A Comprehensive Review of Sustainable and Green Additive Manufacturing: Technologies, Practices, and Future Directions

Abstract

1. Introduction

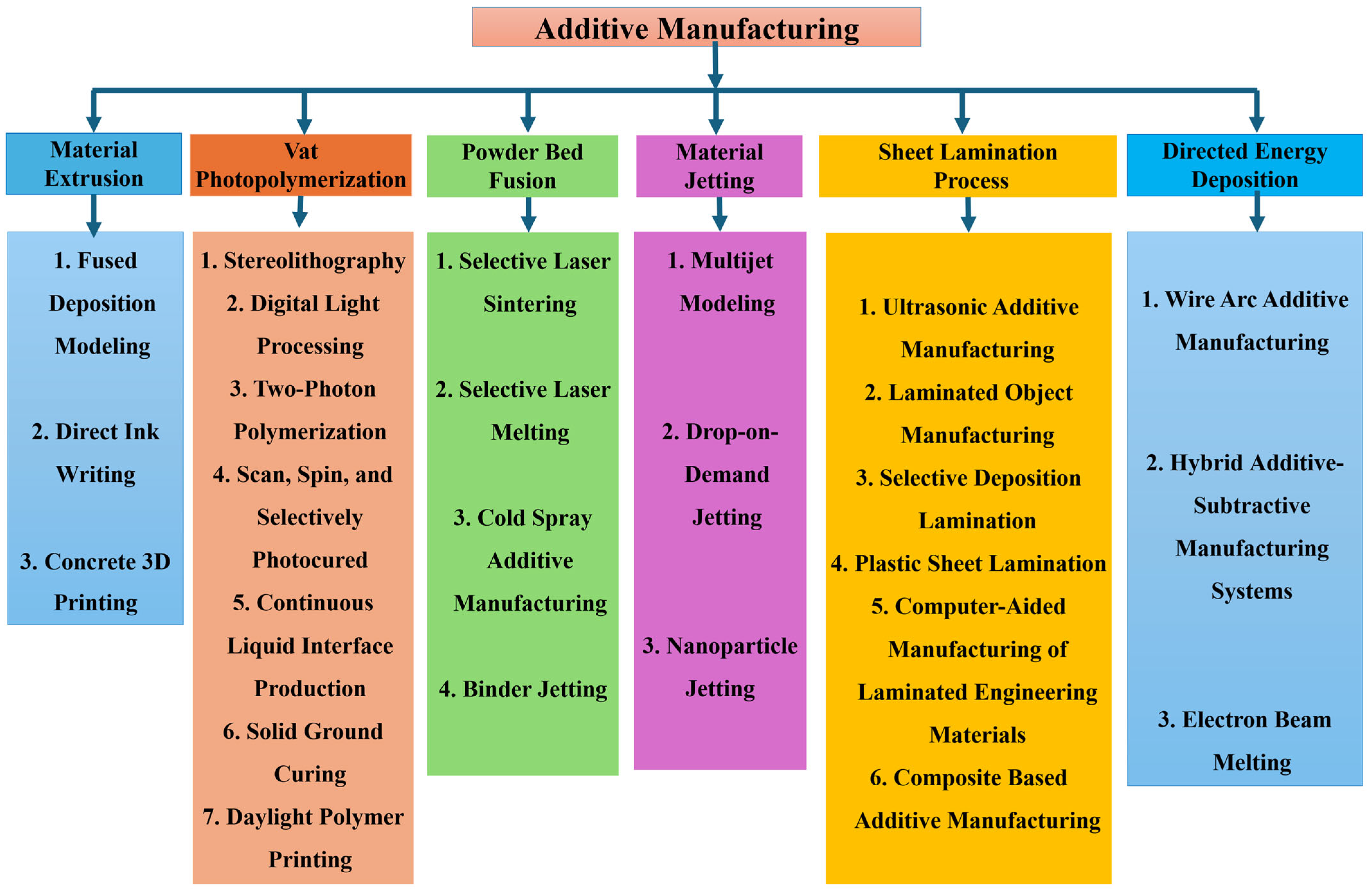

2. Sustainable Green Additive Manufacturing Technologies

2.1. Materials Extrusion

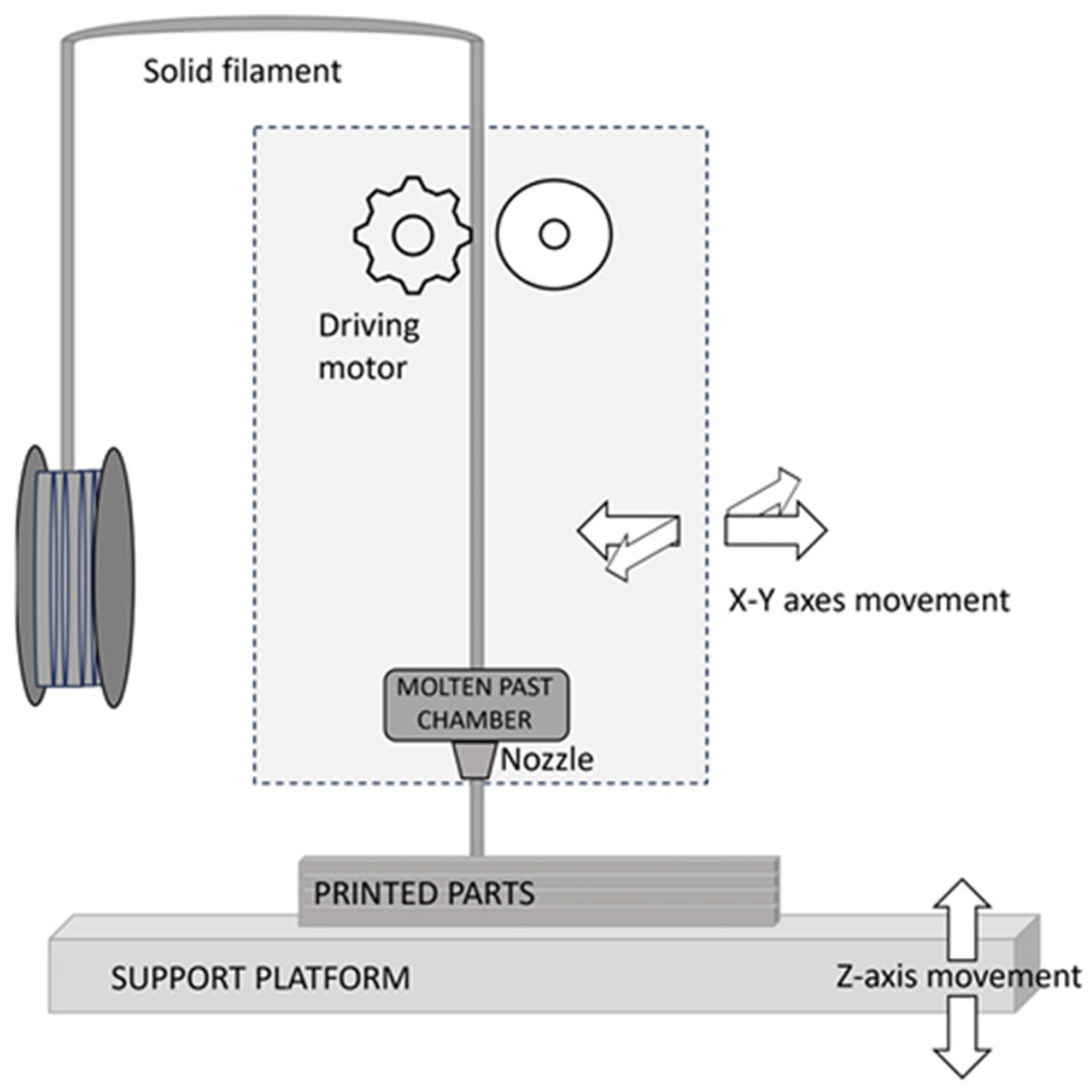

2.1.1. Fused Deposition Modeling (FDM)

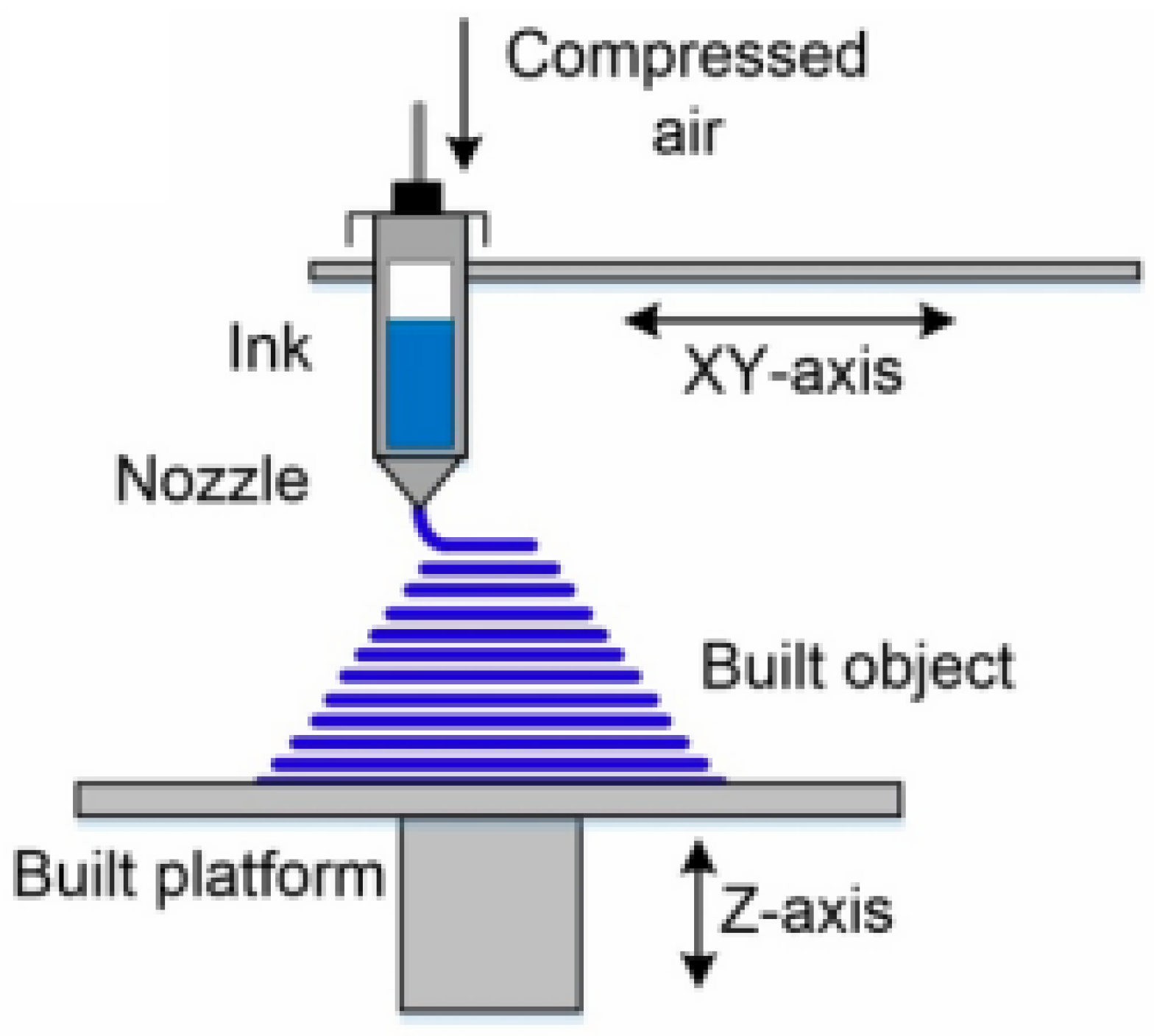

2.1.2. Direct Ink Writing (DIW)

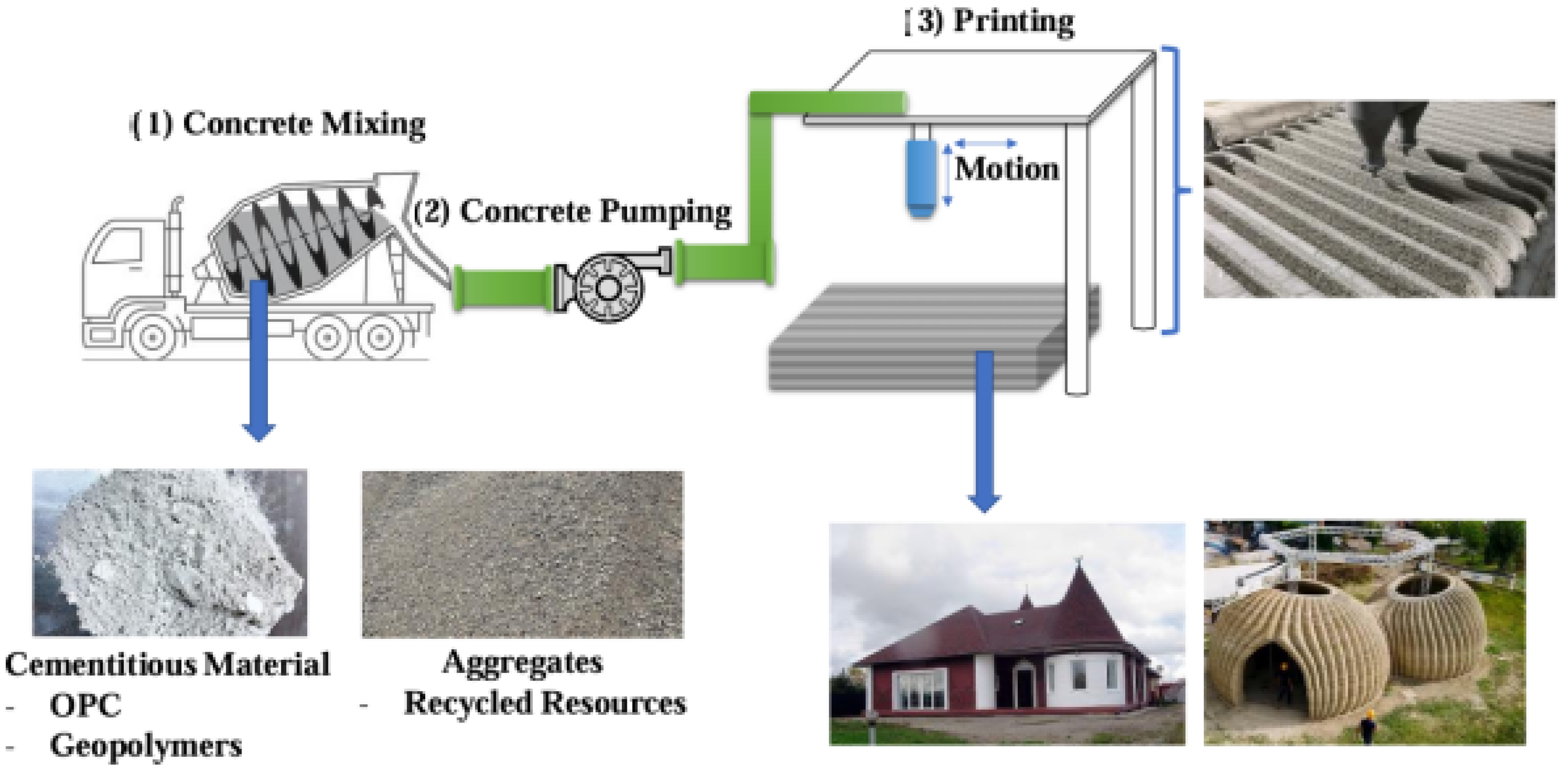

2.1.3. Concrete 3D Printing

2.2. Vat Polymerization

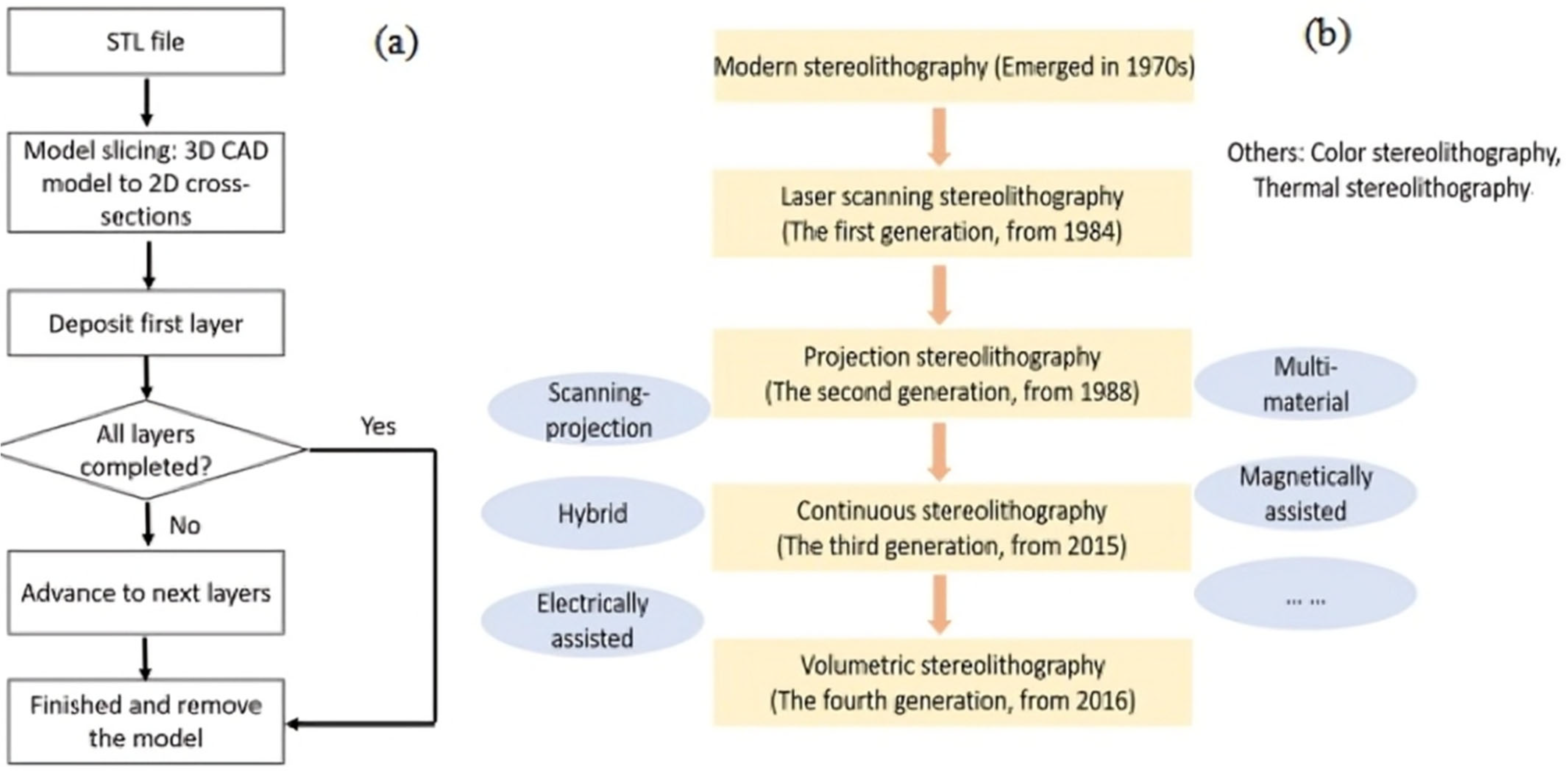

2.2.1. Stereolithography (SLA)

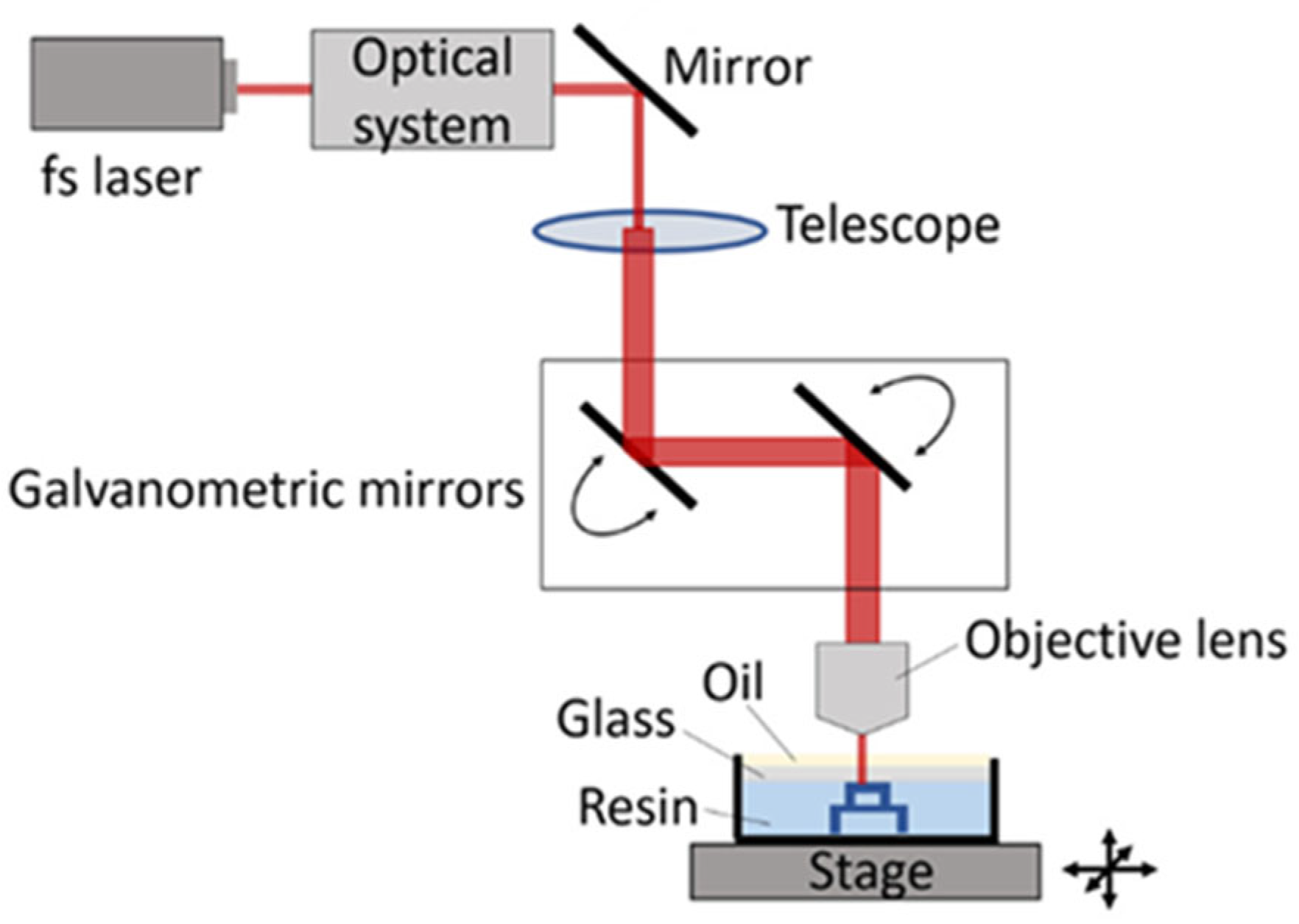

2.2.2. Two-Photon Polymerization

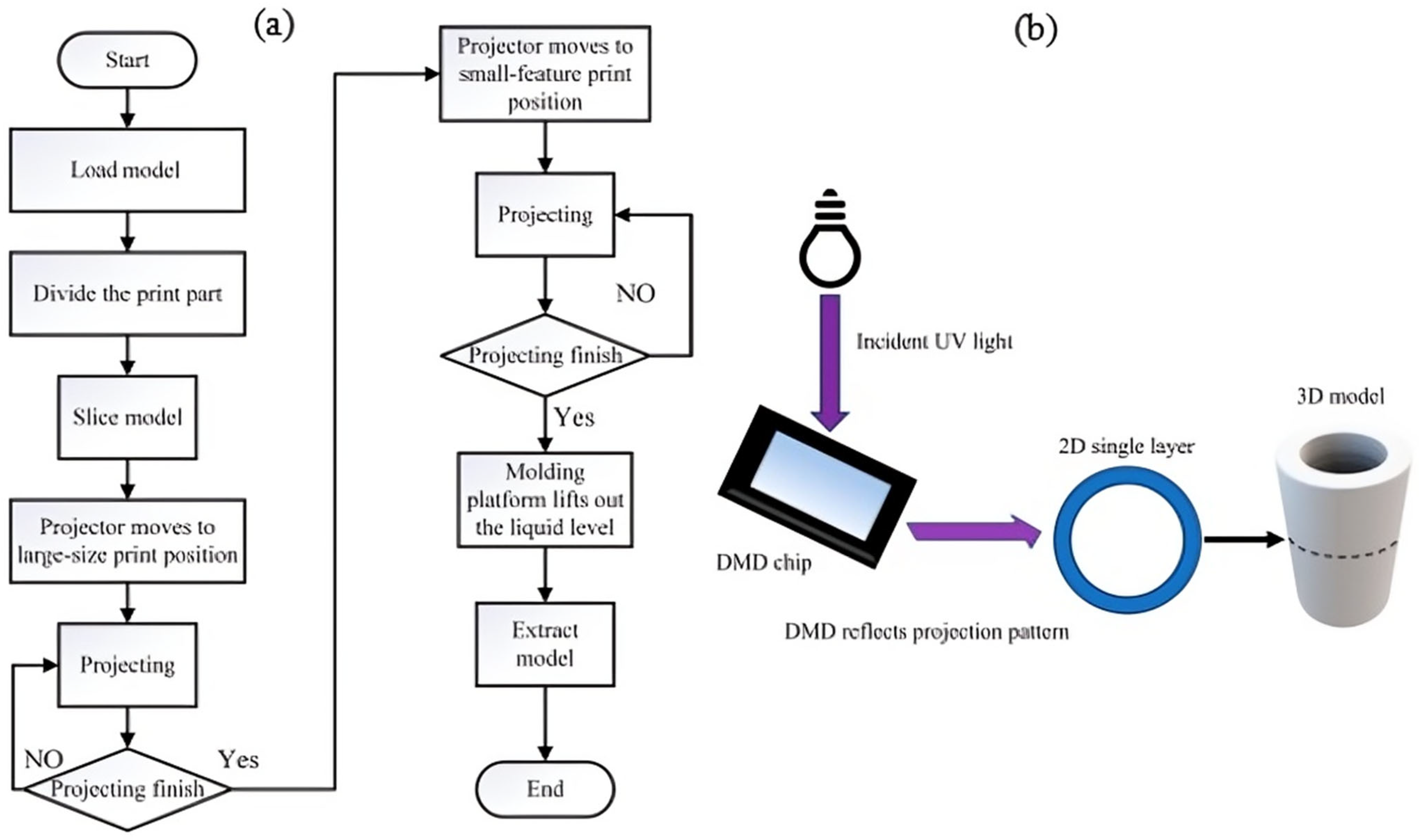

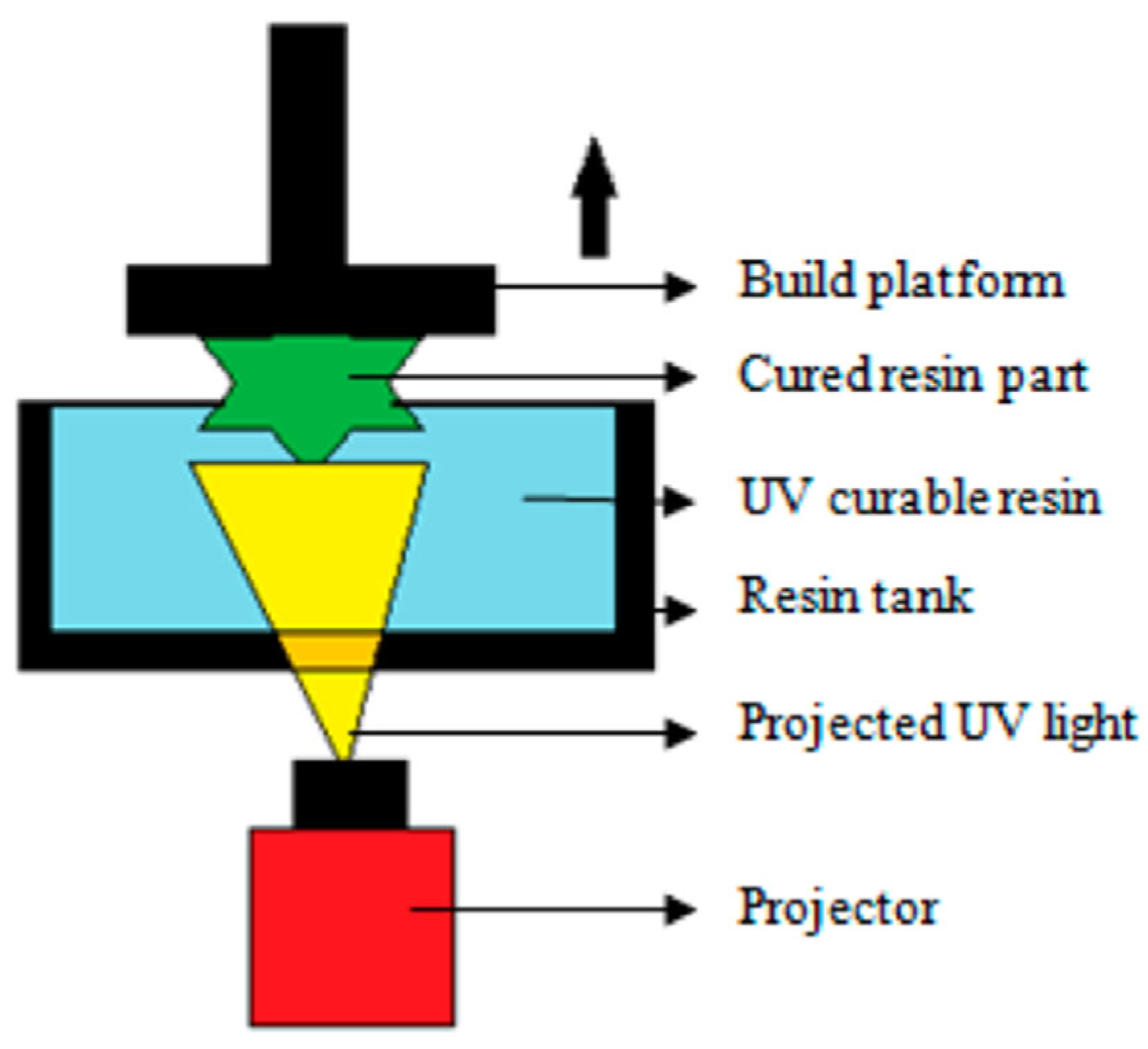

2.2.3. Direct Light Processing (DLP)

2.2.4. Scan, Spin, and Selectively Photocured (3SP)

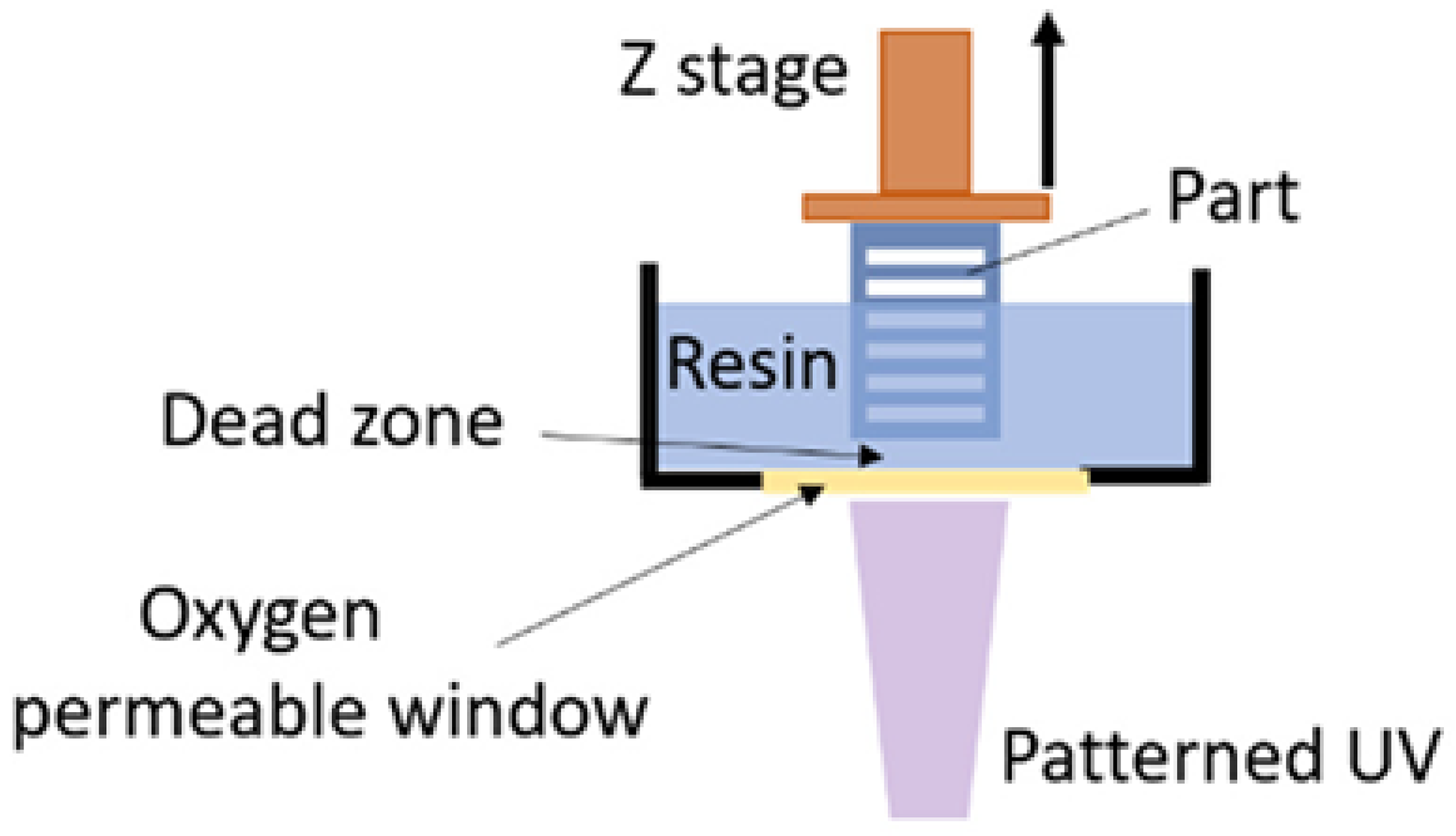

2.2.5. Continuous Liquid Interface Production (CLIP)

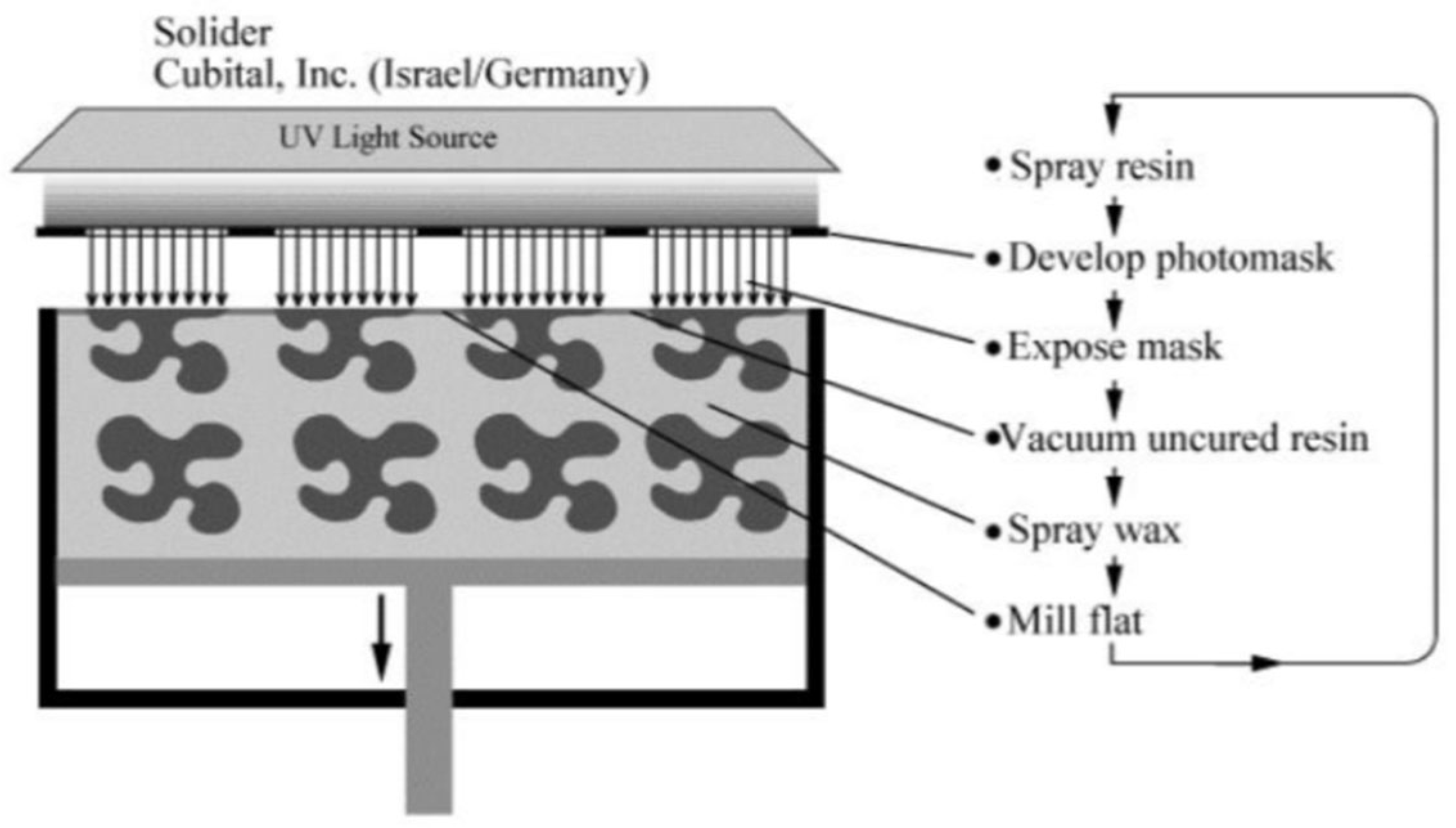

2.2.6. Solid Ground Curing (SGC)

2.2.7. Daylight Polymer Printing (DPP)

2.3. Powder Bed Fusion (PBF)

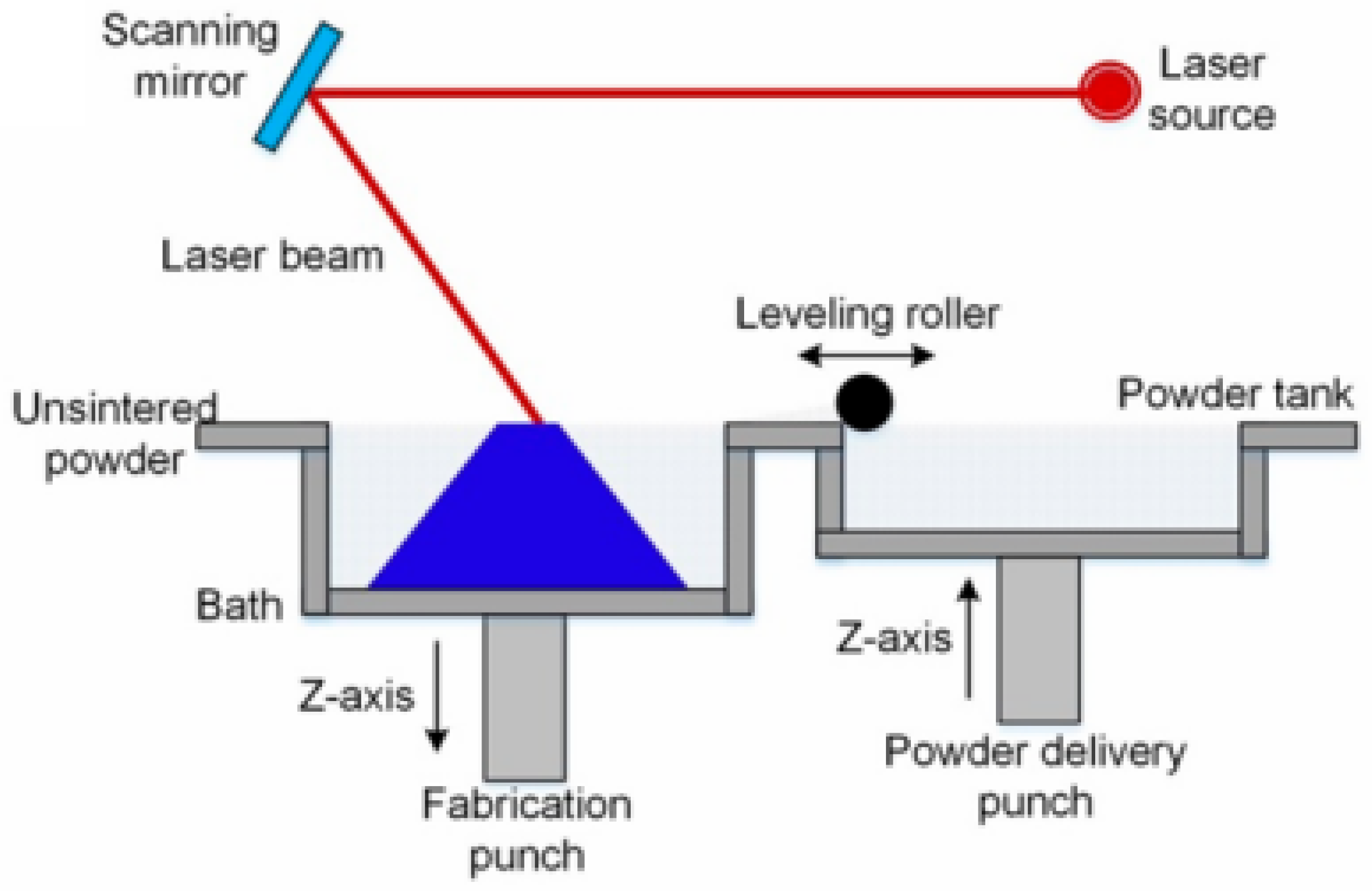

2.3.1. Selective Laser Sintering (SLS)

2.3.2. Selective Laser Melting (SLM)

2.3.3. Cold Spray Additive Manufacturing (CSAM)

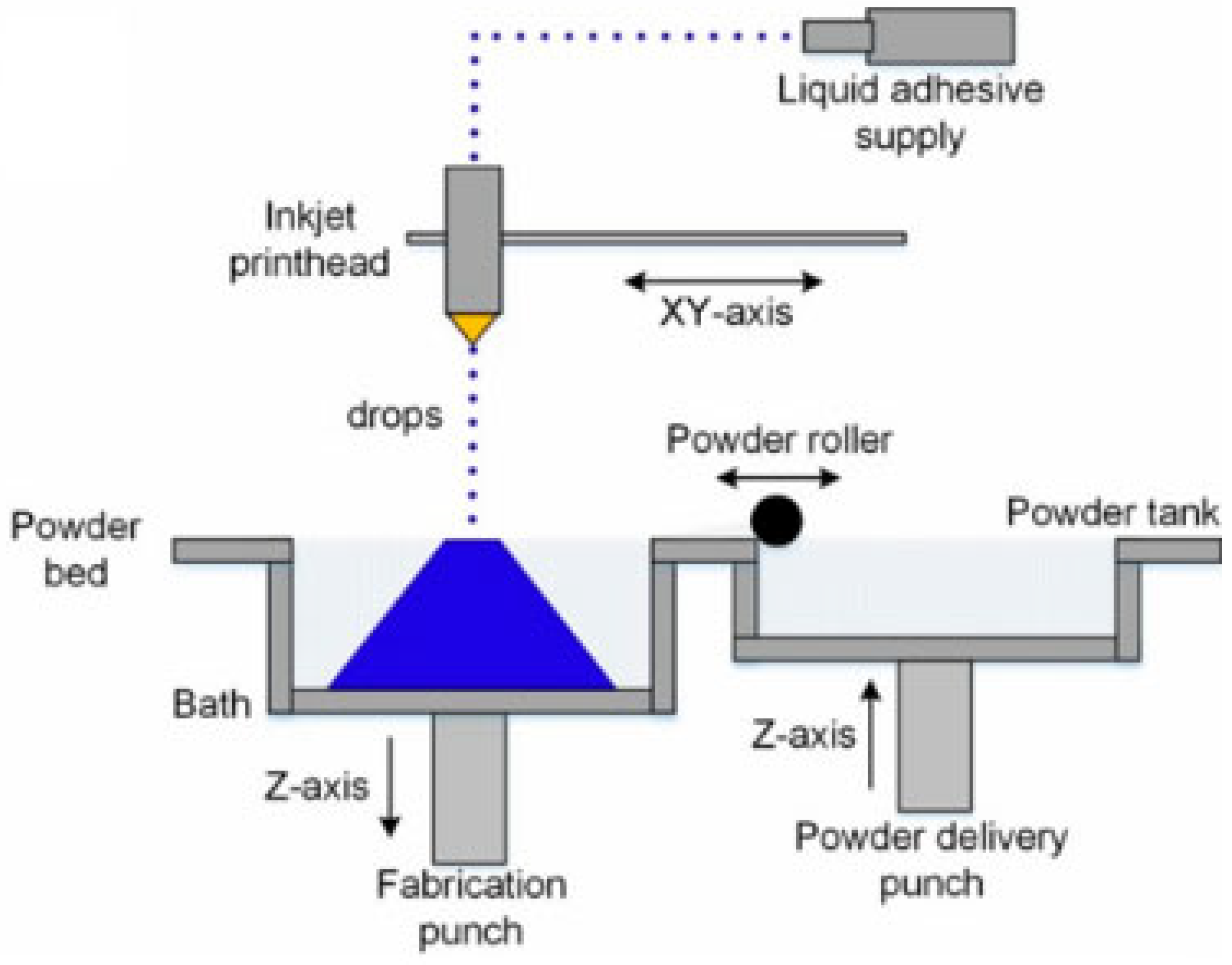

2.3.4. Binder Jetting

2.4. Material Jetting

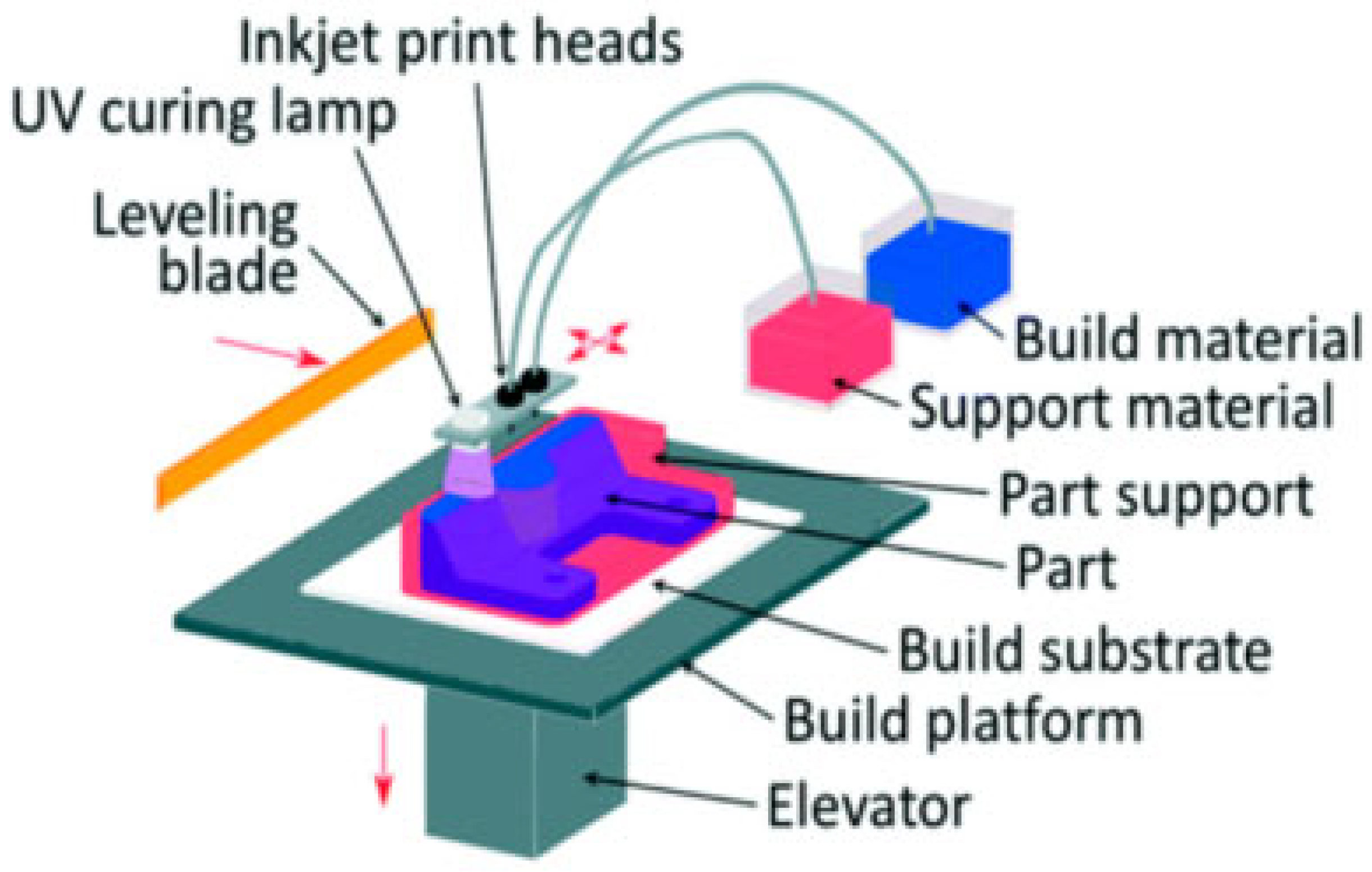

2.4.1. Multijet Modeling (MJM)

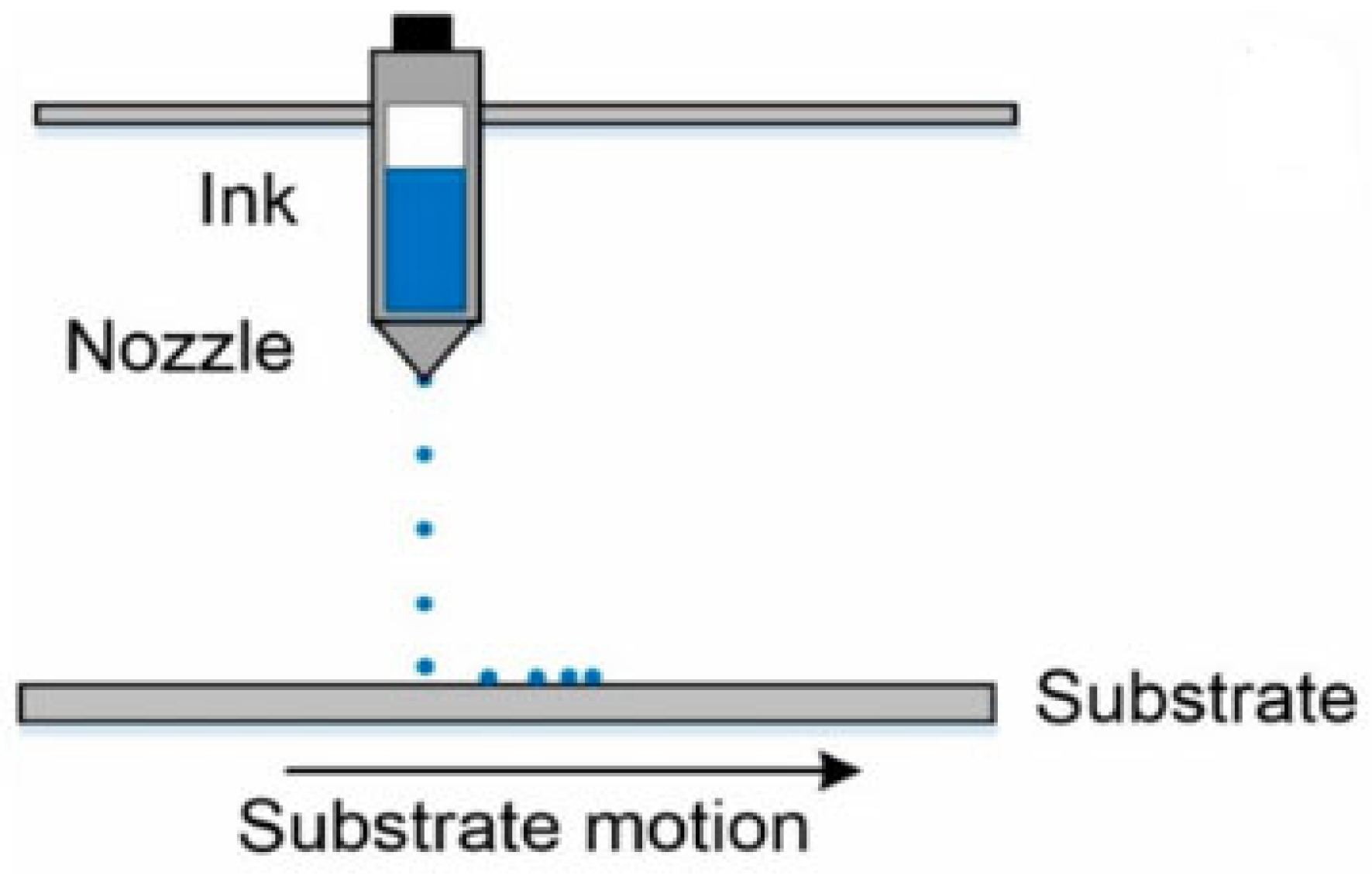

2.4.2. Drop-on-Demand (DOD) Jetting

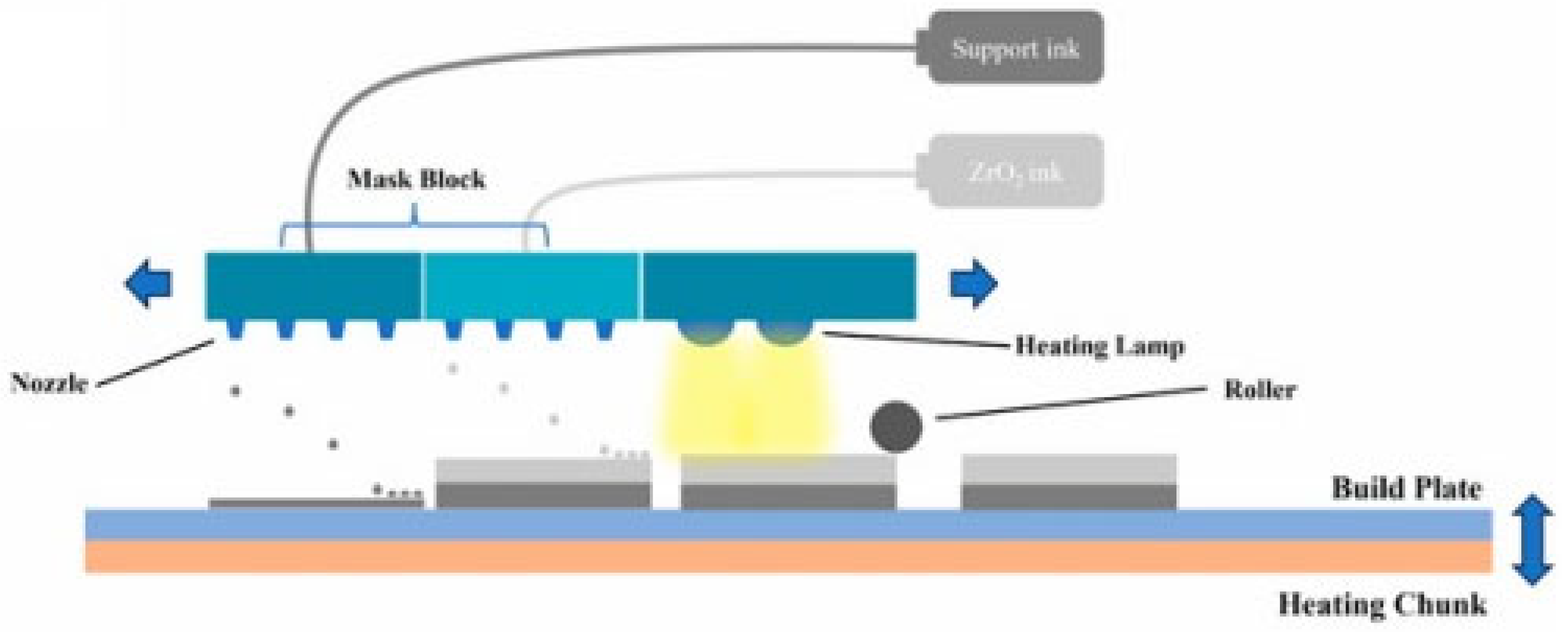

2.4.3. Nanoparticle Jetting

2.5. Sheet Lamination Process

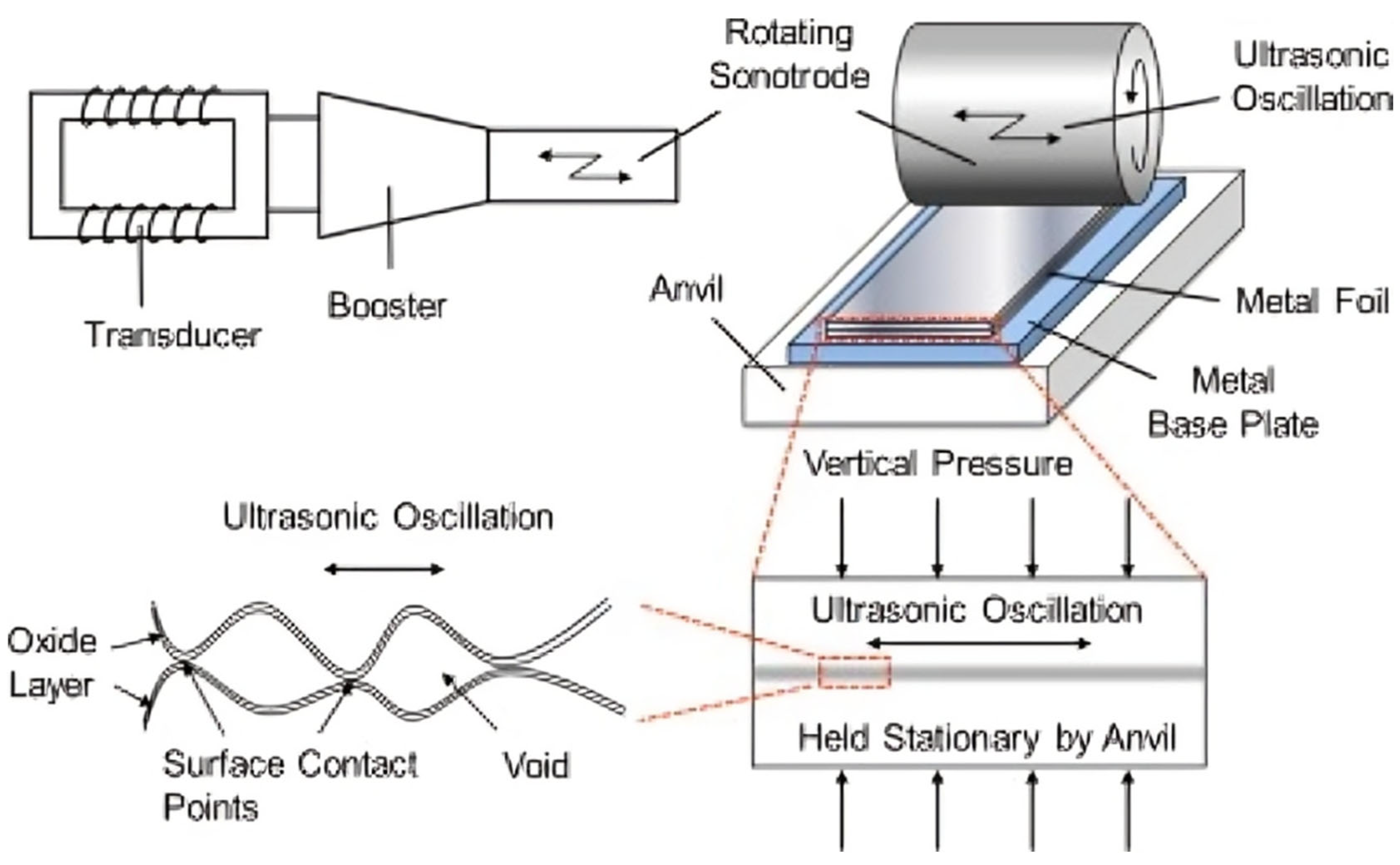

2.5.1. Ultrasonic Additive Manufacturing (UAM)

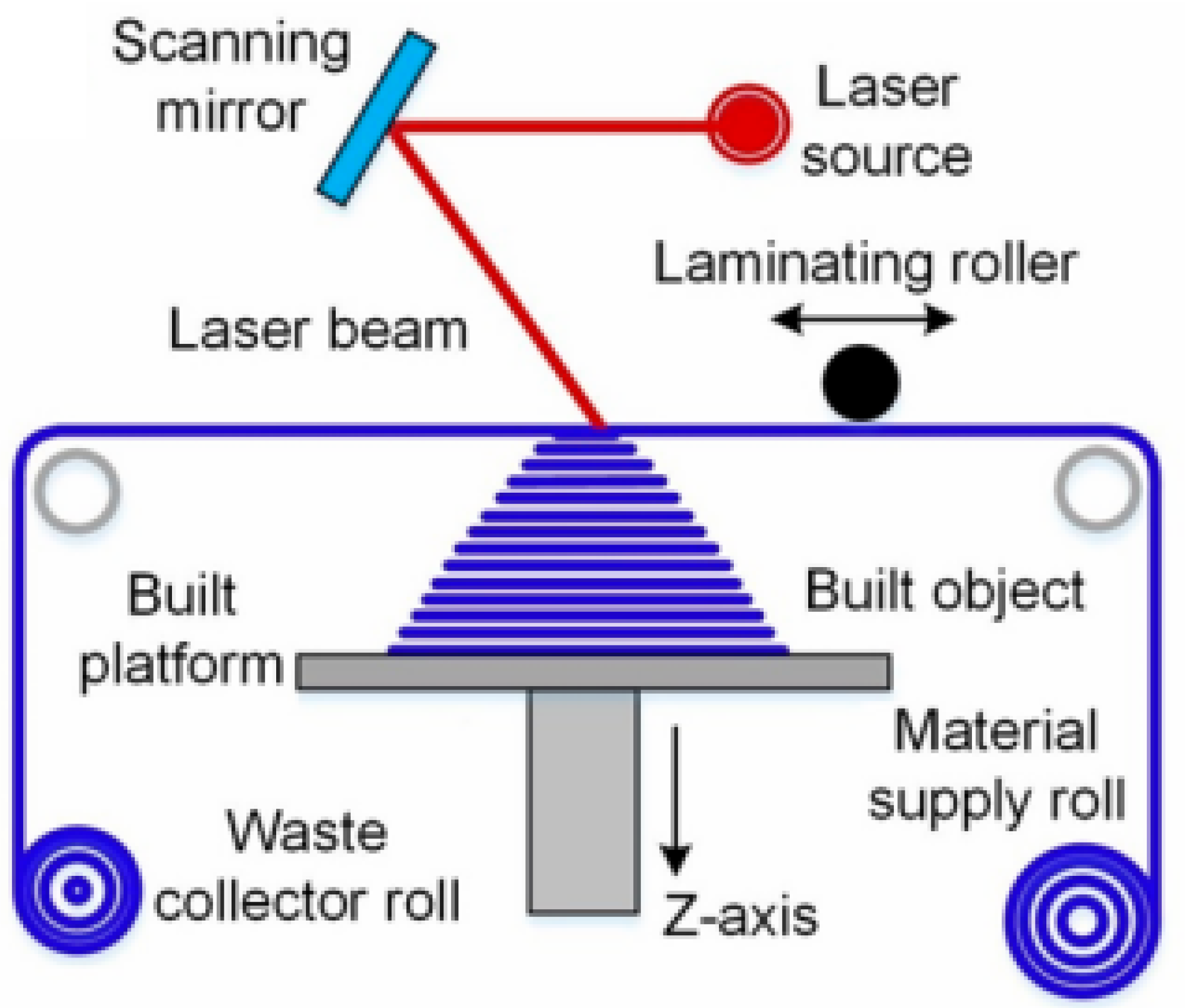

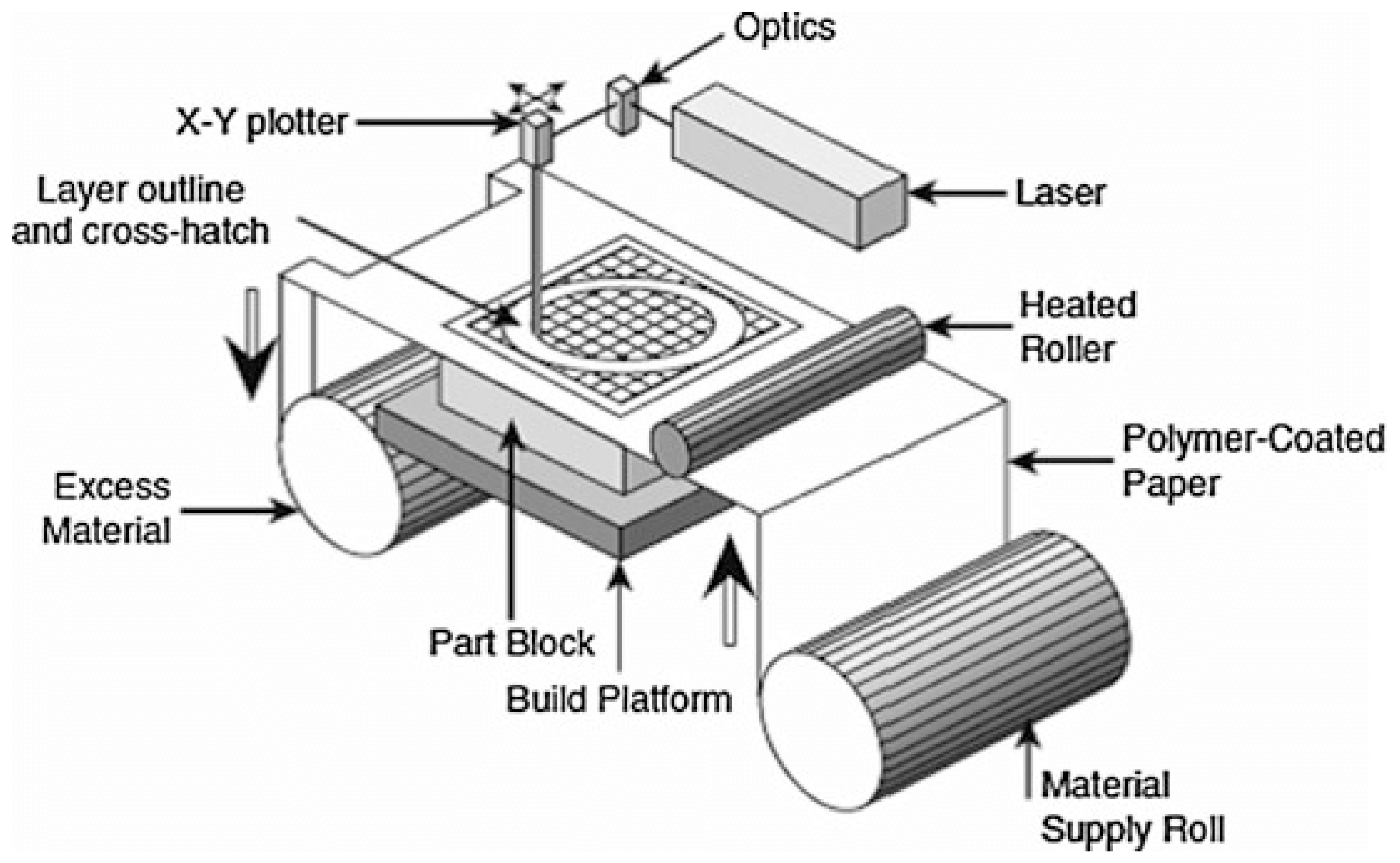

2.5.2. Laminated Object Manufacturing (LOM)

2.5.3. Selective Deposition Lamination (SDL)

2.5.4. Plastic Sheet Lamination (PSL)

2.5.5. Computer-Aided Manufacturing of Laminated Engineering Materials (CAM-LEM)

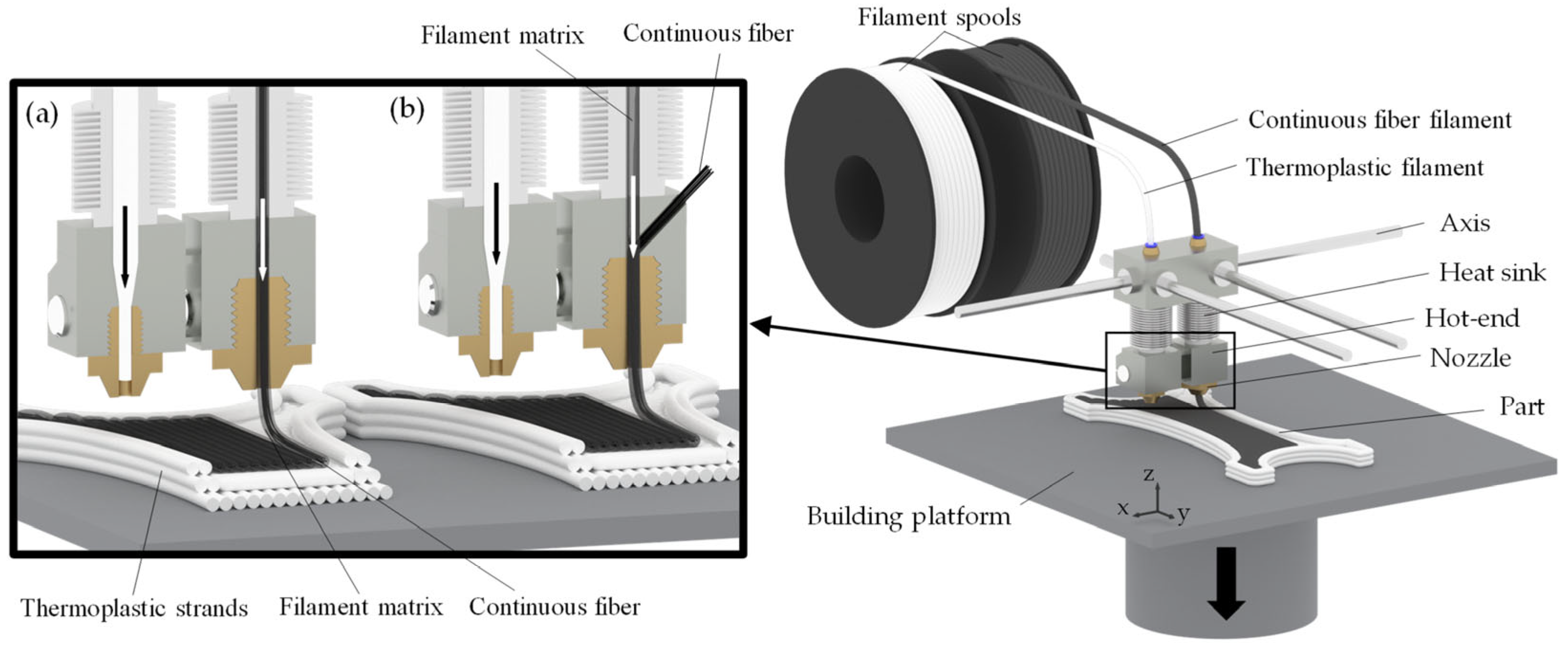

2.5.6. Composite-Based Additive Manufacturing (CBAM)

2.6. Directed Energy Deposition (DED)

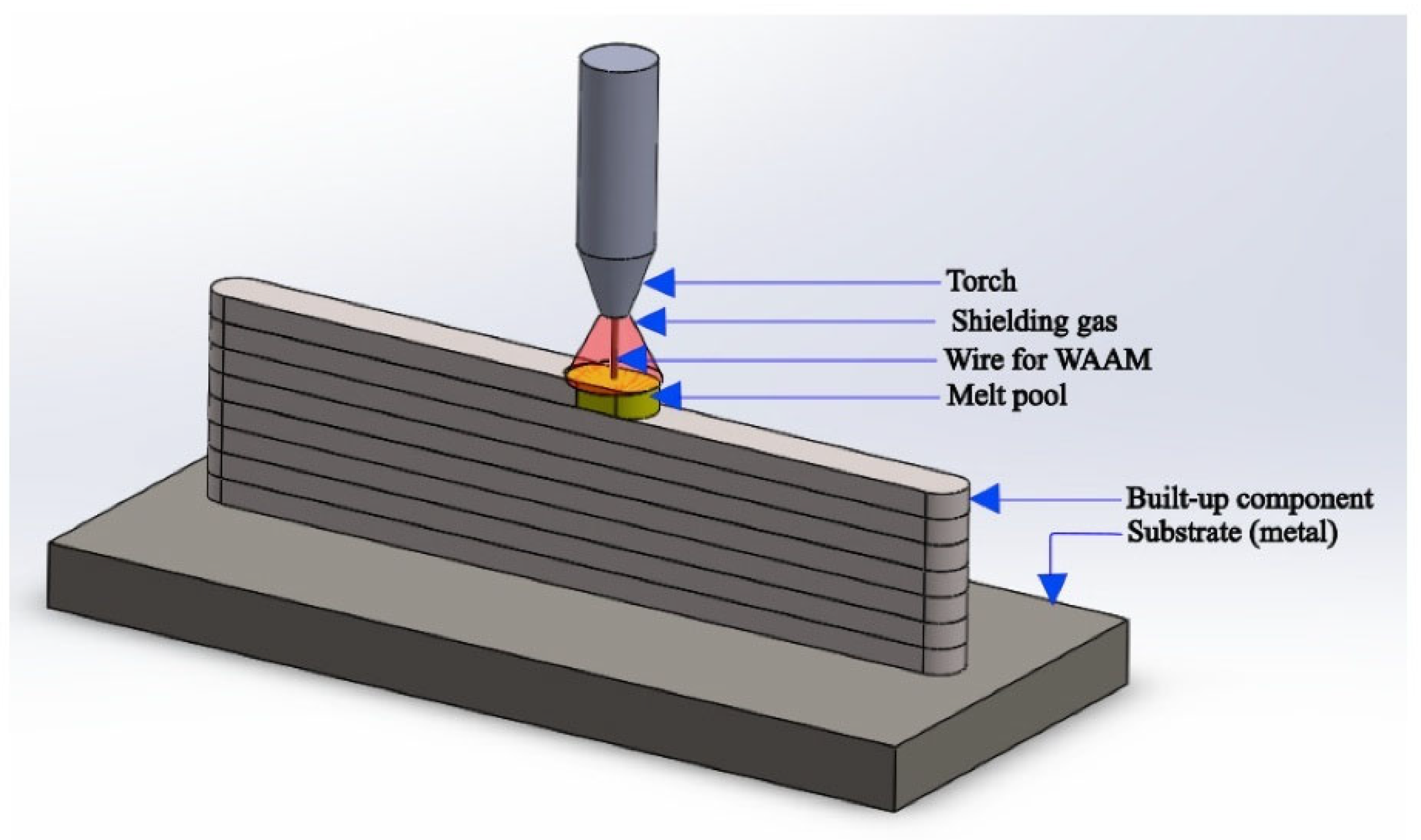

2.6.1. Wire Arc Additive Manufacturing (WAAM)

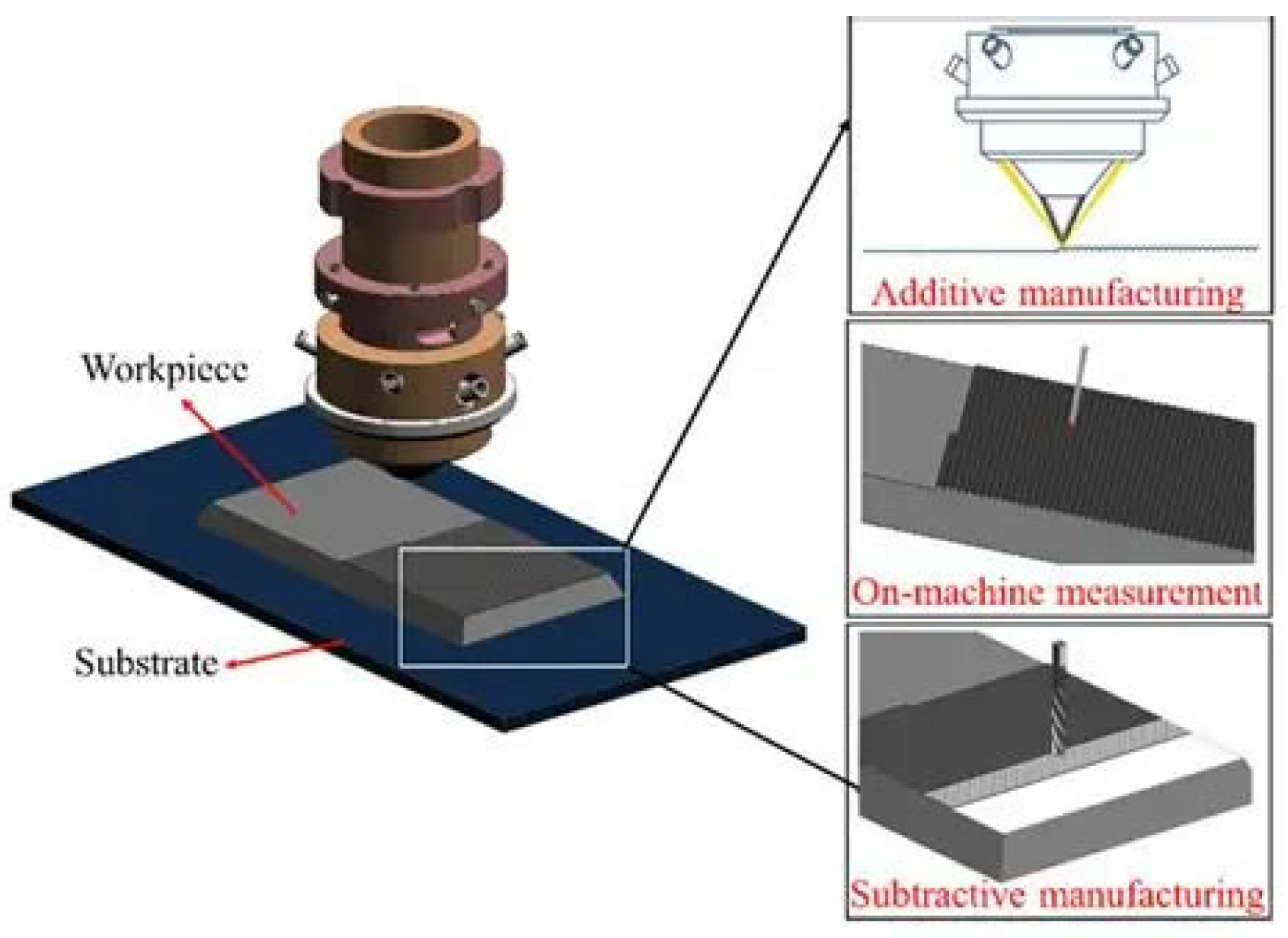

2.6.2. Hybrid Additive–Subtractive Manufacturing

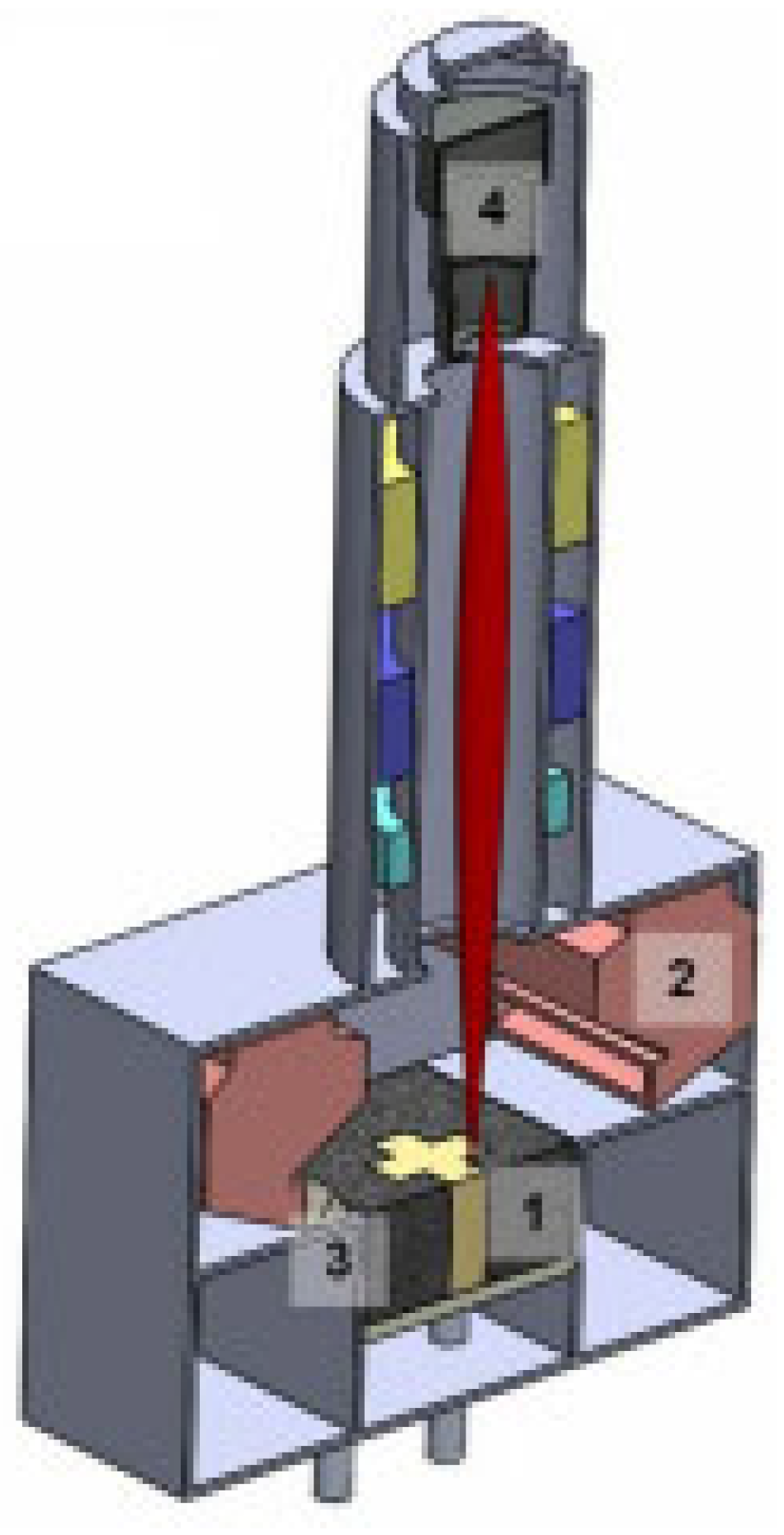

2.6.3. Electron Beam Additive Manufacturing (EBAM)

2.7. Comparative Analysis of Additive Manufacturing Technologies

3. Sustainable Green Additive Manufacturing Practices

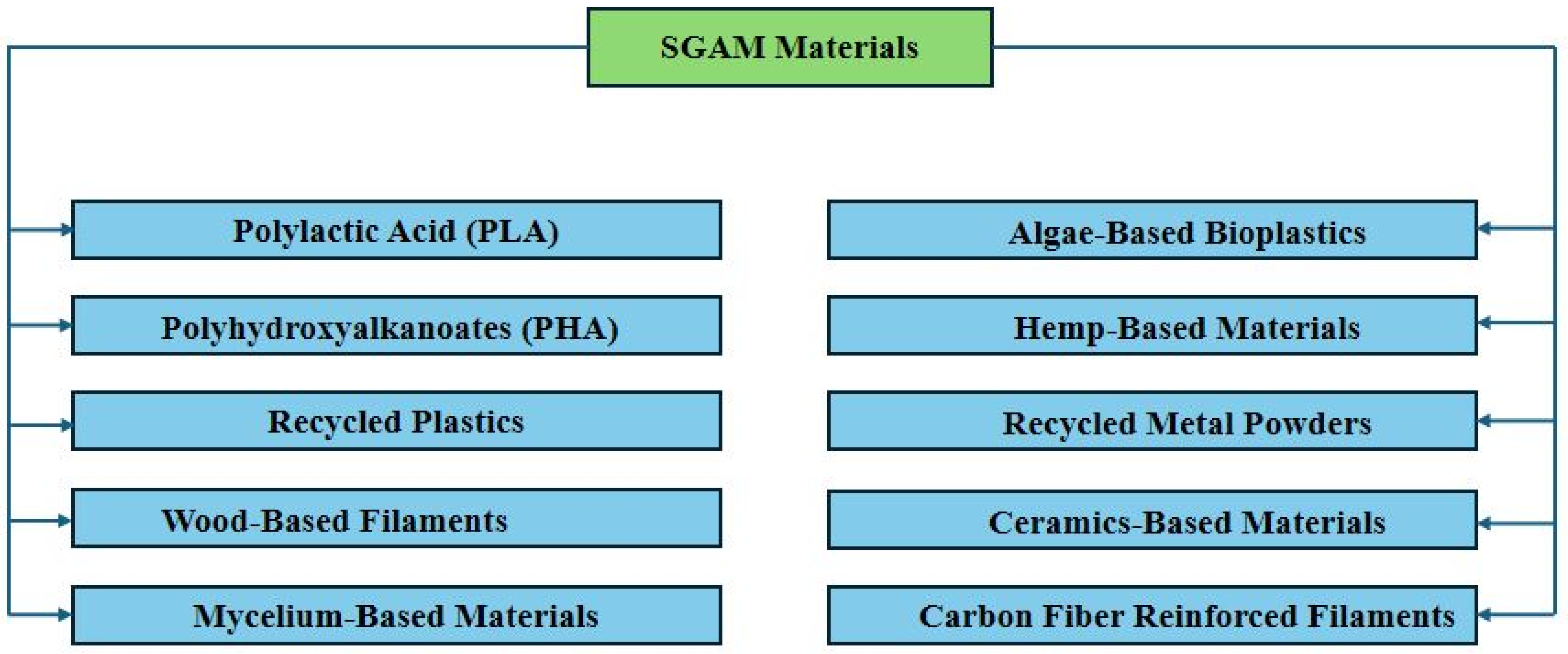

3.1. Use of Sustainable and Biodegradable Materials

3.2. Recycling and Reuse of Printing Materials

3.3. Energy-Efficient Printing Processes

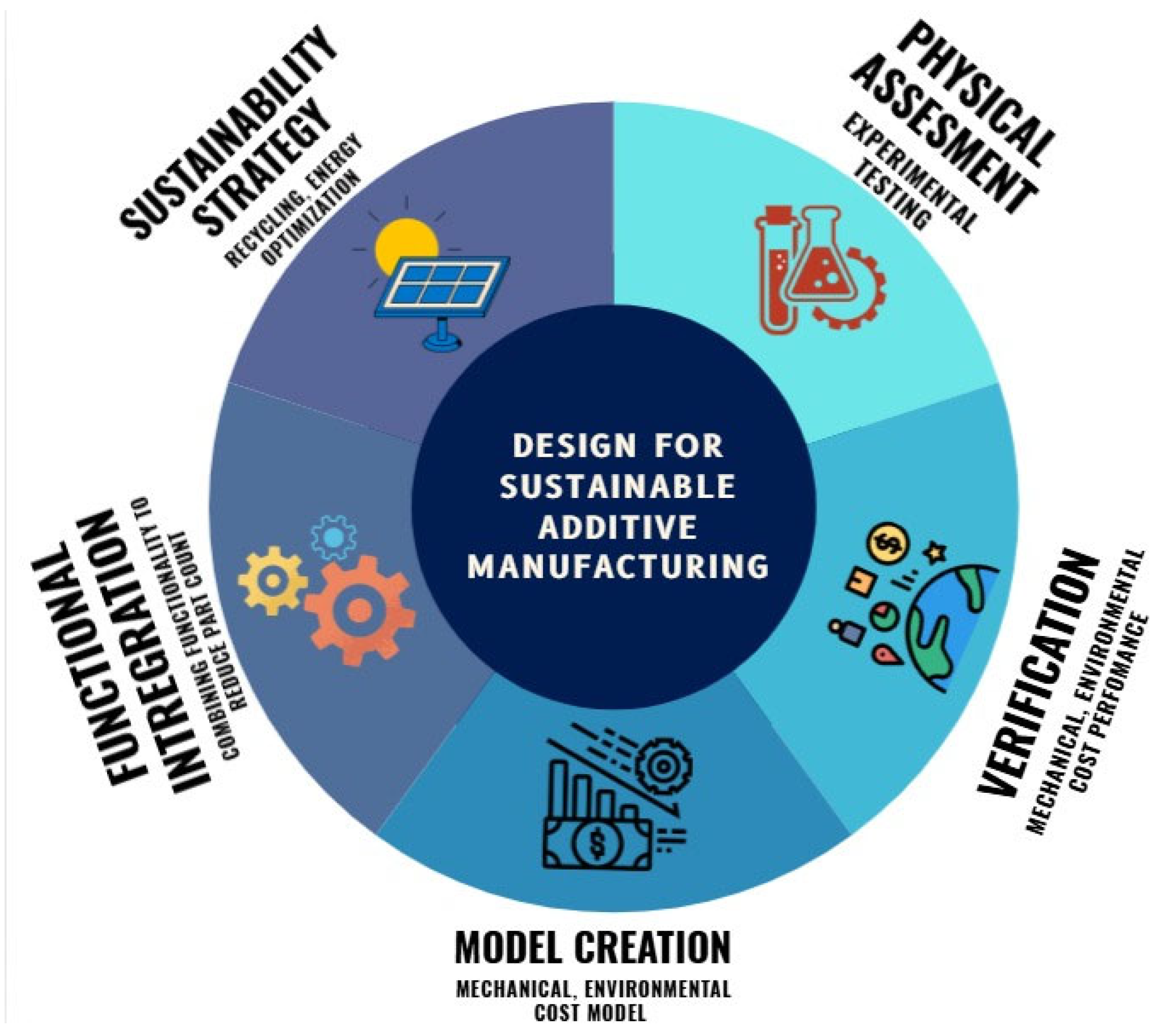

3.4. Design for Sustainability

3.5. Localized and On-Demand Manufacturing

3.6. Minimal or No Support Structure Usage

3.7. Lifecycle Assessment (LCA) and Environmental Impact Evaluation

3.8. Waste Reduction and Material Efficiency

3.9. Eco-Certification and Compliance with Green Standards

3.10. Education, Training, and Stakeholder Awareness

4. Sustainable Green Additive Manufacturing Challenges

4.1. Environmental Aspects

4.2. Material Compatibility

4.3. Scalability of Manufacturing Process

4.4. Mechanical Property Optimization

4.5. Cost of Sustainable Materials

5. Future Directions

5.1. The Development of New Green Materials and Technologies

5.2. Challenges in Material Optimization, Recycling, and Energy Efficiency

5.3. Strategies for Further Integrating Eco-Friendly Materials into AM Processes

6. Summary

- A variety of additive manufacturing processes—including Fused Deposition Modeling, Selective Laser Sintering, Direct Ink Writing, binder jetting, and hybrid and low-energy printing methods—are being adapted or redesigned to accommodate sustainable materials and improve energy efficiency across the production lifecycle.

- Emerging green materials such as PLA, PHA, lignin-based resins, and algae-based bioplastics are increasingly used to reduce fossil fuel dependency and promote biodegradable end-of-life pathways.

- Recycled feedstocks, including rPET, rABS, rHDPE, and reclaimed metal powders, support circular economy principles and help convert post-consumer and industrial waste into valuable inputs for AM.

- Innovative material strategies, like bio-based resins designed for reusability and “green steel” produced through additive-controlled heat cycles, demonstrate how material science contributes to minimizing environmental impact.

- Challenges remain, particularly in ensuring material compatibility, process scalability, and consistent mechanical performance due to the variable properties of green materials.

- Predictive modeling and AI-driven tools are vital in addressing these challenges by simulating material behavior, optimizing printing parameters, and forecasting part performance across various metrics, including strength, thermal stability, and degradation.

- LCA and sustainability analysis tools should be integrated into AM workflows to evaluate and minimize the environmental footprint of products from material selection to end-of-life.

- The integration of material science with machine learning and sustainable design principles will be central to enabling scalable, eco-efficient, and circular additive manufacturing systems.

Author Contributions

Funding

Conflicts of Interest

References

- Su, J.; Ng, W.L.; An, J.; Yeong, W.Y.; Chua, C.K.; Sing, S.L. Achieving Sustainability by Additive Manufacturing: A State-of-the-Art Review and Perspectives. Virtual Phys. Prototyp. 2024, 19, e2438899. [Google Scholar] [CrossRef]

- Ford, S.; Despeisse, M. Additive Manufacturing and Sustainability: An Exploratory Study of the Advantages and Challenges. J. Clean. Prod. 2016, 137, 1573–1587. [Google Scholar] [CrossRef]

- Kawalkar, R.; Dubey, H.K.; Lokhande, S.P. A Review for Advancements in Standardization for Additive Manufacturing. Mater. Today Proc. 2022, 50, 1983–1990. [Google Scholar] [CrossRef]

- Attaran, M. The Rise of 3-D Printing: The Advantages of Additive Manufacturing over Traditional Manufacturing. Bus. Horiz. 2017, 60, 677–688. [Google Scholar] [CrossRef]

- Faheem, A.; Hasan, M.A.; Badhotiya, G.K.; Ali, S.M. A Systematic Literature Review to Examine the Role of Additive Manufacturing in Achieving Sustainable Development Goals. Sustain. Oper. Comput. 2024, 5, 216–226. [Google Scholar] [CrossRef]

- Mehrpouya, M.; Vahabi, H.; Barletta, M.; Laheurte, P.; Langlois, V. Additive Manufacturing of Polyhydroxyalkanoates (PHAs) Biopolymers: Materials, Printing Techniques, and Applications. Mater. Sci. Eng. C 2021, 127, 112216. [Google Scholar] [CrossRef]

- Krapež Tomec, D.; Kariž, M. Use of Wood in Additive Manufacturing: Review and Future Prospects. Polymers 2022, 14, 1174. [Google Scholar] [CrossRef]

- Elsacker, E.; Peeters, E.; De Laet, L. Large-Scale Robotic Extrusion-Based Additive Manufacturing with Living Mycelium Materials. Sustain. Futur. 2022, 4, 100085. [Google Scholar] [CrossRef]

- Cheah, W.Y.; Er, A.C.; Aiyub, K.; Mohd Yasin, N.H.; Ngan, S.L.; Chew, K.W.; Khoo, K.S.; Ling, T.C.; Juan, J.C.; Ma, Z.; et al. Current Status and Perspectives of Algae-Based Bioplastics: A Reviewed Potential for Sustainability. Algal Res. 2023, 71, 103078. [Google Scholar] [CrossRef]

- Malabadi, R.B.; Chalannavar, R.K.; Divakar, B.S.; Kv, K.; Kamble, A.A.; Karamchand, K.S.; Kolkar, K.P.; Tl, N.; Coronado, K.V.C.; Munhoz, A.N.; et al. Industrial Cannabis Sativa (Fiber or Hemp): 3D Printing-Hempcrete-a Sustainable Building Material. World J. Adv. Eng. Technol. Sci. 2025, 14, 253–282. [Google Scholar] [CrossRef]

- Fredriksson, C. Sustainability of Metal Powder Additive Manufacturing. Procedia Manuf. 2019, 33, 139–144. [Google Scholar] [CrossRef]

- Giani, N.; Mazzocchetti, L.; Benelli, T.; Picchioni, F.; Giorgini, L. Towards Sustainability in 3D Printing of Thermoplastic Composites: Evaluation of Recycled Carbon Fibers as Reinforcing Agent for FDM Filament Production and 3D Printing. Compos. Part Appl. Sci. Manuf. 2022, 159, 107002. [Google Scholar] [CrossRef]

- Shifa, S.S.; Hasan Kanok, M.M.; Haque, M.S.; Sultan, T.; Pritha, K.F.; Mubasshira; Al Yeamin, M.; Dipta, S.D. Influence of Heat Treatment and Water Absorption on Mechanical Properties of Cotton-Glass Fiber Reinforced Epoxy Hybrid Composites: An Eco-Friendly Approach for Industrial Materials. Hybrid Adv. 2024, 5, 100181. [Google Scholar] [CrossRef]

- Maware, C.; Muvunzi, R.; Machingura, T.; Daniyan, I. Examining the Progress in Additive Manufacturing in Supporting Lean, Green and Sustainable Manufacturing: A Systematic Review. Appl. Sci. 2024, 14, 6041. [Google Scholar] [CrossRef]

- Gopal, M.; Lemu, H.G.; Gutema, E.M. Sustainable Additive Manufacturing and Environmental Implications: Literature Review. Sustainability 2022, 15, 504. [Google Scholar] [CrossRef]

- Altıparmak, S.C.; Yardley, V.A.; Shi, Z.; Lin, J. Extrusion-Based Additive Manufacturing Technologies: State of the Art and Future Perspectives. J. Manuf. Process. 2022, 83, 607–636. [Google Scholar] [CrossRef]

- Acierno, D.; Patti, A. Fused Deposition Modelling (FDM) of Thermoplastic-Based Filaments: Process and Rheological Properties—An Overview. Materials 2023, 16, 7664. [Google Scholar] [CrossRef] [PubMed]

- Zhou, L.; Miller, J.; Vezza, J.; Mayster, M.; Raffay, M.; Justice, Q.; Tamimi, Z.A.; Hansotte, G.; Sunkara, L.D.; Bernat, J. Additive Manufacturing: A Comprehensive Review. Sensors 2024, 24, 2668. [Google Scholar] [CrossRef] [PubMed]

- Bhatia, A.; Sehgal, A.K. Additive Manufacturing Materials, Methods and Applications: A Review. Mater. Today Proc. 2023, 81, 1060–1067. [Google Scholar] [CrossRef]

- Madhu, N.R.; Erfani, H.; Jadoun, S.; Amir, M.; Thiagarajan, Y.; Chauhan, N.P.S. Fused Deposition Modelling Approach Using 3D Printing and Recycled Industrial Materials for a Sustainable Environment: A Review. Int. J. Adv. Manuf. Technol. 2022, 122, 2125–2138. [Google Scholar] [CrossRef]

- Solís Pinargote, N.W.; Smirnov, A.; Peretyagin, N.; Seleznev, A.; Peretyagin, P. Direct Ink Writing Technology (3D Printing) of Graphene-Based Ceramic Nanocomposites: A Review. Nanomaterials 2020, 10, 1300. [Google Scholar] [CrossRef]

- Cadiou, T.; Demoly, F.; Gomes, S. A Hybrid Additive Manufacturing Platform Based on Fused Filament Fabrication and Direct Ink Writing Techniques for Multi-Material 3D Printing. Int. J. Adv. Manuf. Technol. 2021, 114, 3551–3562. [Google Scholar] [CrossRef]

- Rau, D.A.; Williams, C.B.; Bortner, M.J. Rheology and Printability: A Survey of Critical Relationships for Direct Ink Write Materials Design. Prog. Mater. Sci. 2023, 140, 101188. [Google Scholar] [CrossRef]

- Hao, L.; Tang, D.; Sun, T.; Xiong, W.; Feng, Z.; Evans, K.E.; Li, Y. Direct Ink Writing of Mineral Materials: A Review. Int. J. Precis. Eng. Manuf.-Green Technol. 2021, 8, 665–685. [Google Scholar] [CrossRef]

- Alami, A.H.; Olabi, A.G.; Ayoub, M.; Aljaghoub, H.; Alasad, S.; Abdelkareem, M.A. 3D Concrete Printing: Recent Progress, Applications, Challenges, and Role in Achieving Sustainable Development Goals. Buildings 2023, 13, 924. [Google Scholar] [CrossRef]

- Colyn, M.; van Zijl, G.; Babafemi, A.J. Fresh and Strength Properties of 3D Printable Concrete Mixtures Utilising a High Volume of Sustainable Alternative Binders. Constr. Build. Mater. 2024, 419, 135474. [Google Scholar] [CrossRef]

- Ryan, K.R.; Down, M.P.; Banks, C.E. Future of Additive Manufacturing: Overview of 4D and 3D Printed Smart and Advanced Materials and Their Applications. Chem. Eng. J. 2021, 403, 126162. [Google Scholar] [CrossRef]

- Waheed, S.; Cabot, J.M.; Macdonald, N.P.; Lewis, T.; Guijt, R.M.; Paull, B.; Breadmore, M.C. 3D Printed Microfluidic Devices: Enablers and Barriers. Lab. Chip 2016, 16, 1993–2013. [Google Scholar] [CrossRef] [PubMed]

- Huang, J.; Qin, Q.; Wang, J. A Review of Stereolithography: Processes and Systems. Processes 2020, 8, 1138. [Google Scholar] [CrossRef]

- Meana, V.; Zapico, P.; Cuesta, E.; Giganto, S.; Meana, L.; Martínez-Pellitero, S. Additive Manufacturing of Ceramic Reference Spheres by Stereolithography (SLA). Appl. Sci. 2024, 14, 7530. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, W.; Ladika, D.; Yu, H.; Gailevičius, D.; Wang, H.; Pan, C.; Nair, P.N.S.; Ke, Y.; Mori, T.; et al. Two-Photon Polymerization Lithography for Optics and Photonics: Fundamentals, Materials, Technologies, and Applications. Adv. Funct. Mater. 2023, 33, 2214211. [Google Scholar] [CrossRef]

- Sampson, K.L.; Deore, B.; Go, A.; Nayak, M.A.; Orth, A.; Gallerneault, M.; Malenfant, P.R.L.; Paquet, C. Multimaterial Vat Polymerization Additive Manufacturing. ACS Appl. Polym. Mater. 2021, 3, 4304–4324. [Google Scholar] [CrossRef]

- Almuallim, B.; Harun, W.S.W.; Al Rikabi, I.J.; Mohammed, H.A. Thermally Conductive Polymer Nanocomposites for Filament-Based Additive Manufacturing. J. Mater. Sci. 2022, 57, 3993–4019. [Google Scholar] [CrossRef]

- Huang, J.; Cai, J.; Huangfu, C.; Li, S.; Chen, G.; Yun, H.; Xiao, J. A Scalable Digital Light Processing 3D Printing Method. Micromachines 2024, 15, 1298. [Google Scholar] [CrossRef] [PubMed]

- Chaudhary, R.; Akbari, R.; Antonini, C. Rational Design and Characterization of Materials for Optimized Additive Manufacturing by Digital Light Processing. Polymers 2023, 15, 287. [Google Scholar] [CrossRef]

- Zhou, C.; Xu, H.; Chen, Y. Spatiotemporal Projection-Based Additive Manufacturing: A Data-Driven Image Planning Method for Subpixel Shifting in a Split Second. Adv. Intell. Syst. 2021, 3, 2100079. [Google Scholar] [CrossRef]

- Prashar, G. A Comprehensive Review on Sustainable Cold Spray Additive Manufacturing: State of the Art, Challenges and Future Challenges. J. Clean. Prod. 2021, 310, 127606. [Google Scholar] [CrossRef]

- Kaijage, D.J.; Lee, B.J. Multiphysics Simulation of Continuous Liquid Interface Production (CLIP) 3D Printing Technology. Int. J. Precis. Eng. Manuf.-Green Technol. 2025, 12, 541–552. [Google Scholar] [CrossRef]

- Czajkowska, M.; Walejewska, E.; Zadrożny, Ł.; Wieczorek, M.; Święszkowski, W.; Wagner, L.; Mijiritsky, E.; Markowski, J. Comparison of Dental Stone Models and Their 3D Printed Acrylic Replicas for the Accuracy and Mechanical Properties. Materials 2020, 13, 4066. [Google Scholar] [CrossRef]

- Rosu, M.M.; Radu Frent, C.; Iliescu, M. Technical and Economic Analysis of Manufacturing Process for High Precision Customized Part. Int. J. Mod. Manuf. Technol. 2022, 14, 215–219. [Google Scholar] [CrossRef]

- Abdulhameed, O.; Al-Ahmari, A.; Ameen, W.; Mian, S.H. Additive Manufacturing: Challenges, Trends, and Applications. Adv. Mech. Eng. 2019, 11, 1687814018822880. [Google Scholar] [CrossRef]

- Lipkowitz, G.; Samuelsen, T.; Hsiao, K.; Lee, B.; Dulay, M.T.; Coates, I.; Lin, H.; Pan, W.; Toth, G.; Tate, L.; et al. Injection Continuous Liquid Interface Production of 3D Objects. Sci. Adv. 2022, 8, eabq3917. [Google Scholar] [CrossRef] [PubMed]

- Huang, B.; Hu, R.; Xue, Z.; Zhao, J.; Li, Q.; Xia, T.; Zhang, W.; Lu, C. Continuous Liquid Interface Production of Alginate/Polyacrylamide Hydrogels with Supramolecular Shape Memory Properties. Carbohydr. Polym. 2020, 231, 115736. [Google Scholar] [CrossRef] [PubMed]

- Davoudinejad, A. Vat Photopolymerization Methods in Additive Manufacturing. In Additive Manufacturing; Elsevier: Amsterdam, The Netherlands, 2021; pp. 159–181. ISBN 978-0-12-818411-0. [Google Scholar]

- Gu, P.; Zhang, X.; Zeng, Y.; Ferguson, B. Quality Analysis and Optimization of Solid Ground Curing Process. J. Manuf. Syst. 2001, 20, 250–263. [Google Scholar] [CrossRef]

- Qu, C.; Qin, Y.; Wang, T. From Cement to Geopolymers: Performances and Sustainability Advantages of Ambient Curing. J. Build. Eng. 2024, 91, 109555. [Google Scholar] [CrossRef]

- Qi, Z.; Li, J.; Huang, G.; Zhong, F.; Xue, Q. Developing All-Solid-Waste-Based Curing Agents with Net-Zero Emissions for Engineering Sediment Waste Stabilization. Resour. Conserv. Recycl. 2025, 220, 108354. [Google Scholar] [CrossRef]

- Zol, S.M.; Alauddin, M.S.; Said, Z.; Mohd Ghazali, M.I.; Hao-Ern, L.; Mohd Farid, D.A.; Zahari, N.A.H.; Al-Khadim, A.H.A.; Abdul Aziz, A.H. Description of Poly(Aryl-Ether-Ketone) Materials (PAEKs), Polyetheretherketone (PEEK) and Polyetherketoneketone (PEKK) for Application as a Dental Material: A Materials Science Review. Polymers 2023, 15, 2170. [Google Scholar] [CrossRef]

- Pyteraf, J.; Pacławski, A.; Jamróz, W.; Mendyk, A.; Paluch, M.; Jachowicz, R. Application and Multi-Stage Optimization of Daylight Polymer 3D Printing of Personalized Medicine Products. Pharmaceutics 2022, 14, 843. [Google Scholar] [CrossRef]

- Smith, G.B. Materials and Systems for Efficient Lighting and Delivery of Daylight. Sol. Energy Mater. Sol. Cells 2004, 84, 395–409. [Google Scholar] [CrossRef]

- Saleh Alghamdi, S.; John, S.; Roy Choudhury, N.; Dutta, N.K. Additive Manufacturing of Polymer Materials: Progress, Promise and Challenges. Polymers 2021, 13, 753. [Google Scholar] [CrossRef] [PubMed]

- Charoo, N.A.; Barakh Ali, S.F.; Mohamed, E.M.; Kuttolamadom, M.A.; Ozkan, T.; Khan, M.A.; Rahman, Z. Selective Laser Sintering 3D Printing—An Overview of the Technology and Pharmaceutical Applications. Drug Dev. Ind. Pharm. 2020, 46, 869–877. [Google Scholar] [CrossRef] [PubMed]

- Lekurwale, S.; Karanwad, T.; Banerjee, S. Selective Laser Sintering (SLS) of 3D Printlets Using a 3D Printer Comprised of IR/Red-Diode Laser. Ann. 3D Print. Med. 2022, 6, 100054. [Google Scholar] [CrossRef]

- Nandhakumar, R.; Venkatesan, K. A Process Parameters Review on Selective Laser Melting-Based Additive Manufacturing of Single and Multi-Material: Microstructure, Physical Properties, Tribological, and Surface Roughness. Mater. Today Commun. 2023, 35, 105538. [Google Scholar] [CrossRef]

- Giudice, F.; Barbagallo, R.; Fargione, G. A Design for Additive Manufacturing Approach Based on Process Energy Efficiency: Electron Beam Melted Components. J. Clean. Prod. 2021, 290, 125185. [Google Scholar] [CrossRef]

- Islam, M.A.; Mobarak, M.H.; Rimon, M.I.H.; Al Mahmud, M.Z.; Ghosh, J.; Ahmed, M.M.S.; Hossain, N. Additive Manufacturing in Polymer Research: Advances, Synthesis, and Applications. Polym. Test. 2024, 132, 108364. [Google Scholar] [CrossRef]

- Sefene, E.M. State-of-the-Art of Selective Laser Melting Process: A Comprehensive Review. J. Manuf. Syst. 2022, 63, 250–274. [Google Scholar] [CrossRef]

- Wang, Z.; Ummethala, R.; Singh, N.; Tang, S.; Suryanarayana, C.; Eckert, J.; Prashanth, K.G. Selective Laser Melting of Aluminum and Its Alloys. Materials 2020, 13, 4564. [Google Scholar] [CrossRef] [PubMed]

- Ansari, M.J.; Nguyen, D.-S.; Park, H.S. Investigation of SLM Process in Terms of Temperature Distribution and Melting Pool Size: Modeling and Experimental Approaches. Materials 2019, 12, 1272. [Google Scholar] [CrossRef]

- Farhang, B.; Tanrikulu, A.A.; Ganesh-Ram, A.; Durlov, S.H.; Shayesteh Moghaddam, N. Innovative Fabrication Design for In Situ Martensite Decomposition and Enhanced Mechanical Properties in Laser Powder Bed Fused Ti6Al4V Alloy. J. Manuf. Mater. Process. 2023, 7, 226. [Google Scholar] [CrossRef]

- Tanrikulu, A.A.; Farhang, B.; Ganesh-Ram, A.; Hekmatjou, H.; Durlov, S.H.; Amerinatanzi, A. In Situ Microstructure Modification Using a Layerwise Surface-Preheating Laser Scan of Ti-6Al-4V during Laser Powder Bed Fusion. Materials 2024, 17, 1929. [Google Scholar] [CrossRef]

- Tanrikulu, A.A.; Ganesh-Ram, A.; Hekmatjou, H.; Durlov, S.H.; Salehin, M.N.; Amerinatanzi, A. Single-Composition Functionally Graded Ti-6Al-4V for Mimicking Composite Material Fiber Reinforcement through Post-Heating Laser Scanning. Int. J. Adv. Manuf. Technol. 2025, 136, 1297–1315. [Google Scholar] [CrossRef]

- Sivarupan, T.; Upadhyay, M.; Ali, Y.; El Mansori, M.; Dargusch, M.S. Reduced Consumption of Materials and Hazardous Chemicals for Energy Efficient Production of Metal Parts through 3D Printing of Sand Molds. J. Clean. Prod. 2019, 224, 411–420. [Google Scholar] [CrossRef]

- Ralls, A.M.; Menezes, P.L. Understanding the Tribo-Corrosion Mechanisms of Friction Stir Processed Steel Deposited by High-Pressure Deposition Additive Manufacturing Process. Int. J. Adv. Manuf. Technol. 2023, 128, 823–843. [Google Scholar] [CrossRef]

- Lomo, F.N.; Patel, M.J.; Vargas-Uscategui, A.; King, P.C.; Cole, I.S. A Design and Optimisation Framework for Cold Spray Additive Manufacturing of Lightweight Aerospace Structural Components. Addit. Manuf. 2023, 78, 103891. [Google Scholar] [CrossRef]

- Kafle, A.; Silwal, R.; Koirala, B.; Zhu, W. Advancements in Cold Spray Additive Manufacturing: Process, Materials, Optimization, Applications, and Challenges. Materials 2024, 17, 5431. [Google Scholar] [CrossRef] [PubMed]

- Zou, Y. Cold Spray Additive Manufacturing: Microstructure Evolution and Bonding Features. Acc. Mater. Res. 2021, 2, 1071–1081. [Google Scholar] [CrossRef]

- Blunk, H.; Seibel, A. Design Guidelines for Metal Binder Jetting. Prog. Addit. Manuf. 2024, 9, 725–732. [Google Scholar] [CrossRef]

- Li, M.; Du, W.; Elwany, A.; Pei, Z.; Ma, C. Metal Binder Jetting Additive Manufacturing: A Literature Review. J. Manuf. Sci. Eng. 2020, 142, 090801. [Google Scholar] [CrossRef]

- Gibson, I.; Rosen, D.; Stucker, B.; Khorasani, M. Binder Jetting. In Additive Manufacturing Technologies; Springer International Publishing: Cham, Switzerland, 2021; pp. 237–252. ISBN 978-3-030-56126-0. [Google Scholar]

- Sarila, V.; Koneru, H.P.; Pyatla, S.; Cheepu, M.; Kantumunchu, V.C.; Ramachandran, D. An Overview on 3D Printing of Ceramics Using Binder Jetting Process. In Proceedings of the International Conference on Processing and Performance of Materials (ICPPM 2023), Chennai, India, 2–3 March 2023; MDPI: Basel, Switzerland, 2024; p. 44. [Google Scholar]

- Mostafaei, A.; Elliott, A.M.; Barnes, J.E.; Li, F.; Tan, W.; Cramer, C.L.; Nandwana, P.; Chmielus, M. Binder Jet 3D Printing—Process Parameters, Materials, Properties, Modeling, and Challenges. Prog. Mater. Sci. 2021, 119, 100707. [Google Scholar] [CrossRef]

- Palanisamy, C.; Raman, R.; Dhanraj, P.K. Additive Manufacturing: A Review on Mechanical Properties of Polyjet and FDM Printed Parts. Polym. Bull. 2022, 79, 7065–7116. [Google Scholar] [CrossRef]

- Zhong, S.; Shi, Q.; Deng, Y.; Sun, Y.; Politis, C.; Yang, S. High-Performance Zirconia Ceramic Additively Manufactured via NanoParticle Jetting. Ceram. Int. 2022, 48, 33485–33498. [Google Scholar] [CrossRef]

- Khorasani, M.; Noronha, J.; MacDonald, E.; Kafi, A.; Downing, D.; Ghasemi, A.; Gibson, I.; Brandt, M.; Bateman, S.; Leary, M. Additive Manufacturing for Mass Production: A New Model to Estimate the Crystallinity and Tensile Properties of Polypropylene by Multi-Jet Fusion. Prog. Addit. Manuf. 2024, 10, 5557–5571. [Google Scholar] [CrossRef]

- He, Y.; Wu, Y.; Fu, J.; Gao, Q.; Qiu, J. Developments of 3D Printing Microfluidics and Applications in Chemistry and Biology: A Review. Electroanalysis 2016, 28, 1658–1678. [Google Scholar] [CrossRef]

- Gale, B.K.; Jafek, A.R.; Lambert, C.J.; Goenner, B.L.; Moghimifam, H.; Nze, U.C.; Kamarapu, S.K. A Review of Current Methods in Microfluidic Device Fabrication and Future Commercialization Prospects. Inventions 2018, 3, 60. [Google Scholar] [CrossRef]

- Atzeni, E.; Priarone, P.C.; Salmi, A. An Appraisal of Integrating Multi-Jet Fusion (MJF) Additive Manufacturing into Automotive Production Lines. Prog. Addit. Manuf. 2024, 10, 4689–4703. [Google Scholar] [CrossRef]

- Bikas, H.; Stavropoulos, P.; Chryssolouris, G. Additive Manufacturing Methods and Modelling Approaches: A Critical Review. Int. J. Adv. Manuf. Technol. 2016, 83, 389–405. [Google Scholar] [CrossRef]

- Sochol, R.D.; Sweet, E.; Glick, C.C.; Venkatesh, S.; Avetisyan, A.; Ekman, K.F.; Raulinaitis, A.; Tsai, A.; Wienkers, A.; Korner, K.; et al. 3D Printed Microfluidic Circuitry via Multijet-Based Additive Manufacturing. Lab. Chip 2016, 16, 668–678. [Google Scholar] [CrossRef] [PubMed]

- Simonelli, M.; Aboulkhair, N.; Rasa, M.; East, M.; Tuck, C.; Wildman, R.; Salomons, O.; Hague, R. Towards Digital Metal Additive Manufacturing via High-Temperature Drop-on-Demand Jetting. Addit. Manuf. 2019, 30, 100930. [Google Scholar] [CrossRef]

- Bandh, S.A.; Malla, F.A. Biofuels in Low Carbon Economies and Societies. In Biofuels in Circular Economy; Springer Nature: Singapore, 2022; pp. 31–58. ISBN 978-981-19-5836-6. [Google Scholar]

- Huang, Y.; Li, X.; Chen, H.; Ren, K.; Guo, H.; Qi, H. Effect the Sintering Temperature on the Microstructure and Flexural Strength of ZrO2 Ceramics Produced by NanoParticle Jetting. Materials 2025, 18, 2605. [Google Scholar] [CrossRef]

- Sehrt, J.T.; Kleszczynski, S.; Notthoff, C. Nanoparticle Improved Metal Materials for Additive Manufacturing. Prog. Addit. Manuf. 2017, 2, 179–191. [Google Scholar] [CrossRef]

- Narra, S.P.; Mittwede, P.N.; DeVincent Wolf, S.; Urish, K.L. Additive Manufacturing in Total Joint Arthroplasty. Orthop. Clin. N. Am. 2019, 50, 13–20. [Google Scholar] [CrossRef]

- Izdebska-Podsiadły, J. Sheet Lamination. In Polymers for 3D Printing; Elsevier: Amsterdam, The Netherlands, 2022; pp. 127–136. ISBN 978-0-12-818311-3. [Google Scholar]

- Li, J.; Monaghan, T.; Masurtschak, S.; Bournias-Varotsis, A.; Friel, R.J.; Harris, R.A. Exploring the Mechanical Strength of Additively Manufactured Metal Structures with Embedded Electrical Materials. Mater. Sci. Eng. A 2015, 639, 474–481. [Google Scholar] [CrossRef]

- Ishfaq, K.; Abas, Z.; Saravana Kumar, M.; Mahmood, M.A. Review of Recent Trends in Ultrasonic Additive Manufacturing: Current Challenges and Future Prospects. Rapid Prototyp. J. 2023, 29, 1195–1211. [Google Scholar] [CrossRef]

- Wolcott, P.J.; Hehr, A.; Pawlowski, C.; Dapino, M.J. Process Improvements and Characterization of Ultrasonic Additive Manufactured Structures. J. Mater. Process. Technol. 2016, 233, 44–52. [Google Scholar] [CrossRef]

- Guo, H.; Gingerich, M.B.; Headings, L.M.; Hahnlen, R.; Dapino, M.J. Joining of Carbon Fiber and Aluminum Using Ultrasonic Additive Manufacturing (UAM). Compos. Struct. 2019, 208, 180–188. [Google Scholar] [CrossRef]

- Li, D. A Review of Microstructure Evolution during Ultrasonic Additive Manufacturing. Int. J. Adv. Manuf. Technol. 2021, 113, 1–19. [Google Scholar] [CrossRef]

- Chiu, Y.Y.; Liao, Y.S.; Hou, C.C. Automatic Fabrication for Bridged Laminated Object Manufacturing (LOM) Process. J. Mater. Process. Technol. 2003, 140, 179–184. [Google Scholar] [CrossRef]

- Park, J.; Tari, M.J.; Hahn, H.T. Characterization of the Laminated Object Manufacturing (LOM) Process. Rapid Prototyp. J. 2000, 6, 36–50. [Google Scholar] [CrossRef]

- Seok, I.; Kilula, D.; Guo, Z. Micro/Nanoscale 3-Dimensional Fabrication Using Multi-Photons Polymerization: Review. ES Mater. Manuf. 2023, 21, 849. [Google Scholar] [CrossRef]

- Kim, D.; Shin, S.; Chung, W.; Shin, C.; Lim, K. Application of 3D Printing Technology in Seismic Physical Modeling. J. Korean Soc. Miner. Energy Resour. Eng. 2019, 56, 260–269. [Google Scholar] [CrossRef]

- Gibson, I.; Rosen, D.; Stucker, B.; Khorasani, M. Sheet Lamination Processes. In Additive Manufacturing Technologies; Springer: Boston, MA, USA, 2010; pp. 223–252. ISBN 978-1-4419-1119-3. [Google Scholar]

- Ramos, A.; Angel, V.G.; Siqueiros, M.; Sahagun, T.; Gonzalez, L.; Ballesteros, R. Reviewing Additive Manufacturing Techniques: Material Trends and Weight Optimization Possibilities Through Innovative Printing Patterns. Materials 2025, 18, 1377. [Google Scholar] [CrossRef]

- Kumar, A.; Dixit, A.R.; Sreenivasa, S. Mechanical Properties of Additively Manufactured Polymeric Composites Using Sheet Lamination Technique and Fused Deposition Modeling: A Review. Polym. Adv. Technol. 2024, 35, e6396. [Google Scholar] [CrossRef]

- Dermeik, B.; Travitzky, N. Laminated Object Manufacturing of Ceramic-Based Materials. Adv. Eng. Mater. 2020, 22, 2000256. [Google Scholar] [CrossRef]

- Touri, M.; Kabirian, F.; Saadati, M.; Ramakrishna, S.; Mozafari, M. Additive Manufacturing of Biomaterials—The Evolution of Rapid Prototyping. Adv. Eng. Mater. 2019, 21, 1800511. [Google Scholar] [CrossRef]

- Tang, H.-H.; Yen, H.-C. Slurry-Based Additive Manufacturing of Ceramic Parts by Selective Laser Burn-Out. J. Eur. Ceram. Soc. 2015, 35, 981–987. [Google Scholar] [CrossRef]

- Yasa, E.; Ersoy, K. Additive Manufacturing of Polymer Matrix Composites. In Aircraft Technology; InTech: West Palm Beach, FL, USA, 2018; pp. 147–169. [Google Scholar] [CrossRef]

- Bandyopadhyay, A.; Heer, B. Additive Manufacturing of Multi-Material Structures. Mater. Sci. Eng. R Rep. 2018, 129, 1–16. [Google Scholar] [CrossRef]

- Heitkamp, T.; Girnth, S.; Kuschmitz, S.; Klawitter, G.; Waldt, N.; Vietor, T. Continuous Fiber-Reinforced Material Extrusion with Hybrid Composites of Carbon and Aramid Fibers. Appl. Sci. 2022, 12, 8830. [Google Scholar] [CrossRef]

- Shah, A.; Aliyev, R.; Zeidler, H.; Krinke, S. A Review of the Recent Developments and Challenges in Wire Arc Additive Manufacturing (WAAM) Process. J. Manuf. Mater. Process. 2023, 7, 97. [Google Scholar] [CrossRef]

- Xia, C.; Pan, Z.; Polden, J.; Li, H.; Xu, Y.; Chen, S.; Zhang, Y. A Review on Wire Arc Additive Manufacturing: Monitoring, Control and a Framework of Automated System. J. Manuf. Syst. 2020, 57, 31–45. [Google Scholar] [CrossRef]

- Wu, B.; Pan, Z.; Ding, D.; Cuiuri, D.; Li, H.; Xu, J.; Norrish, J. A Review of the Wire Arc Additive Manufacturing of Metals: Properties, Defects and Quality Improvement. J. Manuf. Process. 2018, 35, 127–139. [Google Scholar] [CrossRef]

- Srivastava, M.; Rathee, S.; Tiwari, A.; Dongre, M. Wire Arc Additive Manufacturing of Metals: A Review on Processes, Materials and Their Behaviour. Mater. Chem. Phys. 2023, 294, 126988. [Google Scholar] [CrossRef]

- Hou, L.; Guo, J.; Chen, Y.; Chen, S.; Li, Y.; Bu, X. Post-Machining Allowance Optimization of Directed Energy Deposited Impeller Blades Using Point Cloud Registration. Manuf. Lett. 2022, 33, 593–601. [Google Scholar] [CrossRef]

- Korkmaz, M.E.; Waqar, S.; Garcia-Collado, A.; Gupta, M.K.; Krolczyk, G.M. A Technical Overview of Metallic Parts in Hybrid Additive Manufacturing Industry. J. Mater. Res. Technol. 2022, 18, 384–395. [Google Scholar] [CrossRef]

- Weflen, E.; Frank, M.C. Hybrid Additive and Subtractive Manufacturing of Multi-Material Objects. Rapid Prototyp. J. 2021, 27, 1860–1871. [Google Scholar] [CrossRef]

- Liu, W.; Deng, K.; Wei, H.; Zhao, P.; Li, J.; Zhang, Y. A Decision-Making Model for Comparing the Energy Demand of Additive-Subtractive Hybrid Manufacturing and Conventional Subtractive Manufacturing Based on Life Cycle Method. J. Clean. Prod. 2021, 311, 127795. [Google Scholar] [CrossRef]

- Zah, M.F.; Lutzmann, S. Modelling and Simulation of Electron Beam Melting. Prod. Eng. 2010, 4, 15–23. [Google Scholar] [CrossRef]

- Wysocki, B.; Maj, P.; Sitek, R.; Buhagiar, J.; Kurzydłowski, K.; Święszkowski, W. Laser and Electron Beam Additive Manufacturing Methods of Fabricating Titanium Bone Implants. Appl. Sci. 2017, 7, 657. [Google Scholar] [CrossRef]

- Kolamroudi, M.K.; Asmael, M.; Ilkan, M.; Kordani, N. Developments on Electron Beam Melting (EBM) of Ti–6Al–4V: A Review. Trans. Indian Inst. Met. 2021, 74, 783–790. [Google Scholar] [CrossRef]

- Zhang, M.; Zhou, X.; Wang, D.; He, L.; Ye, X.; Zhang, W. Additive Manufacturing of In-Situ Strengthened Dual-Phase AlCoCuFeNi High-Entropy Alloy by Selective Electron Beam Melting. J. Alloys Compd. 2022, 893, 162259. [Google Scholar] [CrossRef]

- Winarso, R.; Anggoro, P.W.; Ismail, R.; Jamari, J.; Bayuseno, A.P. Application of Fused Deposition Modeling (FDM) on Bone Scaffold Manufacturing Process: A Review. Heliyon 2022, 8, e11701. [Google Scholar] [CrossRef] [PubMed]

- Yan, J.; Huang, S.; Lim, Y.V.; Xu, T.; Kong, D.; Li, X.; Yang, H.Y.; Wang, Y. Direct-Ink Writing 3D Printed Energy Storage Devices: From Material Selectivity, Design and Optimization Strategies to Diverse Applications. Mater. Today 2022, 54, 110–152. [Google Scholar] [CrossRef]

- Ko, C.-H. Constraints and Limitations of Concrete 3D Printing in Architecture. J. Eng. Des. Technol. 2022, 20, 1334–1348. [Google Scholar] [CrossRef]

- Jipa, A.; Dillenburger, B. 3D Printed Formwork for Concrete: State-of-the-Art, Opportunities, Challenges, and Applications. 3D Print. Addit. Manuf. 2022, 9, 84–107. [Google Scholar] [CrossRef]

- Ligati Schleifer, S.; Regev, O. Additive Manufacturing of Anisotropic Graphene-Based Composites for Thermal Management Applications. Addit. Manuf. 2023, 70, 103567. [Google Scholar] [CrossRef]

- Hu, K.; Zhao, P.; Li, J.; Lu, Z. High-Resolution Multiceramic Additive Manufacturing Based on Digital Light Processing. Addit. Manuf. 2022, 54, 102732. [Google Scholar] [CrossRef]

- Gao, W.; Guo, Y.; Cui, J.; Liang, C.; Lu, Z.; Feng, S.; Sun, Y.; Xia, Q.; Zhang, B. Dual-Curing Polymer Systems for Photo-Curing 3D Printing. Addit. Manuf. 2024, 85, 104142. [Google Scholar] [CrossRef]

- Zhang, X.; Zhou, B.; Zeng, Y.; Gu, P. Model Layout Optimization for Solid Ground Curing Rapid Prototyping Processes. Robot. Comput.-Integr. Manuf. 2002, 18, 41–51. [Google Scholar] [CrossRef]

- Ashokkumar, M.; Thirumalaikumarasamy, D.; Sonar, T.; Deepak, S.; Vignesh, P.; Anbarasu, M. An Overview of Cold Spray Coating in Additive Manufacturing, Component Repairing and Other Engineering Applications. J. Mech. Behav. Mater. 2022, 31, 514–534. [Google Scholar] [CrossRef]

- Fayazfar, H.; Liravi, F.; Ali, U.; Toyserkani, E. Additive Manufacturing of High Loading Concentration Zirconia Using High-Speed Drop-on-Demand Material Jetting. Int. J. Adv. Manuf. Technol. 2020, 109, 2733–2746. [Google Scholar] [CrossRef]

- Rahman, M.; Islam, K.S.; Dip, T.M.; Chowdhury, M.F.M.; Debnath, S.R.; Hasan, S.M.M.; Sakib, M.S.; Saha, T.; Padhye, R.; Houshyar, S. A Review on Nanomaterial-Based Additive Manufacturing: Dynamics in Properties, Prospects, and Challenges. Prog. Addit. Manuf. 2024, 9, 1197–1224. [Google Scholar] [CrossRef]

- Chua, C.K.; Leong, K.F.; An, J. Introduction to Rapid Prototyping of Biomaterials. In Rapid Prototyping of Biomaterials; Elsevier: Amsterdam, The Netherlands, 2020; pp. 1–15. ISBN 978-0-08-102663-2. [Google Scholar] [CrossRef]

- Srivastava, M.; Rathee, S.; Patel, V.; Kumar, A.; Koppad, P.G. A Review of Various Materials for Additive Manufacturing: Recent Trends and Processing Issues. J. Mater. Res. Technol. 2022, 21, 2612–2641. [Google Scholar] [CrossRef]

- Graziosi, S.; Faludi, J.; Stanković, T.; Borgianni, Y.; Meisel, N.; Hallstedt, S.I.; Rosen, D.W. A Vision for Sustainable Additive Manufacturing. Nat. Sustain. 2024, 7, 698–705. [Google Scholar] [CrossRef]

- Javaid, M.; Haleem, A.; Singh, R.P.; Suman, R.; Rab, S. Role of Additive Manufacturing Applications towards Environmental Sustainability. Adv. Ind. Eng. Polym. Res. 2021, 4, 312–322. [Google Scholar] [CrossRef]

- Hosseini, E.S.; Dervin, S.; Ganguly, P.; Dahiya, R. Biodegradable Materials for Sustainable Health Monitoring Devices. ACS Appl. Bio Mater. 2021, 4, 163–194. [Google Scholar] [CrossRef] [PubMed]

- Samir, A.; Ashour, F.H.; Hakim, A.A.A.; Bassyouni, M. Recent Advances in Biodegradable Polymers for Sustainable Applications. Npj Mater. Degrad. 2022, 6, 68. [Google Scholar] [CrossRef]

- Behzadnasab, M.; Yousefi, A.A.; Ebrahimibagha, D.; Nasiri, F. Effects of Processing Conditions on Mechanical Properties of PLA Printed Parts. Rapid Prototyp. J. 2019, 26, 381–389. [Google Scholar] [CrossRef]

- Torres, J.; Cotelo, J.; Karl, J.; Gordon, A.P. Mechanical Property Optimization of FDM PLA in Shear with Multiple Objectives. JOM 2015, 67, 1183–1193. [Google Scholar] [CrossRef]

- Ivorra-Martinez, J.; Peydro, M.Á.; Gomez-Caturla, J.; Sanchez-Nacher, L.; Boronat, T.; Balart, R. The Effects of Processing Parameters on Mechanical Properties of 3D-Printed Polyhydroxyalkanoates Parts. Virtual Phys. Prototyp. 2023, 18, e2164734. [Google Scholar] [CrossRef]

- Chan, C.M.; Vandi, L.-J.; Pratt, S.; Halley, P.; Ma, Y.; Chen, G.-Q.; Richardson, D.; Werker, A.; Laycock, B. Understanding the Effect of Copolymer Content on the Processability and Mechanical Properties of Polyhydroxyalkanoate (PHA)/Wood Composites. Compos. Part Appl. Sci. Manuf. 2019, 124, 105437. [Google Scholar] [CrossRef]

- Tian, J.; Zhang, R.; Wu, Y.; Xue, P. Additive Manufacturing of Wood Flour/Polyhydroxyalkanoates (PHA) Fully Bio-Based Composites Based on Micro-Screw Extrusion System. Mater. Des. 2021, 199, 109418. [Google Scholar] [CrossRef]

- Wachirahuttapong, S.; Thongpin, C.; Sombatsompop, N. Effect of PCL and Compatibility Contents on the Morphology, Crystallization and Mechanical Properties of PLA/PCL Blends. Energy Procedia 2016, 89, 198–206. [Google Scholar] [CrossRef]

- Ostafinska, A.; Fortelny, I.; Nevoralova, M.; Hodan, J.; Kredatusova, J.; Slouf, M. Synergistic Effects in Mechanical Properties of PLA/PCL Blends with Optimized Composition, Processing, and Morphology. RSC Adv. 2015, 5, 98971–98982. [Google Scholar] [CrossRef]

- Luna, C.B.B.; Siqueira, D.D.; Ferreira, E.D.S.B.; Araújo, E.M.; Wellen, R.M.R. Effect of Injection Parameters on the Thermal, Mechanical and Thermomechanical Properties of Polycaprolactone (PCL). J. Elastomers Plast. 2021, 53, 1045–1062. [Google Scholar] [CrossRef]

- Cai, Z.; Senalik, C.A.; Ross, R.J. Mechanical Properties of Wood-Based Composite Materials. In Wood Handbook; FPL-GTR: Madison, WI, USA, 2010. [Google Scholar]

- Pitt, K.; Lopez-Botello, O.; Lafferty, A.D.; Todd, I.; Mumtaz, K. Investigation into the Material Properties of Wooden Composite Structures with In-Situ Fibre Reinforcement Using Additive Manufacturing. Compos. Sci. Technol. 2017, 138, 32–39. [Google Scholar] [CrossRef]

- Jain, A.; Austern, G.; Barath, S. Assessing Thermal-Mechanical Properties of Wood Powder Cellulose-Based Composites for 3D-Printed Architectural Components. Archit. Struct. Constr. 2025, 5, 28. [Google Scholar] [CrossRef]

- Van De Voorde, B.; Katalagarianakis, A.; Huysman, S.; Toncheva, A.; Raquez, J.-M.; Duretek, I.; Holzer, C.; Cardon, L.; Bernaerts, K.V.; Van Hemelrijck, D.; et al. Effect of Extrusion and Fused Filament Fabrication Processing Parameters of Recycled Poly(Ethylene Terephthalate) on the Crystallinity and Mechanical Properties. Addit. Manuf. 2022, 50, 102518. [Google Scholar] [CrossRef]

- Mishra, V.; Ror, C.K.; Negi, S.; Veeman, D. Recycling PET Waste into Functional 3D Printing Material: Effect of Printing Temperature on Physio-Mechanical Properties of PET Parts. J. Mater. Eng. Perform. 2025, 1–13. [Google Scholar] [CrossRef]

- Landolfi, L.; Detry, A.L.H.S.; Cozzolino, E.; Tammaro, D.; Squillace, A. Energy-Saving Approach for Mechanical Properties Enhancement of Recycled PET Additively Manufactured by MEX. Sustain. Mater. Technol. 2024, 41, e01038. [Google Scholar] [CrossRef]

- Al Rashid, A.; Koç, M. Additive Manufacturing for Sustainability and Circular Economy: Needs, Challenges, and Opportunities for 3D Printing of Recycled Polymeric Waste. Mater. Today Sustain. 2023, 24, 100529. [Google Scholar] [CrossRef]

- Cruz Sanchez, F.A.; Boudaoud, H.; Camargo, M.; Pearce, J.M. Plastic Recycling in Additive Manufacturing: A Systematic Literature Review and Opportunities for the Circular Economy. J. Clean. Prod. 2020, 264, 121602. [Google Scholar] [CrossRef]

- Fidan, I.; Naikwadi, V.; Alkunte, S.; Mishra, R.; Tantawi, K. Energy Efficiency in Additive Manufacturing: Condensed Review. Technologies 2024, 12, 21. [Google Scholar] [CrossRef]

- Peng, T.; Sun, W. Energy Modelling for FDM 3D Printing from a Life Cycle Perspective. Int. J. Manuf. Res. 2017, 12, 83. [Google Scholar] [CrossRef]

- Husár, J.; Kaščak, J. Monitoring the Energy Consumption of FDM Device Based on the Variation of Operating Parameters: A Study. In EAI/Springer Innovations in Communication and Computing; Springer International Publishing: Cham, Switzerland, 2022; pp. 237–258. ISBN 978-3-030-90461-6. [Google Scholar]

- Saadi, M.A.S.R.; Maguire, A.; Pottackal, N.T.; Thakur, M.S.H.; Ikram, M.M.d.; Hart, A.J.; Ajayan, P.M.; Rahman, M.M. Direct Ink Writing: A 3D Printing Technology for Diverse Materials. Adv. Mater. 2022, 34, e2108855. [Google Scholar] [CrossRef]

- Gutierrez-Osorio, A.H.; Ruiz-Huerta, L.; Caballero-Ruiz, A.; Siller, H.R.; Borja, V. Energy Consumption Analysis for Additive Manufacturing Processes. Int. J. Adv. Manuf. Technol. 2019, 105, 1735–1743. [Google Scholar] [CrossRef]

- Samudrala, M.; Mujeeb, S.; Lanjewar, B.A.; Chippagiri, R.; Kamath, M.; Ralegaonkar, R.V. 3D-Printable Concrete for Energy-Efficient Buildings. Energies 2023, 16, 4234. [Google Scholar] [CrossRef]

- He, Y.; Zhang, Y.; Zhang, C.; Zhou, H. Energy-Saving Potential of 3D Printed Concrete Building with Integrated Living Wall. Energy Build. 2020, 222, 110110. [Google Scholar] [CrossRef]

- Yadav, R.; Zhang, W.; Kaiwartya, O.; Singh, P.R.; Elgendy, I.A.; Tian, Y.-C. Adaptive Energy-Aware Algorithms for Minimizing Energy Consumption and SLA Violation in Cloud Computing. IEEE Access 2018, 6, 55923–55936. [Google Scholar] [CrossRef]

- Yang, Y.; Li, L.; Pan, Y.; Sun, Z. Energy Consumption Modeling of Stereolithography-Based Additive Manufacturing Toward Environmental Sustainability. J. Ind. Ecol. 2017, 21, S168–S178. [Google Scholar] [CrossRef]

- Wiese, M.; Kwauka, A.; Thiede, S.; Herrmann, C. Economic Assessment for Additive Manufacturing of Automotive End-Use Parts through Digital Light Processing (DLP). CIRP J. Manuf. Sci. Technol. 2021, 35, 268–280. [Google Scholar] [CrossRef]

- Wu, L.; Zhao, L.; Jian, M.; Mao, Y.; Yu, M.; Guo, X. EHMP-DLP: Multi-Projector DLP with Energy Homogenization for Large-Size 3D Printing. Rapid Prototyp. J. 2018, 24, 1500–1510. [Google Scholar] [CrossRef]

- Christ, F.; Schaumann, G.; Schott, N.; Vetter, J.; Blaeser, A.; Roth, M. Two-Photon Polymerization for Inertial Fusion Energy Target Fabrication. Appl. Phys. A 2025, 131, 543. [Google Scholar] [CrossRef]

- Shan, Y.; Hua, J.; Mao, H. 3D Printing of Optical Lenses Assisted by Precision Spin Coating. Adv. Funct. Mater. 2024, 34, 2407165. [Google Scholar] [CrossRef]

- Huang, S.H.; Liu, P.; Mokasdar, A.; Hou, L. Additive Manufacturing and Its Societal Impact: A Literature Review. Int. J. Adv. Manuf. Technol. 2013, 67, 1191–1203. [Google Scholar] [CrossRef]

- Ma, F.; Zhang, H.; Hon, K.K.B.; Gong, Q. An Optimization Approach of Selective Laser Sintering Considering Energy Consumption and Material Cost. J. Clean. Prod. 2018, 199, 529–537. [Google Scholar] [CrossRef]

- Wang, Q.; Gao, M.; Li, Q.; Liu, C.; Li, L.; Li, X.; Liu, Z. A Review on Energy Consumption and Efficiency of Selective Laser Melting Considering Support: Advances and Prospects. Int. J. Precis. Eng. Manuf.-Green Technol. 2024, 11, 259–276. [Google Scholar] [CrossRef]

- Lunetto, V.; Galati, M.; Settineri, L.; Iuliano, L. Unit Process Energy Consumption Analysis and Models for Electron Beam Melting (EBM): Effects of Process and Part Designs. Addit. Manuf. 2020, 33, 101115. [Google Scholar] [CrossRef]

- Liu, Z.Y.; Li, C.; Fang, X.Y.; Guo, Y.B. Energy Consumption in Additive Manufacturing of Metal Parts. Procedia Manuf. 2018, 26, 834–845. [Google Scholar] [CrossRef]

- Kumar, D.; Palanisamy, S.; Krishnan, K.; Alam, M.M. Life Cycle Assessment of Cold Spray Additive Manufacturing and Conventional Machining of Aluminum Alloy Flange. Metals 2023, 13, 1684. [Google Scholar] [CrossRef]

- Rehman, M.; Yanen, W.; Mushtaq, R.T.; Ishfaq, K.; Zahoor, S.; Ahmed, A.; Kumar, M.S.; Gueyee, T.; Rahman, M.M.; Sultana, J. Additive Manufacturing for Biomedical Applications: A Review on Classification, Energy Consumption, and Its Appreciable Role since COVID-19 Pandemic. Prog. Addit. Manuf. 2023, 8, 1007–1041. [Google Scholar] [CrossRef] [PubMed]

- Hehr, A.; Dapino, M.J. Dynamics of Ultrasonic Additive Manufacturing. Ultrasonics 2017, 73, 49–66. [Google Scholar] [CrossRef] [PubMed]

- Jackson, M.A.; Van Asten, A.; Morrow, J.D.; Min, S.; Pfefferkorn, F.E. A Comparison of Energy Consumption in Wire-Based and Powder-Based Additive-Subtractive Manufacturing. Procedia Manuf. 2016, 5, 989–1005. [Google Scholar] [CrossRef]

- Punia, U.; Dhull, S.; Habeeb, A.; Antil, E.; Dahiya, D.; Gupta, D.; Ahlawat, A. Adopting Additive Manufacturing: Spotlight on Sustainability and Material Utilization. Green Mater. 2025, 1–11. [Google Scholar] [CrossRef]

- Yang, J.; Xie, H.; Yu, G.; Liu, M. Achieving a Just–in–Time Supply Chain: The Role of Supply Chain Intelligence. Int. J. Prod. Econ. 2021, 231, 107878. [Google Scholar] [CrossRef]

- Jiang, J.; Xu, X.; Stringer, J. Support Structures for Additive Manufacturing: A Review. J. Manuf. Mater. Process. 2018, 2, 64. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, Y.; Tan, S.; Ding, L.; Bernard, A. Support Point Determination for Support Structure Design in Additive Manufacturing. Addit. Manuf. 2021, 47, 102341. [Google Scholar] [CrossRef]

- Lestari, A.D.A. Farida Pulansari Environmental Impact Analysis on Furniture Industry by Implementing Life Cycle Assessment (LCA) Method. Adv. Sustain. Sci. Eng. Technol. 2024, 7, 0250106. [Google Scholar] [CrossRef]

- Despeisse, M.; Ford, S. The Role of Additive Manufacturing in Improving Resource Efficiency and Sustainability. In IFIP Advances in Information and Communication Technology; Springer International Publishing: Cham, Switzerland, 2015; pp. 129–136. ISBN 978-3-319-22758-0. [Google Scholar]

- Monteiro, H.; Carmona-Aparicio, G.; Lei, I.; Despeisse, M. Energy and Material Efficiency Strategies Enabled by Metal Additive Manufacturing—A Review for the Aeronautic and Aerospace Sectors. Energy Rep. 2022, 8, 298–305. [Google Scholar] [CrossRef]

- ISO 14001:2015; Introduction to ISO 14001. International Organization for Standardization: Geneva, Switzerland, 2015.

- ISO 50001:2018; Energy Management Systems―Requirements with Guidance for Use. ISO: Geneva, Switzerland, 2018.

- ISO 14006; 2020; Environmental Management Systems—Guidelines for Incorporating Ecodesign. International Organization for Standardization ISO: Geneva, Switzerland, 2020.

- Ojiako, U.; Bashir, H.; Almansoori, H.H.B.; AlRaeesi, E.J.H.; Al Zarooni, H.A. Using ISO 14001 Certification to Signal Sustainability Equivalence: An Examination of the Critical Success Factors. Prod. Plan. Control 2025, 36, 1287–1314. [Google Scholar] [CrossRef]

- Shirazi, S.F.S.; Gharehkhani, S.; Mehrali, M.; Yarmand, H.; Metselaar, H.S.C.; Adib Kadri, N.; Osman, N.A.A. A Review on Powder-Based Additive Manufacturing for Tissue Engineering: Selective Laser Sintering and Inkjet 3D Printing. Sci. Technol. Adv. Mater. 2015, 16, 033502. [Google Scholar] [CrossRef] [PubMed]

- Pagac, M.; Hajnys, J.; Ma, Q.-P.; Jancar, L.; Jansa, J.; Stefek, P.; Mesicek, J. A Review of Vat Photopolymerization Technology: Materials, Applications, Challenges, and Future Trends of 3D Printing. Polymers 2021, 13, 598. [Google Scholar] [CrossRef]

- Stavropoulos, P.; Foteinopoulos, P.; Stavridis, J.; Bikas, H. Increasing the Industrial Uptake of Additive Manufacturing Processes: A Training Framework. Adv. Ind. Manuf. Eng. 2023, 6, 100110. [Google Scholar] [CrossRef]

- Schniederjans, D.G.; Khalajhedayati, M. Competitive Sustainability and Stakeholder Engagement: Exploring Awareness, Motivation, and Capability. Bus. Strategy Environ. 2021, 30, 808–824. [Google Scholar] [CrossRef]

- Velu, R.; Tulasi, R.; Ramachandran, M.K. Environmental Impact, Challenges for Industrial Applications and Future Perspectives of Additive Manufacturing. In Nanotechnology-Based Additive Manufacturing; Wiley: Hoboken, NJ, USA, 2023; pp. 691–709. ISBN 978-3-527-34984-5. [Google Scholar]

- Nassar, M.M.A.; Alzebdeh, K.I.; Pervez, T.; Al-Hinai, N.; Munam, A. Progress and Challenges in Sustainability, Compatibility, and Production of Eco-composites: A State-of-art Review. J. Appl. Polym. Sci. 2021, 138, 51284. [Google Scholar] [CrossRef]

- Ilyas, R.A.; Sapuan, S.M.; Harussani, M.M.; Hakimi, M.Y.A.Y.; Haziq, M.Z.M.; Atikah, M.S.N.; Asyraf, M.R.M.; Ishak, M.R.; Razman, M.R.; Nurazzi, N.M.; et al. Polylactic Acid (PLA) Biocomposite: Processing, Additive Manufacturing and Advanced Applications. Polymers 2021, 13, 1326. [Google Scholar] [CrossRef]

- Mondal, S.; Shubhra, G. Economic and Environmental Benefits of Sustainable Materials Adoption in Automotive Manufacturing. J. Process Manag. New Technol. 2024, 12, 65–89. [Google Scholar] [CrossRef]

- Manco, P.; Caterino, M.; Rinaldi, M.; Fera, M. Additive Manufacturing in Green Supply Chains: A Parametric Model for Life Cycle Assessment and Cost. Sustain. Prod. Consum. 2023, 36, 463–478. [Google Scholar] [CrossRef]

- Koren, Y.; Wang, W.; Gu, X. Value Creation through Design for Scalability of Reconfigurable Manufacturing Systems. Int. J. Prod. Res. 2017, 55, 1227–1242. [Google Scholar] [CrossRef]

- Alsaadi, N. Prioritization of Challenges for the Effectuation of Sustainable Additive Manufacturing: A Case Study Approach. Processes 2021, 9, 2250. [Google Scholar] [CrossRef]

- Bi, S.; Zhang, J.; Zhang, G. Scalable Deep-Learning-Accelerated Topology Optimization for Additively Manufactured Materials. arXiv 2020, arXiv:2011.14177. [Google Scholar]

- Zohdi, N.; Yang, R. Material Anisotropy in Additively Manufactured Polymers and Polymer Composites: A Review. Polymers 2021, 13, 3368. [Google Scholar] [CrossRef]

- Chen, J.; Liu, X.; Tian, Y.; Zhu, W.; Yan, C.; Shi, Y.; Kong, L.B.; Qi, H.J.; Zhou, K. 3D-Printed Anisotropic Polymer Materials for Functional Applications. Adv. Mater. 2022, 34, 2102877. [Google Scholar] [CrossRef] [PubMed]

- Yadollahi, A.; Shamsaei, N. Additive Manufacturing of Fatigue Resistant Materials: Challenges and Opportunities. Int. J. Fatigue 2017, 98, 14–31. [Google Scholar] [CrossRef]

- Babu, S.S.; Love, L.; Dehoff, R.; Peter, W.; Watkins, T.R.; Pannala, S. Additive Manufacturing of Materials: Opportunities and Challenges. MRS Bull. 2015, 40, 1154–1161. [Google Scholar] [CrossRef]

- Al-Maharma, A.Y.; Patil, S.P.; Markert, B. Effects of Porosity on the Mechanical Properties of Additively Manufactured Components: A Critical Review. Mater. Res. Express 2020, 7, 122001. [Google Scholar] [CrossRef]

- Sun, X.; Mazur, M.; Cheng, C.-T. A Review of Void Reduction Strategies in Material Extrusion-Based Additive Manufacturing. Addit. Manuf. 2023, 67, 103463. [Google Scholar] [CrossRef]

- Sohrabi, N.; Jhabvala, J.; Logé, R.E. Additive Manufacturing of Bulk Metallic Glasses—Process, Challenges and Properties: A Review. Metals 2021, 11, 1279. [Google Scholar] [CrossRef]

- Liu, W.; Liu, X.; Liu, Y.; Wang, J.; Evans, S.; Yang, M. Unpacking Additive Manufacturing Challenges and Opportunities in Moving towards Sustainability: An Exploratory Study. Sustainability 2023, 15, 3827. [Google Scholar] [CrossRef]

- Torricelli, F.; Alessandri, I.; Macchia, E.; Vassalini, I.; Maddaloni, M.; Torsi, L. Green Materials and Technologies for Sustainable Organic Transistors. Adv. Mater. Technol. 2022, 7, 2100445. [Google Scholar] [CrossRef]

- Jiang, B.; Jiao, H.; Guo, X.; Chen, G.; Guo, J.; Wu, W.; Jin, Y.; Cao, G.; Liang, Z. Lignin-Based Materials for Additive Manufacturing: Chemistry, Processing, Structures, Properties, and Applications. Adv. Sci. 2023, 10, e2206055. [Google Scholar] [CrossRef]

- Kaniuk, Ł.; Stachewicz, U. Development and Advantages of Biodegradable PHA Polymers Based on Electrospun PHBV Fibers for Tissue Engineering and Other Biomedical Applications. ACS Biomater. Sci. Eng. 2021, 7, 5339–5362. [Google Scholar] [CrossRef]

- Younes, S.; Arnold, N.; Paper, M.; Keil, L.; Awad, D.; Brueck, T. Algal-Based Biopolymers. In Value-Added Products from Algae; Springer International Publishing: Cham, Switzerland, 2024; pp. 403–459. ISBN 978-3-031-42025-2. [Google Scholar]

- Tekinalp, H.L.; Lu, Y.; Kunc, V.; Duty, C.E.; Love, L.J.; Peter, W.H.; Ozcan, S. Bio-Reinforced Composite Development for Additive Manufacturing: Nanocellulose-PLA.; Oak Ridge National Laboratory (ORNL): Oak Ridge, TN, USA, 2016.

- Zaaba, N.F.; Jaafar, M.; Ismail, H. Tensile and Morphological Properties of Nanocrystalline Cellulose and Nanofibrillated Cellulose Reinforced PLA Bionanocomposites: A Review. Polym. Eng. Sci. 2021, 61, 22–38. [Google Scholar] [CrossRef]

- Deb, D.; Jafferson, J.M. Natural Fibers Reinforced FDM 3D Printing Filaments. Mater. Today Proc. 2021, 46, 1308–1318. [Google Scholar] [CrossRef]

- Sabbatini, B.; Cambriani, A.; Cespi, M.; Palmieri, G.F.; Perinelli, D.R.; Bonacucina, G. An Overview of Natural Polymers as Reinforcing Agents for 3D Printing. ChemEngineering 2021, 5, 78. [Google Scholar] [CrossRef]

- Yang, P.; Condrich, A.; Lu, L.; Scranton, S.; Hebner, C.; Sheykhhasan, M.; Ali, M.A. Genetic Engineering in Bacteria, Fungi, and Oomycetes, Taking Advantage of CRISPR. DNA 2024, 4, 427–454. [Google Scholar] [CrossRef]

- Chaturvedi, R.; Darokar, H.; Patil, P.P.; Kumar, M.; Sangeeta, K.; Aravinda, K.; Kadhim, A.A. Maximizing towards the Sustainability: Integrating Materials, Energy, and Resource Efficiency in Revolutionizing Manufacturing Industry. E3S Web Conf. 2023, 453, 01036. [Google Scholar] [CrossRef]

- Pimenov, D.Y.; Mia, M.; Gupta, M.K.; Machado, Á.R.; Pintaude, G.; Unune, D.R.; Khanna, N.; Khan, A.M.; Tomaz, Í.; Wojciechowski, S.; et al. Resource Saving by Optimization and Machining Environments for Sustainable Manufacturing: A Review and Future Prospects. Renew. Sustain. Energy Rev. 2022, 166, 112660. [Google Scholar] [CrossRef]

- Siddique, I.M.; Das, S. Innovations in Eco-Friendly Design and Production: Tactics, Obstacles, and Prospects Ahead. Chem. Res. J. 2024, 9, 32–39. [Google Scholar] [CrossRef]

- Gao, C.; Wolff, S.; Wang, S. Eco-Friendly Additive Manufacturing of Metals: Energy Efficiency and Life Cycle Analysis. J. Manuf. Syst. 2021, 60, 459–472. [Google Scholar] [CrossRef]

| AM Category | Technology | Advantages | Limitations | Materials Used | Applications | References |

|---|---|---|---|---|---|---|

| Material Extrusion | FDM | Low cost, wide range of materials, simple and accessible technology. | Visible layer lines, lower resolution, anisotropic part strength. | Thermoplastic filaments: PLA, ABS, PETG, nylon, PC, ASA. | Rapid prototyping, manufacturing tooling, medical models, custom prosthetics. | [19,117] |

| DIW | Extremely versatile material range, can print functional materials. | Slower process, resolution limited by nozzle size, requires post-processing. | Viscous inks: ceramic slurries, polymer/elastomer inks, hydrogels, composite inks. | Bioprinting, flexible electronics, soft robotics, microfluidics, aerospace components. | [22,23,118] | |

| Concrete 3D Printing | Ability to build large-scale structures quickly, reduced labor costs, design freedom for complex shapes. | Rough surface finish, complex material science, structural limitations without reinforcement. | Custom mortar (cement, sand), chemical additives, reinforcing fibers (glass, steel, polymer). | Construction (housing, shelters), infrastructure (bridges), custom urban furniture. | [25,26,119] | |

| Vat Photopolymerization | SLA | Excellent surface finish, high detail and accuracy, isotropic properties. | Materials can be brittle and expensive, messy resin handling, requires post-curing. | UV-curable liquid resins (monomers, oligomers, photoinitiators). | Soft robotics, sensors, medical implants, microfluidic devices, high-detail prototypes. | [29,30,120] |

| DLP | Faster than SLA, high resolution. | Similar to SLA (brittle materials, post-curing), resolution fixed by projector pixels. | Photopolymers (acrylates, epoxies), specialty and hybrid resins, metal-printing resins. | Smart/biomimetic devices, sensors, 4D printing (shape-memory polymers). | [33,121] | |

| 2PP | Extremely high, submicron resolution for creating nano-scale features. | Very slow process, extremely small build volume, very expensive equipment. | Laser-activated resins (acrylate, epoxy, PDMS-like). | Micro-robotics, micro-lenses, biosensors, microneedles, photonic crystals. | [35,122] | |

| 3SP | Very high throughput and speed for a resin-based process, reliable for production. | Proprietary technology and materials, less common than SLA/DLP. | Proprietary UV-curable photopolymer resins. | High-throughput production, medical devices, master patterns for casting. | [39,123] | |

| CLIP | Exceptionally fast printing speed, excellent material properties due to dual-cure process. | Proprietary technology, expensive materials and machines, limited build volume. | Dual-cure resins (rigid/flexible/elastomeric polyurethanes, silicones). | Mass customization (shoe midsoles), end-use automotive parts, medical/dental implants. | [43,44] | |

| SGC | No need for support structures (used wax), good dimensional stability. | Obsolete technology; extremely complex, large, wasteful, and expensive. | UV-curable photopolymer resin, low-melting-point wax, and masking consumables. | Rapid prototyping of large concept models and master patterns. | [47,124] | |

| DPP | Uses safer, lower-intensity visible light; low-cost hardware. | Slower curing times than UV-based methods; more limited material selection. | Proprietary photopolymers that cure with visible light (firm, tough, flexible, castable). | Quick prototyping, dental models, jewelry master patterns, hobbyist/educational models. | [50] | |

| Powder Bed Fusion | SLS | No support structures needed, excellent for complex geometries, produces strong, functional parts. | Rough surface finish, requires significant powder removal post-processing, higher cost. | Polymer powders (PCL, PEEK), bioactive materials, metals, and composites. | Tissue engineering, medical/dental implants, custom healthcare equipment. | [48] |

| SLM | Creates fully dense, high-strength metal parts with high accuracy. | Very expensive, requires support structures, risk of thermal stress/warping, powder handling hazards. | Metal powders: titanium, Inconel, steels, aluminum, cobalt–chrome, precious metals. | Aerospace parts, medical/dental implants, high-performance industrial components. | [56,57] | |

| CSAM | Low-temperature solid-state process, can bond dissimilar materials, great for repair and coatings. | Lower resolution, parts have some porosity, geometry is limited to line-of-sight spraying. | Ductile metal powders/alloys (aluminum, copper, steel, titanium, Inconel). | Repair/restoration of industrial parts (aerospace), manufacturing large components. | [67,125] | |

| Binder Jetting | Fast, scalable, can print in full color, no support needed, lower cost for metal parts. | Green parts are fragile, requires extensive post-processing, which causes shrinkage. | Powder and binder system (metal, ceramic, sand, or gypsum powders). | Serial production (metal), technical components (ceramic), full-color models, sand casting molds. | [70,71] | |

| Material Jetting | MJM | Excellent accuracy, smooth surface finish, can print multi-material and multi-color parts. | Materials can be expensive and have limited mechanical/thermal properties; requires support removal. | UV-curable photopolymer builds resins and a separate wax-based or gel-like support material. | High-fidelity prototypes, medical/dental models, jewelry patterns, manufacturing jigs. | [79,80] |

| DoD Jetting | High precision, extremely broad material compatibility if viscosity is correct. | Can be slow, potential for nozzle clogging, requires careful fluid property control. | Inks, photopolymers, wax, conductive inks, ceramic slurries, and bio-inks. | Industrial graphics, high-fidelity prototypes, printed electronics, bioprinting. | [85,126] | |

| NPJ | High precision and detail with robust end-use materials (metals/ceramics). | Limited to materials available in nanoparticle suspension, relatively new technology. | Suspension of metal (steel, copper) or ceramic (zirconia, alumina) nanoparticles in a liquid. | Small, complex parts for medical/dental (implants), aerospace/electronics (connectors). | [84,127] | |

| Sheet Lamination | UAM | Low-temperature, solid-state process; can bond dissimilar metals and embed electronics. | Limited to foils/tapes, cannot create certain internal geometries, residual stress can be an issue. | Thin metal foils/tapes (aluminum, copper, nickel) and embedded components. | “Smart structures” with embedded sensors, heat exchangers, custom medical implants. | [90,91] |

| LOM | Fast and cheap for large parts, creates stable, wood-like objects. | Tedious manual post-processing, poor material properties (porous, weak). | Sheet materials with adhesive backing, primarily paper but also plastics, composites, foils. | (Obsolete) rapid prototyping of large conceptual models and patterns for casting. | [92,93] | |

| SDL | Low cost, safe, can produce full-color, realistic models directly from the machine. | Layer lines are very visible; parts are brittle and susceptible to moisture without sealing. | Standard office paper, water-based liquid glue, and CMYK ink. | Full-color concept models, architectural/GIS maps, educational visual aids. | [128,129] | |

| PSL | Creates large, durable, solid plastic parts quickly and cost-effectively. | Stair-stepping effect is prominent; resolution is limited by sheet thickness. | Thermoplastic sheets (PVC, PS, ABS) that self-bond when heated and pressed. | Large, durable prototypes, ergonomic mock-ups, and master patterns for manufacturing. | [86,98] | |

| CAM-LEM | Can create complex, multi-material, and functionally graded ceramic/metal parts. | Requires burnout and sintering post-processing, which can cause shrinkage and distortion. | “Green tapes” of ceramics (alumina, zirconia), metals (steels), or composites. | High-value ceramic/multi-material parts for aerospace, energy, electronics, and medicine. | [100,101] | |

| CBAM | Produces very strong, stiff, and lightweight parts by embedding continuous fibers. | Fiber placement is limited by geometry, higher cost than standard FDM. | Thermoplastic matrix (nylon) combined with continuous reinforcing fibers (carbon, fiberglass, Kevlar). | Strong functional parts: jigs, fixtures, robotic tooling, automotive/aerospace components. | [104] | |

| Directed Energy Deposition | WAAM | Very high deposition rate, ideal for building large metal parts, uses low-cost welding wire. | Low resolution and poor surface finish, requires extensive finish machining. | Standard metal welding wire: steels, titanium, Inconel, aluminum, bronze alloys. | Large structural parts for aerospace (ribs), maritime (propellers), oil and gas (flanges). | [107,108] |

| Hybrid Manufacturing | Combines the freedom of additive with the precision of subtractive in one machine; highly efficient. | Extremely high capital cost, complex programming and operation. | High-performance metals in powder or wire form (steels, superalloys, titanium alloys). | Repair of high-value parts, advanced tooling, custom medical implants. | [111,112] | |

| EBM | Excellent for reactive metals like titanium, produces parts with low residual stress in a vacuum. | Requires vacuum environment, rougher surface finish than SLM, limited material selection. | High-performance, conductive metals: titanium, cobalt–chrome, Inconel, copper. | Medical implants, lightweight aerospace/defense components. | [115,116] |

| Material | Source and Type | AM Process | Mechanical Properties | References |

|---|---|---|---|---|

| PLA | Corn starch, sugar cane (bio-based polyester) | FDM, SLA | Moderate strength, high stiffness, brittle. | [98,134,135] |

| PHA | Bacterial fermentation (bio-polyester) | FDM | Like polypropylene, more flexible than PLA. | [136,137,138] |

| PCL | Petroleum-based (biodegradable polyester) | FDM | Low melting point, highly flexible, tough. | [139,140,141] |

| Wood Composites | PLA/PHA mixed with wood, cork, coffee, hemp fibers. | FDM | Lower tensile strength, aesthetic finish, abrasive to nozzles. | [142,143,144] |

| Recycled PET (rPET) | Post-consumer plastic bottles. | FDM | Strong, durable, high thermal resistance. | [145,146,147] |

| AM Category | Specific Process | Energy Source | References |

|---|---|---|---|

| Material Extrusion | FDM | Nozzle and Bed | [151,152] |

| DIW | Mechanical Dispenser | [153,154] | |

| Concrete 3D | Pump and Motor System | [155,156] | |

| Vat Photopolymerization | SLA | High-Precision UV Laser | [157,158] |

| DLP | UV Projector | [159,160] | |

| 2PP | Focused Femtosecond Laser | [161] | |

| 3SP | Low-Power Laser and High-Power UV Flash Lamp | [162] | |

| CLIP | UV Projector and Oxygen-Permeable Membrane | [42] | |

| SGC | High-Power UV Lamp, Wax Heater, Milling Spindle | [163] | |

| DPP | LED Array and Screen | [121] | |

| Powder Bed Fusion | SLS | CO2 Laser, Infrared Heaters | [164] |

| SLM | High-Power Fiber Laser | [165] | |

| EBM | Electron Beam | [166] | |

| Binder Jetting | Piezoelectric Inkjet Head | [167] | |

| CSAM | Heated, High-Pressure Gas | [168] | |

| Material Jetting | MJM | Piezoelectric Printhead | [169] |

| DoD | Piezoelectric Printhead | [81] | |

| NPJ | Inkjet Head, High-Temperature Chamber | [85] | |

| Sheet Lamination | UAM | Ultrasonic Welder, CNC Spindle | [170] |

| LOM | CO2 Laser, Heated Roller | [167] | |

| SDL | Inkjet Head, Heated Roller | [158] | |

| PSL | Thermal Cutter, Heated Plate | [154] | |

| CAM-LEM | Laser Cutter | [99] | |

| CBAM | Nozzle | [102] | |

| Directed Energy Deposition | WAAM | Electric Welding Arc | [171] |

| Hybrid | WAAM Source and CNC Spindle | [109] |

| Material Category | Key Challenges | Material-Level Solutions | Process-Level Solutions | References |

|---|---|---|---|---|

| Biopolymers (PLA, PHA, etc.) | Narrow processing window Thermal degradation Poor mechanical properties (brittleness) | Plasticizers: Increase flexibility and lower processing temp. Impact modifiers: Enhance toughness Nucleating agents: Control crystallization for better strength. | Precise temperature control systems Optimized print speed and cooling Use of enclosed, heated build chambers. | [48,82] |

| Recycled Polymers (rPET, rABS) | Batch-to-batch inconsistency Reduced melt viscosity Presence of contaminants Hydrolytic degradation (moisture) | Drying: Thoroughly dry feedstock to prevent hydrolysis Blending: Mix batches to homogenize properties Chain extenders: “Repair” polymer chains to restore melt strength Filtration: Remove solid contaminants during filament extrusion. | Advanced sorting and cleaning of recycle In-line rheology sensors for real-time process adjustment Wider nozzle diameters to reduce clogging risk. | [146,189] |

| Natural Fiber Composites | Nozzle clogging due to fiber agglomeration Poor fiber–matrix interfacial adhesion Abrasive wear on hardware Moisture absorption by fibers | Coupling agents: Promote bonding between fibers and polymer matrix Fiber surface treatment: Modify fiber surfaces for better compatibility Optimized compounding: Ensure uniform fiber dispersion in the filament. | Use of hardened steel or ruby-tipped nozzles Larger nozzle diameters (>0.5 mm) Reduced retraction settings to prevent clogging Slower print speeds to reduce shear stress. | [7,190] |

| Parameter | Traditional Mass Production | Lab-Scale Green AM | Industrial-Scale Green AM Challenge |

|---|---|---|---|

| Throughput | Very high (e.g., 100–1000 s of parts/hour) | Very low (e.g., <1 part/h) | Must increase deposition rates and minimize failures to approach mass production speeds. |

| Material Consistency | High (standardized, certified material grades) | Low to medium (highly variable recycled or novel bio-feedstocks) | Requires robust supply chains and feedstock qualification standards. |

| Process Control | Highly automated and stable; set-and-forget process. | Manual, iterative tuning for each new material batch | Demands real-time, in situ monitoring and automated feedback loops to manage material inconsistency. |

| Post-Processing | Minimal and often automated (e.g., robotic part removal) | Manual, labor-intensive, and time-consuming | Needs significant investment in robotic systems for support removal, finishing, and handling to prevent bottlenecks. |

| Supply Chain | Mature, global, and reliable | Localized and often unstable | Must establish resilient, large-scale supply chains for certified recycled and biomaterials. |

| Cost Per Part | Very low | Very high | Must reduce costs through automation, speed, and material efficiency to become competitive. |

| Mechanical Challenge | Primary Cause | Material-Level Solutions | Process/Design/Post-Processing Solutions | References |

|---|---|---|---|---|

| Anisotropy (Weak Z-axis) | Poor interlayer thermal fusion. | Use polymers with better melt flow. Additives to lower melt viscosity. | Process: Increase nozzle temp, use heated chamber, reduce cooling fan speed. Design: Optimize part orientation to align layers with non-critical stress paths. | [195,196] |

| Low Strength and Stiffness | Inherently weaker polymer backbone. | Composites: Add carbon, glass, or natural fibers. Blending: Mix with higher-strength polymers. | Process: Optimize infill density and pattern. Design: Use topology optimization and internal lattices to create stiff, efficient geometries. | [197,198] |

| Porosity and Voids | - Imperfect material flow. - Moisture in filament. | Ensure uniform filament diameter. Use additives for stable melt rheology. | Process: Meticulously dry feedstock before printing. Post-Processing: Use infiltration with resins (e.g., epoxy) or surface sealing (vapor smoothing). | [199,200] |

| Low Thermal Resistance | Amorphous nature and low glass transition temp (Tg) of many biopolymers. | Blending: Mix with high-temp polymers (e.g., PC, ABS). Additives: Use nucleating agents to increase crystallinity. | Post-Processing: Anneal parts to increase crystallinity, which raises the Heat Deflection Temperature (HDT). | [201] |

| Cost Factor | Traditional Polymers | Sustainable Feedstocks |

|---|---|---|

| Upfront Material Cost | Low. Benefits from mature, high-volume petrochemical supply chains. | High. Driven by costs of collection, sorting, cleaning, and smaller production scale. |

| R&D and Formulation Cost | Minimal. Well-established, standardized grades. | High. Requires investment in additives and compounding to overcome degradation and ensure consistency. |

| Internal Waste Management | Cost. Scrap material is often a waste stream requiring disposal fees. | Opportunity. Scrap can be re-granulated and recycled in-house, turning waste into a resource. |

| Regulatory and Compliance Cost | Increasing. Facing growing pressure from plastic taxes, EPR schemes, and carbon pricing. | Lower/favorable. Aligned with emerging environmental regulations, potentially eligible for subsidies or tax breaks. |

| Brand and Market Perception | Neutral to negative. Increasing consumer awareness of plastic pollution can be a brand risk. | Positive. Offers a strong marketing narrative around sustainability, innovation, and circularity. |

| End-of-Life Liability | High. Contributes to landfill burden and environmental pollution, a long-term liability. | Low. Designed for circularity, reducing long-term environmental and financial liability. |

| Overall Justification | Based purely on low initial purchase price. | Based on a lifecycle cost, including waste reduction, brand value, and futureproofing. |

| Material Class | Examples | Key Advantages | Primary Challenges | References |

|---|---|---|---|---|

| Advanced Bio-Polymers | PHAs, lignin-based polymers | Biodegradability (PHA), valorization of waste (lignin), non-food feedstock. | Thermal instability, brittleness, high cost, complex processing. | [204,205] |

| Bio-Resins | Algae-derived oligomers | Fast-growing feedstock, CO2 sequestration, potential for high-resolution printing (SLA/DLP). | Lower mechanical properties than petrochemical resins, long-term stability. | [206] |

| Nano-Bio-Composites | Nanocellulose-reinforced PLA | Extremely high strength-to-weight ratio, significant property enhancement at low filler content. | Difficult to disperse uniformly, moisture sensitivity. | [207,208] |

| Agricultural Waste Composites | Rice husk, hemp fiber, or coffee ground fillers | Very low cost, negative carbon footprint (waste valorization), localized supply chains. | Inconsistent properties, poor fiber–matrix adhesion, moisture absorption. | [209,210] |

| Living Materials | Mycelium, engineered bacteria | Self-growing, self-healing potential, fully home-compostable, extremely low embodied energy. | Very slow growth rates, limited structural properties, process control and sterility. | [211] |

| Parameter | Key Challenges | Future Research and Development Directions |

|---|---|---|

| Material Performance | Anisotropy and weak interlayer bonding Lower thermal and mechanical properties Unknown long-term aging behavior | Development of self-healing and functional nanocomposites Computational models for predictive material aging and performance Advanced DfAM techniques to optimize geometry for weaker materials. |

| Circular Recycling | Contamination of recycled feedstocks Difficulty in separating multi-material parts Downcycling of materials during mechanical recycling | Establishing industry standards for design for recycling Scaling up chemical recycling for mixed polymer waste Implementing digital material passports for automated sorting |

| Energy Efficiency | High embodied energy in some feedstocks Inefficient thermal management in printers Energy-intensive post-processing steps | Creation of energy-aware slicing software and build processors Development of low-energy processing (e.g., LED curing, microwave sintering) Integration of AM systems with renewable energy and smart grids |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dipta, S.D.; Rahman, M.M.; Ansari, M.J.; Uddin, M.N. A Comprehensive Review of Sustainable and Green Additive Manufacturing: Technologies, Practices, and Future Directions. J. Manuf. Mater. Process. 2025, 9, 269. https://doi.org/10.3390/jmmp9080269

Dipta SD, Rahman MM, Ansari MJ, Uddin MN. A Comprehensive Review of Sustainable and Green Additive Manufacturing: Technologies, Practices, and Future Directions. Journal of Manufacturing and Materials Processing. 2025; 9(8):269. https://doi.org/10.3390/jmmp9080269

Chicago/Turabian StyleDipta, Sudip Dey, Md. Mahbubur Rahman, Md. Jonaet Ansari, and Md. Nizam Uddin. 2025. "A Comprehensive Review of Sustainable and Green Additive Manufacturing: Technologies, Practices, and Future Directions" Journal of Manufacturing and Materials Processing 9, no. 8: 269. https://doi.org/10.3390/jmmp9080269

APA StyleDipta, S. D., Rahman, M. M., Ansari, M. J., & Uddin, M. N. (2025). A Comprehensive Review of Sustainable and Green Additive Manufacturing: Technologies, Practices, and Future Directions. Journal of Manufacturing and Materials Processing, 9(8), 269. https://doi.org/10.3390/jmmp9080269