Occupational Exposure to Mineral Dust in Mining and Earthmoving Works: A Scoping Review

Abstract

:1. Introduction

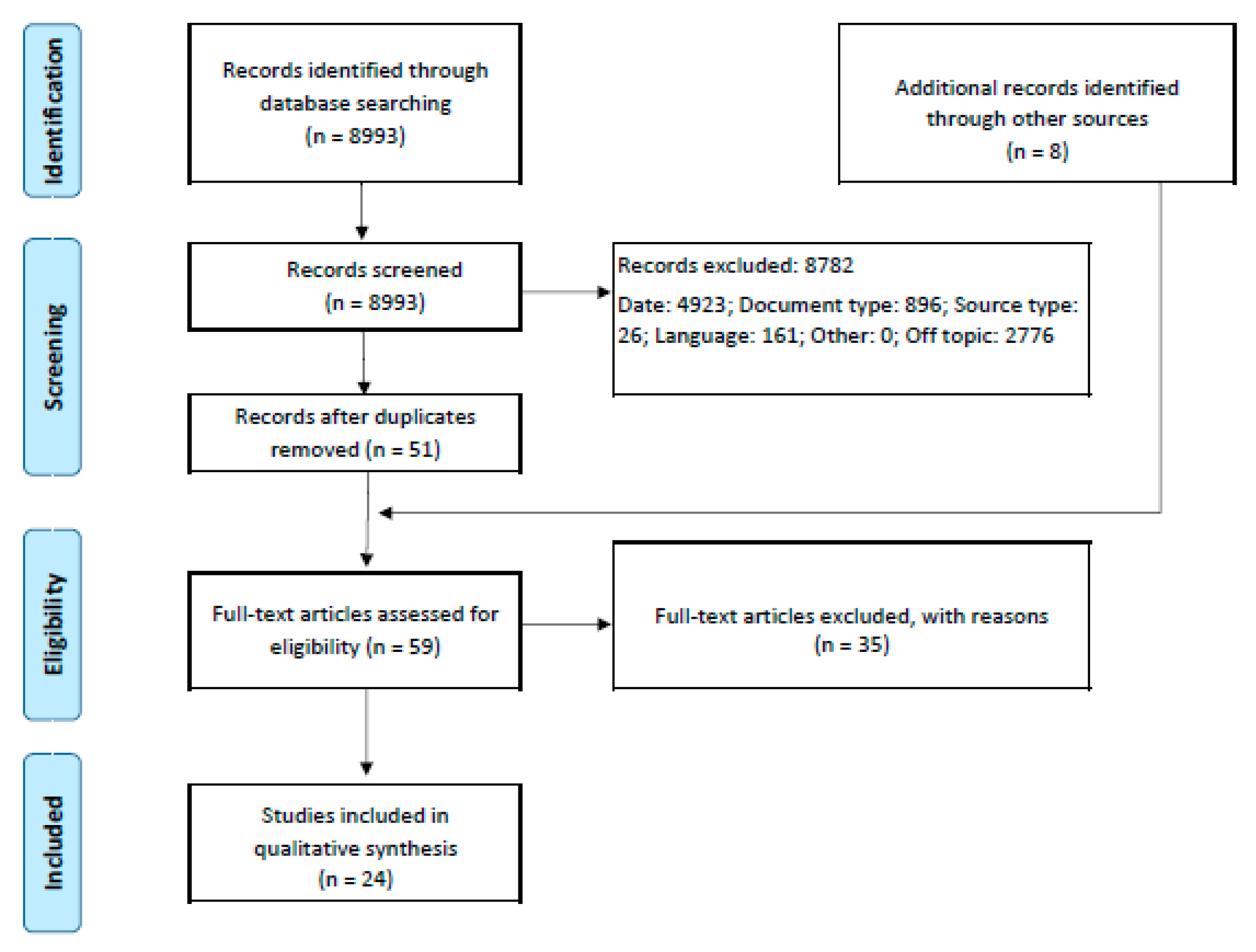

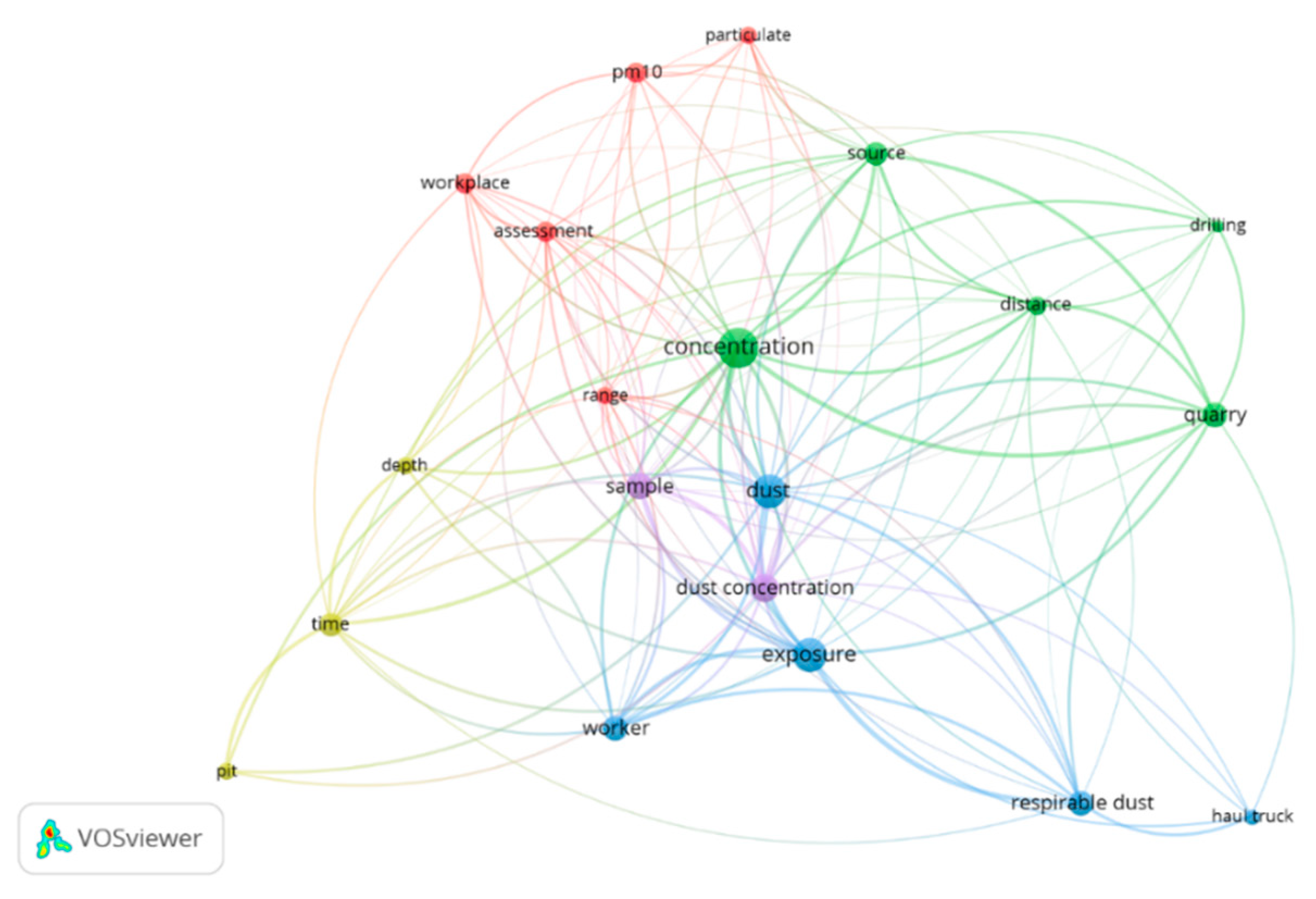

2. Methodology

3. Results

- Job-related variables: activity, job category, site;

- Engineering variables: equipment, transport system;

- Technical variables: distance;

- Physical variables: season, weather.

4. Discussion

4.1. Job-Related Variables

4.1.1. Activity

4.1.2. Job Category

4.1.3. Site

4.2. Engineering Variables

4.2.1. Equipment

4.2.2. Transport System

4.3. Technical Variables

Distance

4.4. Physical Variables

4.4.1. Season

4.4.2. Weather

4.5. Other Variables

4.6. Bias

4.7. Study Limitations

5. Conclusions

Practical Implications

- (1)

- A comprehensive description of the occupational setting;

- (2)

- Analysis of the mineralogical characteristics of the hazardous agent;

- (3)

- Measurement of the exposure to respirable dust, according to international standards, in the workers’ breathing zone during a full shift.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Paper-Related Data | General Information | People-Related Data | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Study | Objective | Substance | Time Period | Ethical Committee | Informed Consent | Population | Sample | Age (Years) | Sex | Control Group |

| [28] | To characterise dust emission and to identify locations of pollution sources | Dust (TSP, PM2.5, PM10) | NM | NA | NA | NM | NM | NM | NM | NM |

| [31] | To characterise dust generated from haul trucks | Dust (PM10,) | Summer of 2002 | NM | NM | NM | NM | NM | NM | NM |

| [41] | To assess occupational exposure to dust | Dust (respirable), silica | 1994–2005 | NA | NA | NM | NM | NM | NM | NM |

| [42] | To determine dust concentrations | Dust (respirable, inhalable) | NM | NM | NM | NM | NM | NM | NM | NM |

| [43] | To estimate annual emissions from construction work | Dust (PM1, PM2.5, PM10) | Earthworks: 3 days, road construction: 3 days | NA | NA | NA | NA | NA | NA | NA |

| [44] | To develop models to predict respirable dust-particle concentration | Dust (PM2.5, PM10) | Pre-summer, summer and winter | NM | NM | NM | NM | NM | NM | NM |

| [45] | To investigate particulate-matter concentration profiles | Dust (PM 10–20 μm, 4–10 μm, and <4 μm) | 21–23 May 2013 (Location 1), 4–6 June 2013 (Location 2), 12–24 October 2013 (Location 3) | NM | NM | NM | NM | NM | NM | NM |

| [46] | To determine exposure levels to respirable dust and respirable crystalline silica of crusher operators | Dust, quartz | NM | Yes | NM | 200 | 70 | NM | NM | NM |

| [47] | To assess levels of exposure to respirable dust and respirable silica | Dust (respirable), silica (respirable) | Mine 1: January–April 2010; Mine 2: November 2010–February 2011; Mine 3: February–May 2011; Mine 4 June 2010; Mine 5: July–September 2010; Mine 6: October 2010 | Yes | Yes | NM | 232 | NM | NM | NM |

| [30] | To characterise exposure to respirable dust | Dust, quartz | 2012–2014 | NM | NM | NM | 69 | NM | NM | NM |

| [48] | To study occupational health exposure to physical and chemical hazards | Dust (PM10) | NM | NA | NA | NM | NM | NM | NM | NM |

| [49] | To study particulate emission | Dust (PM2.5, PM 0.3–20 µm, PM10) | NM | NA | NA | NA | NA | NA | NA | NA |

| [50] | To study respiratory impairment and personal respirable exposure to dust | Dust | NM | NM | Yes | NM | 112 | 21–60 | Male, female | NM |

| [25] | To study inhalable, thoracic, and alveoli particle concentrations | Dust (PM 10–20 μm, 4–10 μm, and <4 μm) | Winter | NA | NA | NA | NA | NA | NA | NA |

| [51] | To study dust emission (and dispersion) from drilling in natural stone quarries | Dust (TSP, PM1, PM2.5, PM10) | Winter | NM | NM | NM | NM | NM | NM | NM |

| [6] | NM | Dust (PM2.5, PM10) | Summer and winter 2015–2016 | NA | NA | NA | NA | NA | NA | NA |

| [52] | To study the concentration and distribution of PM2.5 and PM10 in open-pit mines | Dust (PM2.5, PM10) | NM | NA | NA | NA | NA | NA | NA | NA |

| [9] | To predict dust concentrations from several mine operations | Dust (PM2.5, PM10) | 7–22 December 2015, 30 January to 16 February 2016 | NA | NA | NA | NA | NA | NA | NA |

| [53] | To study respirable dust concentrations and free silica content | Dust (respirable) | September 2013 (post-monsoon period), February 2014 (pre-monsoon period) | NM | Yes | NM | NM | NM | NM | NM |

| [8] | To study dust emission (and dispersion) from crushing in open-pit quarries | Dust (TSP, PM1, PM2.5, PM10) | Winter | NA | NA | NM | NM | NM | NM | NM |

| [32] | To study exposure levels at four workplaces | Dust | August 2016–October 2016 | NM | NM | NM | NM | NM | NM | NM |

| [54] | To study dust-exposure risk at two wasterock crusher plants | Dust (inhalable and respirable) | October 2018 | NM | NM | 100 | 34 | 37 years (range 23 to 68 years) | Male, female | NM |

| [55] | To study emission of respirable dust from stone quarrying, potential health effects, and its management | Dust (PM2.5 and PM10 | June 2019 | NA | NA | NA | NA | NA | NA | NA |

| [56] | To evaluate potential dust emissions in an open-pit coal mine | Dust (PM2.5, PM4, PM10) | NM | NA | NA | NA | NA | NA | NA | NA |

| Study | Occupational Exposure | |||||||

|---|---|---|---|---|---|---|---|---|

| Standards | Duration of the Occupational Exposure | Source of Exposure | Methodology | Measuring Equipment | Equipment Calibration | Sampling Time | Sampling Frequency | |

| [28] | NM | NM | NM | Dust was collected at different distances: 0.05, 0.08, 0.1, 0.15, 0.2, 0.3, 0.4, 1, 7, 10, 11, and 15 km from the extraction outline. Additionally, five more monitoring stations were considered. The particle sizes were determined, and dust composition was analysed through chromatography. | Graseby high-volume sampler (GM-2000), Kimoto PM10 | NM | 1 h | 3 times per season and at each receptor |

| [31] | ASTM standards | NM | Haul truck | The study was conducted in two sites measuring approximately 30 m: a surface-stone quarry (Virginia) and a coal-preparation plant (Pennsylvania). The first had a slight grade and was the main access to the pit. The second was flat and was the main access to the waste dump. Seven monitoring stations were placed for data collection. However, only two were considered for respirable dust: one adjacent to the road and one on the opposite side of the road. | Personal Data RAM (MIE), Personal sampling pumps (Escort ELF), Cascade Impactor | NM | 6–7 h per day | Every 2 s |

| [41] | NM | NM | Overburden loading, stockyard, coal loading, drilling, and coal-handling plant | Data were collected from the Can Lignite Corporation once a year at five different locations. Dust conditions were assessed, and dust samples were dried and weighed. Additionally, silica content was determined. An ANOVA statistical test was used for data treatment. | Gravimetric dust equipment (Casella AFC 123), infrared spectrophotometer | NM | 4 h | 1 per year |

| [42] | NIOSH 7500 | NM | Mountain slash, crusher, administration, road | Samples of total and respirable dust were collected by the gravimetric method. The number of collected samples was 19 for mountain slash (excavation), 19 for various crushers, 9 for administration, and 5 for road. SPSS was used for data treatment. | Sampling pump (SKC) | NM | NM | NM |

| [43] | NM | NA | Earthworks, equipment | All measurements were performed between 20 and 60 m downwind of the sites. Measurements were taken at a height of 4 m. Overall meteorological data were also collected, as well as trace gases (NOx, CO, SO2, O3, and CO2). Total particulate polycyclic aromatic hydrocarbon (p-PAH) mass concentration was recorded. Particle size distributions were analysed by a fast-mobility particle-sizer spectrometer (FMPSS) and an optical particle counter (OPC). | Mobile aerosol research laboratory (MoLA), weather station (WXT520), air quality monitoring system (Airpointer and LI840), FMPSS (Model 3091), OPC (Grimm Aerosoltechnik) | Yes | NM | NM |

| [44] | NM | NM | Drilling | Measurements were collected at different distances from the drilling site, considering different wind directions in three phases: (1) pre-summer, (2) during summer, (3) during winter. Monitoring of air quality was carried out, and both this parameter and dust emission were registered at different distances from the drilling operations, with different wind directions. | Personal dust monitor (5), point sampler (2), meteorological monitoring station | NM | 1 h | Hourly basis |

| [45] | NM | NM | Drilling, excavation, loading, transport | Measurements were taken at different benches (heights) of the open casts, Malanjkhand Copper Project (MCP), Kiriburu Iron OreMine (KIOM), and Meghahatuburu Iron Ore Mine (MIOM). Wind speed and wind direction were also registered. In MCP, the activities were drilling, excavation, loading (shovel), and transport (dumper). Sampling occurred at four benches located at 412, 448, 460, and 580 mRL. In KIOM, these sampling points were located at 818 mRL, and in MIOM, the sampling points were at 846 mRL. | Portable aerosol spectrometer (model 1.108), portable weather stations (Watch Dog 2000 Series) | NM | 30 min | 1 min |

| [46] | NIOSH Manual Analytical Method No. 0600 | NM | Crusher | Long-term personal breathing-zone samples were collected for each shift. Air velocity and humidity were also measured to determine temperature and humidity during the field campaign. These measurements were taken at several locations, during the morning and afternoon. The samples were analysed at an independent laboratory. Data analysis was carried out using Industrial Hygiene Statistic (IH STAT V. 235). | Sampling pump (SKC), anemometer and hygrometer (TSI, 8386-M-GB) | Yes | 8 h | NM |

| [47] | NIOSH 0600, NIOSH 7500 | NM | Mining, crushing, concentrating, pelletising, mobile shop, stationery shop, office/control | Each worker wore a personal air-sampling pump on the waist, with the sampler located in the breathing zone for 70% of their work shift. For each worker, the study was conducted during three different shifts, and one blank sample per day was also collected (quality control). The data received statistical treatment through ANOVA analysis. The information was grouped in SEG form. | Personal air-sampling pump (Apex Pro pump, Casella) | Yes | NM | NM |

| [30] | DGMS guidelines for conducting respirable airborne dust survey | NM | Drill operator, shovel operator, dozer operator, cable man | Dust measurements of 11 categories of workers were collected from an open cast and underground works. Respirable dust collected on the filter was analysed using the Fourier transform infrared spectrometry. Particle-size distribution and quartz content were also analysed. | Personal dust sampler (Sidekick, SKC), X-ray diffractometry (model Ultima-IV), SEM-EDX(FE-SEMSupra 55), Mastersizer 2000 | Yes | NM | NM |

| [48] | NM | NM | 33 different site locations | Measurements were collected at 33 sites (both surface and underground). | NM | NM | NM | NM |

| [49] | NM | NM | Different site locations | Three techniques were adopted: (1) low-volume gravimetric technique to measure longer-term concentrations beyond the boundary of each mine; (2) whenever an interesting activity occurred, an optical particulate monitor was used (particulate range: 0.3–20 µm); (3) microscopy analysis. | (1) MiniVol portable air samplers (Airmetrics); (2) optical particulate monitor (1.105 Grimm); (3) NM | (1) Yes; (2) NM; (3) NM | 18 min–22 days | NM |

| [50] | NM | At least 1 year | Among different job groups (truck, excavator, and dozer operators, quality controller), different activities (haulage, loading materials, clearance and pushing materials, measuring the depth of holes) | Measurements were collected using air sampling pumps on similar exposure groups at breathing level. A questionnaire was used to determine respiratory symptoms, and lung function was measured using spirometry. SPSS was used for data treatment. | Air sampling pumps (Aircheck XR 5000), spirometer (KoKo Legend S× 1000) | Yes | Full shift | NM |

| [25] | NM | NA | Different site locations | Seven residential sites (RS) and ten mine locations (M) near the two open-cast mines were considered. R1–R3 were located near the coal transportation road from mine 1, R4 and R6 were near mine 2 open cast, R5 was located near a road used for coal transportation by both mines, and R7 was located away from the mining area. Meteorological parameters, such as relative humidity, temperature, wind speed, and wind direction, were registered. SPSS was used for data treatment. | Aerosol spectrometer (Model 1.108), portable weather station (Model WatchDog 2000) | NM | 6–8 h | 1 min |

| [51] | NM | NM | Drilling | Dust mass concentrations measurements were collected near the drills and at the same level at different distances downwind, upwind, and side-wind. The sampling height was 1.5 m (approximately breathing level). Weather data, such as temperature, humidity, absolute and relative pressure, wind speed and direction, wind-gust speed, and rainfall, were also registered. | Nephelometers (Turnkey Osiris), weather station (EasyWeather) | NM | 15 min | 5 s |

| [6] | National Ambient Air Quality Standard (NAAQS 2009), I.S.: 5182 Part XIV (2000) | NA | Different site locations | Measurements were collected from eight monitoring stations. PM10 and PM2.5 concentrations were calculated based on the differences in the weight of the filters before and after sampling. | Respirable dust samplers (Envirotech APM 460 NL and Envirotech APM 550) | NM | 24 h | NM |

| [52] | NM | NM | Mining, transportation, dumping | PM measurements were monitored at three sites in the mine: (1) in the pit, away from the operating equipment; (2) near the mining and transport equipment; (3) around the pit. The data received statistical treatment. | Beta-ray particle monitor | NM | NM | 1 min |

| [9] | National Ambient Air Quality Standard (NAAQS) | NA | Different site locations | Measurements of baseline air quality were monitored at 25 different station locations. The resulting data were used to develop emission models. | NM | NM | 24 h | NM |

| [53] | DGMS sampling guidelines | NM | Different site locations, activity | Measurement of respirable dust and determination of free silica content: 12 dust samples were collected in September 2013 (five area samples and seven personal samples). Another 12 were collected in February 2014 (six area samples and six individual samples). The equipment was placed between 5–15 m away from the worker for area sampling, at breathing level height. For personal sampling, the equipment was attached to the worker for an entire shift. Silica estimation was carried out through the Fourier transform infrared (FTIR) spectroscopy. | Personal dust sampler (Sidekick 51Ex) | Yes | 6–7 h per day | NM |

| [8] | NM | NA | Crushing | Measurements were taken at different distances from the crushers, from downwind, upwind, and crosswind. The setup was conducted under real conditions and at crusher level during daylight. Background concentrations were collected at each quarry during the night. | Nephelometers (Turnkey Osiris), weather station (EasyWeather) | NM | 15 min | 5 s |

| [32] | Standard specifications of air sampling for hazardous substances monitoring in the workplace, Ministry of Health 2004 | NM | Coalface, heading face, shotcrete point, trans-shipment | Measurements were collected three times: 10-10 h 15, 14-14 h 15, 17 h-17 h 15 every working day. A total of 582 dust samples were taken: 140 coal face, 168 heading face, 124 shotcrete point, 150 trans-shipment points. | Dust sampler (HXF-35) | Yes | 15 min | NM |

| [54] | NIOSH 7602 | Facility A: 36.8 years old, Facility B: 36.9 years old | Crusher plant: crushing, loading, offloading, screening, final storage, transporting, cleaning, water sprayer, diesel attendant, supervising/foreman, weighing bridge, welding | The protocol was divided into three parts: (1) walkthrough observation, (2) self-administered questionnaire, (3) static dust sampling (18 dust samples: nine inhalable and nine respirable). Statistical analysis was carried out. | Multi-fraction Institute of Occupational Medicine (IOM) samplers | Yes | 8 h | NM |

| [55] | NM | NA | Haul road, crushing area, pit area | Samples were collected from four locations. Ambient temperature, wind speed, humidity, and dominant wind direction were also registered. The instrument was placed at a height of 1.5 m from the ground. | Portable microprocessor-based particulate monitor (HAZDUST-EPAM 5000 model) | NM | 1 h | 60 s |

| [56] | ISO-589, 1981, ISO-1171, 1976, ISO-562, 1974, ASTM D-3286, D-3302M, D3174–12 | NA | Coal-working fronts, tailings-handling sites, road-traffic sites | Samples of deposited dust were collected in trays left at each location for 30 min until reaching 200–500 g. Passive stubs were also used for 1 h. After, they were analysed for particle size and geochemical and mineralogical patterns. Additionally, online measurements of ambient air concentrations of particulate matter, black carbon, and ultrafine particles were performed in the same mine zones where DD was sampled. | Passive stubs | NM | 1 h | NM |

| Study | Prevalence | Main Findings | ||||

|---|---|---|---|---|---|---|

| Questionnaire | Validation | Reported Symptoms | Reported Disease(s) | Results | Limitations | |

| [28] | NA | NA | NA | NA | Limestone exploitation processes cause high dust-emission rates, where the PM2.5/TSP is between 0.15 and 0.28 and PM10/TSP is between 0.31 and 0.78. The study determined that the best control measure is spraying water. | NM |

| [31] | NA | NA | NA | NA | A total of 14.5% of the airborne dust generated from haul trucks consisted of material under 10 μm, and 3.5% was material under 3.5 μm. A total of 85.5% of the dust consisted of larger particles that do not pose a (respirable) threat to the truck operator. The time period of following a truck with maximum exposure occurred between 4 and 15 s. | NM |

| [41] | NA | NA | NA | NA | Activities leading to higher dust emissions were, ordered highest–lowest): drilling, coal-handling plant, stockyard, overburden loading, and coal loading. The measured values were maintained below the Turkish standard; however, they were above the international standards. | NM |

| [42] | NM | NM | NM | NM | The highest respirable dust concentration was measured in the extraction section (10.6 mg·m−3), and the lowest concentration was measured in the administration section (4.02 mg·m−3). The highest total dust concentration was measured in the crusher section (94.3 mg·m−3), and the lowest concentration was measured in the administration section (16.6 mg·m−3). | NM |

| [43] | NA | NA | NA | NA | Emission factors for PM10 were related to earthworks and plate-compactor under dry weather conditions. Comparing emissions under dry and wet weather conditions before and after wetting the ground showed that dust can be reduced to a significant degree. | NM |

| [44] | NA | NA | NA | NA | Measured dust concentrations were between 693 ug·m−3 and 126 ug·m−3. It was confirmed that dust spread up to 80–100 m from the source. | NM |

| [45] | NA | NA | NA | NA | No relation was found between PM concentration and wind speed. The inhalable fraction of PM varied in the range of 37–52%. The fraction of thoracic PM was between 31–36%, and alveoli PM was between 17–29%. | NM |

| [46] | NA | NA | NA | NA | Overall mean worker exposure to respirable dust was 0.426, and to respirable silica was 0.091 mg m−3. | NM |

| [47] | NM | NM | NM | NM | The highest average concentrations of respirable dust were measured in Mine 1, and the lowest were measured in Mine 6. There was little variability across the results for the six mines. | Not all SEGs were present at the all mines. Some samples were excluded: three were overloaded with particles, and six exhibited low sampling volume. Some samples fell outside of the limit of detection (LOD). |

| [30] | NM | NM | NM | NM | Workers in open-cast mines are exposed to high levels of respirable dust. Considering that lower the particles indicate the harmfulness level, the job categories can be “ordered” (from highest to lowest): machine operator, drill man (UG), roof bolter (UG), drill operator (OC), SDL operator (UG), dozer operator (OC), belt operator (UG), shovel operator (OC), explosive carrier (UG), trammer (U.G.), and cable man (UG/OC). | NM |

| [48] | NA | NA | NA | NA | All the measured values were under the permissible level, except for access to the underground mine. | NM |

| [49] | NA | NA | NA | NA | Results are in the form of percentages. Particulate size fractions were found to vary according to mine activities. | Due to technical limitations, direct comparison of the optical-derived source-concentration data is not meaningful. |

| [50] | Questionnaire on respiratory symptoms | Yes | Cough, phlegm, breathlessness, wheezing, chest tightness | NM | The results show that the overall dust exposure geometric mean was 0.26 mg·m−3 over a mean sampling period of 8 h (ranging between 7 and 11 h). The results regarding respiratory symptoms were: phlegm (49.1%), breathlessness (42.9%), cough (37.5%), wheezing (18.8%), and chest tightness (10.7%). | NM |

| [25] | NA | NA | NA | NA | The results showed that the average PM concentrations in mining sites were 1.2–2 times the concentrations at residential sites. PM peak concentrations were observed during peak production time. | NM |

| [51] | NA | NA | NA | NA | Dust concentrations were highest at downwind points, and the lowest concentrations were measured upwind from the drill. Increasing wind speed led to decreased dust concentration. Drilling produces the most coarse dust particles (TSP and PM10). | Nephelometer capacity is not very high when measuring all sizes of particles at once. |

| [6] | NA | NA | NA | NA | The results showed higher concentrations of PM10 and PM2.5 during the winter season. Mining operations contributed to larger fractions of dust particles. | NM |

| [52] | NA | NA | NA | NA | The results showed that dust concentration around working mining equipment is very high. | NM |

| [9] | NA | NA | NA | NA | The results of the study were modelling predictions using the baseline concentrations and models. | NM |

| [53] | NA | NA | NA | NA | Although every measurement was below 3 mg·m−3, concentrations exceeded 50% and 75% of the total value at some monitoring stations. | The study was limited to 24 dust samples. |

| [8] | NA | NA | NA | NA | Results showed that dust concentration decreased with increasing distance with all wind directions and all size categories (TSP, PM10, PM2.5 and PM1). The decrease was most pronounced in the upwind direction. | Nephelometer capacity is not very high when measuring all sizes of particles at once. |

| [32] | NA | NA | NA | NA | Average dust concentrations ranged from 1.29 to 19.38 mg·m−3. | NM |

| [54] | Yes | Yes | NM | NM | Results showed that dust concentrations in Facility B, when compared to Facility A, were higher. The highest levels of respirable dust for both facilities were found at the feeder stations. | NM |

| [55] | NA | NA | NA | NA | The results showed that hauling mined material and crushing activities are associated with the greatest dust generation of PM2.5. | NM |

| [56] | NA | NA | NA | NA | Results show that there are considerable differences in particle size and composition between locations. In the working fronts, there are chemical elements, such as Nb, Th, Cr, Sr, Li, As, Pb, Cu, Zr and Ni, mostly attributed to mining machinery, tyre and brake-wear emissions, and deposition of dust emitted from gangue working zones. | NM |

References

- Gautam, S.; Patra, A.K.; Sahu, S.P.; Hitch, M. Particulate matter pollution in opencast coal mining areas: A threat to human health and environment. Int. J. Min. Reclam. Environ. 2016, 32, 75–92. [Google Scholar] [CrossRef] [Green Version]

- Karanasiou, A.; Moreno, N.; Moreno, T.; Viana, M.; de Leeuw, F.; Querol, X. Health effects from Sahara dust episodes in Europe: Literature review and research gaps. Environ. Int. 2012, 47, 107–114. [Google Scholar] [CrossRef] [PubMed]

- Prakash, B.B.; Kecojevic, V.; Lashgari, A. Analysis of dust emission at coal train loading facility. Int. J. Min. Reclam. Environ. 2018, 32, 56–74. [Google Scholar] [CrossRef]

- Sairanen, M.; Rinne, M.; Selonen, O. A review of dust emission dispersions in rock aggregate and natural stone quarries. Int. J. Min. Reclam. Environ. 2018, 32, 196–220. [Google Scholar] [CrossRef]

- Katra, I. Comparison of diverse dust control products in wind-induced dust emission from unpaved roads. Appl. Sci. 2019, 9, 5204. [Google Scholar] [CrossRef] [Green Version]

- Tripathy, D.P.; Dash, T.R. Assessment of particulate and trace element pollution in airborne dust around a highly mechanized opencast coal mine in talcher, odisha. J. Min. Sci. 2018, 54, 697–708. [Google Scholar] [CrossRef]

- Poinen-Rughooputh, S.; Rughooputh, M.S.; Guo, Y.; Rong, Y.; Chen, W. Occupational exposure to silica dust and risk of lung cancer: An updated meta-analysis of epidemiological studies. BMC Public Health 2016, 16, 1137. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sairanen, M.; Rinne, M. Dust emission from crushing of hard rock aggregates. Atmos. Pollut. Res. 2019, 10, 656–664. [Google Scholar] [CrossRef]

- Chaulya, S.K.; Trivedi, R.; Kumar, A.; Tiwary, R.K.; Singh, R.S.; Pandey, P.K.; Kumar, R. Air quality modelling for prediction of dust concentrations in iron ore mines of Saranda region, Jharkhand, India. Atmos. Pollut. Res. 2019, 10, 675–688. [Google Scholar] [CrossRef]

- Abdollahisharif, J.; Bakhtavar, E.; Nourizadeh, H. Monitoring and assessment of pollutants resulting from bench-blasting operations. J. Min. Environ. 2016, 7, 109–118. [Google Scholar] [CrossRef]

- Arrandale, V.H.; Kalenge, S.; Demers, P.A. Silica exposure in a mining exploration operation. Arch. Environ. Occup. Health 2018, 73, 351–354. [Google Scholar] [CrossRef] [PubMed]

- Bang, K.M.; Mazurek, J.M.; Wood, J.M.; White, G.E.; Hendricks, S.A.; Weston, A. Silicosis Mortality Trends and New Exposures to Respirable Crystalline Silica—United States, 2001–2010. MWR. Morb. Mortal. Wkly. Rep. 2015, 64, 117–120. [Google Scholar]

- Andraos, C.; Utembe, W.; Gulumian, M. Exceedance of environmental exposure limits to crystalline silica in communities surrounding gold mine tailings storage facilities in South Africa. Sci. Total Environ. 2018, 619–620, 504–516. [Google Scholar] [CrossRef] [PubMed]

- Gonzalez-Garcia, M.; Caballero, A.; Jaramillo, C.; Torres-Duque, C.A. Chronic bronchitis: High prevalence in never smokers and underdiagnosis—A population-based study in Colombia. Chron. Respir. Dis. 2018, 16, 1479972318769771. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Markovič Baluchová, B.; Bačík, P.; Mamová, A. The health impact of mineral dust air pollution on the global and local scale (on the example from Slovakia). Neuroendocrinol. Lett. 2019, 40, 24–28. [Google Scholar]

- Bluvshtein, N.; Mahrer, Y.; Sandler, A.; Rytwo, G. Evaluating the impact of a limestone quarry on suspended and accumulated dust. Atmos. Environ. 2011, 45, 1732–1739. [Google Scholar] [CrossRef]

- Utembe, W.; Faustman, E.M.; Matatiele, P.; Gulumian, M. Hazards identified and the need for health risk assessment in the South African mining industry. Hum. Exp. Toxicol. 2015, 34, 1212–1221. [Google Scholar] [CrossRef] [Green Version]

- Yorio, P.L.; Laney, A.S.; Halldin, C.N.; Blackley, D.J.; Moore, S.M.; Wizner, K.; Radonovich, L.J.; Greenawald, L.A. Interstitial lung diseases in the U.S. mining industry: Using MSHA data to examine trends and the prevention effects of compliance with health regulations, 1996–2015. Risk Anal. 2018, 38, 1962–1971. [Google Scholar] [CrossRef]

- Khaniabadi, Y.O.; Polosa, R.; Chuturkova, R.Z.; Daryanoosh, M.; Goudarzi, G.; Borgini, A.; Tittarelli, A.; Basiri, H.; Armin, H.; Nourmoradi, H.; et al. Human health risk assessment due to ambient PM10 and SO2 by an air quality modeling technique. Process Saf. Environ. Prot. 2017, 111, 346–354. [Google Scholar] [CrossRef]

- Kang, M.-Y.; Jung, J.; Koo, J.-W.; Kim, I.; Kim, H.-R.; Myong, J.-P. Increased risk of gastric cancer in workers with occupational dust exposure. Korean J. Intern. Med. 2021, 36, S18–S26. [Google Scholar] [CrossRef]

- Kim, K.-H.; Kabir, E.; Kabir, S. A review on the human health impact of airborne particulate matter. Sci. Direct 2015, 74, 136–143. [Google Scholar] [CrossRef] [PubMed]

- Li, L.; Jiang, M.; Li, X.; Zhou, B. Association between coalmine dust and mortality risk of lung cancer: A meta-analysis. BioMed Res. Int. 2021, 2021, 6624799. [Google Scholar] [CrossRef] [PubMed]

- Kahraman, M.M.; Erkayaoglu, M. A data-driven approach to control fugitive dust in mine operations. Min. Metall. Explor. 2021, 38, 549–558. [Google Scholar] [CrossRef]

- Wippich, C.; Rissler, J.; Koppisch, D.; Breuer, D. Estimating respirable dust exposure from inhalable dust exposure. Ann. Work Expo. Health 2020, 64, 430–444. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sahu, S.P.; Yadav, M.; Rani, N.; Das, A.J. Assessment of occupational health exposure to particulate matter around opencast coal mines, India: A case study. Arab. J. Geosci. 2018, 11, 1–11. [Google Scholar] [CrossRef]

- Huang, Y.; Bao, M.; Xiao, J.; Qiu, Z.; Wu, K. Effects of PM2.5 on cardio-pulmonary function injury in open manganese mine workers. Int. J. Environ. Res. Public Health 2019, 16, 2017. [Google Scholar] [CrossRef] [Green Version]

- Guo, Q.; Ren, W.; Shi, J. Foam for coal dust suppression during underground coal mine tunneling. Tunn. Undergr. Space Technol. 2019, 89, 170–178. [Google Scholar] [CrossRef]

- Chang, C.T. Assessment of Influential Range and Characteristics of Fugitive Dust in Limestone Extraction Processes. J. Air Waste Manag. Assoc. 2004, 54, 141–148. [Google Scholar] [CrossRef] [Green Version]

- Bao, J.; Johansson, J.; Zhang, J. An occupational disease assessment of the mining industry’s occupational health and safety management system based on FMEA and an Improved AHP Model. Sustainability 2017, 9, 94. [Google Scholar] [CrossRef] [Green Version]

- Pandey, J.K.; Agarwal, D.; Gorain, S.; Dubey, R.K.; Vishwakarma, M.K.; Mishra, K.K.; Pal, A.K. Characterisation of respirable dust exposure of different category of workers in Jharia Coalfields. Arab. J. Geosci. 2017, 10, 183. [Google Scholar] [CrossRef]

- Reed, W.R.; Organiscak, J.A. The evaluation of dust exposure to truck drivers following the lead Haul truck. In Proceedings of the 2005 SME Annual Meeting, Salt Lake City, UT, USA, 28 February–2 March 2005; pp. 71–79. [Google Scholar]

- Tong, R.; Cheng, M.; Yang, X.; Yang, Y.; Shi, M. Exposure levels and health damage assessment of dust in a coal mine of Shanxi Province, China. Process Saf. Environ. Prot. 2019, 128, 184–192. [Google Scholar] [CrossRef]

- Duarte, J.; Vaz, M.; Costa, J.T.; Baptista, J.S. Occupational exposure to dust in road construction, earthworks and open-pit mining—A scoping review protocol. Int. J. Occup. Environ. Saf. 2019, 3, 14–19. [Google Scholar] [CrossRef]

- Shamseer, L.; Moher, D.; Clarke, M.; Ghersi, D.; Liberati, A.; Petticrew, M.; Shekelle, P.; Stewart, L.A.; Altman, D.G.; Booth, A.; et al. Preferred reporting items for systematic review and meta-analysis protocols (prisma-p) 2015: Elaboration and explanation. BMJ 2015, 349, 1–25. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tricco, A.C.; Lillie, E.; Zarin, W.; O’Brien, K.K.; Colquhoun, H.; Levac, D.; Moher, D.; Peters, M.D.J.; Horsley, T.; Weeks, L.; et al. PRISMA extension for scoping reviews (PRISMA-ScR): Checklist and explanation. Ann. Intern. Med. 2018, 169, 467–473. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, D.; Li, Z.; Zhang, Z. The study on the earthworks of green construction based on value engineering. IOP Conf. Ser. Earth Environ. Sci. 2019, 218, 012024. [Google Scholar] [CrossRef]

- Wohlin, C. Claes Guidelines for snowballing in systematic literature studies and a replication in software engineering. In Proceedings of the 18th International Conference on Evaluation and Assessment in Software Engineering—EASE’14, London, UK, 13–14 May 2014; ACM Press: New York, NY, USA, 2014; pp. 1–10. [Google Scholar]

- Higgins, J.; Altman, D.; Gøtzsche, P.; Jüni, P.; Moher, D.; Oxman, A.; Savović, J.; Schulz, K.; Weeks, L.; Sterne, J.A.C.C. The cochrane collaboration’s tool for assessing risk of bias in randomised trials. BMJ 2011, 343, d5928. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Moher, D.; Liberati, A.; Tetzlaff, J.; Altman, D.; Altman, D.; Antes, G.; Atkins, D.; Barbour, V.; Barrowman, N.; Berlin, J.; et al. Preferred reporting items for systematic reviews and meta-analyses: The PRISMA statement. PLoS Med. 2009, 6, e1000097. [Google Scholar] [CrossRef] [Green Version]

- Van Eck, N.J.; Waltman, L. Software survey: VOSviewer, a computer program for bibliometric mapping. Scientometrics 2010, 84, 523–538. [Google Scholar] [CrossRef] [Green Version]

- Onder, M.; Yigit, E. Assessment of respirable dust exposures in an opencast coal mine. Environ. Monit. Assess. 2009, 152, 393–401. [Google Scholar] [CrossRef]

- Gholami, A.; Fani, M.J.; Sadeghi, N. Occupational exposure determination to silica dust in an iron-stone ore and comparison with standard. Int. J. Collab. Res. Intern. Med. Public Health 2012, 4, 1141–1149. [Google Scholar]

- Faber, P.; Drewnick, F.; Borrmann, S. Aerosol particle and trace gas emissions from earthworks, road construction, and asphalt paving in Germany: Emission factors and influence on local air quality. Atmos. Environ. 2015, 122, 662–671. [Google Scholar] [CrossRef]

- Sastry, V.R.R.; Chandar, K.R.; Nagesha, K.V.V.; Muralidhar, E.; Mohiuddin, M.S. Prediction and analysis of dust dispersion from drilling operation in opencast coal mines. Procedia Earth Planet. Sci. 2015, 11, 303–311. [Google Scholar] [CrossRef] [Green Version]

- Gautam, S.; Kumar, P.; Patra, A.K. Occupational exposure to particulate matter in three Indian opencast mines. Air Qual. Atmos. Health 2016, 9, 143–158. [Google Scholar] [CrossRef]

- Amran, S.; Latif, M.T.; Khan, M.F.; Goh, E.; Leman, A.M.; Jaafar, S.A. Underestimation of respirable crystalline silica (RCS) compliance status among the granite crusher operators in Malaysian quarries. Air Qual. Atmos. Health 2017, 10, 371–379. [Google Scholar] [CrossRef]

- Hwang, J.; Ramachandran, G.; Raynor, P.C.; Alexander, B.H.; Mandel, J.H. A comprehensive assessment of exposures to respirable dust and silica in the taconite mining industry. J. Occup. Environ. Hyg. 2017, 14, 377–388. [Google Scholar] [CrossRef]

- Rabeiy, R.E.S.; ElTahlawi, M.R.; Boghdady, G.Y. Occupational health hazards in the Sukari Gold Mine, Egypt. J. Afr. Earth Sci. 2018, 146, 209–216. [Google Scholar] [CrossRef]

- Richardson, C.; Rutherford, S.; Agranovski, I. Characterization of particulate emissions from Australian open-cut coal mines: Toward improved emission estimates. J. Air Waste Manag. Assoc. 2018, 68, 598–607. [Google Scholar] [CrossRef]

- Rusibamayila, M.; Meshi, E.; Mamuya, S. Respiratory impairment and personal respirable dust exposure among the underground and open cast gold miners in Tanzania. Ann. Glob. Health 2018, 84, 419–428. [Google Scholar] [CrossRef] [Green Version]

- Sairanen, M.; Selonen, O. Dust formed during drilling in natural stone quarries. Bull. Eng. Geol. Environ. 2018, 77, 1249–1262. [Google Scholar] [CrossRef] [Green Version]

- Wanjun, T.; Qingxiang, C. Dust distribution in open-pit mines based on monitoring data and fluent simulation. Environ. Monit. Assess. 2018, 190, 632. [Google Scholar] [CrossRef]

- Mankar, P.; Mandal, B.B.; Chatterjee, D. Monitoring and assessment of airborne respirable limestone dust and free silica content in an Indian mine. J. Health Pollut. 2019, 9, 190904. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sepadi, M.M.; Chadyiwa, M.; Nkosi, V. Platinum mine workers exposure to dust particles emitted at mine waste rock crusher plants in limpopo, South Africa. Int. J. Environ. Res. Public Health 2020, 17, 655. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ambastha, S.K.; Haritash, A.K. Emission of respirable dust from stone quarrying, potential health effects, and its management. Environ. Sci. Pollut. Res. 2021, 29, 6670–6677. [Google Scholar] [CrossRef] [PubMed]

- Trechera, P.; Moreno, T.; Córdoba, P.; Moreno, N.; Zhuang, X.; Li, B.; Li, J.; Shangguan, Y.; Dominguez, A.O.; Kelly, F.; et al. Comprehensive evaluation of potential coal mine dust emissions in an open-pit coal mine in Northwest China. Int. J. Coal Geol. 2021, 235, 103677. [Google Scholar] [CrossRef]

- Zilaout, H.; Vlaanderen, J.; Houba, R.; Kromhout, H. 15 years of monitoring occupational exposure to respirable dust and quartz within the European industrial minerals sector. Int. J. Hyg. Environ. Health 2017, 220, 810–819. [Google Scholar] [CrossRef] [PubMed]

- Dahmann, D.; Taeger, D.; Kappler, M.; Büchte, S.; Morfeld, P.; Brüning, T.; Pesch, B. Assessment of exposure in epidemiological studies: The example of silica dust. J. Expo. Sci. Environ. Epidemiol. 2008, 18, 452–461. [Google Scholar] [CrossRef] [Green Version]

- Zilaout, H.; Houba, R.; Kromhout, H. Temporal trends in respirable dust and respirable quartz concentrations within the European industrial minerals sector over a 15-year period (2002–2016). Occup. Environ. Med. 2020, 77, 268–275. [Google Scholar] [CrossRef] [Green Version]

- Bell, J.L.; Mazurek, J.M. Trends in pneumoconiosis deaths—United States, 1999–2018. MMWR. Morb. Mortal. Wkly. Rep. 2020, 69, 693–698. [Google Scholar] [CrossRef]

| Author (year) | Country | Dust Limit | Source | Activity | Location Type | Exploited Material | Studied Variables |

|---|---|---|---|---|---|---|---|

| Chang (2004) [28] | Taiwan | 0.25 mg·m−3 | Referred in article | Mining | Quarry | Limestone | Distance, season, transport system, weather |

| Reed & Organiscak (2005) [31] | USA | 2 mg·m−3 | Sought for | Mining | Quarry, mine | Stone, coal | Not mentioned |

| Onder & Yigit (2009) [41] | Turkey | 5 mg·m−3 | Referred in article | Mining | Mine | Coal | Activity, site |

| Gholami et al. (2012) [42] | Iran | 4 mg·m−3 | Sought for | Mining | Mine | Iron | Site |

| Faber et al. (2015) [43] | Germany | 3 mg·m−3 | Sought for | Earthworks, road construction | Construction site | Not applicable | Activity, equipment |

| Sastry et al. (2015) [44] | India | 3 mg·m−3 | Sought for | Mining | Mine | Coal | Distance, weather |

| Gautam et al. (2016) [45] | India | 3 mg·m−3 | Sought for | Mining | Mine (3) | Copper | Activity, site |

| Amran et al. (2017) [46] | Malaysia | 3 mg·m−3 | Referred in article | Mining | Quarry (9) | Granite | Activity, equipment |

| Hwang et al. (2017) [47] | USA | 2 mg·m−3 | Sought for | Mining | Mine (6) | Taconite | Job category |

| Pandey et al. (2017) [30] | India | 3 mg·m−3 | Referred in article | Mining | Mine (7) | Coal | Job category |

| Rabeiy et al. (2018) [48] | Egypt | 3 mg·m−3 | Referred in article | Mining | Mine | Gold | Site |

| Richardson et al. (2018) [49] | Australia | 10 mg·m−3 | Sought for | Mining | Mine (3) | Coal | Not mentioned |

| Rusibamayila et al. (2018) [50] | Tanzania | 5 mg·m−3 | Referred in article | Mining | Mine | Gold | Activity, job category |

| Sahu et al. (2018) [22] | India | 3 mg·m−3 | Sought for | Mining | Mine (2) | Coal | Weather |

| Sairanen & Selonen (2018) [51] | Finland | 0.1 mg·m−3 | Sought for | Mining | Quarry (2) | Aggregates | Not mentioned |

| Tripathy & Dash (2018) [6] | India | 3 mg·m−3 | Referred in article | Mining | Mine | Coal | Activity, season, site |

| Wanjun & Qingxiang (2018) [52] | China | 4 mg·m−3 | Not applicable | Mining | Mine | Coal | Activity |

| Chaulya et al. (2019) [25] | India | 3 mg·m−3 | Sought for | Mining | Mine | Iron, manganese | Activity |

| Mankar et al. (2019) [53] | India | 3 mg·m−3 | Referred in article | Mining | Mine | Limestone | Activity |

| Sairanen & Rinne (2019) [24] | Finland | 0.1 mg·m−3 | Sought for | Mining | Quarry (6) | Aggregates | Not mentioned |

| Tong et al. (2019) [32] | China | 4 mg·m−3 | Referred in article | Mining | Mine | Coal | Job category |

| Sepadi et al. (2020) [54] | South Africa | 3 mg·m−3 | Referred in article | Mining | Mine (2) | Platinum | Equipment, site |

| Ambastha & Haritash (2021) [55] | India | 3 mg·m−3 | Referred in article | Mining | Quarry | Sandstone | Site |

| Trechera et al. (2021) [56] | China | 4 mg·m−3 | Sought for | Mining | Mine | Coal | Site |

| Study | Activity |

|---|---|

| [41] | Overburden loading, coal loading, drilling |

| [43] | Earthworks |

| [45] | Mining |

| [46] | Crushing (primary, secondary, tertiary) |

| [50] | Haulage, loading materials, clearance and pushing materials, measuring the depth of holes |

| [6] | Vehicular movement, mining |

| [52] | Mining, transportation, dumping |

| [25] | Loading point, transport, vehicular movement, truck movement |

| Activity | 8 h conc. (mg·m−3) | Range (mg·m−3) | Range (μg·m−3) | Study |

|---|---|---|---|---|

| Overburden loading | --- | 0.10–3.50 | --- | [41] |

| Coal loading | --- | 0.25–2.10 | --- | |

| Drilling | --- | 0.48–7.29 | --- | |

| Haulage | --- | 0.09–0.27 | --- | [50] |

| Loading materials | --- | 0.10–0.33 | --- | |

| Clearance and pushing materials | --- | 0.10–0.32 | --- | |

| Measuring the depth of holes | --- | 0.21–0.61 | --- | |

| Mining | --- | --- | 31.3–117.6 | [52] |

| Transportation | --- | --- | 31.3–112.4 | |

| Dumping | --- | --- | 47.5–127.8 | |

| Transfer ore from belt conveyor 1 to belt conveyor 2 (PD1) | 0.43 | --- | --- | [53] |

| Transfer ore from belt conveyor 1 to pipe conveyor (PD2) | 1.04 | --- | --- | |

| Shovel operation (PD3) | 0.37 | --- | --- | |

| Dumper operation (PD4) | 0.43 | --- | --- | |

| Shovel operation (PD5) | 0.39 | --- | --- | |

| Drill helper (PD6) | 0.32 | --- | --- | |

| Dumper operation transferring ore to crusher (PD7) | 0.40 | --- | --- | |

| Dumper loading to crusher (AD1) | 0.54 | --- | --- | |

| Crushing of limestone (AD2) | 0.25 | --- | --- | |

| Transfer limestone from belt conveyor to pipe conveyor (AD3) | 0.27 | --- | --- | |

| Dumper movement (AD4) | 0.25 | --- | --- | |

| Dumper and other service vehicle movement (AD5) | 0.33 | --- | --- | |

| Backhoe operator loading onto tipper (PD8) | 0.80 | --- | --- | |

| Backhoe loading overburden onto tipper (PD9) | 1.04 | --- | --- | |

| Tata Hitachi operation (PD10) | 0.85 | --- | --- | |

| Dumper operation (PD11) | 0.66 | --- | --- | |

| Dumper operation (PD12) | 0.62 | --- | --- | |

| Drilling operation (PD13) | 1.23 | --- | --- | |

| Movement of dumpers, tipper, and mine vehicles (AD6) | 1.14 | --- | --- | |

| Drilling operation (AD7) | 1.52 | --- | --- | |

| Shovel loading overburden onto tipper (AD8) | 1.42 | --- | --- | |

| Dumper loading ore onto tipper (AD9) | 1.04 | --- | --- | |

| Transfer ore from one conveyor to another (AD10) | 2.64 | --- | --- | |

| Transfer ore from the belt conveyor to pipe conveyor (AD11) | 1.52 | --- | --- |

| Particle size | Equipment | Facility | Time-Weighted Average |

|---|---|---|---|

| Respirable dust (<10 µm) | Excavator | A | 0.028 |

| B | 0.026 | ||

| Front-end loader | A | 0.022 | |

| Respirable dust (<100 µm) | Excavator | A | 0.132 |

| B | 0.029 | ||

| Front-end loader | A | 0.295 |

| Monitor Site | Term | Vertical Well | Standard Deviation | Conventional System | STD |

|---|---|---|---|---|---|

| Extraction site | Total suspended particles | 301 | 36 | 211 | 25 |

| PM10 | 68 | 14 | 183 | 18 | |

| PM2.5 | 28 | 5 | 56 | 9 | |

| Conveyor system | Total suspended particles | 186 | 21 | 173 | 10 |

| PM10 | 60 | 15 | 125 | 25 | |

| PM2.5 | 45 | 13 | 101 | 31 |

| Study | Methodology | Other | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Task Definition | Equipment Type | Standard Application | Measurement Precision | Sampling Time | Sampling Representativeness | Equipment Calibration | Reporting Quality | References Quality | |

| [28] | LR | LR | HR | UR | HR | HR | HR | LR | HR |

| [31] | HR | LR | LR | UR | LR | LR | HR | LR | HR |

| [41] | LR | LR | HR | UR | HR | HR | HR | LR | HR |

| [42] | HR | LR | LR | UR | UR | UR | LR | HR | HR |

| [43] | LR | LR | HR | UR | UR | UR | LR | LR | LR |

| [44] | LR | LR | HR | UR | HR | HR | HR | LR | HR |

| [45] | LR | LR | HR | UR | HR | UR | HR | LR | LR |

| [46] | LR | LR | LR | UR | LR | UR | LR | LR | LR |

| [47] | LR | LR | LR | UR | UR | UR | LR | LR | HR |

| [30] | LR | LR | LR | UR | UR | UR | LR | LR | LR |

| [48] | HR | UR | HR | UR | UR | UR | HR | HR | LR |

| [49] | LR | LR | HR | UR | UR | UR | LR | LR | LR |

| [50] | LR | LR | HR | UR | LR | UR | LR | LR | LR |

| [25] | LR | LR | HR | UR | LR | LR | HR | LR | LR |

| [51] | LR | LR | HR | UR | HR | LR | HR | LR | LR |

| [6] | LR | LR | LR | UR | LR | UR | HR | LR | LR |

| [52] | LR | LR | HR | UR | LR | UR | HR | LR | LR |

| [9] | HR | UR | LR | UR | LR | HR | HR | LR | LR |

| [53] | LR | LR | LR | UR | LR | UR | HR | LR | HR |

| [8] | LR | LR | HR | UR | HR | LR | HR | LR | LR |

| [32] | LR | LR | LR | UR | HR | LR | LR | LR | LR |

| [54] | LR | LR | LR | UR | LR | LR | LR | LR | HR |

| [55] | LR | UR | HR | UR | LR | LR | HR | LR | HR |

| [56] | HR | HR | HR | HR | HR | HR | HR | HR | HR |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Duarte, J.; Castelo Branco, J.; Rodrigues, F.; Vaz, M.; Santos Baptista, J. Occupational Exposure to Mineral Dust in Mining and Earthmoving Works: A Scoping Review. Safety 2022, 8, 9. https://doi.org/10.3390/safety8010009

Duarte J, Castelo Branco J, Rodrigues F, Vaz M, Santos Baptista J. Occupational Exposure to Mineral Dust in Mining and Earthmoving Works: A Scoping Review. Safety. 2022; 8(1):9. https://doi.org/10.3390/safety8010009

Chicago/Turabian StyleDuarte, Joana, Jacqueline Castelo Branco, Fernanda Rodrigues, Mário Vaz, and João Santos Baptista. 2022. "Occupational Exposure to Mineral Dust in Mining and Earthmoving Works: A Scoping Review" Safety 8, no. 1: 9. https://doi.org/10.3390/safety8010009

APA StyleDuarte, J., Castelo Branco, J., Rodrigues, F., Vaz, M., & Santos Baptista, J. (2022). Occupational Exposure to Mineral Dust in Mining and Earthmoving Works: A Scoping Review. Safety, 8(1), 9. https://doi.org/10.3390/safety8010009