Abstract

Cement-based materials, including cement and concrete, are the most widely used construction materials in the world. In recent years, the investigation and application of fractal theory in cement-based materials have attracted a large amount of attention worldwide. The microstructures of cement-based materials, such as the pore structures, the mesostructures, such as air voids, and the morphological features of powders, as well as the fracture surfaces and cracks, commonly present extremely complex and irregular characteristics that are difficult to describe in terms of geometry but that can be studied by fractal theory. This paper summarizes the latest progress in the investigation and application of fractal theory in cement-based materials. Firstly, this paper summarizes the principles and classification of the seven fractal dimensions commonly used in cement-based materials. These fractal dimensions have different physical meanings since they are obtained from various testing techniques and fractal models. Then, the testing techniques and fractal models for testing and calculating these fractal dimensions are introduced and analyzed individually, such as the mercury intrusion porosimeter (MIP), nitrogen adsorption/desorption (NAD), and Zhang’s model, Neimark’s model, etc. Finally, the applications of these fractal dimensions in investigating the macroproperties of cement-based materials are summarized and discussed. These properties mainly include the mechanical properties, volumetric stability, durability (e.g., permeability, frost and corrosion resistance), fracture mechanics, as well as the evaluation of the pozzolanic reactivity of the mineral materials and the dispersion state of the powders.

1. Introduction

As the most widely used construction materials, cement-based materials, including cement paste, mortar, and concrete, play an indispensable role in the construction of infrastructure and building engineering, such as houses, bridges, tunnels, ports, dams, roadways, etc. [1,2,3,4,5,6,7] Cement-based materials always show highly heterogeneous compositions and complex spatial distributions, from the nano- to the macroscales [8,9,10]. The development of advanced and effective testing techniques during the last decades has demonstrated that the macrolevel properties of cement-based materials, e.g., the mechanical properties, volumetric stability, permeability, and durability, are intrinsically related to their material structure at the micro- and mesoscales [11,12,13,14,15,16,17,18], and resolving their structure–property relationships is essential to the novel design and usage of cement-based materials in practice [9,19,20,21,22,23].

Fractal geometry is a new branch of mathematics, proposed and fundamentally established by French mathematician, Mandelbrot, in 1977, focusing on the irregularities, as well as the haphazard phenomena and behaviors, in nature [24,25]. Since then, fractal theory has been rapidly applied in many research fields, such as civil engineering, materials science, information science, and computer science [26,27]. In 1985, by using the X-ray scattering technique, Winslow [28] first proposed that the internal pore structure of cement paste was essentially fractal and proved that the fractal theory can quantitatively characterize the complexity and self-similarity of the pore network in cement paste. More recently, fractal theory has been used more and more for investigating the multiscale structures of porous materials, including cement-based materials [29]. The microstructures of cement-based materials, including the pore structures and mesostructures, such as the air voids as well as the morphological features of powders and the fracture surfaces, commonly present extremely complex and irregular features, which are difficult to describe in terms of geometry but that can be studied by fractal theory [12,14,30,31]. The fractal dimension, which is determined by various testing techniques and various fractal models, is one of the core contents of fractal theory and can be used to characterize the complexity and irregularity of the microstructures and mesostructures of cement-based materials effectively and quantitatively [4,9,12,31,32,33,34,35,36]. Moreover, many researchers [33,37] have demonstrated that fractal theory links the structures at the micro- and mesoscales with the macroperformance of cement-based materials well, and vice versa. The fractal dimensions of cement-based materials have proven again and again to be closely related to the macroperformance, such as the mechanical strength, permeability, frost resistance, etc. [14,15,30,38]. Since the fractal theory provides a brand-new and effective method for characterizing the microstructures and mesostructures of cement-based materials, as well as the correlations with the macroproperties, fractal theory is of great importance in the study of cement-based materials.

This paper presents a comprehensive review of the application of fractal theory in the research field of cement-based materials in recent years. Herein, the review includes the following parts: (1) A summary of the principles and classification of the commonly used fractal dimensions applied in the research field of cement-based materials; (2) A summary and analysis of the testing techniques and fractal models determining and calculating these fractal dimensions; (3) An introduction and discussion on the application of fractal theory for studying the macroproperties of cement-based materials, including the mechanical properties, volumetric stability, durability (e.g., permeability, frost and corrosion resistance), the fracture mechanism and fracture mechanics, the flexural performance and fracture energy, as well as the pozzolanic reactivity of the mineral materials and the dispersion state of the powders. It is expected that the present review work may help to inspire new ideas and provide a basic guide for researchers who want to study cement-based materials in terms of fractal theory. The aim of this work is also to promote a deeper and more comprehensive investigation and application of fractal theory in cement-based material research.

2. Fractal Dimensions

Many kinds of fractal dimensions have been developed and applied in the research field of cement-based materials, including the fractal dimensions of the pore surface, pore volume, tortuosity, air void, fracture surface, cracks, as well as the particle size distribution, etc. [9,31,32,35,36]. These fractal dimensions have quite different physical meanings since they are obtained from various testing techniques and fractal models, which can be applied to study different material properties. Some commonly used fractal dimensions in cement-based materials are summarized in Table 1. This Section describes the definition and principle of each fractal dimension listed in Table 1.

Table 1.

Some commonly used fractal dimensions in cement-based materials.

2.1. Fractal Dimension of Pore Structure

The pores in cement-based materials are extremely complex and irregular. On the basis of the classification method proposed by Mindess et al. [76], pores from 2.5 to 10 nm, from 10 to 50 nm, and from 50 nm to 10 μm are defined as small capillary (or gel) pores, medium capillary pores, and large capillary pores, respectively. Most of the macroproperties of cement-based materials, such as the mechanical properties, volume stability, frost resistance, and permeability are related to the pore structure [11,12,13,14,15,77,78]. The existing pore structure parameters mainly include the porosity, pore size distribution, pore surface area, pore volume, pore tortuosity, etc., which cannot quantitatively characterize the complexity and inhomogeneity of the pore structures [49,79]. The fractal theory can therefore be adopted to characterize the pore structures. Three main fractal dimensions of the pore structure have been proposed and developed, namely, the fractal dimension of the pore surface (Ds), the fractal dimension of the pore volume (Dv), and the fractal dimension of the pore tortuosity (Dt) [50,53,54]. These fractal dimensions can describe the structural characteristics of the pores in different dimensions [15]. It should be noted that cement-based materials also include many interlayer pores at the subnanometer scale, for example, the size of the interlayer space between the C-S-H layers is around 0.1–1 nm [80]. These pores are of great significance for C-S-H, a primary binding phase of cement-based materials [81]. However, so far, there are no fractal studies on these subnanometric pores. This is a subject needing further investigation, which is beyond the scope of this paper.

2.1.1. Fractal Dimension of Pore Surface (Ds)

Neimark was the first researcher to express the fractal dimension through the pore surface and the pore diameter relation [41]. According to Pfeifer and Avnir [42], the fractal dimension of the pore surface (Ds) reflects the roughness and irregularities of the internal pore surface of porous materials. Theoretically, all of the test methods that are able to probe the pore surfaces can be adopted to calculate the Ds by using some proper fractal models. It is generally accepted that all the fractal dimensions of pore surface (Ds) determined by various methods have the same physical meaning; they have a typical range of 2 ≤ Ds < 3. When the Ds of a porous object is equal to 2, it indicates that the measured object has a perfectly smooth plane. The pore structure becomes rougher and more complex when the Ds value approaches 3 [39,43].

2.1.2. Fractal Dimension of Pore Volume (Dv)

Many researchers have used different techniques and developed different fractal models to calculate the Dv. Overall, the Dv is an index used to describe the pore volume distribution or the complexity of the pore structures in porous materials [33,47,48]. Theoretically, all the techniques that can measure the pore volume, such as the mercury intrusion porosimeter (MIP), 1H low-field nuclear magnetic resonance (1H LF NMR), small-angle neutron scattering (SANS), the small-angle scattering of X-rays (SAXS), low-temperature differential scanning calorimetry (LT-DSC), etc., can be used to determine the Dv by adopting certain fractal models.

However, contrary to the Ds, there is no precise definition for the Dv so far. It can be found from the extensive literature with regard to this that the Dv values determined by different testing techniques and fractal models with different fundamentals are quite different. For example, according to the studies of Li et al. [48], and Zarnaghi et al. [33], the Dv of cement-based materials calculated by the MIP results and the Menger sponge model has a typical range of 2.0~3.0. They concluded that the rougher and more complex the pore structure in cement-based materials, or the broader the pore size distribution, the higher the Dv value will be. On the basis of the MIP results and the space-filling model, it is predicted that the Dv of hardened cement pastes is between 0 and 3 [47]. While, in the study by Tang et al., the Dv values of the cement pastes obtained by the LT-DSC technique are between 1 and 5 [30].

The test methods and fractal models determining the Dv, as well as their basic principles, will be revealed in Section 3.1.2.

2.1.3. Fractal Dimension of Pore Tortuosity (Dt)

Many studies have pointed out that the permeability of cement-based materials is significantly determined by the tortuosity of the pores [77]. The tortuosity of the pore structure (τ) can be calculated by Equation (1) [14,54]:

where Lt(λ) is the actual tortuous length along the flow direction; L0 is the straight length along the gradient; and λ is the diameter of a capillary tube in the object.

The fractal dimension of pore tortuosity (Dt) is an index used to describe the extent of the tortuosity of a porous object. According to Yu et al. [50], a porous object with various internal pore sizes can be considered a bundle of tortuous capillary tubes with variable cross-sectional areas. On the basis of the fractal scaling/tortuosity relationship, first revealed by Wheatcraft and Tyler [53], Yu et al. [50] propose that the relationship between the tube diameter and the length of the capillary tubes exhibits a fractal scaling law, which is shown in Equation (2):

where Dt is the fractal dimension of the pore tortuosity, which refers to the extent of the convolutedness of the capillary pathways for fluid flow through an object. It has a range of , and a Dt value of 1 implies a straight capillary path when Lt is equal to , while a larger Dt value implies a more tortuous capillary. A Dt value of 2 represents a highly tortuous line that fills a plane; λ is the diameter of a capillary tube in the object; Lt(λ) is the actual tortuous length along the flow direction; and is the straight length along the gradient. For a straight capillary, is equal to , while, for a porous object with many inner tortuous capillary tubes, is much larger than .

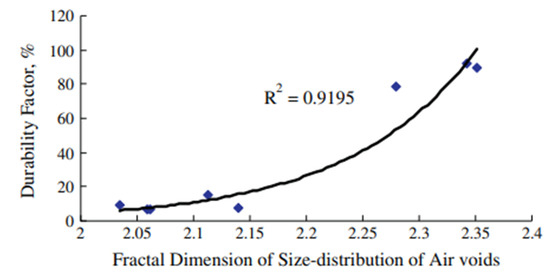

2.2. Fractal Dimension of Air Void (Da)

Cement-based materials in cold regions usually suffer from serious frost damage due to the frequent freeze–thaw cycles. It is well-known that a proper air-void system is needed in normal concrete to prevent frost damage during freeze–thaw cycles, since many closed, small, and evenly distributed air voids in concrete can ease the volumetric expansion and cut off potential water channels to improve the frost resistance of concrete [49,82,83]. According to the classification proposed by Mindess et al. [76], pores in cement-based materials sized over 10 μm are defined as air voids. The air-void parameters, such as the air content (A), the total number of air voids (N), the average air-void diameter (D), and the spacing factor (), etc., are known to significantly affect the frost resistance of concrete [15,49,83]. In addition, it is reported that the pore size distribution of air voids in concrete also plays an important role in determining the frost resistance of concrete [15].

Currently, it is difficult to characterize the air-void distribution through traditional approaches owing to the complexity of air voids in concrete. The fractal dimension of an air void (Da), which was first proposed and deduced by Hu [84], who used a fractal model based on air-void data, is a parameter reflecting the size distribution of the air voids. In order to better assess frost resistance in terms of the air voids in concrete, an improved and more reliable fractal model was proposed by Jin et al. [15] to determine the fractal dimension of the air void (Da), which will be described specifically in Section 3.2.

2.3. Fractal Dimension of Fracture Surface (Dfs)

Cement-based materials are quasi-brittle, and the nature of their fracture surfaces continues to be the subject of intensive research [58,63]. The fracture surfaces are caused not only by the fracture process itself, but also by the inner material texture and the microstructure rearrangement [63]. The main objectives of the studies on the fracture surfaces were to reveal the micromechanism of the fractures, and to evaluate the fracture mechanical properties of cement-based materials [61]. In the last two decades, many attempts have been made to establish the relationship between the fracture surface texture and the mechanical behavior of cement-based materials [62,85]. Moreover, the quantitative description of rough surfaces and interfaces has been an important task and challenge for many years [86].

Fractal analysis is a simple and powerful tool for quantifying the roughness and irregularities of fractured surfaces [86] since rough surfaces can be described quite well in terms of fractal geometry [24,25]. The fractal dimension of fracture surfaces (Dfs) was proposed by Mandelbrot et al. [87], who tried to link this fractal dimension with the fracture toughness of metal materials. According to Pfeifer and Avnir [42], the Dfs reflects the intrinsic surface irregularities: The higher the Dfs, the more irregular the fracture surfaces. Nowadays, more and more attention has been paid to the relationship between the Dfs and the fracture mechanics parameters, which will be introduced in detail in Section 3.3.

2.4. Fractal Dimension of Crack (Dc)

The cracks occurring in the volume and on the surface are considered to be the most common types of damage of cement-based materials, which can weaken the material structure [69]. The deterioration of the material properties of cement-based materials caused by cracks includes a reduction in the mechanical property, reduced watertightness, weakened impermeability to ion ingress, etc. [67]. Therefore, the study of cracks and cracking patterns is one of the key areas in the research field of cement-based materials.

The formation and evolution process of cracks are too complex to be accurately and quantitatively described by traditional mechanical analysis methods [68]. The concept of fractal dimension is typically used in fractal theory to quantify the effectiveness of space occupied by fractal shapes and paths [88]. The larger the fractal dimension, the more complex the fractal shape. In recent years, fractal geometry has been widely used to describe some irregular phenomena in the fracture behavior of materials [71]. Some typical applications of fractal theory are to quantitatively describe the development and evolution process of cracks in cement-based materials, and to establish a relationship between the cracks and their fractal characteristics [68].

According to the fractal theory, the cracking patterns, crack distribution, and crack morphology on the surface of cement-based materials exhibit fractal characteristics [65,67,69]. Thus, it is possible to characterize the cracking degree [67], the geometric complexity of the cracking pattern [26,67,70], the crack distribution [65,68,69] as well as the crack morphology [70] by the fractal theory. In recent years, using the fractal dimension of cracks (Dc) to describe the cracks of cement-based materials, and to probe the relationship between the fractal dimension of cracks and the material properties, have become research hot spots [68].

2.5. Fractal Dimension of Particle Distribution (Dp)

Cement-based materials, such as cement and fly ash, are powder materials. The properties of powder materials are closely related to the composition and structure of the powders. The particle size distribution of the powders and their fineness are the most important physical properties of powder materials, which often determine the physical and chemical properties of the cement-based materials [89].

It has been shown [73,90,91,92] that the particle size distribution and fineness of ordinary silicate cement particles, as well as the mineral admixtures, such as fly ash, can be described by fractal geometry. The fractal dimension of the particle size distribution (Dp) reflects the particle size distribution (gradation) and the fineness of the powder particles, which is a more intuitive parameter for describing the gradation and fineness of powders than traditional parameters [89,93]. Fractal dimensions of this kind can be used to evaluate the particle size distribution (gradation) and the fineness of powders [73,90]. Moreover, many studies have tried to correlate the Dp of mineral material, such as fly ash and silica fume, with their pozzolanic reactivities [93,94].

In addition, fresh cement paste is generally considered to be a suspension system, which is typically featured by typical particle agglomeration and dispersion. These parameters can be reflected by the fractal dimension of the particle spatial distribution (Dp) [74,75]. The Dp can be used to evaluate the dispersion state of cement particles affected by the inclusion of superplasticizers [74,75].

3. Investigation of the Test Methods and Fractal Models of Cement-Based Materials

3.1. Fractal Dimension of Pore Structure

It is important to determine the pore parameters accurately, which is fundamental to the establishment of fractal models. At present, the pore characteristics can be tested by MIP, NMR, SANS, LT-DSC, nitrogen adsorption/desorption isotherm (NAD), scanning electron microscopy (SEM), the noncontact impedance measurement (NCIM), etc. Notably, each of the existing techniques above can only probe pores with a certain scale, which will be discussed later.

In this section, the testing methods and fractal models calculating the main fractal dimensions of the pore structure, namely, the Ds, Dv, and Dt have been described individually.

3.1.1. Fractal Dimension of Pore Surface (Ds)

Ds by MIP, Zhang’s Model, and Neimark’s Model

The MIP is one of the most commonly used pore-testing techniques for analyzing the pore structures of cement-based materials because a MIP can detect a relatively wide pore size, ranging from about ~+2 nm to 100 μm [41]. It should be noted that the accuracy of MIP results is usually compromised by the “ink bottle” effect. This intrinsic drawback sometimes mistakes the large ink-bottle-shaped pores for small pores, thus mistakenly increasing the proportion of small pores [32,47]. Moreover, excessive mercury intrusion pressure may damage the pore structure of materials, especially loose cement-based materials [48]. However, the MIP is the only method available that can evaluate almost all the pore sizes in cement-based materials and, therefore, it has been widely used worldwide [33,47,52,95]. The principle of the MIP method is that cement-based materials cannot be wetted by liquid mercury and, therefore, the pore diameter of concrete can be measured by changing the pressure applied to the liquid mercury [3,96]. During MIP tests, mercury enters the large pores first, and then continuously occupies the small pores by increasing the mercury injection pressure [96]. The pore size can be calculated using the famous Washburn equation [97]. This equation, as shown in Equation (3), which assumes the pores have a cylindrical shape, transforms the pressure, P, of the mercury filling the pore with a radius of r.

where r is the pore radius, m; P is the mercury injection pressure, Pa; is the surface tension of the mercury, which is 0.485 N/m; and is the contact angle between the mercury and the pore surface, in the cases of cement-based materials where θ is equal to 130°.

Additionally, fractal models based on MIP results mainly include the thermodynamic fractal model (e.g., Zhang’s model [39,40] and Neimark’s model [41]), as well as other types of model, such as the space-filling model [47], and the Menger sponge model [42,48]. The principle of the thermodynamic fractal models is that the increase in the mercury surface energy is equal to the work done by the external force to the mercury during the MIP test [98]. Therefore, thermodynamic fractal models are commonly used to calculate the fractal dimension of the pore surface (Ds). The latter two fractal models are usually used to calculate the fractal dimension of the pore volume (Dv), which will be described in later subsections.

According to Neimark’s [41] model, there exists an energy equilibrium between the nonwetting internal surface extension and the external work of the mercury penetrating during the MIP test. Therefore, the internal pore surface (S) can be estimated by Equation (4), based on the MIP results [41]:

According to Pfeifer and Avnir [42], the internal pore surface can exhibit fractal property only if Equation (5) is satisfied:

where stands for the pore radius; and Ds refers to the fractal dimension of pore surface.

Putting Equations (3) and (5) together into Equation (4) produces a logarithmic relationship between the pore internal surface and the intrusion pressure, as exhibited in Equation (6):

Zhang et al. [39,40] provide another different thermodynamic fractal model for calculating the Ds. From Zhang’s fractal model [39,40], there exists a thermodynamic relationship that is, during the MIP test, the accumulated injection work () on the mercury and the total volume mercury intruded into the pores () following a logarithmic law, as presented in Equation (7):

where is the pore radius at the n-th mercury injection; Ds is the fractal dimension of the pore surface; C is a regression constant; n refers to the n-th mercury injection during the MIP test, which is the number between 1 and the total number of mercury injections.

can be determined by Equation (8):

where i refers to the i-th mercury injection, which is the number between 1 and n; is the pressure at the i-th mercury injection; Pa; is the volume of the mercury injected at the i-th mercury injection, m3; and n is the number of mercury injections during the MIP test.

The values of , , , and can be calculated on the basis of the MIP test results and Equation (8). After obtaining these values, the fitting line in Equation (7) can be plotted, and the slope of this line is the target Ds. The correlation coefficient (R2) of the fitting line was also recorded to evaluate the accuracy of the Ds. The closer the R2 value approaches to 1, the better the correlations between and , and a more accurate Ds is calculated.

Moreover, some studies proved Zhang’s model to be more realistic than Neimark’s model in terms of geometry [13,31].

Ds by NAD and FHH Isotherm Equation

NAD is also widely used to evaluate the fractal characteristics of cement-based materials, since NAD is able to provide a great deal of information about the pore surface area and the pore size [30,96]. Unlike the MIP, the NAD method only covers a pore size range between 1 nm and 100 nm [30,32,95,96].

The fundamental of NAD is that the internal surface of pores can adsorb a certain quantity of gas (nitrogen) molecules, and the volume of the gas (nitrogen) in the pores is assumed to be the actual volume of the pores in cement-based materials [96]. During the test, NAD records the nitrogen gas pressure and the adsorbed nitrogen quantity and provides an adsorption isotherm at the same time. When the gas pressure is relatively low, the surface adsorption dominates. With the increase in the gas pressure, nitrogen condensation happens in small pores [95,96]. The relationship between the relative pressure, , and pore size, d, can be expressed by Equation (9), which was deduced from the Kelvin equation [95,99]:

where is the surface tension of the liquid nitrogen (8.85 × 10−3 N/m); V is the molar volume of the liquid nitrogen (3.467 × 10−5 m3/mol); R is the gas constant (8.314 J/K/mol); T is the temperature of the liquid nitrogen (77.3 K); P and P0 are the experimental and saturation pressures of the nitrogen, respectively.

As for the fractal models based on the NAD method, several isotherm equations have been derived for various models of the physical adsorption on fractal surfaces, such as the Frenkel–Halsey–Hill (FHH) equation [43,45] and Neimark’s thermodynamic method [44]. These equations contain the fractal dimension, Ds, as a dominate parameter and describe the surface coverage as a function of the equilibrium pressure [43].

The FHH equation can be expressed as a logarithmic formula, as seen in Equation (10) [32,43,45]:

where V is the amount of nitrogen adsorbed at the relative pressure,; C is a constant, which is the intercept of the straight line shown in Equation (10); is the slope of the same straight line; and is the relative pressure during the NAD test.

Pfeifer et al. [46] and Jaroniec [43] further studied the FHH exponent and its relation with the Ds. They found that, at the beginning of the NAD test, when the relative pressure is low, van der Waals attraction forces are dominating (that is, the liquid/gas surface tension forces are negligible), and then the slope can be estimated by Equation (11). In this case, the van der Waals forces at the gas/solid interface tended to form the adsorbed film, which replicated the surface roughness [43]:

However, with the increase in the relative pressure, the absorbent surface is completely formed, and then the interface is controlled by the liquid/gas surface tension (capillary condensation), due to the greater thickness of the surface film. In this case, the slope,, can be estimated by Equation (12) [43]:

By using the FHH equation and the NAD method, Tang and Li [100] found that the surfaces of cement-based materials exhibited obvious fractal characteristics, and the Ds was in a range between 2.369 and 2.580. Moreover, the addition of mineral admixtures, such as silica fume and slag, could reduce the Ds values.

Ds by NAD and Neimark’s Thermodynamic Method

In addition to the (FHH) equation, Neimark and Unger [44] proposed a thermodynamic method for calculating the Ds based on the NAD results. It should be noted that Neimark’s thermodynamic method is only valid for capillary condensation on a fractal surface. The theoretical basis for this method is a simple relationship between the surface area of the adsorbed liquid film (S) and the average pore radius (r), as shown in Equation (13). The slope of this plot is related to the Ds:

where Ds is the fractal dimension of the pore surface; A is a constant and is the intercept of the line, versus ; r is the average radius of the curvature of this interface, which is the half of the pore size, d, calculated from Equation (9); S is the surface area of the liquid-gas interface at a given value of relative pressure, , which can be calculated on the basis of the NAD test results and the Kiselev equation, as shown in Equation (14) [44]:

where Nmax is the maximum adsorption volume; N is the equilibrium adsorption volume; is the surface tension of the liquid nitrogen (8.85 × 10−3 N/m); R is the gas constant (8.314 J/K/mol); T is the temperature of the liquid nitrogen (77.3 K); P and P0 are the experimental and saturation pressures of the nitrogen, respectively.

Putting Equations (9) and (14) into Equation (13) produces the Ds value.

3.1.2. Fractal Dimension of Pore Volume (Dv)

Dv by the MIP, the Space-Filling Model, and the Menger Sponge Model

It has been reported that the Dv can be calculated on the basis of the MIP results by using the Menger sponge model [33,42,48] and the space-filling model [47], respectively.

In 1983, Pfeifer and Avnir [42] first used the Menger sponge model to build the porous body. They proposed that the Dv can be calculated by using the logarithmic relationship between the intrusion volume, V, and the radius, r, obtained via the MIP tests. Recently, Li et al. [48] and Zarnaghi et al. [33] have specifically described how to use the Menger sponge fractal model to simulate the pore structure of cement-based materials and calculate the Dv values. The typical steps for constructing the Menger sponge model include: (1) Taking an initial cube, with a side length, R, and dividing it equally into m3-small cubes, with side lengths, R/m; (2) Taking out n cubes randomly and the number of remaining small cubes is ; (3) After executing Steps (1) and (2) for k times, then the side length and the amount of the remaining small cubes are and , respectively. According to the principle of fractal geometry, the Dv can be calculated by Equation (15):

As for the space-filling model, Ji et al. [47] constructed a space-filling model for simulating the space-filling process of cement hydration products in cement paste in 1997. The construction process and the theory of this space-fractal model are as follows: Imagine that there is a cube of a unit volume. At first, divide the cube into m3 equal small cubes, with a side length of l/m. The hydration of cement produces many hydration products that can fill in n small cubes (n < m3), resulting in (m3 − n) blank small cubes (pores). This process is called the "generator" of the fractal space-filling process of the solid phases of cement paste. Then, divide every one of the remaining blank (m3 − n) small cubes into m3 smaller cubes, each with a side length of l/m2. With the prolongation of the hydration age, the n smaller subcubes in each of the remaining blank (m3 − n) small cubes are filled with hydration products. By conducting such division and filling processes iteratively, the space-fractal model is established for simulating the space-filling process of cement hydration products in cement paste, due to the continuous cement hydration. According to this model, no matter how completely the cement grains hydrate, there remains some blank space (pores) that cannot be occupied completely by the hydration products. The Dv in the space-filling model can be calculated by Equation (16):

A careful comparison between the Menger sponge model and the space-filling model above demonstrates that their fundamental basis and model construction steps, and even the calculation equations, are almost the same, indicating that these two models are the same, but with different designations. Nevertheless, by using the MIP results and these models, there exists different subsequent equations for calculating the final Dv.

The typical method for calculating the Dv on the basis of MIP data and the Menger sponge model is introduced as follows: Commonly, the cumulative pore volume, V, can be calculated by accumulating the incremental pore volume in the order of greatest pore diameter to smallest pore diameter [49]. Ji et al. [47] propose a new cumulative pore volume, V*, which is defined by accumulating the incremental pore volume in the reversed order, that is, from smallest pore to greatest pore. The number of pores, dM, in the pore radius range from ρ toρ + dρ, calculated by Equation (17):

The total number of air molecules, Na, that the whole network of pores can accept is Equation (18):

where c is a constant, and r is the radius of the air molecules used as a yardstick. Only the pores with the radii, , can accept the air molecules of the radius, . The total number of air molecules, Na, that can be accepted by the pore with the radius, , is determined by Equation (19):

where ρmax is the maximum pore radius in the hardened cement paste that can be measured by the MIP technique.

Combining Equation (18) and Equation (19) yields Equation (20):

Differentiating Equation (20) with respect to r leads to Equation (21):

Assuming that the minimum pore radius in hardened cement paste is 0, then integrate in Equation (21) with respect to from 0 to , giving Equation (22):

By taking the logarithm of Equation (22), Equation (23) can be obtained:

where ; and d is the diameter of the pore, .

If the slope of the straight line of Equation (23) in the double logarithmic coordinate system is k, then:

On the basis of the MIP results and Equation (24), the Dv can be computed.

Moreover, it is interesting to note that there is another method for calculating the Dv on the basis of MIP data and the Menger sponge model, proposed by Li et al. [48]. They pointed out that the structural volume is shown in Equation (25):

When , , , and the pore volume is , then the following Equation (26) can be obtained:

Obviously, the value of the Dv depends on the pore volume, as determined by the MIP. During the MIP tests, the r of the pore is directly related to the intrusion mercury pressure, P, as shown in Equation (3). Let l equal r, putting Equation (26) into Equation (3), and then Equation (27) can be deduced as:

Subsequently, the Dv can be determined by 4 plus the slope of the straight line, versus in Equation (27). In the research, the Dv of cement pastes is in the range between 2.0 and 3.0, and it increases with an increasing curing temperature. Under the impact of the high temperature, the spatial structure of the pores tends to be more complex, thus leading to larger Dv values [48].

Dv by LT-DSC and the Menger Sponge Model

Yu and Cheng [50] indicate that, in a unit cell, the cumulative number, N, of pores with size λ greater than a particular r follows the fractal scaling law, as shown in Equation (28):

Liang et al. [51] further propose that the total number of pores from the minimum radius, rmin, to the maximum radius, rmax, can be defined as Equation (29):

On the basis of the equations above, Tang et al. [30] used a modified equation to calculate the Dv on the basis of the sponge model and the LT-DSC results, which is shown in Equation (30):

where is the pore volume fractal dimension; refers to the total number of volumes larger than ; and are the maximum pore volume and the minimum pore volume, respectively, which are the upper limits and the lower limits of what the LT-DSC techniques can probe.

The LT-DSC technique is a reliable technique for evaluating the porosity and pore volume in cement-based materials at a low scale by quantifying the water enclosed in the small pores [101]. According to [30], the data of the LT-DSC tests are selected on the basis of several criterions: (1) Continuous dataset segments are selected; (2) Temperature is less than 273.15 K; (3) A heat flow <0 for the melting process, and a heat flow >0 for the freezing process; and (4) A pore size in the range of 2–200 nm. Moreover, when the nonfreezable water layer on the pore surface is considered, the modified Gibbs–Thompson equation, associated with the test temperature (Tm) and the pore radius (r), is used, as shown in Equation (31):

where r has the unit of the nanometer;

is 273.15 K; and δ is an empirical parameter, which is 1.2 nm for cement-based materials. With respect to the LT-DSC test, the maximal pore volume, Vmax, is derived by summing up all of the incremental pore volumes (dV), as shown in Equation (32) [52]:

where dt is the time difference of the two adjacent temperatures, Tm1 and Tm2; P1 and P2 are the heat powers at the two temperatures; m is the mass of the investigated cementitious material; ∆Hm1(Tm1) and ∆Hm1(Tm2) are the change in the molar heat of the ice–water transition; ρ(Tm1) and ρ(Tm2) are the densities of the water as a function temperature. The derivations of ∆Hm1(Tm1)), ∆Hm1(Tm2), ρ(Tm1), and ρ(Tm2) can be seen in [52].

Finally, the Dv can be determined by putting Equation (33) into Equation (30) [30] and using the LT-DSC results together.

As described above, it has been found that the Vmax values are difficult to accurately test. In fact, it is not necessary to determine the detailed Vmax values in some studies. For example, Zeng et al. [4] modified Equation (28) as Equation (33) and stated that one can alternatively estimate the Dv by gathering the slope of the lg(N)–λ plot, i.e., Dv∝−lg(N(λ))/lg(λ).

In the work of Zeng et al. [4], the values of lg(N) and λ were calculated by the box-counting method and the SEM images. Then, the lg(N)–lg(λ) relationship can be plotted and the Dv can be estimated, which was close to 1.448.

Dv by 1H Low-Field NMR

The technique, 1H LF NMR, was first used by Halperin et al. [102] to probe the pore structures of cement paste. Since then, it has been widely used, especially in recent years, to effectively monitor the early hydration processes and characterize the microstructures of cement-based materials [103]. Fundamental to the technique is that 1H LF NMR is able to measure the relaxation behavior of the hydrogen protons in water molecules. By collecting the relaxation time and the relaxation signal intensity under nondestructive conditions, 1H LF NMR is able to detect the cement hydration, hydration kinetics, pore size distribution, etc. [104] The primary advantage of the 1H LF NMR technique is that it is a nondestructive method that can probe both the open and closed pores. Moreover, it can be performed at room temperature. Nevertheless, it should be noted that the iron phase, which is common in cementitious material, could greatly affect the precision of the NMR results [32,105,106,107].

The basis of 1H LF NMR, according to Pop et al. [108], is that the transverse relaxation time (T2) correlates with S/V, which is related to the size of the pores. Accordingly, the transverse relaxation time (T2) can be defined by the following Equation (34) [104,108]:

where is the relaxation time of the surface; is the ratio of the pore surface area to the pore volume; is a constant related to the thickness of the surface hydrate water; and r is the pore radius.

Since T2 is proportional to the pore size when the pores are assumed to be spherical and evenly distributed in cement-based materials, a logarithmic formula [32], as shown in Equation (35), has been developed to reveal the relationship between the accumulated volume fraction () and each pore category (T2,i), which is less than T2,max during the 1H LF NMR test.

Finally, the Dv can be calculated according to Equation (35) and the 1H LF NMR test results.

Dv by SANS or SAXS and a Simple Logarithmic Equation

The fractal characteristics of the pores in cement paste can be assessed by using SAXS or SANS since both the SAXS and SANS techniques are powerful tools for investigating the pores, sized from several nm to tens of nm, or even 100–150 nm, in cement-based materials [13,32].

During the SAXS and SANS experiments, an incident wave of X-rays, or neutrons with a wavelength of λ, will be scattered and/or absorbed by the material. The geometric angle (2θ) of the scattering between the incident wave and the scattered beams is transformed into a scattering vector, of magnitude (Q), as shown in Equation (36):

where λ is the neutron or X-ray wavelength. In general, the scattering from the fine microstructure system leads to the large values of the scattering angles or Q, and vice versa. More detailed descriptions of the SAXS and SANS techniques and their testing procedures can be found in [80].

It is noted that the scattering cross-section is a material property. The Dv of cement-based materials can be obtained from the slope of the log–log plotting of the scattering cross-section versus Q [32].

3.1.3. Fractal Dimension of Pore Tortuosity (Dt)

Dt by Image Analysis and the Box-Counting Method

Yu et al. [50] assumed that there is a similarity in the tortuosity of flow pathways among clusters, or particles within clusters. As described in Section 2.1.3, the tortuosity of flow paths between clusters is very similar to the streamtubes, which exhibit a fractal scaling law [53]. Yu et al. [50] propose that the Dt can be determined by the box-counting method. This method is based on the image analysis of a unit cell, or a sufficiently large cross-section of a sample along a plane normal to the flow direction. The image analysis for the box-counting method can be conducted by optical microscope [50], SEM [9], or the BSE technique [4].

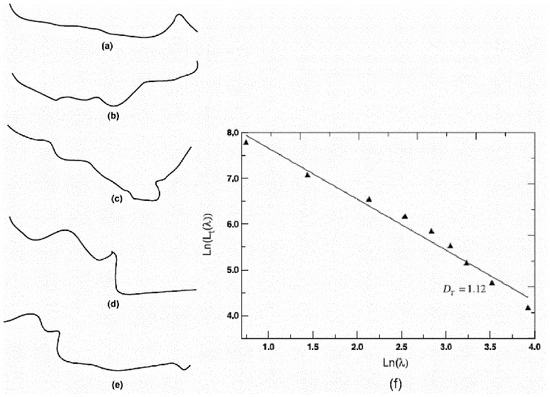

In a study by Yu et al. [50], the calculation of the Dt by image analysis and the box-counting method was described as follows: In their optical microscope images of the polished porous sample, with a porosity of 0.52, the black and white regions are the pores and the clusters formed by the agglomeration of copper particles, respectively. The software, Photoshop 5.0 and Visual C++5.0, were used to record the cumulative number and pore sizes, r, of the macropores. Then, the cross-section of the sample is discretized using square boxes with a size of λ, and the number of boxes, (λ), required to completely cover the tortuous pathways is recorded. Subsequently, the logarithmic plots of the cumulative number of macropores, N(λ ≥ r), versus the pore size, r, are drawn. Finally, the Dt can be determined, which is the slope of a linear line, (λ), versus λ. Figure 1 gives a typical calculation of the Dt based on the box-counting method in the study of Yu et al. [50]. Figure 1a–e present five random flow pathways between the clusters in the porous sample. On the basis of the calculation, the (λ) versus λ line can be drawn in Figure 1f, in which the slope (Dt) can be determined as 1.12. Similarly, the values of the Dt of the other four pathways (Figure 1a–d) can be calculated as 1.07, 1.08, 1.09, and 1.13, respectively.

Figure 1.

The typical calculation of the Dt based on the box-counting method: (a–e) five random flow pathways between clusters in the porous sample; and (f) the calculation of the Dt for the e-th path [50].

Dt by the Backscattered Electron (BSE) Imaging Model

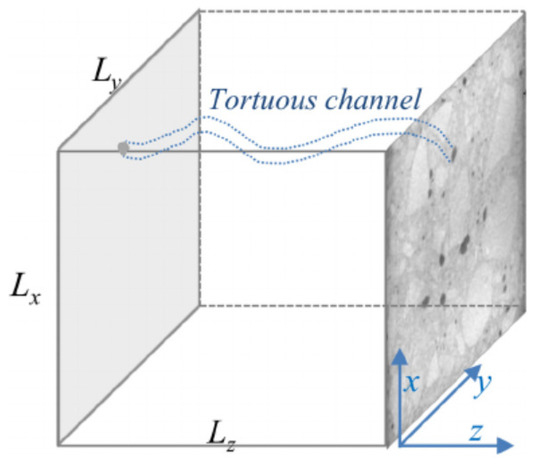

Zeng et al. [4] considered that the actual pores were distributed in the cement matrix in complex three-dimensional (3D) patterns, and provided another method for calculating the Dt based on the backscattered electron (BSE) imaging model. According to Zeng et al. [4], a typical element volume (REV) of porous cement-based materials, shown in Figure 2, where the pores for diffusion are tortuous in the z direction and their x−y cross-sectional sizes obey a fractal distribution. If porous cement-based materials are macroscopically isotropic, one can assume that Lx = Ly = Lz in Figure 2. For an individual tortuous pore (or streamtube), the pore tortuosity, τ, can be obtained by combing Equations (1) and (2), as exhibited in Equation (37):

Figure 2.

A representative element volume (REV) of porous cementitious material with tortuous channels or pores for mass diffusion [4].

Here, the tortuosity fractal dimension, Dt, can be calculated from the series of equations (Equations (38)–(40)) below, proposed by Yu et al. [50,54].

where is the average pore tortuosity; and is the average pore diameter (m).

For a material in a granular compactness, the average pore tortuosity may be given by Equation (39) [50]:

The term can be estimated by Equation (40) [109]:

where θ is a pore parameter identical to λmin/λmax; is porosity and can be approximately determined by the BSE. For the fractal structure of the capillary pores in cement paste determined by the BSE, the pixel ratio of λmin/λmax is around 0.01 [4]. It should be noted that Dt may vary in different models since the equations for determining and are different.

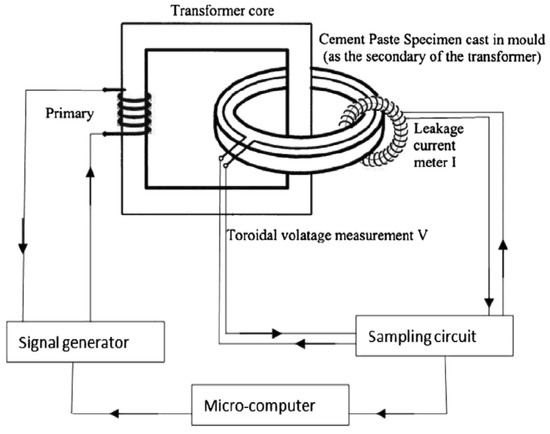

Dt by NCIM Method and Two-Phase Fractal Model

The noncontact impedance measurement (NCIM) is a nondestructive method for studying the hydration, pore structure, ion transportation, and permeability of cement pastes [55,56,57]. The principle of the NCIM is shown in Figure 3 [57]. During the NCIM test, the sine wave, with a frequency ranging from 1 kHz to 100 kHz, is applied on the primary coil of the transformer via the signal generator. The ring-shaped cement paste specimen, with a volume of 1.4 L, can be identified as the secondary coil of the transformer in Figure 3. The current going through the specimen is measured and recorded by the leakage current meter continuously. All the impedance data collected within the first three days of hydration is utilized to analyze the pore structure evolution of the cement paste.

Figure 3.

Illustration of the noncontact impedance measurement (NCIM) [57].

In a study by Tang et al. [56], a novel fractal permeability model based on NCIM results was proposed to compute the Dt. In this model, the Dt is also determined using Equation (37) above, while the and can be calculated using Equations (41)–(43) below:

where is the average pore tortuosity; is the average pore diameter (m); is the porosity and can be determined by the NCIM technique; Df is the fractal dimension of the pore space. Thus far, the Df has been solely reported by Tang et al. [55,56,57] and Yu et al. [50]. The Df is the slope of the logarithmic plot of the cumulative pore number () versus [50]. It should be noted that, since the Df is not a commonly used fractal dimension, with no clear physical meaning and definition, it is not discussed and described in detail in this paper.

For the porous cement paste, the maximal pore diameter () in Equation (42) can be expressed as Equation (43):

where is the mean diameter of the cement particles, which is measured as 15–20 μm. The minimal pore diameter () in Equation (42), determined by the NCIM, is predicted as 6.2 nm [56].

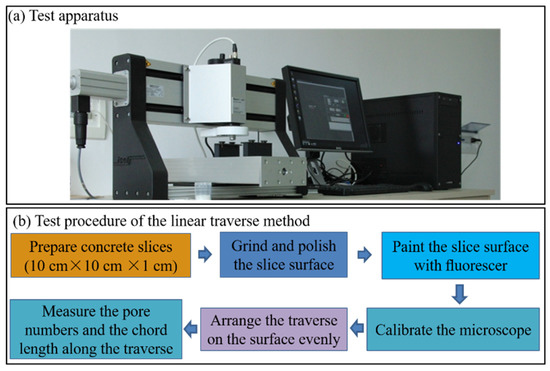

3.2. Fractal Dimension of Air Void (Da) by Air-Void Analyzer and Box-Counting Method

The air-void parameters mainly include the air content (A), the total number of air voids (N), the average air-void diameter (D), and the spacing factor (L). These parameters are usually determined by the air-void analyzer and the linear traverse method [49,82]. The test apparatus, as well as the testing procedure, are schematically illustrated in Figure 4. More detailed information of this test can be seen in ASTM C 457 [110] and the Chinese standard DL/T 5150 [111].

Figure 4.

The air-void test: (a) air-void analyzer; and (b) testing procedure of linear traverse method [82].

Jin et al. [15] report that the fractal dimension of an air void (Da) can be determined by using the air-void analyzer and the box-counting method together. According to this method, the boxes used to cover the air voids in concrete were chosen as circles in the fractal model. The diameter of the air voids, d, was defined as the box-size diameter. Air voids in n groups with different diameters, di (i = 1, 2, ..., n), were used to construct the fractal model. The smallest number of the boxes required to cover all the air voids can be calculated as the equivalent number of air voids, Nei (i = 1, 2, ..., n). On the basis of series sets of the diameters and the equivalent numbers of the air voids, [d1, Ne1], [d2, Ne2]... [dn, Nen], the relationship between di and Nei, as shown in Equation (44), can be revealed by the following linear equation (Equation (44)). The minus of the slope of Equation (44) is defined as Da:

where is the equivalent number of air voids; Da is the fractal dimension of the air-void size distribution; d is the diameter of the air voids; and C is a constant.

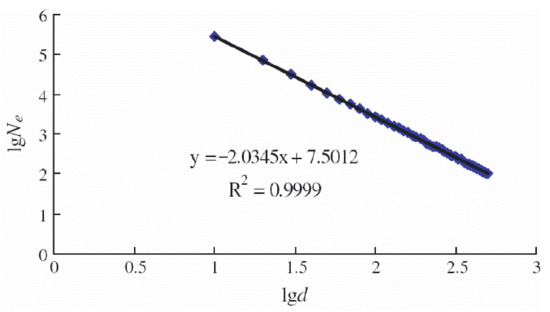

Figure 5 gives an example how to use this box-counting method to calculate the Da of concrete. In Figure 5, the logarithmic diagram of d and Ne is plotted. The slope of the line in Figure 5, which is also the Da, is 2.0345 for this concrete specimen.

Figure 5.

Fractal analysis based on the fractal model proposed in [15] *. Note *: For different studies that have used the box-counting method, the number of boxes have different designations, such as Nei in this subsection, N in Section 3.1.2.2 and Section 3.3.5, (λ) in Section 3.1.3.1, and in Section 3.4. However, all these designations have the same meaning in terms of the box-counting method.

3.3. Fractal Dimension of Fracture Surface (Dfs)

The accurate measurement of the fracture surfaces is the key to developing fractal models of fracture surfaces, and for calculating the fractal dimension of the fracture surface (Dfs). Many effective techniques and fractal models have been utilized together to characterize the Dfs, including stereoscopic scanning electron microscopy (SEM) combined with Friel’s method [60], 3D laser scanning technology combined with the projective covering method [61], the image analysis technique combined with the 2D fast Fourier transform function [58,59], a laser profilometer combined with the chord method [62], as well as the confocal microscope/SEM technique together with box-counting method [63,85].

3.3.1. Dfs by Stereoscopic SEM and Friel’s Method

A fractal study on the fracture surfaces of cement pastes and mortars using the stereoscopic SEM method was conducted by Wang et al. [60]. The fundamental basis of this method is that if the heights of all points on the fracture surface above a base reference plane can be established, its true surface area can be measured. According to this method, a grid of points is placed on the rough fracture surface, from which the surface is “profiled” by subdividing it into an array of triangular cells tilted at various angles to each other. The measured or “profiled” surface areas (adjusted for the raster scan area) were plotted against the measurement scales on a log–log plot. Then, the Dfs can be calculated from the slope of the plot. The equation used for the final calculation, as proposed by Friel and Pande [112], is shown in Equation (45):

where S is the profiled surface area; is a constant; Dfs is the fractal dimension of fracture surface; and is the characteristic measurement scale area.

3.3.2. Dfs by 3D Laser Scanning Technology and the Projective Covering Method

In a study by Yan et al. [61], 3D laser scanning technology based on the triangulation method was used to measure the 3D profile of the fracture surfaces of concrete. First, the surface topographies of all the fracture surfaces were measured using this technique. Then, the digitized fracture surfaces were analyzed directly by using the projective covering method, which is similar to the box-counting method. The Dfs is evaluated from the rate of the divergence of the apparent area, A, as the size of the elements, r, decreases. Then, the projective covering method was established to determine the fractal characteristics of the fracture surface, as shown in Equation (46):

where A is the total area of the fracture surface with the grid size, r.

3.3.3. Dfs by Image Analyzer Method and 2D Fast Fourier Transform Function

The image analyzer method [58] is described as follows. The fracture surface is placed in dyed water. A photo is taken from the top and analyzed by an image analyzer. At each threshold level (intensity of light) increment, new islands appear, and their perimeter and area are measured. Then Equations (47) and (48) are used to compute the Dfs:

where D′ is determined from the power function of the relationship between the area, A, and the perimeter, P, of the islands.

Subsequently, a 2D fast Fourier transform function is used to calculate the Dfs of an image. Within the Fourier domain, the spectral density has a power law dependence on the wave number. The Dfs is related to the slope of the log–log plot of the 2D spectral density versus the wave number, as given in Equation (49) and reported by [113]:

According to this method, the wave numbers of the image, and their corresponding spectral energy densities, are computed. After that, these data are plotted in a log–log diagraph, and its slope can be determined using a linear least squares regression technique. At last, the Dfs can be calculated using Equation (49).

3.3.4. Dfs by Laser Profilometer and the Chord Method

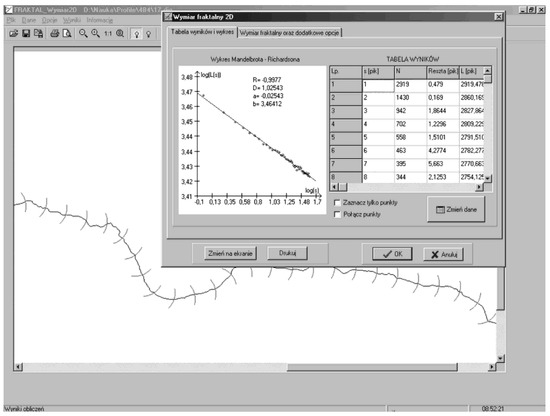

In Janusz and Prokopski’s research [62], the shape of the profile lines of the cracks was obtained using a laser profilometer designed for the fast contactless measurement of 3D surface topography. Then, the obtained data were entered into a software program, named Fractal Dimension2D, and the final computations were made.

The Dfs was calculated by the chord method [62]. According to the chord method, the measurement of the profile line length is taken at varying measurement steps by counting their number and calculating the total profile line length. There is a certain exponential relationship between the value of the measurement step () and a geometric quantity determined using the measurement step, such as the curve length. Then, the logarithmic function revealing the relationship among the Dfs, the curve length, and the measurement step can be expressed as Equation (50):

where is the curve length, as measured by the i-th step, , and is the curve slope in the logarithmic graph in Equation (50).

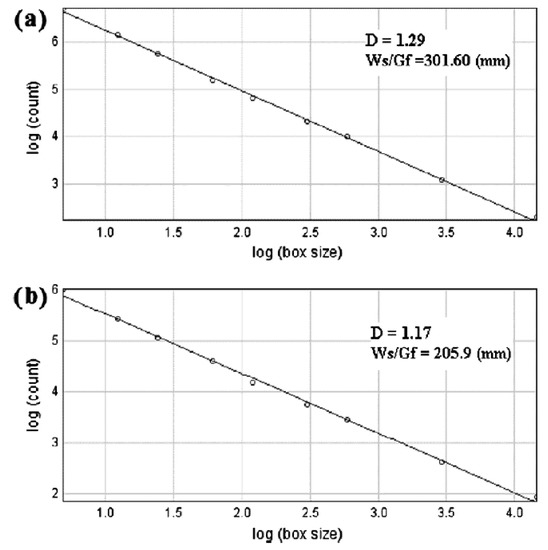

An example of the Dfs calculation in Janusz and Prokopski’s study [62] is given in Figure 6. The values of the si are laid on x-axis, while the values of the logarithms of the length of the curve, L(si), obtained for that step, si, are laid on the y-axis. Then, the Dfs value can be graphically obtained as the slope of the straight line in Figure 6. In the case of Figure 6, the Dfs is determined to be 1.0254.

Figure 6.

An example of the Dfs calculation: A visible concrete fracture surface profile line with the measurement step marked, and the graph of the log(L(si))–log(si) line [62].

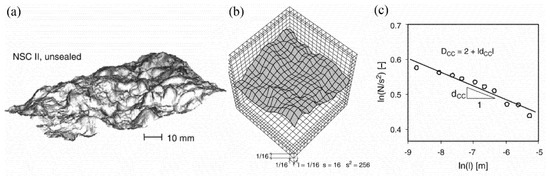

3.3.5. Dfs by Confocal Microscope/SEM and the Box-Counting Method

The confocal microscope technique can be applied to study the contours of concrete fracture surfaces [63,85]. During the confocal microscopic test, laser light reflected from a dichroic mirror into a scanning device moves in a raster scan in an x–y plane. A point source is imaged in the object plane. By coupling a step motor to the focusing unit, whole series of sectional images can be produced by changing the focal plane. This information is used to rebuild a 3D image of an object by overlaying the images of a section series.

From the optical measurement data, the Dfs can be determined by using the box-counting method [63,85]. Figure 7 exhibits an example of the Dfs calculation by confocal microscope and the box-counting method [85]. Figure 7a gives a typical contour of the fracture concrete surface built by the confocal microscope technique. Cubes with the number of s2 are generated to cover the 3D contour data (Figure 7b). The number of cubes, N, that intersect the fracture surface, divided by the s2 cubes necessary to cover the projection surface, is plotted against the inverse of the cube size, l, on a ln–ln scale. If a linear relationship is found, then the Dfs can be determined by adding the fractal increment, dCC (which corresponds to the slope of the linear line), to the dimension of a plane= 2 (Figure 7c). In this study, 512 × 512 mesh data have been used for each monitored spot with a size of 0.64 mm × 0.64 mm.

Figure 7.

An example of the Dfs calculation by confocal microscope and the box-counting method: (a) Typical contour of fracture concrete surface; (b) Coverage of the fracture surface by 3D boxes (l = 1/16); (c) Plot of ln(N/s2)–ln(l) line [85].

Furthermore, some researchers [9] have reported another effective method for determining the Dfs. According to their method, massive SEM pictures of the fracture surfaces were used to calculate the Dfs by the box-counting algorithm, which was programmed on the MATLAB platform. An image with continually distributed grey values, which is in M × M pixels, was first read in the modeling system, then the box-counting method was conducted to analyze the image. Finally, the Dfs can be determined as the slope of the line ln (N) versus the ln (l). A more detailed description of the box-counting method can be found in [9].

3.4. Fractal Dimension of Crack (Dc) by Various Testing Techniques and Box-Counting Method

The proper measurement of cracks is of significance for correctly estimating the fractal characteristics of cracks. Various methods have been adopted to measure the crack paths, including visual observation [68,70], tracing drawing technology of plastic sheets [69], X-ray computed tomography (X-ray CT) [26,65,66], the photoelastic coating set-up [71], a digital camera equipped with image software [64], an optical scanner (or digital camera) combined with machine learning algorithms [67,72].

In Zheng’s research [70], the geometric shapes of cracks and their distribution in concrete beams under flexural load were visually observed. The geometrical morphology of cracks in the research of Zhuang et al. [69] was mapped by tracing them onto a plastic sheet. In Jun et al.’s research [71], the photoclastic coating set-up is applied in order to observe the crack paths in the splitting-tensile tests. Owing to the ability of the X-rays to pass through thick and opaque objects, three-dimensional images of the internal micro-cracks in concrete samples can be obtained by using an X-ray CT [26,65,66]. The captured images can be digitized and converted into binary images to reveal the crack paths by using the computer image analysis software [64]. Furthermore, the cracks in cement pastes can be analyzed an optical scanner (or digital camera) combined with machine learning algorithms. The principle of this method is to implement machine learning algorithms with defined parameters of the desired pattern to produce pixel-based segmentations [67,72].

Overall, the crack paths of concrete specimens can be obtained by many different methods. After obtaining the crack information, the fractal dimension of the cracks (Dc) can be evaluated by using the box-counting method.

The calculation steps of the Dc conforming to the box-counting method are as follows [26,64,65,67,68,69,70,71,72]: The surface crack area of the specimen is covered by multiple square grids of different lengths, and the density of these grids can be changed by adjusting the square length. The total number of grids covering the crack area is counted. For each square length (r), if Equations (51) and (52) are satisfied, the Dc can be determined accordingly [68,114].

where is the total number of the grids covering the crack area; and is the square length.

3.5. Fractal Dimension of Particle Distribution (Dp)

The fractal dimension of the particle distribution can be calculated based on the particle size distribution information of the powders. The laser granulometry can precisely detect the particle size distribution powders with a size range of 20 nm–2000 μm. There are also other testing techniques that can analyze the particle size distribution, such as an optical microscope and the image analysis system [75].

3.5.1. Dp by Laser Granulometry and Yu’s Method

On the basis of the laser granulometry results, the fractal dimension of the particle size distribution (Dp) can be computed by the following fractal equations, proposed by Yu et al. [73] and Wang et al. [74]:

where denotes the ratio of the number of cement particles with sizes less than to the number of particles, and the Dp is the fractal dimension of the cement particle size distribution.

Assuming that the density of each particle in the powder is homogenized at this point, the mass of particles, , with particle sizes ranging between and can be expressed as:

where W is the total mass of particles in the powder; denotes the ratio of the number of cement particles with sizes less than to the number of particles. The particle size distribution of the powder should satisfy the following equation:

It should be noted that the existence of a straight-line segment in the double logarithmic coordinates, ~, indicates that the particle size distribution of the powder has a fractal structure, and the slope was calculated to obtain the fractal dimension of the particle size distribution:

The particle mass cumulative distribution curve obtained by the laser particle size analyzer is described in the double logarithmic coordinate (~), and the particle distribution data is subjected to linear regression analysis under this coordinate system. The slope of the regression line is b = 3 . Then can be estimated as .

3.5.2. Dp by Image Analysis System

The fractal dimension of the particle spatial distribution (Dp) can be determined on the basis of analyzing a large number of particle images captured by an image analysis system. In the research of Zhang et al. [75], a high-resolution image analytical instrument, Morphologi G3, was employed to characterize the morphological properties of the cement grains in a cement suspension sample. During the test, a high-quality image of each cement particle in the tested sample was captured by the instrument. Meanwhile, a 2D projection of the 3D cement grain was performed on these captured images using software inside the instrument. On the basis of the two-dimensional projections of the hundreds of thousands of particles in the cement suspension sample, the Dp can be determined by Equation (58), which was derived from the statistical analysis theory on the mesh simplification on 2D projections of particle images [75]:

where is the side length of the mesh; is the amount of meshes on all 2D projection images during the test. Generally, a larger Dp implies a higher dispersive degree of cement grains in the cement suspension sample, and vice versa.

4. Application of Fractal Theory on Performance of Cement-Based Materials

There are some basic and fundamental macroproperties of cement-based materials, including mainly the mechanical properties, volume stability, permeability, frost resistance, corrosion resistance, fracture behavior, etc. The application of fractal theory on these properties of cement-based materials will be described and discussed individually in this section.

4.1. Mechanical Properties

It is well-known that the pore structure strongly affects the mechanical properties of cement-based materials. Many studies have attempted to reveal the relationship between the fractal dimensions associated with the pore structure and the macroproperties of cement-based materials. Such findings are summarized in Table 2. Table 2 clearly shows that the mechanical properties of cement-based materials are closely related to the fractal dimensions of the pore structure, such as Ds and Dv.

Table 2.

Application of fractal theory on mechanical property of cement-based materials.

As for the Ds, it can be seen from Table 2 that the compressive strength of cement-based materials generally increase as the Ds increases; that is, there is a positive correlation between the Ds and the mechanical property. For example, Jin et al. [31] conducted tests on the strength and pore structure of thirteen cement mortar mixtures, and determined their Ds by a MIP and Zhang’s fractal model. Their results reveal that the relationship between the compressive strength of the mortars and the Ds presents a power function with the correlation coefficient, R2 of 0.7214, and the compressive strength increases with the increase in the Ds. Wang et al. [34] conducted a pore structural and fractal analysis on the influence of 20 wt.% fly ash and 5 wt.% silica fumes on the mechanical property of concrete. They calculated the Ds by using an MIP and Zhang’s fractal model and revealed the compressive strengths of concrete are positively correlated with the Ds, with a R2 value of 0.878. The mechanism beneath is that both the fly ash and silica powder can reduce the porosity of the concrete but can make the pore structure more complex at the same time, thereby increasing the Ds values. It is commonly accepted that the mechanical property of concrete is negatively corelated with the porosity [49,115]; hence, the concrete containing the fly ash and silica that exhibits the lowest porosity and the largest Ds value presents the best mechanical property among all the concretes analyzed in this study. This mechanism is demonstrated again in another study by Wang et al. [37], in which they studied the pore structure and the Ds of silica fume (SF) modified low-heat Portland cement-based materials. In this study, they reported that, with the increase in the SF dosage from 4 wt.% to 12 wt.%, the porosity of the concrete decreases, while the Ds increases since the presence of SF could fill up the pores while making the pore structure more complex. They also report that the compressive strength presents a positive correlation with the Ds, with a high R2 value of 0.924. Hence, they concluded that the effect of SF on the compressive strength of LHP cement concrete can be understood from the perspective of the Ds.

Nevertheless, there also exists a negative correlation between the mechanical property of cementitious material and the Ds. Kim et al. [88] found that the compressive strength of GGBFS-based cement pastes is negatively related to the Ds, which was determined by an MIP and Zhang’s fractal model, with a relatively weak R2 value of 0.493; however, this is only valid for the Ds of pores larger than 100 nm. In fact, among the five different pore size ranges in this study, namely, mesopores (6–10 nm, 10–25 nm, 25–50 nm), middle capillary pores (50–100 nm), and larger capillary pores (>100 nm), only the pores larger than 100 nm, and the mesopores in ranges of 6–10 nm and 10–25 nm, exhibited fractal characteristics. What is more, the Ds of the pores in the range of 6–10 nm and 10–25 nm did not show any correlation with the compressive strength at all. It is also interesting to note that the Ds of all of the ranges of pores in this study is 3.15, which is beyond the range of 2 ≤ Ds < 3 and, hence, the authors themselves considered this result not in accordance with the fundamental assumptions of fractal theory.

As for the Dv, there are also reverse conclusions on the relationships between the mechanical property of cementitious material, and Dv. Naderi et al. reported [33] a positive linear correlation, in which the compressive strength of lightweight self-compacting concrete increases with the increase in the Dv, as determined by an MIP and the Menger sponge model. They explained that, because of the continuous cement hydration, large pores in the concrete were divided into smaller ones, generating more small pores and making the pore structure more dispersed, which, in turn, increased the Dv value. At the same time, smaller porosity and a more condensed pore structure will strengthen the concrete. As a result, the relationship between the compressive strength and the Dv presents a positive linear function, with an acceptable R2 value of 0.8036. On the contrary, Li et al. [48] report that the compressive, flexural, and splitting tensile strengths of high-temperature-treated cement pastes (up to 900 °C) are negatively correlated with the Dv, which was also determined by an MIP and the Menger sponge model. The reason for this negative relation is that the high temperature (especially higher than 700 °C) could coarsen and complicate the pore structures of the cement paste, increasing the Dv values from about 2.2 to 3.0. However, the nano- and macromechanical properties of the cement paste degenerat significantly when the temperature exceeds 700 °C because of the decomposition of the hydration products. As a result, negative correlations between the mechanical strengths of the cement pastes and the Dv in this high-temperature case can be found.

In addition to the pore structure, which is supposed to be closely related to the mechanical properties of cement-based materials, many researchers confirm that the fracture surface texture is related to the mechanical behavior of cement-based materials [62,85]. Accordingly, the fractal dimension of the fracture surface (Dfs) has been verified to be relevant to the mechanical properties of cementitious material by some researchers [9,63]. For instance, Lu et al. [9] showed that the compressive strength of concrete declines linearly with the increase in the Dfs. They assessed the compressive strength and microstructure (the micromorphology and pore structure) of concrete, blended with 0–16% SF by weight of binder, and calculated the Dfs by the box-counting method based on SEM images. In their study, increasing the SF dosage from 0 to 16 wt.% improves the compressive strength by about 40%. Meanwhile, the increased SF dosage changes the concrete matrix from heterogeneous, rough, and porous to homogeneous, flat, and dense, respectively. Since the Dfs reflects the intrinsic surface irregularities [42], the homogenizing effect of SF depresses the irregularity of the fractured surfaces, thereby lowering the Dfs from about 2.8 to 2.5. As a result, the compressive strength presents a negative relationship with the Dfs. However, T. Ficker [63] points out that there is a positive exponential relationship between the compressive strength of cement pastes and the Dfs, which ranged from 2.07 to 2.18, as determined by the box-counting method and a confocal microscope.

Overall, it can be seen that there are no uniform relationships or functions between the mechanical properties of cement-based materials and the various fractal dimensions (Ds, Dv and Dfs), which can be explained by the following possible reasons: (1) The fractal dimensions in these studies are mainly determined by different fractal models and have different physical implications and, thus, they present different correlations with the mechanical properties of concrete. For instance, the addition of SF into concrete can reduce surface irregularities and the Dfs but elevate the complexity of the pore structure and increase the Ds at the same time, thus the complete reverse correlations of the Dfs and the Ds with compressive strength can be observed; (2) Any fractal dimension of the pore structure can only reflect some aspects of one single pore structure parameter, and the pore structure is not the only factor determining the mechanical properties of cement-based materials. After all, the mechanical properties can be affected by many other factors, such as the mixture proportions, compositions, curing time, temperature, etc. As a result, even the same fractal dimension as the Ds exhibits completely different, and even reverse, correlations with the compressive strength; (3) Similarly, although the facture can affect the mechanical properties of cement-based materials significantly, it is still not the only dominant parameter. Thus, the Dfs characterizing the facture features of cement-based materials does not exhibit a uniform relationship with the mechanical properties; (4) Another important factor that cannot be ignored, which is to say that the fractal study on cement-based materials is still in its initial stages, is that there may exist some deviations in the understanding of the physical meanings and the fractal model parameters of the same fractal dimension. Thus, contrary results may be achieved from various studies, even on the same fractal dimension. This phenomenon is more prominent in the fractal study on pore structures. In summary, the specific relationship between the mechanical properties and the fractal dimension of pores or fracture surfaces should be analyzed on a case-by-case basis.

4.2. Volume Stability

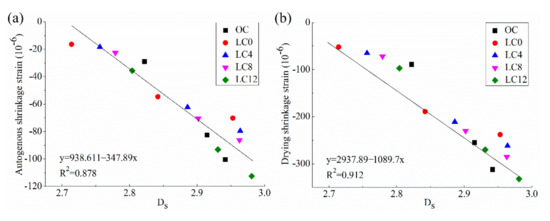

It is widely reported that the shrinkage behavior of concrete is governed by the pore structure [37,116,117,118,119]. Autogenous shrinkage and drying shrinkage are the two main types of concrete volume deformation [37,115,120]. To evaluate the shrinkage behavior of cement-based materials in terms of fractal geometry, the relationships between shrinkage (including the autogenous shrinkage and drying shrinkage) and the Ds of concrete are revealed.

In a study by Wang et al. [37], the pore structure and fractal characteristics of reference concrete (C0), and concrete containing 0 wt.% silica fume (designated as LC0), 4 wt.% silica fume (LC4), 8 wt.% silica fume (LC8) and 12 wt.% silica fume (LC12) were studied. The Ds values were calculated using MIP results and Zhang’s fractal model. They found that the autogenous shrinkage and drying shrinkage, as well as the Ds values of the concrete, increased with the SF dosage. They also report that both the autogenous shrinkage and the drying shrinkage exhibit a positively linear relationship with the Ds, and the R2 are 0.878 and 0.912, respectively, as shown in Figure 8. On this basis, they concluded that the Ds can serve as a new pore structure parameter for evaluating concrete shrinkage behavior. Their conclusion is supported by the following points: (1) It is well-known that the drying shrinkage is caused by the capillary tension arising from the evaporation of water from the capillary pores in concrete in a drying environment, while the autogenous shrinkage is attributed to the capillary tension brought about by the self-desiccation in the pores resulting from the cement hydration [37,116,117]. Many researchers [121,122] further report that the pores with sizes less than 50 nm critically affected both the drying shrinkage and the autogenous shrinkage, since the capillary tension increased rapidly within the pores in this range; (2) The presence of SF could raise the proportions of pores with sizes less than 50 nm significantly and, consequently, the autogenous shrinkage and drying shrinkage of the concrete would increase with the SF dosage; (3) Meanwhile, as the factions of the gel pores (<10 nm) and the medium capillary pores (10–50 nm) increase, the pore structures become more complex and exhibit large pore surface areas, leading to higher Ds values. Thus, the shrinkage exhibits a positive relationship with the Ds values. It is worth noting that this is the first time the parameter fractal dimension has been linked with the shrinkage behavior of cement-based materials.

Figure 8.

Relationship between shrinkage behavior and the Ds of concrete: (a) Autogenous shrinkage strain; (b) Drying shrinkage strain [37].

4.3. Durability

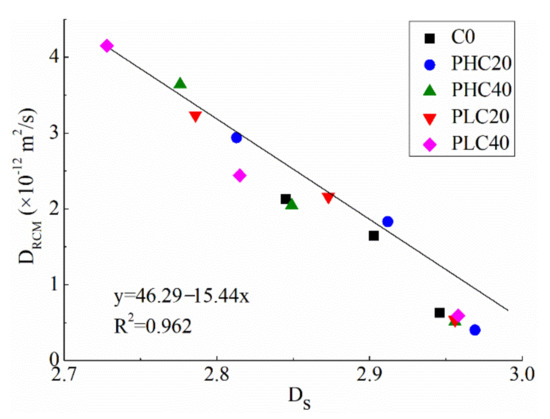

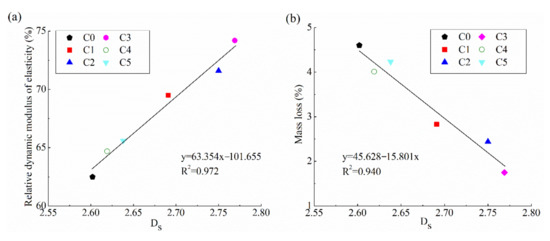

4.3.1. Transport Properties

Mass transport properties (e.g., water/ion/gas diffusion), which are of great significance to the durability of cement-based materials, are believed to be significantly affected by the pore parameters (porosity, tortuosity, pore size, etc.) [32,49,123,124,125,126]. For instance, it has been demonstrated that a higher porosity and a larger pore size facilitated the generation of channels for water/ion/gas penetration and transportation [49,123,124]. Moreover, increasing the tortuosity of the transport path would lower the pore channels, thus inhibiting the corrosion of the materials caused by water/ion/gas diffusion [127,128]. Obviously, improved impermeability is beneficial for the improvement of the durability of cement-based materials. This is true for frost resistance, chloride- and sulfate-penetration resistance, anti-carbonation resistance, and so on. Through experimental and theoretical verifications, many researchers [9,33,50,56,123,129] report that the transport properties of cement-based materials are related to the fractal dimensions of the pore structure, such as the Dt, the Ds , and the Dv. The application of fractal theory on the transport properties of cement-based materials in recent years is summarized in Table 3.

Table 3.

Application of fractal theory on transport properties of cement-based materials.

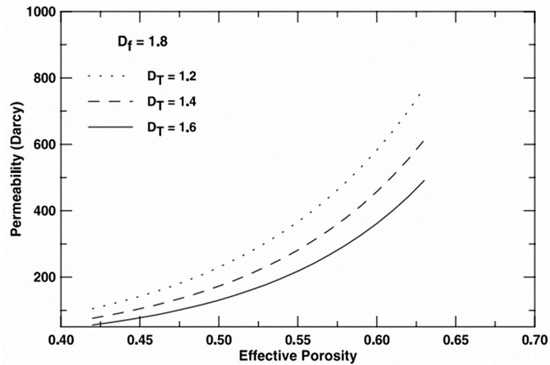

Regarding the relationship between the Dt and transport properties, Yu and Cheng [50] propose a fractal permeability model for bi-dispersed porous media based on the box-counting method. Using Darcy’s law, they obtained a formula to calculate the permeability (K) of a porous medium, as shown in Equation (59):

where is the hydraulic pressure gradient; is the viscosity of the fluid; A and were the cross-section area and representative length of the materials, respectively; Q is the total flow rate; Df is the fractal dimension of the pore space, as described in Section 3.1.3.3; the Dt is the fractal dimension of the pore tortuosity; and is the maximum pore radius.

Their study showed that the permeability (K) decreases with the increase in the Dt, as can be seen in Figure 9. This is because when the Dt increases, the flow pathways are more tortuous, resulting in a better resistance to the fluid flow and a lowered permeability value.

Figure 9.

Effects of on permeability of porous materials [50].

Later, they proposed a modified equation to calculate the permeability (K) of cement-based materials based on Equation (59), as exhibited in Equation (60) [129]:

where ∅; is the porosity.