Abstract

Currently, because of stricter environmental standards and highly competitive markets, machining operations, as the main part of the manufacturing cycle, need to be rigorously optimized. In order to simultaneously maximize the production quality and minimize the environmental issues related to the grinding process, this research study evaluates the performance of minimum quantity lubrication (MQL) grinding using water-based nanofluids in the presence of horizontal ultrasonic vibrations (UV). In spite of the positive impacts of MQL using nanofluids and UV which are extensively reported in the literature, there is only a handful of studies on concurrent utilization of these two techniques. To this end, for this paper, five kinds of water-based nanofluids including multiwall carbon nanotube (MWCNT), graphite, Al2O3, graphene oxide (GO) nanoparticles, and hybrid Al2O3/graphite were employed as MQL coolants, and the workpiece was oscillated along the feed direction with 21.9 kHz frequency and 10 µm amplitude. Machining forces, specific energy, and surface quality were measured for determining the process efficiency. As specified by experimental results, the variation in the material removal nature made by ultrasonic vibrations resulted in a drastic reduction of the grinding normal force and surface roughness. In addition, the type of nanoparticles dispersed in water had a strong effect on the grinding tangential force. Hybrid Al2O3/graphite nanofluid through two different kinds of lubrication mechanisms—third body and slider layers—generated better lubrication than the other coolants, thereby having the lowest grinding forces and specific energy (40.13 J/mm3). It was also found that chemically exfoliating the graphene layers via oxidation and then purification prior to dispersion in water promoted their effectiveness. In conclusion, UV assisted MQL grinding increases operation efficiency by facilitating the material removal and reducing the use of coolants, frictional losses, and energy consumption in the grinding zone. Improvements up to 52%, 47%, and 61%, respectively, can be achieved in grinding normal force, specific energy, and surface roughness compared with conventional dry grinding.

1. Introduction

Surface grinding is a precision machining operation. This method is vastly used in the manufacturing of components which require smooth finishes and fine tolerances. Apart from the reliable properties of the grinding process which make grinding the most practical method for mass production, it suffers from economic and environmental impacts caused mainly by the voluminous consumption of chemical-based cutting fluids, and its poor performance in machining of non-traditional materials.

Technically speaking, in the conventional grinding (CG) process, a relatively slight portion of grains which are present in the grinding zone are actually cut. In other words, many of grains do not remove material in the shape of chips from the workpiece, but rather rub on the surface, which converts a large amount of the specific energy of grinding into heat by plowing and sliding [1]. Consequently, chemical-based cutting fluids via flood cooling are used in order to disperse the undesirable heat. In spite of the fluids’ cooling ability, there are disadvantages, such as environmental pollution from disposal, health hazards to workers (fungi, bacteria, toxicity), as well as the high cost of provision, maintenance, and timely fluid replacement, to name but a few [2]. In order to fully eliminate the consumption of chemical-based cutting fluids used in the grinding process, mechanisms which generate heat in the grinding zone must be primarily debilitated. One method to minimize these technological problems in grinding is ultrasonic assisted grinding (UAG). In UAG, grinding wheel grains proceed in the form of sinusoidal waves. These wavelike grain paths on the workpiece surface generate an interrupted material removal. The use of ultrasonic vibrations during the grinding process has produced notable improvements in almost every aspect of the process such as surface roughness, grinding forces, G-ratio, temperature and heat generation, and material removal rate [3]. This method can be applied to the workpiece or grinding wheel in the form of elliptical or linear vibrations, in various directions, frequencies, and amplitudes. UAG can be performed without the use of coolants [4], but in the absence of adequate lubrication and cooling in UAG, consequences such as poor dimension integrity, inappropriate surface finish, thermal damage on the workpiece, and accelerated wheel wear are unavoidable [4].

Given the importance of cooling in CG and even UAG, there is a critical need for an effective and also economical cooling method. According to recent studies, minimum quantity lubrication (MQL) is a very useful method which can strongly enhance grinding performance. Despite the insignificant use of a cutting fluid, the MQL technique can provide effective lubricating in the grain-material interface, thereby decreasing frictional heat generation [5]. Accordingly, MQL minimizes environmental damage generated by using conventional cutting fluids. Different types of effective MQL coolant/lubricant have been reported, among which nanofluids—a fluid containing nanometer-sized particles—show a great effectiveness [6]. A number of submitted studies illustrate that the presence of nanoparticles in a fluid reinforces its thermal properties. Similarly, nanoparticles can improve the tribological characteristics of the base fluid, which will be practically beneficial for mechanical applications such as machining. The mechanism and efficiency of tribological effects strongly depend on the intrinsic qualities of the nanoparticles dispersed in the base fluid. A comprehensive literature review on the application of nanofluids specifically in machining processes can be found in these papers [6,7].

Both MQL and UAG are being separately employed by manufacturing industries. Given the importance of cooling and lubricating in UAG, we combined these two methods for the first time and used oil-based nanofluids as the MQL lubricants [3]. In the present study, we aim to meticulously evaluate the performance of water-based nanofluids under the same conditions as our previous study. The workpiece material selected was hardened steel (AISI52100), because it is widely used in different industries and, unlike super alloys and ceramics, has no unusual thermal and mechanical behavior in grinding, which makes the analysis of the results straightforward. Obviously, this proposed technique is more practical when difficult-to-cut materials are used as the workpiece. Al2O3, graphite, GO, and multiwall carbon nanotube (MWCNT) were selected as nanoparticles, among which Al2O3 was selected for further investigation due to its spherical shapes, appropriate knoop hardness, and non-toxicity to humans. On the other hand, graphite shows notable lubrication ability due to its layered structure. Since graphite and Al2O3 nanoparticles have different lubrication mechanisms, a nanofluid with two types of nanoparticles (graphite and Al2O3) was produced to determine the possibility of more improvement. Additionally, a new type of water-based nanofluid with graphene oxide (GO) nanoplatelets of reportedly high lubrication performance [8] was developed. MWCNT as another nanoparticle was chosen because of its appealing mechanical, thermal, and chemical qualities. Pure water was selected as the base fluid because, apart from its low cost and high availability, it has no environmental drawbacks, and all of the selected nanoparticles can easily be suspended and stabilized in it.

2. Experimental Procedure

2.1. Ultrasonic Vibration System

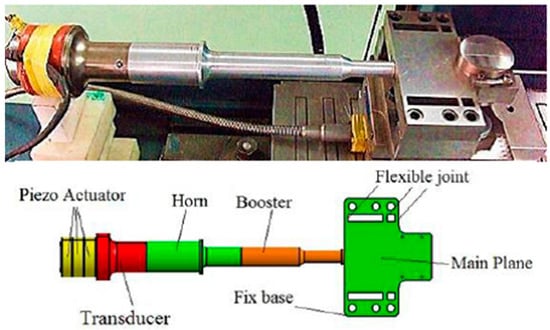

Given the reliability and accuracy of experimental data especially in the grinding process, having a rigorous approach in designing and manufacturing the experimental setup is of great importance. In order to generate high frequency oscillation (>20 kHz) in a desired shape, an experimental setup for ultrasonic assisted grinding was designed by a combination of finite element method (FEM) analysis, mathematical modeling, and optimization. As shown in Figure 1, the proposed UAG system consisted of the flexible structure, a booster, a horn, and a transducer. UAG system details and its design procedure have been presented in [3]. Unlike most ultrasonic vibration systems in the literature, this system indirectly vibrates the workpiece, that is, the booster is not attached to the workpiece, and the vibrations generated and amplified respectively by the transducer and the horn are transferred to the workpiece through flexible joints. The resonance frequency of the system was 21.9 kHz and the amplitude was 10 µm.

Figure 1.

Ultrasonic vibration system [3].

2.2. Grinding Cooling/Lubricating Conditions

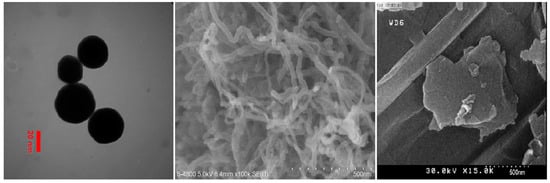

Five types of water-based nanofluids were used in the tests as MQL cutting fluids, including MWCNTs, graphite nanosheets, aluminum oxide (Al2O3) nanoparticles, graphene oxide (GO) nanoplatelets, and hybrid Al2O3/graphite nanoparticles. The water-based Al2O3 nanofluids were prepared in three volume fractions (1.0%, 2.5%, and 4.0%) of 40 nm Al2O3 nanoparticles in deionized water. Additionally, in order to assess the size effect of nanoparticles, a 130 nm Al2O3 nanoparticle at 2.5 vol % was tested. Water-based nanofluids consisting of graphite nanosheets of 50 nm mean thickness and multiwall carbon nanotube in, respectively, 2.5 vol % and 1.0 vol % concentrations were also tested. Moreover, since graphite and Al2O3 nanoparticles have different lubrication mechanisms, a nanofluid with hybrid nanoparticles (2.5 vol % graphite and 1.0 vol % Al2O3) was employed to determine the possibility of more improvement. The dispersion of Al2O3 nanofluids was physically carried out by ultrasound shaker machine without any surfactant, whereas the dispersion of the other above-mentioned nanofluids was carried out by ultrasound shaker machine as well as an ionic surfactant (sodium dodecyl sulfate (SDS)) in order to ensure homogeneity of the dispersions. Finally, GO nanoplatelets were made from graphite flake through 12 h oxidation using the Hummer’s method [9]. For purification and dispersion in water, the method used by Uddin and et al. [10] was employed. It is possible to increase the purification ratio of GO nanoplatelets using different techniques. The synthesized nanoplatelets were dispersed in water with SDS by sonication. The scanning electron microscope (SEM) images of nanoparticles prior to dispersing in water are shown in Figure 2, and Table 1 summarizes the lubricants applied in this research study.

Figure 2.

Microscopic images of nanoparticles Al2O3, multiwall carbon nanotube (MWCNT), and graphite (left to right).

Table 1.

Lubrication Conditions and Characteristics.

2.3. Machining Parameters and Measurement Equipment

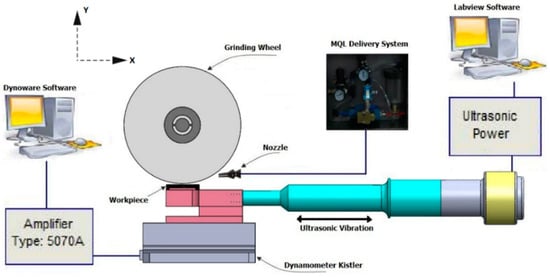

The MQL delivery system specific to nanofluids was designed and assembled by our research group [11]. Before commencing the main tests, the most suitable parameters of MQL system specific to our setup were obtained by running some preliminary tests. A schematic illustration of the grinding test equipment is shown in Figure 3.

Figure 3.

Grinding experiments diagram.

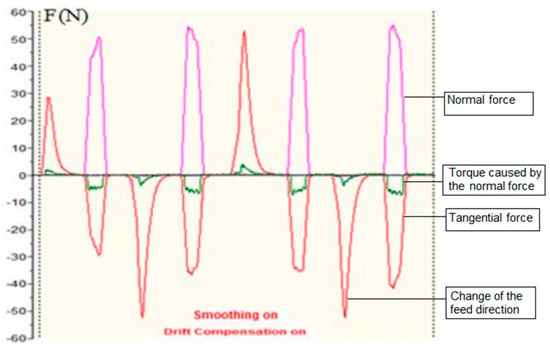

Since this research aims to introduce a novel integrative technique and because surface grinding is a more general process and its outputs can be easily measured and analyzed, we decided to evaluate the proposed method by employing flat surface grinding (JONES-SHIPMAN model 69569 540, Leicester, UK). In-put machining parameters are shown in Table 2. A three-component dynamometer (KISTLER, type B9257, Winterthur, Switzerland) was used to record grinding forces. The grinding force signal was then filtered in DynoWare (software for data acquisition and evaluation) in order to obtain the average force (Figure 4). Each test including 30 grinding passes was repeated six times and the average was calculated. Surface roughness as another evaluation tool was measured parallel to grinding feed direction using a TR200 (Qualitest, Ft. Lauderdale, FL, USA) handheld surface roughness tester.

Table 2.

Machining parameters.

Figure 4.

Grinding forces recorded by dynamometer.

3. Results and Discussion

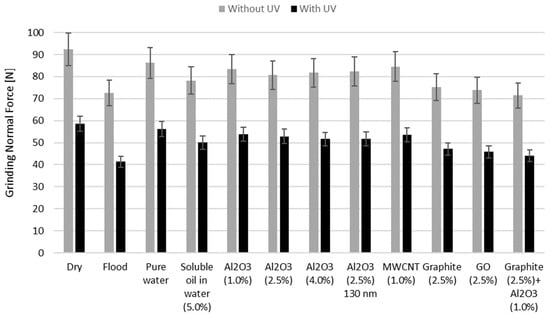

Figure 5 and Figure 6 show grinding forces with and without ultrasonic vibration (UV). In conventional grinding, dry grinding without any lubrication produces the highest normal force and the lowest is obtained in wet grinding. In comparison with pure water, the normal grinding forces of nanofluid MQL grinding are decreased (13% reduction in 2.5 vol % Al2O3, 18.4% in 2.5 vol % graphite, 20% in 2.5 vol % GO, and 22.6 vol % in graphite/Al2O3 nanofluids). This indicates that a nanofluid mist in the MQL system can effectively penetrate into the grinding zone. As shown in our research, although MQL using soluble oil in water does not show lower forces as much as flood cooling does, it makes the process proceed more conveniently compared to dry conditions. Therefore, with respect to its minimum usage of fluid, it is satisfactory.

Figure 5.

Effect of the presence of UV in minimum quantity lubrication (MQL) grinding on the normal force.

Figure 6.

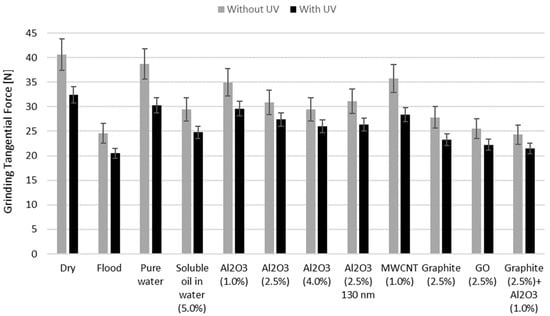

Effect of the presence of UV in MQL grinding on the tangential force.

It is known that normal force is produced by pushing grinding wheel grains into the workpiece material. As a result, this shows a strong correlation between the elongation capacity or Young’s modulus and the yield stress of workpiece material. Therefore, the variations in grinding lubricating/cooling conditions can slightly change the normal force in comparison with the tangential force. In addition, a portion of the grains rubs without plowing, another portion of the grains plows without material removing, and finally, some of them participate in all three actions [12]. To examine the grinding process, we can use the tangential force. It predicts the amount of rubbing and plowing in the grinding zone. When lubrication conditions are improved, rubbing and plowing and, subsequently, the tangential force become lower.

According to Figure 6, in CG the lowest tangential force is obtained under wet conditions and dry grinding has the highest grinding force. Predictably, the results demonstrate that pure water is not able to provide good lubrication since it does not have inherent lubricating qualities. Nevertheless, once nanoparticles such as Al2O3 or graphite are dispersed in deionized water, the grinding outputs such as forces and surface roughness improved even for concentrations of Al2O3 as low as 1.0 vol %. Grinding tangential forces are decreased significantly in comparison with dry conditions (27% reduction in 4.0 vol % Al2O3, 31% in 2.5 vol % graphite, 37% in 2.5 vol % GO, and 40% in 2.5 vol % graphite/Al2O3 nanofluids). The effective penetration of nanoparticles into the contact zone can justify these substantial improvements. Setti et al. [13] have shown that the mist content of nanoparticles can enter the grinding zone through the grinding wheel pores and the grain-fractured grooves to lubricate the contact zone.

It is presumed in MQL grinding with the Al2O3 nanofluid that spherical Al2O3 nanoparticles with high hardness and good dimensional stability can produce ball-bearing effects between frictional surfaces [14]. This lubricating capability can improve tribological characteristics, and it exhibits reduction in tangential force and results in a lower frictional shear stress, and consequently a lower friction coefficient. For example, a 130 nm 2.5 vol % Al2O3 nanofluid generates a slightly higher normal force as compared with a 40 nm nanofluid. With a high concentration and a large size of nanoparticles, we can speculate that nanoparticles fill grain-fractured grooves in the cutting area, and therefore create more pressure in the grinding zone and cause an increase in the normal force.

As it was expected, a nanofluid with graphite additives showed remarkable improvements in grinding forces. Graphite, because of its crystal structure and layered morphology, is widely used as a solid lubricant. The lubrication mechanism of graphite and Al2O3 in the grinding zone differ significantly. Graphite nanoparticle is formed from layered and planar structures called graphene. The distance between these two dimensional planes in graphite is only 0.335 nm. Within each layer of graphite, the carbon atoms are linked together by highly sturdy covalent bonds, sp2 hybridized bonds located in a hexagonal lattice, and the carbon atoms are separated by only 0.142 nm [15]. Weak van der Waals bonds among the layers provide easy sliding among them [15]. It has been previously proved that solid lubricants like graphite or MoS2 in nanoscale usually show better lubricating capability in comparison with their bulk forms [16]. When graphite nanoparticles of layered structure penetrate the contact zone, continuous sliding of the opposite surfaces results in the production of lubricating film from the crushing of the graphite nanoparticles. Chemically exfoliating the graphite nanosheets results in GO nanoplatelets with a thickness of a few nanometers. Because of graphene’s such unique characteristics, a great number of studies have thus far been published about the merits of graphene in lubricating applications [8]. When it comes to the grinding process, our study shows that the presence of GO in water can improve the lubrication in the grinding zone and reduce the sliding friction forces, thereby indicating more lubricating ability than graphite nanosheets. This observation can be elucidated based upon the innate properties of the particles and the lubrication mechanism. The authors speculate that GO nanoplatelets, because of their atomic size, can enter the sliding zone easily and diminish the direct grain to metal contact, and can create a protective and durable tribofilm via their ultra-thin laminated structures which efficiently reduces the contact surface by demonstrating “on-site” lubrication under extreme pressure (EP). However, in this research study, nanofluid with hybrid graphite/Al2O3 shows the best results in terms of grinding forces, which can be attributed to its capability of performing two different kinds of tribological mechanism.

MWCNT is formed from several coaxial circular tubes. These tubes in concentric cylinders are attached to one another by Van der Waals bonds. Due to the cylindrical structure and hybridized bonds between carbon atoms, MWCNT manifests a high modulus and strength, as well as a high length–diameter ratio [17]. Nevertheless, MWCNT does not form an effective lubrication under high pressure by rolling like spherical nanoparticles, that is, because of its hollow structure prone to agglomeration. As a result, it does not show a similar trend and effect on grinding forces compared with graphite and higher concentrations of Al2O3.

Adding ultrasonic vibrations (UV) to the workpiece leads to lower cutting forces under all conditions, although reductions in normal forces are more noticeable, varying between 37% and 52% under different grinding cooling conditions. It is incontrovertibly axiomatic that ultrasonic vibration revolutionizes the cutting mechanism and kinematics of the process. Based on the experimental results, several hypotheses have been postulated to describe the effects of the ultrasonic movement of the workpiece.

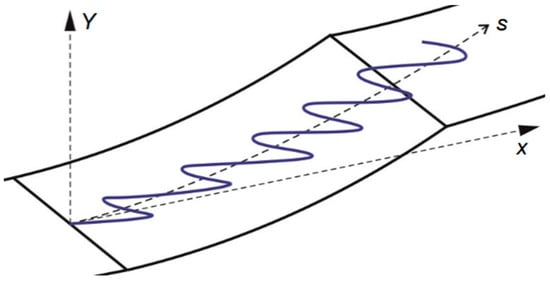

Ghahramani et al. [18] manifested variations of the undeformed chip thickness by means of oscillation, thereby influencing the grinding forces. Ultrasonic vibrations instigate impact loads between the workpiece and abrasive grains, which is expected to generate multiple fractures on the workpiece surface and increase the length of the micro cracks. Impact loads bring about self-sharpening action in the grains, especially in the seeded gel (SG) grinding wheel—made with seeded gel ceramic aluminum oxide abrasive. Accordingly, sharpened grits penetrate the material more easily, which results in reductions in the cutting forces. Abdullah et al. [19] considered the effect of imposing an additional speed component to an individual grain by horizontal ultrasonic vibrations parallel to the workpiece. They found that by means of oscillation, the grain attacks the surface at a larger angle of engagement, that is, a deeper engagement with higher active speed happens in comparison to conventional grinding, as is shown in Figure 7.

Figure 7.

Kinematics of cutting grains in the contact zone.

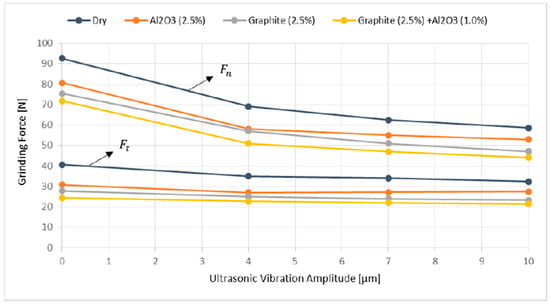

By doing so, the material removal process takes place in a more effective penetration. During UAG, because of different operation kinematics, not only are the contacts between Al2O3 grits and workpiece interrupted periodically, but also the times of these contacts are shortened. As suggested in [20] there are better lubrication conditions and material local softening in UAG. Thus, frictional effects are reduced, which results in tangential force reduction [21]. By increasing the amplitude of vibrations, the contact time lessens; therefore, higher reductions in grinding forces up to particular amounts can be reached (Figure 8).

Figure 8.

Effect of ultrasonic vibration amplitude on grinding forces.

According to the above-mentioned points, UAG takes place at a higher depth of cut, speed, and material removal ratio as well a shorter contact time compared with conventional grinding (CG). Therefore, it can be concluded that UAG is a rougher process than CG. Given the severity of UAG, the lubricating ability of the cutting fluid is of great importance. As shown in Figure 5 and Figure 6, flood cooling has generated lower forces than nanofluids. The efficiency of MQL using nanofluids—even in a small volume of nanoparticles—is much more distinguished when it is merged with ultrasonic vibrations. In ultrasonic vibration assisted grinding, due to the interrupted contact, the penetration of cutting fluid [18] and subsequently nanoparticles to the cutting zone becomes easier [6]. Accordingly, it can be concluded that MQL using nanofluids and UAG are mutually beneficial.

By comparing graphite and graphite/Al2O3 nanofluids, graphite/Al2O3 nanofluid is a better cutting fluid for all aspects of grinding such as forces, specific energy, and surface roughness, because along with ultrasonic vibrations it shows a 47% reduction in tangential force and a 52% reduction in normal force. It is reported [5] that water molecules between graphite sheets promote their effectiveness as a lubricant and that is why graphite has a better performance under wet conditions compared to dry environments. On the other hand, injected Al2O3 hard and spherical nanoparticles into the grinding zone can facilitate sliding between frictional surfaces through the physical adsorption on the surfaces, acting as ball bearings [22]. Therefore, hybrid graphite/Al2O3 nanofluid enjoys two different kinds of lubrication mechanisms and generates better lubrication than the other nanofluids. As discussed earlier, UAG GO nanoplatelets—because of their innate qualities—form a tribofilm between frictional surfaces, which shows a superior load-carrying capability and low adhesion between surfaces. The resistance of this tribofilm to destruction results in an appropriate distribution of grinding forces. By comparing CG and UAG parameters pertinent to the MWCNT nanofluid, it can be interpreted that the performance of MWCNT is reinforced by ultrasonic vibration. It has been reported that under high contact pressures, carbon nanotubes can physically lubricate and generate a tribological layer among frictional pairs by means of being deformed and adopting a lamellar shape. Despite the acceptable performance in the case of grinding forces, MWCNT—because of its high aspect ratio (2–10 μm length and 5–20 nm diameter)—agglomerates and may wrap around abrasive grains, which creates an increase in the surface roughness quality (Figure 9).

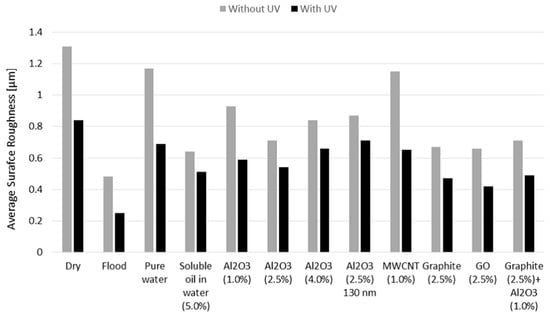

Figure 9.

Effect of the presence of UV in MQL grinding on average surface roughness.

Apart from the effect of the specific energy of grinding, which is defined as energy utilized per unit volume of material removed, on process efficiency, it has been proven by recent fundamental research that there is a strong correlation between specific energy and thermal damage on the workpiece [23]. The following formulation has been developed for calculating specific grinding energy () in CG [3]:

where, is the grinding power, is the material removal ratio, b is the grinding zone width, is the tangential grinding force, is the work or feed speed, is the depth of cut, and is the wheel speed.

Since grinding parameters are constant during the experiments, tangential force is the decisive factor in determining the specific energy. Therefore, the plot demonstrating the effects of cooling/lubricating conditions in the grinding specific energy will be similar to Figure 6. The effects of different oil-based nanofluids in UAG were studied in our previous paper [3]. Based on the above formulation, a comparison between these two research studies shows that oil-based nanofluids with MoS2 nanoparticles have the lowest specific grinding energy (32.2 J/mm3 for paraffin oil and 35.7 J/mm3 for soybean oil-based nanofluids). Thus, it appears that MQL grinding using paraffin oil with MoS2 nanoparticles is the optimum condition, which shows up to a 58% reduction in specific energy compared to dry grinding. However, water-based nanofluid with graphite/Al2O3 nanoparticles consumed an acceptable amount of energy (40.13 J/mm3), and it should also be taken into account that the preparation procedure of water-based nanofluids is much more economical than oil-based nanofluids.

As is shown in Figure 9, after ultrasonic vibration is imposed, the flood condition which possesses excellent chip flushing and lubrication shows the lowest roughness. All MQL grindings with nanofluids outperform pure water, due to its poor lubricating ability. But MQL grindings with nanofluids have worse surfaces compared to the flood cooling. It is known that normal grinding force compared to tangential force plays a prominent role in surface roughness and plastic deformation. Due to the reduction of forces in UAG, and when vibrations are applied, the adhesion of material to grains is decreased, thereby reducing redeposition. Thus, improvements in roughness, surface integrity, and temperature are expected. Among nanofluids, GO has the best surface roughness and the authors speculate that GO nanoplatelets, because of their very small dimensions, fill the cracks, grooves, or micro-scratches and produce a better surface quality.

4. Conclusions

In this important finding, it has been shown that minimum quantity lubrication (MQL) with water-based nanofluids can provide a key value-added quality to ultrasonic vibration assisted surface grinding. The following points encapsulate the experimental observations of this research.

- Apart from exceptional tribological abilities of nanofluids proven again in this study, the type and concentration of nanoparticles in the base fluid are of great importance. It was found that the shape of the nanoparticles and their molecular structures were deciding factors in their behavior.

- Deionized water containing graphite/Al2O3 nanoparticles showed better performance compared with the other types of nanofluid. Because of the layered structure of graphite and the spherical shape of Al2O3, a reduction of 23% and 39% was obtained compared to dry conditions in normal and tangential forces, respectively.

- Superimposing horizontal ultrasonic vibration onto the workpiece showed a 36% normal force reduction in dry grinding, but a 21% reduction in the tangential force. Improvements in the material removal process in UAG were attributed to the variation of the cutting mechanism in UAG, which was changed into a multiple-impact operation resulting in a reduction in plastic deformations and grinding forces.

- As an important achievement, the simultaneous application of UAG and nanofluid-MQL presents a series of complementary mechanisms. In this novel technique, the grains penetrate more deeply, whereas friction is reduced by the introduction of the third body formed by nanoparticles, thereby performing material removal more efficiently. The ultrasonic vibration assisted grinding demonstrated reductions up to 52% and 47%, respectively, in normal force and specific grinding energy when a hybrid graphite/Al2O3 nanofluid was employed.

The notable effectiveness of an integrated nanofluid-MQL and UAG presents a window of opportunity for providing an environmentally friendly grinding process and promoting its performance by virtue of enhancing surface quality, reducing grinding energy, and minimizing the volume of lubricants consumed. This technique can be applied to other machining processes such as turning, milling, and fine-finishing.

Author Contributions

J.A. conceived the idea of this research. M.M.M. designed and built the set-up, synthesized the nanofluids, and run the tests. M.M.M wrote the paper, and A.Z. contributed in analyzing the results.

Funding

This research received no external funding.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Marinescu, I.D.; Hitchiner, M.P.; Uhlmann, E.; Rowe, W.B.; Inasaki, I. Handbook of Machining with Grinding Wheels; CRC Press: Boca Raton, FL, USA, 2006. [Google Scholar]

- Passman, F.J.; Rossmore, H.W. Reassessing the Health Risks Associated with Employee Exposure to Metalworking Fluid Microbes. Lubr. Eng. 2009, 58, 30–38. [Google Scholar]

- Molaie, M.M.; Akbari, J.; Movahhedy, M.R. Ultrasonic assisted grinding process with minimum quantity lubrication using oil-based nanofluids. J. Clean. Prod. 2016, 129, 212–222. [Google Scholar] [CrossRef]

- Tawakoli, T.; Azarhoushang, B.; Rabiey, M. Ultrasonic assisted dry grinding of 42CrMo4. Int. J. Adv. Manuf. Technol. 2009, 42, 883–891. [Google Scholar] [CrossRef]

- Gupta, M.K.; Sood, P.K.; Sharma, V.S. Machining Parameters Optimization of Titanium Alloy using Response Surface Methodology and Particle Swarm Optimization under Minimum-Quantity Lubrication Environment. Mater. Manuf. Process. 2016, 31, 1671–1682. [Google Scholar] [CrossRef]

- Sharma, A.K.; Tiwari, A.K.; Dixit, A.R. Progress of Nanofluid Application in Machining: A Review. Mater. Manuf. Process. 2015, 30, 813–828. [Google Scholar] [CrossRef]

- Sharma, A.K.; Tiwari, A.K.; Dixit, A.R. Rheological behaviour of nanofluids: A review. Renew. Sustain. Energy Rev. 2016, 53, 779–791. [Google Scholar] [CrossRef]

- Berman, D.; Erdemir, A.; Sumant, A.V. Graphene: A new emerging lubricant. Mater. Today 2014, 17, 31–42. [Google Scholar] [CrossRef]

- Zhang, J.; Lei, J.; Pan, R.; Xue, Y.; Ju, H. Highly sensitive electrocatalytic biosensing of hypoxanthine based on functionalization of graphene sheets with water-soluble conducting graft copolymer. Biosens. Bioelectron. 2010, 26, 371–376. [Google Scholar] [CrossRef] [PubMed]

- Uddin, M.E.; Kuila, T.; Nayak, G.C.; Kim, N.H.; Ku, B.C.; Lee, J.H. Effects of various surfactants on the dispersion stability and electrical conductivity of surface modified graphene. J. Alloys Compd. 2013, 562, 134–142. [Google Scholar] [CrossRef]

- Majid, M.M.; Reza, M.M.; Javad, A. MQL Delivery System Special to Nanofluids. Patent Application No. 88326, 12 April 2016. [Google Scholar]

- Rowe, W.B. Principles of Modern Grinding Technology; William Andrew: New York, NY, USA, 2013. [Google Scholar]

- Setti, D.; Sinha, M.K.; Ghosh, S.; Rao, P.V. Performance evaluation of Ti–6Al–4V grinding using chip formation and coefficient of friction under the influence of nanofluids. Int. J. Mach. Tools Manuf. 2015, 88, 237–248. [Google Scholar] [CrossRef]

- Mao, C.; Huang, Y.; Zhou, X.; Gan, H.; Zhang, J.; Zhou, Z. The tribological properties of nanofluid used in minimum quantity lubrication grinding. Int. J. Adv. Manuf. Technol. 2014, 71, 1221–1228. [Google Scholar] [CrossRef]

- Dappe, Y.J.; Basanta, M.A.; Flores, F.; Ortega, J. Weak chemical interaction and van der Waals forces between graphene layers: A combined density functional and intermolecular perturbation theory approach. Phys. Rev. B 2016, 74, 205434. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, C.; Jia, D.; Zhang, D.; Zhang, X. Experimental evaluation of MoS2 nanoparticles in jet MQL grinding with different types of vegetable oil as base oil. J. Clean. Prod. 2015, 87, 930–940. [Google Scholar] [CrossRef]

- Street, K.W.; Kazuhisa, M.; Vander, W.R. Application of carbon based nano-materials to aeronautics and space lubrication. In Superlubricity; Elsevier: Kidlington, UK, 2007; pp. 311–340. [Google Scholar]

- Nik, M.G.; Movahhedy, M.R.; Akbari, J. Ultrasonic-Assisted Grinding of Ti6Al4V Alloy. Procedia CIRP 2012, 1, 353–358. [Google Scholar] [CrossRef]

- Abdullah, A.; Farhadi, A.; Pak, A. Ultrasonic-assisted dry creep-feed up-grinding of superalloy Inconel738LC. Exp. Mech. 2012, 52, 843–853. [Google Scholar] [CrossRef]

- Hecker, R.; Liang, S.; Wu, X.; Xia, P.; Jin, D. Grinding force and power modeling based on chip thickness analysis. Int. J. Adv. Manuf. Technol. 2007, 33, 449–459. [Google Scholar] [CrossRef]

- Tawakoli, T.; Azarhoushang, B. Influence of ultrasonic vibrations on dry grinding of soft steel. Int. J. Mach. Tools Manuf. 2008, 48, 1585–1591. [Google Scholar] [CrossRef]

- Luo, T.; Wei, X.; Huang, X.; Huang, L.; Yang, F. Tribological properties of Al2O3 nanoparticles as lubricating oil additives. Ceram. Int. 2014, 40, 7143–7149. [Google Scholar] [CrossRef]

- Malkin, S. Grinding Technology: Theory and Applications of Machining with Abrasives; Society of Manufacturing Engineers: Dearborn, MI, USA, 1989. [Google Scholar]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).