Power Law Kernel Analysis of MHD Maxwell Fluid with Ramped Boundary Conditions: Transport Phenomena Solutions Based on Special Functions

Abstract

:1. Introduction

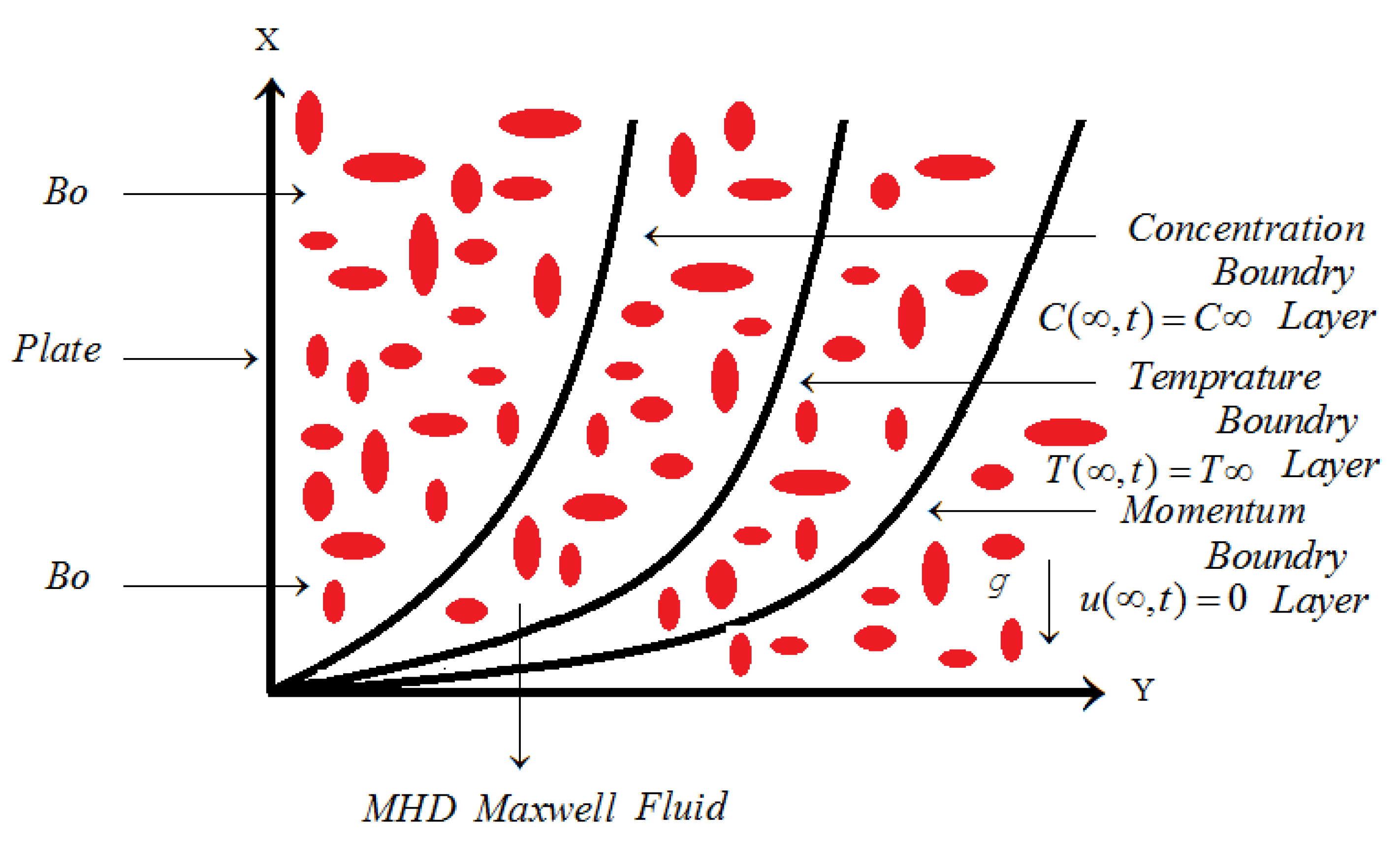

2. Mathematical Model

- Temperature and velocity functions are only composed of variables y and t because the flow is unidirectional and one dimensional.

- Magnetic and radiation effects are neglected along the flow direction.

- The induced magnetic field exerts an insignificant impact on flow.

- Viscous dissipation influence in the temperature equation is neglected.

3. Preliminaries

4. Solution of the Problem

4.1. Exact Solution of Heat Profile with Caputo Time Fractional Derivative

4.2. Exact Solution of Mass Profile with Caputo Time Fractional Derivative

4.3. Exact Solution of Velocity Profile with Caputo Time Fractional Derivative

4.4. Solution of Shear Stress

5. Limiting Cases

6. Results and Discussion

7. Conclusions

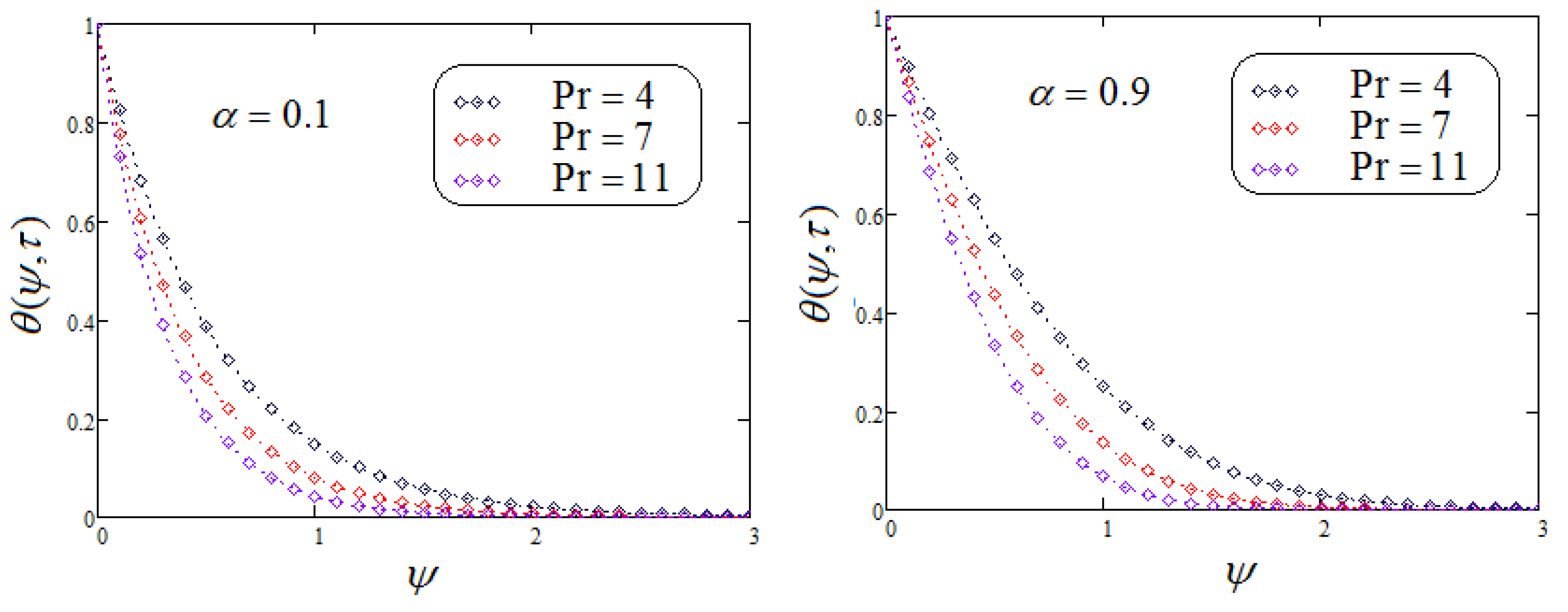

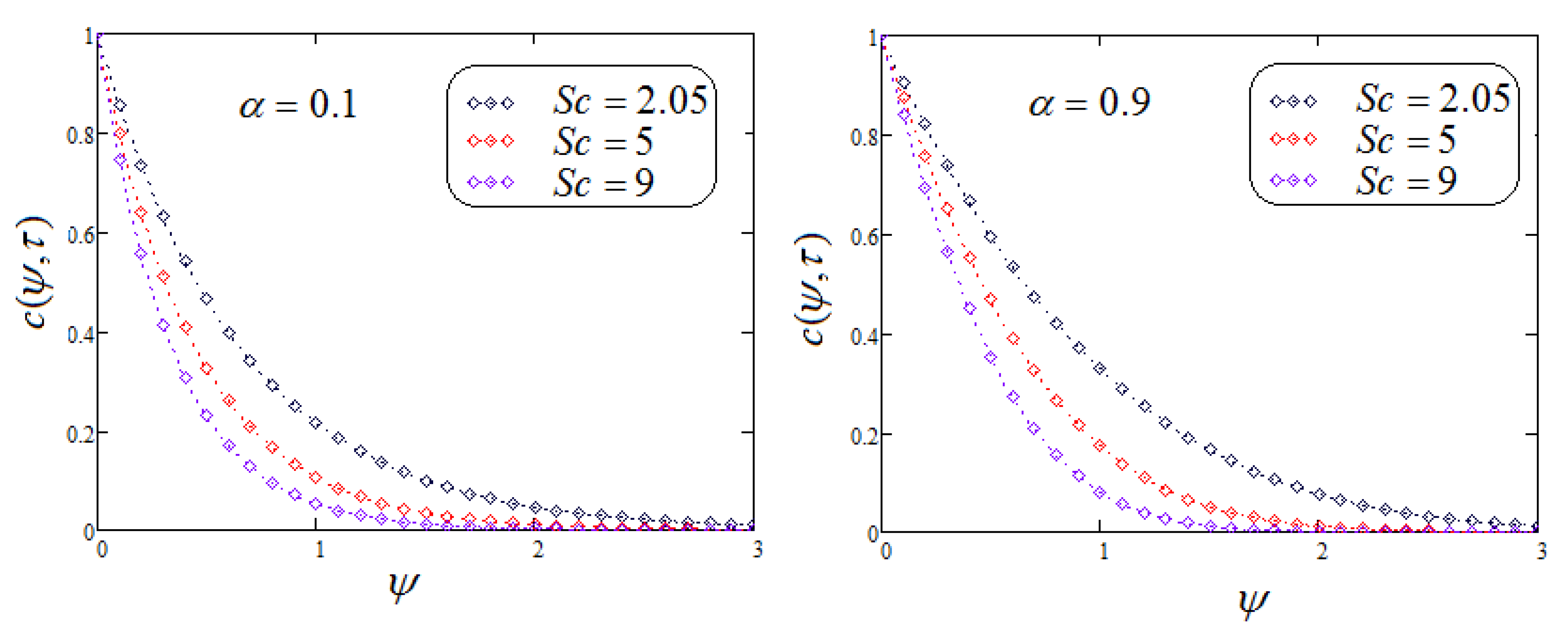

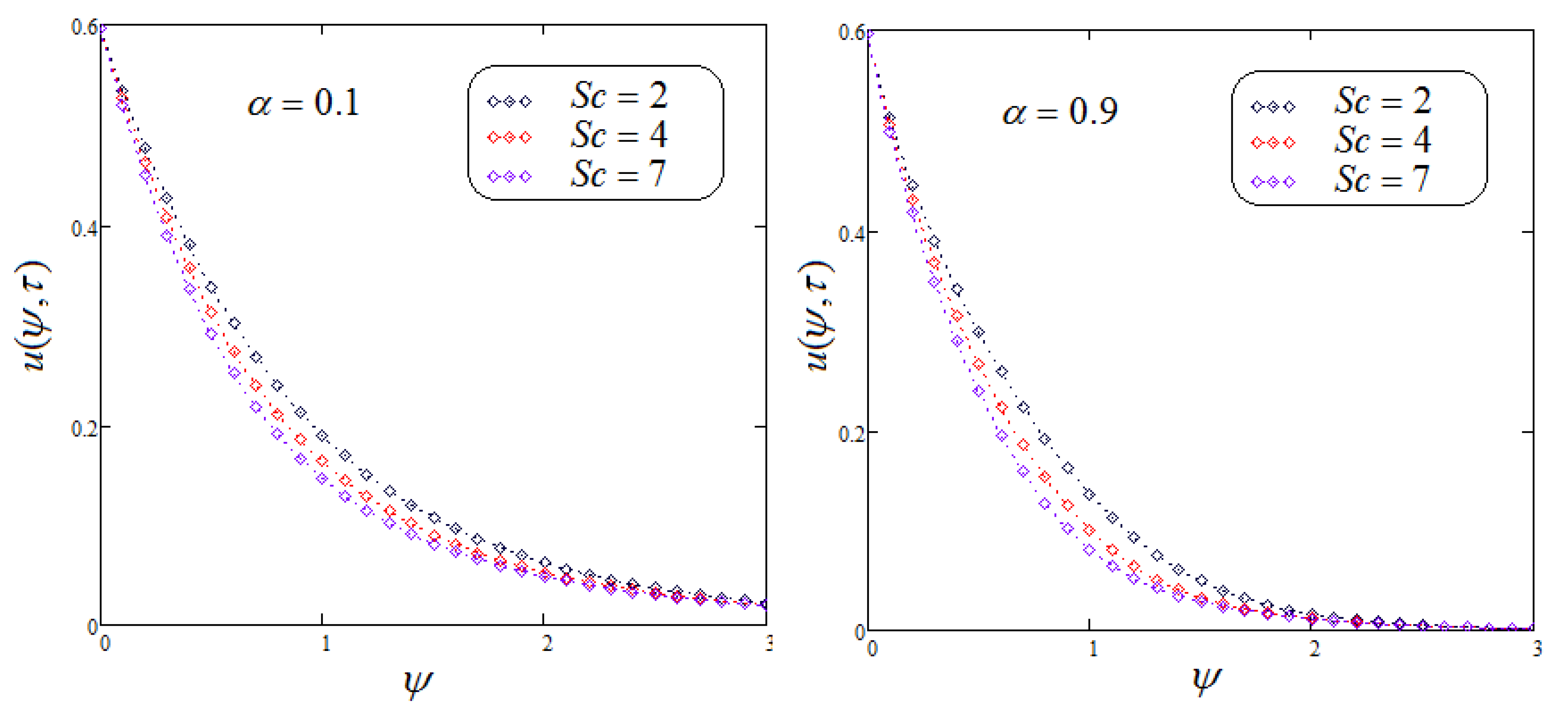

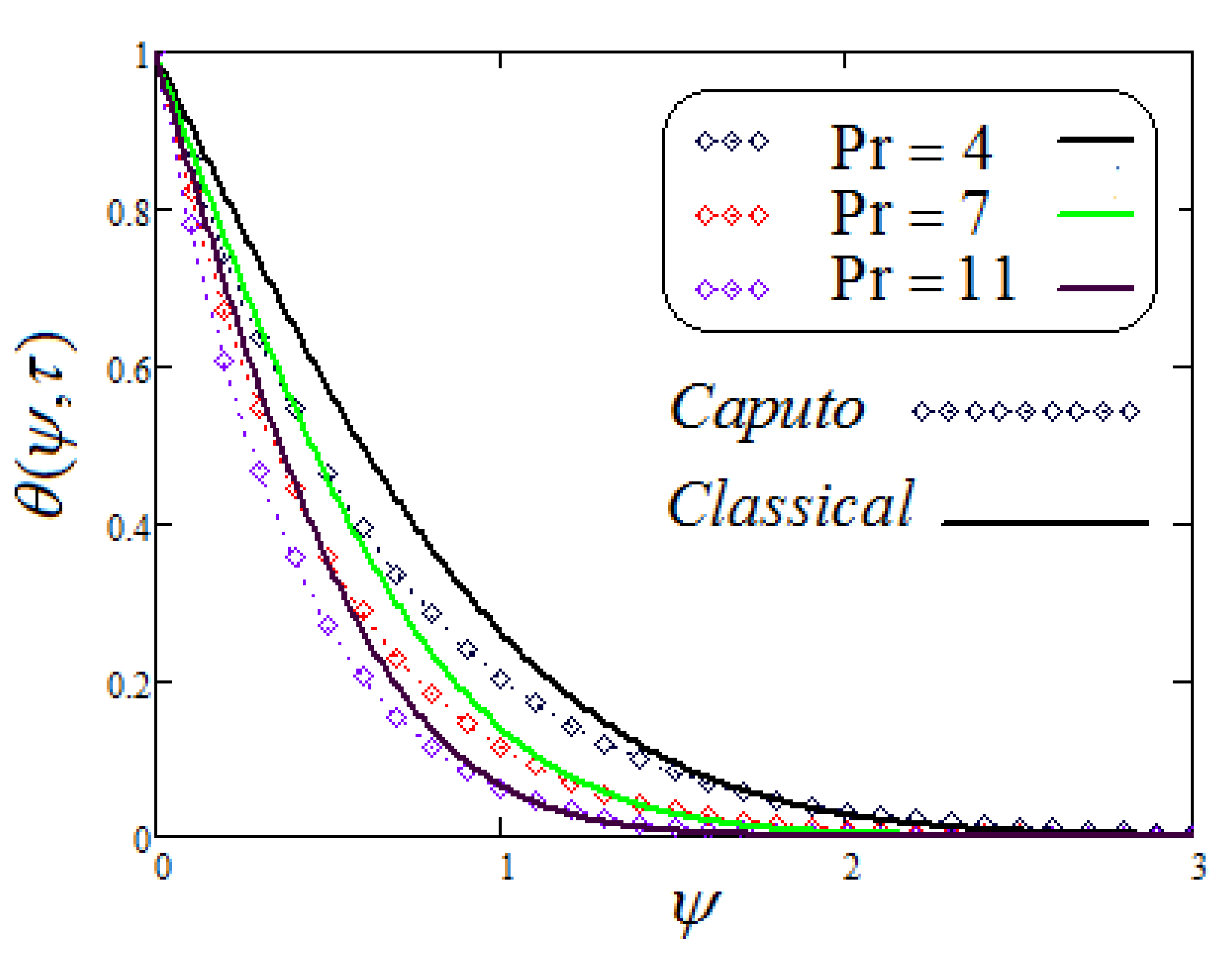

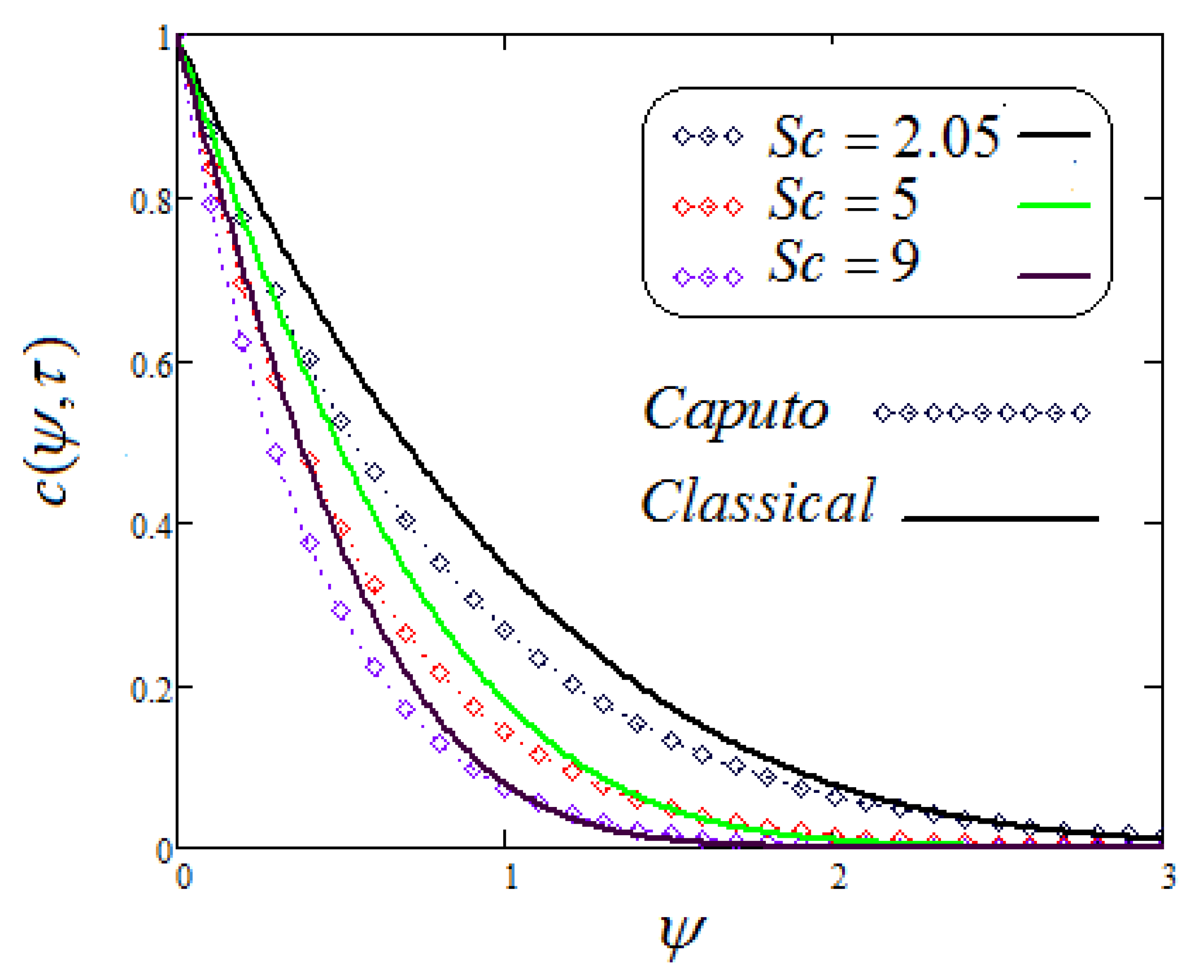

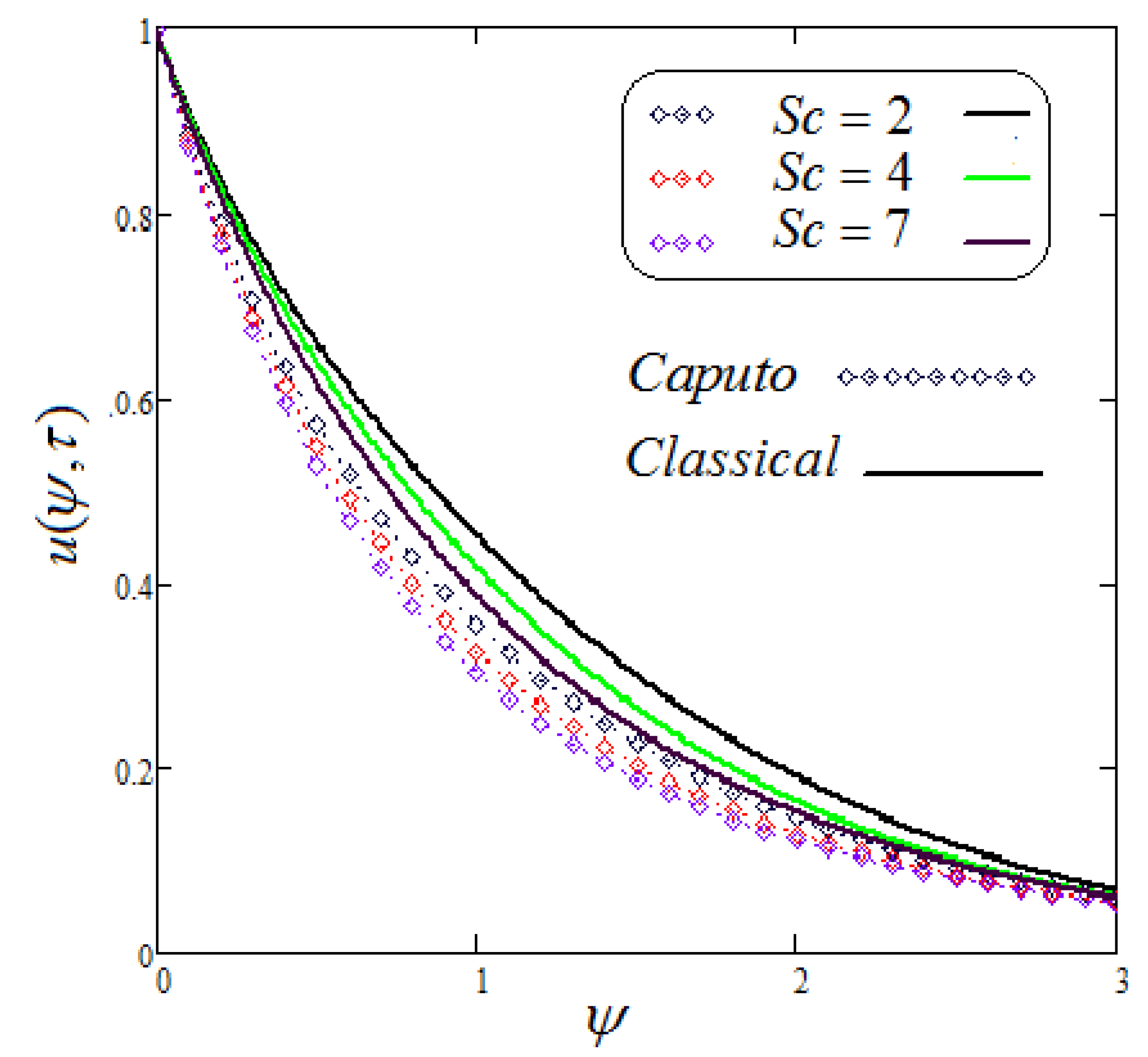

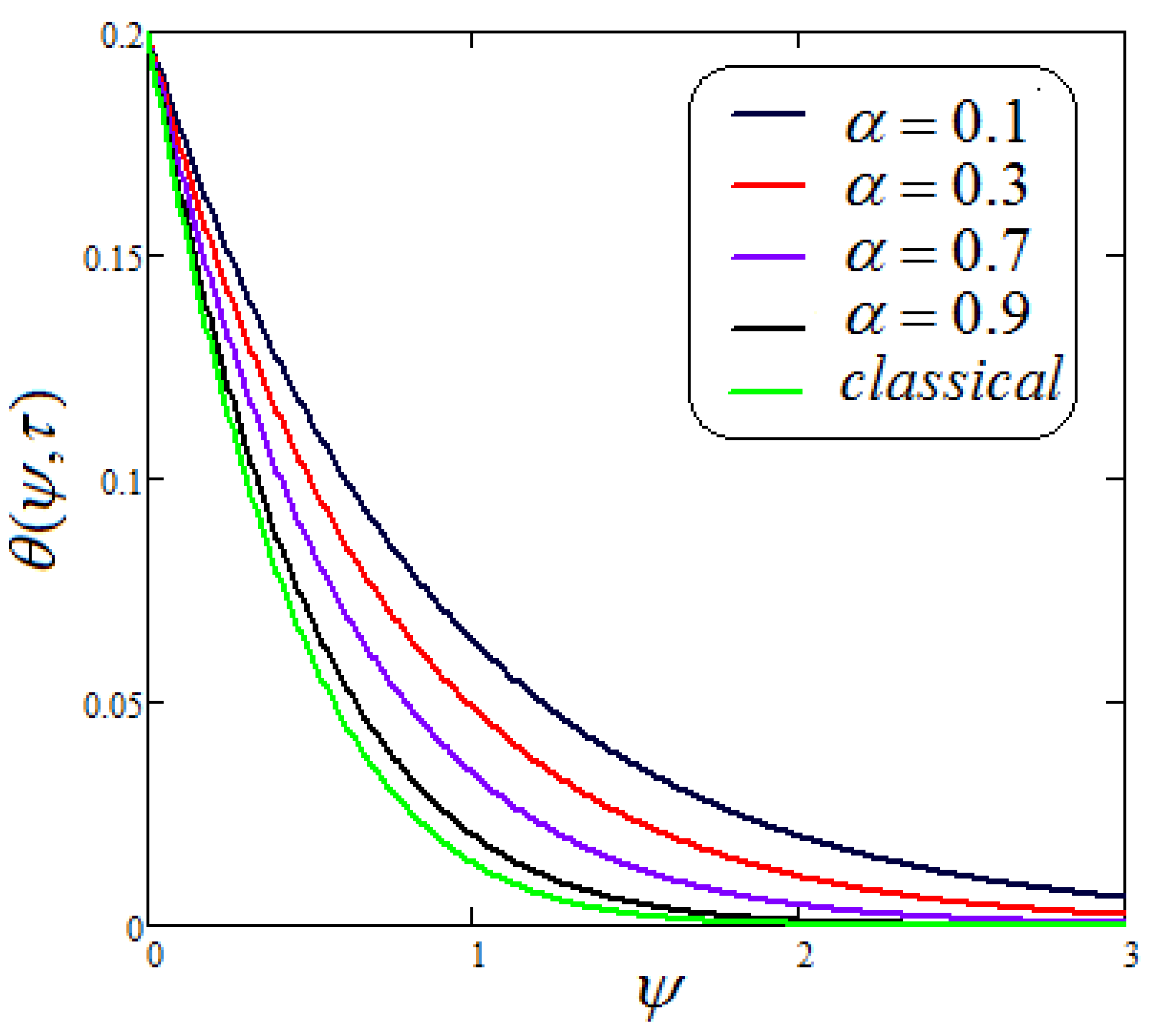

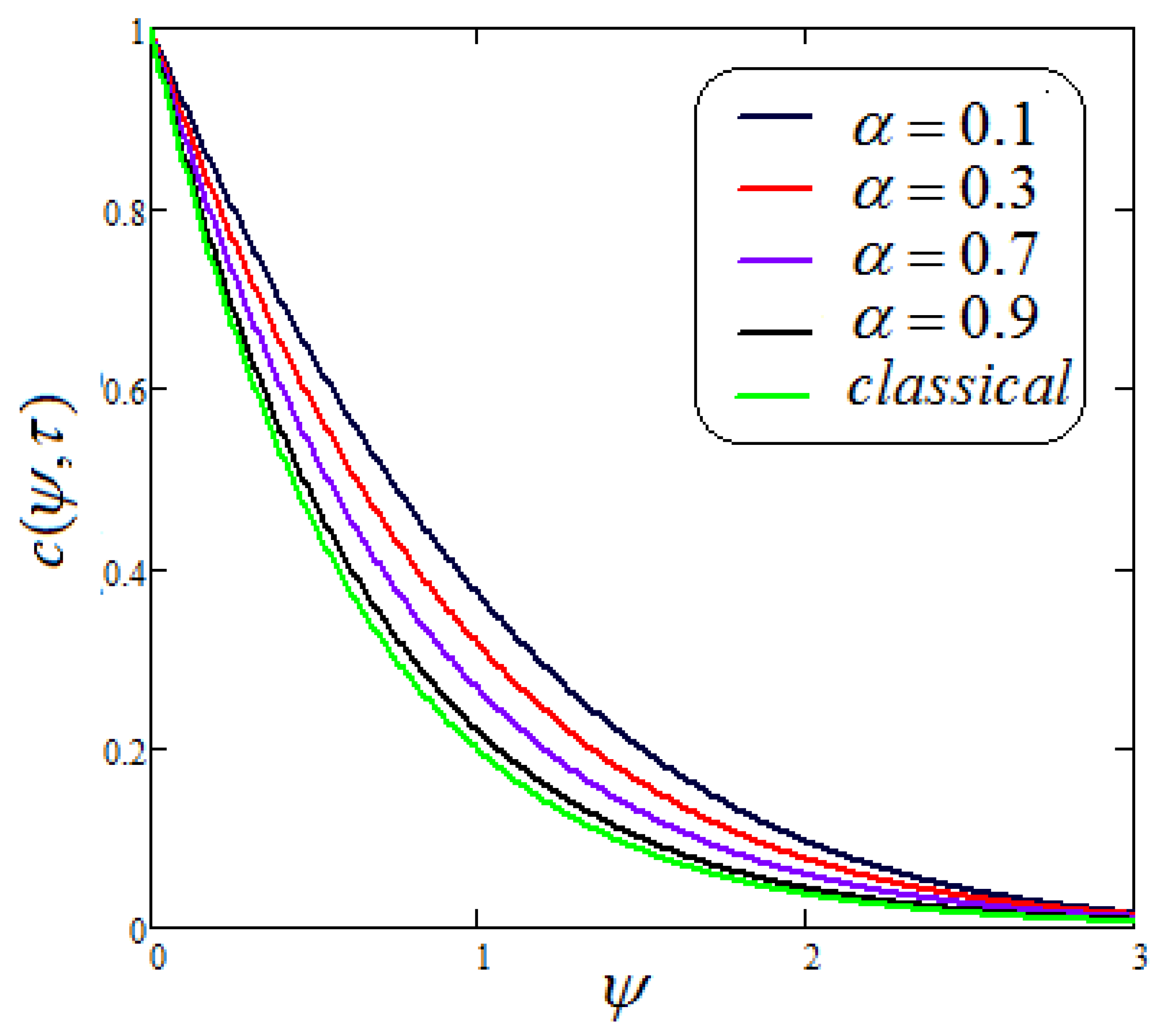

- The temperature field declines with larger values of . Furthermore, we noted a reduced concentration for increasing values of .

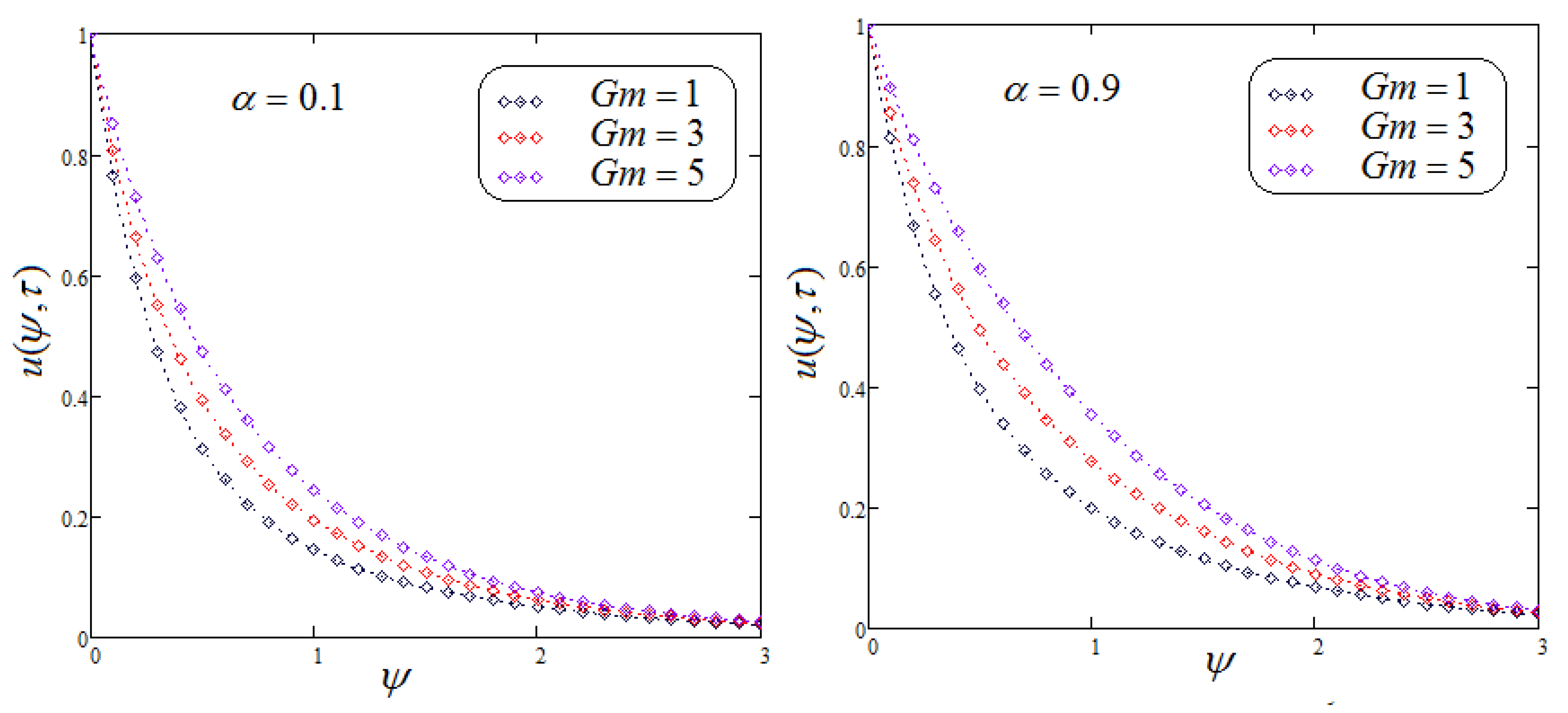

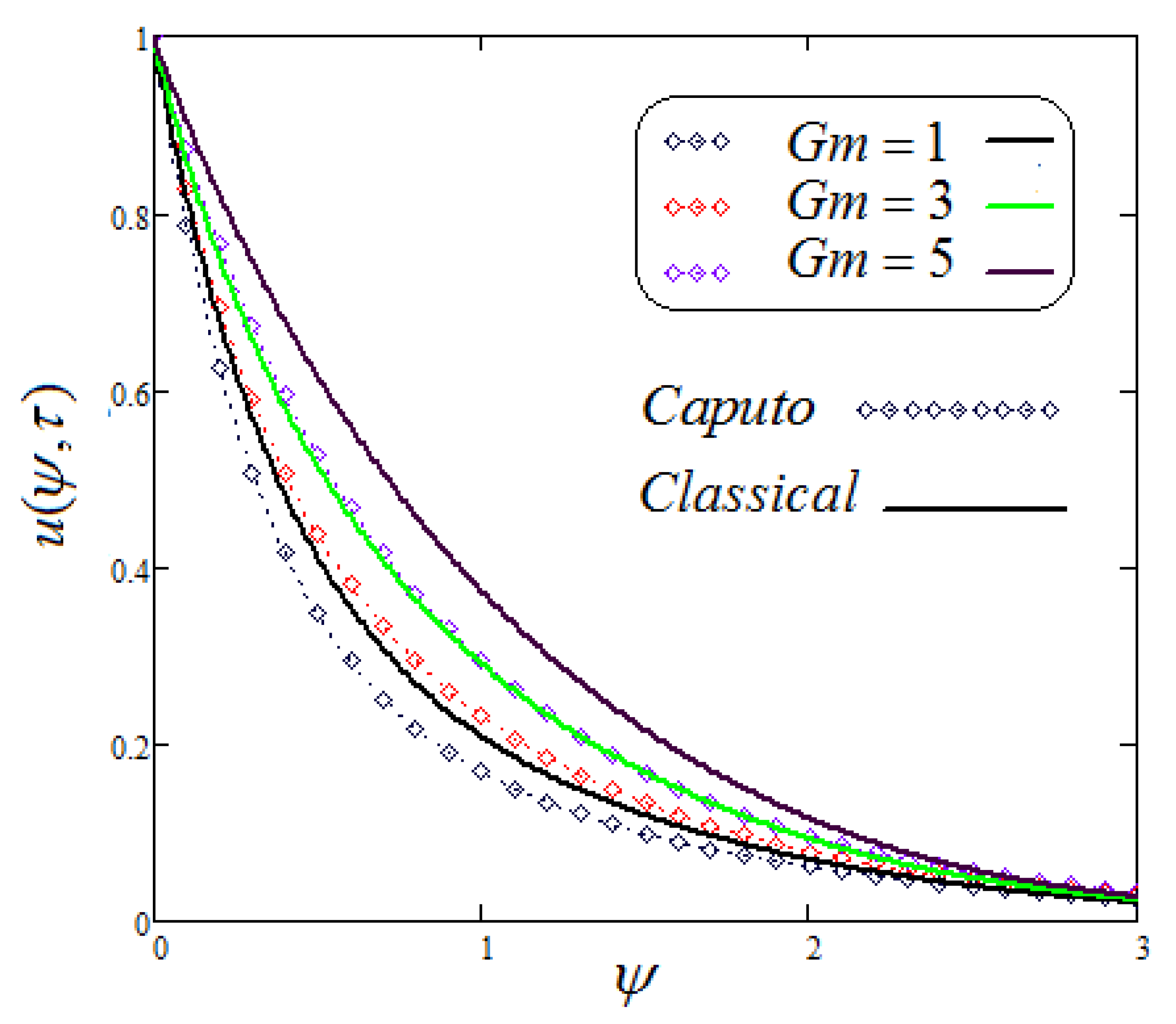

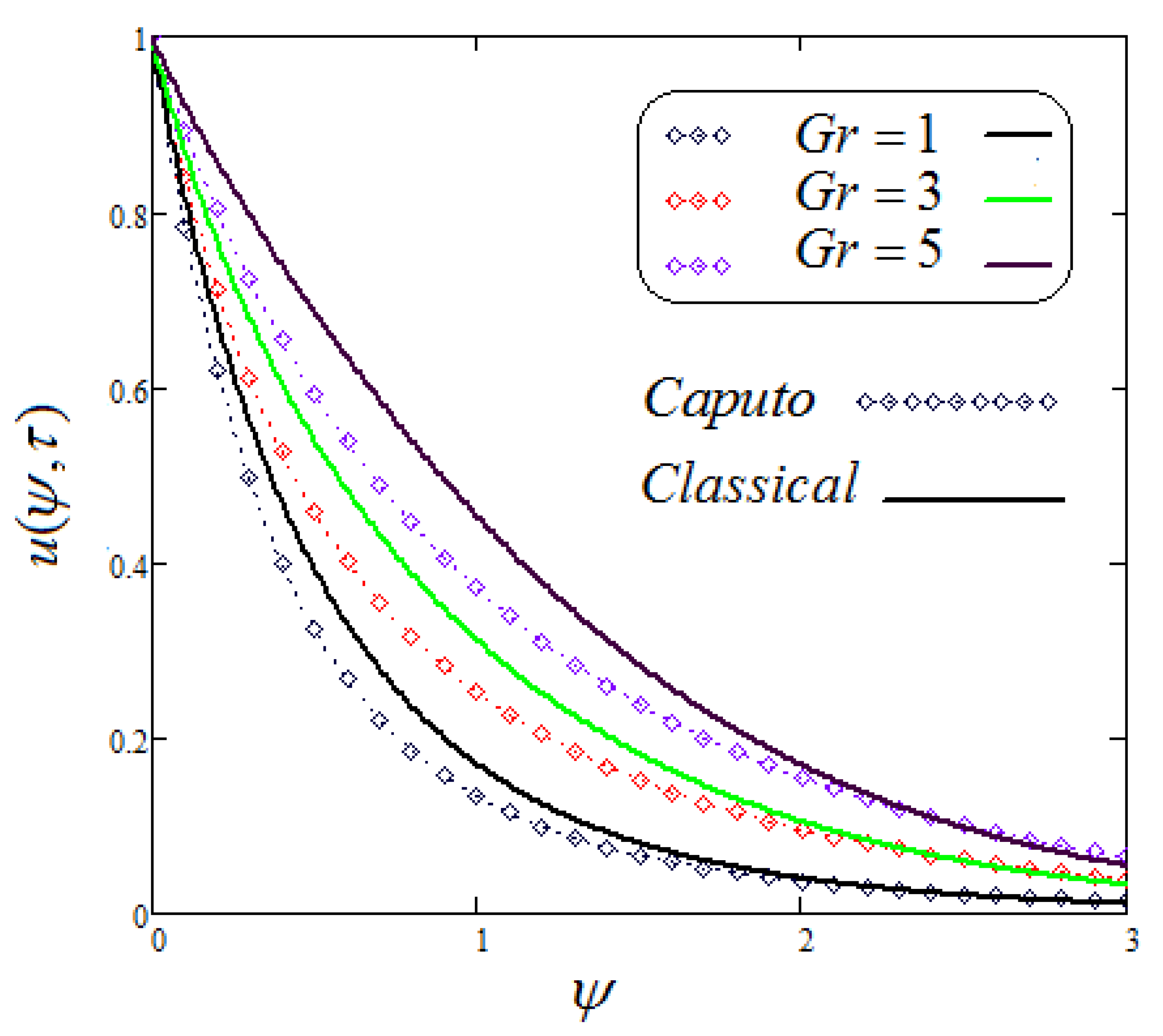

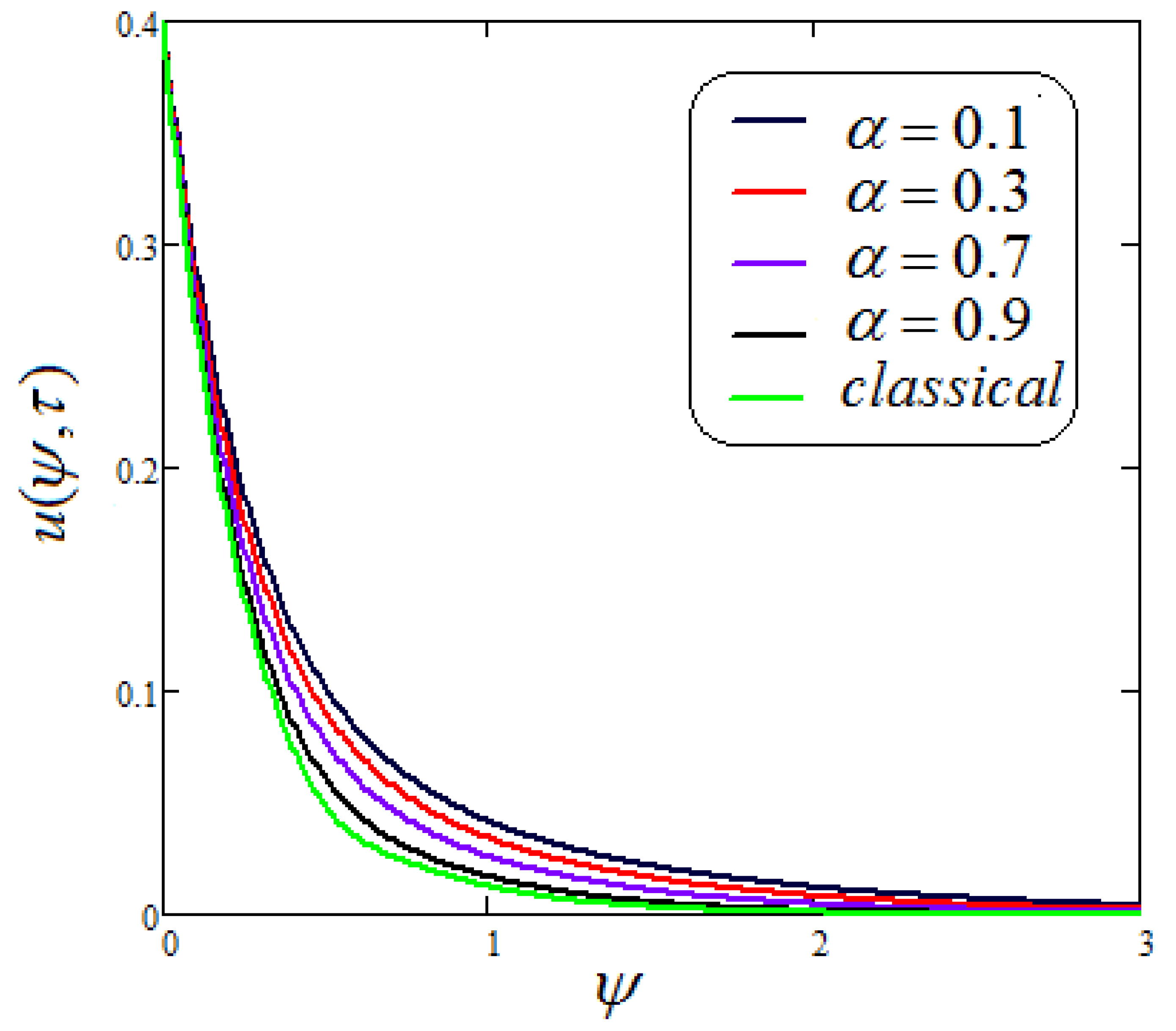

- Curves for Temperature, Concentration, and Velocity are deaccelerated via Caputo as compared to the classical derivative.

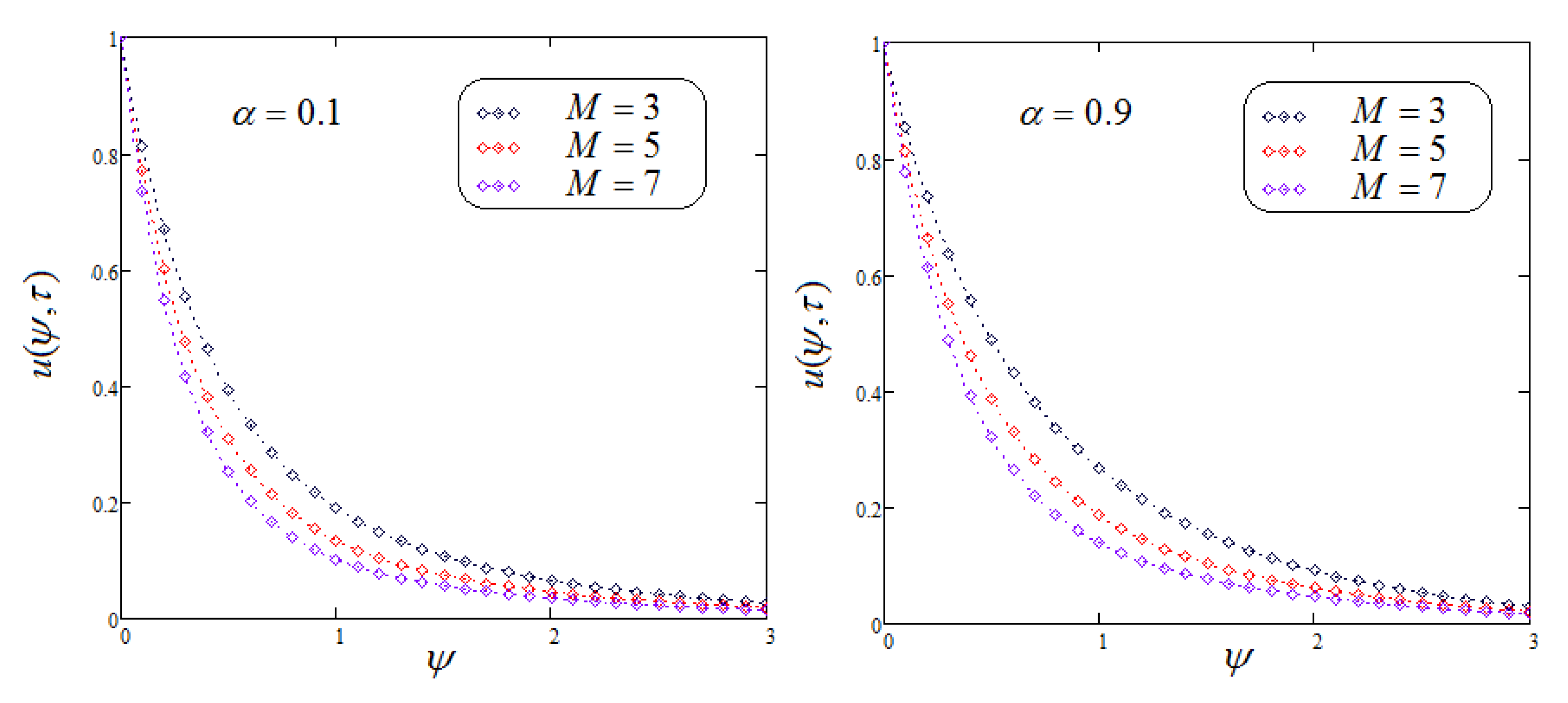

- With higher values of M, the fluid velocity is decreased.

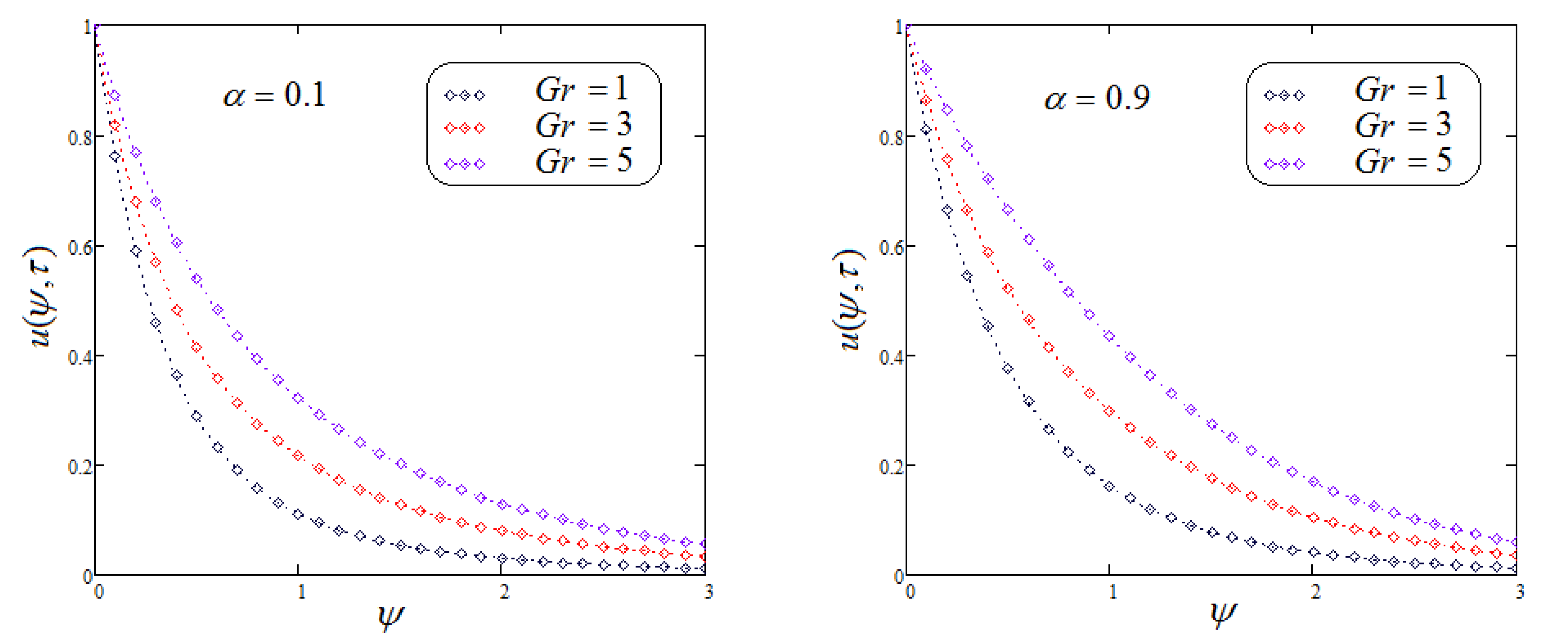

- Increasing values of Grashof numbers and stimulate velocity distribution.

- The accumulative values of the parameters and decrease the velocity distribution.

- The involvement of the concentration factor of fluid velocity in the fluid movement is significant and cannot be overlooked.

- The Caputo fractional time derivative converges to that of the classical model when .

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| Symbol | Quantity | Units |

| Fractional parameter | (-) | |

| Dynamic viscosity | (Kgms) | |

| Kinematic coefficient of viscosity | (ms) | |

| g | Acceleration due to gravity | (m.s) |

| Volumetric coefficient of thermal expansion | (K) | |

| Volumetric coefficient of concentration expansion | (K) | |

| Fluid density | (Kgm) | |

| Electrical conductivity | (sm) | |

| Specific heat at constant pressure | (jKgK) | |

| s | Laplace parameter | (-) |

| Q | Heat generation/absorption | (JKms) |

| u | Non-dimensional velocity | (-) |

| Dimensionless temperature | (-) | |

| Thermal Grashof number | (-) | |

| Mass Grashof number | (-) | |

| Concentration of the fluid near the plate | (kgm) | |

| Concentration of the fluid far away from the plate | (kgm) | |

| Temperature of the plate | (K) | |

| Temperature of fluid far away from the plate | (K) | |

| Relaxation time | (-) | |

| Mass diffusivity | (ms) | |

| Prandtl number | (-) | |

| Schmidt number | (-) | |

| Imposed Magnetic field | (Wm) | |

| M | Total Magnetic field | (-) |

| k | Thermal conductivity of the fluid | (WmK) |

| t | Time | (s) |

| P | Pressure | (N m) |

References

- Maxwell, J.C.I. IV. On the dynamical theory of gases. Philos. Trans. R. Soc. Lond. 1867, 157, 49–88. [Google Scholar]

- Jordan, P.; Puri, A.; Boros, G. On a new exact solution to Stokes’ first problem for Maxwell fluids. Int. J. Non-Linear Mech. 2004, 39, 1371–1377. [Google Scholar] [CrossRef]

- Fetecau, C.; Jamil, M.; Fetecau, C.; Siddique, I. A note on the second problem of Stokes for Maxwell fluids. Int. J. Non-Linear Mech. 2009, 44, 1085–1090. [Google Scholar] [CrossRef]

- Fetecau, C.; Fetecau, C. A new exact solution for the flow of a Maxwell fluid past an infinite plate. Int. J. Non-Linear Mech. 2003, 38, 423–427. [Google Scholar] [CrossRef]

- Noor, N.F.M. Analysis for MHD flow of a Maxwell fluid past a vertical stretching sheet in the presence of thermophoresis and chemical reaction. World Acad. Sci. Eng. Technol. 2012, 64, 1019–1023. [Google Scholar]

- Bhojraj, L.; Abro, K.A.; Abdul, W.S. Thermodynamical analysis of heat transfer of gravity-driven fluid flow via fractional treatment: An analytical study. J. Therm. Anal. Calorim. 2020, 144, 155–165. [Google Scholar] [CrossRef]

- Solangi, K.H.; Kazi, S.N.; Luhur, M.R.; Badarudin, A.; Amiri, A.; Sadri, R.; Zubir, M.N.M.; Gharehkhani, S.; Teng, K.H. A comprehensive review of thermo-physical properties and convective heat transfer to nanofluids. Energy 2015, 89, 1065e86. [Google Scholar] [CrossRef]

- Soomro, F.A.; Haq, R.U.; Khan, Z.H.; Zhang, Q. Passive control of nanoparticle due to convective heat transfer of Prandtl fluid model at the stretching surface. Chin. J. Phys. 2017, 55, 1561–1568. [Google Scholar] [CrossRef]

- Shafiq, A.; Hammouch, Z.; Sindhu, T.N. Bioconvective MHD flow of tangent hyperbolic nanofluid with Newtonian heating. Int. J. Mech. Sci. 2017, 133, 759–766. [Google Scholar] [CrossRef]

- Kashif, A.A.; Ali, D.C.; Irfan, A.A.; Ilyas, K. Dual thermal analysis of magnetohydrodynamic flow of nanofluids via modern approaches of Caputo–Fabrizio and Atangana–Baleanu fractional derivatives embedded in porous medium. J. Therm. Anal. Calorim. 2018, 53, 2197–2207. [Google Scholar] [CrossRef]

- Hamid, M.; Usman, M.; Khan, Z.H. Dual solutions and stability analysis of flow and heat transfer of Casson fluid over a stretching sheet. Phys. Lett. A 2019, 383, 400–2408. [Google Scholar] [CrossRef]

- Abro, K.A.; Irfan, A.A.; Sikandar, M.A.; Ilyas, K. On the Thermal Analysis of Magnetohydrodynamic Jeffery Fluid via Modern Non Integer Order derivative. J. King Saud-Univ.-Sci. 2019, 31, 973–979. [Google Scholar] [CrossRef]

- Sheikholeslami, M.; Mehryan, S.A.M.; Shafee, A.; Sheremet, M.A. Variable magnetic forces impact on magnetizable hybrid nanofluid heat transfer through a circular cavity. J. Mol. Liquids 2019, 277, 388–396. [Google Scholar] [CrossRef]

- Abdelmalek, Z.; Tayebi, T.; Dogonchi, A.S.; Chamkha, A.J.; Ganji, D.D.; Tlili, I. Role of various configurations of a wavy circular heater on convective heat transfer within an enclosure filled with nanofluid. Int. Commun. Heat Mass Transf. 2020, 113, 104525. [Google Scholar] [CrossRef]

- Kashif, A.A. A Fractional and Analytic Investigation of Thermo-Diffusion Process on Free Convection Flow: An Application to Surface Modification Technology. Eur. Phys. J. Plus 2020, 135, 31. [Google Scholar] [CrossRef]

- Siddique, I.; Shah, N.A.; Abro, K. Thermography of Ferromagnetic Walter’s-B Fluid through Varying Thermal Stratification. S. Afr. J. Chem. Eng. 2020, 36, 118–126. [Google Scholar] [CrossRef]

- Siddique, I.; Akgül, A. Analysis of blood liquor model via nonlocal and singular constant proportional Caputo hybrid differential operator. Math. Methods Appl. Sci. 2021. [Google Scholar] [CrossRef]

- Siddique, I.; Bukhari, S.M. Analysis of the effect of generalized fractional Fourier’s and Fick’s laws on convective flows of non-Newtonian fluid subject to Newtonian heating. Eur. Phys. J. Plus 2020, 135, 45. [Google Scholar] [CrossRef]

- Reddy, M.G. Heat and mass transfer on magnetohydrodynamic peristaltic flow in a porous medium with partial slip. Alex. Eng. J. 2016, 55, 1225–1234. [Google Scholar] [CrossRef]

- Abro, K.A.; Gomez-Aguilar, J.F. Fractional modeling of fin on non-Fourier heat conduction via modern fractional differential operators. Arab. J. Sci. Eng. 2021. [Google Scholar] [CrossRef]

- Yin, C.; Zheng, L.; Zhang, C.; Zhang, X. Flow and heat transfer of nanofluids over a rotating disk with uniform stretching rate in the radial direction. Propuls. Power Res. 2017, 6, 25–30. [Google Scholar] [CrossRef]

- Imran, M.A.; Riaz, M.B.; Shah, N.A.; Zafar, A.A. Boundary layer ow of MHD generalized Maxwell fluid over an exponentially accelerated infinite vertical surface with slip and Newtonian heating at the boundary. Results Phys. 2018, 8, 1061–1067. [Google Scholar] [CrossRef]

- Kashif, A.A.; Abdon, A. Role of Non-integer and Integer Order Differentiations on the Relaxation Phenomena of Viscoelastic Fluid. Phys. Scr. 2020, 95, 035228. [Google Scholar] [CrossRef]

- Shaheen, A.; Asjad, M.I. Peristaltic flow of a Sisko fluid over a convectively heated surface with viscous dissipation. J. Phys. Chem. Solids 2018, 122, 210–227. [Google Scholar] [CrossRef]

- Aslani, K.; Sarris, I. Effect of micromagnetorotation on magnetohydrodynamic Poiseuille micropolar flow: Analytical solutions and stability analysis. J. Fluid Mech. 2021, 920, A25. [Google Scholar] [CrossRef]

- Aslani, K.E.; Mahabaleshwar, U.S.; Singh, J.; Sarris, I.E. Combined Effect of Radiation and Inclined MHD Flow of a Micropolar Fluid Over a Porous Stretching/Shrinking Sheet with Mass Transpiration. Int. J. Appl. Comput. Math. 2021, 7, 60. [Google Scholar] [CrossRef]

- Abro, K.A. Numerical study and chaotic oscillations for aerodynamic model of wind turbine via fractal and fractional differential operators. Numer. Methods Partial. Differ. Equ. 2020. [Google Scholar] [CrossRef]

- Wakif, A.; Boulahia, Z.; Mishra, S.R.; Rashidi, M.M.; Sehaqui, R. Influence of a uniform transverse magnetic field on the thermohydrodynamic stability in water-based nanofluids with metallic nanoparticles using the generalized Buongiorno’s mathematical model. Eur. Phys. J. Plus 2018, 133, 181. [Google Scholar] [CrossRef]

- Imran, M.A.; Aleem, M.; Riaz, M.B.; Ali, R.; Khan, I. A comprehensive report on convective flow of fractional (ABC) and (CF) MHD viscous fluid subject to generalized boundary conditions. Chaos Solitons Fractals 2018, 118, 274–289. [Google Scholar] [CrossRef]

- Muhammad, A.; Makinde, O.D. Thermo-dynamic analysis of unsteady MHD mixed convection with slip and thermal radiation over a permeable surface. Defect Diffus. Forum 2017, 374, 29–46. [Google Scholar] [CrossRef]

- Bhatti, M.M.; Rashidi, M.M. Study of heat and mass transfer with Joule heating on magnetohydrodynamic (MHD) peristaltic blood flow under the influence of Hall effect. Propuls. Power Res. 2017, 6, 177–185. [Google Scholar] [CrossRef]

- Memon, I.Q.; Abro, K.A.; Solangi, M.A.; Shaikh, A.A. Functional shape effects of nanoparticles on nanofluid suspended in ethylene glycol through Mittage-Leffler approach. Phys. Scr. 2020, 96, 025005. [Google Scholar] [CrossRef]

- Abro, K.A. Fractional characterization of fluid and synergistic effects of free convective flow in circular pipe through Hankel transform. Phys. Fluids 2020, 32, 123102. [Google Scholar] [CrossRef]

- Riaz, M.B.; Atangana, A.; Saeed, S.T. MHD Free Convection Flow over a Vertical Plate with Ramped Wall Temperature and Chemical Reaction in View of Non-Singular Kernel; Wiley: Hoboken, NJ, USA, 2020; pp. 253–279. [Google Scholar]

- Riaz, M.B.; Saeed, S.T.; Baleanu, D.; Ghalib, M. Computational results with non-singular and non-local kernel flow of viscous fluid in vertical permeable medium with variant temperature. Front. Phys. 2020, 8, 275. [Google Scholar] [CrossRef]

- Ali, A.K.; Atangana, A. Dual fractional modeling of rate type fluid through non-local differentiation. Numer. Methods Partial. Differ. Equ. 2020. [Google Scholar] [CrossRef]

- Afridi, M.I.; Qasim, M.; Wakif, A.; Hussanan, A. Second law analysis of dissipative nanofluid flow over a curved surface in the presence of Lorentz force: Utilization of the Chebyshev–Gauss–Lobatto spectral method. Nanomaterials 2019, 9, 195. [Google Scholar] [CrossRef] [Green Version]

- Abro, K.A.; Atangana, A. Numerical and mathematical analysis of induction motor by means of AB–fractal–fractional differentiation actuated by drilling system. Numer. Methods Partial. Differ. Equ. 2020. [Google Scholar] [CrossRef]

- Abro, K.A.; Siyal, A.; Souayeh, B.; Atangana, A. Application of Statistical Method on Thermal Resistance and Conductance during Magnetization of Fractionalized Free Convection Flow. Int. Commun. Heat Mass Transf. 2020, 119, 104971. [Google Scholar] [CrossRef]

- Abro, K.A.; Soomro, M.; Atangana, A.; Aguilar, J.F.G. Thermophysical properties of Maxwell Nanoluids via fractional derivatives with regular kernel. J. Therm. Anal. Calorim. 2020. [Google Scholar] [CrossRef]

- Khan, I.; Saeed, S.T.; Riaz, M.B.; Abro, K.A.; Husnine, S.M.; Nissar, K.S. Influence in a Darcy’s Medium with Heat Production and Radiation on MHD Convection Flow via Modern Fractional Approach. J. Mater. Res. Technol. 2020, 9, 10016–10030. [Google Scholar] [CrossRef]

- Atangana, A.; Baleanu, D. New fractional derivative with non local and non-singular kernel: Theory and application to heat transfer model. Therm. Sci. 2016, 20, 763–769. [Google Scholar] [CrossRef] [Green Version]

- Khan, I.; Ali, F.; Shafie, S. Exact Solutions for Unsteady Magnetohydrodynamic oscillatory flow of a Maxwell fluid in a porous medium. Z. Naturforschung A 2013, 68, 635–645. [Google Scholar] [CrossRef]

- Khan, I.; Shah, N.A.; Mahsud, Y.; Vieru, D. Heat transfer analysis in a Maxwell fluid over an oscillating vertical plate using fractional Caputo-Fabrizio derivatives. Eur. Phys. J. Plus 2017, 132, 194. [Google Scholar] [CrossRef]

- Riaz, M.B.; Atangana, A.; Iftikhar, N. Heat and mass transfer in Maxwell fluid in view of local and non-local differential operators. J. Therm. Anal. Calorim. 2020, 143, 4313–4329. [Google Scholar] [CrossRef]

- Riaz, M.B.; Iftikhar, N. A comparative study of heat transfer analysis of MHD Maxwell fluid in view of local and non-local differential operators. Chaos Solitons Fractals 2020, 132, 109556. [Google Scholar]

- Rehman, A.U.; Riaz, M.B.; Awrejcewicz, J.; Baleanu, D. Exact solutions of thermomagetized unsteady non-singularized jeffery fluid: Effects of ramped velocity, concentration with Newtonian heating. Results Phys. 2021, 26, 104367. [Google Scholar] [CrossRef]

- Rehman, A.U.; Riaz, M.B.; Akgül, A.; Saeed, S.T.; Baleanu, D. Heat and mass transport impact on MHD second grade fluid: A comparative analysis of fractional operators. Heat Transf. 2021, 50, 7042–7064. [Google Scholar] [CrossRef]

- Riaz, M.B.; Awrejcewicz, J.; Rehman, A.U.; Akgül, A. Thermophysical Investigation of Oldroyd-B Fluid with Functional Effects of Permeability: Memory Effect Study Using Non-Singular Kernel Derivative Approach. Fractal Fract. 2021, 5, 124. [Google Scholar] [CrossRef]

- Rehman, A.U.; Riaz, M.B.; Saeed, S.T.; Yao, S. Dynamical Analysis of Radiation and Heat Transfer on MHD Second Grade Fluid. Comput. Model. Eng. Sci. 2021, 129, 689–703. [Google Scholar] [CrossRef]

- Riaz, M.B.; Abro, K.A.; Abualnaja, K.M.; Akgül, A.; Rehman, A.U.; Abbas, M.; Hamed, Y.S. Exact solutions involving special functions for unsteady convective flow of magnetohydrodynamic second grade fluid with ramped conditions. Adv. Differ. Equ. 2021, 408. [Google Scholar] [CrossRef]

- Akgül, A. A novel method for a fractional derivative with non-local and non-singular kernel. Chaos Solitons Fractals 2018, 114, 478–482. [Google Scholar] [CrossRef]

- Akgül, A.; Akgxuxl, E.K. A novel method for solutions of fourth-order fractional boundary value problems. Fractal Fract. 2019, 3, 33. [Google Scholar] [CrossRef] [Green Version]

- Akgül, E.K.; Akgxuxl, A.; Yavuz, M. New illustrative applications of integral transforms to financial models with different fractional derivatives. Chaos Solitons Fractals 2021, 146, 110877. [Google Scholar] [CrossRef]

- Akgül, E.K.; Akgxuxl, A.; Baleanu, D. Laplace transform method for economic models with constant proportional Caputo derivative. Fractal Fract. 2020, 4, 30. [Google Scholar] [CrossRef]

- Anwar, T.; Kumam, P.; Watthayu, W. Asifa Influence of ramped wall temprature and ramped wall velocity on unsteady magnetohydrodynamic convective maxwell fluid flow. Symmetry 2020, 12, 392. [Google Scholar] [CrossRef] [Green Version]

- Durbin, F. Numerical inversion of Laplace transforms: An efficient improvement to Dubner and Abate’s method. Comput. J. 1974, 17, 371–376. [Google Scholar] [CrossRef]

- Seth, G.; Nandkeolyar, R.; Ansari, M.S. Effect of rotation on unsteady hydromagnetic natural convection flow past an impulsively moving vertical plate with ramped temperature in a porous medium with thermal diffusion and heat absorption. Int. J. Appl. Math. Mech. 2011, 7, 52–69. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Riaz, M.B.; Rehman, A.-U.; Awrejcewicz, J.; Akgül, A. Power Law Kernel Analysis of MHD Maxwell Fluid with Ramped Boundary Conditions: Transport Phenomena Solutions Based on Special Functions. Fractal Fract. 2021, 5, 248. https://doi.org/10.3390/fractalfract5040248

Riaz MB, Rehman A-U, Awrejcewicz J, Akgül A. Power Law Kernel Analysis of MHD Maxwell Fluid with Ramped Boundary Conditions: Transport Phenomena Solutions Based on Special Functions. Fractal and Fractional. 2021; 5(4):248. https://doi.org/10.3390/fractalfract5040248

Chicago/Turabian StyleRiaz, Muhammad Bilal, Aziz-Ur Rehman, Jan Awrejcewicz, and Ali Akgül. 2021. "Power Law Kernel Analysis of MHD Maxwell Fluid with Ramped Boundary Conditions: Transport Phenomena Solutions Based on Special Functions" Fractal and Fractional 5, no. 4: 248. https://doi.org/10.3390/fractalfract5040248

APA StyleRiaz, M. B., Rehman, A.-U., Awrejcewicz, J., & Akgül, A. (2021). Power Law Kernel Analysis of MHD Maxwell Fluid with Ramped Boundary Conditions: Transport Phenomena Solutions Based on Special Functions. Fractal and Fractional, 5(4), 248. https://doi.org/10.3390/fractalfract5040248