On the Relationship between Lightning Strike Parameters and Measured Free Surface Velocities in Artificial Lightning Strike Tests on Composite Panels

Abstract

:1. Introduction

2. Material and Methods

2.1. Material

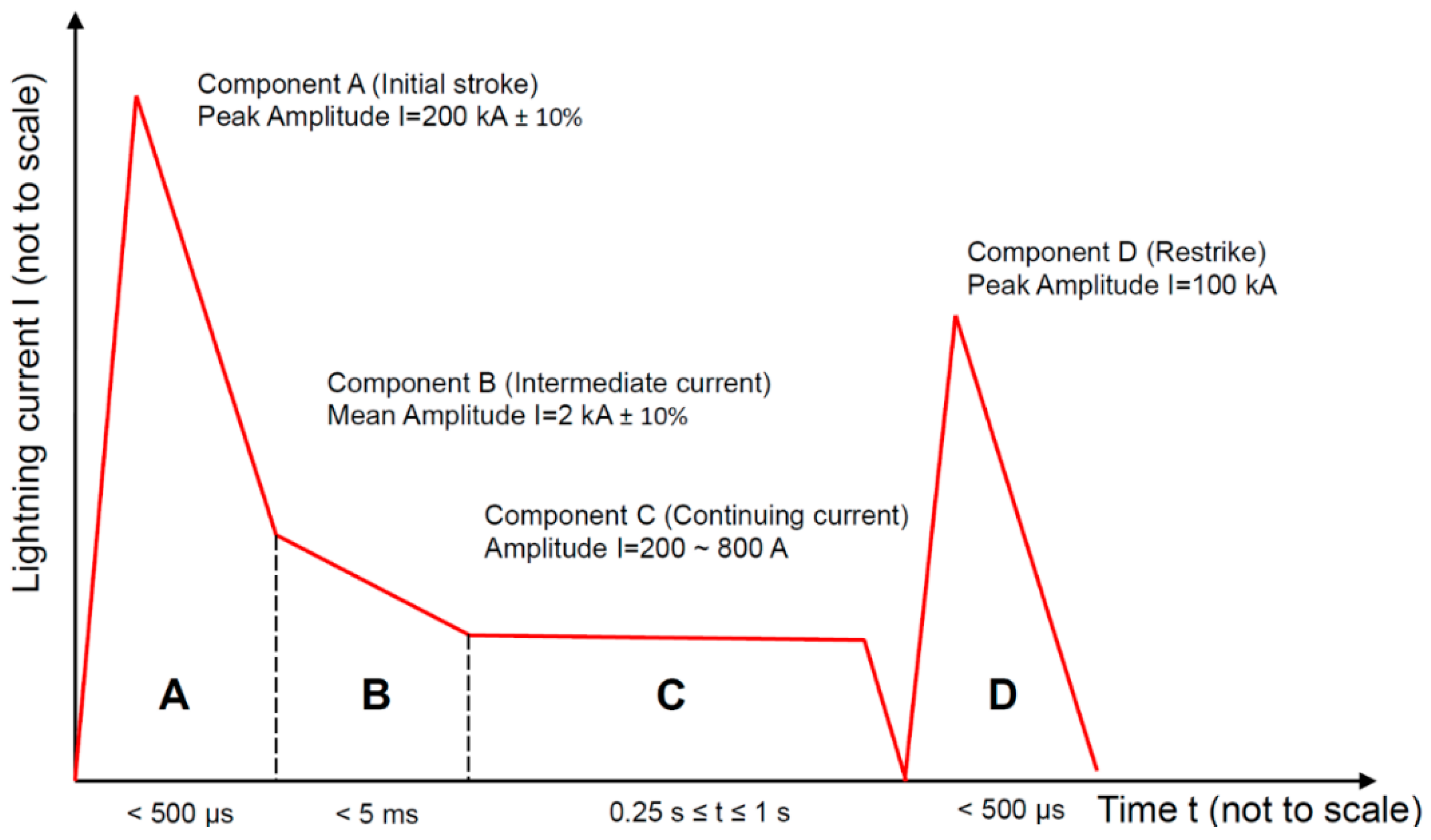

2.2. Artificial Lighnting Strike Tests

2.3. Analysis Method

3. Results

3.1. Phenomenology

3.2. Relationships between Lightning Strike Parameters and Back-Surface Velocity

- the peak velocity increases with increasing peak current for constant levels of protection

- and the peak velocity reduces with increasing levels of protection for constant levels of applied peak current.

4. Conclusions

- The peak velocity increases with increasing peak current for constant levels of protection.

- The peak velocity decreases with increasing levels of protection for constant levels of applied peak current.

- Both the medium (area weight 195 g/m²) and the heavy (area weight 815 g/m²) copper mesh successfully protected the composite from the artificial current component A lighting strike. In consequence, all protected panels did not suffer any delamination. The medium level of protection therefore seems to be sufficient for protecting quasi-isotropic AS4/8552 carbon/epoxy composites from lightning strike events.

- For the tested composite panels with protection, no severe structural damage (e.g., delamination) was observed. The back surface velocity can therefore not be taken as a measure of threat for the composite panels.

- The relationship between the peak velocity and the total panel weight normalized with the peak electric current can be described by a linear master curve, which is independent of the level of protection.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- May, M. Measuring the rate-dependent mode I fracture toughness of composites—A review. Compos. Part A Appl. Sci. Manuf. 2016, 81, 1–12. [Google Scholar] [CrossRef]

- Imbert, M.; Kilchert, S.; Maurer, M.; May, M. Experimental investigations of hail impacts over a wide range of high velocities. Int. J. Impact Eng. 2023, 178, 104627. [Google Scholar] [CrossRef]

- Foster, P.; Abeladl, G.; Murphy, A. Quantifying the Influence of Lightning Strike Pressure Loading on Composite Specimen Damage. Appl. Compos. Mater. 2019, 26, 115–137. [Google Scholar] [CrossRef] [Green Version]

- Sasikumar, A.; Costa, J.; Trias, D.; Gonzalez, E.V.; Garica-Rodriguez, S.M.; Maimi, P. Unsymmetrical stacking sequences as a novel approach to tailor damage resistance under out-of-plane impact loading. Compos. Sci. Technol. 2019, 173, 125–135. [Google Scholar] [CrossRef]

- Sasikumar, A.; Trias, D.; Costa, J.; Blanco, N.; Orr, J.; Linde, P. Effect of ply thickness and ply level hybridization on the compression after impact strength of thin laminates. Compos. Part A Appl. Sci. Manuf. 2018, 121, 232–243. [Google Scholar] [CrossRef]

- May, M.; Hallett, S.R. A combined model for initiation and propagation of damage under fatigue loading for cohesive interface elements. Compos. Part A Appl. Sci. Manuf. 2010, 41, 1787–1796. [Google Scholar] [CrossRef]

- May, M.; Hallett, S.R. An assessment of through-thickness shear tests for initiation of fatigue failure. Compos. Part A Appl. Sci. Manuf. 2010, 41, 1570–1578. [Google Scholar] [CrossRef]

- Karch, C.; Arteiro, A.; Nobis, F.; Duval, Y.; Wolfrum, J. Modelling and Simulation of Lightning-Induced Damage on CFRP Structures. In Proceedings of the 2017 International Conference on Lightning and Static Electricity, Nagoya, Japan, 13–15 September 2017. [Google Scholar]

- Karch, C.; Metzner, C. Lighnting Protection of Carbon Fibre Reinforced Plastics—An Overview. In Proceedings of the 2016 33rd International Conference on Lightning Protection (ICLP), Estoril, Portugal, 25–30 September 2016. [Google Scholar]

- Ogasaware, T.; Hirano, Y.; Yoshimura, A. Coupled thermal-electrical analysis for carbon fiber/epoxy composite laminate. Compos. Part A Appl. Sci. Manuf. 2010, 41, 973–981. [Google Scholar] [CrossRef]

- Hirano, Y.; Katsumata, S.; Iwahori, Y.; Todoroki, A. Artificial lightning testing on graphite/epoxy composite laminate. Compos. Part A Appl. Sci. Manuf. 2010, 41, 1461–1470. [Google Scholar] [CrossRef]

- Wang, Y. Multiphysics Analysis of Lightning Strike Damage in Laminated Carbon/Glass Fiber Reinforced Polymer Matrix Composites: A Review of problem Formulation and Computational Modeling. Compos. Part A Appl. Sci. Manuf. 2017, 101, 543–553. [Google Scholar] [CrossRef]

- Wang, Y.; Zhupanska, O. Lightning strike thermal damage model for glass fiber reinforced polymer matrix composites and its application to wind turbine blades. Compos. Struct. 2015, 132, 1182–1191. [Google Scholar] [CrossRef]

- Lepetit, B.; Escure, C.; Guinard, S.; Revel, I.; Peres, G. Thermo-mechanical effects induced by lightning on carbon fiber composite materials. In Proceedings of the International Conference on Lightning & Static Electricity (ICOLSE), Oxford, UK, 6–8 September 2011. [Google Scholar]

- ARP5412B; Aircraft Lightning Environment and Related Test Waveforms. AE Aerospace Recommended Practice. SAE International: Warrendale, PA, USA, 2013.

- May, M.; Kuder, J.; Hahn, P.; Isakov, M.; Schopferer, S. Artificial lighnting strike onto composite structures—Effect of local mesh geometry. In Proceedings of the AIAA SciTech 2021 Forum, Virtual, online, 11–15 January 2021; p. 253579. [Google Scholar] [CrossRef]

- Hannemann, B.; Backe, S.; Schmeer, S.; Balle, F.; Breuer, U.; Schuster, J. Hybridisation of CFRP by the use of continuous metal fibers (MCFRP) for damage tolerant and electrically conductive lightweight structures. Compos. Struct. 2017, 172, 374–382. [Google Scholar] [CrossRef]

- Kawakami, H.; Feraboli, P. Lightning strike damage resistance and tolerance of scarf-repaired mesh-protected carbon fiber composites. Compos. Part A—Appl. Sci. Manuf. 2011, 42, 1247–1262. [Google Scholar] [CrossRef]

- Dong, Q.; Wan, G.; Xu, Y.; Guo, Y.; Du, T.; Yi, X.; Jia, Y. Lightning damage of carbon Fiber/epoxy laminates with interlayers modified by nickel-coated multi-walled carbon nanotubes. Appl. Compos. Mater. 2017, 24, 1339–1351. [Google Scholar] [CrossRef]

- Karch, C.; Arteiro, A.; Camanho, P.P. Modelling mechanical lightning loads in carbon fibre-reinforced polymers. Int. J. Solids Struct. 2019, 162, 217–243. [Google Scholar] [CrossRef]

- Dolan, D.H. Extreme measurements with Photonic Doppler Velocimetry (PDV). Rev. Sci. Instrum. 2020, 91, 51501. [Google Scholar] [CrossRef] [PubMed]

| Test No. | Panel Type | Peak Current [kA] | Back-Surface Velocity [m/s] |

|---|---|---|---|

| 1 | Medium protection (B) | 180 | 51.8 |

| 2 | Medium protection (B) | 185 | 54.6 |

| 3 | Strong protection (C) | 200 | 54.6 |

| 4 | Strong protection (C) | 212 | 60.8 |

| 5 | Strong protection (C) | 183 | 47.5 |

| 6 | Strong protection (C) | 175 | 43.7 |

| 7 | No protection (A) | 133 | 35.6 |

| 8 | No protection (A) | 212 | 86.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

May, M.; Schopferer, S. On the Relationship between Lightning Strike Parameters and Measured Free Surface Velocities in Artificial Lightning Strike Tests on Composite Panels. J. Compos. Sci. 2023, 7, 268. https://doi.org/10.3390/jcs7070268

May M, Schopferer S. On the Relationship between Lightning Strike Parameters and Measured Free Surface Velocities in Artificial Lightning Strike Tests on Composite Panels. Journal of Composites Science. 2023; 7(7):268. https://doi.org/10.3390/jcs7070268

Chicago/Turabian StyleMay, Michael, and Sebastian Schopferer. 2023. "On the Relationship between Lightning Strike Parameters and Measured Free Surface Velocities in Artificial Lightning Strike Tests on Composite Panels" Journal of Composites Science 7, no. 7: 268. https://doi.org/10.3390/jcs7070268

APA StyleMay, M., & Schopferer, S. (2023). On the Relationship between Lightning Strike Parameters and Measured Free Surface Velocities in Artificial Lightning Strike Tests on Composite Panels. Journal of Composites Science, 7(7), 268. https://doi.org/10.3390/jcs7070268