A Computer-Aided Sustainable Modelling and Optimization Analysis of CNC Milling and Turning Processes

Abstract

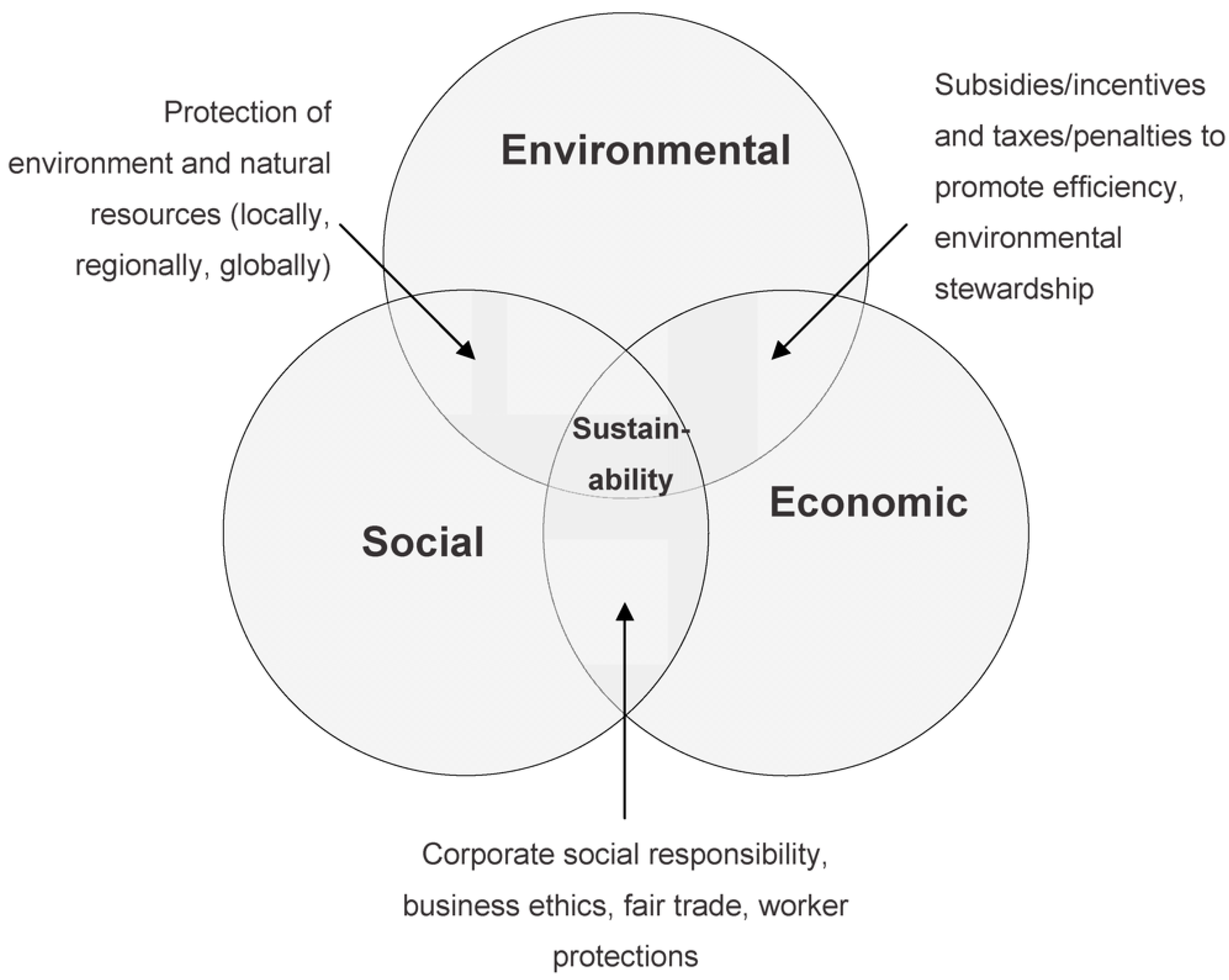

1. Introduction

- Cost (labor, machine apparatuses, cutting instruments—as a capacity of machining time).

- Environment (energy used, material and process emission from use of cutting solutions).

- Quality (process capacity, scrap rate, in process control needs and so forth).

- Lead time (material evacuation rates, diminished set-up times—consequently diminished standby circumstances).

- Flexibility (routines, knowledge base engineering and competence) it is vital to comprehend the interrelation between various machining factors, choices, imperatives and so forth and their separate effect on the machining result.

- complex mathematical relations are involved;

- manual calculations need to be used that are prone to error;

- a lot of literature needs to be referred to for collecting the data;

- lot of human effort is required at every stage;

- this is an iterative and time-consuming process [17].

- To determine performance metrics for a milling and turning process.

- To propose a methodology for determining science-based measurements for both machining processes.

- To develop a computer model that could evaluate sustainability of machining processes from process plan of the part with the help of MATLAB Software.

- To verify the proposed methodology, compare output data obtained from the machining processes (face milling, peripheral milling and turning).

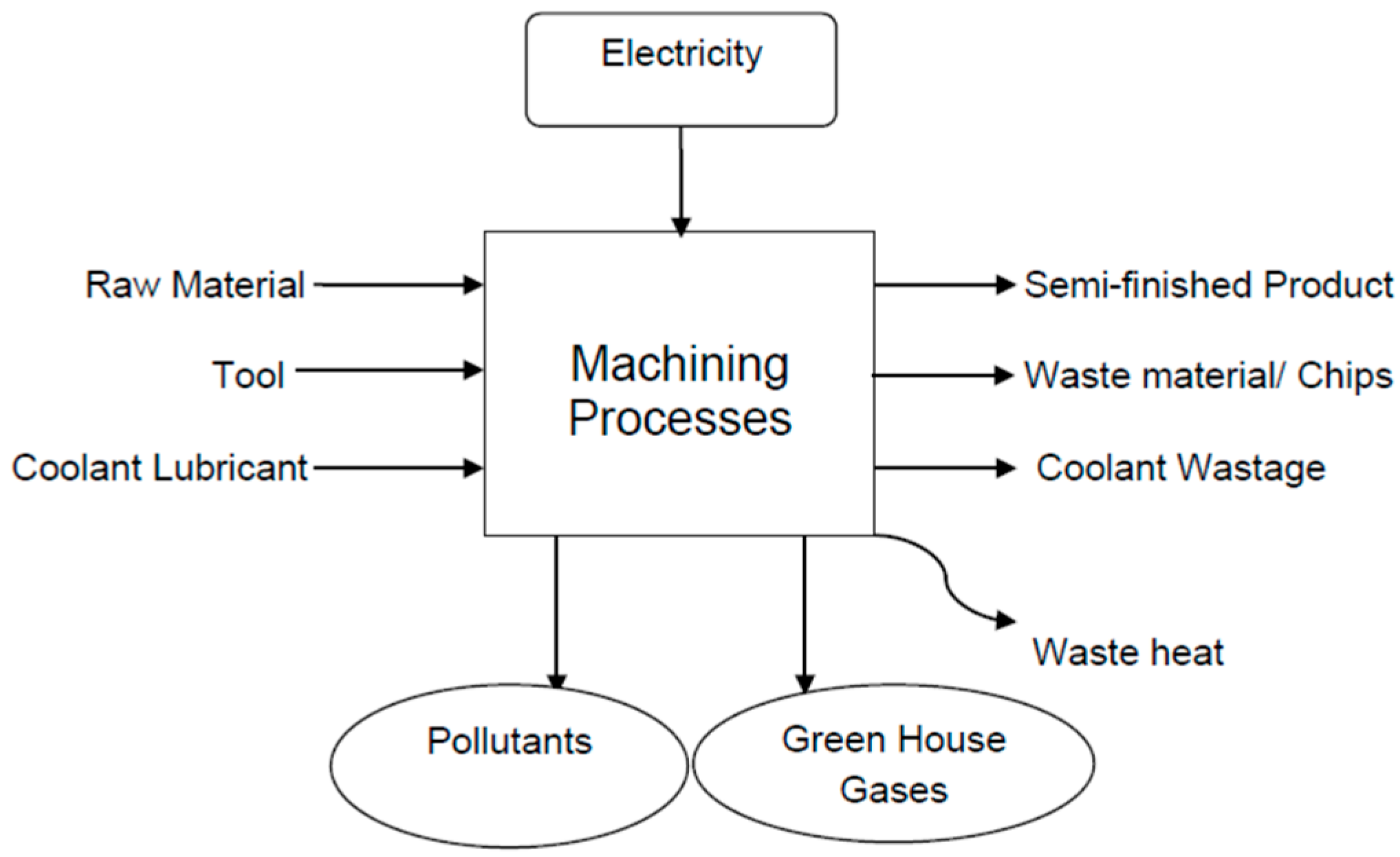

2. Methodology for Sustainable Modeling for Milling/Turning Process

- input sources or materials;

- energy requirements;

- material loss (whether recycle or waste);

- the main machine (or material) factors which relate the inputs shown in Figure 2 to the outputs.

2.1. Sustainability Analysis for the Machining Process

- = Basic power;

- = Basic time;

- = Ideal power;

- = Ideal time;

- = Machining power;

- = Machining time.

- = Width of cut;

- = Depth of cut;

- = Volume of material;

- = Mass of chip.

- = Initial workpiece diameter;

- = Final workpiece diameter.

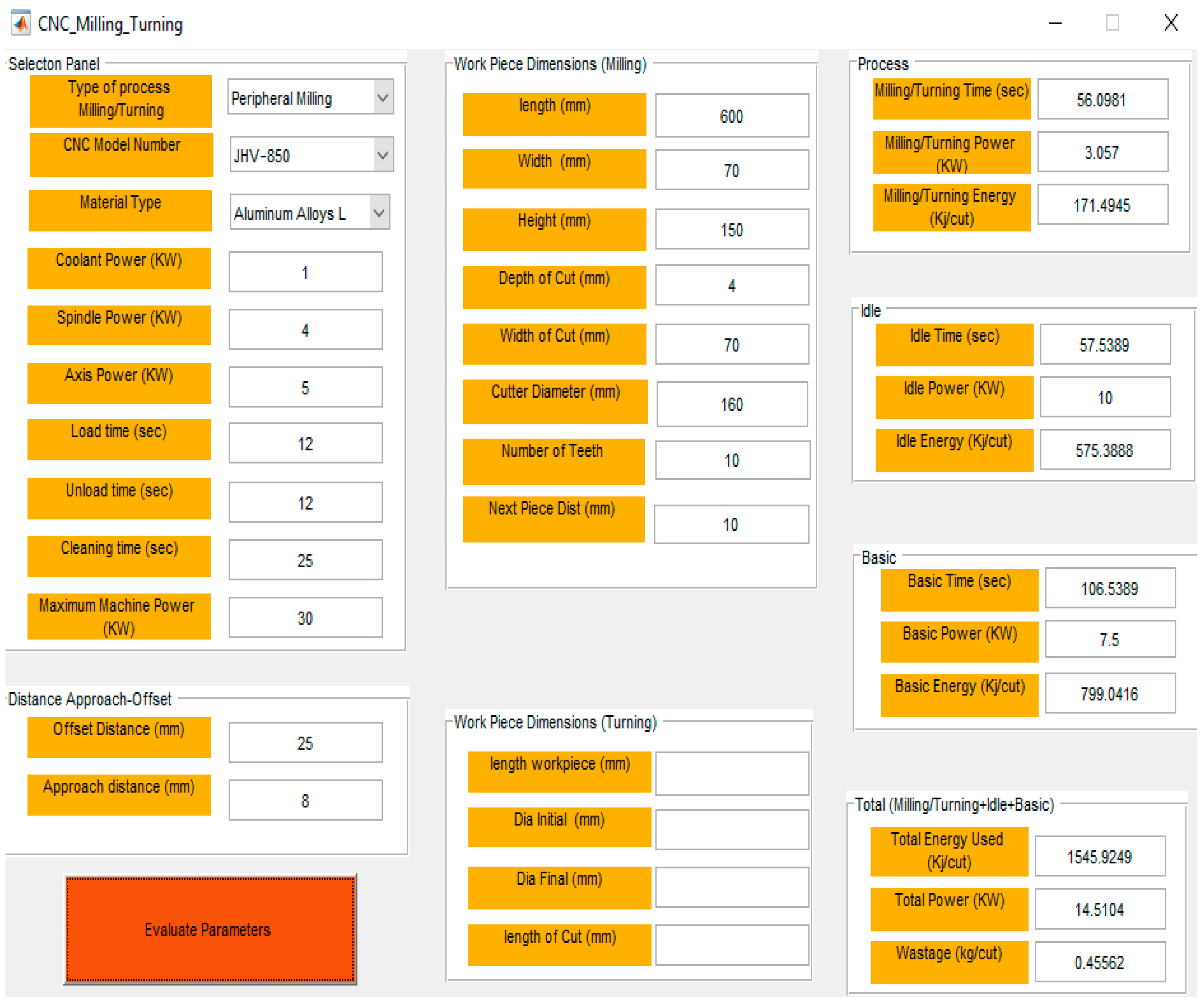

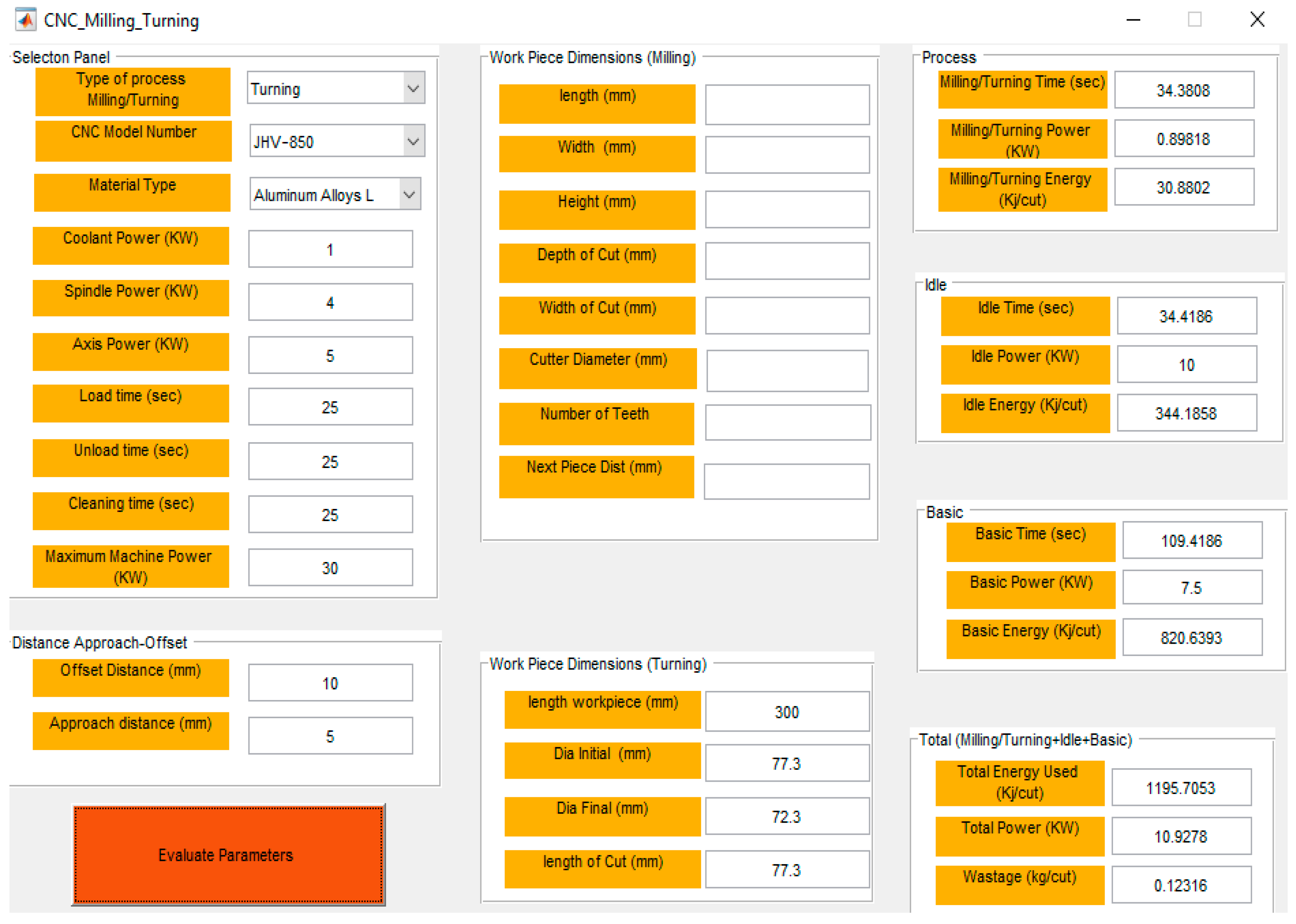

2.2. Developing Graphical User Interface in MATLAB

- specific cutting energy (W/mm3 per sec),

- cutting speed (m/min),

- feed per teeth (mm/rev),

- density (kg/m3) and

- X-Y transverse speeds while retracting step for different types of workpiece materials.

2.2.1. Case Study 1, the Milling Process

2.2.2. Case Study 2, the Turning Process

3. Analysis for Sustainability Optimization

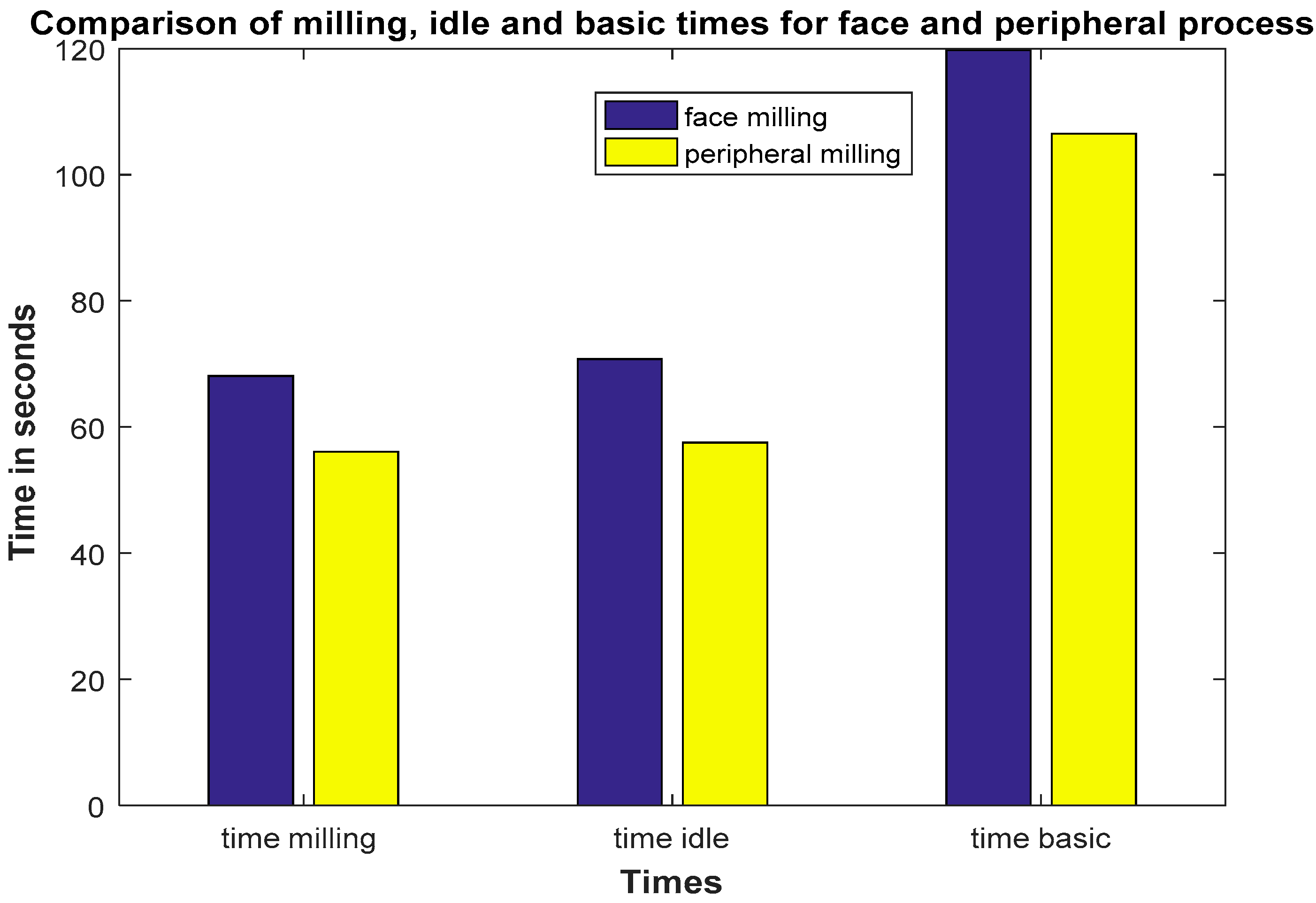

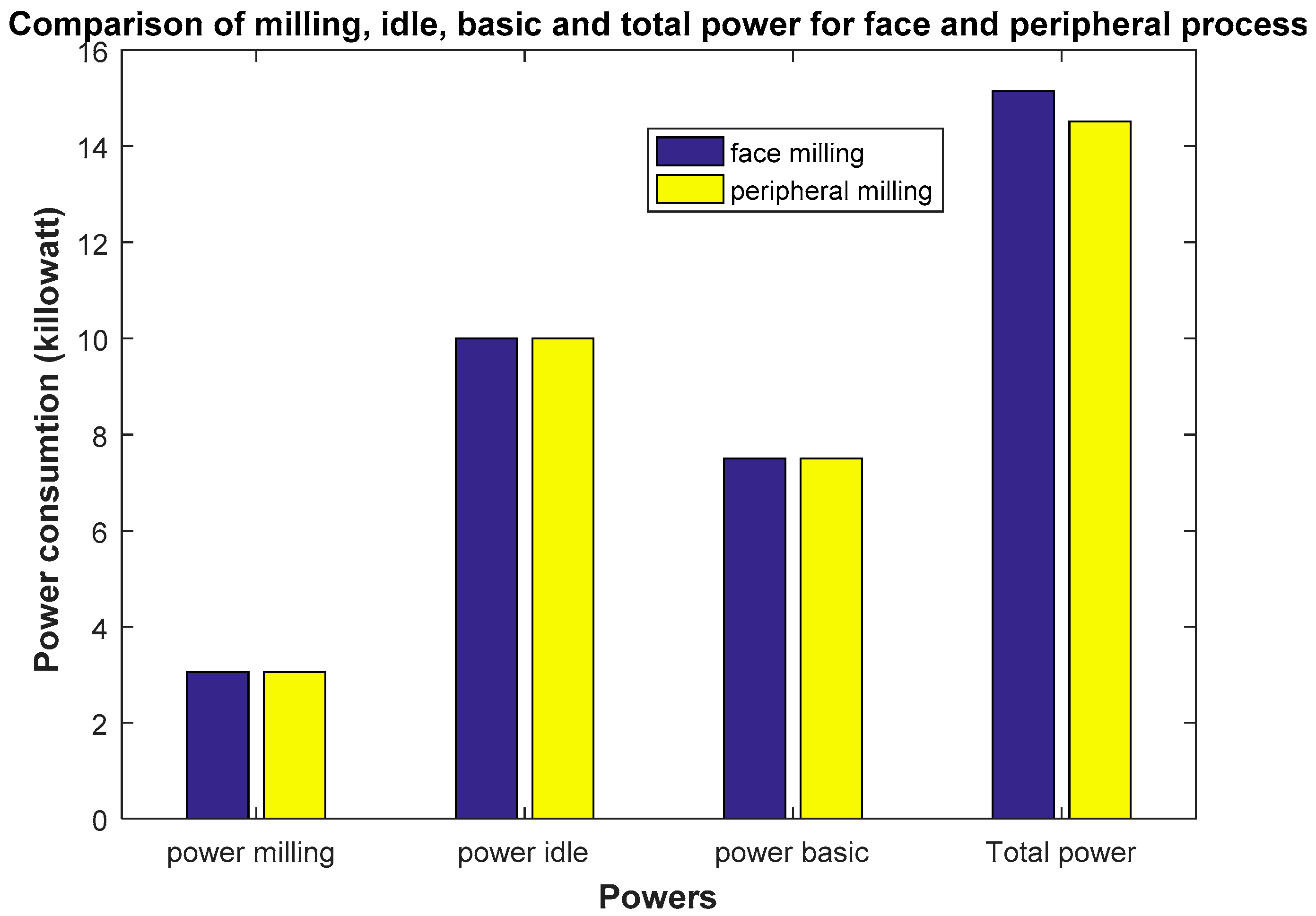

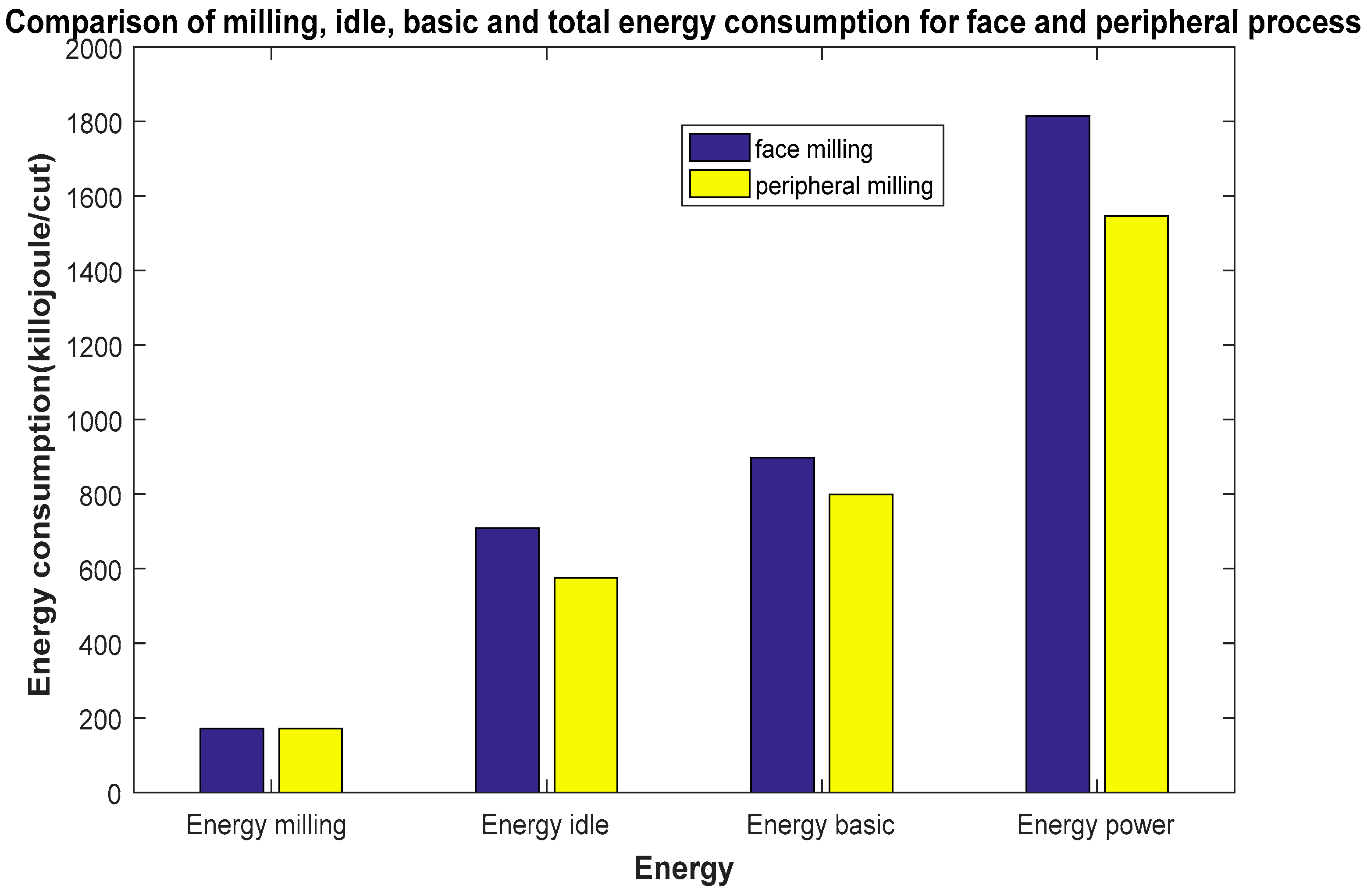

3.1. Comparison of Face and Peripheral Milling Operations for Different Output Parameters

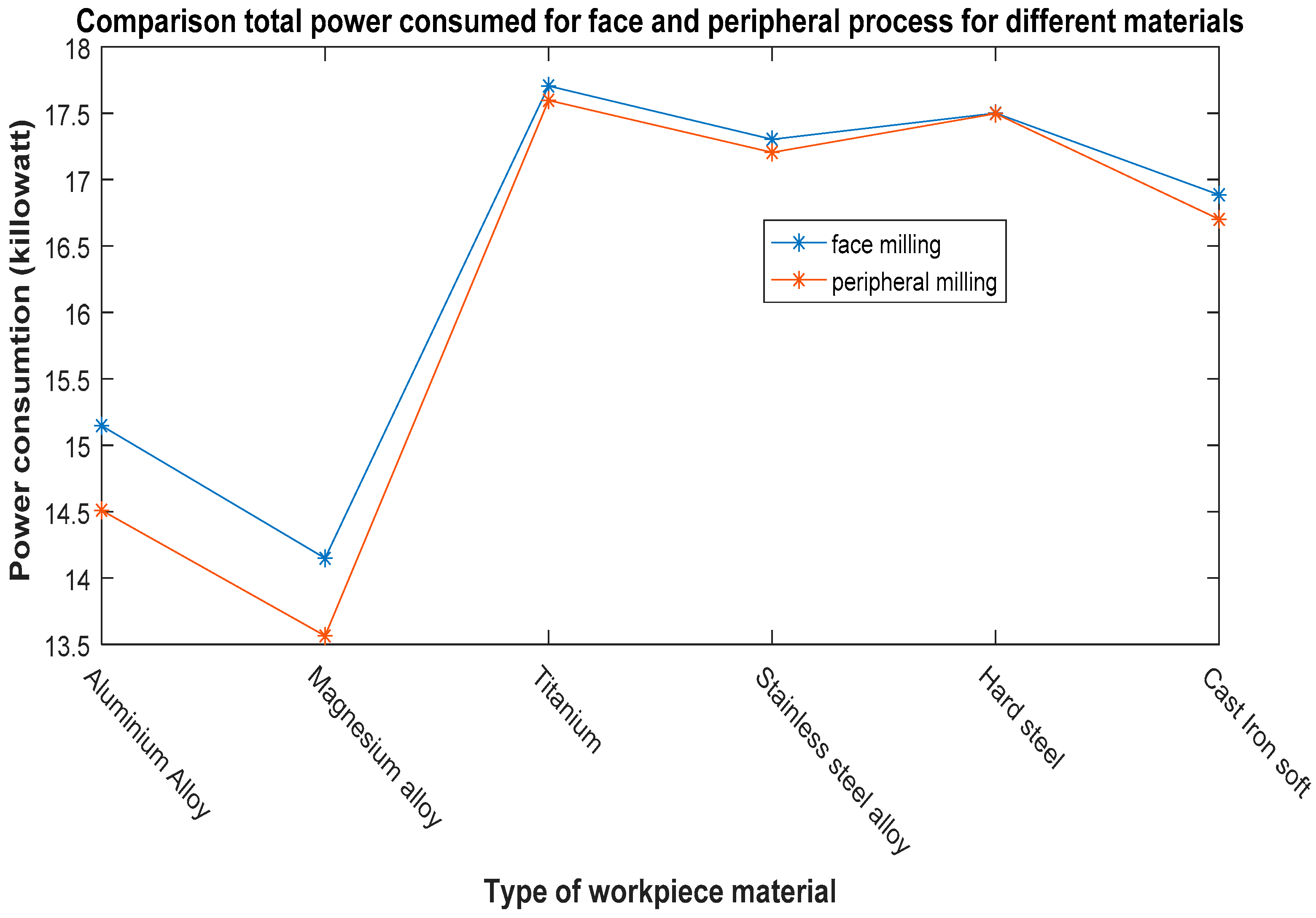

3.2. Effect of Material Selection on the Sustainability Parameters in the Milling Process

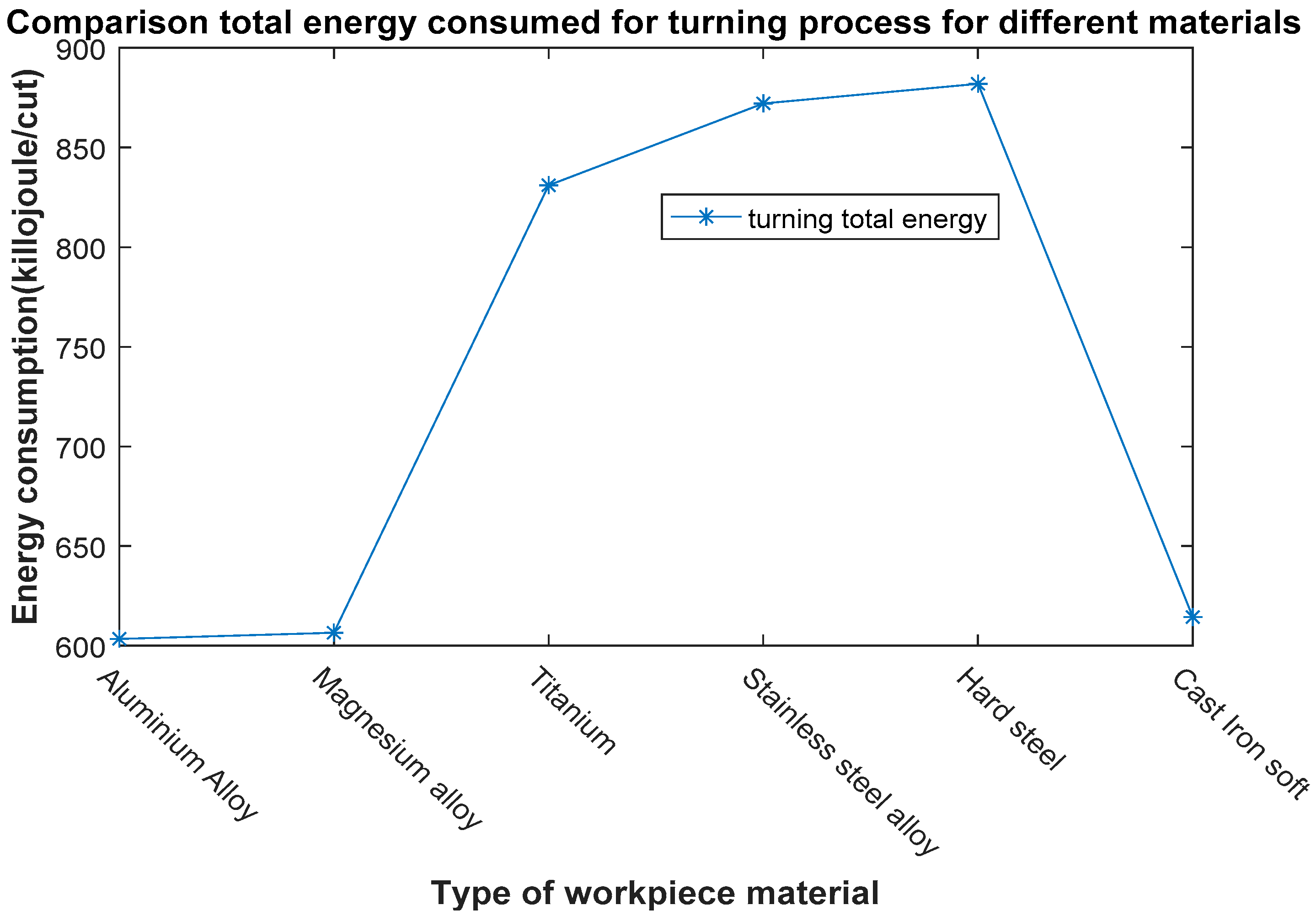

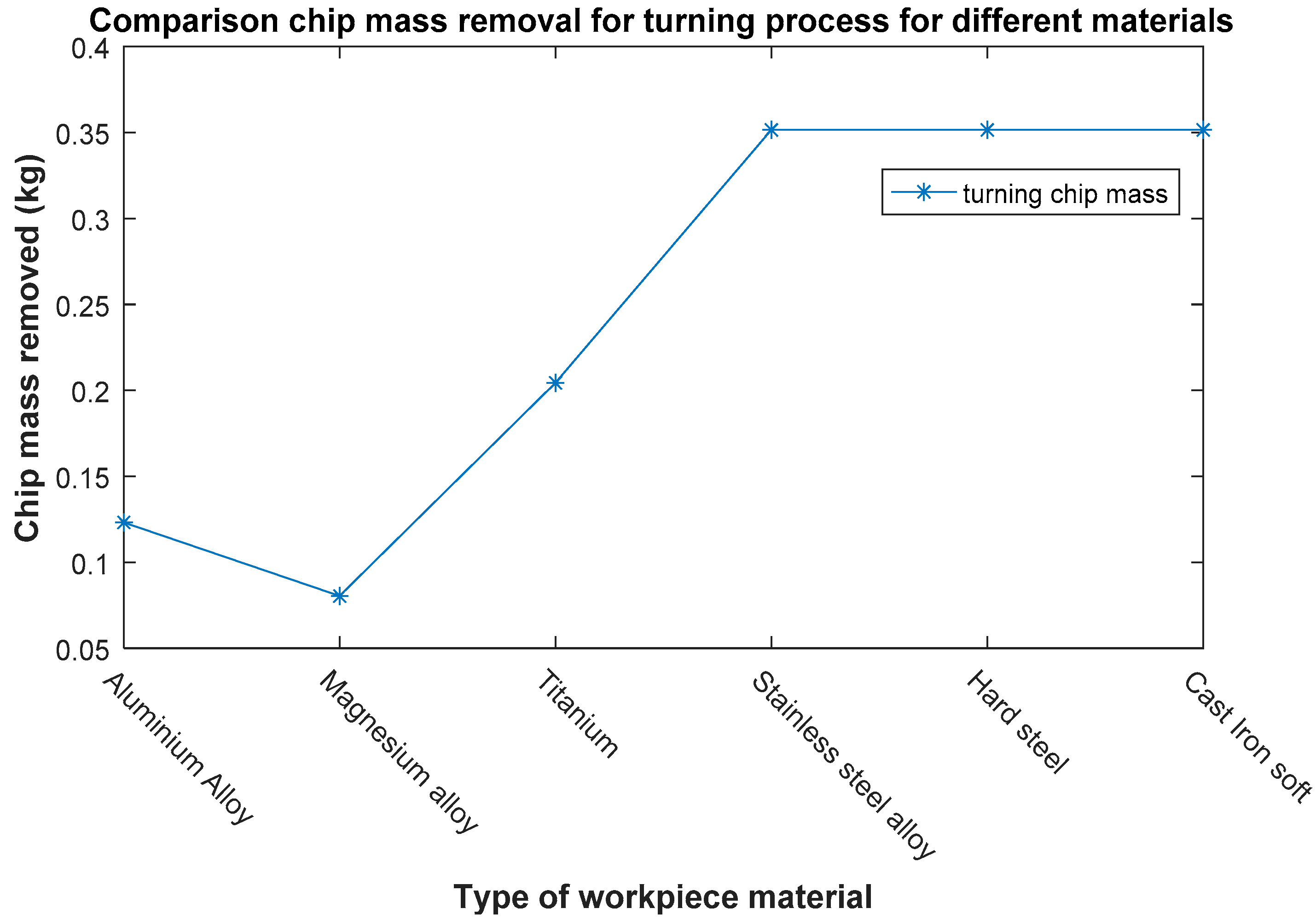

3.3. Effect of Material Selection on the Sustainability Parameters in the Turning Process

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Deaib, I. On Energy Efficient and Sustainable Machining through Hybrid Processes. Mater. Manuf. Process. 2014, 29, 1338–1345. [Google Scholar] [CrossRef]

- Anderberg, S.; Beno, T.; Pejryd, L. Energy and cost efficiency in CNC machining from a process planning perspective. In Sustainable Manufacturing; Springer: Berlin/Heidelberg, Germany, 2012; pp. 393–398. [Google Scholar]

- Lee, J.Y.; Kang, H.S.; Noh, S.D. MAS2: An integrated modeling and simulation-based life cycle evaluation approach for sustainable manufacturing. J. Clean. Prod. 2014, 66, 146–163. [Google Scholar] [CrossRef]

- Bhanot, N.; Rao, P.V.; Deshmukh, S.G. An integrated sustainability assessment framework: A case of turning process. Clean Technol. Environ. Policy 2016, 18, 1475–1513. [Google Scholar] [CrossRef]

- Li, Y.-F.; Wang, Y.-L.; He, Y.; Wang, Y.; Lin, S.-L. Modeling Method for Flexible Energy Behaviors in CNC Machining Systems. Chin. J. Mech. Eng. 2018, 31, 1–11. [Google Scholar] [CrossRef]

- Peng, T. An interoperable energy consumption analysis system for CNC machining. J. Clean. Prod. 2017, 140, 1828–1841. [Google Scholar] [CrossRef]

- Gutowski, T.; Dahmus, J.; Thiriez, A. Electrical energy requirements for manufacturing processes. In Proceedings of the 13th CIRP International Conference on Life Cycle Engineering, Leuven, Belgium, 31 May–2 June 2006; pp. 1–6. [Google Scholar]

- DIaz, N.; Redelsheimer, E.; Dornfeld, D. Energy Consumption Characterization and Reduction Strategies for Milling Machine Tool Use. In Proceedings of the CIRP International Conference on Life Cycle Engineering, Braunschweig, Germany, 2–4 May 2011; Springer: Berlin/Heidelberg, Germany, 2011; pp. 263–267. [Google Scholar]

- Rajemi, M.; Mativenga, P.; Aramcharoen, A. Sustainable machining: Selection of optimum turning conditions based on minimum energy considerations. J. Clean. Prod. 2010, 18, 1059–1065. [Google Scholar] [CrossRef]

- Mori, M.; Fujishima, M.; Inamasu, Y.; Oda, Y. A study on energy efficiency improvement for machine tools. CIRP Ann. 2011, 60, 145–148. [Google Scholar] [CrossRef]

- Avram, O.; Xirouchakis, P. Evaluating the use phase energy requirements of a machine tool system. J. Clean. Prod. 2011, 19, 699–711. [Google Scholar] [CrossRef]

- Hu, S.; Liu, F.; He, Y.; Hu, T. An on-line approach for energy efficiency monitoring of machine tools. J. Clean. Prod. 2012, 27, 133–140. [Google Scholar] [CrossRef]

- Calvanese, M.L.; Albertelli, P.; Matta, A.; Taisch, M. Analysis of Energy Consumption in CNC Machining Centers and Determination of Optimal Cutting Conditions. In Proceedings of the CIRP International Conference on Life Cycle Engineering, Singapore, 17–19 April 2013; Springer: Singapore, 2013; pp. 227–232. [Google Scholar]

- Draganescu, F.; Gheorghe, M.; Doicin, C. Models of machine tool efficiency and specific consumed energy. J. Mater. Process. Technol. 2003, 141, 9–15. [Google Scholar] [CrossRef]

- Kara, S.; Qureshi, F.; Li, W.; Herrmann, C. Unit process energy consumption models for material removal processes. CIRP Ann. 2011, 60, 37–40. [Google Scholar] [CrossRef]

- Guo, Y.; Loenders, J.; Duflou, J.; Lauwers, B. Optimization of Energy Consumption and Surface Quality in Finish Turning. Procedia CIRP 2012, 1, 512–517. [Google Scholar] [CrossRef]

- Singh, K.; Sultan, I. Framework for Sustainability Performance Assessment for Manufacturing Processes—A Review. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2017; Volume 73, pp. 1–6. [Google Scholar]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Singh, K.; Sultan, I.A. A Computer-Aided Sustainable Modelling and Optimization Analysis of CNC Milling and Turning Processes. J. Manuf. Mater. Process. 2018, 2, 65. https://doi.org/10.3390/jmmp2040065

Singh K, Sultan IA. A Computer-Aided Sustainable Modelling and Optimization Analysis of CNC Milling and Turning Processes. Journal of Manufacturing and Materials Processing. 2018; 2(4):65. https://doi.org/10.3390/jmmp2040065

Chicago/Turabian StyleSingh, Karmjit, and Ibrahim A. Sultan. 2018. "A Computer-Aided Sustainable Modelling and Optimization Analysis of CNC Milling and Turning Processes" Journal of Manufacturing and Materials Processing 2, no. 4: 65. https://doi.org/10.3390/jmmp2040065

APA StyleSingh, K., & Sultan, I. A. (2018). A Computer-Aided Sustainable Modelling and Optimization Analysis of CNC Milling and Turning Processes. Journal of Manufacturing and Materials Processing, 2(4), 65. https://doi.org/10.3390/jmmp2040065