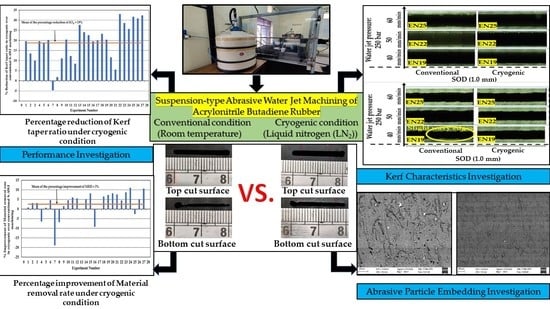

Investigation on Performance and Kerf Characteristics during Cryogenic-Assisted Suspension-Type Abrasive Water Jet Machining of Acrylonitrile Butadiene Rubber

Abstract

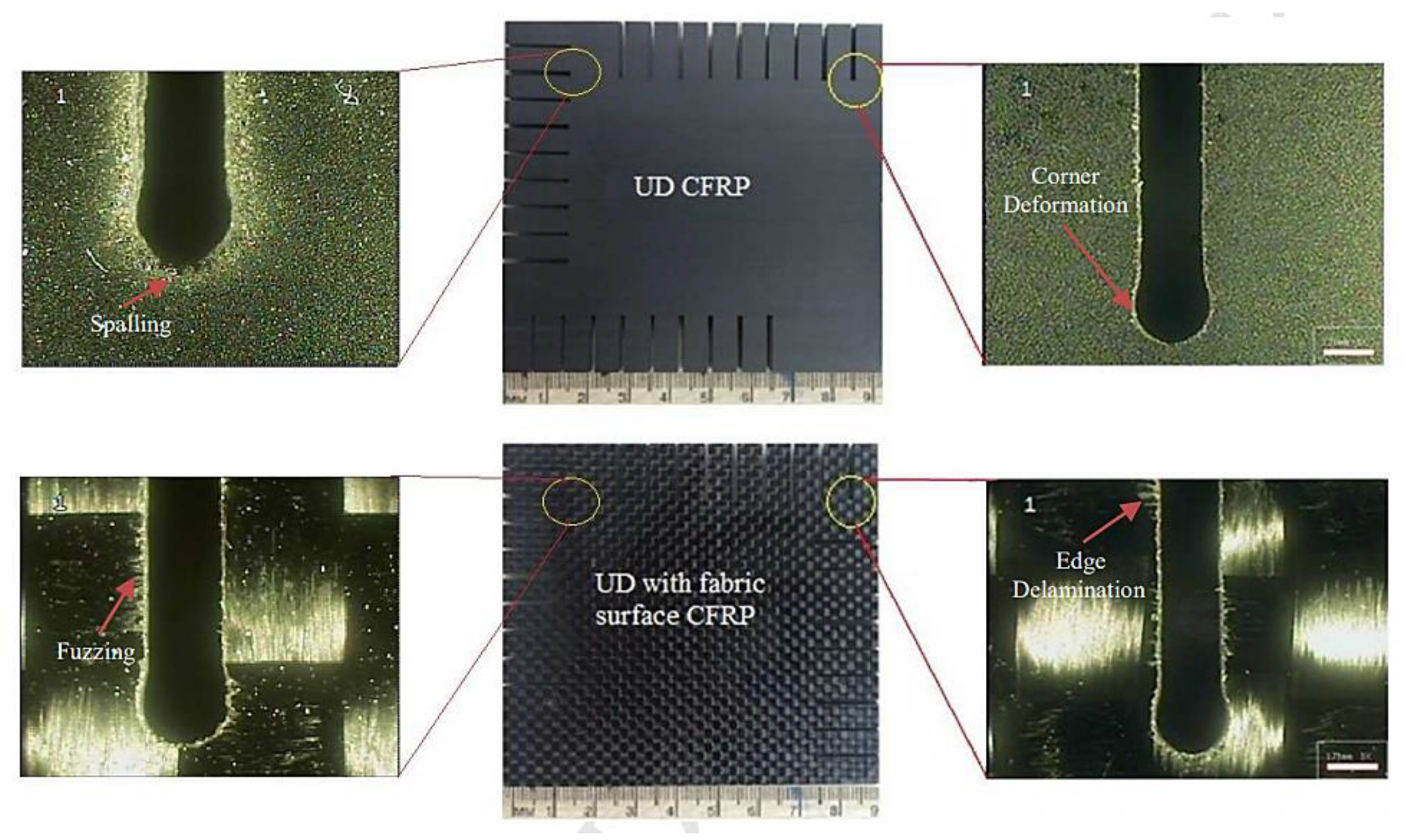

1. Introduction

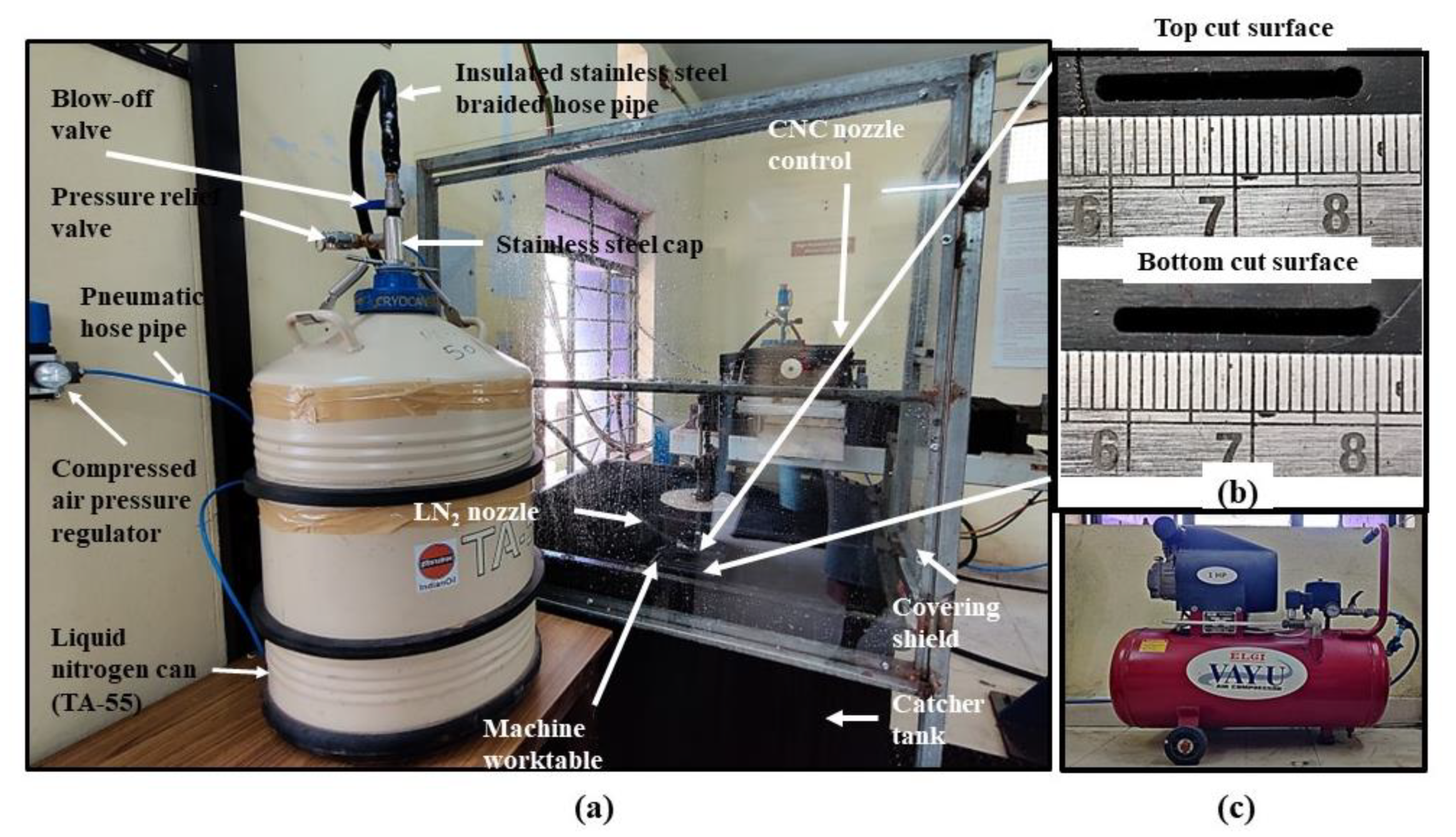

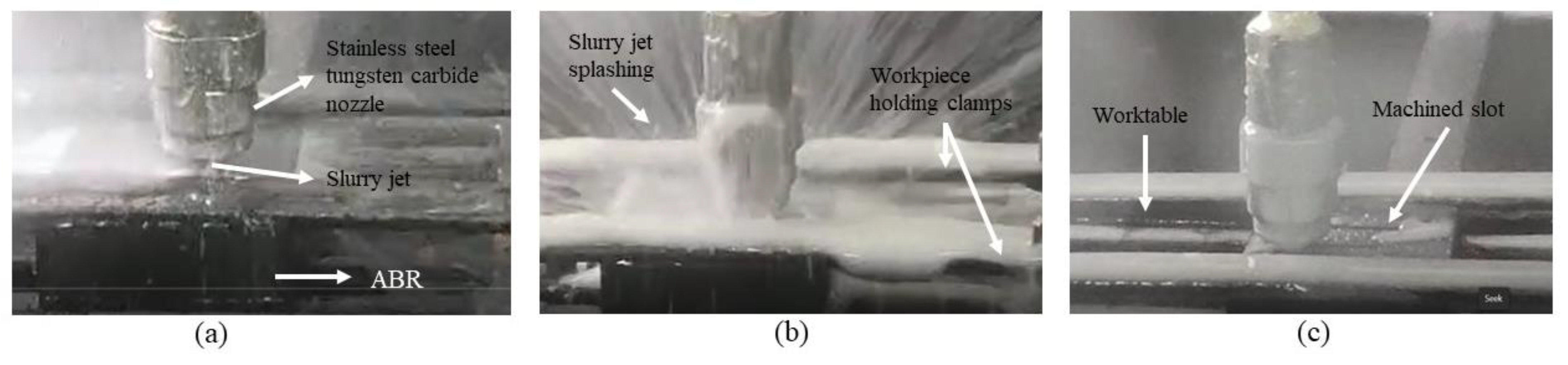

2. Materials and Methods

2.1. Cryogenic-Assisted S-AWJ Test Setup, Test Procedure, and Work Material

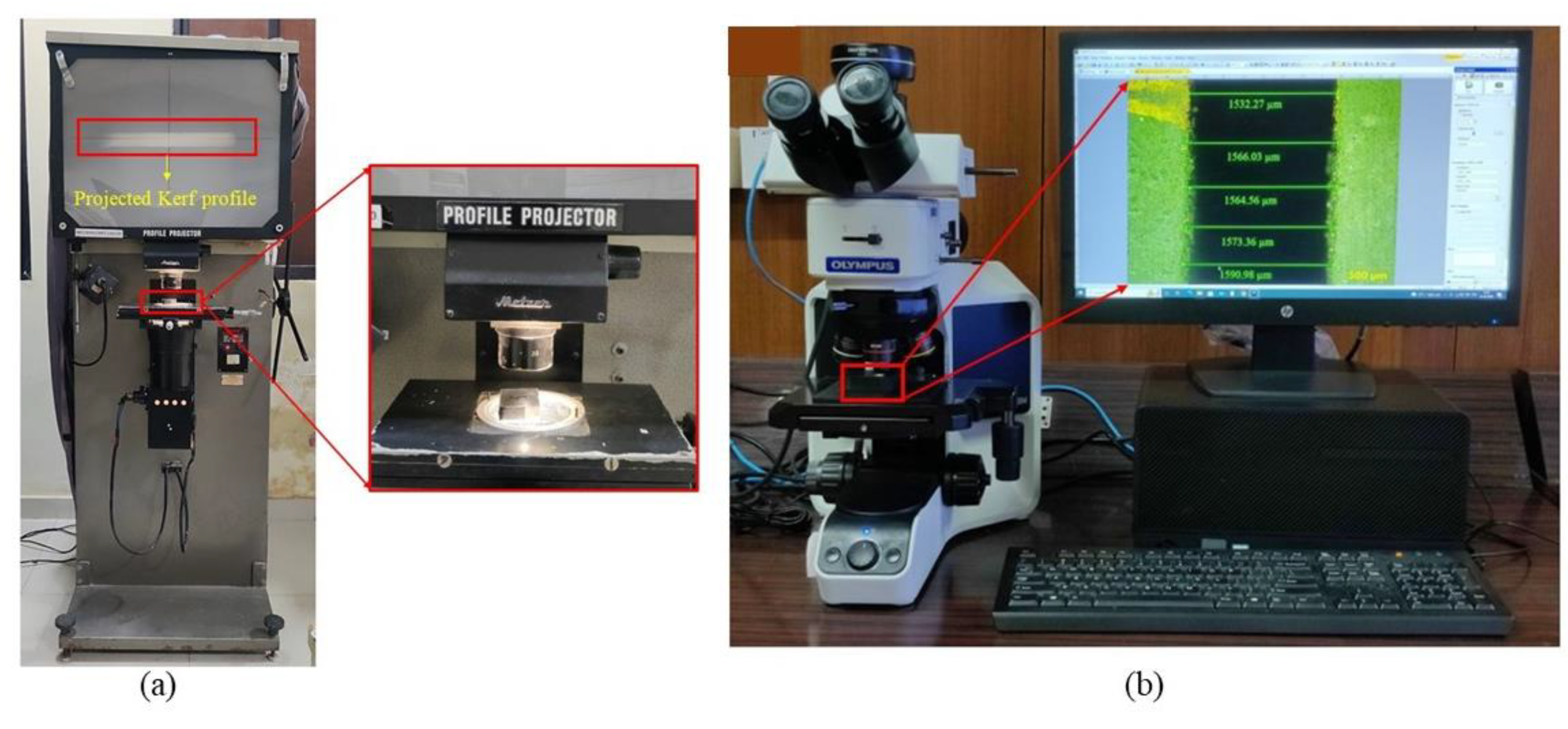

2.2. Selection of Machining Process Parameters, Experiment Test Sequence and Performance Parameters

2.3. Surface Morphology

3. Results and Discussions

3.1. SEM and EDX Results of Garnet and ABR

3.2. Effect of Cryogenic Cooling on Kerf Taper Ratio and Material Removal Rate in Slot Machining of ABR

3.3. Effect of Cryogenic Cooling on Kerf Profile Produced during Slot Machining of the ABR Material

3.3.1. At WJP 150 Bar

3.3.2. At WJP 200 Bar

3.3.3. At WJP 250 Bar

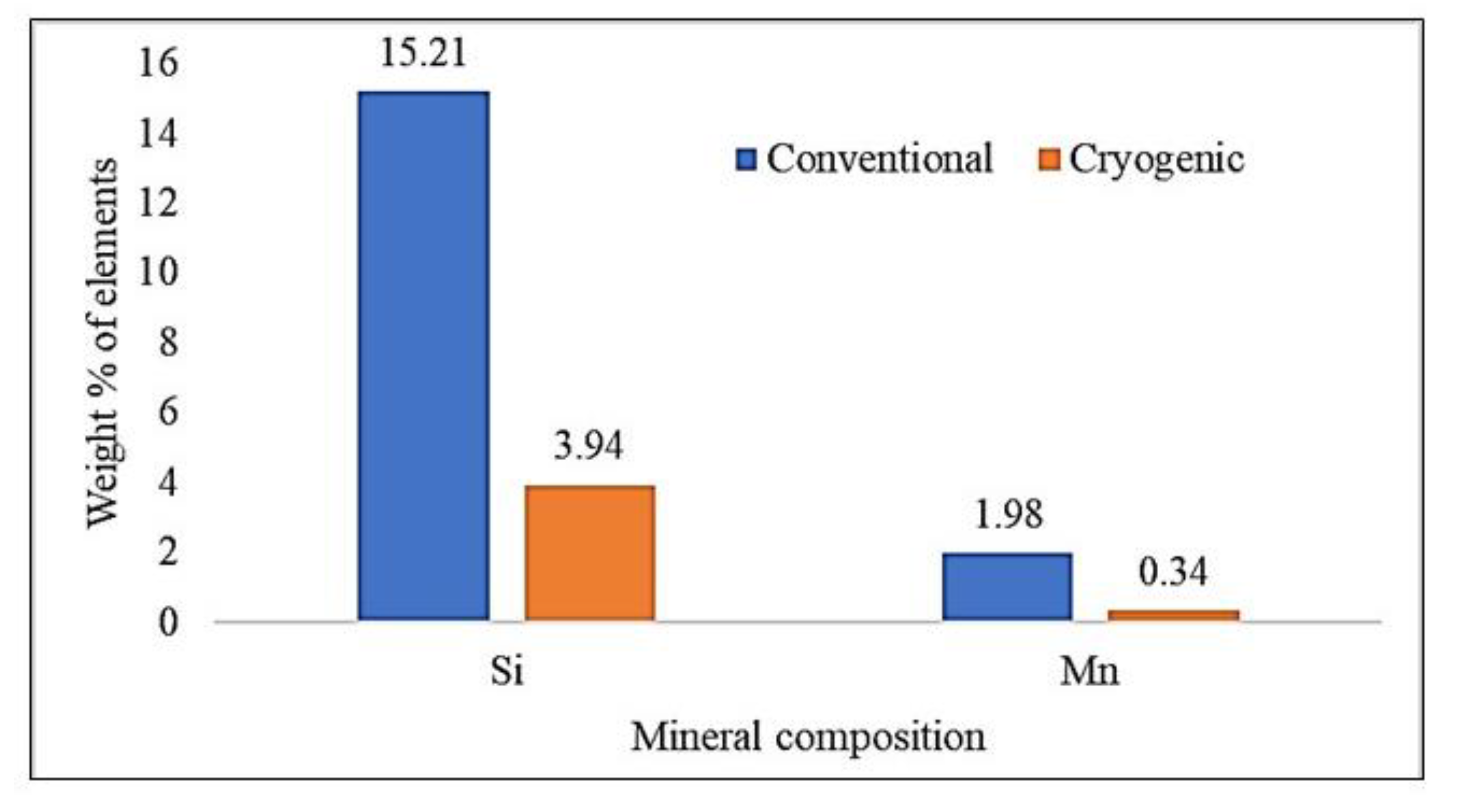

3.4. Effect of Cryogenic Conditions on the Abrasive Contamination during the AWJ Machining of ABR

4. Conclusions

- The lowest KTR (1.25) was achieved under cryogenic conditions of WJP of 200 bar, Vf of 40 mm/min, and SOD of 1.0 mm.

- The highest MRR (1604.84 mm3/min) was achieved under cryogenic conditions of WJP of 250 bar, Vf of 60 mm/min, and SOD of 2.0 mm.

- The cryogenic conditions improved the machined cut profile to a large extent.

- The reduced waviness during the cryogenic-assisted S-AWJ machining showed better uniformity in the geometry of the cut slot compared to conventional conditions due to increased Young’s modulus and decreased elasticity of ABR.

- Under conventional conditions, particularly with low WJP, high SOD, and Vf levels, severe and slight wavy edges could be seen at the bottom kerf profiles.

- Slight wavy edges were also observed in the bottom kerf profiles produced at low WJP under cryogenic conditions.

- The use of LN2 during S-AWJ machining of ABR resulted in the decreased percentage of Si and Mn particles on the top kerf machined profile due to the increased elastic modulus of ABR and the change in the erosion process.

- The cryogenic-assisted S-AWJ-machined ABR workpiece showed enhanced surface quality.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ma, Q.; Lin, J.; Yang, K.; Xie, H.; Guo, C. Experimental study on abrasive recycling in cutting with abrasive suspension water jet. Int. J. Adv. Manuf. Technol. 2021, 114, 969–979. [Google Scholar] [CrossRef]

- Trzepieciński, T.; Najm, S.M.; Lemu, H.G. Current concepts for cutting metal-based and polymer-based composite materials. J. Compos. Sci. 2022, 6, 150. [Google Scholar] [CrossRef]

- Hu, Y.; Kang, Y.; Wang, X.-C.; Li, X.H.; Long, X.-P.; Zhai, G.-Y.; Huang, M. Mechanism and experimental investigation of ultra-high pressure water jet on rubber cutting. Int. J. Precis. Eng. Manuf. 2014, 15, 1973–1978. [Google Scholar] [CrossRef]

- Maurya, P.; Kamath, R.C.; Vijay, G.S. Suspension-type abrasive water jet machining of slot on nitrile butadiene rubber: A preliminary study. Mater. Today Proc. 2022, 63, 219–225. [Google Scholar] [CrossRef]

- Hollinger, R.H.; Perry, W.D.; Swanson, R.K. Precision cutting with a low pressure, coherent abrasive suspension jet. In Proceedings of the 5th American Water Jet Conference, Toronto, Canada, 29–31 August 1989. [Google Scholar]

- Maurya, P.; GS, V.; Shivamurthy, B. Cryogenic machining of elastomer: A review. Mach. Sci. Technol. 2021, 25, 477–525. [Google Scholar] [CrossRef]

- Nayak, R.; Nayak, A.; Shetty, R. Low temperature machining of nitrile rubber. Int. J. Automot. Mech. Eng. 2018, 15, 5500–5510. [Google Scholar]

- Davim, J.P. Surface Integrity in Machining, 1st ed.; Springer: London, UK; Dordrecht, The Netherlands; Berlin/Heidelberg, Germany; New York, NY, USA, 2010; pp. 1–32. [Google Scholar]

- Ding, W.; Gong, C.; Mosalam, K.M.; Soga, K. Development and application of the integrated sealant test apparatus for sealing gaskets in tunnel segmental joints. Tunn. Undergr. Space Technol. 2017, 63, 54–68. [Google Scholar] [CrossRef]

- Li, M.; Lin, X.; Yang, X.; Wu, H.; Meng, X. Study on kerf characteristics and surface integrity based on physical energy model during abrasive waterjet cutting of thick CFRP laminates. Int. J. Adv. Manuf. Technol. 2021, 113, 73–85. [Google Scholar] [CrossRef]

- Yuvaraj, N.; Kumar, M.P. Cutting of aluminum alloy with abrasive water jet and cryogenic assisted abrasive water jet: A comparative study of the surface integrity approach. Wear 2016, 362, 18–32. [Google Scholar] [CrossRef]

- Jebaraj, M.; Kumar, M.P.; Yuvaraj, N.; Anburaj, R. Investigation of surface integrity in end milling of 55NiCrMoV7 die steel under the cryogenic environments. Mach. Sci. Technol. 2020, 24, 465–488. [Google Scholar] [CrossRef]

- Pahuja, R.; Ramulu, M.; Hashish, M. Abrasive waterjet profile cutting of thick titanium/graphite fiber metal laminate. In Proceedings of the ASME International Mechanical Engineering Congress and Exposition, Phoenix, AZ, USA, 11–17 November 2016. [Google Scholar]

- Arola, D.; Ramulu, M. A study of kerf characteristics in abrasive waterjet machining of graphite/epoxy composite. J. Eng. Mater. Technol. 1996, 118, 256–265. [Google Scholar] [CrossRef]

- Kumaran, S.T.; Ko, T.J.; Uthayakumar, M.; Islam, M.M. Prediction of surface roughness in abrasive water jet machining of CFRP composites using regression analysis. J. Alloys Compd. 2017, 724, 1037–1045. [Google Scholar] [CrossRef]

- Mardi, K.B.; Dixit, A.R.; Mallick, A.; Pramanik, A.; Ballokova, B.; Hvizdos, P.; Foldyna, J.; Scucka, J.; Hlavacek, P.; Zelenak, M. Surface integrity of Mg-based nanocomposite produced by Abrasive Water Jet Machining (AWJM). Mater. Manuf. Process. 2017, 32, 1707–1714. [Google Scholar] [CrossRef]

- Liao, Z.; Abdelhafeez, A.; Li, H.; Yang, Y.; Diaz, O.G.; Axinte, D. State-of-the-art of surface integrity in machining of metal matrix composites. Int. J. Mach. Tools Manuf. 2019, 143, 63–91. [Google Scholar] [CrossRef]

- Salinas, L.C.; Moussaoui, K.; Hejjaji, A.; Salem, M.; Hor, A.; Zitoune, R. Influence of abrasive water jet parameters on the surface integrity of Inconel 718. Int. J. Adv. Manuf. Technol. 2021, 114, 997–1009. [Google Scholar] [CrossRef]

- Ramakrishnan, S. Investigating the effects of abrasive water jet machining parameters on surface integrity, chemical state in machining of Ti-6Al-4V. Mater. Today Commun. 2022, 31, 103480. [Google Scholar] [CrossRef]

- Kowsari, K.; Schwartzentruber, J.; Spelt, J.K.; Papini, M. Erosive smoothing of abrasive slurry-jet micro-machined channels in glass, PMMA, and sintered ceramics: Experiments and roughness model. Precis. Eng. 2017, 49, 332–343. [Google Scholar] [CrossRef]

- Tamannaee, N.; Spelt, J.K.; Papini, M. Abrasive slurry jet micro-machining of edges, planar areas and transitional slopes in a talc-filled copolymer. Precis. Eng. 2015, 43, 52–62. [Google Scholar] [CrossRef]

- Anjaiah, D.; Chincholkar, A.M. Cutting of glass using low-pressure abrasive water suspension jet with the addition of zycoprint polymer. In Proceedings of the 19th International Conference Water Jet, Nottingham, UK, 15–17 October 2008. [Google Scholar]

- Syazwani, H.; Mebrahitom, G.; Azmir, A.A. Review on nozzle wear in abrasive water jet machining application. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Orlando, FL, USA, 10–14 October 2021. [Google Scholar]

- Pusavec, F.; Courbon, C.; Rech, J.; Kopac, J.; Jawahir, I.S. An investigation of the effect of nitrogen phase on cryogenic machining performance and a case study on machining of Inconel 718 alloy. In Proceedings of the International Manufacturing Science and Engineering Conference, Detroit, MI, USA, 9–13 June 2014. [Google Scholar]

- Ayed, Y.; Germain, G.; Melsio, A.P.; Kowalewski, P.; Locufier, D. Impact of supply conditions of liquid nitrogen on tool wear and surface integrity when machining the Ti-6Al-4V titanium alloy. Int. J. Adv. Manuf. Technol. 2017, 93, 1199–1206. [Google Scholar] [CrossRef]

- Khanna, N.; Aggarwal, C.; Pimenov, D.Y.; Singla, A.K.; Machado, A.R.; da Silva, L.R.R.; Gupta, M.K.; Sarikaya, M.; Krolczyk, G.M. Review on design and development of cryogenic machining setups for heat resistant alloys and composites. J. Manuf. Process. 2021, 68, 398–422. [Google Scholar] [CrossRef]

- Balaji, V.; Ravi, S.; Chandran, P.N.; Damodaran, K.M. Review of the cryogenic machining in turning and milling process. Int. J. Res. Eng. Technol. 2015, 4, 38–42. [Google Scholar]

- Momber, A. Water jet usage in German civil engineering—state of art. In Geomechanics 93: Strata Mechanics/Numerical Methods/Water Jet Cutting/Mechanical Rock Disintegration, 1st ed.; Rakowski, Z., Ed.; Taylor & Francis, Routledge: London, UK, 2017; pp. 1–12. [Google Scholar]

- Fowler, G.; Pashby, I.R.; Shipway, P.H. The effect of particle hardness and shape when abrasive water jet milling titanium alloy Ti6Al4V. Wear 2009, 266, 613–620. [Google Scholar] [CrossRef]

- Zhang, G.; Sun, Y.; Gao, H.; Liu, X.; Zuo, D. Characteristics of cryogenic abrasive air-jet direct-write machining: A comparison with abrasive air-jet direct-write machining at oblique angles. J. Mater. Process. Technol. 2022, 299, 117394. [Google Scholar] [CrossRef]

- Louis, H.; Pude, F.; Rad, C.V.; Versemann, R. Abrasive water suspension jet technology fundamentals, application and developments. Weld. World 2007, 51, 11–16. [Google Scholar] [CrossRef]

- Haghbin, N.; Ahmadzadeh, F.; Spelt, J.K.; Papini, M. Effect of entrained air in abrasive water jet micro-machining: Reduction of channel width and waviness using slurry entrainment. Wear 2015, 344, 99–109. [Google Scholar] [CrossRef]

- Jegaraj, J.J.R.; Babu, N.R. A strategy for efficient and quality cutting of materials with abrasive waterjets considering the variation in orifice and focusing nozzle diameter. Int. J. Mach. Tools Manuf. 2005, 45, 1443–1450. [Google Scholar] [CrossRef]

- Deepak, D.; Devineni, A. Effect of process parameters on the surface roughness produced during machining of ceramics using AWSJ: An experimental investigation by Taguchi signal to noise ratio. In Proceedings of the WJTA American Waterjet Conference, New Orleans, LA, USA, 25–27 October 2017; pp. 1–8. [Google Scholar]

- Natarajan, Y.; Murugasen, P.K.; Sundarajan, L.R.; Arunachalam, R. Experimental investigation on cryogenic assisted abrasive water jet machining of aluminum alloy. Int. J. Precis. Eng. Manuf. Green Technol. 2019, 6, 415–432. [Google Scholar] [CrossRef]

- Zhao, W.; Guo, C. Topography and microstructure of the cutting surface machined with abrasive water jet. Int. J. Adv. Manuf. Technol. 2014, 73, 941–947. [Google Scholar] [CrossRef]

- Kalla, D.K.; Zhang, B.; Asmatulu, R.; Dhanasekaran, P.S. Current research trends in abrasive water jet machining of fiber reinforced composites. Mater. Sci. Forum 2012, 713, 37–42. [Google Scholar] [CrossRef]

- Fowler, G.; Shipway, P.H.; Pashby, I.R. Abrasive water jet-controlled depth milling of Ti6Al4V alloy—An investigation of the role of jet-workpiece traverse speed and abrasive grit size on the characteristics of the milled material. J. Mater. Process. Technol. 2005, 161, 407–414. [Google Scholar] [CrossRef]

- Getu, H.; Spelt, J.K.; Papini, M. Cryogenically assisted abrasive jet micromachining of polymers. J. Micromechanics Microengineering 2008, 18, 115010. [Google Scholar] [CrossRef]

- Getu, H.; Spelt, J.K.; Papini, M. Reduction of particle embedding in solid particle erosion of polymers. Wear 2011, 270, 922–928. [Google Scholar] [CrossRef]

- Gradeen, A.G.; Spelt, J.K.; Papini, M. Cryogenic abrasive jet machining of polydimethylsiloxane at different temperatures. Wear 2012, 274, 335–344. [Google Scholar] [CrossRef]

| Item | Description |

|---|---|

| Hydraulic plunger pump | Triplex reciprocating pump Direct driven Power = 40 HP Discharge = 16 ltr/min Delivery Pressure = 60 MPa |

| Floating piston cylinder | Capacity = 10 ltr |

| Suspension charging tank | Capacity = 50 ltr |

| Suspension mixing tank | Capacity = 100 ltr |

| Air compressor | Power = 1 HP Capacity = 45 ltr Delivery pressure = 12 bar |

| CNC nozzle movement | Two axis control Maximum travel in X-direction = 450 mm Maximum travel in Y-direction = 450 mm |

| Process Parameters | |

|---|---|

| Fixed | Variable |

| Jet impingement angle: 90° | Water jet pressure (WJP): 150, 200 and 250 bar |

| Number of passes: 2 | Traverse rate (Vf): 40, 50 and 60 mm/min |

| Abrasive: garnet | Stand-off distance (SOD): 1, 1.5 and 2 mm |

| Abrasive mesh size: #80 | |

| Focusing nozzle: Stainless steel | |

| Orifice: tungsten carbide | |

| Nozzle orifice diameter: 1 mm | |

| LN2 flow pressure: 0.6 bar | |

| LN2 flow angle: 80° (with nozzle axis) | |

| LN2 flow rate: 1.5 lpm | |

| Mass percentage of Zycoprint polymer (ωp): 0.8% | |

| Mass percentage of garnet (ωa): 3% | |

| Particle Number (Pn) | Shape Factor |

|---|---|

| Pn1 | 0.3 |

| Pn2 | 0.5 |

| Pn3 | 0.4 |

| Pn4 | 0.7 |

| Pn5 | 0.3 |

| Pn6 | 0.4 |

| Pn7 | 0.6 |

| Pn8 | 0.6 |

| Pn9 | 0.4 |

| Pn10 | 0.4 |

| Pn11 | 0.6 |

| Pn12 | 0.6 |

| Pn13 | 0.4 |

| Pn14 | 0.6 |

| Pn15 | 0.5 |

| Pn16 | 0.6 |

| Pn17 | 0.5 |

| Pn18 | 0.6 |

| Pn19 | 0.5 |

| Pn20 | 0.4 |

| Pn21 | 0.5 |

| Pn22 | 0.5 |

| Pn23 | 0.8 |

| Pn24 | 0.5 |

| Pn25 | 0.6 |

| Mean | 0.5 |

| Standard Deviation | 0.12 |

| Experiment No. | WJP | Vf | SOD | KTR | % Reduction of KTR in Cryogenic over Conventional S-AWJ Machining | |

|---|---|---|---|---|---|---|

| Conventional | Cryogenic | |||||

| EN1 | 150 | 40 | 1.0 | 1.79 | 1.44 | 19.56 |

| EN2 | 150 | 40 | 1.5 | 1.71 | 1.48 | 13.46 |

| EN3 | 150 | 40 | 2.0 | 1.69 | 1.52 | 10.06 |

| EN4 | 150 | 50 | 1.0 | 2.20 | 1.77 | 19.55 |

| EN5 | 150 | 50 | 1.5 | 2.21 | 1.80 | 18.56 |

| EN6 | 150 | 50 | 2.0 | 2.28 | 1.82 | 20.18 |

| EN7 | 150 | 60 | 1.0 | 2.13 | 2.23 | −4.70 |

| EN8 | 150 | 60 | 1.5 | 2.28 | 2.24 | 1.76 |

| EN9 | 150 | 60 | 2.0 | 2.54 | 2.26 | 11.03 |

| EN10 | 200 | 40 | 1.0 | 1.57 | 1.25 | 20.39 |

| EN11 | 200 | 40 | 1.5 | 1.47 | 1.29 | 12.25 |

| EN12 | 200 | 40 | 2.0 | 1.42 | 1.30 | 8.46 |

| EN13 | 200 | 50 | 1.0 | 1.92 | 1.39 | 27.61 |

| EN14 | 200 | 50 | 1.5 | 1.87 | 1.42 | 24.07 |

| EN15 | 200 | 50 | 2.0 | 1.86 | 1.44 | 22.59 |

| EN16 | 200 | 60 | 1.0 | 1.95 | 1.57 | 19.49 |

| EN17 | 200 | 60 | 1.5 | 2.00 | 1.60 | 20.00 |

| EN18 | 200 | 60 | 2.0 | 2.11 | 1.62 | 23.23 |

| EN19 | 250 | 40 | 1.0 | 1.72 | 1.37 | 20.35 |

| EN20 | 250 | 40 | 1.5 | 1.56 | 1.38 | 11.54 |

| EN21 | 250 | 40 | 2.0 | 1.46 | 1.38 | 5.48 |

| EN22 | 250 | 50 | 1.0 | 2.15 | 1.44 | 33.03 |

| EN23 | 250 | 50 | 1.5 | 2.03 | 1.45 | 28.58 |

| EN24 | 250 | 50 | 2.0 | 1.95 | 1.45 | 25.65 |

| EN25 | 250 | 60 | 1.0 | 2.24 | 1.53 | 31.70 |

| EN26 | 250 | 60 | 1.5 | 2.24 | 1.55 | 30.81 |

| EN27 | 250 | 60 | 2.0 | 2.29 | 1.55 | 32.32 |

| Experiment No. | WJP | Vf | SOD | MRR | % Improvement of MRR in Cryogenic over Conventional S-AWJ Machining | |

|---|---|---|---|---|---|---|

| Conventional | Cryogenic | |||||

| EN1 | 150 | 40 | 1.0 | 795.12 | 801.09 | 0.75 |

| EN2 | 150 | 40 | 1.5 | 856.80 | 884.16 | 3.10 |

| EN3 | 150 | 40 | 2.0 | 918.35 | 947.82 | 3.11 |

| EN4 | 150 | 50 | 1.0 | 995.72 | 934.95 | −6.50 |

| EN5 | 150 | 50 | 1.5 | 1018.47 | 1025.55 | 0.70 |

| EN6 | 150 | 50 | 2.0 | 1041.05 | 1091.85 | 4.66 |

| EN7 | 150 | 60 | 1.0 | 1346.15 | 1132.43 | −18.88 |

| EN8 | 150 | 60 | 1.5 | 1308.21 | 1225.17 | −6.78 |

| EN9 | 150 | 60 | 2.0 | 1270.07 | 1288.80 | 1.46 |

| EN10 | 200 | 40 | 1.0 | 926.09 | 969.90 | 4.52 |

| EN11 | 200 | 40 | 1.5 | 973.92 | 1035.51 | 5.95 |

| EN12 | 200 | 40 | 2.0 | 1021.61 | 1081.68 | 5.56 |

| EN13 | 200 | 50 | 1.0 | 1141.22 | 1140.57 | −0.06 |

| EN14 | 200 | 50 | 1.5 | 1146.65 | 1209.30 | 5.19 |

| EN15 | 200 | 50 | 2.0 | 1151.90 | 1253.78 | 8.13 |

| EN16 | 200 | 60 | 1.0 | 1498.89 | 1372.55 | −9.21 |

| EN17 | 200 | 60 | 1.5 | 1440.17 | 1439.10 | −0.08 |

| EN18 | 200 | 60 | 2.0 | 1381.24 | 1476.54 | 6.46 |

| EN19 | 250 | 40 | 1.0 | 1018.87 | 1099.11 | 7.31 |

| EN20 | 250 | 40 | 1.5 | 1052.85 | 1147.20 | 8.23 |

| EN21 | 250 | 40 | 2.0 | 1086.68 | 1175.97 | 7.60 |

| EN22 | 250 | 50 | 1.0 | 1238.99 | 1296.57 | 4.45 |

| EN23 | 250 | 50 | 1.5 | 1227.10 | 1343.48 | 8.67 |

| EN24 | 250 | 50 | 2.0 | 1215.03 | 1366.13 | 11.07 |

| EN25 | 250 | 60 | 1.0 | 1594.36 | 1553.27 | −2.65 |

| EN26 | 250 | 60 | 1.5 | 1514.85 | 1593.63 | 4.95 |

| EN27 | 250 | 60 | 2.0 | 1435.14 | 1604.84 | 10.58 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Maurya, P.; Vijay, G.S.; Kamath, R.C. Investigation on Performance and Kerf Characteristics during Cryogenic-Assisted Suspension-Type Abrasive Water Jet Machining of Acrylonitrile Butadiene Rubber. J. Compos. Sci. 2022, 6, 397. https://doi.org/10.3390/jcs6120397

Maurya P, Vijay GS, Kamath RC. Investigation on Performance and Kerf Characteristics during Cryogenic-Assisted Suspension-Type Abrasive Water Jet Machining of Acrylonitrile Butadiene Rubber. Journal of Composites Science. 2022; 6(12):397. https://doi.org/10.3390/jcs6120397

Chicago/Turabian StyleMaurya, Preeti, Gaddale Srinivas Vijay, and Raghavendra Cholpadi Kamath. 2022. "Investigation on Performance and Kerf Characteristics during Cryogenic-Assisted Suspension-Type Abrasive Water Jet Machining of Acrylonitrile Butadiene Rubber" Journal of Composites Science 6, no. 12: 397. https://doi.org/10.3390/jcs6120397

APA StyleMaurya, P., Vijay, G. S., & Kamath, R. C. (2022). Investigation on Performance and Kerf Characteristics during Cryogenic-Assisted Suspension-Type Abrasive Water Jet Machining of Acrylonitrile Butadiene Rubber. Journal of Composites Science, 6(12), 397. https://doi.org/10.3390/jcs6120397