Abstract

Crumb rubber (CR) obtained from end-of-life tyres (ELT) has gained significant attention in the sustainable design of asphalt pavements in recent years, showing a promising perspective in the enhancement of pavement performance related to its structural and functional properties. Existing research on CR influence on pavement performance mostly focused on peculiarities of asphalt mixture modification procedures—dry and wet processes, CR content in the mixture and CR particle size. In this study, a laboratory-based experimental investigation of CR effect on two different mixture gradations, namely dense-graded and gap-graded mixtures with three different binder contents, was performed. CR was added in mixtures through binder modification, with a constant CR content of 18% by binder weight in all mixtures. Volumetric properties—maximum mixture density, bulk density and void characteristics, alongside mechanical properties determined by the Marshall test method—were determined on unmodified and modified mixtures. The goal was to evaluate the influence of CR modification with respect to three different binder contents. The results showed that gap-graded mixtures are more sensitive to change in CR modified binder content in comparison to dense-graded mixtures in terms of air voids content. Furthermore, the mechanical properties of CR-modified mixtures were slightly enhanced in gap-graded mixtures, showing a promising potential of CR modification for pavement performance. However, the choice of optimal binder content in CR-modified mixtures was shown to be a critical mixture design parameter due to the increased sensitivity of binder content change to the analysed voids properties and permanent deformations.

1. Introduction

Asphalt pavements play a critical role in modern infrastructure, providing durable surfaces for roadways, airports and other transportation networks. However, traditional asphalt mixtures face challenges related to durability, environmental impact and maintenance costs. Research on the possibility of using recycled materials in different asphalt pavement layers has been intensified in the last decades in order to find a sustainable solution for pavement construction and rehabilitation. One of the materials that is used in asphalt mixtures and pavement base courses is crumb rubber (CR) obtained from vehicle tyres, called end-of-life tyres (ELTs). The incorporation of crumb rubber from waste tyres into asphalt has gained significant attention in both research and practice. Crumb rubber-modified asphalt mixtures (CRMA) improve the performance of asphalt pavements, offering enhanced resistance to rutting, fatigue cracking, temperature-induced deformation, increased stiffness and durability, making it a superior alternative to conventional asphalt mixtures. Furthermore, functional properties such as noise emission [1,2] and skid resistance are also found to be improved by CR modification of asphalt pavement wearing courses, though there is a lack of comprehensive studies on the skid resistance of CR-modified gap-graded mixtures [3]. The influence of CR on asphalt mix properties is determined by the method of CRMA production. Crumb rubber modification of asphalt mixtures is achieved through two main processes: the dry process and the wet process. Alternatively, two additional processes, the terminal blend process and asphalt rubber modifier pellets, are exploited for the production of rubberised asphalt binders. The choice of the type of production of CRMA depends on the desired characteristics of the mixtures and applicability of the production process (Table 1).

Table 1.

Types of crumb rubber-modified asphalt mixture production.

In general, CR particles can be classified into four groups based on CR particle size: coarse (6.3 mm–9.5 mm), medium (0.6 mm–2 mm), fine (0.18 mm–0.425 mm) and superfine (0.075–0.15 mm) [4]. The choice of CR particle size depends on the selected CRMA production method. In the dry process, CR particles are used as a partial replacement for either coarse or fine aggregates, while in the wet process, CR particles serve as a modifier for the asphalt binder. The recommended CR particle size is up to 2 mm, resulting in improved mixture’s overall performance, while larger CR particles have been shown to degrade the mixture’s stiffness [5]. However, larger CR particles improved CRMA mixture resistance to deformation in gap-graded mixtures [5,6]. In general, the addition of CR particle sizes up to 2 mm has been shown to be beneficial for air void content as these particles fill up the voids, especially in gap-graded mixtures [5]. The amount of CR particles in rubberised HMA mixtures varies with respect to the CRMA production method. Previous studies evaluated the optimal CR content in dry process CRMA mixtures, varying from 1 to 3% by total mixture weight [5,6,7]. In the wet process, the range of CR content for binder modification is 5–25% by binder weight [7], with 20% being the most common upper threshold value in most research [8].

Comparing the dry and wet processes, the wet process resulted in a superior dense-graded CRMA with improved low-temperature and fatigue properties [9]. Also, from several other literature reviews in this field [1,6,10], it could be concluded that more positive effects are brought by the wet process, so this paper will focus on rubberised asphalt production by the wet process. Dense-graded CRMA prepared by the wet process requires increased optimal binder content but results in increased indirect tensile strength [11], Marshall stability and stiffness [4]. Furthermore, CR improves the moisture [12], temperature [4] and freeze–thaw resistance [13] of dense-graded CRMA. As for the gap-graded mixtures, CRMA achieved a higher optimum binder content and volume of air voids regarding the reference mixture, with superior fatigue resistance [14]. Similar to asphalt concrete (AC) mixtures, for stone mastic asphalt (SMA) mixtures modified by CR, the Marshall stability, Marshall flow and stiffness increased with the increase in CR content, while the AC mixtures performed much better than the SMA mixtures [4]. Finally, according to the review presented in [1], dense-graded CRMA usually improved stiffness, rutting, fatigue and thermal cracking resistance compared to virgin binder AC; gap-graded CRMA may increase stiffness, fatigue and moisture resistance; and rutting and thermal cracking resistance usually remained unchanged compared to other polymer-modified binder mixtures. The volumetric properties of AC mixtures modified by CR powder are investigated in [15], pointing out the reduction in bulk density and voids filled with a binder, while voids in mineral aggregates and voids in AC mixture (Va) increased. An increase in air voids in CRMA has a detrimental effect on the rutting resistance, as pointed out in [16].

As a potentially limiting feature of CRMA, a higher production cost is highlighted, ranging from 20 to 30% in comparison to the direct costs of conventional mixtures [1]. The increased cost is mostly due to higher energy consumption and necessary asphalt plant modifications when CR is introduced in the mixture [17]. However, CRMA has a lower annual cost [17] due to a better response to plastic deformation [18], and it can be successfully recycled [19,20].

Previous research showed that in the CRMA production process, CR content in the mixture and particle size significantly affect HMA properties. Furthermore, CR presence influences differently dense-graded and gap-graded mixtures’ properties, again depending on CR content and particle size. In a review article by [8], the most common investigated parameters in CRMA mixtures analysis are rubber content, maximum CR size, binder type, mixing time and temperature and shear mix. The investigation of CRMA produced by the wet process indicates that a higher optimum binder content is required regardless of the mixture type. However, there is a lack of information on CR influence on CRMA properties depending on different binder contents in the mixture. Also, comparative research on the influence of CR modification on AC and SMA mixtures is limited, particularly by using the same materials (i.e., CR and binder). Research gaps also exist in defining CR influence on volumetric properties since most of the existing research deals with other mechanical characteristics (i.e., stability, high and low temperature resistance, rutting resistance…). Therefore, this study aims to investigate the performance of HMA mixtures with different binder contents when modified with CR by the wet process. For this purpose, two HMA mixtures, one dense-graded and one gap-graded, were produced and modified with equal CR content and particle size, varying three different binder contents. Mixtures were evaluated by selected volumetric and mechanical properties to investigate the effect of different binder contents on unmodified and CR-modified mixtures’ performance.

2. Materials and Methods

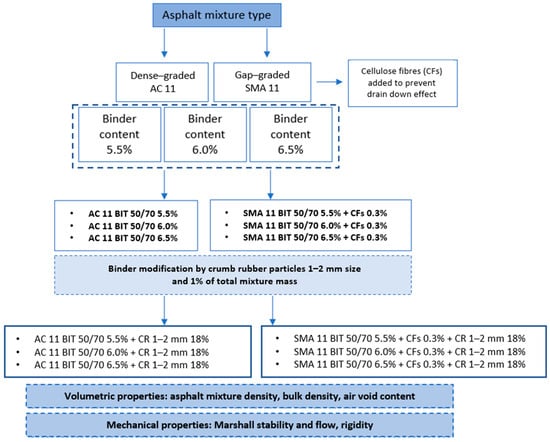

This research focused on the investigation of CR influence on volumetric and mechanical properties of HMA mixtures with different binder contents. Mixtures were modified by CR particles blended in the binder in equal amounts in all mixtures. The research methodology, with specifications of selected mixtures and performed laboratory tests, is given in Figure 1. The following sections provide a thorough description of the materials used and research activities performed.

Figure 1.

A schematic overview of defined research methodology.

2.1. Materials

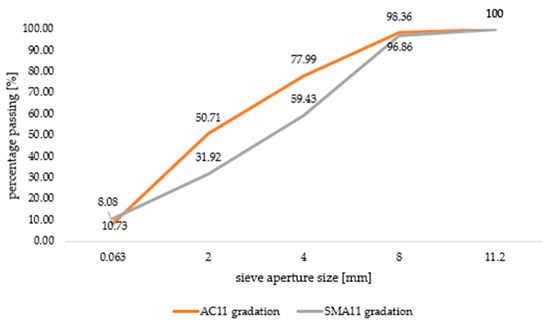

In this study, two typical wearing course HMA mixture types were selected for the laboratory investigation of the selected properties and the investigation of crumb rubber effect on volumetric and mechanical properties: a dense-graded asphalt concrete mixture, AC 11, and gap-graded stone mastic asphalt mixture, SMA 11. Both mixtures were designed with equal natural mineral material of eruptive origin, with a nominal maximum aggregate size of 11.2 mm. All aggregate fractions used in the mixture were extracted from the same local quarry with a density of 2.73 Mg/m3. Prior to the mixture preparation, mineral material was washed and dried, and afterwards sieved into selected fractions with respect to EN 933-1 standard [21]. The aggregate gradation of both mixtures selected in this research is given in Figure 2. The same mineral material was used as a filler (aggregate particle size < 0.063 mm), having a density of 2.73 Mg/m3.

Figure 2.

Aggregate grain size distribution.

The selected binder type was bitumen with penetration grade 50/70, recognised as the most common for the modification with crumb rubber [1], with a density of 1.018 Mg/m3. The specific properties of the selected binder type are given by the manufacturer and presented in Table 2.

Table 2.

Declared properties of used binder type BIT 50/70.

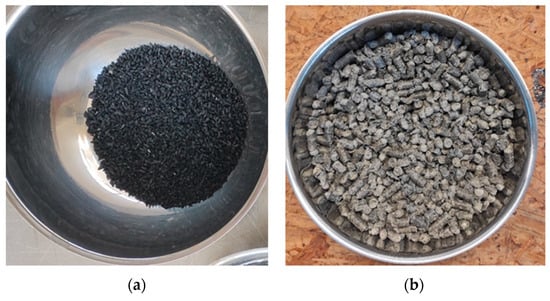

Modified mixtures were prepared by adding CR into the heated binder to create rubber-modified bitumen. For this purpose, waste rubber originating from the processing of collected tyres of mixed origins (car, truck, buses and agricultural and construction machinery) was used. Generally, all tyres are made of four basic materials: 40–45% of rubber (natural and synthetic), 23–27% of fillers (carbon black, silica, chalk, or carbon), 11–13% reinforcing materials (metals and textiles) and facilitators (plasticisers, vulcanising agents—sulphur and zinc oxide and additives), and the final composition is dependent on tyre purpose (passenger car, truck…) [22,23]. CR was obtained by ambient mechanical processing of collected tyres, i.e., gradual grinding, which was preceded by the individual separation of the steel and textile. The density of CR was 1.123 Mg/m3, determined by the EN 1097-6:2013 [24] standard using ethanol. The specific surface area, determined using a Brunauer, Emmett and Teller (BET) machine according to the ISO 9277:2010 standard [25], was 7.77 m2/g. CR fraction 1–2 mm was used for binder modification, corresponding to the recommendations for maximum crumb rubber size in the binder modification procedure (Figure 3a) [6,14]. This fraction was selected after the initially obtained raw CR material was sieved, using sieves with aperture sizes of 1 mm and 2 mm. The fraction smaller than 1 mm was rejected as it contained a significant amount of impurities in the form of dust and fibres. Furthermore, particles larger than 2 mm were also rejected, being larger than the recommended crumb rubber size in the wet procedure. In SMA mixtures, cellulose pellets with a density of 1.5 Mg/m3 were added in 0,3% of the total mixture mass to prevent the binder drain down effect (Figure 3b). A total of 12 HMA mixtures were designed and investigated in this research, with the mixture composition presented in Table 3.

Figure 3.

CR particles 1–2 mm (a) and cellulose pellets (b) used for binder modification.

Table 3.

CRMA mixture composition.

2.2. Specimen Preparation

HMA mixture preparation was performed in laboratory conditions by following the EN 12697-35 standard [26] for laboratory mixing. Aggregate gradation was held constant in all mixtures, as shown in Figure 1, while binder content was varied. Three different binder contents were explored: 5.5%, 6.0% and 6.5% by total mixture mass for both mixture types. These binder contents were selected based on common practice in the Republic of Croatia, particularly for preliminary laboratory testing of asphalt mixtures. The selected range is representative of typical values used in similar studies and provides a sufficient basis for observing the behaviour of the mixtures across a relevant interval. The results obtained from this initial investigation will be used to define the optimal binder content in the subsequent stages of the research. The mass amount of crumb rubber in all mixtures was set to be 1% by total mixture mass, equal to 18% by binder mass. This amount corresponds to the recommendations from previous research where crumb rubber was used for the modification of binder [1]. Crumb rubber was added as a substitution for a proportion of binder content, so the total binder content in the mixtures remained equal to the unmodified mixtures. Crumb rubber content was held constant in all mixtures to exclude the influence of different rubber content on the investigated properties.

The blending procedure was performed manually by hand mixing crumb rubber into heated binder with a spatula, separately for each specimen. A small amount of pre-heated binder (66 g–78 g, depending on the binder amount) was manually blended with 12 g of crumb rubber until the mixture resembled homogenous structure in a way that no crumb rubber particles were dominantly present at the top or bottom of the binder and there were no crumb rubber clusters—crumb rubber was equally dispersed in the binder. The hand mixing procedure was performed for approximately 15 min for each specimen or until the previously defined homogenous structure was obtained. The produced rubber-modified binder was additionally heated for two hours at a temperature of 180 °C to enable the rubber particles to dissolve in the binder. Afterwards, the rubber-modified binder was added to heated aggregates and mixed to create a homogenous asphalt mixture according to the standard EN 12697-35 [26]. For each type of rubberised mixture, one trial mixture was prepared to consider the producibility of a homogeneous mixture with a rubber-modified binder. All three AC mixtures were successfully prepared; however, the SMA mixtures did not meet the expectations in the mixing procedure. The aggregate grains were not fully covered with the binder, indicating that the binder content should be higher to create a desirable homogenous mixture (Figure 4). For this reason, the SMA modified mixtures were created by adding the crumb rubber in the total binder content equal to the unmodified mixtures’ binder content, rather than replacing 1% of the binder with crumb rubber.

Figure 4.

Optimal binder content (OBC) in SMA mixtures: the left mixture did not meet the expectations of OBC; therefore, the binder content was increased in the right SMA mixture.

Cylindrical asphalt specimens were produced by following the EN 12697-30 standard [27] for specimen preparation using an impact compaction device. The selected specimen mass was 1200 g, corresponding to the limit mass values given in the relevant standard (1050 g–1400 g). No trial compaction was performed for the establishment of specimen mass, as target specimen height and density were not investigated in this study. Prepared mixtures were heated to the target mixing temperature of 150 °C, selected to correspond to the requirements for the selected binder type given in the EN 12697-35 standard [26]. The compaction of cylindrical specimens was performed by an impact compaction device. Specimens were compacted by 50 blows from each side to correspond to the Marshall test requirements given in the EN 12697-34 standard [28]. When the compaction was finished, the specimens were installed on a cooling plate before the extraction from the steel moulds. For each mixture, a batch of three specimens was produced for further analysis. After the extraction, the specimens were visually examined to investigate if there were any deformations or serious loss of aggregate grains on the specimen surface, which would influence further analysis. None of the compacted specimens from both mixture types showed any significant deformation; therefore, they were adopted for further examination of volumetric properties.

The modified material was also analysed using a scanning electron microscope (SEM). The analysis was performed visually under an accelerating voltage of 1.0 kV, using secondary electron detection (SED) at a magnification of 50×. These parameters were selected based on the size of the material’s components in order to ensure clear and comprehensive visualisation. Prior to analysis, the material was thoroughly dried and coated with a conductive layer of gold.

2.3. Volumetric Properties of HMA Mixtures

In this study, the maximum density of designed HMA mixtures, bulk density of compacted specimens, and void characteristics were selected as target volumetric properties, determined from compacted specimens. Maximum density of HMA mixtures represents the mass per unit volume of asphalt mixture without the air voids. It was determined by the EN 12697-5 standard, procedure C [29], where the mixture’s maximum density is calculated from mixture composition proportions expressed in the percentage of the total mixture mass and declared densities of the mixture constituents. The bulk density of the compacted specimens represents the mass per unit volume of the asphalt mixture specimen, including air voids, determined by the EN ISO 12697-6 standard [30]. For all produced specimens, the applied procedure for bulk density determination was procedure B in the standard, named “saturated surface dry (SSD)”. This method was selected as it is considered to be suitable for dense-graded mixtures (AC mixtures) and mixtures with expected large diameter voids in the specimen (SMA mixtures). The void characteristics of asphalt mixture specimens were obtained by following the EN 12697-8 standard [31]. Two different void contents were determined: air void content, Va, and the void content in the mineral aggregate filled with binder (and additives), VFB. Air void content Va represents the amount of air voids in a compacted asphalt mixture specimen expressed in percentage of total specimen volume, and void content in aggregate filled with binder VFB (and additives) is the void content in the aggregate skeleton filled with binder and additives.

2.4. Mechanical Properties of HMA Mixtures

The investigation of mechanical properties was performed on a compression testing device, corresponding to the requirements given in EN 12697-34 standard [28] for the Marshall test performance. Fabricated HMA specimens were conditioned in a water bath at a temperature of 60 °C prior to the test execution. Each specimen was loaded until a constant rate of deformation of 50 ± 2 mm/min was achieved. Afterwards, the load corresponding to the target deformation rate was applied to the specimen until failure. The rest results are given as maximum load applied and corresponding deformation, equal to the Marshall stability and flow values, respectively. The ratio of stability and flow values for each specimen is marked as the Marshall quotient or rigidity value.

3. Results and Discussion

3.1. Volumetric Properties of HMA Mixtures

Maximum density, bulk density and void characteristics were selected as the volumetric properties to be analysed in this study, with the results presented in Table 3. Bulk density and void characteristics values given in Table 4 represent the mean values calculated for each mixture type from the corresponding specimen group of three specimens. Coefficients of variation (CV) of bulk density values and void characteristics were determined for each specimen group of mixture types. The obtained values indicate that bulk density CV is below 1%, void content Va CV is below 10% and void content in the mineral aggregate filled with binder VFB CV is below 5% amongst the specimens of each group.

Table 4.

Volumetric properties of analysed mixture types.

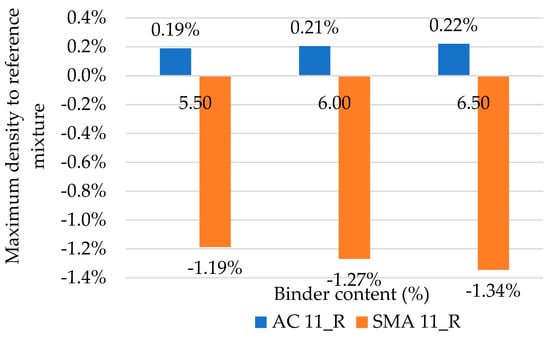

The highest value of maximum mixture density was obtained for the AC11_5.5%_R mixture, while SMA11_6.5%_R obtained the lowest value of the maximum mixture density. Generally, all mixtures follow the same trend: an increase in binder content reduces the maximum density of the mixture. Maximum density values of the CR-modified mixtures are compared to the unmodified mixtures, defined as reference mixtures, with equal binder content, as shown in Figure 5. For AC mixtures, the maximum density of the CR-modified mixtures is slightly higher than the maximum density of the reference mixtures with equal binder content, and vice versa for SMA mixtures. SMA CR-modified mixtures obtained lower maximum density values, regardless of the binder content (around 1.25%), while AC CR-modified mixtures obtained slightly higher maximum density values compared to reference mixtures (about 0.2%). In AC mixtures, the mixture’s maximum density is less affected by crumb rubber. Generally, it can be concluded that CR-modified SMA is slightly sensitive to maximum density changes, while CR-modified AC is unaffected. The results are, to some extent, expected due to a difference in constituent densities, particularly in higher aggregate density compared to bitumen and a slight difference in bitumen and CR densities.

Figure 5.

Influence of CR on CRMA maximum density.

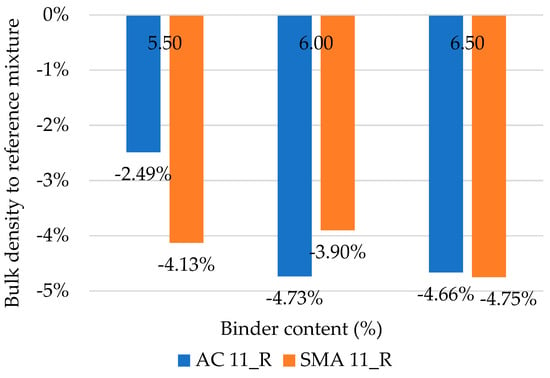

As presented in Table 4, unmodified SMA mixtures obtained the highest bulk density values for all three binder contents. The highest bulk density value is recorded for SMA11_6.5%, while the lowest value is recorded for AC11_6.0%_R. Bulk density increases with higher binder content in all mixtures except CR-modified AC mixtures, where a slight decrease in bulk density with binder increase was observed. This is due to a more binder available for filling voids within the aggregate skeleton. In research by [32], similar results are recorded for SMA mixtures. Crumb rubber generally reduced the bulk density values for all analysed mixtures, regardless of the binder content, as presented in Figure 6, but that decrease is within 5% for all tested mixtures. A reduction in the bulk density by CR modification may be discussed by means of a change in the CR molecular structure when mixing it with heated bitumen. The molecules of bitumen diffuse in the rubber structure, inducing a relaxation of the links between the rubber atoms, causing a decrease in its bulk density [33]. Also, this phenomenon of CR absorbing maltenes, the light component of bitumen, is causing more void space with the aggregate particles and therefore a reduction in density [34].

Figure 6.

Bulk density of CRMA mixtures compared to reference mixtures.

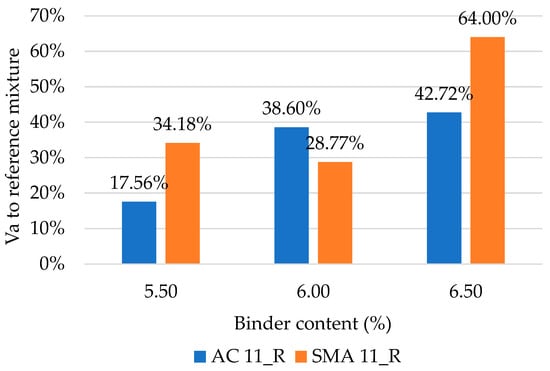

Void characteristics of specimens were analysed by air void content, Va, and void content in aggregate filled with binder, VFB, and presented in Table 4. Generally, an increase in binder content resulted in a decrease in Va, while CR modification resulted in an increase in Va in both mixtures. The highest Va is recorded for AC11_6.0%_R, while the lowest Va is recorded for SMA11_6.5%. A decrease in Va due to an increase in binder content is expected since more voids between the aggregate skeleton are filled with the binder. Crumb rubber presence in AC mixtures contributed to the increase in Va, but the difference between unmodified and modified mixtures is generally less significant for AC mixtures compared to SMA mixtures (Figure 7). Namely, for the CR mixture with 6.5% binder content, the increase in Va for the SMA mixture is more than 50%, which makes it highly sensitive to CR-modified binder content changes.

Figure 7.

Air void content of CRMA mixtures compared to reference mixtures.

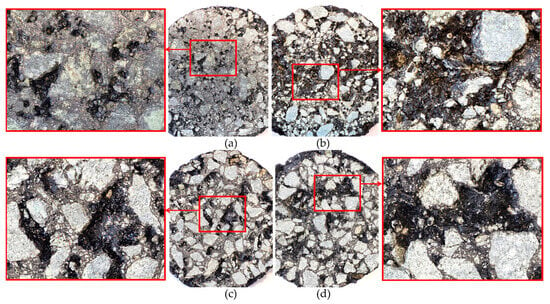

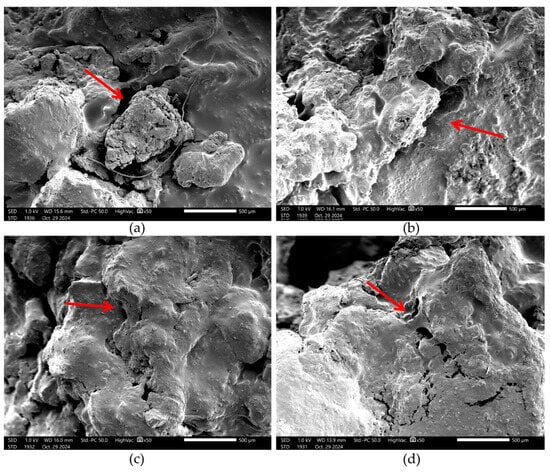

Differences in Va between CR-modified and reference AC and SMA mixtures are also presented in Figure 8. CR-modified samples are clearly affected by higher porosity (Figure 8b,d), and pores are bigger compared to those in unmodified binder samples (Figure 8a,c). Despite the fact that Va content is higher for AC mixtures, the pores are still smaller in size in AC mixtures compared to SMA mixtures. As pointed out in research by [32], CR particle absorbs the binder, which is required to encapsulate the aggregate and subsequently fill the voids between aggregates, increasing the Va.

Figure 8.

Cross-section of the samples of AC11 (a), CR-modified AC11 (b), SMA11 (c) and CR-modified SMA11 (d).

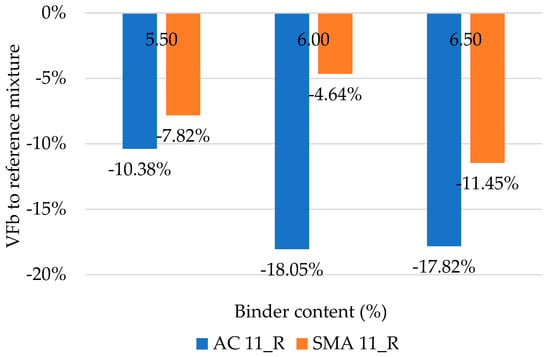

Another void characteristic analysed in this study is VFB—void content in mineral aggregate filled with binder. VFB content values are generally higher for SMA mixtures, both modified and unmodified. An increase in binder content resulted in an increase in VFB for all analysed mixtures. Crumb rubber presence reduced the VFB content for all mixture types. As presented in Figure 9, AC mixtures are more sensitive to VFB reduction by CR binder modification, with a decrease in VFB between 10 and 20%. CR bitumen modification results in CR swelling since it absorbs light components of bitumen, leading to an increase in the CR-modified binder viscosity [3]. Consequently, increased binder viscosity leads to difficulties in aggregate coating by the modified binder [1].

Figure 9.

VFB values of CRMA compared to reference mixtures.

By observing the analysed volumetric properties, it can be seen that both CR-modified mixture types follow the same trend for bulk density and void characteristics—bulk density is reduced, air void content increases and VFB content is reduced by CR binder modification. The maximum density of mixtures follows an inverse trend for different mixture types when they are modified with crumb rubber. For AC mixtures, crumb rubber slightly increases the maximum density values, and SMA mixtures exhibit a more notable decrease in maximum density values, regardless of the binder content in the mixture. The reduction in bulk density and increase in air void content are not desirable properties for AC and SMA mixtures, as these properties imply the reduction in the mixture’s stability, fatigue performance and stiffness [35]. What is indicative is that mixtures having higher binder content performed better in analysed volumetric properties, especially SMA mixtures with higher filler content, which were closer to the recommended air void content (usually 6%) in comparison to AC mixtures.

3.2. Mechanical Properties of HMA Mixtures

The results of the Marshall stability test are presented in Table 5. For each mixture, the presented results are calculated as the mean value of the obtained test results for each specimen of a given mixture. The difference between obtained stability values for a single specimen in a batch of each mixture was within 15% of mean stability value and obtained flow values were within the 20% difference with respect to the mean flow value, defined as test results reliability criteria in the Marshall test standard EN ISO 12697-34 [27].

Table 5.

Results of Marshall stability test for analysed asphalt mixtures.

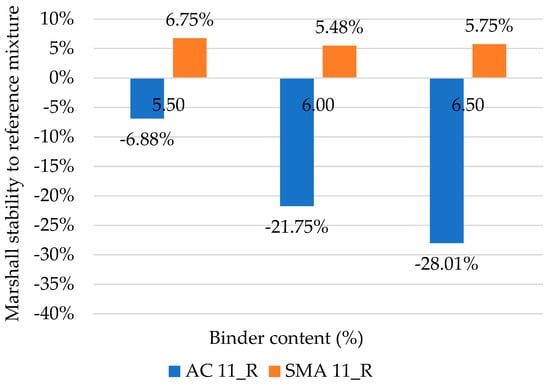

Marshall stability values expectedly showed higher values for SMA mixtures compared to AC mixtures, both modified and unmodified mixtures. As presented in Table 5, SMA mixtures had higher bulk density and lower Va content, which made them more stable. The highest Marshall stability value was obtained for SMA11_6.5%_R, while the lowest was recorded for AC11_6.0%_R. Marshall stability values shown in Figure 10 indicate that CR modification has a different effect on AC and SMA mixtures, improving the stability of SMA (up to 7%) and reducing it for AC mixtures (more than 25%). According to the presented results, it may be concluded that tested CR-modified SMA mixtures are much less sensitive to deviation from optimal binder content compared to CR-modified AC mixtures.

Figure 10.

Marshall stability for CRMA compared to reference mixture.

The results presented by the authors of [4] indicate that Marshall stability increases for both dense-graded and gap-graded mixtures, but finer CR was used in that study (0.3–0.6 mm). The viscosity of the binder increased with the inclusion of crumb rubber. The higher viscosity of the modified binder developed better adhesion between the materials in the mix, thus contributing to enhancing their stability [4]. For SMA mixtures, cellulose pellets were used to prevent the binder drain-down effect. Cellulose fibres themselves increase the viscosity of the SMA mixture, and adding CR for binder modification resulted in an additional increase in viscosity compared to the pure CR effect present in the tested AC mixture. SEM analysis showed that the sample containing the additive exhibited a more uniform and smoother surface morphology, with particles appearing more evenly coated. These morphological changes may indicate improved dispersion and interaction between the components, potentially associated with increased system viscosity. Although this conclusion aligns with [36], where the addition of 15% rubber by asphalt mass nearly doubled the viscosity, further rheological measurements are required to confirm this assumption. This increased viscosity in SMA mixtures is presented in Figure 11. In Figure 11a,b, Scanning Electron Microscope (SEM) images of unmodified and CR-modified bitumen from AC samples after the Marshall stability test are presented. It is clear that within the AC mixture, homogeneity is limited and slightly increases with CR modification. Lines of broken structure are clear and sharp. On the other hand, cellulose pellets (Figure 11c,d) demonstrate a soft and homogeneous layer, particularly with CR modification.

Figure 11.

SEM image of pure and CR-modified binder after Marshall test: (a) AC mix; (b) CR-modified AC mix; (c) SMA mix; (d) CR-modified SMA mix.

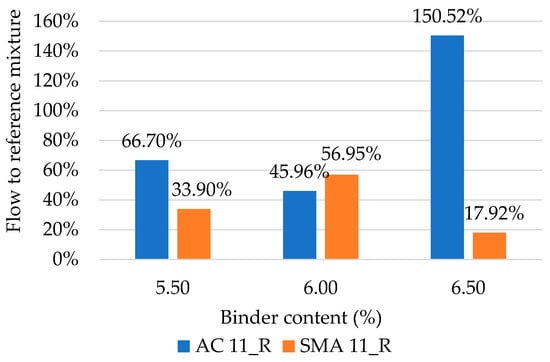

Furthermore, the flow values in Table 5 and Figure 12 indicate that CR addition to the mixture increased the flow in all tested mixtures. A similar finding was reported in research exploring the effects of crumb rubber addition to hot asphalt mixtures [34,37]. High flow values indicate the mixture’s lower resistance to high-temperature deformations. However, if the flow values are too low, mixtures are more prone to cracking [5]. Flow values generally increase with an increase in binder content in all asphalt mixtures. The results obtained in this study showed no significant trend in flow values with respect to the binder content in modified mixtures. The extreme values are recorded for AC mixtures: minimal for AC11_6.5% and maximal for AC11_5.0%_R. In general, flow values exhibited less difference between modified and unmodified mixtures with equal binder content in SMA mixtures. On the other hand, as presented in Figure 12, CR modification resulted in a flow increase while the sensitivity for binder content change is similar for AC and SMA mixtures, except for the highest binder content. Air voids Va increased with CR modification as presented previously in Figure 7, and bulk density decreased as presented in Figure 6, which may be an explanation for the flow increase with CR modification. Higher flow values indicate a more flexible mixture, and more compaction may be required, but it does not necessarily imply a higher tendency of the mixture to flow or deform under load [32]. Also, asphalt mixtures having lower stability and higher flow values are more susceptible to permanent deformations or rutting [14]. From that point of view, the mixture AC11_6.5%_R presents the weakest mixture, with low stability and the highest flow value, while the SMA11_6.5%_R mixture presents a modified mixture with enhanced properties, having slightly increased stability and flow with respect to the reference mixture.

Figure 12.

Flow values for analysed CRMA compared to reference mixtures.

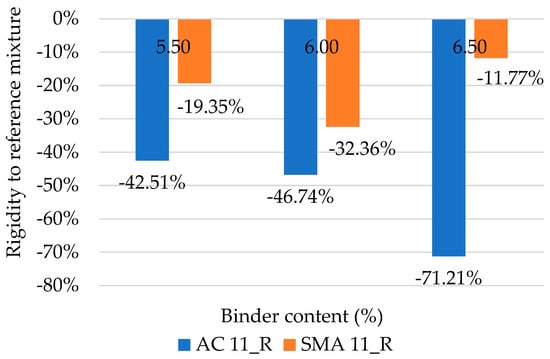

Stability versus flow ratio is expressed as the Marshall quotient or rigidity, indicating the stiffness of the designed mixture [38]. Generally, all mixtures obtained rigidity values between 1.5 kN/mm and 2 kN/mm with the exception of CR-modified AC mixtures (about 0.85 kN/mm) and AC11_6.5% (2.99 kN/mm). Higher Marshall quotient values indicate a mixture’s superior performance in terms of flexibility; thus, the designed mixture is less prone to permanent deformations. CR modification in this study resulted in an increase in both stability and flow values for SMA mixtures. Crumb rubber-modified SMA mixtures obtained notably higher rigidity values in comparison to AC-modified mixtures, indicating a better performance in terms of the mixture’s tendency to permanent deformation. According to normalised values presented in Figure 13, CR-modified SMA mixtures are less sensitive to rigidity change (decrease compared to the reference mixture) compared to CR-modified AC mixtures. Also, CR modification of AC mixtures is more sensitive to rigidity decreasing with the increase in the binder content.

Figure 13.

Rigidity values for analysed CRMA compared to reference mixtures.

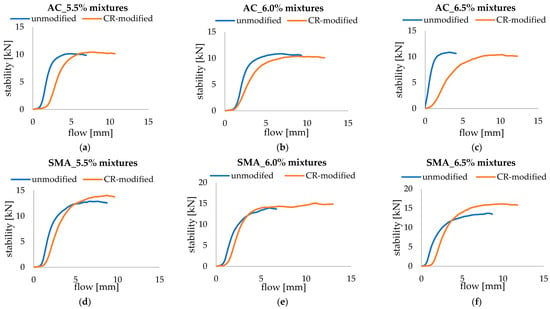

Stability versus flow curves were compared for modified and unmodified mixture equivalents with respect to the binder content for all designed mixtures. The curves were plotted for the representative specimen of each mixture, i.e., the specimen having the stability value closest to the calculated mean stability value in the specific specimen group. Figure 14. shows stability versus flow plots for all twelve investigated mixture types.

Figure 14.

Marshall stability versus flow values for a representative specimen of all investigated HMA mixtures: (a) AC11_5.5% and AC11_5.5%_R, (b) AC11_6.0% and AC11_6.0%_R, (c) AC11_6.5% and AC11_6.5%_R, (d) SMA11_5.5% and SMA11_5.5%_R, (e) SMA11_6.0% and SMA11_6.0%_R, (f) SMA11_6.5% and SMA11_6.5%_R.

Plotted curves for all analysed mixtures have a typical shape for the Marshall test results, as given in standard EN ISO 12697-34 [28]. Stability versus flow curves for modified mixtures’ specimens are shifted in comparison to their unmodified equivalents. The initial values of viscoelastic deformations for modified mixtures are higher compared to unmodified mixtures for equal load values. By observing the linear elastic regime behaviour of modified and unmodified mixtures, it can be seen that all modified mixtures exhibit lower curve slopes in comparison to the unmodified equivalents. Calculated curve slopes are given in Table 6, where it can be seen that AC mixtures exhibit a greater difference in curve slope for unmodified and modified mixtures with equal binder content. What can be seen from the curves is that for all modified AC mixtures, peak load is reached for higher flow values in comparison to obtained peak loads of unmodified mixtures. An interesting observation is related to AC mixtures’ curves having the highest binder content, 6.5% (Figure 14c). In the initial loading stage, the rubber-modified AC mixture exhibited flow values almost equal to the flow values recorded at the end of the linear elastic regime phase of the unmodified mixture. The unmodified AC mixture exhibited significantly higher stability value for a relatively low flow value in comparison to other analysed mixtures, while its modified equivalent showed to have the weakest performance amongst all mixtures.

Table 6.

Load/deformation curve slope calculation results.

The behaviour of unmodified and modified SMA mixtures is similar for binder content equivalents. The modified mixtures also exhibit the shift in linear elastic regime due to higher initial viscoelastic deformations; however, the difference between unmodified and modified mixtures is not as distinctive as for AC mixtures. Calculated curve slopes given in Table 6 show that the slope difference between unmodified mixtures and their modified equivalents is smaller than for the AC mixtures. The plotted stability versus flow curves in Figure 14 show that modified SMA mixtures have higher stability values in comparison to their unmodified equivalents, indicating superior performance of CR-modified SMA mixtures with respect to the permanent deformation. Furthermore, the obtained flow values of CR-modified mixtures are higher, contributing to the flexibility of the mixtures. However, the peak load was reached for higher flow values, resulting in lower rigidity values. This is especially notable for modified SMA mixtures with 6.0% binder, which showed to have the lowest rigidity amongst SMA mixtures in the previous analysis. The increased stability suggests that rubber modification enhances resistance to deformation under high temperatures and loads. However, the higher flow values at peak load indicate reduced rigidity in the early stages of loading. While the improved stability may delay permanent deformation (e.g., rutting), the higher initial deformation could increase the risk of permanent damage over time. Thus, rubber-modified SMA mixtures may offer better performance under heavy loading but need careful management to avoid excessive long-term deformation.

4. Conclusions

In this study, the effect of CR modification on the volumetric and mechanical properties of two HMA mixtures with different gradings was evaluated with respect to different binder contents in the mixtures. For this purpose, a dense-graded AC 11 mixture and a gap-graded SMA 11 mixture were designed, having equal aggregate gradation and three different binder contents: 5.5%, 6.0% and 6.5%. The reference mixtures were modified with CR particles of size 1–2 mm, obtained from ambient mechanical processing of collected tyres and added to virgin 50/70 bitumen by 18% of binder weight in all mixtures. The binder modification was performed by a manual blending procedure of CR particles. The effect of CR modification on volumetric properties of mixtures having two different gradation types was evaluated through maximum density, bulk density and void characteristic properties of CRMA mixtures with different binder contents. Furthermore, the mechanical properties of CRMA mixtures, stability, flow and rigidity, were evaluated through the Marshall test results and compared to the performance of unmodified mixtures with different binder contents. The research conclusions can be summarised as follows:

- In terms of the mixture’s maximum density determined from its constituent materials, CR modification was shown to have no significant effect on the analysed mixtures, regardless of the binder content. For dense-graded mixtures, CR slightly increased maximum density in all mixtures (approximately 0.2%), and for gap-graded mixtures, the maximum density decreased with CR presence in the mixtures (approximately 1.25%). In general, it can be concluded that gap-graded mixtures was shown to be more sensitive to the mixture’s maximum density change with the addition of CR, where the mixture’s sensitivity to CR modification increases by binder content.

- CR modification contributed to a general reduction in bulk density values for both mixture types and all binder contents. However, the decrease in bulk density values was within 5% for all CR-modified mixtures. Therefore, it can be concluded that there is no significant effect of CR modification on the bulk density of the investigated mixtures.

- Void characteristics were shown to be the most affected volumetric property of HMA mixtures by CR modification. In all mixtures, CR particles contributed to a significant increase in void content Va. Gap-graded mixtures were shown to be more sensitive to CR modification, especially for higher binder content, 6.5%, where Va content increased by more than 60% in comparison to the unmodified SMA mixture. This result indicates high sensitivity of Va to rubberised binder content change, requiring careful selection of optimal binder content for gap-graded modified mixtures. The void content in mineral aggregate filled with binder (VFB) was another analysed volumetric property of CR-modified mixtures, which was also shown to be significantly affected by CR presence. In all mixtures, VFB values decreased with CR modification, and dense-graded mixtures showed to be more sensitive, having 10–20% less VFB in comparison to unmodified mixtures. In gap-graded mixtures, the reduction in VFB was less emphasised, especially for mixtures with lower binder content (up to 10%)

- Marshall stability values for CR-modified mixtures observed a very different trend for different gradation types: CR dense-graded mixtures experienced a significant reduction in stability values, especially for higher binder content, where the reduction in the Marshall stability was more than 25% in comparison to the unmodified mixture. On the contrary, gap-graded mixtures modified with CR showed a steady increase in the Marshall stability of approximately 5%, regardless of the binder content. The highest Marshall stability value for all investigated mixtures was obtained for the SMA CR-modified mixture with 6.5% binder content, indicating the superior performance of mixtures modified with CR. However, the analysed flow values also showed an increase in comparison to unmodified mixtures, especially the dense-graded mixture with 6.5% binder content. By analysing stability and flow values of CR-modified mixtures, it can be concluded that the gap-graded mixture with the highest binder content of 6.5% showed the best overall performance in terms of the mixture’s resistance to permanent deformations in comparison to its unmodified equivalent.

The results of this study point out the superior performance of gap-graded mixtures modified by CR in comparison to dense-graded mixtures with equal binder content and CR content in the mixture. The detected high sensitivity of void characteristics with respect to the binder content, especially Va content in CR-modified SMA mixtures, indicates the necessity of adequate optimal binder content selection in the mixture design procedure. Furthermore, Va content optimisation might contribute to improvements in the mechanical properties of CR-modified mixtures, especially flow values, which were shown to be relatively high for modified mixtures. Besides optimal binder content and Va content, CR particle size is another property to be targeted in further research on rubberised mixtures’ performance. Smaller size CR particles might contribute to the reduction in the mixture’s porosity and reduce the size of pores in the specimen due to better interaction with the binder, resulting in better mechanical performance of CR-modified mixtures in terms of long-term deformations. Further investigation of gap-graded mixtures containing binder modified by CR particles will also consider the mechanical blending procedure and the effect of the methodology on modified binder preparation and the physical and mechanical properties investigated in this study.

Author Contributions

Conceptualization, I.B. (Ivana Ban), I.B. (Ivana Barišić), M.C. and M.Z.; methodology, I.B. (Ivana Ban), I.B. (Ivana Barišić) and M.C.; software, I.B. (Ivana Ban), I.B. (Ivana Barišić) and M.Z.; validation, I.B. (Ivana Ban) and I.B. (Ivana Barišić); formal analysis, I.B. (Ivana Ban), I.B. (Ivana Barišić) and M.C.; investigation, I.B. (Ivana Ban), I.B. (Ivana Barišić) and M.Z.; resources, I.B. (Ivana Ban) and M.C.; data curation, I.B. (Ivana Ban) and I.B. (Ivana Barišić); writing—original draft preparation, I.B. (Ivana Ban), I.B. (Ivana Barišić), M.C. and M.Z.; writing—review and editing, I.B. (Ivana Ban) and I.B. (Ivana Barišić); visualisation, I.B. (Ivana Ban) and I.B. (Ivana Barišić); supervision, I.B. (Ivana Ban); funding acquisition, I.B. (Ivana Ban), I.B. (Ivana Barišić) and M.C. All authors have read and agreed to the published version of the manuscript.

Funding

The authors acknowledge financial support and funding from Croatian Science Foundation under the project UIP-2019-04-8195 “Cement stabilized base courses with waste rubber for sustainable pavements—RubSuPave” and University of Rijeka scientific projects uniri-mladi-tehnic-23-20 “Application of CROP method for pavement texture analysis in sustainable asphalt mixtures” and uniri-mladi-tehnic-23-45 “Porous asphalt mixtures—a tool for mitigating urban heat island”.

Data Availability Statement

The research data supporting reported results are available upon request from the authors and the supporting scientific projects databases.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Picado-Santos, L.G.; Capitão, S.D.; Neves, J.M.C. Crumb rubber asphalt mixtures: A literature review. Constr. Build. Mater. 2020, 247, 118577. [Google Scholar] [CrossRef]

- Sangiorgi, C.; Tataranni, P.; Simone, A.; Vignali, V.; Lantieri, C.; Dondi, G. Stone mastic asphalt (SMA) with crumb rubber according to a new dry-hybrid technology: A laboratory and trial field evaluation. Constr. Build. Mater. 2018, 182, 200–209. [Google Scholar] [CrossRef]

- Zakerzadeh, M.; Shahbodagh, B.; Ng, J.; Khalili, N. The use of waste tyre rubber in Stone Mastic Asphalt mixtures: A critical review. Constr. Build. Mater. 2024, 418, 135420. [Google Scholar] [CrossRef]

- Khiong, L.M.; Safiuddin, M.; Mannan, M.A.; Resdiansyah. Material properties and environmental benefits of hot-mix asphalt mixes including local crumb rubber obtained from scrap tires. Environments 2021, 8, 47. [Google Scholar] [CrossRef]

- Alfayez, S.A.; Suleiman, A.R.; Nehdi, M.L. Recycling tire rubber in asphalt pavements: State of the art. Sustainability 2020, 12, 9076. [Google Scholar] [CrossRef]

- Ghabchi, R.; Arshadi, A.; Zaman, M.; March, F. Technical challenges of utilizing ground tire rubber in asphalt pavements in the United States. Materials 2021, 14, 4482. [Google Scholar] [CrossRef]

- Chavez, F.; Marcobal, J.; Gallego, J. Laboratory evaluation of the mechanical properties of asphalt mixtures with rubber incorporated by the wet, dry, and semi-wet process. Constr. Build. Mater. 2019, 205, 164–174. [Google Scholar] [CrossRef]

- Bressi, S.; Fiorentini, N.; Huang, J.; Losa, M. Crumb rubber modifier in road asphalt pavements: State of the Art and statistics. Coatings 2019, 9, 384. [Google Scholar] [CrossRef]

- Riekstins, A.; Baumanis, J.; Barbars, J. Laboratory investigation of crumb rubber in dense graded asphalt by wet and dry processes. Constr. Build. Mater. 2021, 292, 123459. [Google Scholar] [CrossRef]

- Shu, X.; Huang, B. Recycling of waste tire rubber in asphalt and portland cement concrete: An overview. Constr. Build. Mater. 2014, 67, 217–224. [Google Scholar] [CrossRef]

- Bilema, M.; Aman, M.; Hassan, N.; Haloul, M.; Modibbo, S. Influence of crumb rubber size particles on moisture damage and strength of the hot mix asphalt. Mater. Today Proc. 2021, 42, 2387–2391. [Google Scholar] [CrossRef]

- Paul, D.; Pal, M.; Majumdar, K.; Suresh, M. Effect of rubber polymeric materials on moisture susceptibility of asphalt mixtures: Optimization and evaluation study. Mater. Today Proc. 2022, 57, 454–459. [Google Scholar] [CrossRef]

- Guo, Z.; Wang, L.; Feng, L.; Guo, Y. Research on fatigue performance of composite crumb rubber modified asphalt mixture under freeze thaw cycles. Constr. Build. Mater. 2022, 323, 126603. [Google Scholar] [CrossRef]

- Liu, Y.; Han, S.; Zhang, Z.; Xu, O. Design and evaluation of gap-graded asphalt rubber mixtures. Mater. Des. 2012, 35, 873–877. [Google Scholar] [CrossRef]

- Sarsam, S.I. Influence of Ageing on Volumetric Properties of Rubber Modified Asphalt Concrete. Indian J. Eng. 2021, 18, 267–276. [Google Scholar]

- Lee, S.-J.; Amirkhanian, S.N.; Putman, B.J.; Kim, K.W. Laboratory Study of the Effects of Compaction on the Volumetric and Rutting Properties of CRM Asphalt Mixtures. J. Mater. Civ. Eng. 2007, 19, 1079–1089. [Google Scholar] [CrossRef]

- Riekstins, A.; Haritonovs, V.; Straupe, V. Economic and environmental analysis of crumb rubber modified asphalt. Constr. Build. Mater. 2022, 335, 127468. [Google Scholar] [CrossRef]

- Moreno, F.; Sol, M.; Martín, J.; Pérez, M.; Rubio, M.C. The effect of crumb rubber modifier on the resistance of asphalt mixes to plastic deformation. Mater. Des. 2013, 47, 274–280. [Google Scholar] [CrossRef]

- Li, D.; Leng, Z.; Yao, L.; Cao, R.; Zou, F.; Li, G.; Wang, H.; Wang, H. Mechanical, economic, and environmental assessment of recycling reclaimed asphalt rubber pavement using different rejuvenation schemes. Resour. Conserv. Recycl. 2024, 204, 107534. [Google Scholar] [CrossRef]

- Bocci, E.; Prosperi, E. Recyclability of reclaimed asphalt rubber pavement. Constr. Build. Mater. 2023, 403, 133040. [Google Scholar] [CrossRef]

- EN 933-1; Tests for Geometrical Properties of Aggregates—Part 1: Determination of Particle Size Distribution—Sieving Method. European Committee for Standardization: Brussels, Belgium, 1997.

- Mohajerani, A.; Burnett, L.; Smith, J.V.; Markovski, S.; Rodwell, G.; Rahman, M.T.; Kurmus, H.; Mirzababaei, M.; Arulrajah, A.; Horpibulsuk, S.; et al. Recycling waste rubber tyres in construction materials and associated environmental considerations: A review. Resour. Conserv. Recycl. 2020, 155, 104679. [Google Scholar] [CrossRef]

- Shulman, V.L. Tyre Recycling; Smithers Rapra Publishing: Shawbury, UK, 2004; Volume 15. [Google Scholar]

- EN 1097-6; Tests for Mechanical and Physical Properties of Aggregates—Part 6: Determination of Particle Density and Water Absorption. European Committee for Standardization (CEN): Brussels, Belgium, 2013.

- HRN ISO 9277:2016; BET Metoda, Determination of the Specific Surface Area of Solids by Gas Adsorption—BET Method. European Committee for Standardization (CEN): Brussels, Belgium, 2016.

- HRN EN 12697-35; Bituminous Mixtures—Test Methods—Part 35: Laboratory Mixing. European Committee for Standardization (CEN): Brussels, Belgium, 2016.

- EN 12697-30; Bituminous Mixtures—Test Methods for Hot Mix Asphalt—Part 30: Specimen Preparation by Impact Compactor. European Committee for Standardization (CEN): Brussels, Belgium, 2018.

- EN 12697-34; Bituminous Mixtures—Test Methods—Part 34: Marshall Test. European Committee for Standardization (CEN): Brussels, Belgium, 2020.

- EN 12697-5; Bituminous Mixtures—Test Methods—Part 5: Determination of the Maximum Density. European Committee for Standardization (CEN): Brussels, Belgium, 2018.

- EN 12697-6; Bituminous Mixtures—Test Methods—Part 6: Determination of Bulk Density of Bituminous Specimens. European Committee for Standardization (CEN): Brussels, Belgium, 2020.

- EN 12697-8; Bituminous Mixtures—Test Methods—Part 8: Determination of Void Characteristics of Bituminous Specimens. European Committee for Standardization (CEN): Brussels, Belgium, 2019.

- Mashaan, N.S.; Ali, A.H.; Koting, S.; Karim, M.R. Performance evaluation of crumb rubber modified stone mastic asphalt pavement in Malaysia. Adv. Mater. Sci. Eng. 2013, 2013, 304676. [Google Scholar] [CrossRef]

- Peralta, J.; Silva, H.M.; Machado, A.V.; Pais, J.; Pereira, P.A.; Sousa, J.B. Changes in rubber due to its interaction with bitumen when producing asphalt rubber. Road Mater. Pavement Des. 2011, 11, 1009–1031. [Google Scholar] [CrossRef]

- Rashed, A.M.; Al-Hadidy, A. Comparative performance of DG mixes and SMA mixes with waste crumb rubber as aggregate replacement. Case Stud. Constr. Mater. 2023, 19, e02615. [Google Scholar] [CrossRef]

- Zaltuom, A.M. A review study of the effect of air voids on asphalt pavement life. In Proceedings of the First Conference for Engineering Sciences and Technology (CEST-2018), Garaboulli, Libya, 25–27 September 2018; Elalem, M.A., Ed.; AIJR Publisher: New Delhi, India, 2018. [Google Scholar]

- Zumrawi, M.M.E. Effect of crumb rubber modifiers (CRM) on characteristics of asphalt binders in Sudan. Int. J. Mater. Sci. Appl. 2017, 6, 1–6. [Google Scholar]

- Mohammed, A.H.; Yang, Q.; Al-Bukhaiti, K. Using crumb of tires in hot asphalt mixture as a part of aggregate. In IOP Conference Series: Materials Science and Engineering, Proceedings of the International Conference on Road and Airfield Pavement Technologies (ICPT 2019), Kuala Lumpur, Malaysia, 10–12 July 2019; Muniandy, R., Hassim, I.S., Jakarni, F.M., Ab Razak, M.S., Eds.; IOP Publishing: Bristol, UK, 2021; Volume 1075, p. 012005. [Google Scholar]

- Elnihum, A.; Lu, Q.; Alharthai, M.; Alamri, M.; Chen, C.; Elmagarhe, A. Evaluation of an asphalt mixture containing a high content of reclaimed asphalt pavement (RAP) materials with epoxy asphalt. Sustainability 2024, 16, 4988. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).