Support Structures for Additive Manufacturing: A Review

Abstract

1. Introduction

2. Methods

3. 3D Printing Technologies and Support Structures

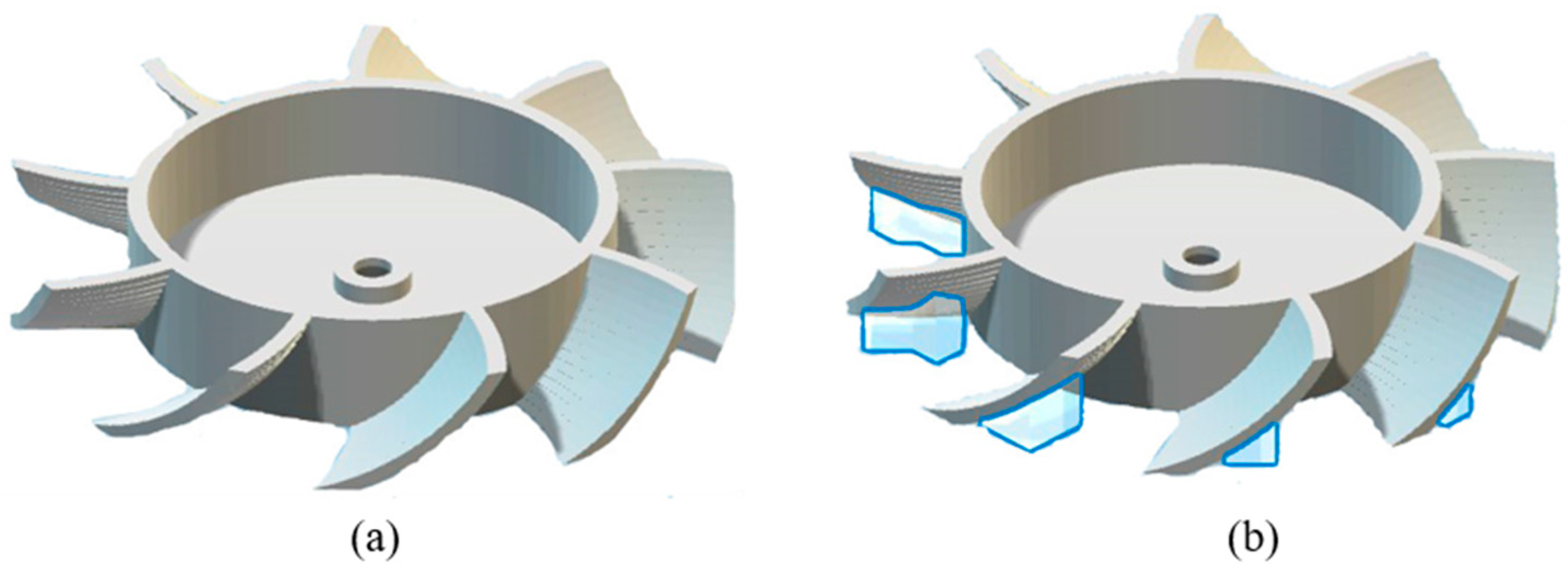

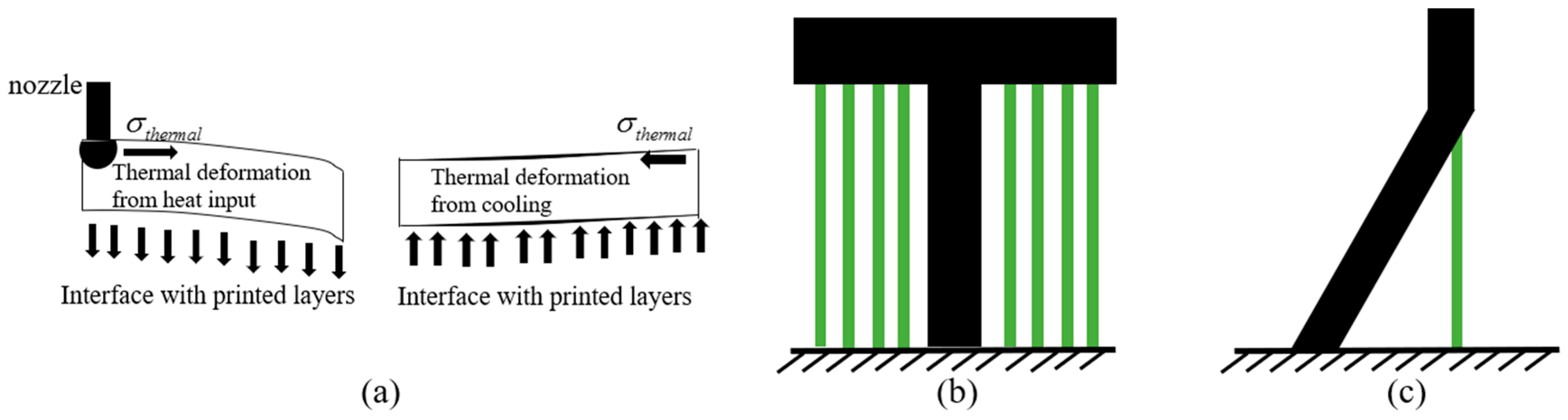

- Some printing processes may include high thermal gradients, especially metal processes. Therefore, shape distortions and residual stresses may occur due to this excessive heat accumulation [17]. In this case, the support structures play the role of both a heat diffuser and rigidity enhancer. Figure 3a shows an illustration of thermal deformation due to residual stresses.

- Local deposition processes (such as fused deposition modeling (FDM), Direct metal deposition (DMD)) can only deposit material on existing surfaces below. A support structure is, therefore, necessary to ensure that material is deposited at the intended height and the expected output geometry is achieved. Figure 3b shows such an example schematically.

- Shapes of the printed parts may move or deform during the printing process, typically when fabricating unbalanced parts or the raw material (powder, resin) is unable to sustain the weight of that part. In this case, the support structure plays the role of a fixture. Figure 3c shows an example of part balance. Here in this figure, if there is no support structure, the part is unable to stand in balance and will collapse. Further, a support structure can act as a tether in powder bed processes to stop any shift, especially layer shift during re-coating processes.

- The removal of support structures after printing often requires a significant amount of manual work, especially in the case of metal processes. Support structures need extra time to be cut, ground or milled off after printing. Consequently, labor and time to manufacture the part increases. Different support methods will also lead to different finish surface roughness, thus, influencing the post-processing.

- The requirement of manually removing the support from the part constrains the geometric freedom of the part as there needs to be hand/tool access.

- Support structures typically result in wasted feedstock material as they are not reusable and have to be discarded after removal if not recyclable.

- When adding a support structure to a part, the print time will be longer as the support structure also needs to be printed. As additive manufacturing processes typically have energy costs that scale with the volume of material used, this leads to increased energy usage.

- A support structure may be detrimental to the surface finish when the structure is removed.

- Extra time is required to design the part to accommodate the support structure and the design of the support structure itself. This implies a larger data file for the part. As printing speed increases and the complexity of a single voxel increases by incorporation of information such as color and material, the speed of data transfer may become a limitation.

- The set-up of STL (or equivalent data file) models ready for printing requires the specification of the print orientation and the subsequent generation and placement of support structures. This generally requires manual intervention based on the expertise of the operator.

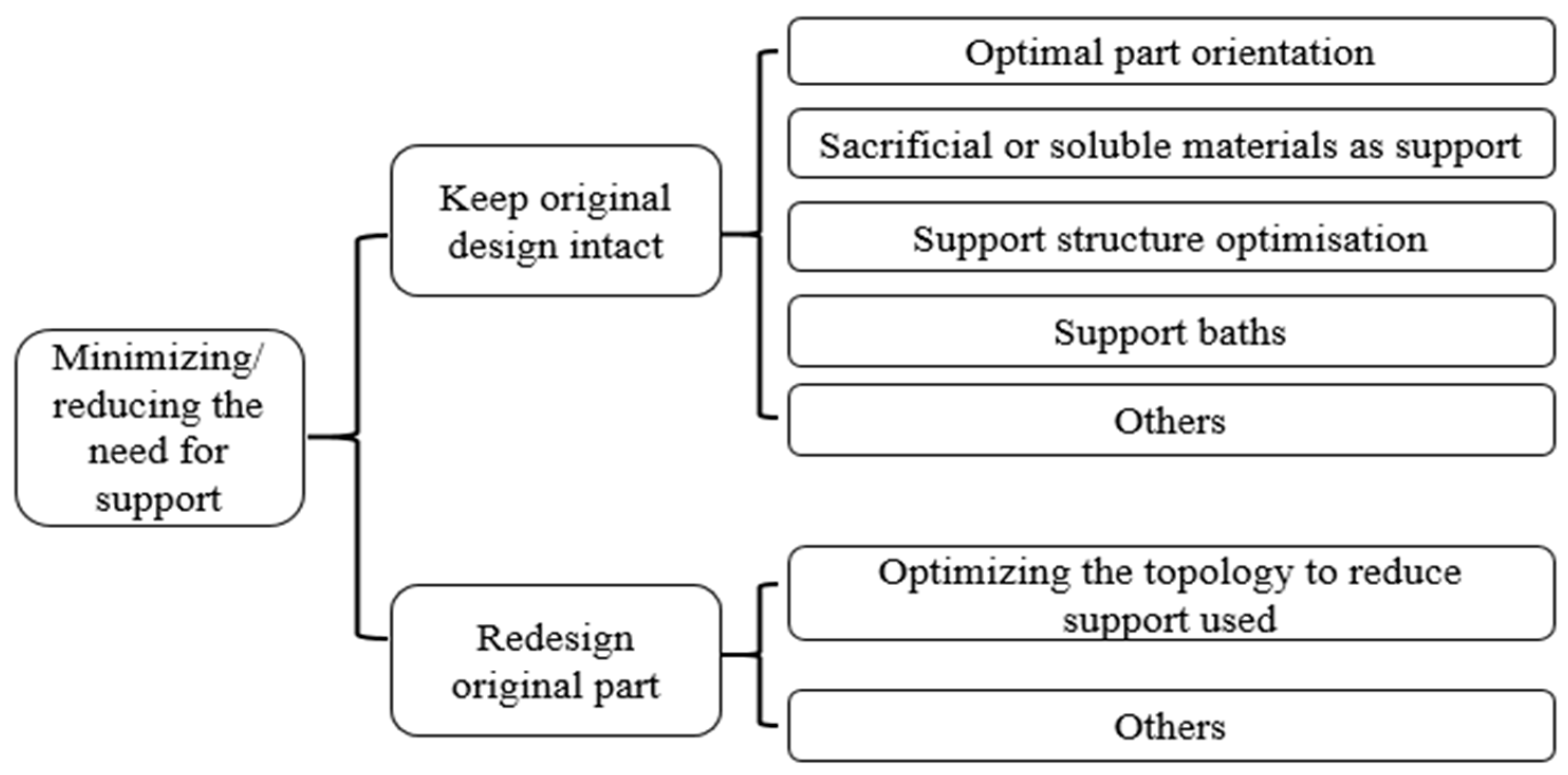

4. Support Structure Methods in 3D Printing

4.1. Keep Original Design Intact

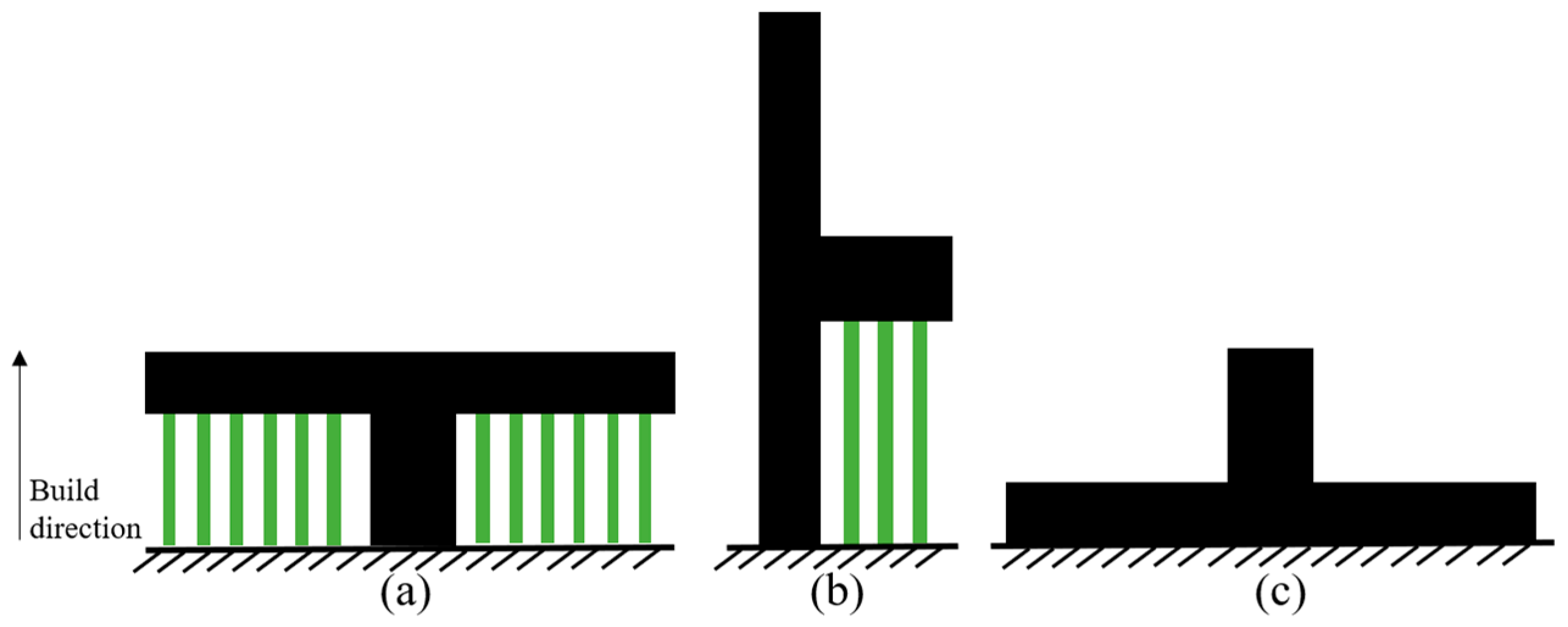

4.1.1. Optimal Part Orientation

4.1.2. Sacrificial or Soluble Materials as Support

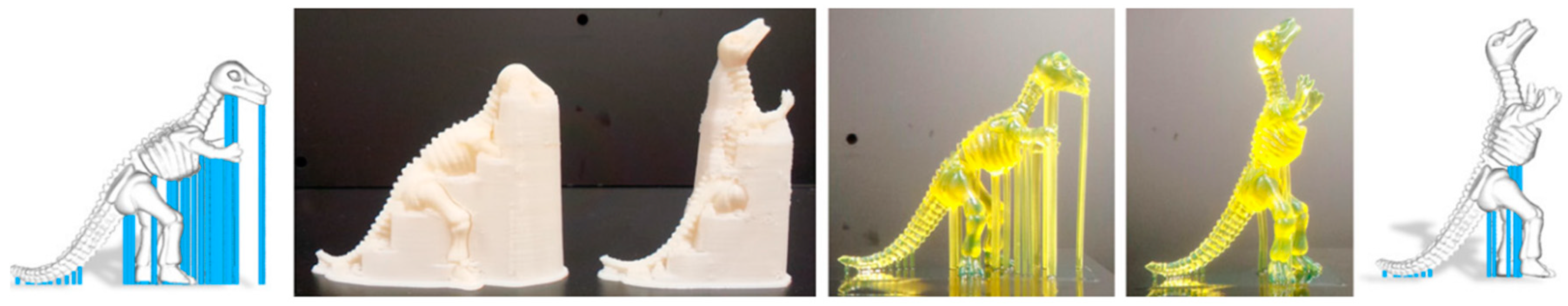

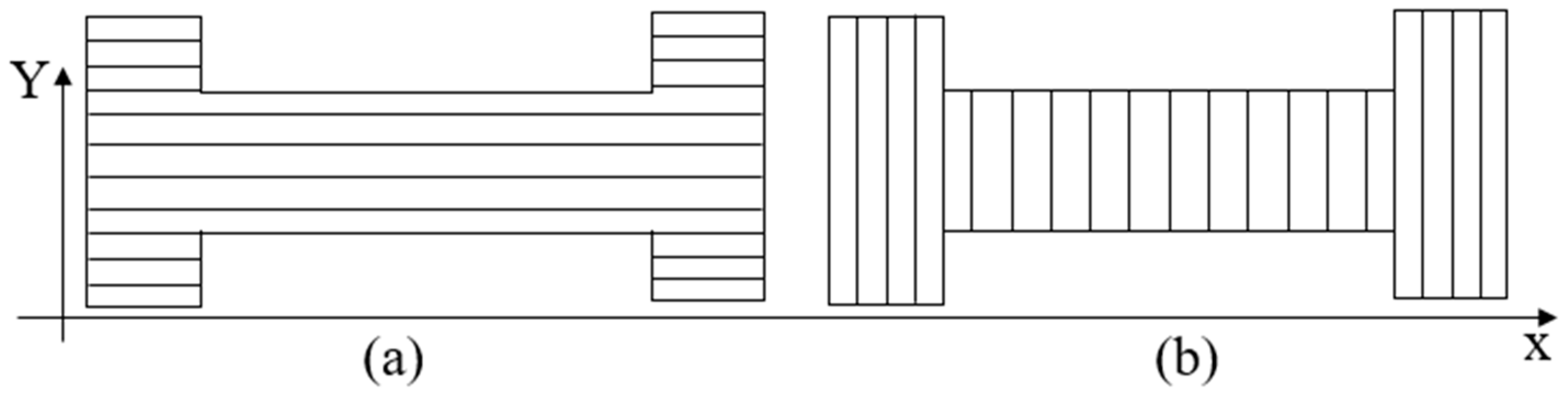

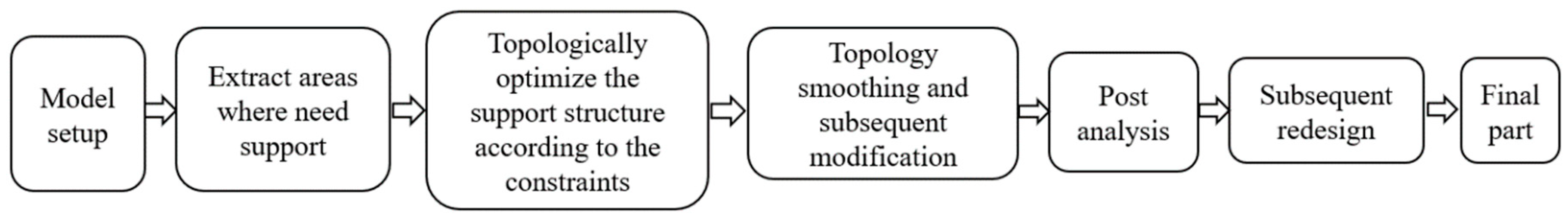

4.1.3. Support Structure Optimization

4.1.4. Support Baths

4.1.5. Others

4.2. Redesign Original Part

4.2.1. Optimizing the Topology to Reduce Support Used

4.2.2. Others

5. Discussion and Future Directions

5.1. Limitations of Current Methods

5.2. Efforts in Eliminating Supports

5.3. Principles of Support Design

- The support should be able to prevent parts from collapse/warping, especially the outer contour area which needs support; for metal processes, stress and strain needs to be considered and thermal simulation modeling can be conducted for design;

- The connection between the support and final parts should be of minimal strength to perform the support function, with the aim of easily removing support;

- The contact area between the support and final parts should be as small as possible to reduce surface deterioration after support removal;

- When designing the support, material consumption and build time should be considered as a significant factor, as well as the trade-off between them and the final printed quality.

5.4. Support Structure Modeling

5.5. Integrating Topology Optimization into Support Structure

5.6. Standardized Model for Support Structure Comparison in Different Processes

5.7. Criteria for Comparing Different Support Methods

5.8. Balance Support Methods and Printed Quality

6. Conclusions

Funding

Acknowledgments

Conflicts of Interest

References

- Bourell, D.L. Perspectives on Additive Manufacturing. Annu. Rev. Mater. Res. 2016, 46, 1–18. [Google Scholar] [CrossRef]

- Berman, B. 3-D printing: The new industrial revolution. Bus. Horiz. 2012, 55, 155–162. [Google Scholar] [CrossRef]

- Wohlers, T.; Gornet, T. History of Additive Manufacturing. In Wohlers Report 2014—3D Printing and Additive Manufacturing State of the Industry; Cambridge University Press: Cambridge, UK, 2014; pp. 1–34. [Google Scholar] [CrossRef]

- Hopkinson, N.; Dickens, P.M. Analysis of rapid manufacturing—Using layer manufacturing processes for production. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2003, 217, 31–39. [Google Scholar] [CrossRef]

- Khajavi, S.H.; Partanen, J.; Holmström, J. Additive manufacturing in the spare parts supply chain. Comput. Ind. 2014, 65, 50–63. [Google Scholar] [CrossRef]

- Huang, S.H.; Liu, P.; Mokasdar, A.; Hou, L. Additive manufacturing and its societal impact: A literature review. Int. J. Adv. Manuf. Technol. 2013, 67, 1191–1203. [Google Scholar] [CrossRef]

- Kwok, T.-H.; Ye, H.; Chen, Y.; Zhou, C.; Xu, W. Mass Customization: Reuse of Digital Slicing for Additive Manufacturing. J. Comput. Inf. Sci. Eng. 2017, 17, 021009. [Google Scholar] [CrossRef]

- Weng, Y.; Li, M.; Tan, M.J.; Qian, S. Design 3D printing cementitious materials via Fuller Thompson theory and Marson-Percy model. Constr. Build. Mater. 2018, 163, 600–610. [Google Scholar] [CrossRef]

- Wang, C.; Tan, X.; Liu, E.; Tor, S.B. Process parameter optimization and mechanical properties for additively manufactured stainless steel 316L parts by selective electron beam melting. Mater. Des. 2018, 147, 157–166. [Google Scholar] [CrossRef]

- Thomas, D.; Gilvert, S. Costs and Cost Effectiveness of Additive Manufacturing; U.S. Department of Commerce: Washington, DC, USA, 2014; pp. 31–32. [CrossRef]

- Folgar, L.N.; Folgar, C.E. Direct Writing for Additive Manufacturing Systems. U.S. Patent 9,533,451 B2, 3 January 2017. [Google Scholar]

- Panchagnula, J.S.; Simhambhatla, S. Manufacture of complex thin-walled metallic objects using weld-deposition based additive manufacturing. Robot. Comput.-Integr. Manuf. 2018, 49, 194–203. [Google Scholar] [CrossRef]

- Xu, J.; Hou, W.; Sun, Y.; Lee, Y.-S. PLSP based layered contour generation from point cloud for additive manufacturing. Robot. Comput.-Integr. Manuf. 2018, 49, 1–12. [Google Scholar] [CrossRef]

- ISO. Additive Manufacturing—General Principles—Terminology; ISO/ASTM 52900; ISO: Geneva, Switzerland, 2015; pp. 1–26. [Google Scholar] [CrossRef]

- Bikas, H.; Stavropoulos, P.; Chryssolouris, G. Additive manufacturing methods and modelling approaches: A critical review. Int. J. Adv. Manuf. Technol. 2016, 83, 389–405. [Google Scholar] [CrossRef]

- Gardan, J. Additive manufacturing technologies: State of the art and trends. Int. J. Prod. Res. 2016, 54, 3118–3132. [Google Scholar] [CrossRef]

- Zhang, Y.; Chou, K.; Chou, Y. A parametric study of part distortions in fused deposition modelling using three-dimensional finite element analysis. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2008, 222, 959–967. [Google Scholar] [CrossRef]

- Salonitis, K.; Tsoukantas, G.; Stavropoulos, P.; Stournaras, A. A critical review of stereolithography process modeling. In Virtual Modelling and Rapid Manufacturing—Advanced Research in Virtual and Rapid Prototyping; CRC Press: Leiria, Portugal, 2003. [Google Scholar]

- Gebhardt, I.A. Rapid Prototyping: Industrial Rapid Prototyping System: Prototyper: Solid Ground Curing; Cubital: Ra’anana, Israel, 2003; pp. 105–109. [Google Scholar]

- Dahotre, N.B.; Harimkar, S.P. Laser Fabrication and Machining of Materials; Springer: Berlin, Germany, 2008. [Google Scholar]

- Sachs, E.; Cima, M.; Cornie, J. Three-Dimensional Printing: Rapid Tooling and Prototypes Directly from a CAD Model. CIRP Ann. 1990, 39, 201–204. [Google Scholar] [CrossRef]

- Calvert, P. Inkjet Printing for Materials and Devices. Chem. Mater. 2001, 13, 3299–3305. [Google Scholar] [CrossRef]

- Upcraft, S.; Fletcher, R. The rapid prototyping technologies. Assem. Autom. 2003, 23, 318–330. [Google Scholar] [CrossRef]

- Pham, D.; Gault, R. A comparison of rapid prototyping technologies. Int. J. Mach. Tools Manuf. 1998, 38, 1257–1287. [Google Scholar] [CrossRef]

- Bremen, S.; Meiners, W.; Diatlov, A. Selective Laser Melting. Laser Tech. J. 2012, 9, 33–38. [Google Scholar] [CrossRef]

- Lü, L.; Fuh, J.Y.H.; Wong, Y. Selective laser sintering. In Laser-Induced Materials and Processes for Rapid Prototyping; Springer: Berlin, Germany, 2001; pp. 89–142. [Google Scholar]

- Grünberger, T.; Domröse, R. Direct Metal Laser Sintering. Laser Tech. J. 2015, 12, 45–48. [Google Scholar] [CrossRef]

- Wong, K.V.; Hernandez, A. A review of additive manufacturing. ISRN Mech. Eng. 2012. [Google Scholar] [CrossRef]

- Cesarano, J. A Review of Robocasting Technology. MRS Proc. 2011, 542, 133–139. [Google Scholar] [CrossRef]

- Comb, J.W.; Priedeman, W.R.; Turley, P.W. FDM technology process improvements. In Proceedings of the Solid Freeform Fabrication Symposium, Austin, TX, USA, 8–10 August 1994; pp. 42–49. [Google Scholar]

- Atwood, C.; Ensz, M.; Greene, D.; Griffith, M.; Harwell, L.; Reckaway, D.; Romero, T.; Schlienger, E.; Smugeresky, J. Laser Engineered Net Shaping (LENS(TM)): A Tool for Direct Fabrication of Metal Parts. In Proceedings of the 17th International Congress on Applications of Lasers and Elector-Optics, Orlando, FL, USA, 16–19 November 1998. [Google Scholar]

- Lewis, K.G.; Schlienger, E. Practical considerations and capabilities for laser assisted direct metal deposition. Mater. Des. 2000, 21, 417–423. [Google Scholar] [CrossRef]

- Costa, L.; Vilar, R. Laser powder deposition. Rapid Prototyp. J. 2009, 15, 264–279. [Google Scholar] [CrossRef]

- Liu, J.; Li, L. In-time motion adjustment in laser cladding manufacturing process for improving dimensional accuracy and surface finish of the formed part. Opt. Laser Technol. 2004, 36, 477–483. [Google Scholar] [CrossRef]

- Mekonnen, B.G.; Bright, G.; Walker, A. A Study on State of the Art Technology of Laminated Object Manufacturing (LOM); Springer: Berlin, Germany, 2016. [Google Scholar]

- Qian, B.; Zhang, L.; Shi, Y.; Liu, G. Support fast generation algorithm based on discrete-marking in stereolithgraphy rapid prototyping. Rapid Prototyp. J. 2011, 17, 451–457. [Google Scholar] [CrossRef]

- Jin, Y.; He, Y.; Fu, J.Z. Support generation for additive manufacturing based on sliced data. Int. J. Adv. Manuf. Technol. 2015, 80, 2041–2052. [Google Scholar] [CrossRef]

- Thrimurthulu, K.P.P.M.; Pandey, P.M.; Reddy, N.V. Optimum part deposition orientation in fused deposition modeling. Int. J. Mach. Tools Manuf. 2004, 6, 585–594. [Google Scholar] [CrossRef]

- Cantrell, J.; Rohde, S.; Damiani, D.; Gurnani, R.; DiSandro, L.; Anton, J.; Young, A.; Jerez, A.; Steinbach, D.; Kroese, C.; et al. Experimental characterization of the mechanical properties of 3D-printed ABS and polycarbonate parts. Rapid Prototyp. J. 2017, 23, 811–824. [Google Scholar] [CrossRef]

- Das, P.; Mhapsekar, K.; Chowdhury, S.; Samant, R.; Anand, S. Selection of build orientation for optimal support structures and minimum part errors in additive manufacturing. Comput.-Aided Des. Appl. 2017, 1–13. [Google Scholar] [CrossRef]

- Frank, D.; Fadel, G. Expert system-based selection of the preferred direction of build for rapid prototyping processes. J. Intell. Manuf. 1995, 6, 339–345. [Google Scholar] [CrossRef]

- Pham, D.T.; Dimov, S.S.; Gault, R.S. Part orientation in stereolithography. Int. J. Adv. Manuf. Technol. 1999, 15, 674–682. [Google Scholar] [CrossRef]

- Strano, G.; Hao, L.; Everson, R.M.; Evans, K.E. A new approach to the design and optimisation of support structures in additive manufacturing. Int. J. Adv. Manuf. Technol. 2013, 66, 1247–1254. [Google Scholar] [CrossRef]

- Luo, Z.; Yang, F.; Dong, G.; Tang, Y.; Zhao, Y.F. Orientation optimization in layer-based additive manufacturing process. In Proceedings of the ASME Design Engineering Technical Conference, Charlotte, NC, USA, 21–24 August 2016; pp. 1–10. [Google Scholar] [CrossRef]

- Allen, S.; Dutta, D. On the computation of part orientation using support structures in layered manufacturing. In Proceedings of the Solid Freeform Fabrication Symposium, Austin, TX, USA, 8–10 August 1994; pp. 259–269. [Google Scholar]

- Zhao, J. Determination of optimal build orientation based on satisfactory degree theory for RPT. In Proceedings of the Ninth International Conference on Computer Aided Design and Computer Graphics, CAD/CG 2005, Hong Kong, China, 7–10 December 2005; pp. 225–230. [Google Scholar] [CrossRef]

- Pandey, P.M.; Thrimurthulu, K.; Reddy, N.V. Optimal part deposition orientation in FDM by using a multicriteria genetic algorithm. Int. J. Prod. Res. 2004, 42, 4069–4089. [Google Scholar] [CrossRef]

- Paul, R.; Anand, S. Optimization of layered manufacturing process for reducing form errors with minimal support structures. J. Manuf. Syst. 2015, 36, 231–243. [Google Scholar] [CrossRef]

- Das, P.; Chandran, R.; Samant, R.; Anand, S. Optimum Part Build Orientation in Additive Manufacturing for Minimizing Part Errors and Support Structures. Procedia Manuf. 2015, 1, 343–354. [Google Scholar] [CrossRef]

- Yang, Y.; Fuh, J.Y.H.; Loh, H.T.; Wong, Y.S. Multi-orientational deposition to minimize support in the layered manufacturing process. J. Manuf. Syst. 2003, 22, 116–129. [Google Scholar] [CrossRef]

- Gao, W.; Zhang, Y.; Nazzetta, D.C.; Ramani, K.; Cipra, R.J.; Lafayette, W. RevoMaker: Enabling Multi-directional and Functionally-embedded 3D Printing using a Rotational Cuboidal Platform. In Proceedings of the 28th Annual ACM Symposium on User Interface Software & Technology (UIST ’15), Hong Kong, China, 7–10 December 2015; pp. 437–446. [Google Scholar] [CrossRef]

- Zhang, X.; Le, X.; Panotopoulou, A.; Whiting, E.; Wang, C.C.L. Perceptual models of preference in 3D printing direction. ACM Trans. Graph. 2015, 34, 1–12. [Google Scholar] [CrossRef]

- Zhao, H.M.; He, Y.; Fu, J.Z.; Qiu, J.J. Inclined layer printing for fused deposition modeling without assisted supporting structure. Robot. Comput.-Integr. Manuf. 2018, 51, 1–13. [Google Scholar] [CrossRef]

- Domonoky, BonsaiBrain. Support—Full Disclosure 2016. Available online: http://ifeelbeta.de/index.php/support/support-full-disclosure (accessed on 11 September 2017).

- Hopkins, P.E.; Priedeman, W.R., Jr.; Bye, J.F. Support Material for Digital Manufacturing Systems. U.S. Patent 8,246,888 B2, 21 August 2009. [Google Scholar]

- Ni, F.; Wang, G.; Zhao, H. Fabrication of water-soluble poly(vinyl alcohol)-based composites with improved thermal behavior for potential three-dimensional printing application. J. Appl. Polym. Sci. 2017, 134. [Google Scholar] [CrossRef]

- Hildreth, O.J.; Nassar, A.R.; Chasse, K.R.; Simpson, T.W. Dissolvable Metal Supports for 3D Direct Metal Printing. 3D Print. Addit. Manuf. 2016, 3, 90–97. [Google Scholar] [CrossRef]

- Mumtaz, K.A.; Vora, P.; Hopkinson, N. A Method to Eliminate Anchors/Supports from Directly Laser Melted Metal Powder Bed Processes. In Proceedings of the Solid Freeform Fabrication Symposium, Austin, TX, USA, 8–10 August 2011; pp. 55–64. [Google Scholar]

- Lefky, C.S.; Zucker, B.; Wright, D.; Nassar, A.R.; Simpson, T.W.; Hildreth, O.J. Dissolvable Supports in Powder Bed Fusion-Printed Stainless Steel. 3D Print. Addit. Manuf. 2017, 4, 3–11. [Google Scholar] [CrossRef]

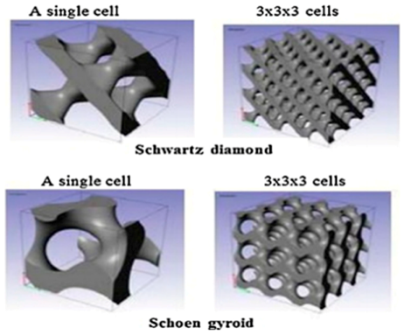

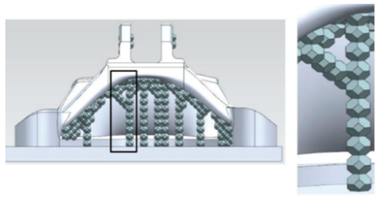

- Hussein, A.; Yan, C.; Everson, R.; Hao, L. Preliminary investigation on cellular support structures using SLM process. In Innovative Developments in Virtual and Physical Prototyping; Taylor & Francis Group: London, UK, 2011. [Google Scholar]

- Hussein, A.; Hao, L.; Yan, C.; Everson, R.; Young, P. Advanced lattice support structures for metal additive manufacturing. J. Mater. Process. Technol. 2013, 213, 1019–1026. [Google Scholar] [CrossRef]

- Vaidya, R.; Anand, S. Optimum Support Structure Generation for Additive Manufacturing Using Unit Cell Structures and Support Removal Constraint. Procedia Manuf. 2016, 5, 1043–1059. [Google Scholar] [CrossRef]

- Dijkstra, E.W. A note on two problems in connexion with graphs. Numer. Math. 1959, 1, 269–271. [Google Scholar] [CrossRef]

- Lu, L.; Sharf, A.; Zhao, H.S.; Wei, Y.; Fan, Q.N.; Chen, X.L.; Savoye, Y.; Tu, C.; Cohen-Or, D.; Chen, B. Build-to-Last: Strength to Weight 3D Printed Objects. ACM Trans. Graph. 2014, 33, 1–10. [Google Scholar] [CrossRef]

- Wei, X.R.; Geng, G.H.; Zhang, Y.H. Steady and low consuming supporting for fused deposition modeling. Zidonghua Xuebao/Acta Autom. Sin. 2016, 42, 98–106. [Google Scholar] [CrossRef]

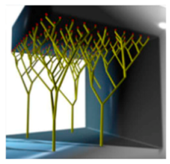

- Vanek, J.; Galicia, J.A.G.; Benes, B. Clever Support: Efficient Support Structure Generation for Digital Fabrication. Comput. Graph. Forum 2014, 33, 117–125. [Google Scholar] [CrossRef]

- Schmidt, R.; Umetani, N. Branching Support Structures for 3D Printing. In Proceedings of the ACM SIGGRAPH 2014 Conference, Vancouver, BC, Canada, 10–14 August 2014. [Google Scholar] [CrossRef]

- Shen, Z.H. Bridge support structure generation for 3D printing. In Materials, Manufacturing Technology, Electronics and Information Science; World Scientific: Singapore, 2016. [Google Scholar]

- Shen, Z.; Dai, N.; Li, D.; Wu, C. Generation of Branching Support Structures Based on Critical COnstraint. China Mech. Eng. 2016, 27, 1107–1112. [Google Scholar]

- Gan, M.X.; Wong, C.H. Practical support structures for selective laser melting. J. Mater. Process. Technol. 2016, 238, 474–484. [Google Scholar] [CrossRef]

- Zhao, G.; Zhou, C.; Das, S. Solid mechanics based design and optimization for support structure generation in stereolithography based additive manufacturing. In Proceedings of the ASME Design Engineering Technical Conference, Boston, MA, USA, 2–5 August 2015. [Google Scholar] [CrossRef]

- Dumas, J.; Hergel, J.; Lefebvre, S. Bridging the Gap: Automated Steady Scaffoldings for 3D Printing. ACM Trans. Graph. 2014, 33, 1–98. [Google Scholar] [CrossRef]

- Habib, M.A.; Khoda, B. Support grain architecture design for additive manufacturing. J. Manuf. Process. 2017, 29, 332–342. [Google Scholar] [CrossRef]

- Jin, Y.; Compaan, A.; Chai, W.; Huang, Y. Functional Nanoclay Suspension for Printing-Then-Solidification of Liquid Materials. ACS Appl. Mater. Interfaces 2017, 9, 20057–20066. [Google Scholar] [CrossRef] [PubMed]

- Jin, Y.; Compaan, A.; Bhattacharjee, T.; Huang, Y. Granular gel support-enabled extrusion of three-dimensional alginate and cellular structures. Biofabrication 2016, 8, 025016. [Google Scholar] [CrossRef] [PubMed]

- Hinton, T.J.; Hudson, A.; Pusch, K.; Lee, A.; Feinberg, A.W. 3D Printing PDMS Elastomer in a Hydrophilic Support Bath via Freeform Reversible Embedding. ACS Biomater. Sci. Eng. 2016, 2, 1781–1786. [Google Scholar] [CrossRef] [PubMed]

- Yu, Y.; Liu, F.; Zhang, R.; Liu, J. Suspension 3D Printing of Liquid Metal into Self-Healing Hydrogel. Adv. Mater. Technol. 2017, 2, 1700173. [Google Scholar] [CrossRef]

- Chalasani, K.; Jones, L.; Roscoe, L.; Chalasani, K.; Jones, L.; Roscoe, L. Support generation for fused deposition modeling. In Proceedings of the Solid Freeform Fabrication Symposium, Austin, TX, USA, 7–9 August 1995. [Google Scholar]

- Huang, X.; Ye, C.; Wu, S.; Guo, K.; Mo, J. Sloping wall structure support generation for fused deposition modeling. Int. J. Adv. Manuf. Technol. 2009, 42, 1074–1081. [Google Scholar] [CrossRef]

- Calignano, F. Design optimization of supports for overhanging structures in aluminum and titanium alloys by selective laser melting. Mater. Des. 2014, 64, 203–213. [Google Scholar] [CrossRef]

- Barnett, E.; Gosselin, C. Weak support material techniques for alternative additive manufacturing materials. Addit. Manuf. 2015, 8, 95–104. [Google Scholar] [CrossRef]

- Jiang, J.; Stringer, J.; Xu, X.; Zhong, R. Investigation of Printable Threshold Overhang Angle in Extrusion-based Additive Manufacturing for Reducing Support Waste. Int. J. Comput. Integr. Manuf. 2018, 31, 961–969. [Google Scholar] [CrossRef]

- Wang, W.; Wang, T.Y.; Yang, Z.; Liu, L.; Tong, X.; Tong, W.; Deng, J.; Chen, F.; Liu, X. Cost-effective printing of 3D objects with skin-frame structures. ACM Trans. Graph. 2013, 32, 1–10. [Google Scholar] [CrossRef]

- Zhang, X.; Xia, Y.; Wang, J.; Yang, Z.; Tu, C.; Wang, W. Medial axis tree—An internal supporting structure for 3D printing. Comput. Aided Geom. Des. 2015, 35–36, 149–152. [Google Scholar] [CrossRef]

- Lee, J.; Lee, K. Block-based inner support structure generation algorithm for 3D printing using fused deposition modeling. Int. J. Adv. Manuf. Technol. 2017, 89, 2151–2163. [Google Scholar] [CrossRef]

- Brackett, D.; Ashcroft, I.; Hague, R. Topology optimization for additive manufacturing. In Proceedings of the Solid Freeform Fabrication Symposium, Austin, TX, USA, 3–5 August 2011; pp. 348–362. [Google Scholar] [CrossRef]

- Aremu, A.; Ashcroft, I.; Hague, R.; Wildman, R.; Tuck, C. Suitability of SIMP and BESO Topology Optimization Algorithms for Additive Manufacture. In Proceedings of the Solid Freeform Fabrication Proceedings, Austin, TX, USA, 9–11 August 2010; pp. 679–692. [Google Scholar]

- Dias, M.R.; Guedes, J.M.; Flanagan, C.L.; Hollister, S.J.; Fernandes, P.R. Optimization of scaffold design for bone tissue engineering: A computational and experimental study. Med. Eng. Phys. 2014, 36, 448–457. [Google Scholar] [CrossRef] [PubMed]

- Gardan, N.; Schneider, A.; Gardan, J. Material and process characterization for coupling topological optimization to additive manufacturing. Comput.-Aided Des. Appl. 2016, 13, 39–49. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, D.Z.; Dong, P.; Kucukkoc, I. A lightweight and support-free design method for selective laser melting. Int. J. Adv. Manuf. Technol. 2017, 90, 2943–2953. [Google Scholar] [CrossRef]

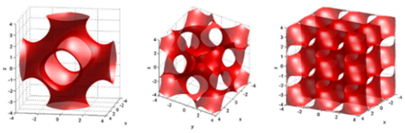

- Wu, J.; Wang, C.C.L.; Zhang, X.; Westermann, R. Self-supporting rhombic infill structures for additive manufacturing. CAD Comput. Aided Des. 2016, 80, 32–42. [Google Scholar] [CrossRef]

- Wu, J.; Dick, C.; Westermann, R. A system for high-resolution topology optimization. IEEE Trans. Visual. Comput. Graph. 2016, 22, 1195–1208. [Google Scholar] [CrossRef] [PubMed]

- Gaynor, A.T.; Guest, J.K. Topology optimization considering overhang constraints: Eliminating sacrificial support material in additive manufacturing through design. Struct. Multidiscip. Optim. 2016, 54, 1157–1172. [Google Scholar] [CrossRef]

- Guest, J.K.; Prévost, J.H.; Belytschko, T. Achieving minimum length scale in topology optimization using nodal design variables and projection functions. Int. J. Numer. Methods Eng. 2004, 61, 238–254. [Google Scholar] [CrossRef]

- Mirzendehdel, A.M.; Suresh, K. Support structure constrained topology optimization for additive manufacturing. CAD Comput. Aided Des. 2016, 81, 1–13. [Google Scholar] [CrossRef]

- Cloots, M.; Spierings, A.B.; Wegener, K. Assessing new support minimizing strategies for the additive manufacturing technology SLM. In Proceedings of the International Solid Freeform Fabrication Symposium on Additive Manufacturing Conference, Austin, TX, USA, 12–14 August 2013; pp. 131–139. [Google Scholar] [CrossRef]

- Leary, M.; Merli, L.; Torti, F.; Mazur, M.; Brandt, M. Optimal topology for additive manufacture: A method for enabling additive manufacture of support-free optimal structures. Mater. Des. 2014, 63, 678–690. [Google Scholar] [CrossRef]

- Langelaar, M. Topology optimization of 3D self-supporting structures for additive manufacturing. Addit. Manuf. 2016, 12, 60–70. [Google Scholar] [CrossRef]

- Kuo, Y.-H.; Cheng, C.-C.; Lin, Y.-S.; San, C.-H. Support structure design in additive manufacturing based on topology optimization. Struct. Multidiscip. Optim. 2018, 57, 183–195. [Google Scholar] [CrossRef]

- Hu, K.; Jin, S.; Wang, C.C.L. Support slimming for single material based additive manufacturing. CAD Comput. Aided Des. 2015, 65, 1–10. [Google Scholar] [CrossRef]

- Afrose, M.F.; Masood, S.H.; Nikzad, M.; Iovenitti, P. Effects of Build Orientations on Tensile Properties of PLA Material Processed by FDM. Adv. Mater. Res. 2014, 1044–1045, 31–34. [Google Scholar] [CrossRef]

- Jin, J.; Chen, Y. Highly removable water support for Stereolithography. J. Manuf. Process. 2017, 28, 541–549. [Google Scholar] [CrossRef]

- Coupek, D.; Friedrich, J.; Battran, D.; Riedel, O. Reduction of Support Structures and Building Time by Optimized Path Planning Algorithms in Multi-axis Additive Manufacturing. Procedia CIRP 2018, 67, 221–226. [Google Scholar] [CrossRef]

- Hehr, A.; Wenning, J.; Terrani, K.; Babu, S.S.; Norfolk, M. Five-Axis Ultrasonic Additive Manufacturing for Nuclear Component Manufacture. JOM 2017, 69, 485–490. [Google Scholar] [CrossRef]

- Ding, Y.; Dwivedi, R.; Kovacevic, R. Process planning for 8-axis robotized laser-based direct metal deposition system: A case on building revolved part. Robot. Comput.-Integr. Manuf. 2017, 44, 67–76. [Google Scholar] [CrossRef]

- Casavola, C.; Cazzato, A.; Moramarco, V.; Pappalettera, G. Residual stress measurement in Fused Deposition Modelling parts. Polym. Test. 2017, 58, 249–255. [Google Scholar] [CrossRef]

- Coogan, T.J.; Kazmer, D.O. Healing simulation for bond strength prediction of FDM. Rapid Prototyp. J. 2017, 23, 551–561. [Google Scholar] [CrossRef]

- Wang, T.M.; Xi, J.T.; Jin, Y. A model research for prototype warp deformation in the FDM process. Int. J. Adv. Manuf. Technol. 2007, 33, 1087–1096. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, X.Z.; Yu, W.W.; Deng, Y.H. Numerical investigation of the influence of process conditions on the temperature variation in fused deposition modeling. Mater. Des. 2017, 130, 59–68. [Google Scholar] [CrossRef]

- Zhou, X.; Hsieh, S.-J.; Sun, Y. Experimental and numerical investigation of the thermal behaviour of polylactic acid during the fused deposition process. Virtual Phys. Prototyp. 2017, 12, 221–233. [Google Scholar] [CrossRef]

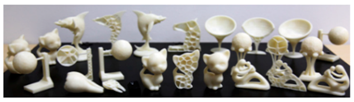

- Jiang, J.; Stringer, J.; Xu, X.; Zheng, P. A benchmarking part for evaluating and comparing support structures of additive manufacturing. In Proceedings of the 3rd International Conference on Progress in Additive Manufacturing (Pro-AM 2018), Singapore, 14–17 May 2018; pp. 196–202. [Google Scholar] [CrossRef]

- Fahad, M.; Hopkinson, N. A new benchmarking part for evaluating the accuracy and repeatability of Additive Manufacturing (AM) processes. In Proceedings of the 2nd International Conference on Mechanical, Production, and Automobile Engineering, Singapore, 28–29 April 2012; pp. 234–238. [Google Scholar]

- Mahesh, M.; Wong, Y.; Fuh, J.; Loh, H. Benchmarking for comparative evaluation of RP systems and processes. Rapid Prototyp. J. 2004, 10, 123–135. [Google Scholar] [CrossRef]

| 3D Printing Category (ISO, 2015) | Definition | Technologies | Material Used | Does This Technique Need Support Structure? | The Functions of Support Structure | ||

|---|---|---|---|---|---|---|---|

| For Thermal Dissipation | For Printability | For Part Balance | |||||

| Vat photopolymerization | Liquid photopolymer in a vat is selectively cured by light-activated polymerization. | Stereolithography (SLA) [18] | Photopolymers | Yes | √ | √ | |

| Solid ground curing (SGC) [19] | Photopolymers | NO | |||||

| Liquid thermal polymerization (LTP) [20] | Thermosetting polymers | Yes | √ | √ | √ | ||

| Beam interference solidification (BIS)/Holographic interference solidification (HIS) [20] | Photosensitive polymers | Yes | √ | √ | |||

| Binder jetting | Liquid bonding agent is selectively deposited to join powder materials | Three-dimensional printing (3DP) [21] | Powder materials | Yes | √ | √ | |

| Material jetting | Droplets of build material are selectively deposited. | Inkjet printing (IJP)/Multijet modeling (MJM)/Thermojet [15,22,23] | Liquid materials | NO | |||

| Ballistic particle manufacturing (BPM) [24] | Thermoplastics and metals that easily melt and solidify | Yes | √ | √ | |||

| Powder bed fusion | Thermal energy selectively fuses regions of a powder bed. | Selective laser melting (SLM) [25] | Powder materials, including stainless steel, tool steel, cobalt chrome, titanium and aluminum | Yes | √ | √ | √ |

| Selective laser sintering (SLS) [26] | Powder materials, including metal powders, nylon, nylon composites, sand, wax, polycarbonates etc. | Generally not necessary, depending on the materials used. If yes, it is for thermal dissipation only | √ | ||||

| Direct metal laser sintering (DMLS) [27] | Metallic powder only | Yes | √ | ||||

| Electron beam manufacturing (EBM) [28] | Metal powder | Yes | √ | √ | √ | ||

| Material extrusion | Material is selectively dispensed through a nozzle or orifice. | Robocasting [29] | Ceramic slurry | Yes | √ | √ | |

| Fused deposition modeling (FDM) [30] | Thermoplastic material | Yes | √ | √ | √ | ||

| Directed energy deposition | Focused thermal energy is used to fuse materials by melting as they are being deposited. | Direct metal deposition (DMD)/Laser engineered net shaping (LENS) [31,32] | Metal powder | Yes | √ | √ | √ |

| Laser powder deposition (LPD) [33] | Powder materials | Yes | √ | √ | √ | ||

| Selective laser cladding (SLC) [34] | Metal powder | NO | |||||

| Sheet lamination | Sheets of material are bonded to form an object. | Laminated object manufacturing (LOM) [35] | Adhesive backed paper | NO | |||

| Solid foil polymerization (SFP) [20] | Semi-polymerized foil | NO | |||||

| Support Methods | Suitable Techniques | Examples |

|---|---|---|

| Lattice support [61] | Metal AM processes |  |

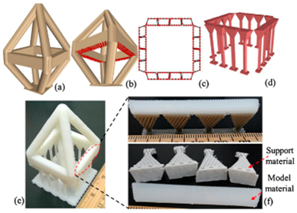

| Unit cell support [62] | All processes |  |

| Cellular support [43] | SLM |  |

| Honeycomb support [64] | FDM |  |

| Sparse tree support [65] | FDM/DLP |  |

| Tree-like support [66] | FDM |  |

| Space-efficient branching support [67] | FDM |  |

| Bridge support [68] | FDM |  |

| “Y”, “IY” and Pin support [70] | SLM |  |

| Grain support [73] | FDM |  |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, J.; Xu, X.; Stringer, J. Support Structures for Additive Manufacturing: A Review. J. Manuf. Mater. Process. 2018, 2, 64. https://doi.org/10.3390/jmmp2040064

Jiang J, Xu X, Stringer J. Support Structures for Additive Manufacturing: A Review. Journal of Manufacturing and Materials Processing. 2018; 2(4):64. https://doi.org/10.3390/jmmp2040064

Chicago/Turabian StyleJiang, Jingchao, Xun Xu, and Jonathan Stringer. 2018. "Support Structures for Additive Manufacturing: A Review" Journal of Manufacturing and Materials Processing 2, no. 4: 64. https://doi.org/10.3390/jmmp2040064

APA StyleJiang, J., Xu, X., & Stringer, J. (2018). Support Structures for Additive Manufacturing: A Review. Journal of Manufacturing and Materials Processing, 2(4), 64. https://doi.org/10.3390/jmmp2040064