Effect of Different Types of Block Copolymers on Morphology, Mechanical Properties, and Fracture Mechanisms of Bisphenol-F Based Epoxy System

Abstract

:1. Introduction

2. Materials and Methods

2.1. Differential Scanning Calorimetry

2.2. Dynamic-Mechanical Thermal Analysis

2.3. Mechanical Properties

2.4. Fracture Test

2.5. Microscopy Studies

3. Results and Discussion

3.1. Glass Transition Temperature and Viscoelastic Properties

3.2. Tensile Properties

3.3. Fracture-Mechanics Properties

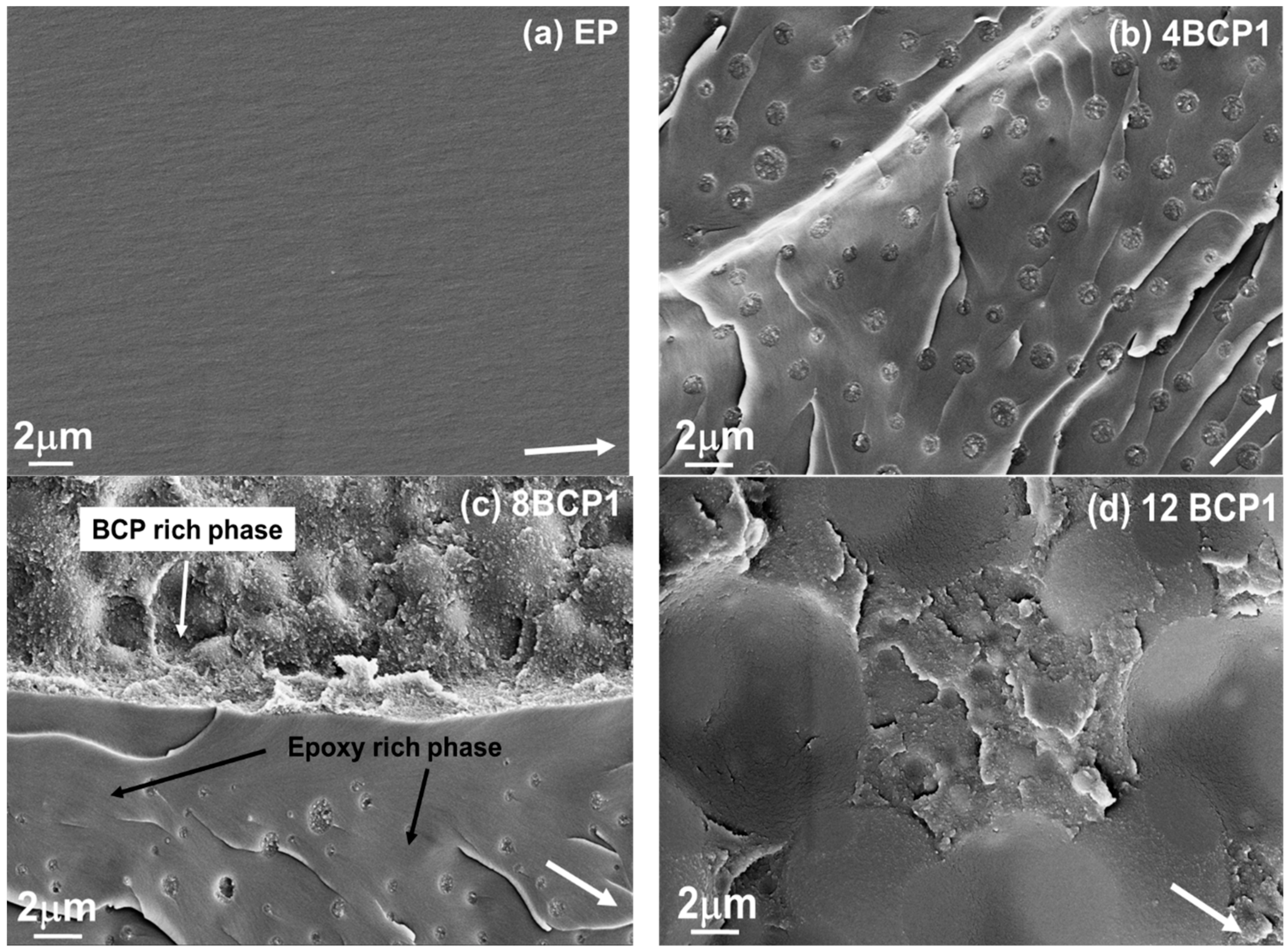

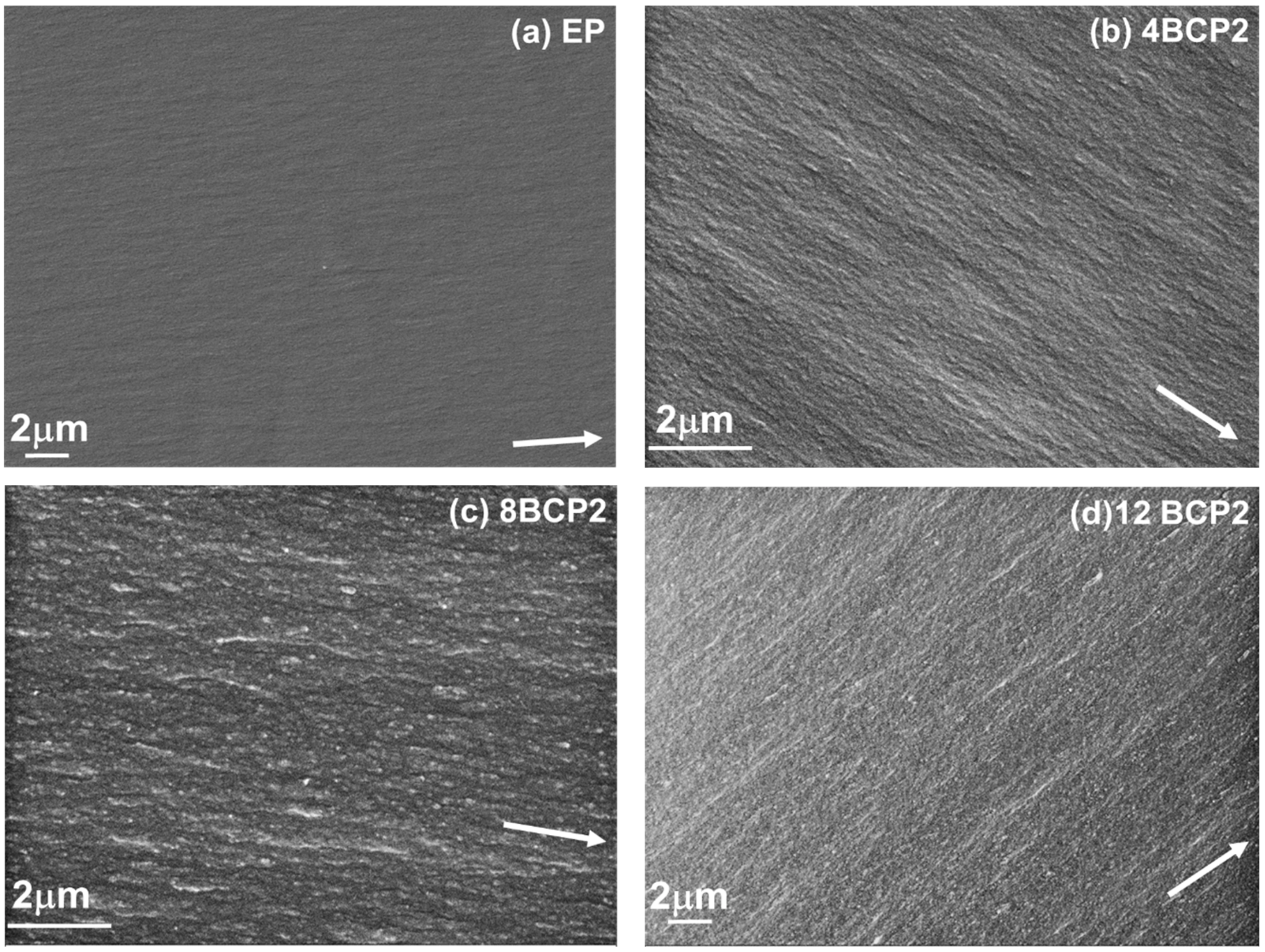

3.4. Fractography Studies

3.4.1. BCP Modified Epoxies

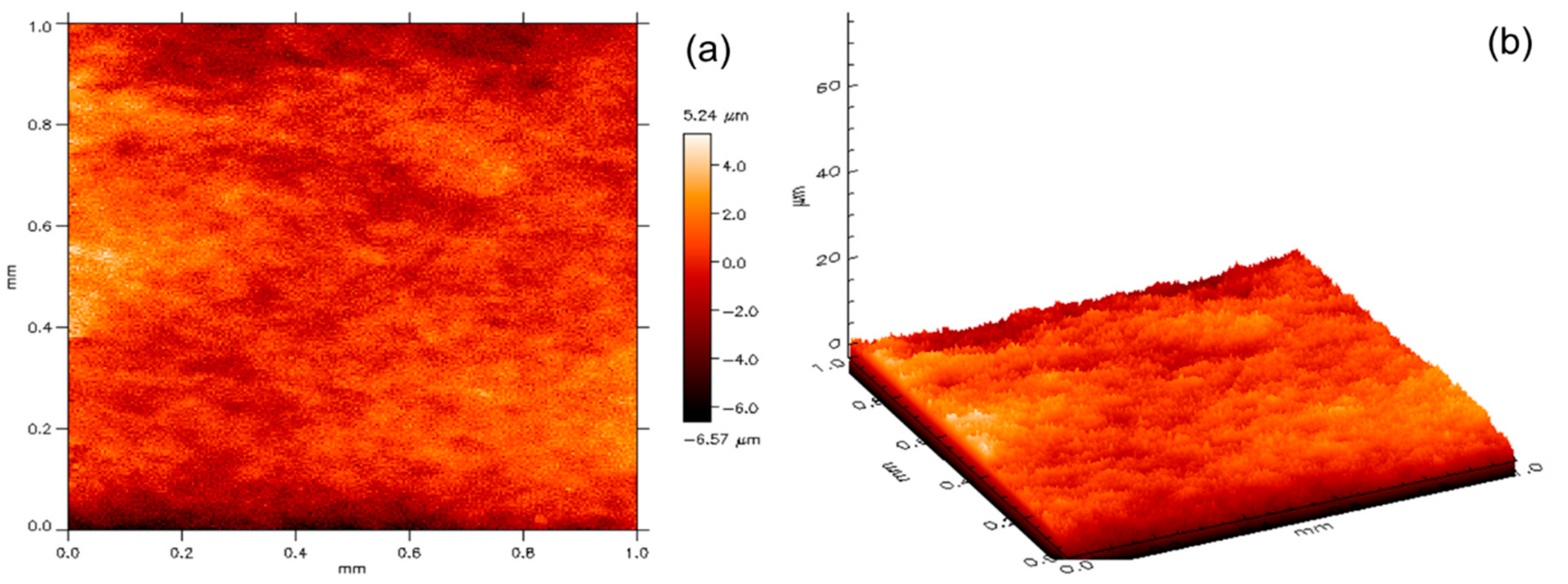

3.4.2. Plastic Zone Size

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Sultan, J.N.; McGarry, F. Effect of rubber particle size on deformation mechanisms in glassy epoxy. Polym. Eng. Sci. 1973, 13, 29–34. [Google Scholar] [CrossRef]

- Ratna, D. Toughened Thermoset Resins. In Handbook of Thermosets; Smithers—A Smithers Group Company: Shawbury, UK, 2009; pp. 187–188. [Google Scholar]

- Kishore, K.S. Analysis of deformation behaviour and fracture features in glass-epoxy composites toughened by rubber and carbon additions. J. Mater. Sci. Lett. 1992, 11, 86–88. [Google Scholar]

- Riew, C. Rubber, Chemistry and Technology; Rubber Division, American Chemical Society: Akron, OH, USA, 1985; p. 622. [Google Scholar]

- Liu, J.; Thompson, Z.J.; Sue, H.J.; Bates, F.S.; Hillmayer, M.A.; Dettlof, M.; Jacob, G.; Verghese, N.; Pham, H. Toughening of Epoxies with Block Copolymer Micelles of Wormlike Morphology. Macromolecules 2010, 43, 7238–7243. [Google Scholar] [CrossRef]

- Barsotti, R.; Fine, T.; Inoubli, R.; Gerard, P.; Schmidt, S.; Macy, N.; Magnet, S.; Navarro, C. Nanostrength Block Copolymers for Epoxy Toughening; Thermoset Resin Formulators Association: Chicago, IL, USA, 2008. [Google Scholar]

- Kishi, H.; Kunimitsu, Y.; Nakashima, Y.; Imade, J.; Oshita, S.; Morishita, Y.; Asada, M. Relationship between the mechanical properties of epoxy/PMMA-b-PNBA-b-PMMA block copolymer blends and their three-dimensional nanostructures. Express Polym. Lett. 2017, 11, 765–777. [Google Scholar] [CrossRef]

- Kishi, H.; Kunimitsu, Y.; Nakashima, Y.; Abe, T.; Imade, J.; Oshita, S. Control of nanostructures generated in epoxy matrices blended with PMMA-b-PnBA-b-PMMA triblock copolymer. Express Polym. Lett. 2015, 9, 23–25. [Google Scholar] [CrossRef]

- Klingler, A.; Wetzel, B. Fatigue crack propagation in triblock copolymer toughened epoxy nanocomposites. Polym. Eng. Sci. 2017, 57, 579–587. [Google Scholar] [CrossRef]

- Klingler, A.; Bajpai, A.; Wetzel, B. The effect of block copolymer and core-shell rubber hybrid toughening on morphology and fracture of epoxy-based fibre reinforced composites. Eng. Fract. Mech. 2018, 203, 81–101. [Google Scholar] [CrossRef]

- Bajpai, A.; Alapati, A.; Klingler, A.; Wetzel, B. Tensile properties, fracture mechanics properties and toughening mechanisms of epoxy systems modified with soft block copolymers, rigid TiO2 nanoparticles and their hybrids. J. Compos. Sci. 2018, 2, 72. [Google Scholar] [CrossRef]

- Bajpai, A.; Alapati, A.K.; Wetzel, B. Toughening and Mechanical Properties of Epoxy Modified with Block Co-polymers and MWCNTs. Procedia Struct. Integr. 2016, 2, 104–111. [Google Scholar] [CrossRef] [Green Version]

- Pearson, R.; Bacigalupo, L.; Liang, Y.; Marouf, B.; Oldak, R. Plastic zone size—Fracture toughness correlations in rubber-modified epoxies. In Proceedings of the 31st Annual Meeting of the Adhesion Society, Austin, TX, USA, 17 February 2008. [Google Scholar]

- Thio, Y.; Wu, J.; Bates, F. The role of inclusion size in toughening of epoxy resins by spherical micelles. J. Polym. Sci. Part B Polym. Phys. 2009, 47, 1125–1129. [Google Scholar] [CrossRef]

- Hexion Inc. Product Specifications for the EPON862 and Technical Data Sheet; Hexion Inc.: Columbus, OH, USA, 2005. [Google Scholar]

- Moore, D. Application of Fracture Mechanics to Polymers, Adhesives and Composites; Elsevier Science: Amsterdam, The Netherlands, 2003. [Google Scholar]

- Plastics—Determination of Fracture Toughness (GIc and KIc)—Linear Elastic Fracture Mechanics (LEFM) Approach; ISO 13586:2000(E); ISO (the International Organization for Standardization): Geneva, Switzerland, 2000.

- Kinloch, A.J. Stresses in Adhesive Joints. In Adhesion and Adhesives: Science and Technology; Springer: Berlin, Germany, 1987; p. 209. [Google Scholar]

- Fan, W.; Wang, L.; Zheng, S. Nanostructures in thermosetting blends of epoxy resin with polydimethylsiloxane-block-poly(ε-caprolactone)-block-polystyrene ABC triblock copolymer. Macromolecules 2009, 42, 327–336. [Google Scholar] [CrossRef]

- Redline, E.M.; Declet-Perez, C.; Bates, F.S.; Francis, L.F. Effect of block copolymer concentration and core composition on toughening epoxies. Polymer 2014, 55, 4172–4181. [Google Scholar] [CrossRef]

- Chen, J.; Taylor, A.C. Epoxy modified with triblock copolymers: Morphology, mechanical properties and fracture mechanisms. Mater. Sci. 2012, 47, 4546–4560. [Google Scholar] [CrossRef]

- Chong, H.M.; Taylor, A.C. The microstructure and fracture performance of styrene–butadiene–methylmethacrylate block copolymer-modified epoxy polymers. Mater. Sci. 2013, 48, 6762–6777. [Google Scholar] [CrossRef]

- Ritzenthaler, S.; Girard-Reydet, E.; Pascault, J.P. Influence of epoxy hardener on miscibility of blends of poly(methyl methacrylate) and epoxy networks. Polymer 2000, 41, 6375–6386. [Google Scholar] [CrossRef]

- Ritzenthaler, S.; Court, F.; David, L.; Girard-Reydet, E.; Leibler, L.; Pascault, J.P. ABC Triblock Copolymers/Epoxy—Diamine Blends. 1. Keys To Achieve Nanostructured Thermosets. Macromolecules 2002, 35, 6245–6254. [Google Scholar] [CrossRef]

- Arkema. Technical Data Sheet—Nanostrength® Epoxy Application; Arkema: Paris, France, 2013. [Google Scholar]

- Hull, D. Fractography: Observing, Measuring and Interpreting Fracture Structure Topography; Cambridge University Press: Cambridge, UK, 1999. [Google Scholar]

- Fraaije, J.; Sevink, G. Model for pattern formation in polymer surfactant nanodroplets. Macromolecules 2003, 36, 7891–7893. [Google Scholar] [CrossRef]

- Dean, J.; Grubbs, R.B.; Saad, W.; Cook, R.; Bates, F. Mechanical properties of block copolymer vesicle and micelle modified epoxies. J. Polym. Sci. Part B Polym. Phys. 2003, 41, 2444–2456. [Google Scholar] [CrossRef]

- Bagheri, R.; Pearson, R.A. Role of plastic cavitation in rubber toughened epoxies. Polymer 1996, 37, 5597–5600. [Google Scholar] [CrossRef]

- Wu, J.; Thio, Y.S.; Bates, F.S. Structure and properties of PBO-PEO diblock copolymer modified epoxy. J. Polym. Sci. Part B Polym. Phys. 2005, 43, 1950–1965. [Google Scholar] [CrossRef]

- Kinloch, A.J.; Young, R.J. Fracture Behaviour of Polymers; Elsevier Applied Science: New York, NY, USA, 1983. [Google Scholar]

| Series | BCP (wt %) | BCP (vol.%) |

|---|---|---|

| EP_H | 0 | 0 |

| EP_2 BCP1 | 2 | 2.14 |

| EP_4 BCP1 | 4 | 4.26 |

| EP_6 BCP1 | 6 | 6.39 |

| EP_8 BCP1 | 8 | 8.50 |

| EP_10 BCP1 | 10 | 10.62 |

| EP_12 BCP1 | 12 | 12.72 |

| EP_2 BCP2 | 2 | 2 |

| EP_4 BCP2 | 4 | 4 |

| EP_6 BCP2 | 6 | 6 |

| EP_8 BCP2 | 8 | 8 |

| EP_10 BCP2 | 10 | 10 |

| EP_12 BCP2 | 12 | 12 |

| BCP1 (wt %) | Tg (°C) DSC | Tg (°C) tan δ | BCP2 (wt %) | Tg (°C) DSC | Tg (°C) tan δ |

|---|---|---|---|---|---|

| 0 | 141 | 140 | 0 | 141 | 140 |

| 2 | 142 | 137 | 2 | 140 | 137 |

| 4 | 140 | 136 | 4 | 137 | 136 |

| 6 | 142 | 137 | 6 | 138 | 136 |

| 8 | 142 | 136 | 8 | 138 | 136 |

| 10 | 142 | 135 | 10 | 137 | 135 |

| 12 | 143 | 140 | 12 | 138 | 137 |

| System | Et (MPa) | σm (MPa) | εm (%) | KIc (MPa·m1/2) | GIc (kJ/m2) |

|---|---|---|---|---|---|

| EP | 3410 (±68) | 92 (±0.7) | 5.7 (±0.01) | 0.59 (±0.09) | 0.10 (±0.05) |

| EP_2BCP1 | 3280 (±24) | 88 (±0.5) | 5.6 (±0.03) | 1.5 (±0.20) | 0.60 (±0.20) |

| EP_4BCP1 | 3140 (±11) | 83(±1.9) | 4.9 (±0.66) | 1.91 (±0.10) | 1.01 (±0.11) |

| EP_6BCP1 | 2930 (±10) | 80 (±0.9) | 5.3 (±0.44) | 2.20 (±0.02) | 1.44 (±0.04) |

| EP_8BCP1 | 2830 (±6) | 40 (±0.7) | 1.8 (±0.07) | 2.32 (±0.10) | 1.66 (±0.14) |

| EP_10BCP1 | 2800 (±22) | 34 (±0.2) | 1.3 (±0.01) | 2.75 (±0.12) | 2.37 (±0.20) |

| EP_12BCP1 | 2700 (±10) | 31 (±1.9) | 1.3 (±0.12) | 1.45 (±0.08) | 0.69 (±0.06) |

| EP_2BCP2 | 3400 (±31) | 90 (±0.3) | 5.2 (±0.2) | 0.70 (±0.09) | 0.13 (±0.07) |

| EP_4BCP2 | 3150 (±32) | 84 (±0.3) | 5.1 (±0.2) | 0.95 (±0.05) | 0.25 (±0.06) |

| EP_6BCP2 | 2960 (±29) | 79 (±0.5) | 5.1 (±0.3) | 1.12 (±0.12) | 0.37 (±0.11) |

| EP_8BCP2 | 2840 (±20) | 75 (±0.5) | 5.0 (±0.5) | 1.25 (±0.11) | 0.48 (±0.13) |

| EP_10BCP2 | 2570 (±11) | 70 (±0.4) | 5.4 (±0.6) | 1.37 (±0.14) | 0.64 (±0.12) |

| EP_12BCP2 | 2300 (±10) | 61 (±0.4) | 5.5 (±0.6) | 1.65 (±0.13) | 1.04 (±0.13) |

| System | Surface Roughness (µm) | Plastic Zone Predicted (µm) |

|---|---|---|

| EP | 0.157 | 2.18 |

| EP_2 BCP1 | 0.283 | 15.4 |

| EP_4 BCP1 | 0.351 | 28.1 |

| EP_6 BCP1 | 0.478 | 40.1 |

| EP_8 BCP1 | 0.544 | 178.6 |

| EP_10 BCP1 | 1.557 | 347.2 |

| EP_12 BCP1 | 5.176 | 116.1 |

| EP_2 BCP2 | 0.167 | 2.2 |

| EP_4 BCP2 | 0.183 | 3.1 |

| EP_6 BCP2 | 0.196 | 6.8 |

| EP_8 BCP2 | 0.205 | 10.7 |

| EP_10 BCP2 | 0.216 | 20.3 |

| EP_12 BCP2 | 0.230 | 38.8 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bajpai, A.; Wetzel, B. Effect of Different Types of Block Copolymers on Morphology, Mechanical Properties, and Fracture Mechanisms of Bisphenol-F Based Epoxy System. J. Compos. Sci. 2019, 3, 68. https://doi.org/10.3390/jcs3030068

Bajpai A, Wetzel B. Effect of Different Types of Block Copolymers on Morphology, Mechanical Properties, and Fracture Mechanisms of Bisphenol-F Based Epoxy System. Journal of Composites Science. 2019; 3(3):68. https://doi.org/10.3390/jcs3030068

Chicago/Turabian StyleBajpai, Ankur, and Bernd Wetzel. 2019. "Effect of Different Types of Block Copolymers on Morphology, Mechanical Properties, and Fracture Mechanisms of Bisphenol-F Based Epoxy System" Journal of Composites Science 3, no. 3: 68. https://doi.org/10.3390/jcs3030068

APA StyleBajpai, A., & Wetzel, B. (2019). Effect of Different Types of Block Copolymers on Morphology, Mechanical Properties, and Fracture Mechanisms of Bisphenol-F Based Epoxy System. Journal of Composites Science, 3(3), 68. https://doi.org/10.3390/jcs3030068