Direct Ink Writing and Characterization of ZrC-Based Ceramic Pellets for Potential Nuclear Applications

Abstract

1. Introduction

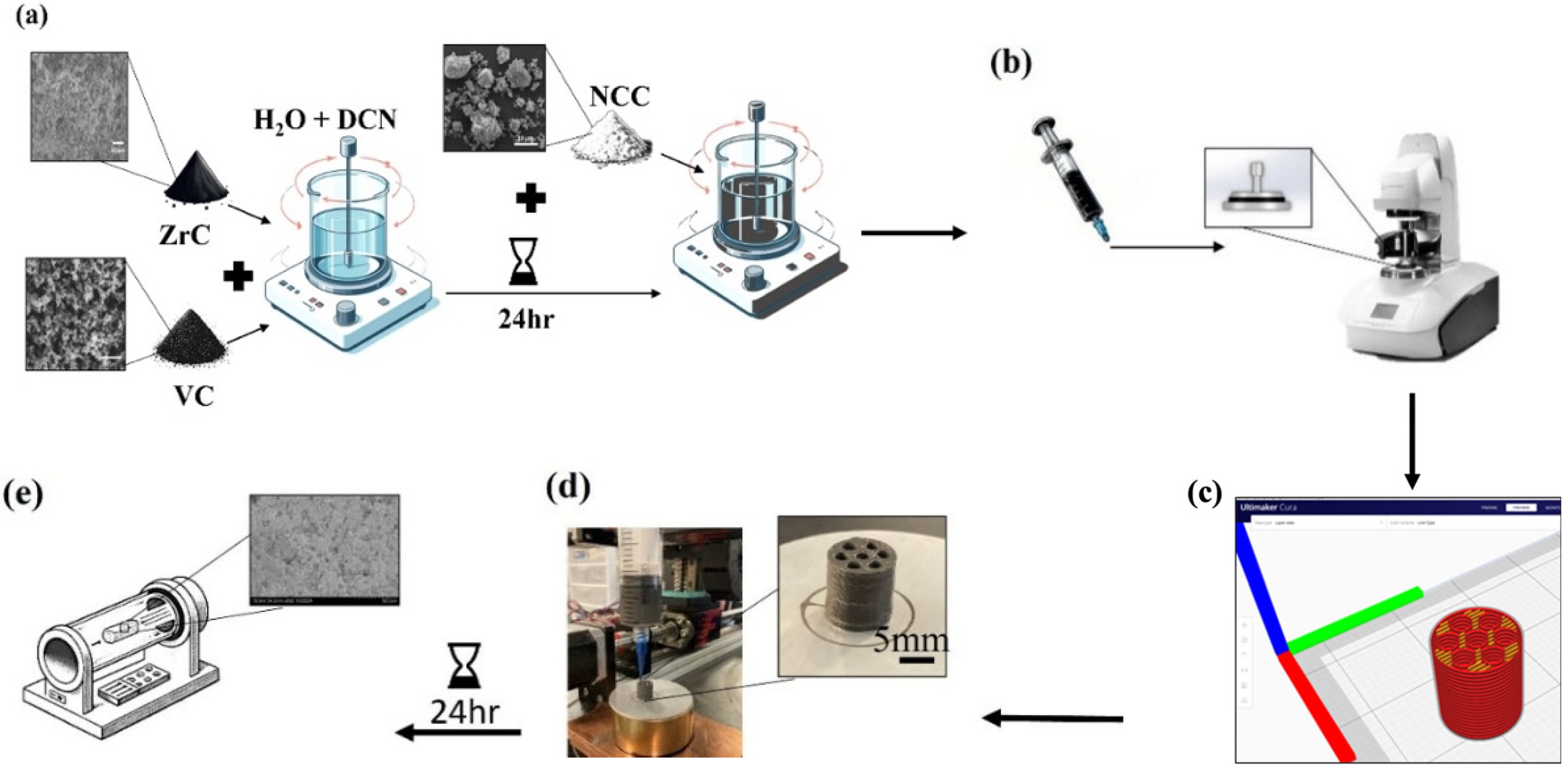

2. Experimental Procedure

2.1. Ink Preparation

2.2. Experimental Design

2.3. Rheological Characterization of the ZrC Ink

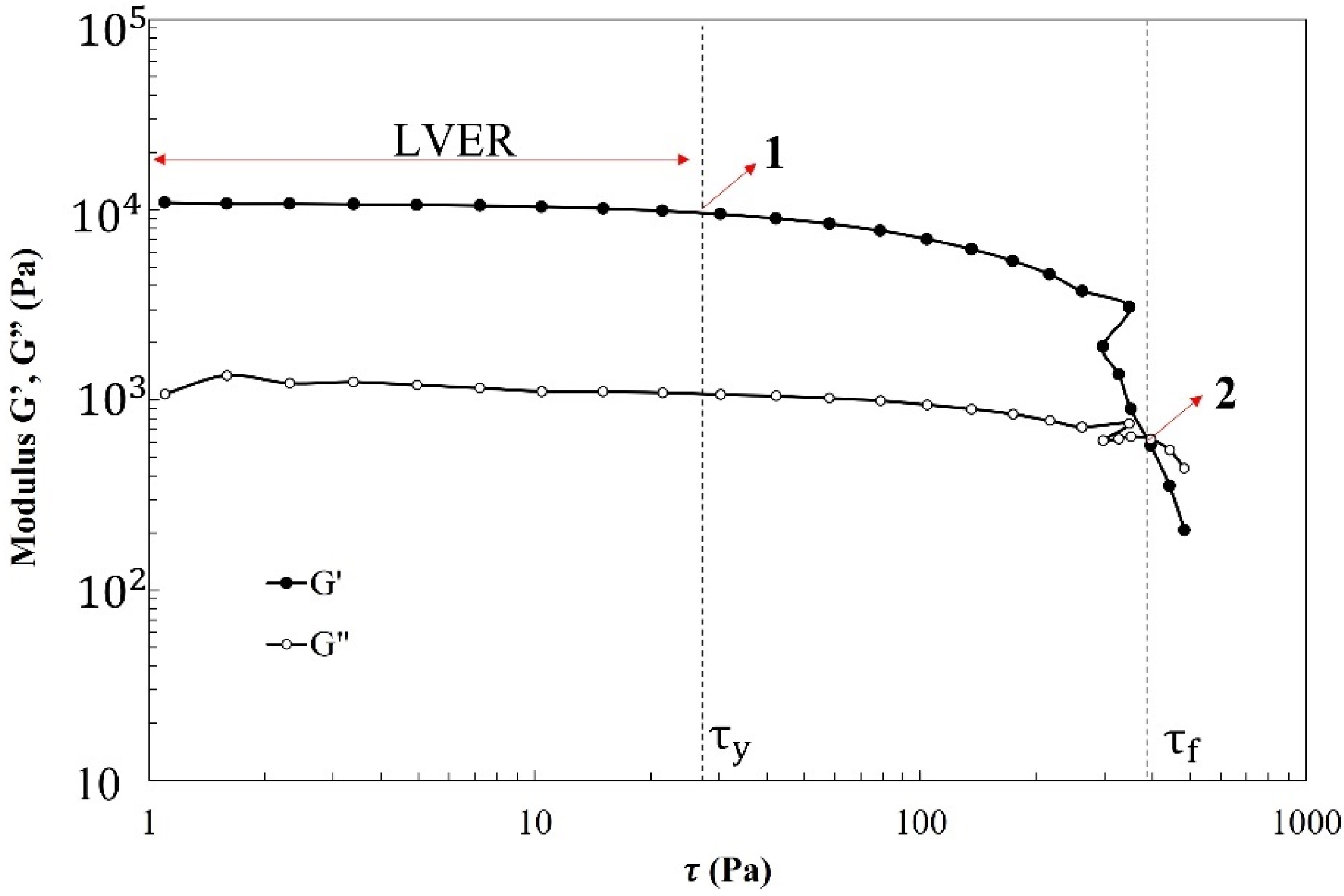

2.3.1. Amplitude Sweep Test

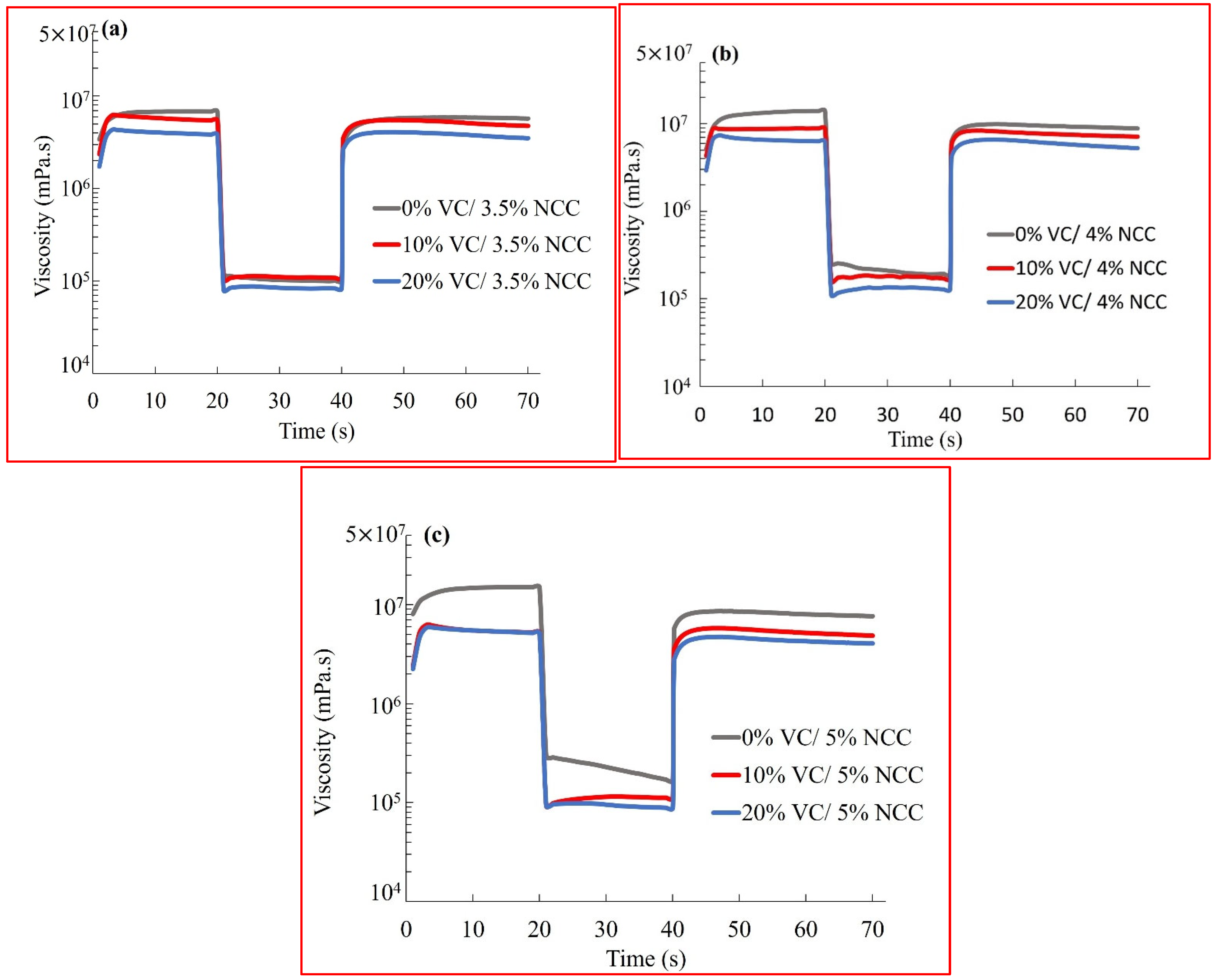

2.3.2. Three Interval Thixotropy Test

2.4. 3D Printing and Image Analysis

2.5. Sintering Process

2.6. Microstructural Characterization and Materials Testing

3. Results and Discussion

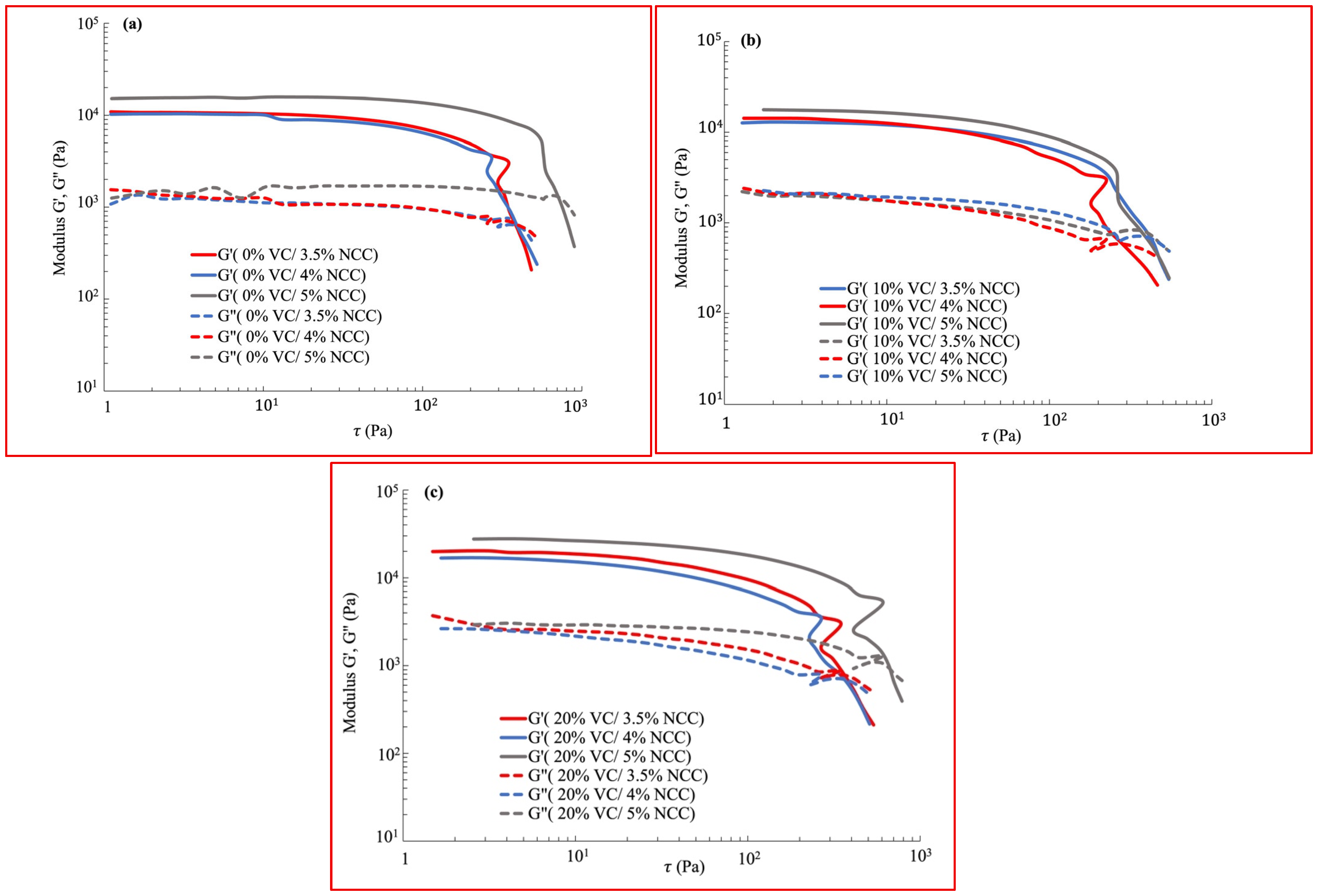

3.1. Ink Rheological Properties

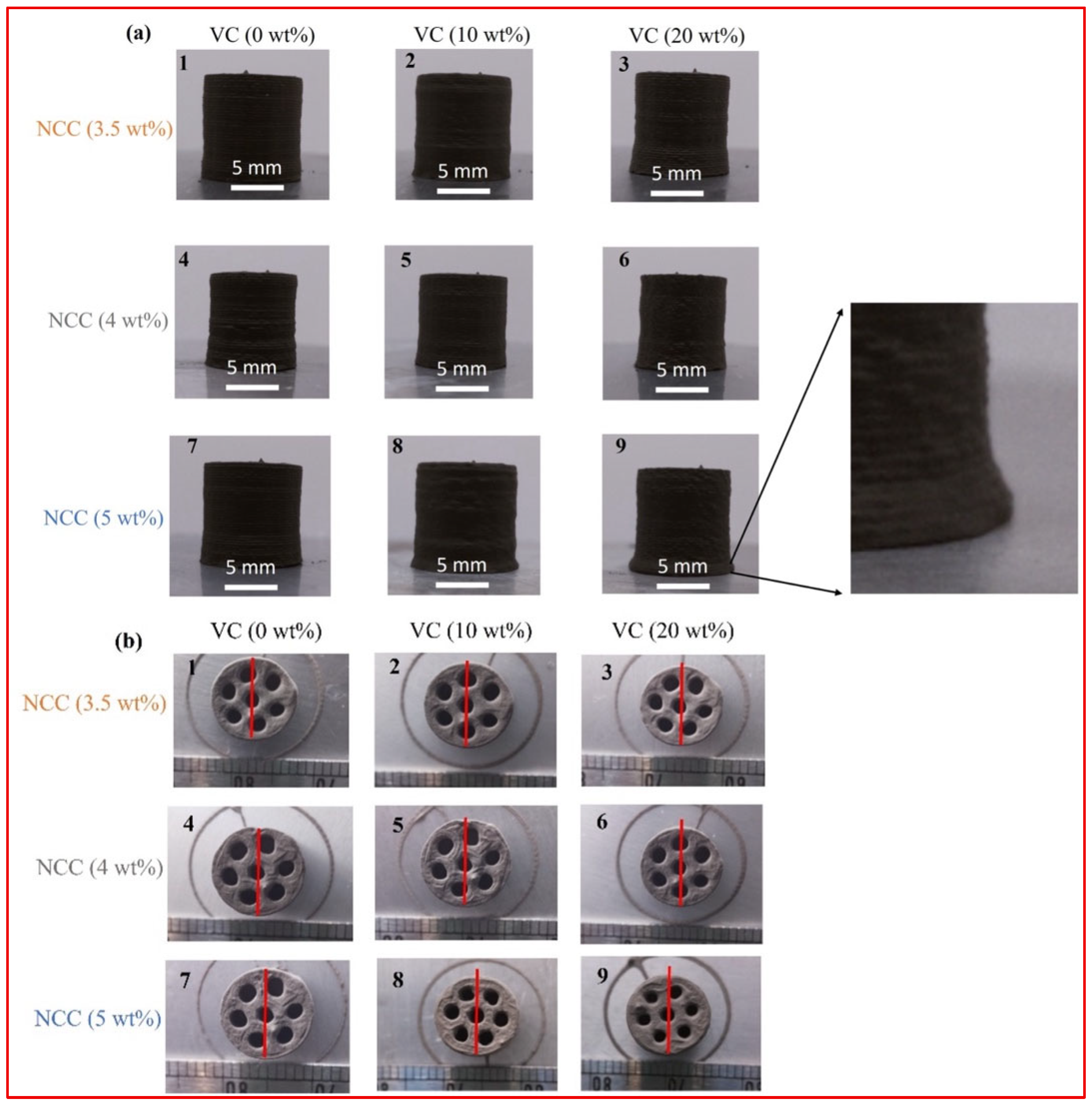

3.2. Shrinkage of Printed Samples

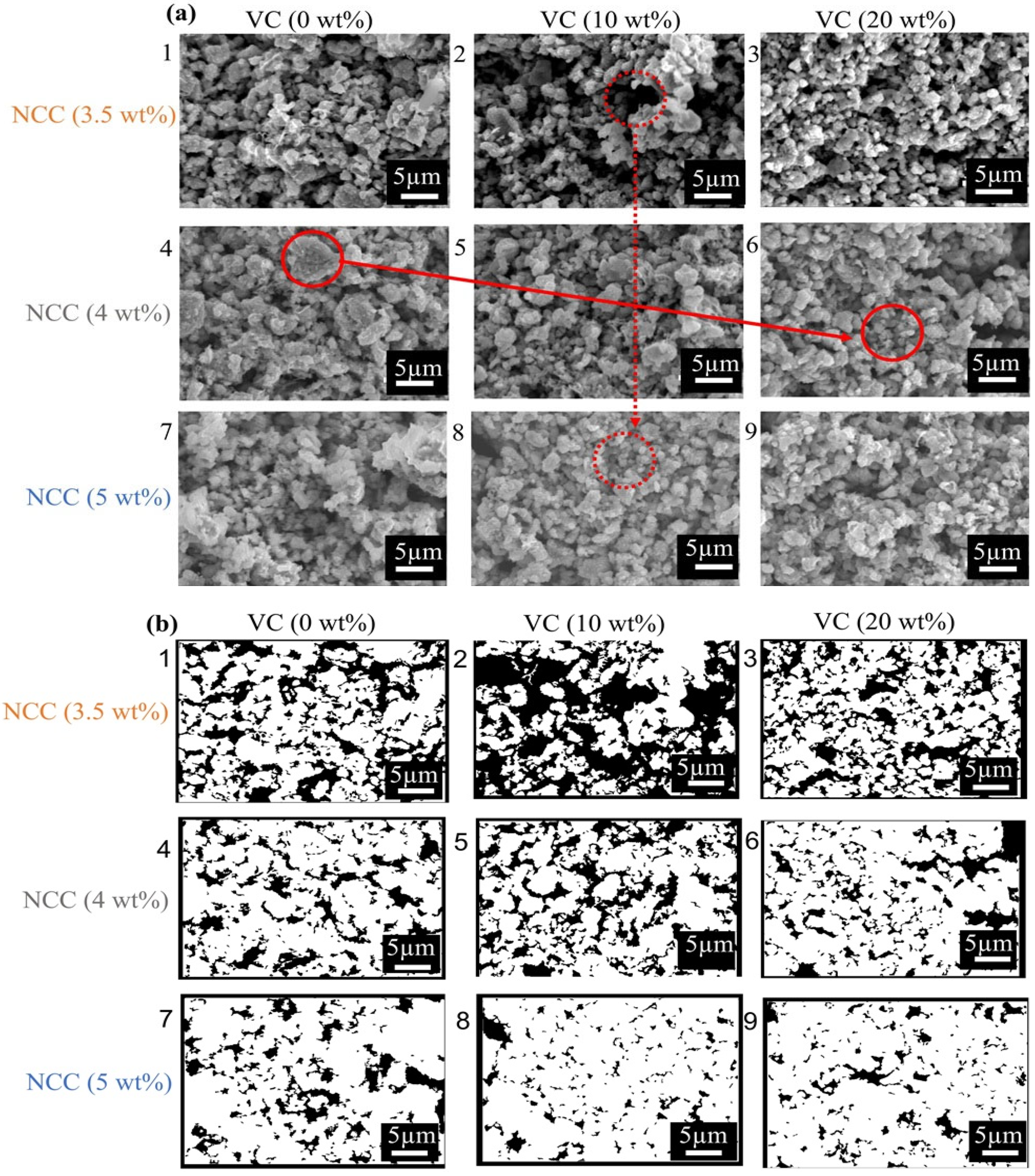

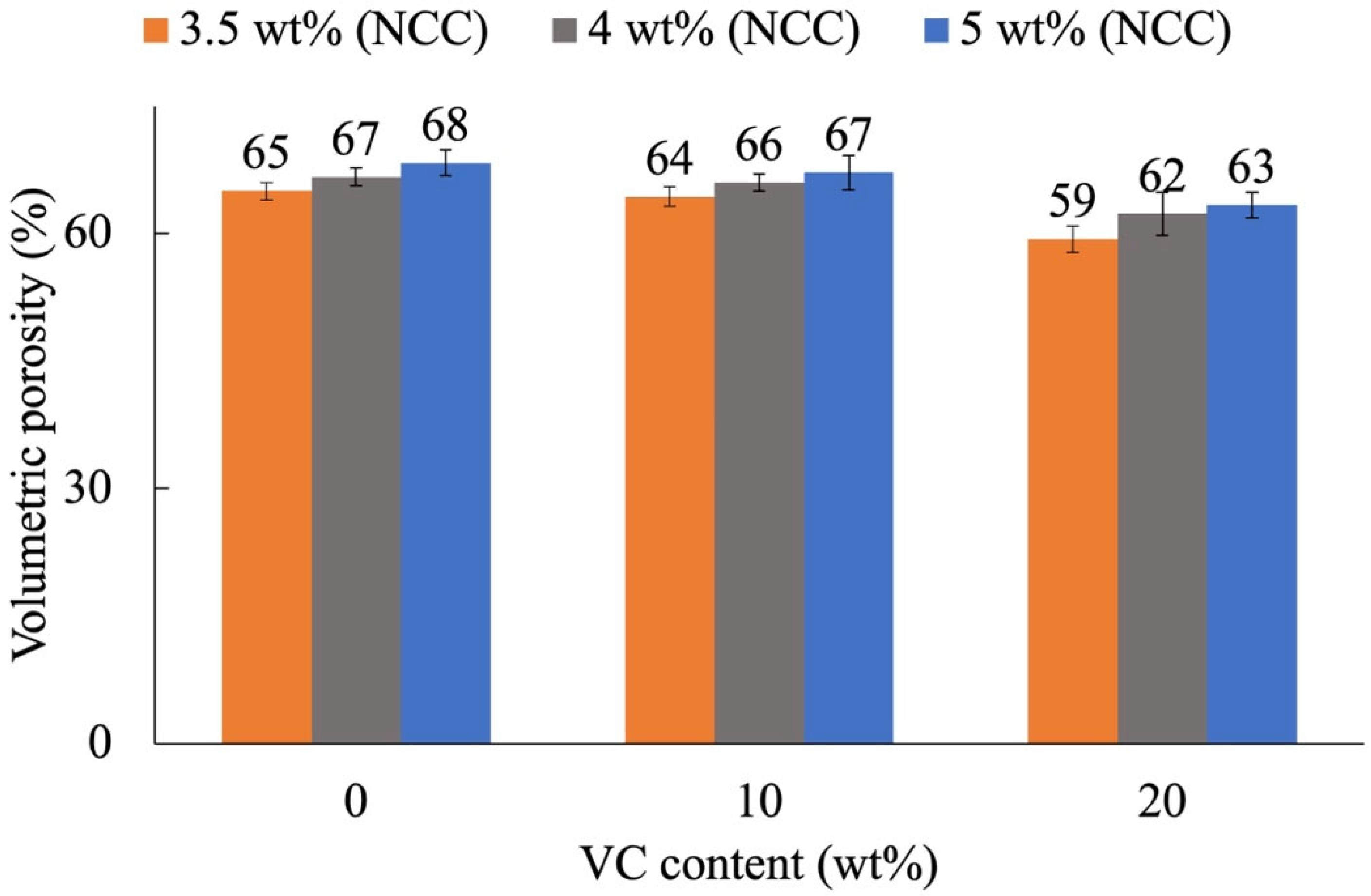

3.3. Microstructure and Porosity

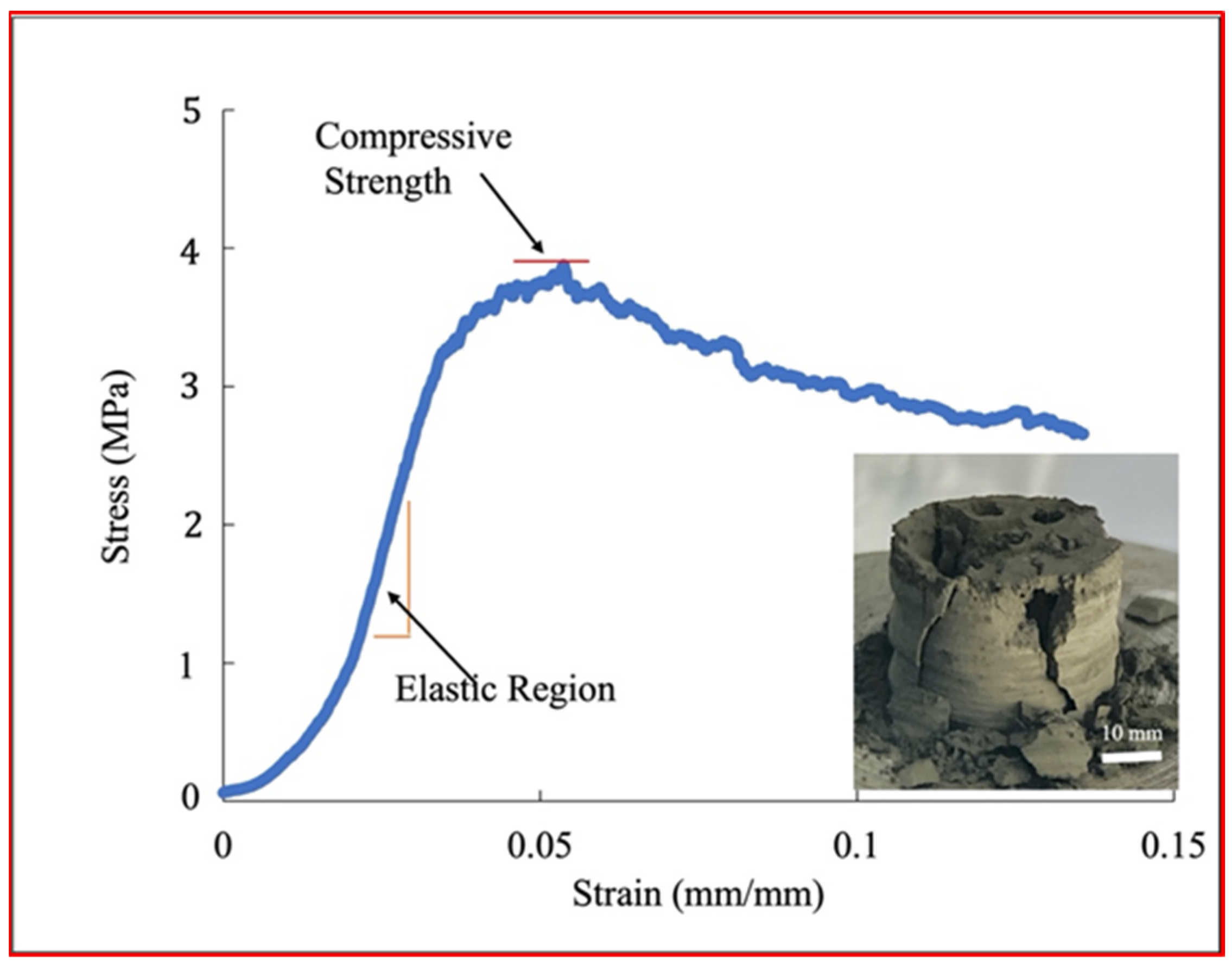

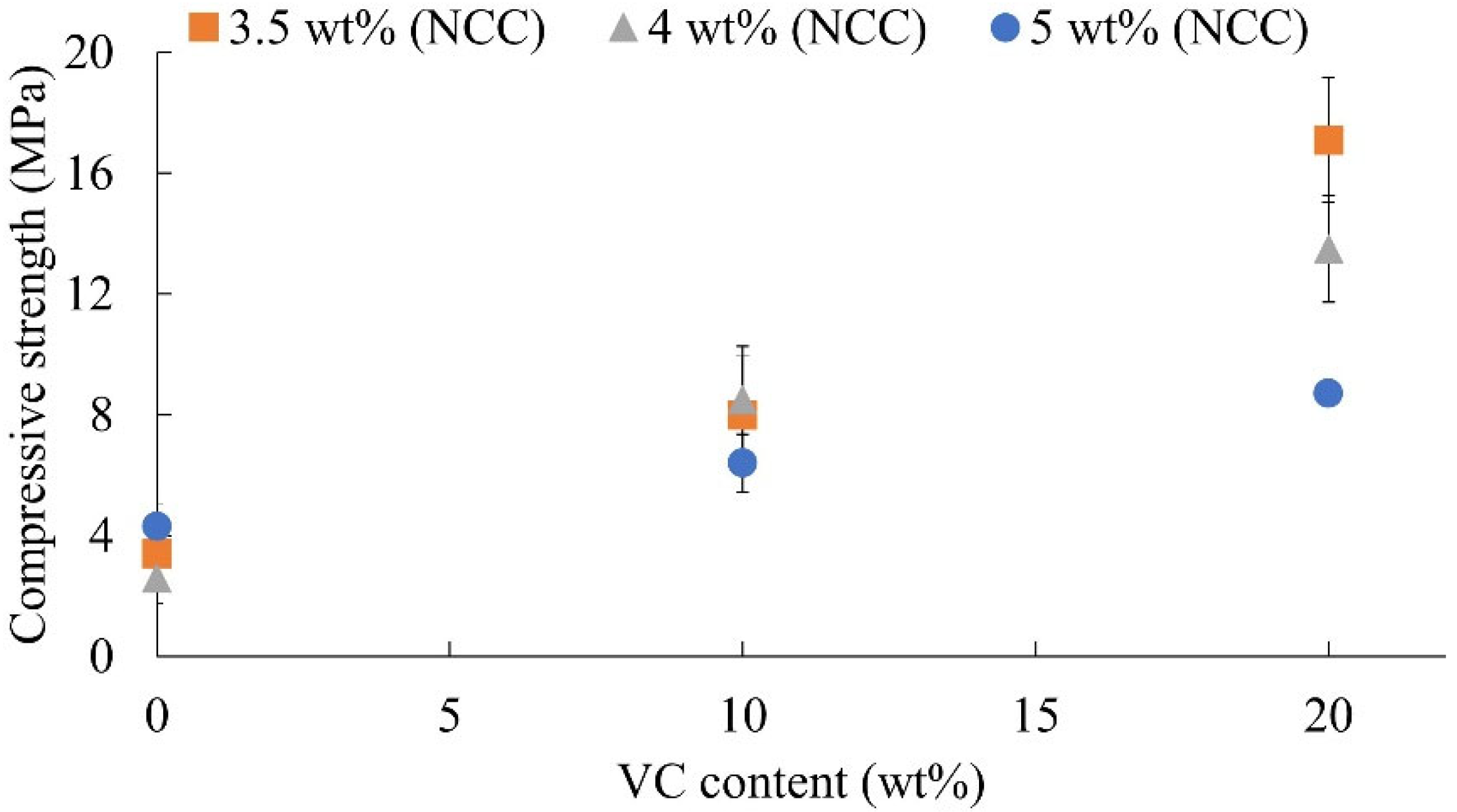

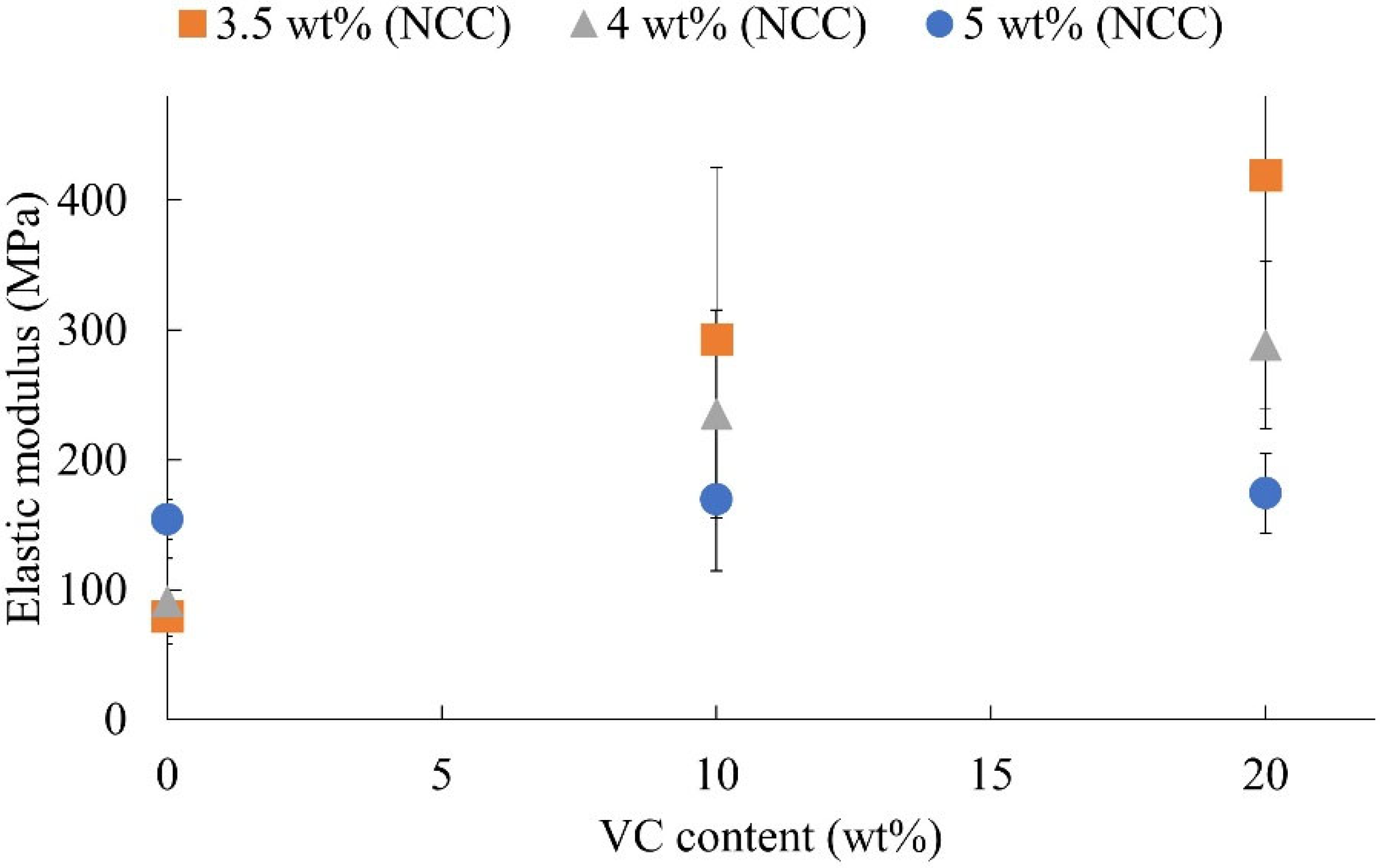

3.4. Mechanical Properties

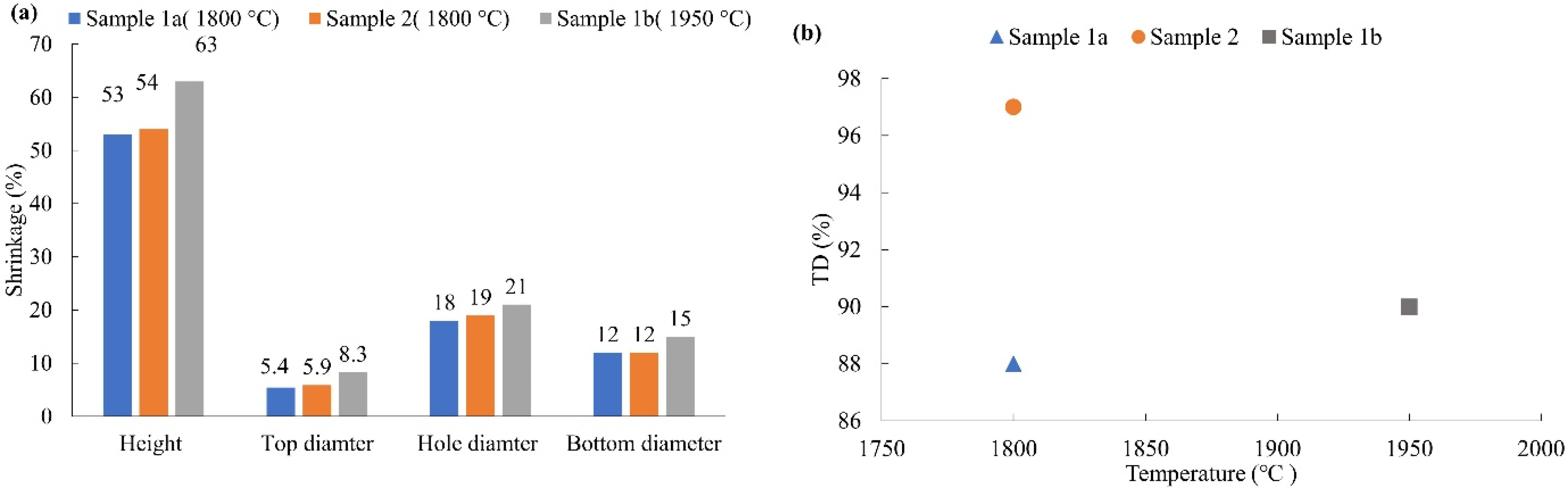

3.5. High-Temperature Spark Plasma Sintering

4. Conclusions

- Printing complex structures with multiple holes in a small area requires ink with acceptable printability. Balancing the water and NCC content addressed this issue in this study. While adding VC reduces the recovery time by decreasing both the viscosity and flow point, it also causes deformation, especially in samples with the highest VC content.

- Increasing VC decreases the ink viscosity and increases linear shrinkage. After drying, the sample height changes the most, and this trend is expected to continue after sintering.

- Microstructural analysis confirms that increasing both NCC and water content leads to smaller pores. In samples with VC powders, the small particle size of VC filled the interstitial spaces, reducing void size, and consequently improving the mechanical properties. Results from compressive testing revealed that the addition of VC has a beneficial effect on the compressive strength and elastic modulus of the sintered samples.

- The porosity level remained high for all the nine samples after conventional furnace sintering at 1750 °C. High temperature SPS helps increase the density of the ZrC/VC ceramic structures while maintaining the shape integrity. Achieving a densified structure with a final height of less than 40% of the initial height through spark plasma sintering validates the volumetric porosity calculations, which indicates porosity exceeding 60%.

- While this study demonstrated the feasibility of DIW of ZrC based ceramic pellets, further research is needed in all aspects of the printing process to show its capacity to produce structurally sound ceramic pallets as well as its economic viability. Also, future efforts will focus on enhanced sintering protocols and radiation stability testing to advance DIW for practical nuclear applications.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Cárdenas, R.C.A.; Collazos Morales, C.A.; Amaya, J.C.; Castro, F.C.; Mora, C.E.; Gonzalez, R.E.; Simancas-García, J.L.; Meléndez Pertuz, F.A. Review on Nuclear Thermal Propulsion Analysis of Fuel Element and Simulation Methods. In Lecture Notes in Computer Science (Including Subseries Lecture Notes in Artificial Intelligence and Lecture Notes in Bioinformatics); Springer: Berlin/Heidelberg, Germany, 2023. [Google Scholar] [CrossRef]

- Supko, E. Nuclear fuel fabrication. In Uranium for Nuclear Power: Resources, Mining and Transformation to Fuel; Woodhead Publishing: Cambridge, UK, 2016. [Google Scholar] [CrossRef]

- Hao, S.; Ma, J.; Zhao, X.; Wang, Y.; Zhou, X.; Deng, C. Large-scale production of UO2 kernels by sol–gel process at INET. Nucl. Eng. Des. 2014, 271, 158–161. [Google Scholar] [CrossRef]

- Nagarajan, K.; Vaidya, V.N. Sol-gel processes for nuclear fuel fabrication. In Sol-Gel Processing for Conventional and Alternative Energy; Springer: Boston, MA, USA, 2012. [Google Scholar] [CrossRef]

- Nelson, A.T. Prospects for additive manufacturing of nuclear fuel forms. Prog. Nucl. Energy 2023, 155, 104493. [Google Scholar] [CrossRef]

- Andersson, D.A.; Stanek, C.R.; Matthews, C.; Uberuaga, B.P. The past, present, and future of nuclear fuel. MRS Bull. 2023, 48, 1154–1162. [Google Scholar] [CrossRef]

- Guillon, O. Advanced Ceramics for Energy Conversion and Storage; Elsevier: Amsterdam, The Netherlands, 2019. [Google Scholar] [CrossRef]

- Marra, J. Advanced ceramic materials for next-generation nuclear applications. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2011. [Google Scholar] [CrossRef]

- Lee, W.E.; Gilbert, M.; Murphy, S.T.; Grimes, R.W.; Green, D.J. Opportunities for Advanced Ceramics and Composites in the Nuclear Sector. J. Am. Ceram. Soc. 2013, 96, 2005–2030. [Google Scholar] [CrossRef]

- Watkins, J.K.; Wagner, A.R.; Gonzales, A.; Jaques, B.J.; Sooby, E.S. Challenges and opportunities to alloyed and composite fuel architectures to mitigate high uranium density fuel oxidation: Uranium diboride and uranium carbide. J. Nucl. Mater. 2022, 560, 153502. [Google Scholar] [CrossRef]

- Frost, R.T. The carbides of uranium. J. Nucl. Mater. 1963, 10, 265–300. [Google Scholar] [CrossRef]

- Greenough, M.M.; Griffiths, R.J.; Ferrier, M.G.; Childs, B.C.; Silva, C.M.; Di Pietro, S.A.; Swift, A.J.; Burks, J.N.; Martin, A.A.; Holliday, K.S.; et al. Formation of uranium oxy-carbide and uranium carbide via conversion of polymer covered uranium dioxide by laser-based thermal processing. J. Nucl. Mater. 2024, 592, 154946. [Google Scholar] [CrossRef]

- Taylor, B.; Emrich, B.; Tucker, D.; Barnes, M.; Donders, N.; Benensky, K. Study of a tricarbide grooved ring fuel element for nuclear thermal propulsion. In Nuclear and Emerging Technologies for Space; The American Nuclear Society: Downers Grove, IL, USA, 2016; NETS 2018. [Google Scholar]

- Kumar, D.; Singh, K. High hardness-high toughness WC-20Co nanocomposites: Effect of VC variation and sintering temperature. Mater. Sci. Eng. A 2016, 663, 21–28. [Google Scholar] [CrossRef]

- Roy, R. New Processes as Drivers for Revolutions in Materials Research. In Materials Science and Engineering Serving Society; Elsevier Science BV: Amsterdam, The Netherlands, 1998. [Google Scholar] [CrossRef]

- Nelson, A.T. Features that Further Performance Limits of Nuclear Fuel Fabrication: Opportunities for Additive Manufacturing of Nuclear Fuels; Oak Ridge National Laboratory (ORNL): Oak Ridge, TN, USA, 2019. Available online: http://www.osti.gov/biblio/1669784 (accessed on 3 November 2024).

- Chen, Z.; Li, Z.; Li, J.; Liu, C.; Lao, C.; Fu, Y.; Liu, C.; Li, Y.; Wang, P.; He, Y. 3D printing of ceramics: A review. J. Eur. Ceram. Soc. 2019, 39, 661–687. [Google Scholar] [CrossRef]

- Saadi, M.A.S.R.; Maguire, A.; Pottackal, N.T.; Thakur, S.H.; Ikram, M.M.; Hart, A.J.; Ajayan, P.M.; Rahman, M.M. Direct Ink Writing: A 3D Printing Technology for Diverse Materials. Adv. Mater. 2022, 34, e2108855. [Google Scholar] [CrossRef] [PubMed]

- Bergeron, A.; Crigger, J. Early progress on additive manufacturing of nuclear fuel materials. J. Nucl. Mater. 2018, 508, 344–347. [Google Scholar] [CrossRef]

- Schappel, D.; Linton, K.D.; Helmreich, G.W.; Keever, T.J.; Petrie, C.M. Failure analysis of nuclear transient-tested UN tristructural isotropic fuel particles in a 3D printed SiC matrix. J. Nucl. Mater. 2023, 586, 154691. [Google Scholar] [CrossRef]

- Rau, D.A.; Williams, C.B.; Bortner, M.J. Rheology and printability: A survey of critical relationships for direct ink write materials design. Prog. Mater. Sci. 2023, 140, 101188. [Google Scholar] [CrossRef]

- Duffy, J. The physical characteristics of dispersed particles have a large impact on overall rheological properties. Chem. Eng. 2015, 122, 34–39. [Google Scholar]

- Del-Mazo-Barbara, L.; Ginebra, M.-P. Rheological characterisation of ceramic inks for 3D direct ink writing: A review. J. Eur. Ceram. Soc. 2021, 41, 18–33. [Google Scholar] [CrossRef]

- Li, W.; Olevsky, E.A.; Khasanov, O.L.; Back, C.A.; Izhvanov, O.; Opperman, J.; Khalifa, H.E. Spark plasma sintering of agglomerated vanadium carbide powder. Ceram. Int. 2015, 41, 3748–3759. [Google Scholar] [CrossRef]

- Sabata, C.; Martin, A.J.; Watts, J.L.; Hilmas, G.E. Development of a highly loaded zirconium carbide paste for material extrusion additive manufacturing. J. Eur. Ceram. Soc. 2025, 45, 116881. [Google Scholar] [CrossRef]

- Qian, J.; Wu, C.-Y.; Gong, H.-R. Phase transition, thermodynamic and elastic properties of ZrC. Trans. Nonferrous Met. Soc. China 2018, 28, 2520–2527. [Google Scholar] [CrossRef]

- Yamazaki, K.; Risbud, S.; Aoyama, H.; Shoda, K. PAS (Plasma activated sintering): Transient sintering process control for rapid consolidation of powders. J. Mech. Work. Technol. 1996, 56, 955–965. [Google Scholar] [CrossRef]

- Ke, B.; Ji, W.; Zou, J.; Wang, W.; Fu, Z. Densification mechanism, microstructure and mechanical properties of ZrC ceramics prepared by high-pressure spark plasma sintering. J. Eur. Ceram. Soc. 2023, 43, 3053–3061. [Google Scholar] [CrossRef]

| Ink # | ZrC (wt%) | NCC (wt%) | VC (wt%) | DC_N(wt%) | Water (wt%) |

|---|---|---|---|---|---|

| 1 | 68 | 3.5 | 0 | 1 | 28 |

| 2 | 58 | 3.5 | 10 | 1 | 28 |

| 3 | 48 | 3.5 | 20 | 1 | 28 |

| 4 | 66 | 4 | 0 | 1 | 29 |

| 5 | 56 | 4 | 10 | 1 | 29 |

| 6 | 46 | 4 | 20 | 1 | 29 |

| 7 | 63 | 5 | 0 | 1 | 31 |

| 8 | 53 | 5 | 10 | 1 | 31 |

| 9 | 43 | 5 | 20 | 1 | 31 |

| Parameters | Value |

|---|---|

| Layer height | 0.25 mm |

| Line width | 0.5 mm |

| Infill density | 99% |

| Nozzle diameter | 0.41 mm |

| Infill direction | 90° |

| Hole horizontal expansion | 0.15 mm |

| Ink Number | Flow Point (Pa) | Recovery Time (s) |

|---|---|---|

| 3.5 wt% NCC & 0 wt% VC | 390 | 6.7 |

| 3.5 wt% NCC & 10 wt% VC | 360 | 1.2 |

| 3.5 wt% NCC & 20 wt% VC | 365 | 1.6 |

| 4 wt% NCC & 0 wt% VC | 400 | 2.6 |

| 4 wt% NCC & 10 wt% VC | 300 | 1.2 |

| 4 wt% NCC & 20 wt% VC | 400 | 1.5 |

| 5 wt% NCC & 0 wt% VC | 750 | 3.8 |

| 5 wt% NCC & 10 wt% VC | 420 | 2.1 |

| 5 wt% NCC & 20 wt% VC | 660 | 3.1 |

| Ink Number | Radius of Curvature (mm) | STD |

|---|---|---|

| 3.5 wt% NCC & 0 wt% VC | 4.65 | 0.27 |

| 3.5 wt% NCC & 10 wt% VC | 4.8 | 0.25 |

| 3.5 wt% NCC & 20 wt% VC | 5.2 | 0.45 |

| 4 wt% NCC & 0 wt% VC | 4.7 | 0.35 |

| 4 wt% NCC & 10 wt% VC | 5.0 | 0.41 |

| 4 wt% NCC & 20 wt% VC | 5.2 | 0.52 |

| 5 wt% NCC & 0 wt% VC | 4.8 | 0.48 |

| 5 wt% NCC & 10 wt% VC | 5.0 | 0.41 |

| 5 wt% NCC & 20 wt% VC | 5.2 | 0.55 |

| NCC (wt%) | VC (0 wt%) | VC (10 wt%) | VC (20 wt%) |

|---|---|---|---|

| 3.5 | 5 | 3.85 | 3.7 |

| 4 | 6.24 | 5.74 | 1.12 |

| 5 | 3.8 | 3.5 | 1.28 |

| Sample | Material | Sintering | Annealing Condition | |||

|---|---|---|---|---|---|---|

| Temperature (°C) | Pressure (MPa) | Time (min) | Temperature (°C) | Time (h) | ||

| 1a | ZrC + 3.5 wt% NCC | 1800 | 50 | 5 | 500 | 5 |

| 1b | ZrC + 3.5 wt% NCC | 1950 | 50 | 5 | 500 | 5 |

| 2 | ZrC + 10 wt% VC + 3.5 wt% NCC | 1800 | 50 | 5 | 700 | 5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Malmir, N.; Yang, G.; Poirier, T.; Cavanaugh, N.; Zhao, D.; Taylor, B.; Churi, N.; Yao, T.; Lian, J.; Edgar, J.H.; et al. Direct Ink Writing and Characterization of ZrC-Based Ceramic Pellets for Potential Nuclear Applications. J. Manuf. Mater. Process. 2025, 9, 270. https://doi.org/10.3390/jmmp9080270

Malmir N, Yang G, Poirier T, Cavanaugh N, Zhao D, Taylor B, Churi N, Yao T, Lian J, Edgar JH, et al. Direct Ink Writing and Characterization of ZrC-Based Ceramic Pellets for Potential Nuclear Applications. Journal of Manufacturing and Materials Processing. 2025; 9(8):270. https://doi.org/10.3390/jmmp9080270

Chicago/Turabian StyleMalmir, Narges, Guang Yang, Thomas Poirier, Nathaniel Cavanaugh, Dong Zhao, Brian Taylor, Nikhil Churi, Tiankai Yao, Jie Lian, James H. Edgar, and et al. 2025. "Direct Ink Writing and Characterization of ZrC-Based Ceramic Pellets for Potential Nuclear Applications" Journal of Manufacturing and Materials Processing 9, no. 8: 270. https://doi.org/10.3390/jmmp9080270

APA StyleMalmir, N., Yang, G., Poirier, T., Cavanaugh, N., Zhao, D., Taylor, B., Churi, N., Yao, T., Lian, J., Edgar, J. H., Lin, D., & Lei, S. (2025). Direct Ink Writing and Characterization of ZrC-Based Ceramic Pellets for Potential Nuclear Applications. Journal of Manufacturing and Materials Processing, 9(8), 270. https://doi.org/10.3390/jmmp9080270