Statistical Analysis of the Tensile Strength of Cold Recycled Cement-Treated Materials and Its Influence on Pavement Design

Abstract

1. Introduction

2. Experimental Program

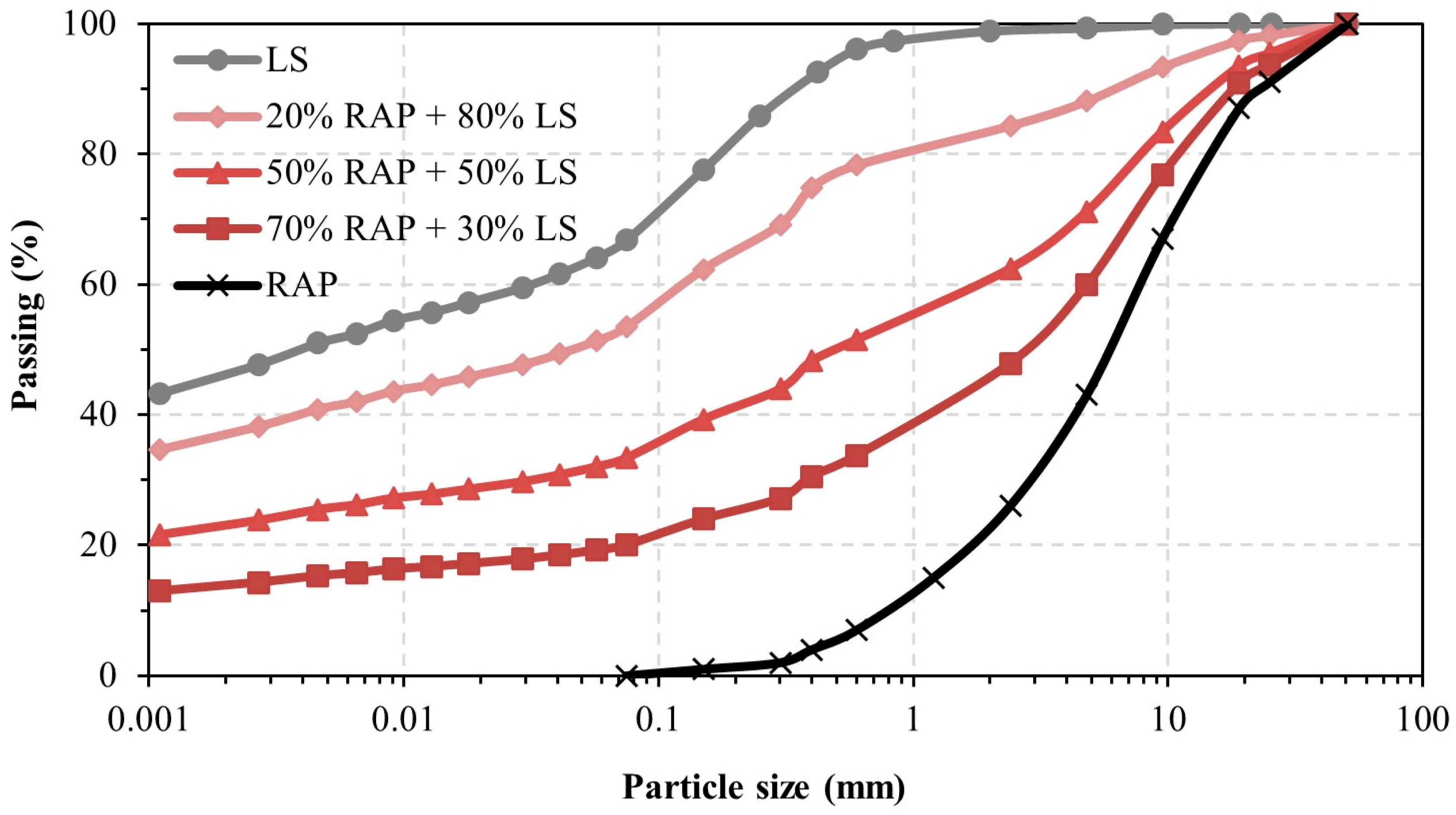

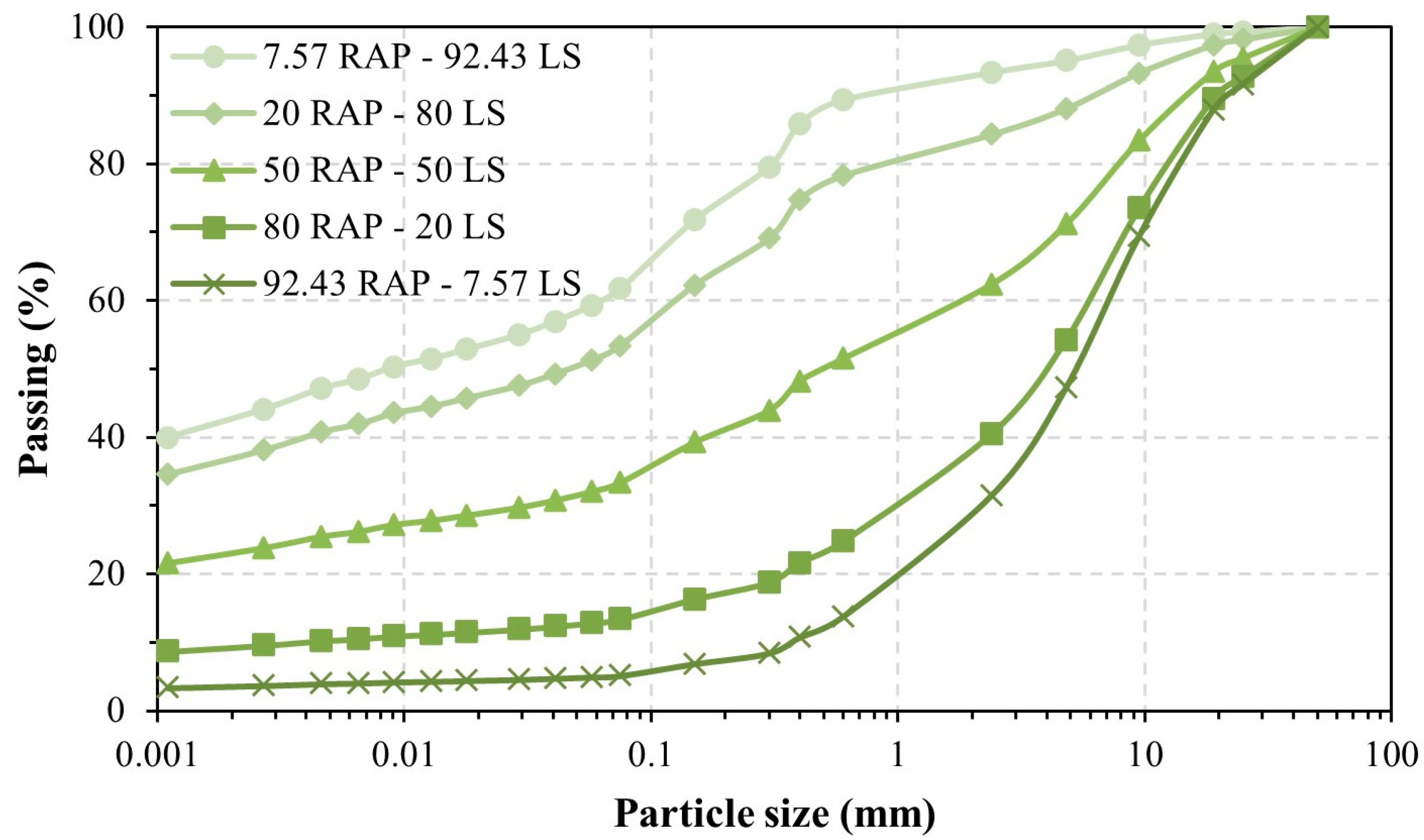

2.1. Materials

2.2. Methods

2.2.1. Compaction Tests

2.2.2. Flexural Tensile Strength Tests

2.2.3. Indirect Tensile Strength Tests

3. Mechanistic Pavement Design

4. Results and Discussion

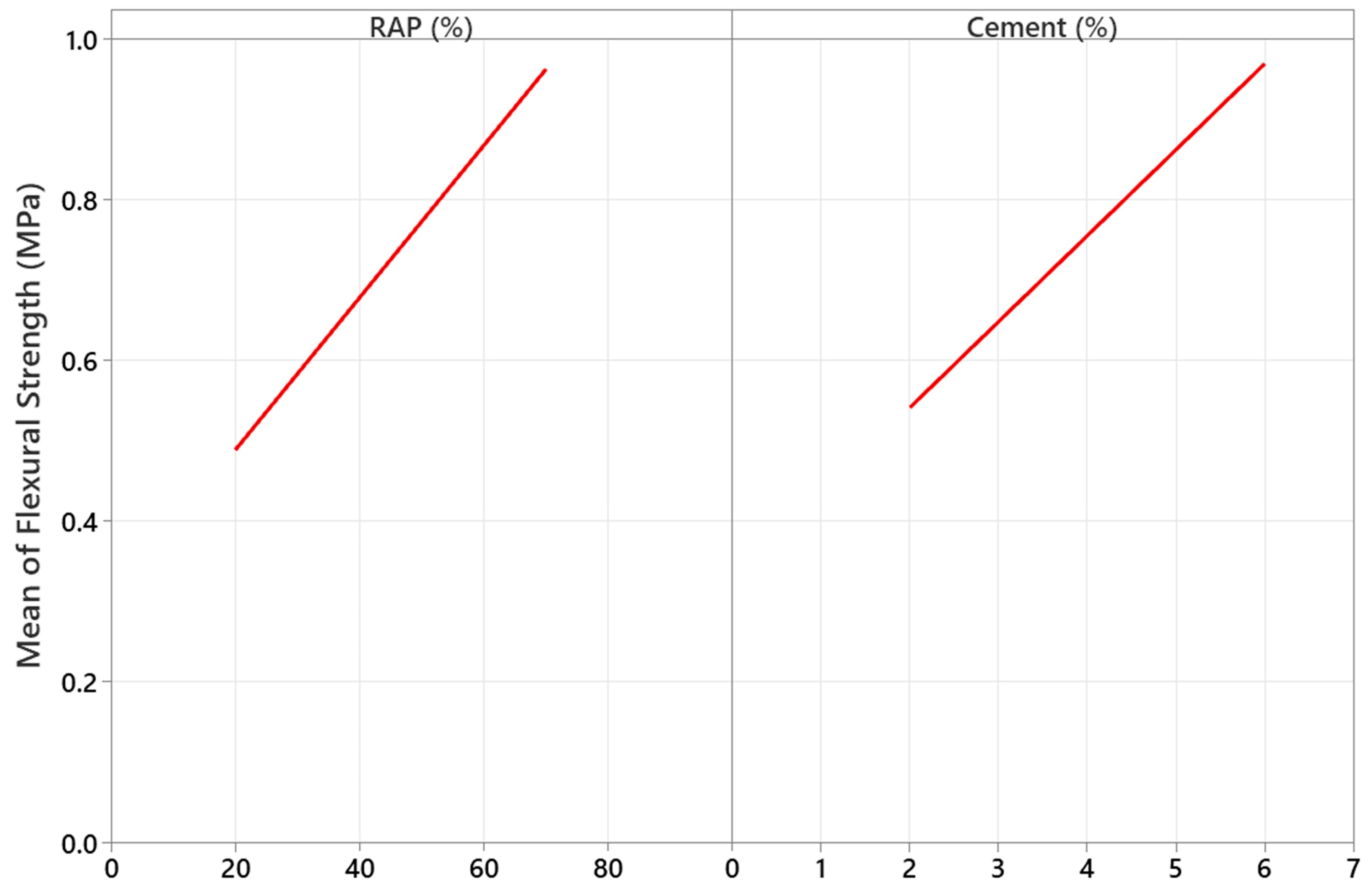

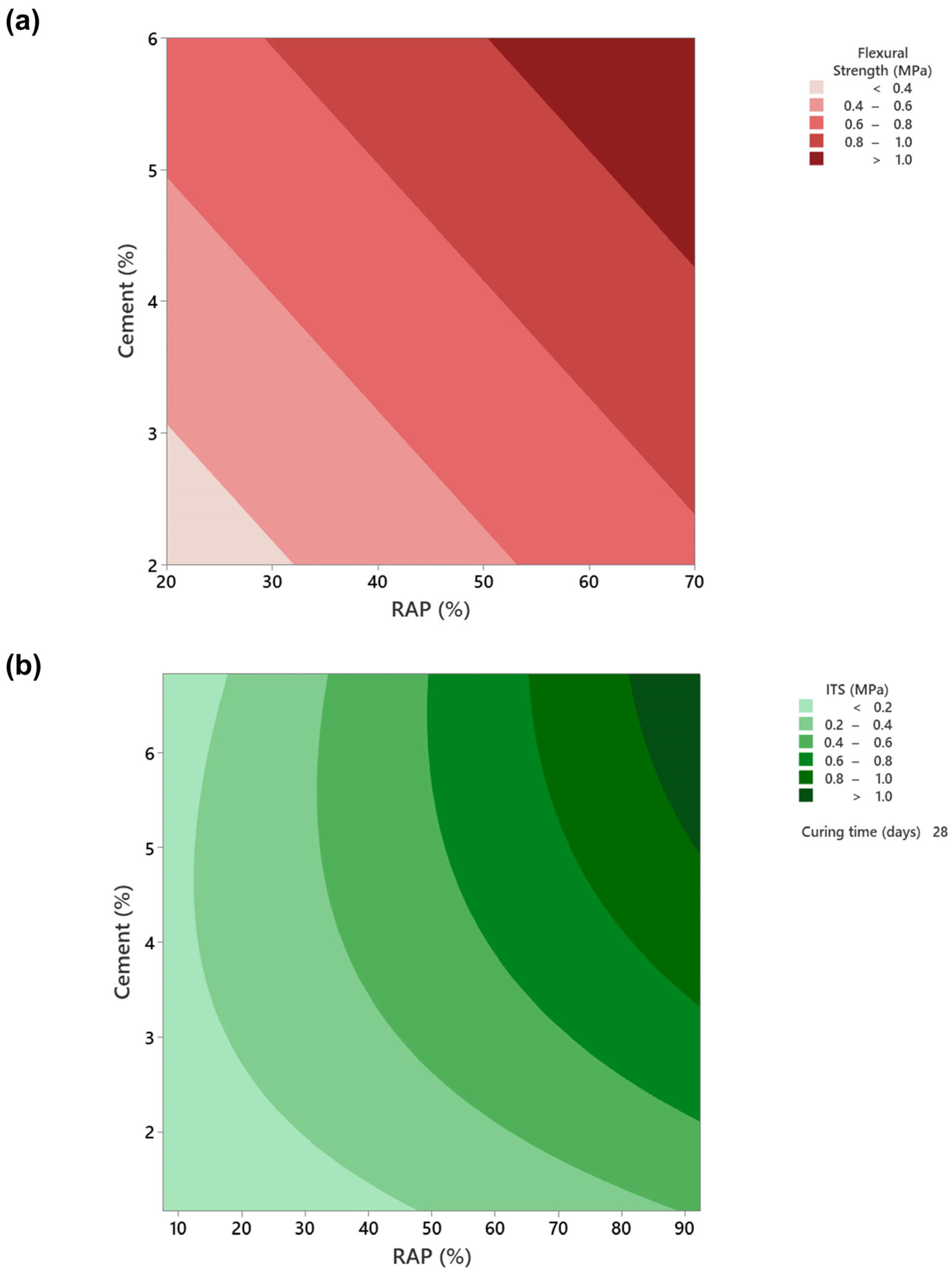

4.1. Flexural Tensile Strength

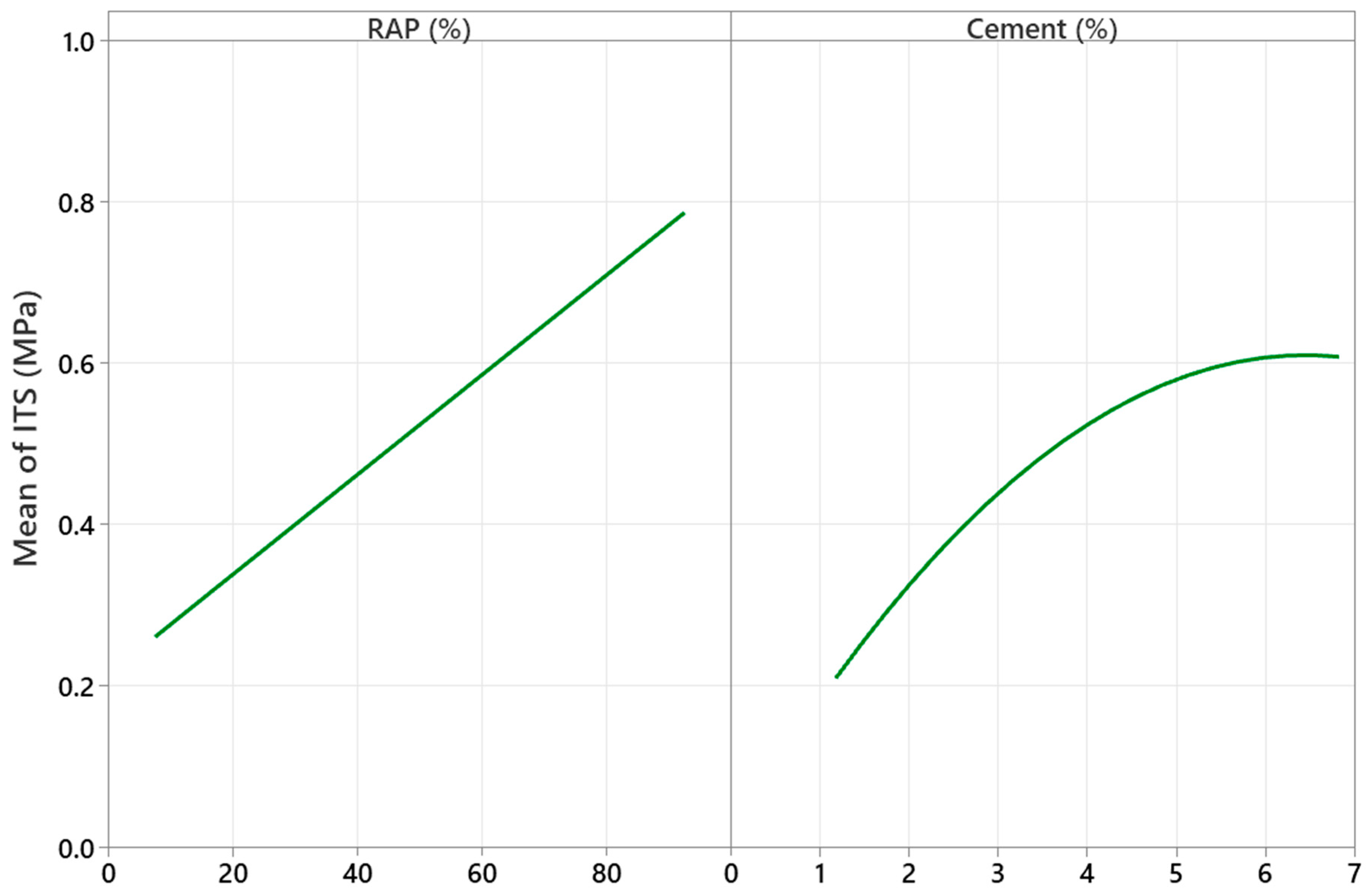

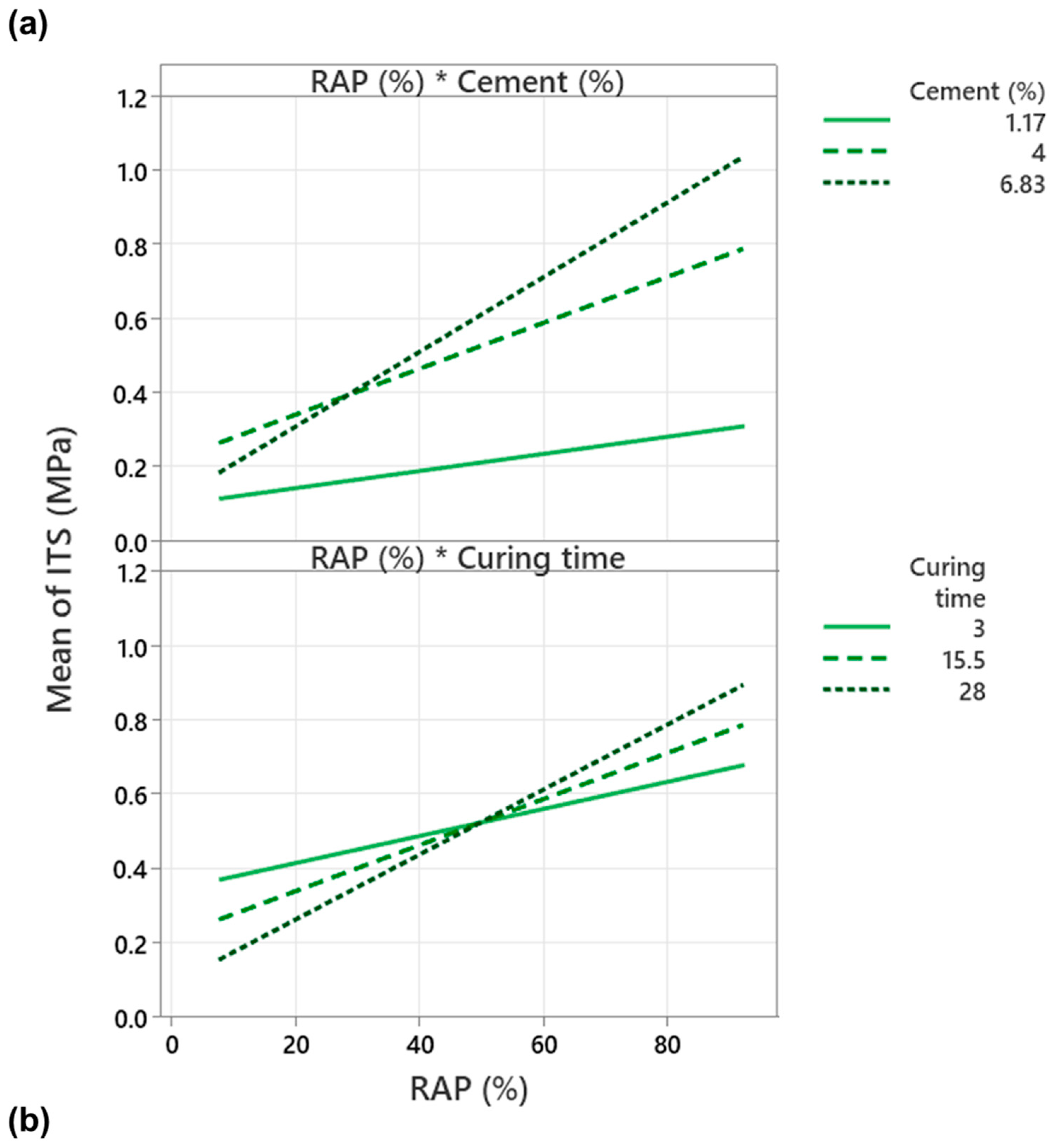

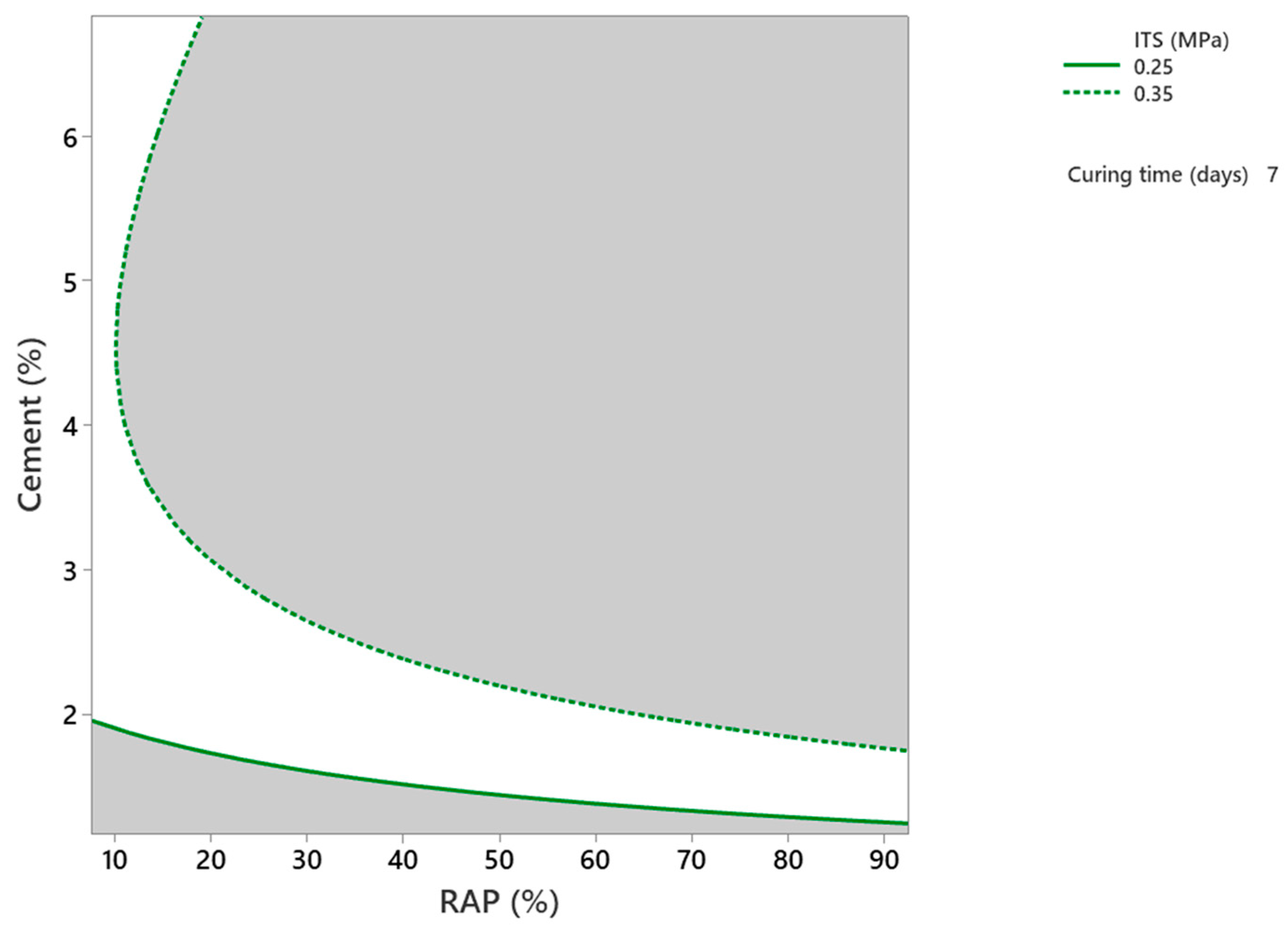

4.2. Indirect Tensile Strength

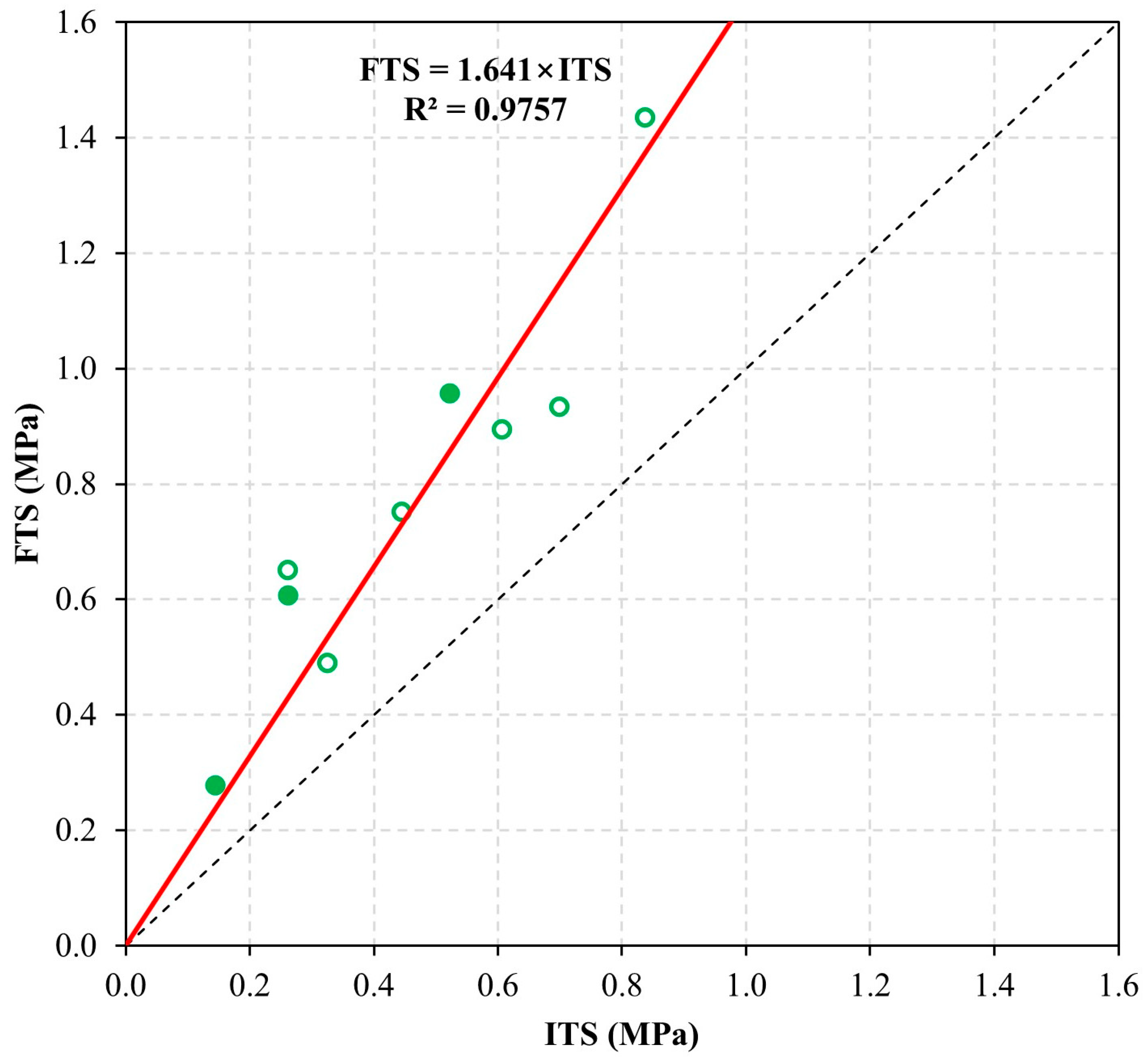

4.3. Comparison Between Flexural and Indirect Tensile Strengths

4.4. Mechanistic Pavement Design Results

5. Conclusions

- The effects of cement and RAP contents on tensile strength were significant, with both contributing to its increase. This suggests that CRCTMs incorporating similar materials may benefit from higher RAP contents, in contrast to much of the academic and industry experience. Furthermore, mechanistic analysis showed that a lower RAP content leads to the necessity for thicker pavement structures. Such findings suggest that optimizing RAP content could help reduce costs and environmental impacts.

- For ITS, both cement content and curing time showed significant interactions with RAP content. Moreover, RAP content had the most significant effect on the ITS. These outcomes demonstrate the key role of RAP in achieving an adequate mix design of CRCTMs.

- FTS is, on average, about 65% higher than ITS. However, when ITS is used in pavement design, the resulting structures are 1.7 to 3.3 times thicker than those designed with FTS for the same service life. This emphasizes the importance of properly characterizing CRCTMs for design purposes. In this regard, flexural tests are recommended, as they not only provide a closer simulation of field behavior but also appear to result in more cost-effective pavement structures.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AEMC | Multiple layer elastic analysis |

| ANOVA | Analysis of Variance |

| BL | Base Layer |

| C | Cement |

| CCD | Central Composite Design |

| CRCTM | Cold recycled cement-treated mixtures |

| DoE | Design of Experiments |

| DTS | Direct Tensile Strength |

| FDR-PC | Full-depth reclamation with Portland cement |

| FTS | Flexural tensile strength |

| ITS | Indirect tensile strength |

| LS | Lateritic soil |

| MCT | Miniature, Compacted, Tropical |

| MDUW | Maximum dry unit weight |

| MeDiNa | National Design Method |

| NS’ | Non-lateritic silty soil |

| OMC | Optimum moisture content |

| RAP | Reclaimed asphalt pavement |

| SR | Stress Ratio |

| WC | Wearing Course |

References

- Guthrie, W.S.; Brown, A.V.; Eggett, D.L. Cement Stabilization of Aggregate Base Material Blended with Reclaimed Asphalt Pavement. Transp. Res. Rec. J. Transp. Res. Board 2007, 2026, 47–53. [Google Scholar] [CrossRef]

- Chen, X.; Wang, H. Enhancement of Roadway Pavement Resilience to Flooding: Impact Assessment and Mitigation Strategies. Transp. Res. D Transp. Environ. 2025, 148, 104946. [Google Scholar] [CrossRef]

- Lee, J.L.; Balmaceda, P.; Hansen, B. Pavement Stabilization Techniques to Restore Flood-Affected Roads in Queensland. In Proceedings of the Pavement Performance Monitoring, Modeling, and Management, Yichang, China, 20–22 July 2014; American Society of Civil Engineers: Reston, VA, USA, 2014; pp. 92–99. [Google Scholar]

- Fedrigo, W.; Núñez, W.P.; Kleinert, T.R.; Matuella, M.F.; Ceratti, J.A.P. Strength, Shrinkage, Erodibility and Capillary Flow Characteristics of Cement-Treated Recycled Pavement Materials. Int. J. Pavement Res. Technol. 2017, 10, 393–402. [Google Scholar] [CrossRef]

- Suddeepong, A.; Intra, A.; Horpibulsuk, S.; Suksiripattanapong, C.; Arulrajah, A.; Shen, J.S. Durability against Wetting-Drying Cycles for Cement-Stabilized Reclaimed Asphalt Pavement Blended with Crushed Rock. Soils Found. 2018, 58, 333–343. [Google Scholar] [CrossRef]

- Luvizão, G.; Trichês, G. Case Study on Life Cycle Assessment Applied to Road Restoration Methods. Sustainability 2023, 15, 6679. [Google Scholar] [CrossRef]

- Xiao, F.; Yao, S.; Wang, J.; Li, X.; Amirkhanian, S. A Literature Review on Cold Recycling Technology of Asphalt Pavement. Constr. Build. Mater. 2018, 180, 579–604. [Google Scholar] [CrossRef]

- Crayton, A.; Schmidt, J.; Torres-Machi, C. Does Recycling Compromise Long-Term Performance and Life-Cycle Costs? A Comparative Analysis of Full-Depth Reclamation and Overlay Pavements. Transp. Res. Rec. J. Transp. Res. Board 2025, 2679, 466–480. [Google Scholar] [CrossRef]

- Austroads. Mix Design for Stabilised Pavement Materials; AP-T16; Austroads Publication: Sydney, Australia, 2002; p. 31. [Google Scholar]

- Castañeda López, M.A.; Fedrigo, W.; Kleinert, T.R.; Matuella, M.F.; Núñez, W.P.; Ceratti, J.A.P. Flexural Fatigue Evaluation of Cement-Treated Mixtures of Reclaimed Asphalt Pavement and Crushed Aggregates. Constr. Build. Mater. 2018, 158, 320–325. [Google Scholar] [CrossRef]

- Ren, J.; Zhang, L.; Zhao, H.; Zhao, Z.; Wang, S. Determination of the Fatigue Equation for the Cement-Stabilized Cold Recycled Mixtures with Road Construction Waste Materials Based on Data-Driven. Int. J. Fatigue 2022, 158, 106765. [Google Scholar] [CrossRef]

- Melese, E.; Baaj, H.; Tighe, S. Fatigue Behaviour of Reclaimed Pavement Materials Treated with Cementitious Binders. Constr. Build. Mater. 2020, 249, 118565. [Google Scholar] [CrossRef]

- Dong, S.; Wei, J.; Zhao, N.; Dong, Q. Characterization of Fatigue Damage Accumulation and Prediction of Modulus Deterioration for Cement Stabilized Base. Int. J. Pavement Eng. 2023, 24, 2209263. [Google Scholar] [CrossRef]

- Lv, S.; Peng, X.; Yuan, J.; Liu, H.; Hu, L.; Yang, S.; Liu, J. Stress Path Investigation of Fatigue Characteristics of Cement Stabilized Macadam. Constr. Build. Mater. 2021, 292, 123446. [Google Scholar] [CrossRef]

- Dong, S.; Hao, P.; Wang, J.; Bi, J.; Zhang, M. A Novel Method for Testing the Fatigue Performance of Cement Stabilized Base Field Coring Samples. Constr. Build. Mater. 2021, 274, 122065. [Google Scholar] [CrossRef]

- Fedrigo, W.; Kleinert, T.R.; Núñez, W.P.; Graeff, Â.G.; Pinto da Silva Filho, L.C.; Brito, L.A.T. Shrinkage of Cold Recycled Cement-Treated Mixtures of Asphalt Pavement Materials. J. Test. Eval. 2023, 51, 2230–2244. [Google Scholar] [CrossRef]

- Euch Khay, S.E.; Euch Ben Said, S.E.; Loulizi, A.; Neji, J. Laboratory Investigation of Cement-Treated Reclaimed Asphalt Pavement Material. J. Mater. Civ. Eng. 2015, 27, 04014192-1–04014192-7. [Google Scholar] [CrossRef]

- Mandal, T.; Edil, T.B.; Tinjum, J.M. Study on Flexural Strength, Modulus, and Fatigue Cracking of Cementitiously Stabilised Materials. Road Mater. Pavement Des. 2018, 19, 1546–1562. [Google Scholar] [CrossRef]

- Mandal, T.; Tinjum, J.M.; Gokce, A.; Edil, T.B. Protocol for Testing Flexural Strength, Flexural Modulus, and Fatigue Failure of Cementitiously Stabilized Materials Using Third-Point Flexural Beam Tests. Geotech. Test. J. 2016, 39, 91–105. [Google Scholar] [CrossRef]

- Wen, H.; Muhunthan, B.; Wang, J.; Li, X.; Edil, T.; Tinjum, J.M. Characterization of Cementitiously Stabilized Layers for Use in Pavement Design and Analysis; Transportation Research Board: Washington, DC, USA, 2014; ISBN 978-0-309-30813-7. [Google Scholar]

- Fedrigo, W.; Núñez, W.P.; Visser, A.T. A Review of Full-Depth Reclamation of Pavements with Portland Cement: Brazil and Abroad. Constr. Build. Mater. 2020, 262, 120540. [Google Scholar] [CrossRef]

- Abdo, J.; Serfass, J.-P.; Pellevoisin, P. Pavement Cold In-Place Recycling with Hydraulic Binders: The State of the Art in France. Road Mater. Pavement Des. 2013, 14, 638–665. [Google Scholar] [CrossRef]

- Preteseille, M.; Lenoir, T.; Gennesseaux, E.; Hornych, P. Structural Test at the Laboratory Scale for the Utilization of Stabilized Fine-Grained Soils in the Subgrades of High Speed Rail Infrastructures: Analytical and Numerical Aspects. Constr. Build. Mater. 2014, 61, 164–171. [Google Scholar] [CrossRef]

- Fedrigo, W.; Núñez, W.P.; Castañeda López, M.A.; Kleinert, T.R.; Ceratti, J.A.P. A Study on the Resilient Modulus of Cement-Treated Mixtures of RAP and Aggregates Using Indirect Tensile, Triaxial and Flexural Tests. Constr. Build. Mater. 2018, 171, 161–169. [Google Scholar] [CrossRef]

- Kolias, S. Mechanical Properties of Cement-Treated Mixtures of Milled Bituminous Concrete and Crushed Aggregates. Mater. Struct. 1996, 29, 411–417. [Google Scholar] [CrossRef]

- Kolias, S. The Influence of the Type of Loading and Temperature on the Modulus of Elasticity of Cement-Bound Mixes of Milled Bituminous Concrete and Crushed Aggregates. Mater. Struct. 1996, 29, 543–551. [Google Scholar] [CrossRef]

- Gonzalo-Orden, H.; Linares-Unamunzaga, A.; Pérez-Acebo, H.; Díaz-Minguela, J. Advances in the Study of the Behavior of Full-Depth Reclamation (FDR) with Cement. Appl. Sci. 2019, 9, 3055. [Google Scholar] [CrossRef]

- Katsakou, M.; Kolias, S. Mechanical Properties of Cement-Bound Recycled Pavements. Proc. Inst. Civ. Eng.-Constr. Mater. 2007, 160, 171–179. [Google Scholar] [CrossRef]

- Biswal, D.R.; Sahoo, U.C.; Dash, S.R. Non-Destructive Strength and Stiffness Evaluation of Cement-Stabilised Granular Lateritic Soils. Road Mater. Pavement Des. 2020, 21, 835–849. [Google Scholar] [CrossRef]

- Biswal, D.R.; Sahoo, U.C.; Dash, S.R. Durability and Shrinkage Studies of Cement Stabilsed Granular Lateritic Soils. Int. J. Pavement Eng. 2019, 20, 1451–1462. [Google Scholar] [CrossRef]

- Biswal, D.R.; Sahoo, U.C.; Dash, S.R. Mechanical Characteristics of Cement Stabilised Granular Lateritic Soils for Use as Structural Layer of Pavement. Road Mater. Pavement Des. 2020, 21, 1201–1223. [Google Scholar] [CrossRef]

- de Paiva, C.E.L.; de Oliveira, P.C.A.; de Franco Peixoto, C. The Influence of Milling Asphalt Rates from Wearing Surface to the Flexural Strength Applied to a Recycled Layer with Portland Cement. Constr. Build. Mater. 2017, 154, 1294–1300. [Google Scholar] [CrossRef]

- Fedrigo, W.; Núñez, W.P.; Schreinert, G.G.; Kleinert, T.R.; Matuella, M.F.; Castañeda López, M.A.; Ceratti, J.A.P. Flexural Strength, Stiffness and Fatigue of Cement-Treated Mixtures of Reclaimed Asphalt Pavement and Lateritic Soil. Road Mater. Pavement Des. 2019, 22, 1004–1022. [Google Scholar] [CrossRef]

- Suebsuk, J.; Horpibulsuk, S.; Suksan, A.; Suksiripattanapong, C.; Phoo-ngernkham, T.; Arulrajah, A. Strength Prediction of Cement-Stabilised Reclaimed Asphalt Pavement and Lateritic Soil Blends. Int. J. Pavement Eng. 2019, 20, 332–338. [Google Scholar] [CrossRef]

- de Oliveira, P.C.A.; de Paiva, C.E.L. Full Depth Reclamation with Cement of Gravel Base with Lateritic Fines. Int. J. Pavement Res. Technol. 2019, 12, 546–552. [Google Scholar] [CrossRef]

- Suebsuk, J.; Kampala, A.; Waiyakorn, P.; Suksiripattanapong, C.; Chindaprasirt, P. Variations in Strength and Stiffness of Cement-Stabilized Reclaimed Asphalt Pavement and Marginal Lateritic Soil Blends in Tropical Climate. Constr. Build. Mater. 2023, 409, 134062. [Google Scholar] [CrossRef]

- Nogami, J.S.; Villibor, D.F. A New Soil Classification System for Pavement Applications. In Proceedings of the Brazilian Symposium of Tropical Soils in Engineering; COPPE/CNPq/ABMS: Rio de Janeiro, Brazil, 1981. [Google Scholar]

- Wirtgen GmbH. Wirtgen Cold Recycling Technology; Wirtgen GmbH: Windhagen, Germany, 2012. [Google Scholar]

- AASHTO T 180-01; Standard Method of Test for Moisture-Density Relations of Soils Using a 4.54-Kg (10-Lb) Rammer and a 457-Mm (18-in.) Drop. American Association of State Highway and Transportation Officials (AASHTO): Washington, DC, USA, 2025.

- Castaneda-Lopez, M.; Lenoir, T.; Sanfratello, J.P.; Thorel, L. Data-Driven Prediction of Cement-Stabilized Soils Tensile Properties. Infrastructures 2023, 8, 146. [Google Scholar] [CrossRef]

- Castaneda-Lopez, M.; Lenoir, T.; Thorel, L.; Sanfratello, J.-P. Determination of Mohr–Coulomb Failure Criterion of Cement-Treated Materials Using Mixture Design Properties. Infrastructures 2025, 10, 267. [Google Scholar] [CrossRef]

- Ait-Amir, B.; Pougnet, P.; El Hami, A. Meta-Model Development. In Embedded Mechatronic Systems 2; Elsevier: Amsterdam, The Netherlands, 2015; pp. 151–179. [Google Scholar]

- Wagner, J.R.; Mount, E.M.; Giles, H.F. Design of Experiments. In Extrusion; Elsevier: Amsterdam, The Netherlands, 2014; pp. 291–308. [Google Scholar]

- Montgomery, D.C. Design and Analysis of Experiments, 5th ed.; John Willey & Sons, Inc.: New York, NY, USA, 2001. [Google Scholar]

- Ribeiro, J.L.D.; ten Caten, C.S. Design of Experiments: Quality Monographic Series; Federal University of Rio Grande do Sul: Porto Alegre, Brazil, 2014. [Google Scholar]

- Kleinert, T.R.; Fedrigo, W.; ten Caten, C.S.; Núñez, W.P.; Ceratti, J.A.P. Application of the Design of Experiments Methodology to the Mix Design of Full-Depth Reclamation with Cement. Transportes 2019, 27, 111–127. [Google Scholar] [CrossRef]

- ASTM D6931-12; Test Method for Indirect Tensile (IDT) Strength of Bituminous Mixtures. American Society for Testing and Materials (ASTM): West Conshohocken, PA, USA, 2012.

- Kleinert, T.R. Full-Depth Reclamation of Semi-Rigid Pavements with Cement: Contribution the Development of a Mix Design Method. Master’s Dissertation, Federal University of Rio Grande do Sul, Farroupilha, Brazil, 2016. [Google Scholar]

- Franco, F.A.C.P.; Motta, L.M.G. Manual of Use of the MeDiNa Program Version 1.1.4: Introduction to the Programs; National Department of Transport Infrastructure (DNIT): Brasília, Brazil, 2020. [Google Scholar]

- Fedrigo, W.; Heller, L.F.; Brito, L.A.T.; Núñez, W.P. Fatigue of Cold Recycled Cement-Treated Pavement Layers: Experimental and Modeling Study. Sustainability 2023, 15, 7816. [Google Scholar] [CrossRef]

- Grilli, A.; Bocci, M.; Tarantino, A.M. Experimental Investigation on Fibre-Reinforced Cement-Treated Materials Using Reclaimed Asphalt. Constr. Build. Mater. 2013, 38, 491–496. [Google Scholar] [CrossRef]

- Adresi, M.; Khishdari, A.; Ahmadi, A.; Rooholamini, H. Influence of High Content of Reclaimed Asphalt on the Mechanical Properties of Cement-Treated Base under Critical Environmental Conditions. Int. J. Pavement Eng. 2019, 20, 1098–1105. [Google Scholar] [CrossRef]

- Chakravarthi, S.; Boyina, A.; Singh, A.K.; Shankar, S. Evaluation of Cement Treated Reclaimed Asphalt Pavement and Recycled Concrete Pavement Bases. Int. J. Pavement Res. Technol. 2019, 12, 581–588. [Google Scholar] [CrossRef]

- Ji, X.; Jiang, Y.; Liu, Y. Evaluation of the Mechanical Behaviors of Cement-Stabilized Cold Recycled Mixtures Produced by Vertical Vibration Compaction Method. Mater. Struct. 2016, 49, 2257–2270. [Google Scholar] [CrossRef]

- Jiang, Y.; Liu, H.; Xue, J. Fatigue Performance of Vertical Vibration Compacted Cement-Stabilized Recycled Pavement Materials. J. Test. Eval. 2018, 46, 2251–2264. [Google Scholar] [CrossRef]

- Isola, M.; Betti, G.; Marradi, A.; Tebaldi, G. Evaluation of Cement Treated Mixtures with High Percentage of Reclaimed Asphalt Pavement. Constr. Build. Mater. 2013, 48, 238–247. [Google Scholar] [CrossRef]

- Ma, T.; Wang, H.; Zhao, Y.-L.; Huang, X.-M. Laboratory Investigation on Residual Strength of Reclaimed Asphalt Mixture for Cold Mix Recycling. Int. J. Pavement Res. Technol. 2015, 8, 17–22. [Google Scholar]

- Yuan, D.; Nazarian, S.; Hoyos, L.R.; Puppala, A.J. Evaluation and Mix Design of Cement-Treated Base Materials with High Content of Reclaimed Asphalt Pavement. Transp. Res. Rec. J. Transp. Res. Board 2011, 2212, 110–119. [Google Scholar] [CrossRef]

- Grilli, A.; Bocci, E.; Graziani, A. Influence of Reclaimed Asphalt Content on the Mechanical Behaviour of Cement-Treated Mixtures. Road Mater. Pavement Des. 2013, 14, 666–678. [Google Scholar] [CrossRef]

- DNIT 167/2013–ES; Pavements: Full-Depth Reclamation with Portland Cement–Construction Specification. National Department of Transport Infrastructure (DNIT): Brasília, Brazil, 2013.

- Xiao, F. Development of Fatigue Predictive Models of Rubberized Asphalt Concrete (RAC) Containing Reclaimed Asphalt Pavement (RAP) Mixtures. Ph.D. Dissertation, Clemson University, Clemson, SC, USA, 2006. [Google Scholar]

| Cement, C (%) 1 | RAP (%) 1 | Mixture Code | OMC (%) | MDUW (kN/m3) |

|---|---|---|---|---|

| 2 (−1) | 20 (−1) | 2 C-20 RAP | 14.2 | 17.10 |

| 2 (−1) | 50 (0.2) | 2 C-50 RAP 2 | 8.6 | 19.30 |

| 2 (−1) | 70 (+1) | 2 C-70 RAP 2 | 7.1 | 20.73 |

| 4 (0) | 20 (−1) | 4 C-20 RAP | 14.2 | 17.41 |

| 4 (0) | 50 (0.2) | 4 C-50 RAP | 10.9 | 19.59 |

| 4 (0) | 70 (+1) | 4 C-70 RAP | 10.1 | 20.10 |

| 6 (+1) | 20 (−1) | 6 C-20 RAP | 12.7 | 18.11 |

| 6 (+1) | 50 (0.2) | 6 C-50 RAP 2 | 12.8 | 19.43 |

| 6 (+1) | 70 (+1) | 6 C-70 RAP 2 | 8.2 | 21.03 |

| Cement, C (%) 1 | RAP (%) 1 | Mixture Code | OMC (%) | MDUW (kN/m3) |

|---|---|---|---|---|

| 1.17 (−α = −1.414) | 50 (0) | 1.17 C-50 RAP | 8.6 | 19.30 |

| 2 (−1) | 20 (−1) | 2 C-20 RAP | 14.2 | 17.10 |

| 2 (−1) | 80 (+1) | 2 C-80 RAP | 7.1 | 20.73 |

| 4 (0) | 7.57 (−α = −1.414) | 4 C-7.57 RAP | 18.0 | 17.57 |

| 4 (0) | 50 (0) | 4 C-50 RAP | 10.9 | 19.59 |

| 4 (0) | 92.43 (+α = + 1.414) | 4 C-92.43 RAP | 5.8 | 21.64 |

| 6 (+1) | 20 (−1) | 6 C-20 RAP | 12.7 | 18.11 |

| 6 (+1) | 80 (+1) | 6 C-80 RAP | 8.2 | 21.03 |

| 6.83 (+α = +1.414) | 50 (0) | 6.83 C-50 RAP | 12.8 | 19.43 |

| Layer | Material | Thickness (mm) | Modulus (MPa) | Poisson’s ratio |

|---|---|---|---|---|

| Wearing course | Asphalt concrete (Asphalt PEN 30/45 #12.5 mm Sepetiba) 1 | 150 | 9000 | 0.30 |

| Base | Stabilized (studied CRCTMs) | 200 | Table 4 | 0.25 |

| Subbase | Granular (Graded crushed stone—Gneiss C5) 1 | 200 | 381 | 0.35 |

| Subgrade | Silty soil (Brazilian MCT classification NS’) 1,2 | - | 189 | 0.45 |

| Mixture | Resilient Modulus (MPa) | FTS (MPa) 1 | ITS (MPa) 1 | Fatigue Model 2 | ||

|---|---|---|---|---|---|---|

| k1 | k2 | R 2 | ||||

| 4 C-20 RAP | 2041 | 0.65 | 0.26 | 9.8504 | −40.028 | 0.90 |

| 4 C-50 RAP | 3505 | 0.96 | 0.52 | 10.527 | −43.446 | 0.78 |

| 4 C-70 RAP | 4163 | 0.93 | 0.70 | 9.0449 | −28.538 | 0.69 |

| Mixture | FTS (MPa) | Standard Deviation (MPa) |

|---|---|---|

| 2 C-20 RAP | 0.28 | 0.05 |

| 2 C-50 RAP | 0.49 | 0.03 |

| 2 C-70 RAP | 0.75 | 0.20 |

| 4 C-20 RAP | 0.65 | 0.06 |

| 4 C-50 RAP | 0.96 | 0.05 |

| 4 C-70 RAP | 0.93 | 0.09 |

| 6 C-20 RAP | 0.61 | 0.07 |

| 6 C-50 RAP | 0.90 | 0.11 |

| 6 C-70 RAP | 1.43 | - 1 |

| Term | Coefficient | p-Value |

|---|---|---|

| Constant | −0.118 | 2.2 × 10−14 |

| Cement (%) | 0.1068 | 2.0 × 10−5 |

| RAP (%) | 0.00948 | 4.7 × 10−5 |

| Mixture | 3-Day ITS (MPa) | 7-Day ITS (MPa) | 14-Day ITS (MPa) | 28-Day ITS (MPa) |

|---|---|---|---|---|

| 1.17 C-50 RAP | 0.22 | 0.17 | 0.10 | 0.05 |

| 2 C-20 RAP | 0.34 | 0.26 | 0.18 | 0.16 |

| 2 C-80 RAP | 0.44 | 0.52 | 0.47 | 0.58 |

| 4 C-7.57 RAP | 0.38 | 0.42 | 0.26 | 0.42 |

| 4 C-50 RAP | 0.56 [0.09] | 0.64 [0.09] | 0.42 [0.04] | 0.50 [0.05] |

| 4 C-92.43 RAP | 0.48 | 0.72 | 0.85 | 0.86 |

| 6 C-20 RAP | 0.37 | 0.24 | 0.21 | 0.22 |

| 6 C-80 RAP | 0.71 | 0.81 | 0.98 | 0.84 |

| 6.83 C-50 RAP | 0.57 | 0.63 | 0.70 | 0.84 |

| Term | Coefficient | p-Value |

|---|---|---|

| Constant | 0.5234 | 0.000 |

| Cement (%) | 0.1990 | 1.5 × 10−14 |

| RAP (%) | 0.2627 | 4.4 × 10−12 |

| Cement (%) * Cement (%) | −0.1148 | 0.002 |

| Cement (%) * RAP (%) | 0.1648 | 0.001 |

| RAP (%) * Curing time (days) | 0.1083 | 0.006 |

| Mixture | Initially Defined Structure | Structure Designed Using FTS | Structure Designed Using ITS | |||

|---|---|---|---|---|---|---|

| WC (mm) | BL (mm) | WC (mm) | BL (mm) | WC (mm) | BL (mm) | |

| 4 C-20 RAP | 150 | 200 | 150 | 450 | 500 | 450 |

| 4 C-50 RAP | 150 | 200 | 150 | 400 | 380 | 400 |

| 4 C-70 RAP | 150 | 200 | 150 | 430 | 260 | 430 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fedrigo, W.; Kleinert, T.R.; Schreinert, G.G.; Brito, L.A.T.; Núñez, W.P. Statistical Analysis of the Tensile Strength of Cold Recycled Cement-Treated Materials and Its Influence on Pavement Design. Infrastructures 2025, 10, 284. https://doi.org/10.3390/infrastructures10110284

Fedrigo W, Kleinert TR, Schreinert GG, Brito LAT, Núñez WP. Statistical Analysis of the Tensile Strength of Cold Recycled Cement-Treated Materials and Its Influence on Pavement Design. Infrastructures. 2025; 10(11):284. https://doi.org/10.3390/infrastructures10110284

Chicago/Turabian StyleFedrigo, William, Thaís Radünz Kleinert, Gabriel Grassioli Schreinert, Lélio Antônio Teixeira Brito, and Washington Peres Núñez. 2025. "Statistical Analysis of the Tensile Strength of Cold Recycled Cement-Treated Materials and Its Influence on Pavement Design" Infrastructures 10, no. 11: 284. https://doi.org/10.3390/infrastructures10110284

APA StyleFedrigo, W., Kleinert, T. R., Schreinert, G. G., Brito, L. A. T., & Núñez, W. P. (2025). Statistical Analysis of the Tensile Strength of Cold Recycled Cement-Treated Materials and Its Influence on Pavement Design. Infrastructures, 10(11), 284. https://doi.org/10.3390/infrastructures10110284