosphate biomineralisation on an inert alumina surface. Acta Biomater. 2015, 13, 335–343. [Google Scholar] [CrossRef]

- Jaroszewicz, J.; Idaszek, J.; Choinska, E.; Szlazak, K.; Hyc, A.; Osiecka-Iwan, A.; Swieszkowski, W.; Moskalewski, S. Formation of calcium phosphate coatings within polycaprolactone scaffolds by simple, alkaline phosphatase based method. Mater. Sci. Eng. C 2019, 96, 319–328. [Google Scholar] [CrossRef] [PubMed]

- Erkmen, Z.E. The effect of heat treatment on the morphology of D-gun sprayed hydroxyapatite coatings. J. Biomed. Mater. Res. Appl. Biomater. 1999, 48, 861–868. [Google Scholar] [CrossRef]

- Lynn, A.K.; DuQuesnay, D.L. Hydroxyapatite-coated Ti–6Al–4V. Part 2: The effects of post-deposition heat treatment at low temperatures. Biomaterials 2002, 23, 1947–1953. [Google Scholar] [CrossRef]

- Yang, Y.; Agarwal, C.M.; Kim, K.H.; Martin, H.; Schul, K.; Bumgardner, J.M.; Ong, J.L. Characterization and dissolution behavior of sputtered calcium phosphate coatings after different postdeposition heat treatment temperatures. J. Oral Implant. 2003, 29, 270–277. [Google Scholar] [CrossRef]

- Lee, Y.P.; Wang, C.K.; Huang, T.H.; Chen, C.C.; Kao, C.T.; Ding, S.J. In vitro characterization of post heat-treated plasma-sprayed hydroxyapatite coatings. Surf. Coat. Tech. 2005, 197, 367–374. [Google Scholar] [CrossRef]

- Johnson, S.; Haluska, M.; Narayan, R.J.; Snyder, R.L. In situ annealing of hydroxyapatite thin films. Mater. Sci. Eng. C 2006, 26, 1312–1316. [Google Scholar] [CrossRef]

- Cannillo, V.; Lusvarghi, L.; Sola, A.; Barletta, M. Post-deposition laser treatment of plasma sprayed titania-hydroxyapatite functionally graded coatings. J. Eur. Ceram. Soc. 2009, 29, 3147–3158. [Google Scholar] [CrossRef]

- Drevet, R.; Fauré, J.; Benhayoune, H. Thermal treatment optimization of electrodeposited hydroxyapatite coatings on Ti6Al4V substrate. Adv. Eng. Mater. 2012, 14, 377–382. [Google Scholar] [CrossRef]

- Berkin, A.B.; Deryabina, V.V.; Sharafutdinov, M.R.; Karmanov, N.S. Structural changes in calcium phosphate thin films on titanium during heat treatment. Russ. Phys. J. 2014, 56, 1124–1129. [Google Scholar] [CrossRef]

- Azis, S.A.A.; Kennedy, J.; Cao, P. Effect of annealing on microstructure of hydroxyapatite coatings and their behaviours in simulated body fluid. Adv. Mater. Res. 2014, 922, 657–662. [Google Scholar] [CrossRef]

- Shirdar, M.R.; Izman, S.; Taheri, M.M.; Assadian, M.; Kadir, M.R.A. Effect of post-treatment techniques on corrosion and wettability of hydroxyapatite-coated Co–Cr–Mo alloy. Arab. J. Sci. Eng. 2015, 40, 1197–1203. [Google Scholar] [CrossRef]

- Jaber, N.B.; Drevet, R.; Fauré, J.; Demangel, C.; Potiron, S.; Tara, A.; Larbi, A.B.C.; Benhayoune, H. A new process for the thermal treatment of calcium phosphate coatings electrodeposited on Ti6Al4V substrate. Adv. Eng. Mater. 2015, 17, 1608–1615. [Google Scholar] [CrossRef]

- Hontsu, S.; Nakamori, M.; Tabata, H.; Ishii, J.; Kawai, T. Pulsed laser deposition of bioceramic hydroxyapatite thin films on polymer materials. Jpn. J. Appl. Phys. 1996, 35, L1208–L1210. [Google Scholar] [CrossRef]

- Hontsu, S.; Nakamori, M.; Kato, N.; Tabata, H.; Ishii, J.; Matsumoto, T.; Kawai, T. Formation of hydroxyapatite thin films on surface-modified polytetrafluoroethylene substrates. Jpn. J. Appl. Phys. 1998, 37, L1169–L1171. [Google Scholar] [CrossRef]

- Chen, C.; Wang, D.; Bao, Q.; Zhang, L.; Lei, T. Influence of laser remelting on the microstructure and phases constitution of plasma sprayed hydroxyapatite coatings. Appl. Surf. Sci. 2005, 250, 98–103. [Google Scholar] [CrossRef]

- Feddes, B.; Vredenberg, A.M.; Wehner, M.; Wolke, J.C.G.; Jansen, J.A. Laser-induced crystallization of calcium phosphate coatings on polyethylene (PE). Biomaterials 2005, 26, 1645–1651. [Google Scholar] [CrossRef]

- dos Santos, E.A.; Moldovan, S.; Mateescu, M.; Faerber, J.; Acosta, M.; Pelletier, H.; Anselme, K.; Werckmann, J. Physical–chemical and biological behavior of an amorphous calcium phosphate thin film produced by RF-magnetron sputtering. Mater. Sci. Eng. C 2012, 32, 2086–2095. [Google Scholar] [CrossRef] [PubMed]

- Cao, Y.; Weng, J.; Chen, J.; Feng, J.; Yang, Z.; Zhang, X. Water vapor-treated hydroxyapatite coatings after plasma spraying and their characteristics. Biomaterials 1996, 17, 419–424. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Kim, K.H.; Agarwal, C.M.; Ong, J.L. Effect of post-deposition heating temperature and the presence of water vapor during heat treatment on crystallinity of calcium phosphate coatings. Biomaterials 2003, 24, 5131–5137. [Google Scholar] [CrossRef]

- Yang, C.W.; Lee, T.M.; Lui, T.S.; Chang, E. A comparison of the microstructural feature and bonding strength of plasma-sprayed hydroxyapatite coatings with hydrothermal and vacuum post-heat treatment. Mater. Trans. 2005, 46, 709–715. [Google Scholar] [CrossRef]

- Li, H.; Khor, K.A.; Cheang, P. Effect of steam treatment during plasma spraying on the microstructure of hydroxyapatite (HA) splats and coatings. J. Therm. Spray Tech. 2006, 15, 610–616. [Google Scholar] [CrossRef]

- Yang, C.W.; Lui, T.S. Microstructural self-healing effect of hydrothermal crystallization on bonding strength and failure mechanism of hydroxyapatite coatings. J. Eur. Ceram. Soc. 2008, 28, 2151–2159. [Google Scholar] [CrossRef]

- Yang, C.W.; Lui, T.S. Kinetics of hydrothermal crystallization under saturated steam pressure and the self-healing effect by nanocrystallite for hydroxyapatite coatings. Acta Biomater. 2009, 5, 2728–2737. [Google Scholar] [CrossRef]

- Huang, Y.; Qu, Y.; Yang, B.; Li, W.; Zhang, B.; Zhang, X. In vivo biological responses of plasma sprayed hydroxyapatite coatings with an electric polarized treatment in alkaline solution. Mater. Sci. Eng. C 2009, 29, 2411–2416. [Google Scholar] [CrossRef]

- Chen, H.T.; Wang, M.C.; Chang, K.M.; Wang, S.H.; Shih, W.J.; Li, W.L. Phase transformation and morphology of calcium phosphate prepared by electrochemical deposition process through alkali treatment and calcinations. Metall. Mater. Trans. A 2014, 45, 2260–2269. [Google Scholar] [CrossRef]

- Wang, C.; Li, K.Z.; Zhai, Y.Q.; Li, H.J.; Wang, J.L.; Jiao, G.S. Study of fluorhydroxyapatite coatings on carbon/carbon composites. Surf. Coat. Tech. 2009, 203, 1771–1775. [Google Scholar] [CrossRef]

- Su, Y.; Lu, Y.; Su, Y.; Hu, J.; Lian, J.; Li, G. Enhancing the corrosion resistance and surface bioactivity of a calcium-phosphate coating on a biodegradable AZ60 magnesium alloy via a simple fluorine post-treatment method. RSC Adv. 2015, 5, 56001–56010. [Google Scholar] [CrossRef]

- Kato, R.; Nakamura, S.; Katayama, K.; Yamashita, K. Electrical polarization of plasma-spray-hydroxyapatite coatings for improvement of osteoconduction of implants. J. Biomed. Mater. Res. A 2005, 74A, 652–658. [Google Scholar] [CrossRef] [PubMed]

- Yang, C.W.; Lui, T.S.; Chen, L.H. Hydrothermal crystallization effect on the improvement of erosion resistance and reliability of plasma-sprayed hydroxyapatite coatings. Thin Solid Films 2009, 517, 5380–5385. [Google Scholar] [CrossRef]

- Saju, K.K.; Reshmi, R.; Jayadas, N.H.; James, J.; Jayaraj, M.K. Polycrystalline coating of hydroxyapatite on TiAl6V4 implant material grown at lower substrate temperatures by hydrothermal annealing after pulsed laser deposition. Proc. Inst. Mech. Eng. H 2009, 223, 1049–1057. [Google Scholar] [CrossRef]

- Ozeki, K.; Aoki, H.; Masuzawa, T. Influence of the hydrothermal temperature and pH on the crystallinity of a sputtered hydroxyapatite film. Appl. Surf. Sci. 2010, 256, 7027–7031. [Google Scholar] [CrossRef]

- Hahn, B.D.; Lee, J.M.; Park, D.S.; Choi, J.J.; Ryu, J.; Yoon, W.H.; Choi, J.H.; Lee, B.K.; Kim, J.W.; Kim, H.E.; et al. Enhanced bioactivity and biocompatibility of nanostructured hydroxyapatite coating by hydrothermal annealing. Thin Solid Films 2011, 519, 8085–8090. [Google Scholar] [CrossRef]

- Ubele, D.; Pluduma, L.; Gross, K.A.; Viksna, A. Hydrothermal processing for increasing the hydroxyl ion concentration in hydroxyl depleted hydroxyapatite. Key Eng. Mater. 2018, 762, 42–47. [Google Scholar] [CrossRef]

- Tian, Y.S.; Qian, X.L.; Chen, M.Q. Effect of saturated steam treatment on the crystallinity of plasma-sprayed hydroxyapatite coatings. Surf. Coat. Tech. 2015, 266, 38–41. [Google Scholar] [CrossRef]

- Han, Y.; Xu, K.; Lu, J. Morphology and composition of hydroxyapatite coatings prepared by hydrothermal treatment on electrodeposited brushite coatings. J. Mater. Sci. Mater. Med. 1999, 10, 243–248. [Google Scholar] [CrossRef]

- Kumar, M.; Dasarathy, H.; Riley, C. Electrodeposition of brushite coatings and their transformation to hydroxyapatite in aqueous solutions. J. Biomed. Mater. Res. 1999, 45, 302–310. [Google Scholar] [CrossRef]

- Han, Y.; Fu, T.; Lu, J.; Xu, K. Characterization and stability of hydroxyapatite coatings prepared by an electrodeposition and alkaline-treatment process. J. Biomed. Mater. Res. 2001, 54, 96–101. [Google Scholar] [CrossRef] [PubMed]

- Su, Y.; Li, G.; Lian, J. A chemical conversion hydroxyapatite coating on AZ60 magnesium alloy and its electrochemical corrosion behavior. Int. J. Electrochem. Sci. 2012, 7, 11497–11511. [Google Scholar] [CrossRef]

- da Rocha, D.N.; de Oliveira Cruz, L.R.; de Campos, J.B.; Marçal, R.L.S.B.; Mijares, D.Q.; Coelho, P.G.; da Silva, M.H.P. Mg substituted apatite coating from alkali conversion of acidic calcium phosphate. Mater. Sci. Eng. C 2017, 70, 408–417. [Google Scholar] [CrossRef]

- Prezas, P.R.; Soares, M.J.; Borges, J.P.; Silva, J.C.; Oliveira, F.J.; Graça, M.P.F. Bioactivity enhancement of plasma-sprayed hydroxyapatite coatings through non-contact corona electrical charging. Nanomaterials 2023, 13, 1058. [Google Scholar] [CrossRef]

- Zhang, J.; Yu, Z.; Hu, J. A study of bionics micro-textures on the surface of HA bio-coatings prepared by nanosecond laser. Ceram. Int. 2023, 49, 11999–12011. [Google Scholar] [CrossRef]

- Eliaz, N.; Shmueli, S.; Shur, I.; Benayahu, D.; Aronov, D.; Rosenman, G. The effect of surface treatment on the surface texture and contact angle of electrochemically deposited hydroxyapatite coating and on its interaction with bone-forming cells. Acta Biomater. 2009, 5, 3178–3191. [Google Scholar] [CrossRef]

- Gregor, M.; Plecenik, T.; Tofail, S.A.M.; Zahoran, M.; Truchly, M.; Vargova, M.; Laffir, F.; Plesch, G.; Kus, P.; Plecenik, A. Hydrophobicity of electron beam modified surface of hydroxyapatite films. Appl. Surf. Sci. 2015, 337, 249–253. [Google Scholar] [CrossRef]

- Sedelnikova, M.B.; Ivanov, K.V.; Ugodchikova, A.V.; Kashin, A.D.; Uvarkin, P.V.; Sharkeev, Y.P.; Tolkacheva, T.V.; Tolmachev, A.I.; Schmidt, J.; Egorkin, V.S.; et al. The effect of pulsed electron irradiation on the structure, phase composition, adhesion and corrosion properties of calcium phosphate coating on Mg0.8Ca alloy. Mater. Chem. Phys. 2023, 294, 126996. [Google Scholar] [CrossRef]

- Kostuchenko, A.V.; Kannykin, S.V.; Kuschev, S.B.; Dybov, V.A. Synthesis of composite calcium-phosphate coatings via pulsed photon processing. Bull. Russ. Acad. Sci. Phys. 2016, 80, 1161–1164. [Google Scholar] [CrossRef]

- Zhang, L.; Jiang, Y.; Zai, W.; Li, G.; Liu, S.; Lian, J.; Jiang, Z. Fabrication of superhydrophobic calcium phosphate coating on Mg-Zn-Ca alloy and its corrosion resistance. J. Mater. Eng. Perform. 2017, 26, 6117–6129. [Google Scholar] [CrossRef]

- Yoshinari, M.; Oda, Y.; Inoue, T.; Matsuzaka, K.; Shimono, M. Bone response to calcium phosphate-coated and bisphosphonate-immobilized titanium implants. Biomaterials 2002, 23, 2879–2885. [Google Scholar] [CrossRef] [PubMed]

- Cattini, A.; Bellucci, D.; Sola, A.; Pawłowski, L.; Cannillo, V. Functional bioactive glass topcoats on hydroxyapatite coatings: Analysis of microstructure and in-vitro bioactivity. Surf. Coat. Tech. 2014, 240, 110–117. [Google Scholar] [CrossRef]

- Yanovska, A.; Kuznetsov, V.; Stanislavov, A.; Danilchenko, S.; Sukhodub, L. Calcium–phosphate coatings obtained biomimetically on magnesium substrates under low magnetic field. Appl. Surf. Sci. 2012, 258, 8577–8584. [Google Scholar] [CrossRef]

- Liu, C.; Tian, A.; Yang, H.; Xu, Q.; Xue, X. Electrodeposited hydroxyapatite coatings on the TiO2 nanotube in static magnetic field. Appl. Surf. Sci. 2013, 287, 218–222. [Google Scholar] [CrossRef]

- Nelea, V.; Pelletier, H.; Iliescu, M.; Werckmann, J.; Craciun, V.; Mihailescu, I.N.; Ristoscu, C.; Ghica, C. Calcium phosphate thin film processing by pulsed laser deposition and in situ assisted ultraviolet pulsed laser deposition. J. Mater. Sci. Mater. Med. 2002, 13, 1167–1173. [Google Scholar] [CrossRef]

- Xiong, X.B.; Zeng, X.R.; Zou, J.Z.; Xie, S.H. Preparation of improved hydroxyapatite coating on HT-C/C by modified induction heating deposition/hydrothermal treatment technologies. Surf. Eng. 2011, 27, 591–594. [Google Scholar] [CrossRef]

- Zhao, X.; Li, H.; Chen, M.; Li, K.; Lu, J.; Zhang, L.; Cao, S. Nano/micro-sized calcium phosphate coating on carbon/carbon composites by ultrasonic assisted electrochemical deposition. Surf. Interface Anal. 2012, 44, 21–28. [Google Scholar] [CrossRef]

- Yamamoto, E.; Kato, N.; Hatoko, Y.; Hontsu, S. Optimization of humid conditions using an ultrasonic nebulizer for the fabrication of hydroxyapatite film with the Er:YAG laser deposition method. Key Eng. Mater. 2017, 720, 269–274. [Google Scholar] [CrossRef]

- Mostaghimi, J.; Passandideh-Fard, M.; Chandra, S. Dynamics of splat formation in plasma spray coating process. Plasma Chem. Plasma P 2002, 22, 59–84. [Google Scholar] [CrossRef]

- Fauchais, P.; Vardelle, A.; Dussoubs, B. Quo Vadis thermal spraying? J. Therm. Spray Tech. 2001, 10, 44–66. [Google Scholar] [CrossRef]

- Aoyagi, M.; Hayashi, M.; Yoshida, Y.; Yao, Y. Implants for Bones, Joints and Tooth Roots. U.S. Patent US4146936, 3 April 1979. [Google Scholar]

- Zhao, G.L.; Wen, G.; Song, Y.; Wu, K. Near surface martensitic transformation and recrystallization in a Ti–24Nb–4Zr–7.9Sn alloy substrate after application of a HA coating by plasma spraying. Mater. Sci. Eng. C 2011, 31, 106–113. [Google Scholar] [CrossRef]

- Gligorijević, B.R.; Vilotijević, M.; Šćepanović, M.; Vuković, N.S.; Radović, N. Substrate preheating and structural properties of power plasma sprayed hydroxyapatite coatings. Ceram. Int. 2016, 42, 411–420. [Google Scholar] [CrossRef]

- Saber-Samandari, S.; Alamara, K.; Saber-Samandari, S.; Gross, K.A. Micro-Raman spectroscopy shows how the coating process affects the characteristics of hydroxylapatite. Acta Biomater. 2013, 9, 9538–9546. [Google Scholar] [CrossRef]

- Saber-Samandari, S.; Alamara, K.; Saber-Samandari, S. Calcium phosphate coatings: Morphology, micro-structure and mechanical properties. Ceram. Int. 2014, 40, 563–572. [Google Scholar] [CrossRef]

- Freidberg, J.P. Plasma Physics and Fusion Energy; Cambridge University Press: Cambridge, UK, 2007; 692p. [Google Scholar]

- Herman, H. Plasma-sprayed coatings. Sci. Am. 1988, 9, 112–117. [Google Scholar] [CrossRef]

- Fauchais, P. Understanding plasma spraying. J. Phys. D Appl. Phys. 2004, 37, R86–R108. [Google Scholar] [CrossRef]

- Quek, C.H.; Khor, K.A.; Cheang, P. Influence of processing parameters in the plasma spraying of hydroxyapatite/Ti–6Al–4V composite coatings. J. Mater. Process. Tech. 1999, 89–90, 550–555. [Google Scholar] [CrossRef]

- Paital, S.R.; Dahotre, N.B. Calcium phosphate coatings for bio-implant applications: Materials, performance factors, and methodologies. Mater. Sci. Eng. R 2009, 66, 1–70. [Google Scholar] [CrossRef]

- Layrolle, P. 1.16 Calcium phosphate coatings. In Comprehensive Biomaterials II; Ducheyne, P., Healy, K., Hutmacher, D.W., Grainger, D.W., Kirkpatrick, C.J., Eds.; Elsevier: Amsterdam, The Netherlands, 2017; Volume 1, pp. 360–367. [Google Scholar]

- Surmenev, R.A. A review of plasma-assisted methods for calcium phosphate-based coatings fabrication. Surf. Coat. Tech. 2012, 206, 2035–2056. [Google Scholar] [CrossRef]

- Heimann, R.B. Thermal spraying of biomaterials. Surf. Coat. Tech. 2006, 201, 2012–2019. [Google Scholar] [CrossRef]

- Xu, J.L.; Joguet, D.; Cizek, J.; Khor, K.A.; Liao, H.L.; Coddet, C.; Chen, W.N. Synthesis and characterization on atmospheric plasma sprayed amorphous silica doped hydroxyapatite coatings. Surf. Coat. Tech. 2012, 206, 4659–4665. [Google Scholar] [CrossRef]

- Su, Y.; Li, K.; Guan, K.; Zhu, X.; Sun, J. Mechanical properties of the supersonic atmospheric plasma sprayed Ca–P coating post-processed by a microwave-hydrothermal method. Mater. Sci. Eng. C 2019, 95, 49–56. [Google Scholar] [CrossRef] [PubMed]

- Gledhill, H.C.; Turner, I.G.; Doyle, C. Direct morphological comparison of vacuum plasma sprayed and detonation gun sprayed hydroxyapatite coatings. Biomaterials 1999, 20, 315–322. [Google Scholar] [CrossRef]

- Gledhill, H.C.; Turner, I.G.; Doyle, C. In vitro fatigue behavior of vacuum plasma and detonation gun sprayed hydroxyapatite coatings. Biomaterials 2001, 22, 1233–1240. [Google Scholar] [CrossRef]

- Ganvir, A.; Nagar, S.; Markocsan, N.; Balani, K. Deposition of hydroxyapatite coatings by axial plasma spraying: Influence of feedstock characteristics on coating microstructure, phase content and mechanical properties. J. Eur. Ceram. Soc. 2021, 41, 4637–4649. [Google Scholar] [CrossRef]

- Gross, K.A.; Saber-Samandari, S. Revealing mechanical properties of a suspension plasma sprayed coating with nanoindentation. Surf. Coat. Tech. 2009, 203, 2995–2999. [Google Scholar] [CrossRef]

- Pawłowski, L. Suspension and solution thermal spray coatings. Surf. Coat. Tech. 2009, 203, 2807–2829. [Google Scholar] [CrossRef]

- Podlesak, H.; Pawłowski, L.; D’Haese, R.; Laureyns, J.; Lampke, T.; Bellayer, S. Advanced microstructural study of suspension plasma sprayed hydroxyapatite coatings. J. Therm. Spray Tech. 2010, 19, 657–664. [Google Scholar] [CrossRef]

- Łatka, L.; Pawłowski, L.; Chicot, D.; Pierlot, C.; Petit, F. Mechanical properties of suspension plasma sprayed hydroxyapatite coatings submitted to simulated body fluid. Surf. Coat. Tech. 2010, 205, 954–960. [Google Scholar] [CrossRef]

- d’Haese, R.; Pawłowski, L.; Bigan, M.; Jaworski, R.; Martel, M. Phase evolution of hydroxapatite coatings suspension plasma sprayed using variable parameters in simulated body fluid. Surf. Coat. Tech. 2010, 204, 1236–1246. [Google Scholar] [CrossRef]

- Pateyron, B.; Pawłowski, L.; Calve, N.; Delluc, G.; Denoirjean, A. Modeling of phenomena occurring in plasma jet during suspension spraying of hydroxyapatite coatings. Surf. Coat. Tech. 2013, 214, 86–90. [Google Scholar] [CrossRef]

- Xu, H.; Geng, X.; Liu, G.; Xiao, J.; Li, D.; Zhang, Y.; Zhu, P.; Zhang, C. Deposition, nanostructure and phase composition of suspension plasma-sprayed hydroxyapatite coatings. Ceram. Int. 2016, 42, 8684–8690. [Google Scholar] [CrossRef]

- Huang, Y.; Song, L.; Liu, X.; Xiao, Y.; Wu, Y.; Chen, J.; Wu, F.; Gu, Z. Hydroxyapatite coatings deposited by liquid precursor plasma spraying: Controlled dense and porous micorstructures and osteoblastic cell responses. Biofabrication 2010, 2, 045003. [Google Scholar] [CrossRef] [PubMed]

- Candidato, R.T.; Sokołowski, P.; Pawłowski, L.; Denoirjean, A. Preliminary study of hydroxyapatite coatings synthesis using solution precursor plasma spraying. Surf. Coat. Tech. 2015, 277, 242–250. [Google Scholar] [CrossRef]

- Candidato, R.T.; Sokołowski, P.; Pawłowski, L.; Lecomte-Nana, G.; Constantinescu, C.; Denoirjean, A. Development of hydroxyapatite coatings by solution precursor plasma spray process and their microstructural characterization. Surf. Coat. Tech. 2017, 318, 39–49. [Google Scholar] [CrossRef]

- Morks, M.F.; Kobayashi, A. Effect of gun current on the microstructure and crystallinity of plasma sprayed hydroxyapatite coatings. Appl. Surf. Sci. 2007, 253, 7136–7142. [Google Scholar] [CrossRef]

- Wu, G.M.; Hsiao, W.D.; Kung, S.F. Investigation of hydroxyapatite coated polyether ether ketone composites by gas plasma sprays. Surf. Coat. Tech. 2009, 203, 2755–2758. [Google Scholar] [CrossRef]

- Morks, M.F.; Kobayashi, A.; Fahim, N.F. Abrasive wear behavior of sprayed hydroxyapitite coatings by gas tunnel type plasma spraying. Wear 2007, 262, 204–209. [Google Scholar] [CrossRef]

- Kobayashi, A.; Subramanian, B. Hydroxyapatite and YSZ reinforced hydroxyapatite coatings by gas tunnel type plasma spraying. Key Eng. Mater. 2013, 529–530, 213–216. [Google Scholar] [CrossRef]

- Nakamura, M.; Kobayashi, A.; Nozaki, K.; Horiuchi, N.; Nagai, A.; Yamashita, K. Improvement of osteoblast adhesion through polarization of plasma-sprayed hydroxyapatite coatings on metal. J. Med. Biol. Eng. 2014, 34, 44–48. [Google Scholar] [CrossRef]

- Inagaki, M.; Yokogawa, Y.; Kameyama, T. Formation of highly oriented hydroxyapatite in hydroxyapatite/titanium composite coating by radio-frequency thermal plasma spraying. J. Mater. Sci. Mater. Med. 2003, 14, 919–922. [Google Scholar] [CrossRef] [PubMed]

- Inagaki, M.; Kameyama, T. Phase transformation of plasma-sprayed hydroxyapatite coating with preferred crystalline orientation. Biomaterials 2007, 28, 2923–2931. [Google Scholar] [CrossRef] [PubMed]

- Demnati, I.; Parco, M.; Grossin, D.; Fagoaga, I.; Drouet, C.; Barykin, G.; Combes, C.; Braceras, I.; Goncalves, S.; Rey, C. Hydroxyapatite coating on titanium by a low energy plasma spraying mini-gun. Surf. Coat. Tech. 2012, 206, 2346–2353. [Google Scholar] [CrossRef]

- Gligorijević, B.R.; Vilotijević, M.; Šćepanović, M.; Vidović, D.; Radović, N.A. Surface structural heterogeneity of high power plasma-sprayed hydroxyapatite coatings. J. Alloys Compd. 2016, 687, 421–430. [Google Scholar] [CrossRef]

- Boi, M.; Bianchi, M.; Gambardella, A.; Liscio, F.; Kaciulis, S.; Visani, A.; Barbalinardo, M.; Valle, F.; Iafisco, M.; Lungaro, L.; et al. Tough and adhesive nanostructured calcium phosphate thin films deposited by the pulsed plasma deposition method. RSC Adv. 2015, 5, 78561–78571. [Google Scholar] [CrossRef]

- Gambardella, A.; Bianchi, M.; Kaciulis, S.; Mezzi, A.; Brucale, M.; Cavallini, M.; Herrmannsdoerfer, T.; Chanda, G.; Uhlarz, M.; Cellini, A.; et al. Magnetic hydroxyapatite coatings as a new tool in medicine: A scanning probe investigation. Mater. Sci. Eng. C 2016, 62, 444–449. [Google Scholar] [CrossRef]

- Jinawath, S.; Hengst, M.; Heimann, R.B. Plasma-sprayed DCPD/CaCO3 coatings on Ti6Al4V substrates. J. Sci. Res. Chula Univ. 2004, 29, 33–43. [Google Scholar]

- Chahal, H.K.; Matthews, S.; Jones, M.I. Fabrication of calcium phosphate coatings by the inflight reaction of precursor feedstocks using plasma spraying. J. Therm. Spray Tech. 2023, 32, 1465–1481. [Google Scholar] [CrossRef]

- Dey, A.; Mukhopadhyay, A.K. Anisotropy in nanohardness of microplasma sprayed hydroxyapatite coating. Adv. Appl. Ceram. 2010, 109, 346–354. [Google Scholar] [CrossRef]

- Dey, A.; Nandi, S.K.; Kundu, B.; Kumar, C.; Mukherjee, P.; Roy, S.; Mukhopadhyay, A.K.; Sinha, M.K.; Basu, D. Evaluation of hydroxyapatite and β-tri calcium phosphate microplasma spray coated pin intra-medullary for bone repair in a rabbit model. Ceram. Int. 2011, 37, 1377–1391. [Google Scholar] [CrossRef]

- Dey, A.; Mukhopadhyay, A.K. Evaluation of residual stress in microplasma sprayed hydroxyapatite coating by nanoindentation. Ceram. Int. 2014, 40, 1263–1272. [Google Scholar] [CrossRef]

- Dey, A.; Mukhopadhyay, A.K. Microplasma Sprayed Hydroxyapatite Coatings; CRC Press: Boca Raton, FL, USA, 2015; 234p. [Google Scholar]

- Liu, X.; He, D.; Zhou, Z.; Wang, G.; Wang, Z.; Guo, X. Effect of post-heat treatment on the microstructure of micro-plasma sprayed hydroxyapatite coatings. Surf. Coat. Tech. 2019, 367, 225–230. [Google Scholar] [CrossRef]

- Lu, Y.P.; Jiao, Y.; Wang, J.H.; Xu, W.H.; Xiao, G.Y.; Zhu, R.F. A further insight into pores in plasma sprayed hydroxyapatite coating. Surf. Coat. Tech. 2012, 206, 3550–3553. [Google Scholar] [CrossRef]

- de Groot, K.; Geesink, R.G.T.; Klein, C.P.A.T.; Serekian, P. Plasma sprayed coatings of hydroxylapatite. J. Biomed. Mater. Res. 1987, 21, 1375–1381. [Google Scholar] [CrossRef]

- Gross, K.A.; Berndt, C.C. Thermal processing of hydroxyapatite for coating production. J. Biomed. Mater. Res. 1998, 39, 580–587. [Google Scholar] [CrossRef]

- Gross, K.A.; Berndt, C.C.; Stephens, P.; Dinnebier, R. Oxyapatite in hydroxyapatite coatings. J. Mater. Sci. 1998, 33, 3985–3991. [Google Scholar] [CrossRef]

- Gross, K.A.; Berndt, C.C.; Herman, H. Amorphous phase formation in plasma-sprayed hydroxyapatite coatings. J. Biomed. Mater. Res. 1998, 39, 407–414. [Google Scholar] [CrossRef]

- Sun, L.; Berndt, C.C.; Gross, K.A.; Kucuk, A. Material fundamentals and clinical performance of plasma sprayed hydroxyapatite coatings: A review. J. Biomed. Mater. Res. Appl. Biomater. 2001, 58, 570–592. [Google Scholar] [CrossRef]

- Sun, L.; Berndt, C.C.; Grey, C.P. Phase, structural and microstructural investigations of plasma sprayed hydroxyapatite coatings. Mater. Sci. Eng. A 2003, 360, 70–84. [Google Scholar] [CrossRef]

- Li, H.; Ng, B.S.; Khor, K.A.; Cheang, P.; Clyne, T.W. Raman spectroscopy determination of phases within thermal sprayed hydroxyapatite splats and subsequent in vitro dissolution examination. Acta Mater. 2004, 52, 445–453. [Google Scholar] [CrossRef]

- Roy, M.; Bandyopadhyay, A.; Bose, S. Induction plasma sprayed nano hydroxyapatite coatings on titanium for orthopaedic and dental implants. Surf. Coat. Tech. 2011, 205, 2785–2792. [Google Scholar] [CrossRef] [PubMed]

- Demnati, I.; Grossin, D.; Combes, C.; Rey, C. Plasma-sprayed apatite coatings: Review of physical-chemical characteristics and their biological consequences. J. Med. Biol. Eng. 2014, 34, 1–7. [Google Scholar] [CrossRef]

- Heimann, R.B. Structural changes of hydroxylapatite during plasma spraying: Raman and NMR spectroscopy results. Coatings 2021, 11, 987. [Google Scholar] [CrossRef]

- Yang, Y.C.; Chang, E. Influence of residual stress on bonding strength and fracture of plasma-sprayed hydroxyapatite coatings on Ti–6Al–4V substrate. Biomaterials 2001, 22, 1827–1836. [Google Scholar] [CrossRef]

- Yang, Y.C.; Chang, E.; Lee, S.Y. Mechanical properties and Young’s modulus of plasma-sprayed hydroxyapatite coating on Ti substrate in simulated body fluid. J. Biomed. Mater. Res. A 2003, 67A, 886–899. [Google Scholar] [CrossRef]

- Yang, Y.; Chang, E. Measurements of residual stresses in plasma-sprayed hydroxyapatite coatings on titanium alloy. Surf. Coat. Tech. 2005, 190, 122–131. [Google Scholar] [CrossRef]

- Carradò, A. Structural, microstructural, and residual stress investigations of plasma-sprayed hydroxyapatite on Ti–6Al–4V. ACS Appl. Mater. Interf. 2010, 2, 561–565. [Google Scholar] [CrossRef]

- Yang, Y.C. Investigation of residual stress generation in plasma-sprayed hydroxyapatite coatings with various spraying programs. Surf. Coat. Tech. 2011, 205, 5165–5171. [Google Scholar] [CrossRef]

- Cizek, J.; Khor, K.A.; Prochazka, Z. Influence of spraying conditions on thermal and velocity properties of plasma sprayed hydroxyapatite. Mater. Sci. Eng. C 2007, 27, 340–344. [Google Scholar] [CrossRef]

- Cizek, J.; Khor, K.A. Role of in-flight temperature and velocity of powder particles on plasma sprayed hydroxyapatite coating characteristics. Surf. Coat. Tech. 2012, 206, 2181–2191. [Google Scholar] [CrossRef]

- Levingstone, T.J.; Ardhaoui, M.; Benyounis, K.; Looney, L.; Stokes, J.T. Plasma sprayed hydroxyapatite coatings: Understanding process relationships using design of experiment analysis. Surf. Coat. Tech. 2015, 283, 29–36. [Google Scholar] [CrossRef]

- Hasan, M.F.; Wang, J.; Berndt, C.C. Effect of power and stand-off distance on plasma sprayed hydroxyapatite coatings. Mater. Manuf. Process. 2013, 28, 1279–1285. [Google Scholar] [CrossRef]

- Cheang, P.; Khor, K.A. Thermal spraying of hydroxyapatite (HA) coatings: Effects of powder feedstock. J. Mater. Process. Tech. 1995, 48, 429–436. [Google Scholar] [CrossRef]

- Kweh, S.W.K.; Khor, K.A.; Cheang, P. Plasma-sprayed hydroxyapatite (HA) coatings with flame-spheroidized feedstock: Microstructure and mechanical properties. Biomaterials 2000, 21, 1223–1234. [Google Scholar] [CrossRef]

- Singh, T.P.; Singh, H.; Singh, H. Characterization of thermal sprayed hydroxyapatite coatings on some biomedical implant materials. J. Appl. Biomater. Funct. Mater. 2014, 12, 48–56. [Google Scholar] [CrossRef]

- Liu, X.; He, D.; Zhou, Z.; Wang, Z.; Wang, G. The influence of process parameters on the structure, phase composition, and texture of micro-plasma sprayed hydroxyapatite coatings. Coatings 2018, 8, 106. [Google Scholar] [CrossRef]

- Gross, K.A.; Petzold, C.; Pluduma-LaFarge, L.; Kumermanis, M.; Haugen, H.J. Structural and chemical hierarchy in hydroxyapatite coatings. Materials 2020, 13, 4447. [Google Scholar] [CrossRef]

- Khor, K.A.; Cheang, P. Characterization of plasma sprayed hydroxyapatite powders and coatings. In Thermal Spray Coatings: Research, Design and Applications; Berndt, C.C., Bernecki, T.F., Eds.; ASM International: Novelty, OH, USA, 1993; pp. 347–352. [Google Scholar]

- Dyshlovenko, S.; Pateyron, B.; Pawłowski, L.; Murano, D. Numerical simulation of hydroxyapatite powder behaviour in plasma jet. Surf. Coat. Tech. 2004, 179, 110–117, Erratum in Surf. Coat. Tech. 2004, 187, 408–409. [Google Scholar] [CrossRef]

- Heimann, R.B. Plasma-sprayed hydroxylapatite-based coatings: Chemical, mechanical, microstructural, and biomedical properties. J. Therm. Spray Tech. 2016, 25, 827–850. [Google Scholar] [CrossRef]

- Jacquot, L.; Bonnin, M.P.; Machenaud, A.; Chouteau, J.; Saffarini, M.; Vidalain, J.P. Clinical and radiographic outcomes at 25–30 years of a hip stem fully coated with hydroxylapatite. J. Arthroplast. 2018, 33, 482–490. [Google Scholar] [CrossRef] [PubMed]

- Burgess, A.V.; Story, B.J.; La, D.; Wagner, W.R.; LeGeros, J.P. Highly crystalline MP-1™ hydroxylapatite coating. Part I: In vitro characterization and comparison to other plasma-sprayed hydroxylapatite coatings. Clin. Oral Implant. Res. 1999, 10, 245–256. [Google Scholar] [CrossRef] [PubMed]

- Oguchi, H.; Ishikawa, K.; Ojima, S.; Hirayama, Y.; Seto, K.; Eguchi, G. Evaluation of a high-velocity flame-spraying technique for hydroxyapatite. Biomaterials 1992, 13, 471–477. [Google Scholar] [CrossRef]

- Sobolev, V.V.; Guilemany, J.M. Dynamic processes during high velocity oxyfuel spraying. Int. Mater. Rev. 1996, 41, 13–32. [Google Scholar] [CrossRef]

- Khor, K.A.; Li, H.; Cheang, P. Processing-microstructure-property relations in HVOF sprayed calcium phosphate based bioceramic coatings. Biomaterials 2003, 24, 2233–2243. [Google Scholar] [CrossRef]

- Khor, K.A.; Li, H.; Cheang, P. Significance of melt-fraction in HVOF sprayed hydroxyapatite particles, splats and coatings. Biomaterials 2004, 25, 1177–1186. [Google Scholar] [CrossRef]

- Li, H.; Khor, K.A.; Cheang, P. Adhesive and bending failure of thermal sprayed hydroxyapatite coatings: Effect of nanostructures at interface and crack propagation phenomenon during bending. Eng. Fract. Mech. 2007, 74, 1894–1903. [Google Scholar] [CrossRef]

- Ramdan, R.D.; Prawara, B.; Suratman, R.; Pradana, I.A.; Rinaldi, A. Development of HVOF coating of hydroxy apatite on titanium alloy with carbon nano tube intermediate layer. Appl. Mech. Mater. 2014, 660, 937–941. [Google Scholar] [CrossRef]

- Saber-Samandari, S.; Gross, K.A. The use of thermal printing to control the properties of calcium phosphate deposits. Biomaterials 2010, 31, 6386–6393. [Google Scholar] [CrossRef]

- Stiegler, N.; Bellucci, D.; Bolelli, G.; Cannillo, V.; Gadow, R.; Killinger, A.; Lusvarghi, L.; Sola, A. High-velocity suspension flame sprayed (HVSFS) hydroxyapatite coatings for biomedical applications. J. Therm. Spray Tech. 2012, 21, 275–287. [Google Scholar] [CrossRef]

- Bolelli, G.; Bellucci, D.; Cannillo, V.; Gadow, R.; Killinger, A.; Lusvarghi, L.; Müller, P.; Sola, A. Comparison between suspension plasma sprayed and high velocity suspension flame sprayed bioactive coatings. Surf. Coat. Technol. 2015, 280, 232–249. [Google Scholar] [CrossRef]

- Blum, M.; Sayed, M.; Mahmoud, E.M.; Killinger, A.; Gadow, R.; Naga, S.M. In vitro evaluation of biologically derived hydroxyapatite coatings manufactured by high velocity suspension spraying. J. Therm. Spray Tech. 2021, 30, 1891–1904. [Google Scholar] [CrossRef]

- Tiwari, S.; Mishra, S.B. Post annealing effect on corrosion behavior, bacterial adhesion, and bioactivity of LVOF sprayed hydroxyapatite coating. Surf. Coat. Tech. 2021, 405, 126500. [Google Scholar] [CrossRef]

- Taqriban, R.B.; Fitriyana, D.F.; Ismail, R.; Jamari, J.; Bayuseno, A.P. Flame spray coating of α-tricalcium phosphate on AISI 316L alloy. Cogent Eng. 2022, 9, 2113014. [Google Scholar] [CrossRef]

- Cuerno, R.; Barabási, A.L. Dynamic scaling of ion-sputtered surfaces. Phys. Rev. Lett. 1995, 74, 4746–4749. [Google Scholar] [CrossRef] [PubMed]

- van Dijk, K.; Verhoeven, J.; Marée, C.H.M.; Habraken, F.H.P.M.; Jansen, J.A. Study of the influence of oxygen on the composition of thin films obtained by r.f. sputtering from a Ca5(PO4)3OH target. Thin Solid Films 1997, 304, 191–195. [Google Scholar] [CrossRef]

- Barthell, B.L.; Archuleta, T.A.; Kossowsky, R. Ion beam deposition of calcium hydroxyapatite. Mater. Res. Soc. Symp. Proc. 1989, 110, 709–715. [Google Scholar] [CrossRef]

- Ong, J.L.; Harris, L.A.; Lucas, L.C.; Lacefield, W.R.; Rigney, D. X-ray photoelectron spectroscopy characterization of ion beam sputter deposited calcium phosphate coatings. J. Am. Ceram. Soc. 1991, 74, 2301–2304. [Google Scholar] [CrossRef]

- Choi, J.M.; Kim, H.E.; Lee, I.S. Ion-beam-assisted deposition (IBAD) of hydroxyapatite coating layer on Ti-based metal substrate. Biomaterials 2000, 21, 469–473. [Google Scholar] [CrossRef]

- Wang, C.X.; Chen, Z.Q.; Guan, L.M.; Wang, M.; Liu, Z.Y.; Wang, P.L. Fabrication and characterization of graded calcium phosphate coatings produced by ion beam sputtering/mixing deposition. Nucl. Instr. Methods Phys. Res. B 2001, 179, 364–372. [Google Scholar] [CrossRef]

- Lee, I.S.; Whang, C.N.; Lee, G.H.; Cui, F.Z.; Ito, A. Effects of ion beam assist on the formation of calcium phosphate film. Nucl. Instr. Methods Phys. Res. B 2003, 206, 522–526. [Google Scholar] [CrossRef]

- Lee, E.J.; Lee, S.H.; Kim, H.W.; Kong, Y.M.; Kim, H.E. Fluoridated apatite coatings on titanium obtained by electron-beam deposition. Biomaterials 2005, 26, 3843–3851. [Google Scholar] [CrossRef] [PubMed]

- Rabiei, A.; Thomas, B.; Jin, C.; Narayan, R.; Cuomo, J.; Yang, Y.; Ong, J.L. A study on functionally graded HA coatings processed using ion beam assisted deposition with in situ heat treatment. Surf. Coat. Tech. 2006, 200, 6111–6116. [Google Scholar] [CrossRef]

- Blalock, T.; Bai, X.; Rabiei, A. A study on microstructure and properties of calcium phosphate coatings processed using ion beam assisted deposition on heated substrates. Surf. Coat. Tech. 2007, 201, 5850–5858. [Google Scholar] [CrossRef]

- Bai, X.; Sandukas, S.; Appleford, M.R.; Ong, J.L.; Rabiei, A. Deposition and investigation of functionally graded calcium phosphate coatings on titanium. Acta Biomater. 2009, 5, 3563–3572. [Google Scholar] [CrossRef] [PubMed]

- Jeong, Y.H.; Choe, H.C.; Brantley, W.A.; Sohn, I.B. Hydroxyapatite thin film coatings on nanotube-formed Ti–35Nb–10Zr alloys after femtosecond laser texturing. Surf. Coat. Tech. 2013, 217, 13–22. [Google Scholar] [CrossRef]

- Cooley, D.R.; van Dellen, A.F.; Burgess, J.O.; Windeler, S. The advantages of coated titanium implants prepared by radiofrequency sputtering from hydroxyapatite. Prosthet. Dent. 1992, 67, 93–100. [Google Scholar] [CrossRef]

- van Dijk, K.; Schaeken, H.G.; Wolke, J.G.C.; Jansen, J.A. Influence of annealing temperature on RF magnetron sputtered calcium phosphate coatings. Biomaterials 1996, 17, 405–410. [Google Scholar] [CrossRef]

- Nelea, V.; Morosanu, C.; Iliescu, M.; Mihailescu, I.N. Microstructure and mechanical properties of hydroxyapatite thin films grown by RF magnetron sputtering. Surf. Coat. Tech. 2003, 173, 315–322. [Google Scholar] [CrossRef]

- Wan, T.; Aoki, H.; Hikawa, J.; Lee, J.H. RF-magnetron sputtering technique for producing hydroxyapatite coating film on various substrates. Bio-Med. Mater. Eng. 2007, 17, 291–297. [Google Scholar]

- Ozeki, K.; Fukui, Y.; Aoki, H. Influence of the calcium phosphate content of the target on the phase composition and deposition rate of sputtered films. Appl. Surf. Sci. 2007, 253, 5040–5044. [Google Scholar] [CrossRef]

- Ueda, K.; Narushima, T.; Goto, T.; Taira, M.; Katsube, T. Fabrication of calcium phosphate films for coating on titanium substrates heated up to 773 K by RF magnetron sputtering and their evaluations. Biomed. Mater. 2007, 2, S160–S166. [Google Scholar] [CrossRef]

- Pichugin, V.F.; Surmenev, R.A.; Shesterikov, E.V.; Ryabtseva, M.A.; Eshenko, E.V.; Tverdokhlebov, S.I.; Prymak, O.; Epple, M. The preparation of calcium phosphate coatings on titanium and nickel-titanium by RF-magnetron sputtered deposition: Composition, structure and micromechanical properties. Surf. Coat. Tech. 2008, 202, 3913–3920. [Google Scholar] [CrossRef]

- Snyders, R.; Bousser, E.; Music, D.; Jensen, J.; Hocquet, S.; Schneider, J.M. Influence of the chemical composition on the phase constitution and the elastic properties of RF-sputtered hydroxyapatite coatings. Plasma Process. Polym. 2008, 5, 168–174. [Google Scholar] [CrossRef]

- O’Kane, C.; Duffy, H.; Meenan, B.J.; Boyd, A.R. The influence of target stoichiometry on the surface properties of sputter deposited calcium phosphate thin films. Surf. Coat. Tech. 2008, 203, 121–128. [Google Scholar] [CrossRef]

- Boyd, A.R.; O’Kane, C.; Meenan, B.J. Control of calcium phosphate thin film stoichiometry using multi-target sputter deposition. Surf. Coat. Tech. 2013, 233, 131–139. [Google Scholar] [CrossRef]

- López, E.O.; Mello, A.; Sendão, H.; Costa, L.T.; Rossi, A.L.; Ospina, R.O.; Borghi, F.F.; Filho, J.G.S.; Rossi, A.M. Growth of crystalline hydroxyapatite thin films at room temperature by tuning the energy of the RF-magnetron sputtering plasma. ACS Appl. Mater. Interfaces 2013, 5, 9435–9445. [Google Scholar] [CrossRef]

- Surmeneva, M.A.; Surmenev, R.A.; Nikonova, Y.A.; Selezneva, I.I.; Ivanova, A.A.; Putlyaev, V.I.; Prymak, O.; Epple, M. Fabrication, ultra-structure characterization and in vitro studies of RF magnetron sputter deposited nano-hydroxyapatite thin films for biomedical applications. Appl. Surf. Sci. 2014, 317, 172–180. [Google Scholar] [CrossRef]

- Bramowicz, M.; Braic, L.; Azem, F.A.; Kulesza, S.; Birlik, I.; Vladescu, A. Mechanical properties and fractal analysis of the surface texture of sputtered hydroxyapatite coatings. Appl. Surf. Sci. 2016, 379, 338–346. [Google Scholar] [CrossRef]

- Cotell, C.M.; Chrisey, D.B.; Grabowski, K.S.; Sprague, J.A.; Gosset, C.R. Pulsed laser deposition of hydroxylapatite thin films on Ti–6Al–4V. J. Appl. Biomater. 1992, 3, 87–93. [Google Scholar] [CrossRef]

- Baeri, P.; Torrisi, L.; Marino, N.; Foti, G. Ablation of hydroxyapatite by pulsed laser irradiation. Appl. Surf. Sci. 1992, 54, 210–214. [Google Scholar] [CrossRef]

- Cleries, L.; Martinez, E.; Fernandez-Pradas, J.M.; Sardin, G.; Esteve, J.; Morenza, J.L. Mechanical properties of calcium phosphate coatings deposited by laser ablation. Biomaterials 2000, 21, 967–971. [Google Scholar] [CrossRef] [PubMed]

- Nelea, V.; Ristoscu, C.; Chiritescu, C.; Ghica, C.; Mihailescu, I.N.; Pelletier, H.; Mille, P.; Cornet, A. Pulsed laser deposition of hydroxyapatite thin films on Ti–5Al–2.5Fe substrates with and without buffer layers. Appl. Surf. Sci. 2000, 168, 127–131. [Google Scholar] [CrossRef]

- Fernández-Pradas, J.M.; Clèries, L.; Martinez, E.; Sardin, G.; Esteve, J.; Morenza, J.L. Influence of thickness on the properties of hydroxyapatite coatings deposited by KrF laser ablation. Biomaterials 2001, 22, 2171–2175. [Google Scholar] [CrossRef]

- Fernández-Pradas, J.M.; Clèries, L.; Sardin, G.; Morenza, J.L. Characterization of calcium phosphate coatings deposited by Nd:YAG laser ablation at 355 nm: Influence of thickness. Biomaterials 2002, 23, 1989–1994. [Google Scholar] [CrossRef]

- Socol, G.; Torricelli, P.; Bracci, B.; Iliescu, M.; Miroiu, F.; Bigi, A.; Werckmann, J.; Mihailescu, I.N. Biocompatible nanocrystalline octacalcium phosphate thin films obtained by pulsed laser deposition. Biomaterials 2004, 25, 2539–2545. [Google Scholar] [CrossRef]

- Kim, H.; Vohra, Y.K.; Louis, P.J.; Lacefield, W.R.; Lemons, J.E.; Camata, R.P. Biphasic and preferentially oriented microcrystalline calcium phosphate coatings: In vitro and in vivo studies. Key Eng. Mater. 2005, 284–286, 207–210. [Google Scholar] [CrossRef]

- Bigi, A.; Bracci, B.; Cuisinier, F.; Elkaim, R.; Fini, M.; Mayer, I.; Mihailescu, I.N.; Socol, G.; Sturba, L.; Torricelli, P. Human osteoblast response to pulsed laser deposited calcium phosphate coatings. Biomaterials 2005, 26, 2381–2389. [Google Scholar] [CrossRef]

- Koch, C.F.; Johnson, S.; Kumar, D.; Jelinek, M.; Chrisey, D.B.; Doraiswamy, A.; Jin, C.; Narayan, R.J.; Mihailescu, I.N. Pulsed laser deposition of hydroxyapatite thin films. Mater. Sci. Eng. C 2007, 27, 484–494. [Google Scholar] [CrossRef]

- Kim, H.; Camata, R.P.; Lee, S.; Rohrer, G.S.; Rollett, A.D.; Vohra, Y.K. Crystallographic texture in pulsed laser deposited hydroxyapatite bioceramic coatings. Acta Mater. 2007, 55, 131–139. [Google Scholar] [CrossRef]

- Dinda, G.P.; Shin, J.; Mazumder, J. Pulsed laser deposition of hydroxyapatite thin films on Ti–6Al–4V: Effect of heat treatment on structure and properties. Acta Biomater. 2009, 5, 1821–1830. [Google Scholar] [CrossRef]

- Tri, L.Q.; Chua, D.H.C. An investigation into the effects of high laser fluence on hydroxyapatite/calcium phosphate films deposited by pulsed laser deposition. Appl. Surf. Sci. 2009, 256, 76–80. [Google Scholar] [CrossRef]

- Rau, J.V.; Generosi, A.; Laureti, S.; Komlev, V.S.; Ferro, D.; Cesaro, S.N.; Paci, B.; Albertini, V.R.; Agostinelli, E.; Barinov, S.M. Physicochemical investigation of pulsed laser deposited carbonated hydroxyapatite films on titanium. ACS Appl. Mater. Interfaces 2009, 1, 1813–1820. [Google Scholar] [CrossRef] [PubMed]

- Gomes, G.C.; Borghi, F.F.; Ospina, R.O.; López, E.O.; Borges, F.O.; Mello, A. Nd:YAG (532 nm) pulsed laser deposition produces crystalline hydroxyapatite thin coatings at room temperature. Surf. Coat. Tech. 2017, 329, 174–183. [Google Scholar] [CrossRef]

- González-Estrada, O.A.; Comas, A.D.P.; Ospina, R. Characterization of hydroxyapatite coatings produced by pulsed-laser deposition on additive manufacturing Ti6Al4V ELI. Thin Solid Films 2022, 763, 139592. [Google Scholar] [CrossRef]

- Akazawa, H.; Ueno, Y. Growth of preferentially c-axis oriented hydroxyapatite thin films on Si(100) substrate by electron-cyclotron-resonance plasma sputtering. Appl. Surf. Sci. 2013, 276, 217–222. [Google Scholar] [CrossRef]

- Akazawa, H.; Ueno, Y. Control of composition and crystallinity in hydroxyapatite films deposited by electron cyclotron resonance plasma sputtering. J. Phys. Chem. Solids 2014, 75, 94–99. [Google Scholar] [CrossRef]

- Akazawa, H.; Ueno, Y. Distinct crystallinity and orientations of hydroxyapatite thin films deposited on C- and A-plane sapphire substrates. J. Cryst. Growth 2014, 404, 241–245. [Google Scholar] [CrossRef]

- Akazawa, H.; Ueno, Y. Low-temperature crystallization and high-temperature instability of hydroxyapatite thin films deposited on Ru, Ti, and Pt metal substrates. Surf. Coat. Tech. 2015, 266, 42–48. [Google Scholar] [CrossRef]

- Massaro, C.; Baker, M.A.; Cosentino, F.; Ramires, P.A.; Klose, S.; Milella, E. Surface and biological evaluation of hydroxyapatite-based coatings on titanium deposited by different techniques. J. Biomed. Mater. Res. 2001, 58, 651–657. [Google Scholar] [CrossRef]

- León, B.; Jansen, J.A. (Eds.) Thin Calcium Phosphate Coatings for Medical Implants; Springer: New York, NY, USA, 2009; 326p. [Google Scholar]

- Zalm, P.C. Quantitative sputtering. In Handbook of Ion Beam Processing Technology; Cuomo, J.J., Rossnagel, S.M., Kaufman, H.R., Eds.; Noyes Publications: Park Ridge, NJ, USA, 1989; pp. 78–111. [Google Scholar]

- Elayaraja, K.; Chandra, V.S.; Joshy, M.I.A.; Suganthi, R.V.; Asokan, K.; Kalkura, S.N. Nanocrystalline biphasic resorbable calcium phosphate (HAp/β-TCP) thin film prepared by electron beam evaporation technique. Appl. Surf. Sci. 2013, 274, 203–209. [Google Scholar] [CrossRef]

- Hamdi, M.; Hakamata, S.; Ektessabi, A.M. Coating of hydroxyapatite thin film by simultaneous vapor deposition. Thin Solid Films 2000, 377–378, 484–489. [Google Scholar] [CrossRef]

- Hamdi, M.; Ide-Ektessabi, A. Preparation of hydroxyapatite layer by ion beam assisted simultaneous vapor deposition. Surf. Coat. Tech. 2003, 163–164, 362–367. [Google Scholar] [CrossRef]

- Hamdi, M.; Ide-Ektessabi, A. Calcium phosphate coatings: A comparative study between simultaneous vapor deposition and electron beam deposition techniques. Surf. Coat. Tech. 2006, 201, 3123–3128. [Google Scholar] [CrossRef]

- Hamdi, M.; Ide-Ektessabi, A. Dissolution behavior of simultaneous vapor deposited calcium phosphate coatings in vitro. Mater. Sci. Eng. C 2007, 27, 670–674. [Google Scholar] [CrossRef]

- Ali, M.Y.; Hung, W.; Yongqi, F. A review of focused ion beam sputtering. Int. J. Precision Eng. Manuf. 2010, 11, 157–170. [Google Scholar] [CrossRef]

- Yoshinari, M.; Ohtsuka, Y.; Dérand, T. Thin hydroxyapatite coating produced by the ion beam dynamic mixing method. Biomaterials 1994, 15, 529–535. [Google Scholar] [CrossRef]

- Yoshinari, M.; Ohtsuka, Y.; Dérand, T. The biocomatibility (cell culture and histologic study) of hydroxyapatite-coated implants created by ion beam dynamic mixing method. Clin. Oral Impl. Res. 1996, 7, 96–100. [Google Scholar] [CrossRef]

- Amy, R.L.; Storb, R. Selective mitochondrial damage by a ruby laser microbeam: An electron microscopic study. Science 1955, 122, 756–758. [Google Scholar] [CrossRef]

- Singh, R.K.; Narayan, J. Pulsed-laser evaporation technique for deposition of thin films: Physics and theoretical model. Phys. Rev. B 1990, 41, 8843–8859. [Google Scholar] [CrossRef]

- Jedynski, M.; Hoffman, J.; Mroz, W.; Szymanski, Z. Plasma plume induced during ArF laser ablation of hydroxyapatite. Appl. Surf. Sci. 2008, 255, 2230–2236. [Google Scholar] [CrossRef]

- Katayama, H.; Katto, M.; Nakayama, T. Laser-assisted laser ablation method for high-quality hydroxyapatite coating onto titanium substrate. Surf. Coat. Tech. 2009, 204, 135–140. [Google Scholar] [CrossRef]

- Bao, Q.; Chen, C.; Wang, D.; Lei, T.; Liu, J. Pulsed laser deposition of hydroxyapatite thin films under Ar atmosphere. Mater. Sci. Eng. A 2006, 429, 25–29. [Google Scholar] [CrossRef]

- Fernandez-Pradas, J.M.; Cleries, L.; Martinez, E.; Sardin, G.; Esteve, J.; Morenza, J.L. Calcium phosphate coatings deposited by laser ablation at 355 nm under different substrate temperatures and water vapour pressures. Appl. Phys. A 2000, 71, 37–42. [Google Scholar] [CrossRef]

- Ievlev, V.M. Coatings based on calcium phosphates for metallic medical implants. Russ. Chem. Rev. 2013, 82, 131–149. [Google Scholar] [CrossRef]

- Rau, J.V.; Smirnov, V.V.; Laureti, S.; Generosi, A.; Varvaro, G.; Fosca, M.; Ferro, D.; Cesaro, S.N.; Albertini, V.R.; Barinov, S.M. Properties of pulsed laser deposited fluorinated hydroxyapatite films on titanium. Mater. Res. Bull. 2010, 45, 1304–1310. [Google Scholar] [CrossRef]