Reliability Study of Electronic Components on Board-Level Packages Encapsulated by Thermoset Injection Molding

Abstract

1. Introduction

2. Materials and Methods

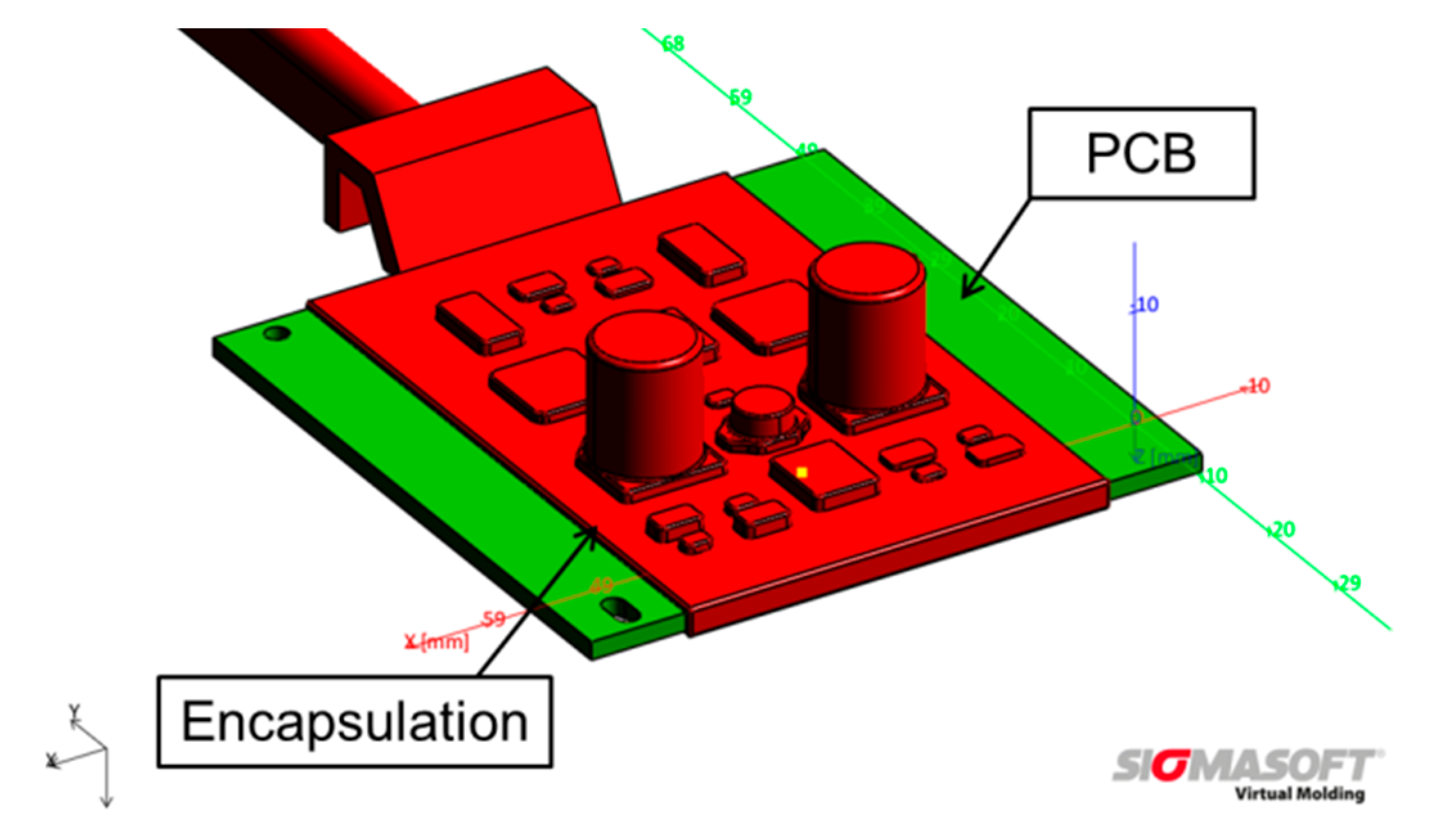

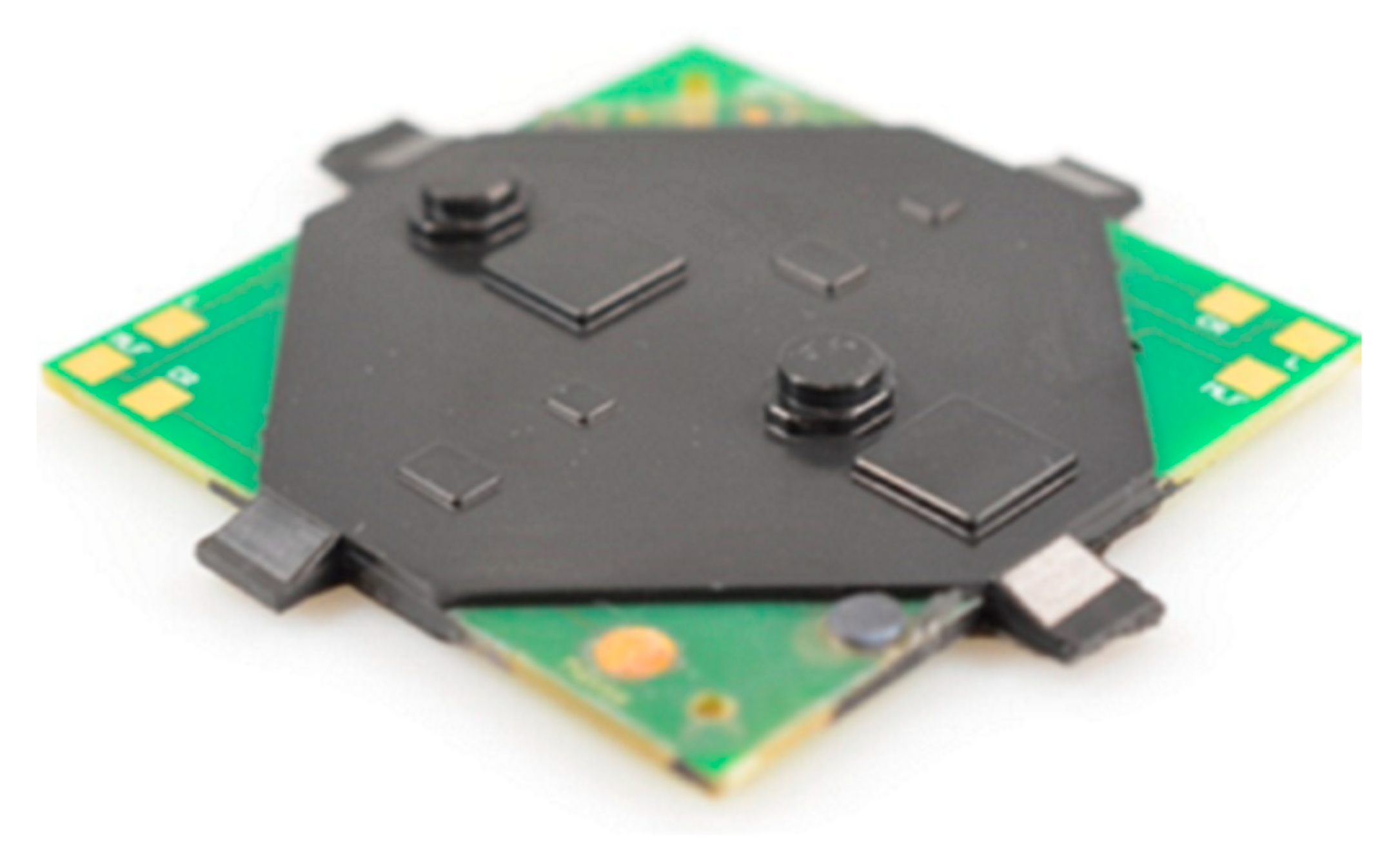

2.1. Conception of the Package

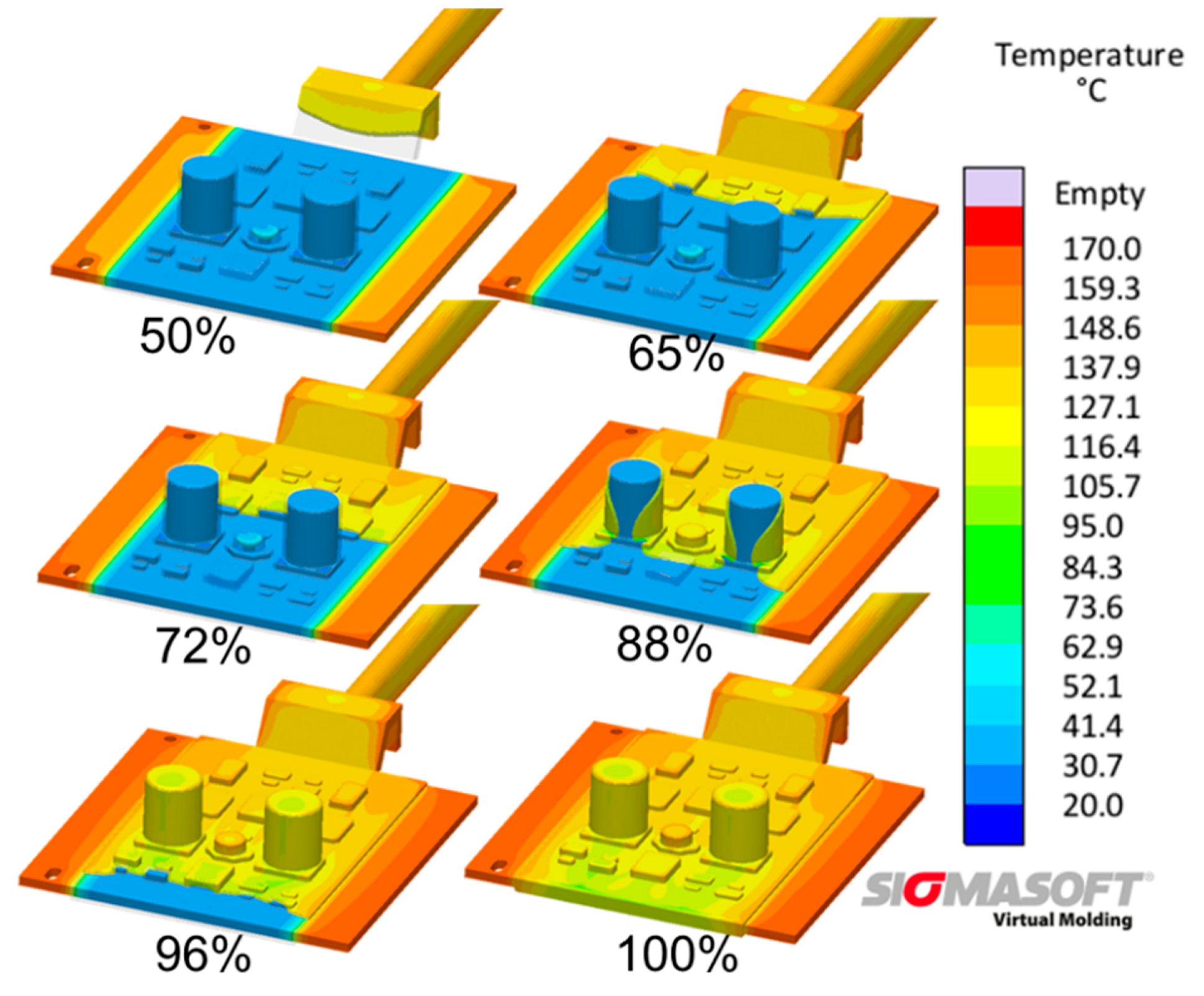

2.2. Process Simulation

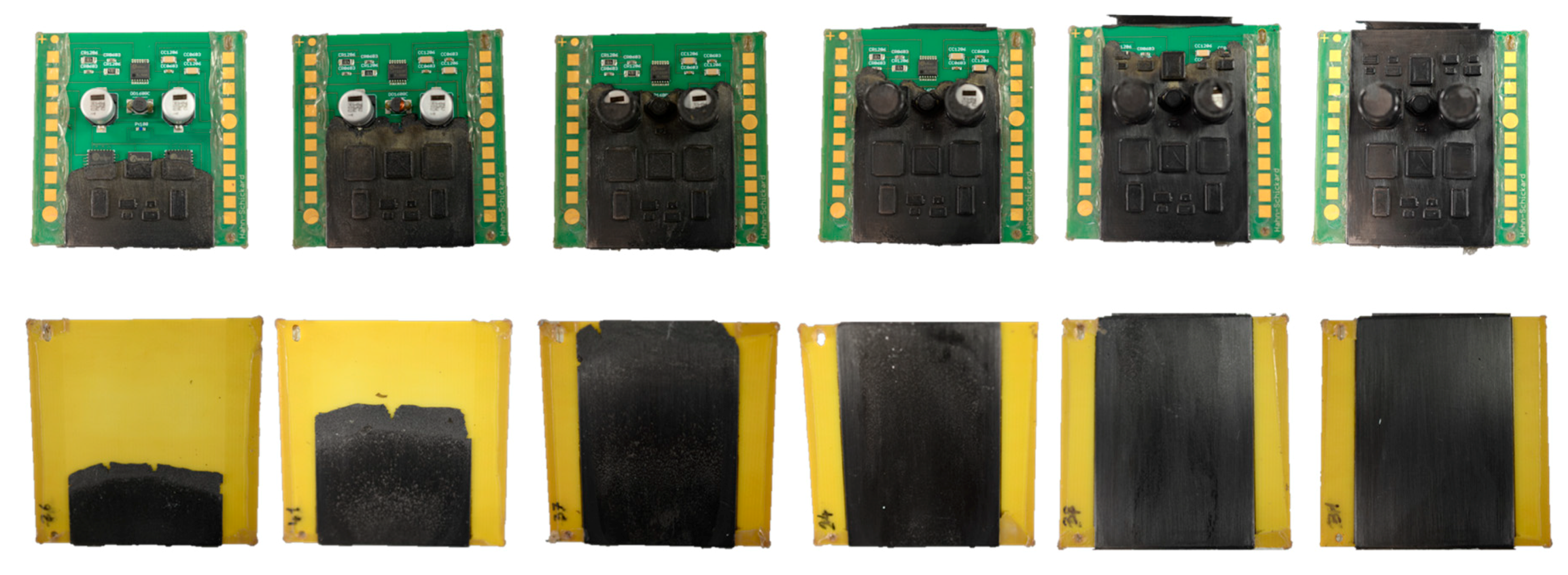

2.3. Mold Trials

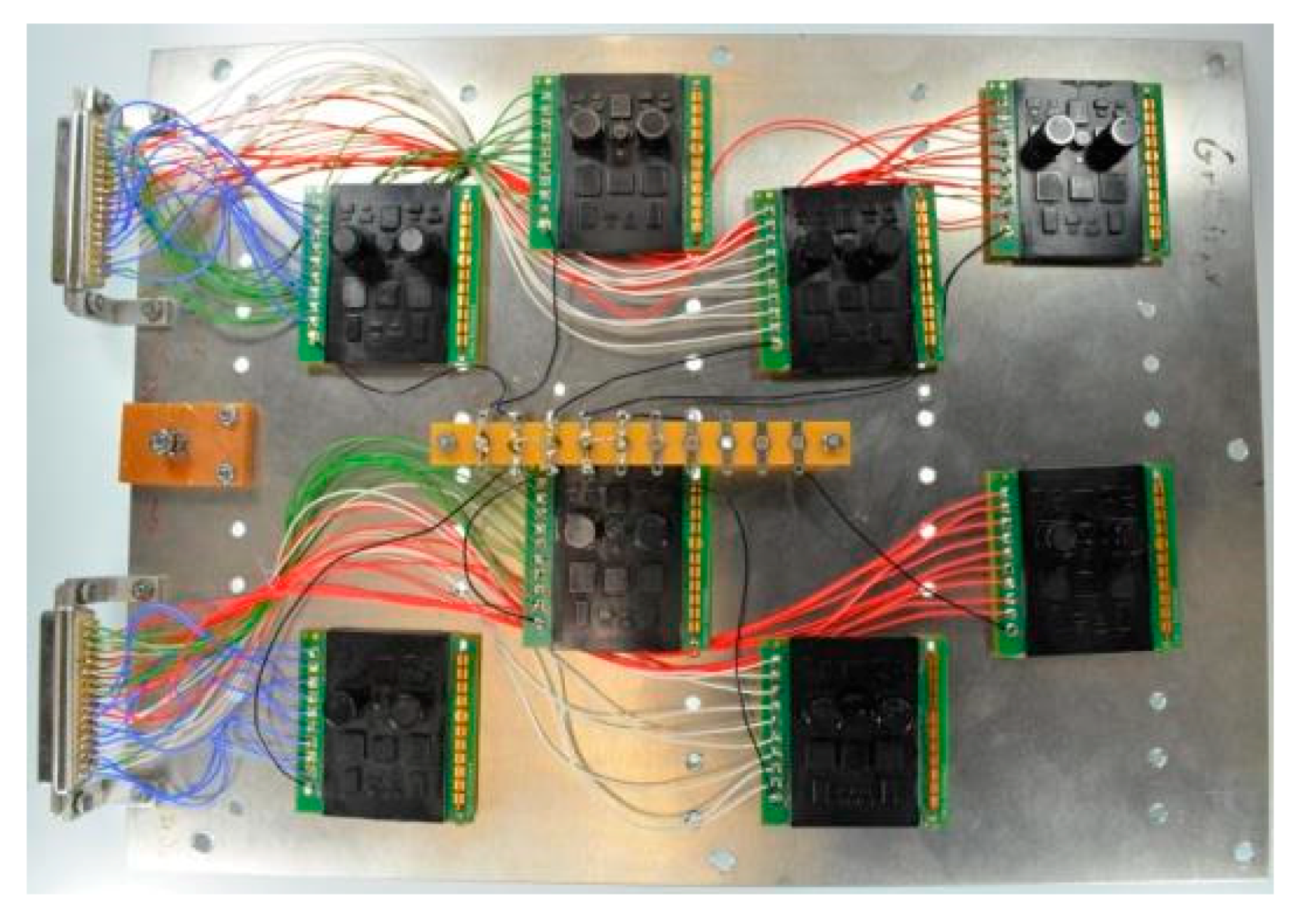

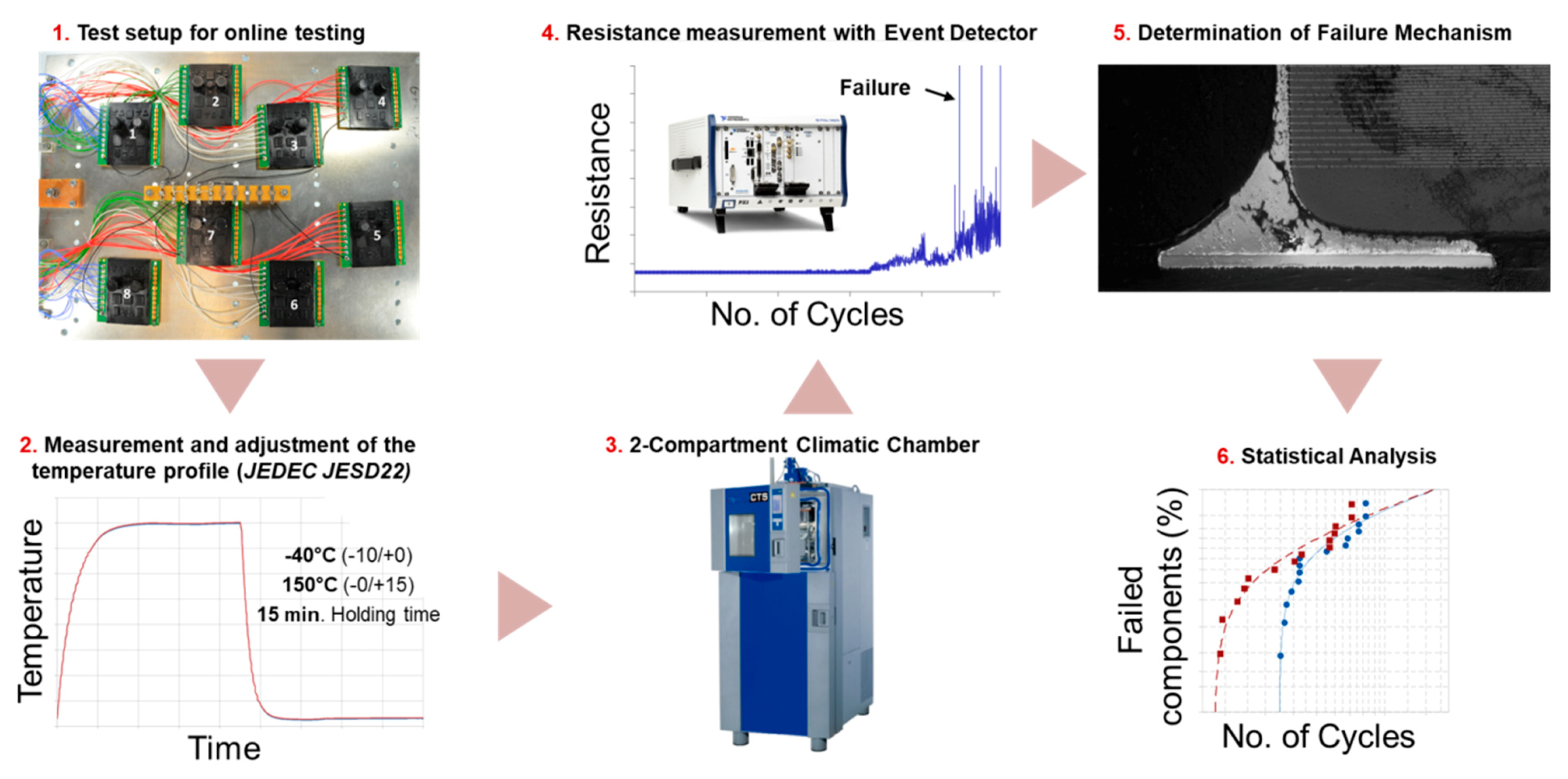

2.4. Test Setup

2.5. Running of Tests

3. Results

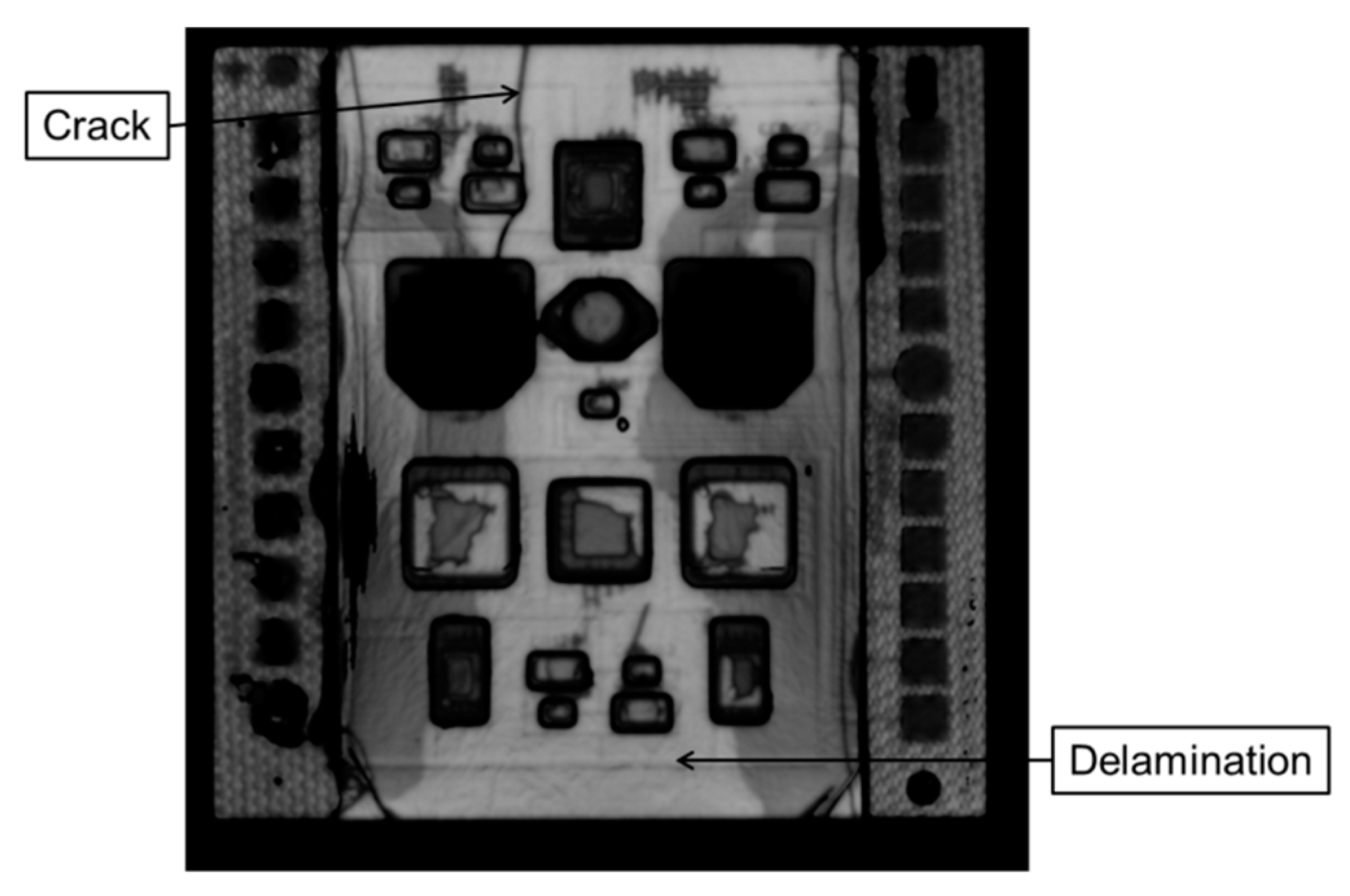

3.1. Mechanisms of Failure

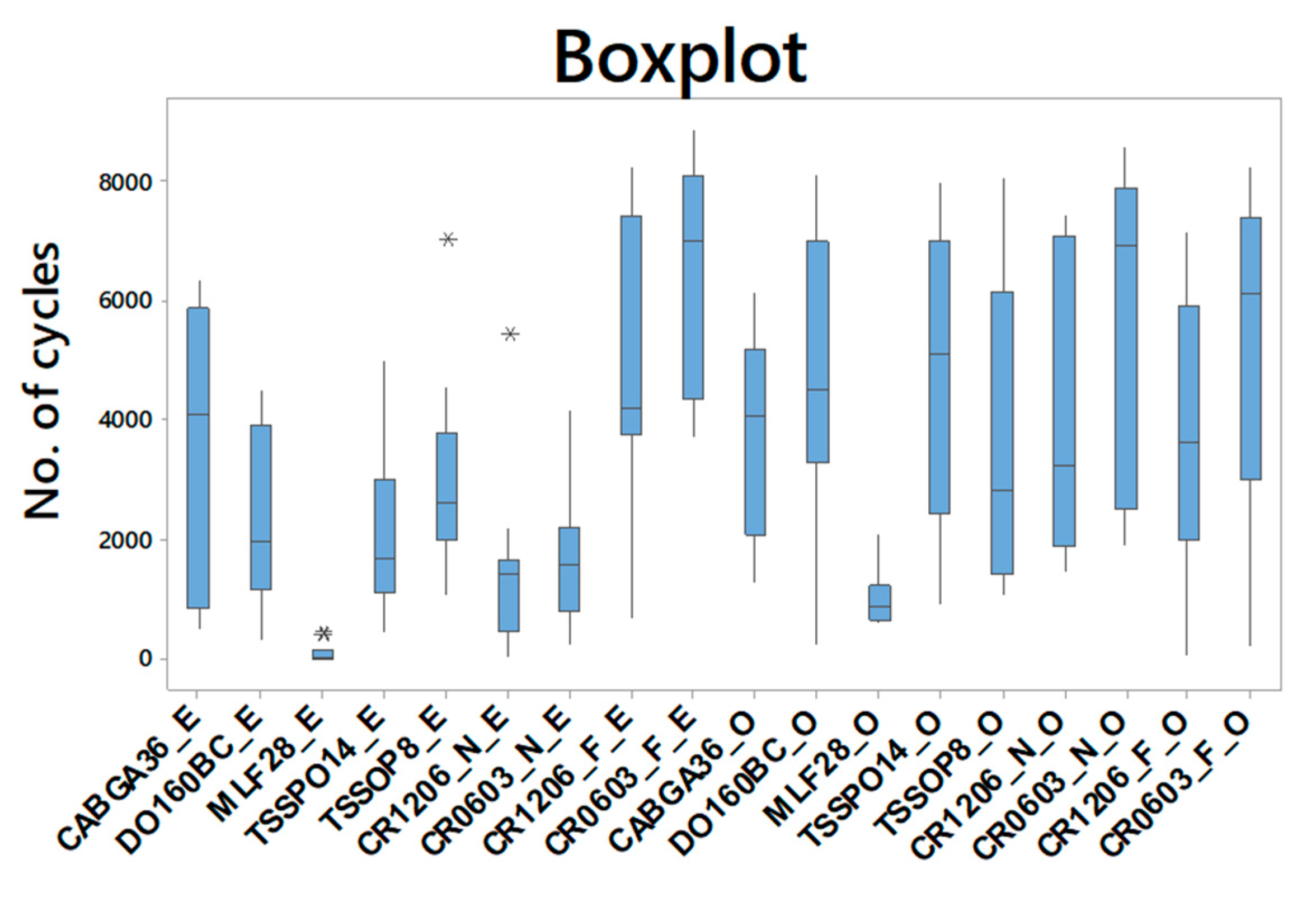

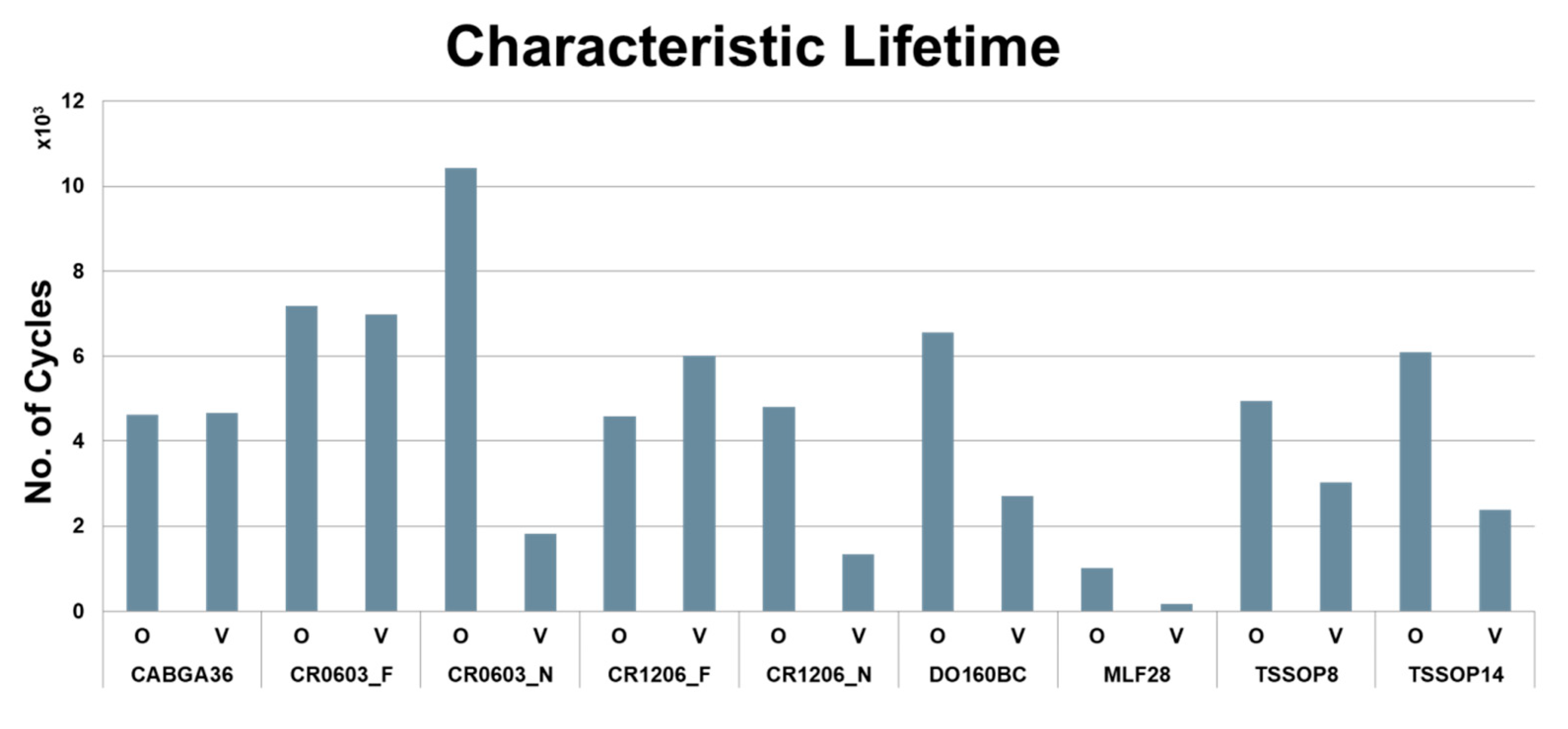

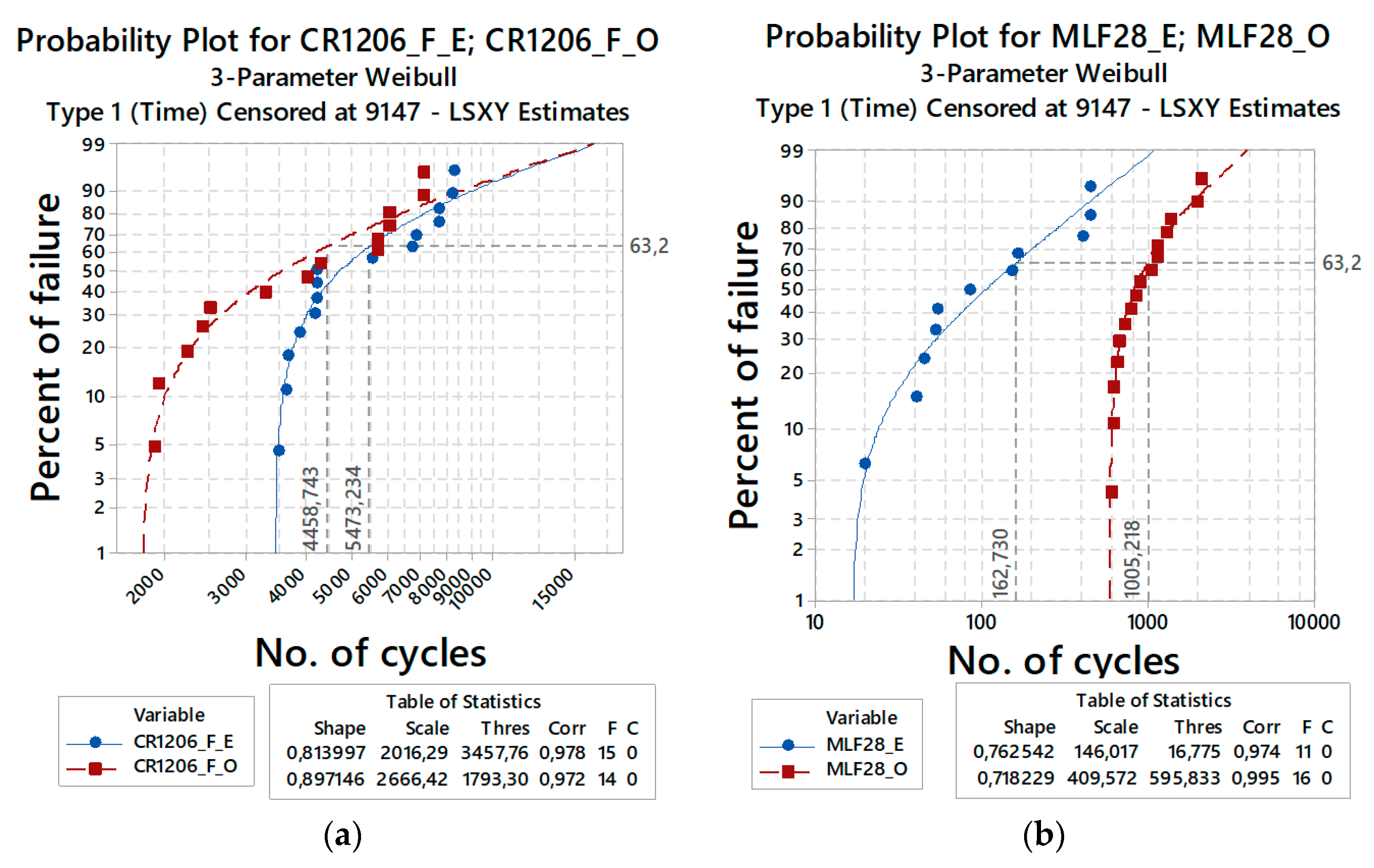

3.2. Statistical Analysis of Reliability

- The correlation coefficient should be greater than for the second-best distribution.

- The data in the Weibull plot indicate a curvature (concave curve).

- A large sample size (n > 20) is available; with previous knowledge of a time without failure, eight to ten must be sufficient.

- A physical explanation of why a failure-free can occur.

4. Discussion and Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

| Phase | Parameter | Unit | Phase 1 | Phase 2 | Phase 3 |

|---|---|---|---|---|---|

| Injection | Feeding volume | cm3 | 12.650 | ||

| Flow flux | cm3/s | 1 | 0.5 | 0.3 | |

| Pressure | bar | 900 | 850 | 800 | |

| Switching volume | cm3 | 6.7 | 4.5 | 1.0 | |

| Packing | Flow flux | cm3/s | 1 | ||

| Pressure | bar | 100 | 50 | 25 | |

| Duration | s | 0.10 | 29.80 | 0.10 | |

| Phase | Parameter | Unit | Phase 1 |

|---|---|---|---|

| Feeding | Pre-heating time | s | 30 |

| Screw speed | RPM | 80 | |

| Pressure | bar | 10 | |

| Volume | cm3 | 12.650 | |

| Decompression | Decompression flux | cm3/s | 2 |

| Decompression volume | cm3 | 0.5 | |

| Tempering | Cylinder temperature | °C | 55 |

| Nozzle temperature | °C | 70 | |

| Tool temperature up | °C | 170 | |

| Tool temperature down | °C | 170 |

| Distribution | CABGA36_E | DO160BC_E | MLF28_E | TSSOP14_E | TSSOP8_E | CR1206_N_E | CR0603_N_E | CR1206_F_E | CR0603_F_E | CABGA36_O | DO160BC_O | MLF28_O | TSSOP14_O | TSSOP8_O | CR1206_N_O | CR0603_N_O | CR1206_F_O | CR0603_F_O |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Weibull | 0.899 | 0.97 | 0.947 | 0.99 | 0.991 | 0.948 | 0.966 | 0.899 | 0.954 | 0.943 | 0.895 | 0.905 | 0.948 | 0.928 | 0.943 | 0.941 | 0.951 | 0.887 |

| Lognormal | 0.936 | 0.945 | 0.967 | 0.986 | 0.985 | 0.881 | 0.941 | 0.936 | 0.942 | 0.911 | 0.843 | 0.962 | 0.901 | 0.964 | 0.965 | 0.936 | 0.958 | 0.831 |

| Loglogistic | 0.925 | 0.945 | 0.961 | 0.989 | 0.982 | 0.885 | 0.942 | 0.925 | 0.934 | 0.91 | 0.858 | 0.957 | 0.902 | 0.953 | 0.957 | 0.936 | 0.948 | 0.848 |

| 3-P Weibull | 0.978 | 0.972 | 0.974 | 0.99 | 0.994 | 0.974 | 0.969 | 0.978 | 0.959 | 0.964 | 0.989 | 0.995 | 0.974 | 0.99 | 0.983 | 0.955 | 0.972 | 0.97 |

| 3-P Lognormal | 0.959 | 0.966 | 0.971 | 0.994 | 0.992 | 0.967 | 0.972 | 0.959 | 0.955 | 0.96 | 0.987 | 0.985 | 0.962 | 0.982 | 0.972 | 0.949 | 0.959 | 0.955 |

| 3-P Loglogistic | 0.952 | 0.963 | 0.967 | 0.996 | 0.988 | 0.962 | 0.973 | 0.952 | 0.945 | 0.96 | 0.99 | 0.979 | 0.959 | 0.98 | 0.969 | 0.938 | 0.949 | 0.958 |

| Smallest Extreme Value | 0.879 | 0.939 | 0.825 | 0.901 | 0.958 | 0.965 | 0.907 | 0.879 | 0.951 | 0.964 | 0.988 | 0.835 | 0.974 | 0.859 | 0.895 | 0.939 | 0.928 | 0.97 |

| Normal | 0.928 | 0.963 | 0.89 | 0.953 | 0.988 | 0.968 | 0.952 | 0.928 | 0.955 | 0.96 | 0.987 | 0.915 | 0.962 | 0.92 | 0.941 | 0.949 | 0.959 | 0.956 |

| Logistic | 0.917 | 0.959 | 0.884 | 0.956 | 0.984 | 0.963 | 0.956 | 0.917 | 0.945 | 0.96 | 0.99 | 0.914 | 0.96 | 0.904 | 0.929 | 0.944 | 0.949 | 0.959 |

References

- Kulkarni, R.; Wappler, P.; Soltani, M.; Haybat, M.; Guenther, T.; Groezinger, T.; Zimmermann, A. An Assessment of Thermoset Injection Molding for Thin-Walled Conformal Encapsulation of Board-Level Electronic Packages. J. Manuf. Mater. Process. 2019, 3, 18. [Google Scholar] [CrossRef]

- Ardebili, H.; Zhang, J.; Pecht, M. Encapsulation Technologies for Electronic Applications; William Andrew: Oxford, UK, 2018. [Google Scholar]

- Baïri, A.; Nithyadevi, N.; Baïri, I.; Martin-Garín, A.; Millán-García, J.A. Thermal design of a sensor for building control equipped with QFN electronic devices subjected to free convection. Effects of the encapsulating resin. Energy Build. 2017, 141, 218–225. [Google Scholar] [CrossRef]

- Sasajima, H.; Watanabe, I.; Takamoto, M.; Dakede, K.; Itoh, S.; Nishitani, Y.; Tabei, J.; Mori, T. New Development Trend of Epoxy Molding Compound for Encapsulating Semiconductor Chips. In Materials for Advanced Packaging; Lu, D., Wong, C.P., Eds.; Springer International Publishing: Cham, Switzerland, 2017; pp. 373–419. ISBN 978-3-319-45098-8. [Google Scholar]

- Wang, K.; Cohen, C.; Koch, D.; Hieber, C.; Yoon, K.; Gupta, M.; Harlen, O. Cornell Injection Molding Program; Progress Report; Cornell University: Ithaca, NY, USA, 1991. [Google Scholar]

- Chih-Chung, H.; Vallury, S.; Vallury, S.; Lin, K.; Yang, A. A study on warpage behavior of EMC in post-mold cure stage using Moldex3D. Addit. Conf. (Device Packag. HiTEC HiTEN CICMT) 2016, 2016, 826–850. [Google Scholar] [CrossRef]

- Kersjes, S.H.M.; Zijl, J.L.J.; de Jong, N.; Wensink, H. Exposed Die Fan-Out Wafer Level Packaging by Transfer Molding. In Proceedings of the 2018 International Wafer Level Packaging Conference (IWLPC), San Jose, CA, USA, 23–25 October 2018; pp. 1–6. [Google Scholar]

- Kim, J.; Kim, J.; Kwon, K.-H.; Yong, Y.-S.; Kim, J.-H.; Lee, D.-H.; Kim, S.-K.; Park, D. Large Area Encapsulation: Solid Type Epoxy Molding Compound. In Proceedings of the 2018 International Wafer Level Packaging Conference (IWLPC), San Jose, CA, USA, 23–25 October 2018; pp. 1–5. [Google Scholar]

- Chiu, T.-C.; Yeh, E.-Y. Warpage simulation for the reconstituted wafer used in fan-out wafer level packaging. Microelectron. Reliab. 2018, 80, 14–23. [Google Scholar] [CrossRef]

- Müller-Fiedler, R.; Knoblauch, V. Reliability aspects of microsensors and micromechatronic actuators for automotive applications. Microelectron. Reliab. 2003, 43, 1085–1097. [Google Scholar] [CrossRef]

- Lall, P.; Deshpande, S.; Kothari, N.; Suhling, J.; Nguyen, L. Effect of Thermal Cycling on Reliability of QFN Packages. In Proceedings of the 2018 17th IEEE Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems (ITherm), San Diego, CA, USA, 29 May–1 June 2018; pp. 1357–1365. [Google Scholar]

- Caswell, G.; Tulkoff, C.; Solutions, D. The effect of coating and potting on the reliability of QFN devices. In Proceedings of the 2013 SMTA International Conference, Fort Worth, TX, USA, 13–17 October 2013; pp. 41–47. [Google Scholar]

- Lin, P.; Lv, X.; Ding, Y. Study on the solder joint reliability of plastic ball grid array package for high reliability application. In Proceedings of the 2017 18th International Conference on Electronic Packaging Technology (ICEPT), Harbin, China, 16–19 August 2017; pp. 1429–1433. [Google Scholar]

- Qian, Q.; Liu, Y. Board level solder reliability simulation for epoxy mold compound based power package. In Proceedings of the 2017 IEEE 19th Electronics Packaging Technology Conference (EPTC), Singapore, 6–9 December 2017; pp. 1–5. [Google Scholar]

- Syed, A.; Kang, W. Board level assembly and reliability considerations for QFN type packages. In Proceedings of the SMTA International Conference, Chicago, IL, USA, 21–25 September 2003; pp. 181–188. [Google Scholar]

- Tong, L.; Jiang, C.; Ao, G. Research on the Board Level Reliability of High Density CBGA and CCGA under Thermal Cycling. In Proceedings of the 2018 19th International Conference on Electronic Packaging Technology (ICEPT), Shanghai, China, 8–11 August 2018; pp. 1382–1386. [Google Scholar]

- Yoon, S.W.; Hong, J.K.; Kim, H.J.; Byun, K.Y. Board-level reliability of Pb-free solder joints of TSOP and various CSPs. IEEE Trans. Electron. Packag. Manuf. 2005, 28, 168–175. [Google Scholar] [CrossRef]

- Huang, X.; Denprasert, P.M.; Zhou, L.; Vest, A.N.; Kohan, S.; Loeb, G.E. Accelerated life-test methods and results for implantable electronic devices with adhesive encapsulation. BioMed Microdev. 2017, 19, 46. [Google Scholar] [CrossRef] [PubMed]

- Zhang, W.; Feng, G. A Quick PCB Thermal Calculation for Power Electronic Devices with Exposed Pad Packages. In Proceedings of the PCIM Asia 2019; International Exhibition and Conference for Power Electronics, Intelligent Motion, Renewable Energy and Energy Management, Shanghai, China, 26–28 June 2019; pp. 1–8. [Google Scholar]

- Sytsma, S.; Wrightson, M.; Sunstrand, H. Lead-free solder durability testing at accelerated thermal excursions for QFN and DFN package interconnects. In Proceedings of the SMTA Pan Pacific Symposium, Maui, HI, USA, 30 January–1 February 2007. [Google Scholar]

- Bertsche, B. Reliability in Automotive and Mechanical Engineering: Determination of Component and System Reliability; Springer Science & Business Media: Berlin, Germany, 2008. [Google Scholar]

- Grözinger, T. Untersuchungen zu Zuverlässigkeit und Lebensdauermodellen für Gelötete SMD auf Spritzgegossenen Schaltungsträgern. Ph.D. Thesis, Universität Stuttgart, Stuttgart, Germany, 2015. [Google Scholar]

- Technical Datasheet NU 6110V; Duresco GmbH: Witterswill, Switzerland, 2018.

- Abernethy, R.B. The New Weibull Handbook: Reliability and Statistical Analysis for Predicting Life, Safety, Supportability, Risk, Cost and Warranty Claims; The New Weibull Handbook: North Palm Beach, FL, USA, 2004. [Google Scholar]

- JEDEC Solid State Technology Association. Early Life Failure Rate Calculation Procedure for Semiconductor Components; JESD74A; JEDEC Solid State Technology Association: Arlington, VA, USA, 2007. [Google Scholar]

- Soltani, M.; Kulkarni, R.; Scheinost, T.; Groezinger, T.; Zimmermann, A. A Novel Approach for Reliability Investigation of LEDs on Molded Interconnect Devices Based on FE-Analysis Coupled to Injection Molding Simulation. IEEE Access. 2019, 7, 56163–56173. [Google Scholar] [CrossRef]

| Legend (For Figure 2) | Electronic Component | Component Type | Quantity (Per PCB) |

|---|---|---|---|

| CR0603 | Chip Resistor (Ceramic) | 4 |

| CR1206 | Chip Resistor (Ceramic) | 4 |

| CC0603 | Ceramic Capacitor | 2 |

| CC1206 | Ceramic Capacitor | 2 |

| MLF28 | Quad Flat No Leads Package (QFN) | 2 |

| ElKo | Aluminum Electrolytic Capacitor | 2 |

| TSSOP8 | Small outline package | 2 |

| TSSOP14 | Small outline package | 1 |

| CABGA36 | Ball grid array (BGA) | 1 |

| DO1608C | Inductor coil | 1 |

| PT100 | Thermal resistor | 1 |

| Parameter | Value |

|---|---|

| Injection temperature | 70 °C |

| Tool temperature | 170 °C |

| Pre heat time | 5 s |

| Flow control | 1–2 cm3/s |

| Curing pressure | 250 bar |

| Curing time | 30 s |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kulkarni, R.; Soltani, M.; Wappler, P.; Guenther, T.; Fritz, K.-P.; Groezinger, T.; Zimmermann, A. Reliability Study of Electronic Components on Board-Level Packages Encapsulated by Thermoset Injection Molding. J. Manuf. Mater. Process. 2020, 4, 26. https://doi.org/10.3390/jmmp4010026

Kulkarni R, Soltani M, Wappler P, Guenther T, Fritz K-P, Groezinger T, Zimmermann A. Reliability Study of Electronic Components on Board-Level Packages Encapsulated by Thermoset Injection Molding. Journal of Manufacturing and Materials Processing. 2020; 4(1):26. https://doi.org/10.3390/jmmp4010026

Chicago/Turabian StyleKulkarni, Romit, Mahdi Soltani, Peter Wappler, Thomas Guenther, Karl-Peter Fritz, Tobias Groezinger, and André Zimmermann. 2020. "Reliability Study of Electronic Components on Board-Level Packages Encapsulated by Thermoset Injection Molding" Journal of Manufacturing and Materials Processing 4, no. 1: 26. https://doi.org/10.3390/jmmp4010026

APA StyleKulkarni, R., Soltani, M., Wappler, P., Guenther, T., Fritz, K.-P., Groezinger, T., & Zimmermann, A. (2020). Reliability Study of Electronic Components on Board-Level Packages Encapsulated by Thermoset Injection Molding. Journal of Manufacturing and Materials Processing, 4(1), 26. https://doi.org/10.3390/jmmp4010026