Confinement of Masonry Columns with the FRCM-System: Theoretical and Experimental Investigation †

Abstract

1. Introduction

2. Experimental Work

2.1. Specimen Details

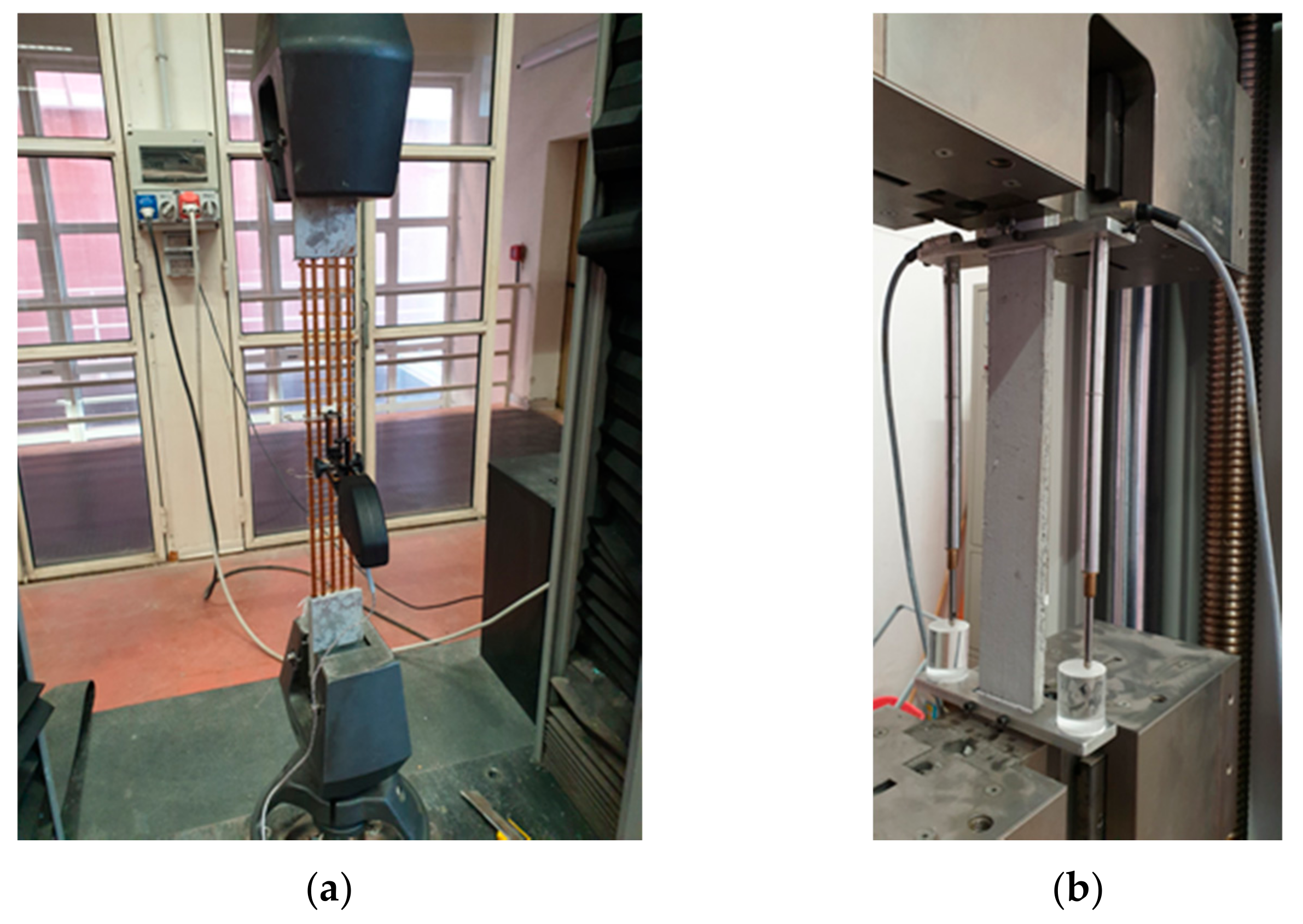

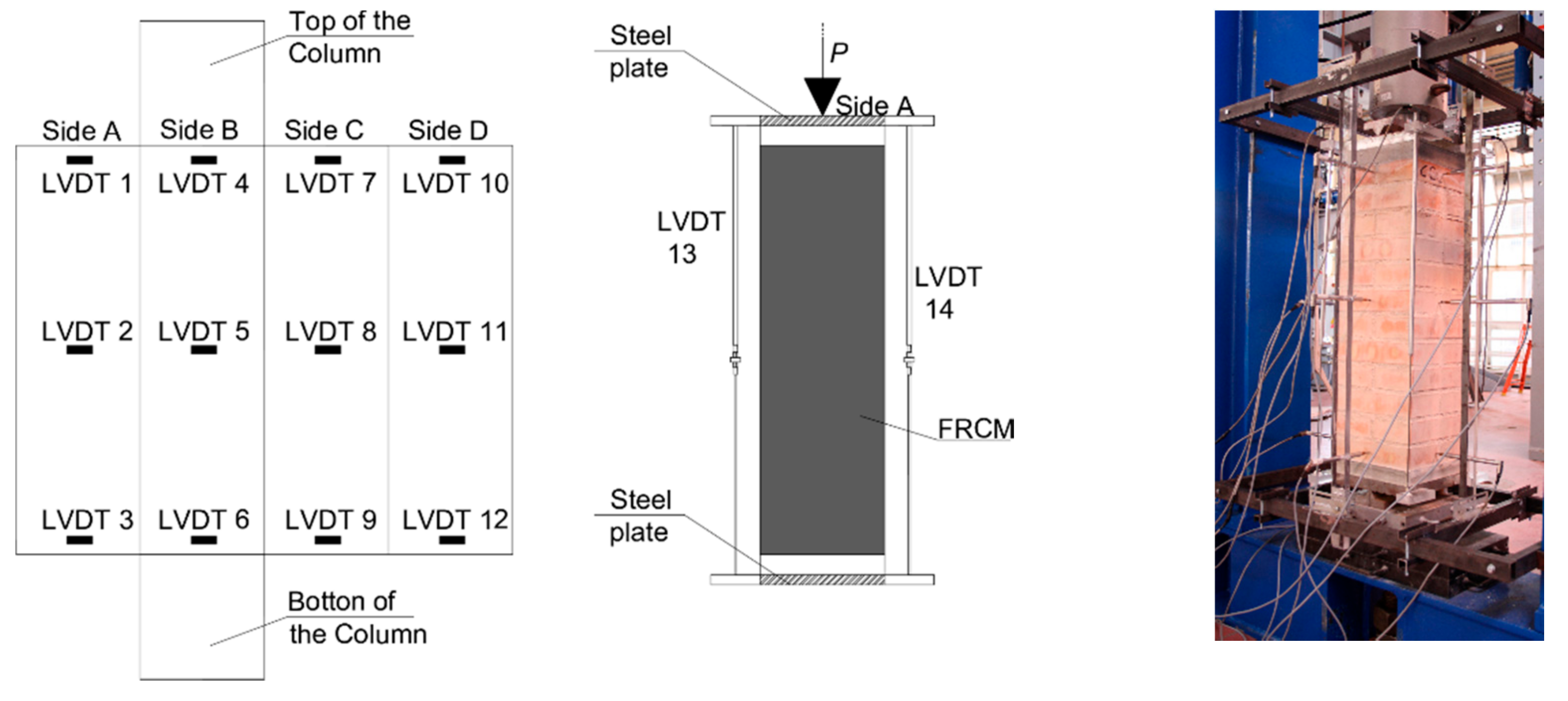

2.2. Strengthening System, Specimen Preparation, and Test Setup

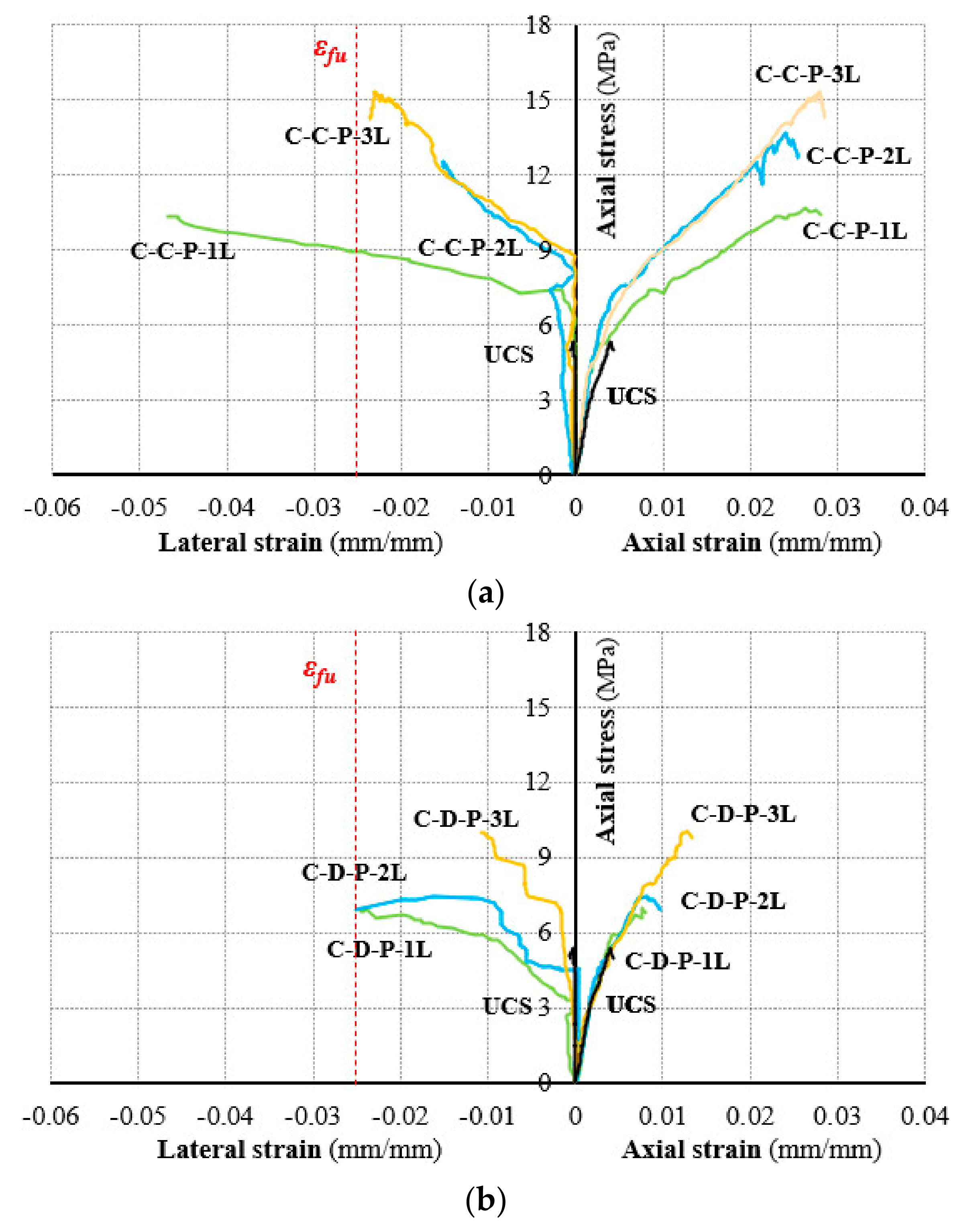

2.3. Experimental Results and Discussion

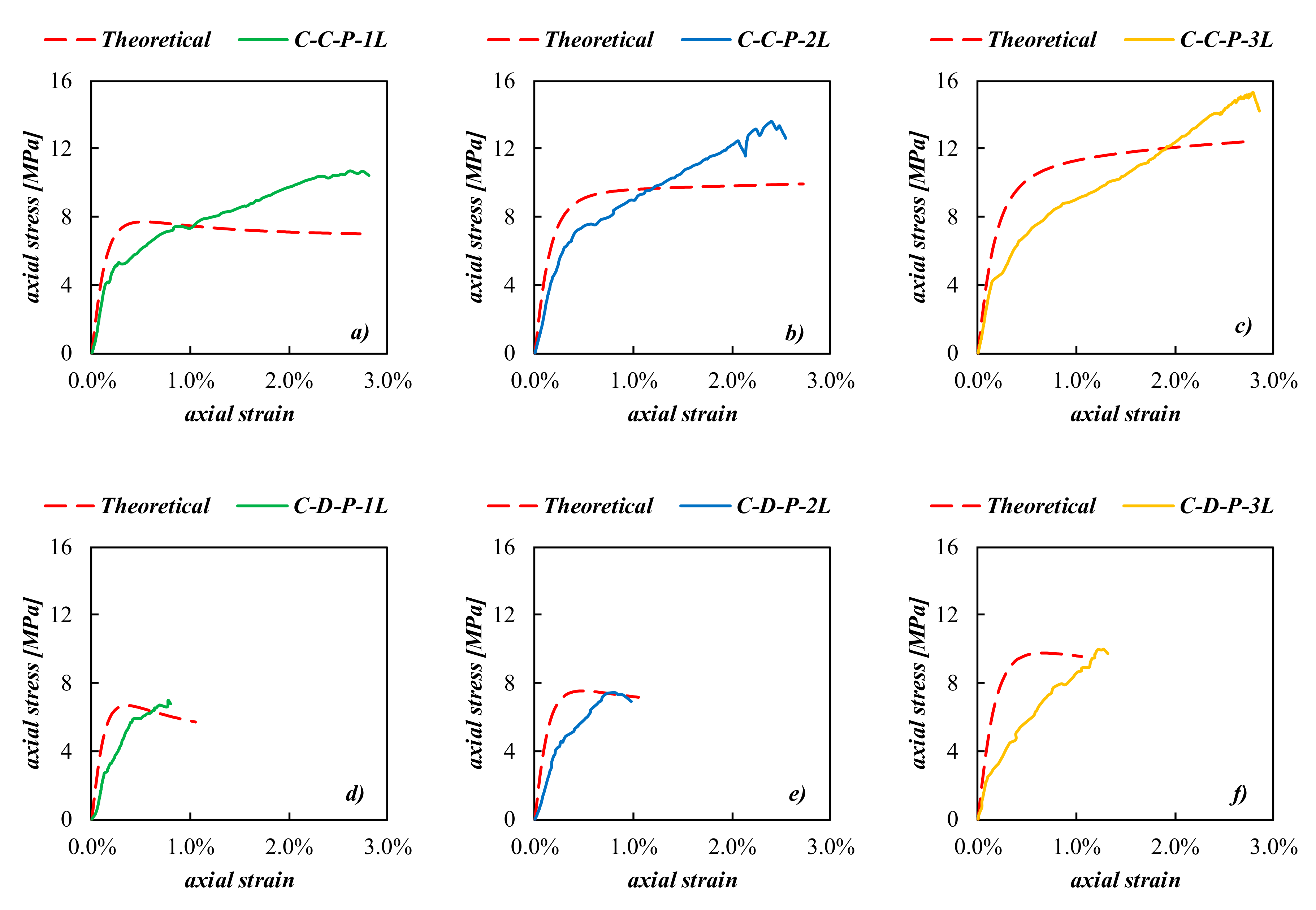

Axial Stress–Strain Law

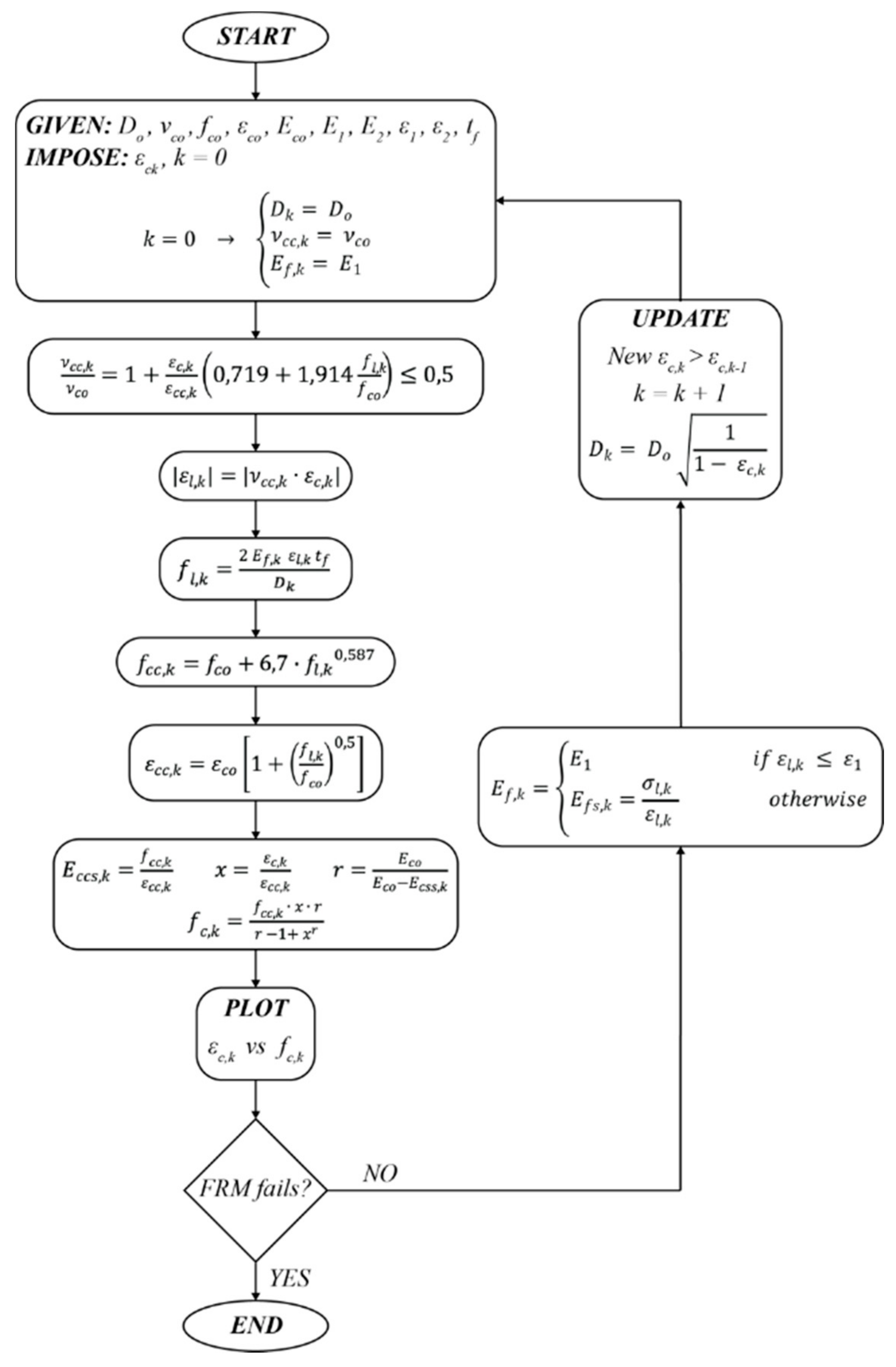

3. Theoretical Prediction

- b is the width of the column cross-section (mm);

- D is the diagonal of the column cross-section (mm);

- Ef is the Young modulus of the fabric (MPa);

- fc,mat is the compressive strength of the FRCM-matrix (MPa);

- fm is the compressive strength of the un-confined column (MPa);

- gm is the mass density of the masonry (kg/m3);

- h is the height of the column cross-section (mm);

- ρf is the spacing in between two consecutive strips (mm); and

- εf is the ultimate tensile strain of the fabric (-).

4. Conclusions

- FRCM confinement systems improved the axial strength of the columns with respect to the un-confined ones in all cases;

- the confinement effectiveness increased with the number of FRCM-layers; in particular, passing from one to three layers, the axial strength gained about 50% and 43% for the continuous and discontinuous configuration, respectively. Moreover, the correlation between the number of layers and the compressive strength was linear for the case of the continuous-confined column (in fact 2-layer confinement resulted in 23% compressive strength gain) while the 2-layer partial confinement showed a 6% efficiency with respect to the single layer;

- partial-wrapping resulted in being less effective with respect to full-wrapping even if the load bearing capacity of the masonry core was improved;

- the theoretical prediction of the axial strength by means of available models was performed and the outcomes were found to be satisfactory enough for both continuous and discontinuous configurations (theoretical versus experimental scatter almost lesser than 25%);

- the theoretical prediction of the axial stress–strain behavior by means of available AOM was also performed and the curve matching were affected by a larger scatter, mostly in the post-peak branch; this result was due to the fact that a softening behavior was assumed by the model while a hardening result was found by the tests. For this reason, further experimental investigations are needed in order to better understand this aspect and perform possible improvements of the available AOM model.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Aiello, M.A.; Cascardi, A.; Ombres, L.; Verre, S. Open issue for confinement of masonry columns with FRCM-system: Theoretical and experimental investigation. In Proceedings of the 8th Euro-American Congress Construction Pathology, Rehabilitation Technology and Heritage Management, Rehabend 2020-CODE 158, Granada, Spain, 28 September 2020. [Google Scholar]

- Cascardi, A.; Dell’Anna, R.; Micelli, F.; Lionetto, F.; Aiello, M.A.; Maffezzoli, A. Reversible techniques for FRP-confinement of masonry columns. Constr. Build. Mater. 2019, 225, 415–428. [Google Scholar] [CrossRef]

- Bakis, C.E.; Bank, L.C.; Brown, V.L.; Cosenza, E.; Davalos, J.F.; Lesko, J.J.; Machida, A.; Rizkalla, S.H.; Triantafillou, T.C. Fiber-Reinforced polymer composites for construction—state-of-the-art review. J. Compos. Constr. 2002, 6, 73–87. [Google Scholar] [CrossRef]

- Micelli, F.; Di Ludovico, M.; Balsamo, A.; Manfredi, G. Mechanical behaviour of FRP-confined masonry by testing of full-scale columns. Mater. Struct. 2014, 47, 2081–2100. [Google Scholar] [CrossRef]

- Cascardi, A.; Micelli, F.; Aiello, M.A. FRCM-confined masonry columns: Experimental investigation on the effect of the inorganic matrix properties. Constr. Build. Mater. 2018, 186, 811–825. [Google Scholar] [CrossRef]

- Maddaloni, G.; Cascardi, A.; Balsamo, A.; Di Ludovico, M.; Micelli, F.; Aiello, M.A.; Prota, A. Confinement of full-scale masonry columns with FRCM systems. Key Eng. Mater. 2017, 747, 374–381. [Google Scholar] [CrossRef]

- Di Ludovico, M.; Cascardi, A.; Balsamo, A.; Aiello, M.A. Uniaxial experimental tests on full-scale limestone masonry columns confined with glass and basalt FRCM systems. J. Compos. Constr. 2020, 24, 04020050. [Google Scholar] [CrossRef]

- Ombres, L.; Iorfida, A.; Mazzuca, S.; Verre, S. Bond analysis of thermally conditioned FRCM-masonry joints. Measurement 2018, 125, 509–515. [Google Scholar] [CrossRef]

- Micelli, F.; Maddaloni, G.; Longo, F.; Prota, A. Axial stress–strain model for frcm confinement of masonry columns. J. Compos. Constr. 2021, 25, 04020078. [Google Scholar] [CrossRef]

- Bilotta, A.; Ceroni, F.; Nigro, E.; Pecce, M. Experimental tests on FRCM strengthening systems for tuff masonry elements. Constr. Build. Mater. 2017, 138, 114–133. [Google Scholar] [CrossRef]

- Borri, A.; Castori, G.; Corradi, M. Masonry Columns Confined by Steel Fiber Composite Wraps. Materials 2011, 4, 311–326. [Google Scholar] [CrossRef]

- Ombres, L.; Verre, S. Flexural Strengthening of RC Beams with Steel-Reinforced Grout: Experimental and Numerical Investigation. J. Compos. Constr. 2019, 23, 04019035. [Google Scholar] [CrossRef]

- Ombres, L.; Verre, S. Analysis of the Behavior of FRCM Confined Clay Brick Masonry Columns. Fibers 2020, 8, 11. [Google Scholar] [CrossRef]

- Fossetti, M.; Minafò, G. Comparative experimental analysis on the compressive behaviour of masonry columns strengthened by FRP, BFRCM or steel wires. Compos. Part B: Eng. 2017, 112, 112–124. [Google Scholar] [CrossRef]

- Minafò, G.; La Mendola, L. Experimental investigation on the effect of mortar grade on the compressive behaviour of FRCM confined masonry columns. Compos. Part B: Eng. 2018, 146, 1–12. [Google Scholar] [CrossRef]

- Mezrea, P.E.; Yilmaz, I.A.; Ispir, M.; Binbir, E.; Bal, I.E.; Ilki, A. External Jacketing of Unreinforced Historical Masonry Piers with Open-Grid Basalt-Reinforced Mortar. J. Compos. Constr. 2017, 21, 04016110. [Google Scholar] [CrossRef]

- Verre, S.; Cascardi, A.; Aiello, M.A.; Ombres, L. Numerical Modelling of FRCMs Confined Masonry Column. Key Eng. Mater. 2019, 817, 9–14. [Google Scholar] [CrossRef]

- D’Antino, T.; Pellegrino, C.; Carloni, C.; Sneed, L.H.; Giacomin, G. Experimental analysis of the bond behaviour of glass, carbon and steel FRCM composite. Key Eng. Mater. 2015, 64, 371–378. [Google Scholar]

- Santandrea, M.; Quartarone, G.; Carloni, C.; Gu, X.L. Confinement of Masonry Columns with Steel and Basalt FRCM Composites. Key Eng. Mater. 2017, 747, 342–349. [Google Scholar] [CrossRef]

- Ombres, L.; Verre, S. Numerical Modeling Approaches of FRCMs/SRG Confined Masonry Columns. Front. Built Environ. 2019, 5, 5. [Google Scholar] [CrossRef]

- Ombres, L. Confinement Effectiveness in Eccentrically Loaded Masonry Columns Strengthened by Fiber Reinforced Cementitious Matrix (FRCM) Jackets. Key Eng. Mater. 2014, 624, 551–558. [Google Scholar] [CrossRef]

- Kreivakais, T. Experimental study on carbon fiber textile reinforced mortar system as a means for confinement of masonry columns. Constr. Build. Mater. 2019, 208, 723–733. [Google Scholar] [CrossRef]

- Ombres, L.; Verre, S. Masonry columns strengthened with Steel Fabric Reinforced Cementitious Matrix (S-FRCM) jackets: Experimental and numerical analysis. Measurement 2018, 127, 238–245. [Google Scholar] [CrossRef]

- Carloni, C.; Mazzotti, C.; Savoia, M.; Subramaniam, K.V. Confinement of Masonry Columns with PBO FRCM Composites. Key Eng. Mater. 2014, 624, 644–651. [Google Scholar] [CrossRef]

- Sneed, L.H.; Carloni, C.; Baietti, G.; Fraioli, G. Confinement of Clay Masonry Columns with SRG. Key Eng. Mater. 2017, 747, 350–357. [Google Scholar] [CrossRef]

- Ombres, L.; Iorfida, A.; Verre, S. Confinement of Masonry Columns with PBO and Basalt FRCM Composites. Key Eng. Mater. 2019, 817, 392–397. [Google Scholar] [CrossRef]

- Cascardi, A.; Longo, F.; Micelli, F.; Aiello, M.A. Compressive strength of confined column with Fiber Reinforced Mortar (FRM): New design-oriented-models. Constr. Build. Mater. 2017, 156, 387–401. [Google Scholar] [CrossRef]

- Cascardi, A.; Aiello, M.A.; Triantafillou, T. Analysis-oriented model for concrete and masonry confined with fiber reinforced mortar. Mater. Struct. 2017, 50, 202. [Google Scholar] [CrossRef]

- Balsamo, A.; Cascardi, A.; Di Ludovico, M.; Aiello, M.A.; Morandini, G. Analytical study on the effectiveness of the FRCM-confinement of masonry columns. In Proceedings of the Construction Pathology, Rehabilitation Technology and Heritage Management 2017, Cáceres, Spain, 15–18 May 2018. [Google Scholar]

- CNR-DT215. Istruzioni per la Progettazione, l’Esecuzione ed il Controllo di Interventi di Consolidamento Statico mediante l’utilizzo di Compositi Fibrorinforzati a Matrice Inorganica; CNR: Roma, Italy, 2018. [Google Scholar]

- Newredil s.r.l. Available online: www.ruredil.it (accessed on 30 September 2019).

- Consiglio Superiore dei Lavori Pubblici. Linea Guida per la Identificazione, la Qualificazione ed il Controllo di Accettazione di Compositi Fibrorinforzati a Matrice Inorganica (FRCM) da Utilizzarsi per il Consolidamento Strutturale di Costruzioni Esistenti; Consiglio Superiore dei Lavori Pubblici: Roma, Italy, 2018. [Google Scholar]

- UNI EN 12190:2000. Product and System for the Protection and Repair Concrete Structures–Test Methods –Determination of Compressive Strength of Repair Mortar; UNI EN: Roma, Italy, 1998. [Google Scholar]

- EN 1015-11. Methods of Test for Mortar for Masonry Part 11: Determination of Flexural and Compressive Strength of Hardened Mortar; CEN: Brussels, Belgium, 2006. [Google Scholar]

- DT200, C.N.R. Guide for the Design and Construction of an Externally Bonded FRP System for Strengthening Existing Structures; Italian National Research Council: Rome, Italy, 2004. [Google Scholar]

| Label | tmat (mm) | n (-) | Confinement Scheme | wf/sf |

|---|---|---|---|---|

| UCS | - | - | - | - |

| C-C-P-1L | 6 | 1 | Continuous | 1 |

| C-C-P-2L | 9 | 2 | Continuous | 1 |

| C-C-P-3L | 12 | 3 | Continuous | 1 |

| C-D-P-1L | 6 | 1 | Discontinuous | 0.5 |

| C-D-P-2L | 9 | 2 | Discontinuous | 0.5 |

| C-D-P-3L | 12 | 3 | Discontinuous | 0.5 |

| Label | Eel (MPa) | σp (MPa) | εp (mm/mm) | εlu (mm/mm) | ξ (-) | µ (-) | β = εlu/εfu (-) |

|---|---|---|---|---|---|---|---|

| UCS | 1510 | 5.19 | 0.0025 | 0.003 | - | 0.84 | - |

| C-C-P-1L | 3181 | 10.59 | 0.0026 | 0.047 | 2.04 | 3.38 | 1.88 |

| C-C-P-2L | 2608 | 13.60 | 0.0259 | 0.015 | 2.62 | 3.32 | 0.60 |

| C-C-P-3L | 3184 | 15.23 | 0.0279 | 0.023 | 2.93 | 3.65 | 0.92 |

| C-D-P-1L | 2321 | 6.97 | 0.0077 | 0.024 | 1.34 | 1.56 | 0.96 |

| C-D-P-2L | 1909 | 7.41 | 0.0081 | 0.025 | 1.42 | 1.70 | 1.00 |

| C-D-P-3L | 1443 | 10.02 | 0.0128 | 0.011 | 1.93 | 2.10 | 0.44 |

| Equation | Variable | Description | [27]-Cascardi et al. (2017) | [30]-CNR DT 215 (2018) |

|---|---|---|---|---|

| (1) | kH | Horizontal geometrical efficiency coefficient | ||

| (2) | kV | Vertical geometrical efficiency coefficient | ||

| (3) | ρmat | Geometrical percentage of FRCM-matrix | ||

| (4) | kmat | FRCM-matrix efficiency coefficient | ||

| (5) | fl | Confining pressure | ||

| (6) | fl,eff | Effective confining pressure | ||

| (7) | k’ | Masonry typology efficiency coefficient | - | |

| (8) | fcm | Compressive strength of the FRCM-confined column | ||

| Analytical Model | Label | fcm,exp (MPa) | fcm,theo (MPa) | Mean ± Co.V | Median | MAPE (%) | R2 | |

|---|---|---|---|---|---|---|---|---|

| Cascardi et al. (2017) [27] | C-C-P-1L | 10.65 | 10.78 | 0.99 | 0.81 ± 22% | 0.81 | 27.8 | 0.96 |

| C-C-P-2L | 13.60 | 16.88 | 0.81 | |||||

| C-C-P-3L | 15.31 | 24.17 | 0.63 | |||||

| C-D-P-1L | 6.97 | 8.94 | 0.78 | 0.75 ± 4% | 0.73 | 34.1 | 1.00 | |

| C-D-P-2L | 9.41 | 12.96 | 0.73 | |||||

| C-D-P-3L | 13.02 | 17.77 | 0.73 | |||||

| CNR DT 215 (2018) [30] | C-C-P-1L | 10.65 | 7.67 | 1.39 | 1.29 ± 10% | 1.33 | 21.7 | 0.96 |

| C-C-P-2L | 13.60 | 10.26 | 1.33 | |||||

| C-C-P-3L | 15.31 | 11.85 | 1.15 | |||||

| C-D-P-1L | 6.97 | 6.88 | 1.01 | 1.11 ± 10% | 1.10 | 9.4 | 1.00 | |

| C-D-P-2L | 9.41 | 8.59 | 1.10 | |||||

| C-D-P-3L | 13.02 | 9.64 | 1.22 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aiello, M.A.; Cascardi, A.; Ombres, L.; Verre, S. Confinement of Masonry Columns with the FRCM-System: Theoretical and Experimental Investigation. Infrastructures 2020, 5, 101. https://doi.org/10.3390/infrastructures5110101

Aiello MA, Cascardi A, Ombres L, Verre S. Confinement of Masonry Columns with the FRCM-System: Theoretical and Experimental Investigation. Infrastructures. 2020; 5(11):101. https://doi.org/10.3390/infrastructures5110101

Chicago/Turabian StyleAiello, Maria Antonietta, Alessio Cascardi, Luciano Ombres, and Salvatore Verre. 2020. "Confinement of Masonry Columns with the FRCM-System: Theoretical and Experimental Investigation" Infrastructures 5, no. 11: 101. https://doi.org/10.3390/infrastructures5110101

APA StyleAiello, M. A., Cascardi, A., Ombres, L., & Verre, S. (2020). Confinement of Masonry Columns with the FRCM-System: Theoretical and Experimental Investigation. Infrastructures, 5(11), 101. https://doi.org/10.3390/infrastructures5110101