Environmental Impact Assessment of Construction Waste Recycling versus Disposal Scenarios Using an LCA-BIM Tool during the Design Stage

Abstract

1. Introduction

- RQ1. During the design phase, is it possible to obtain the impact reduction achieved with the recycling versus disposal scenarios of CW, without being an LCA expert and without time consumption?

- RQ2. Is CW recycling always the most beneficial option with respect to CW disposal?

- RQ3. Which environmental impact categories are most influenced by CW recycling?

- RQ4. Which CW and building elements have the greatest impact on CW management and which CW benefits the most from recycling?

2. Results and Discussion

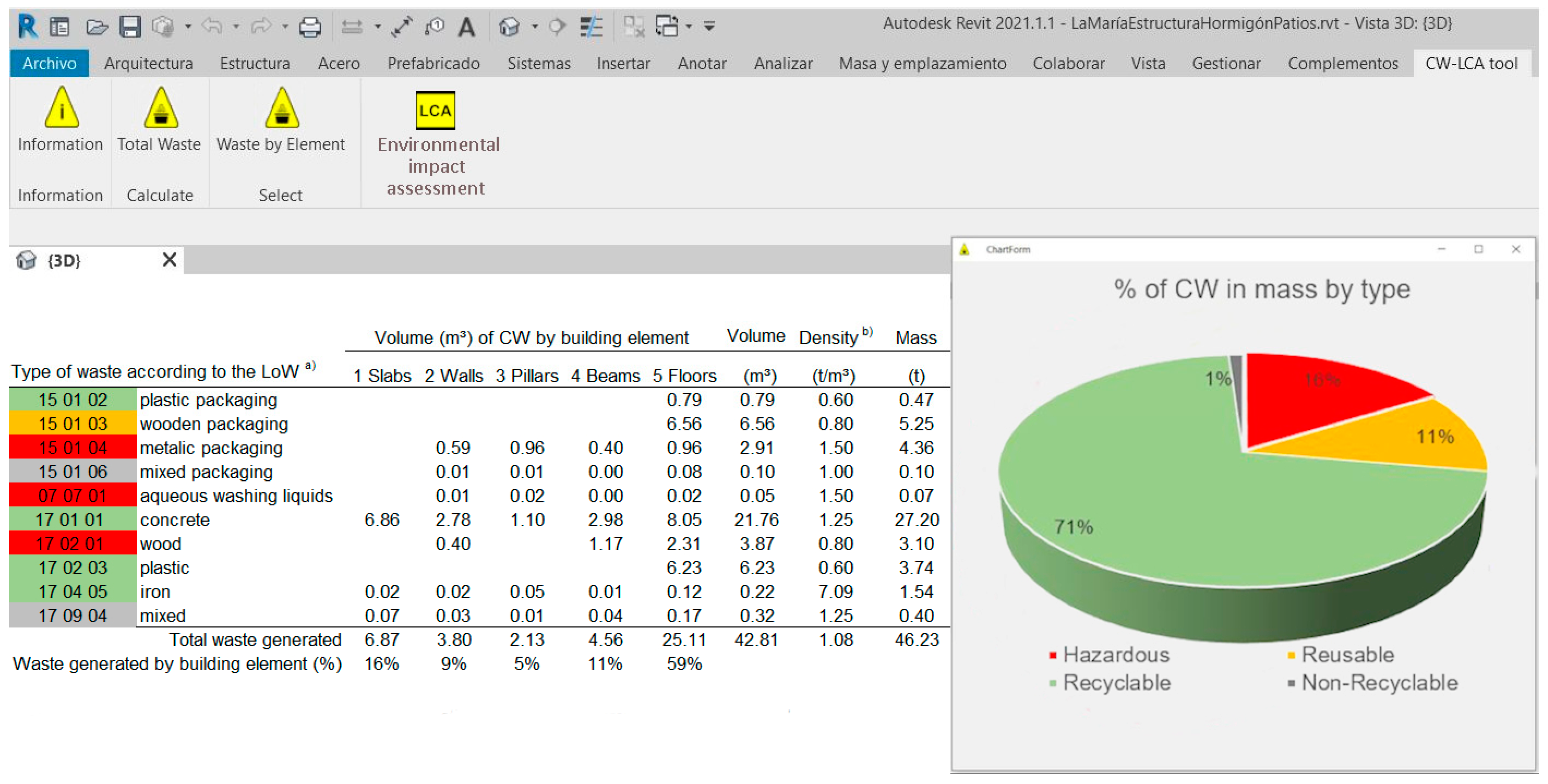

- Hazardous waste (16%) (in red): (i) timber formworks and (ii) metal cans contaminated by release agents; and (iii) release agent residues, which must be separated and removed by a specialized waste manager in accordance with Spanish regulations [50].

- Reusable waste (11%) (in orange): (i) wooden pallets that are usually stockpiled on site and removed by the same supplier of the materials.

- Non-recyclable waste (1%) (in grey): (i) mixed waste and (ii) mixed packaging, the recycling of which is economically and technically unfeasible since their heterogeneous mixtures may be difficult to separate on site as explained in [47].

- Recyclable waste (71%) (in green), variables “i” and “Q”: (i) concrete (27.2 t); (ii) plastics (4.2 t); and (iii) steel (1.5 t).

- Recycling scenario (R), in which each recyclable fraction is separated on site and transported to its corresponding recycling plant by an authorized manager (see Figure S1). These recycling plants would produce the by-products: recycled aggregates, recycled steel, and recycled plastic, considering the processes explained in [13,47];

- Disposal scenario (D), in which each recyclable fraction is separated on site and transported to its corresponding landfill (concrete to the landfill of inert waste; and steel and plastics to the landfill of non-inert waste) by an authorized manager (see Figure S1); considering the processes explained in [13,47].

2.1. Case Study Validation and Answers to the Research Questions (RQ)

2.2. Implications of Findings

2.3. Limitations and Future Work

3. Materials and Methods

3.1. Basic Assumptions

- ‘Recycling’ means any recovery operation by which waste materials are reprocessed into products, materials, or substances whether for the original or other purposes. This includes the reprocessing of organic material but does not include energy recovery and the reprocessing into materials that are to be used as fuels or for backfilling operations. This is used in the recycling scenario.

- ‘Disposal’ (also called landfill, elimination, or dumping in the literature) refers to any operation which is not recovery even where the operation has, as a secondary consequence, the reclamation of substances or energy. This is used in the disposal scenario.

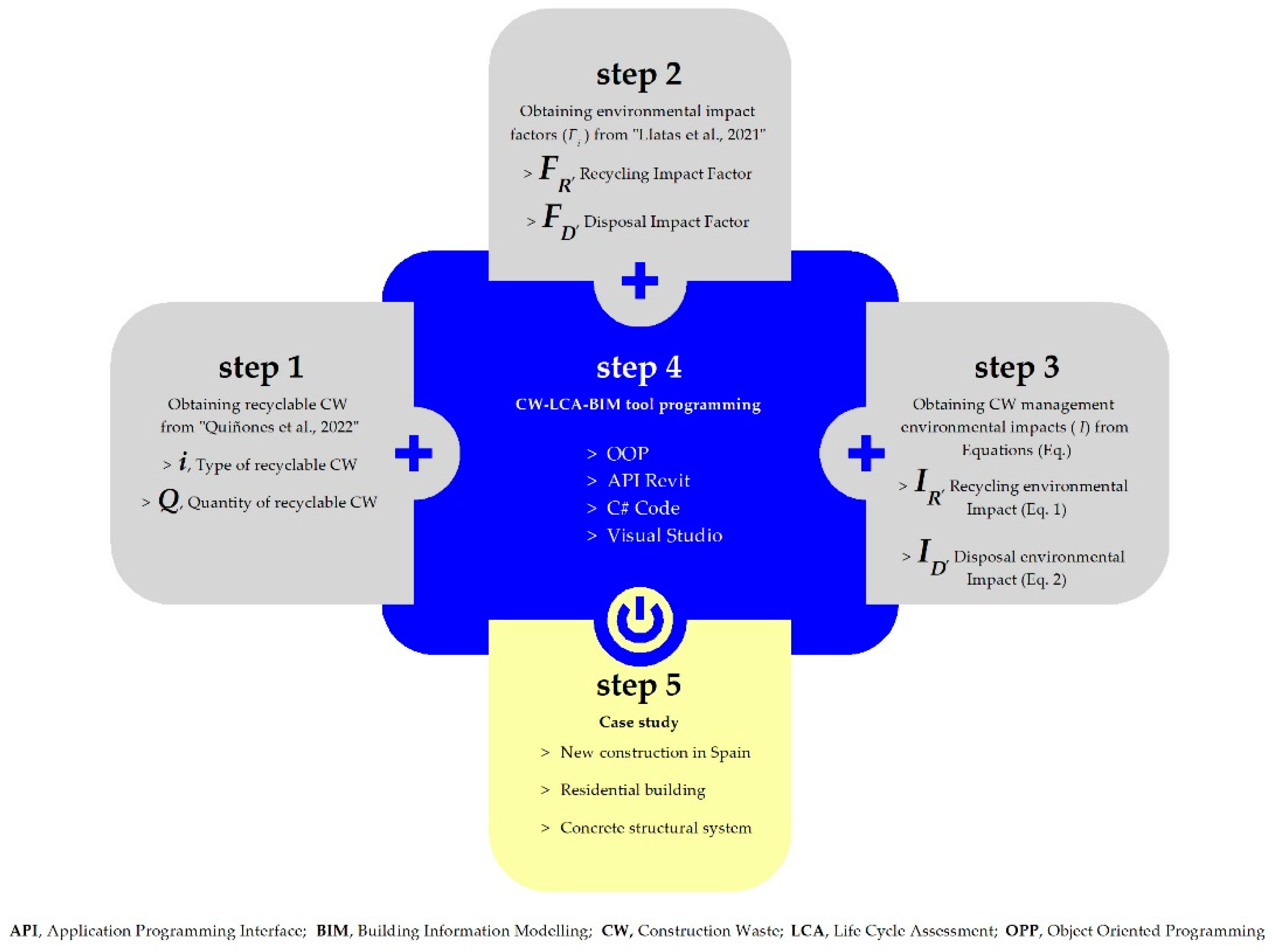

3.2. Steps

3.2.1. Step 1: Quantifying the Types and Quantities of Recyclable CW in BIM

3.2.2. Step 2: Implementing the LCA-Based Environmental Impact Factors in BIM

- FD is the final environmental impact produced by the disposal of 1 ton of each type of CW according to each impact category (AP, EP, GWP, etc.). This factor corresponds to FΩD Downstream Impact Factor of Disposal in [47];

- FR is the final environmental impact produced by the recycling of 1 ton of each type of CW according to each impact category (AP, EP, GWP, etc.). This factor corresponds to FΩR Downstream Impact Factor of Recycling in [47].

3.2.3. Step 3: Quantifying the Environmental Impacts in BIM

- is the total recycling impact of the environmental impact category “j”;

- is the total disposal impact of the environmental impact category “j”;

- is the quantity in tons of the fraction “i” of recyclable CW generated on site;

- is the environmental impact of the category “j” of 1 ton of the recycled CW “i”;

- is the environmental impact of the category “j” of 1 ton of the disposed CW “i”.

3.2.4. Step 4: Programming the CW-LCA-BIM Tool

- First, the designer classifies the building elements by grouping them according to their main function (e.g., walls, pillars, beams). This step can be carried out manually; however, by default, the CW-LCA-BIM tool classifies the building elements according to the Base de Costes de la Construcción de Andalucía (BCCA) [52]. This step enables the environmental impact of each group of building elements to be evaluated and compared;

- Second, the CW-LCA-BIM tool allows the designer to classify CW into 4 main groups according to their main management option: (i) hazardous waste (e.g., wood contaminated with release agents, paint cans, solvent residues); (ii) reusable waste with little or no treatment (e.g., wooden pallets, super-plus construction materials); (iii) recyclable waste (e.g., concrete/ceramic waste and those that can be assimilated to urban solid waste such as paper, cardboard, plastics, and metals); and (iv) non-recyclable waste (e.g., mixed waste). By default, the tool advises the designer of the most common option for each type of waste generated. This step enables the identification of recyclable waste;

- Third, once the types and quantities of recyclable waste have been identified, the tool, by default, evaluates their recycling versus their disposal. However, the designer could compare other scenarios by selecting only those types of waste that would be recycled.

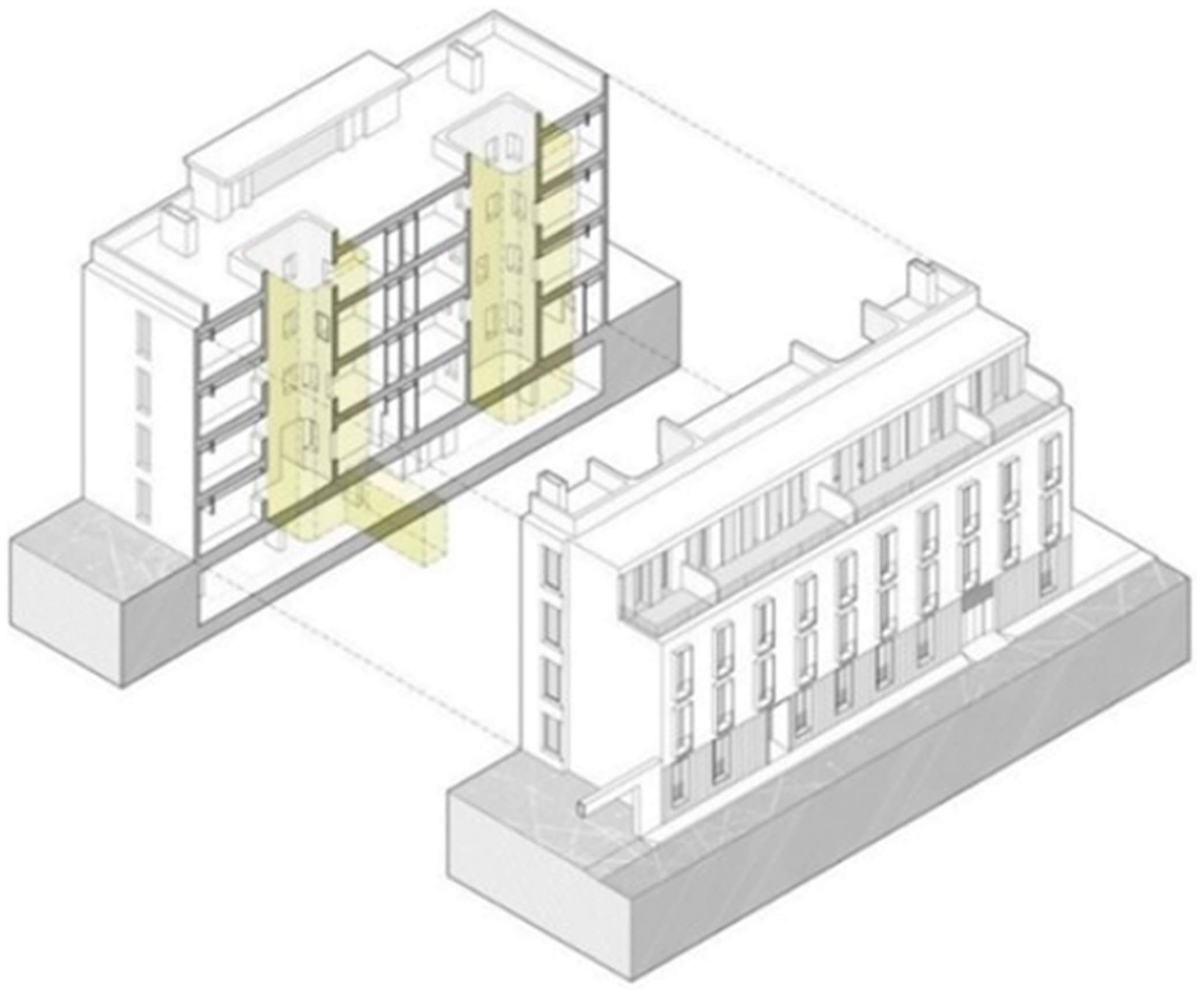

3.2.5. Step 5: Applying the Tool to a Case Study

4. Conclusions

- (i)

- Although an LCA expert is required to develop the tool, it is possible to obtain the results during the design without an LCA expert and without time consumption, as RQ1 queried;

- (ii)

- Four groups of CW were obtained: hazardous waste (16%), reusable waste (11%), non-recyclable waste (1%), and recyclable waste (71%);

- (iii)

- The management of the following three types of recyclable waste was assessed: concrete (27.2 t), plastics (4.2 t), and steel (1.5 t);

- (iv)

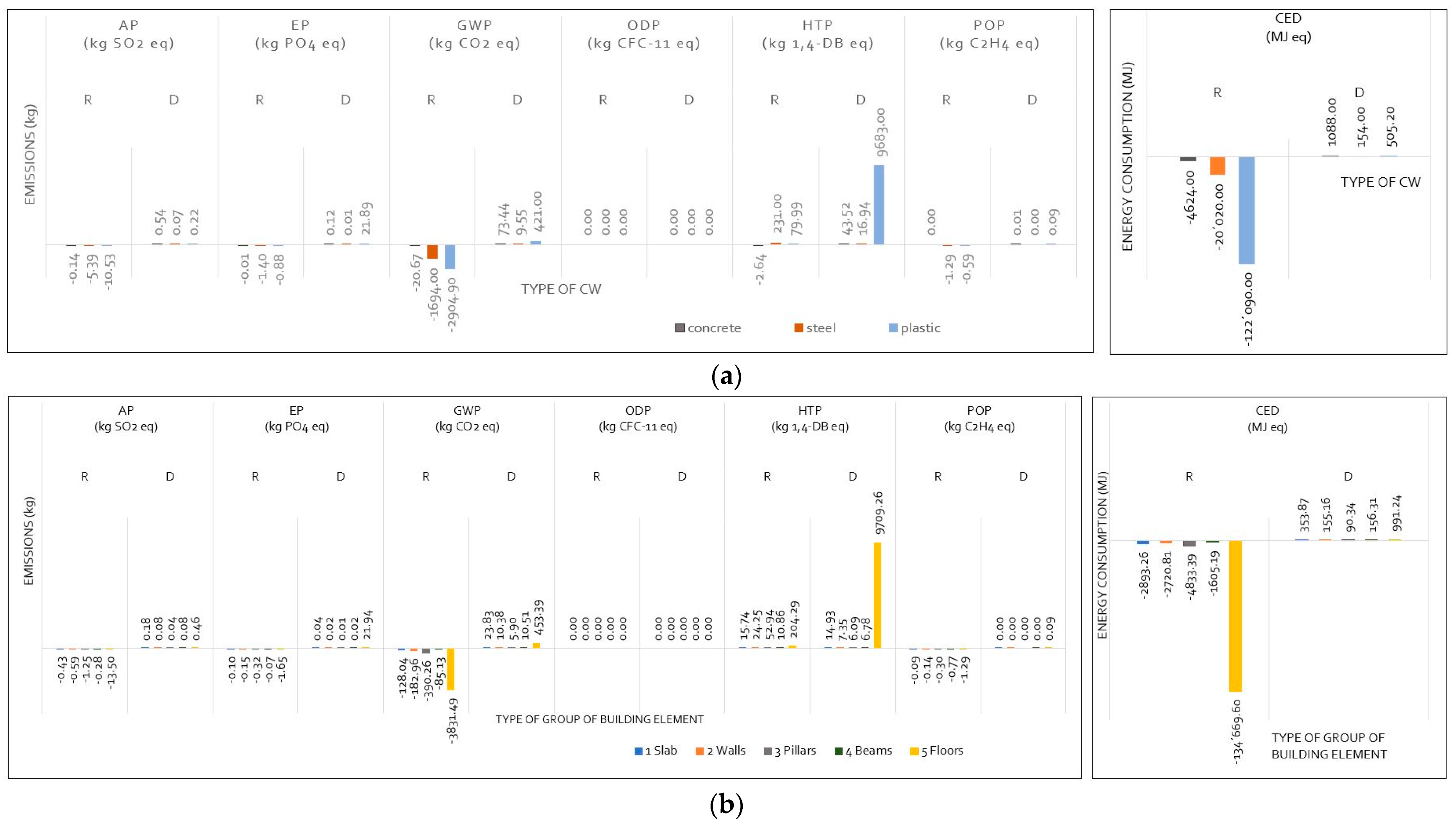

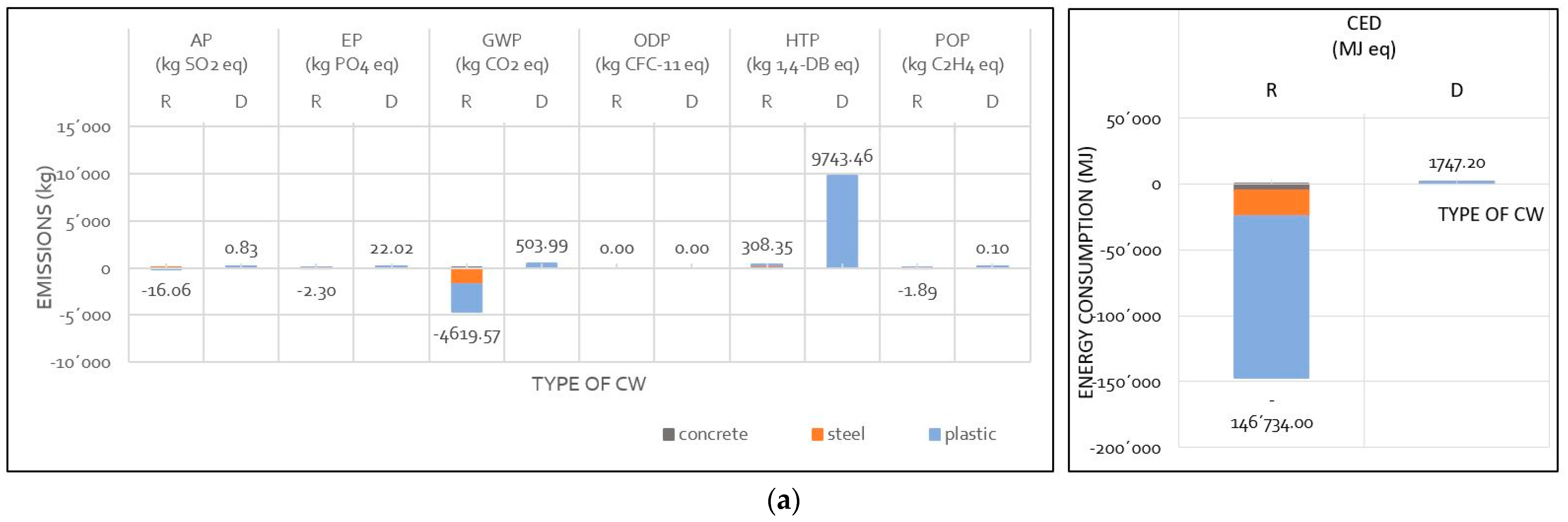

- Although recycling would be the best option for the entire structural system since it could prevent 14.6 t of emissions (1.4 times that of the disposal scenario) and could save 148.5 GJ of energy consumption (8.5 times that of the disposal scenario), recycling would not always be the most beneficial option with respect to CW disposal for all types of CW and categories, as queried by RQ2;

- (v)

- The recycling scenario would be less beneficial for plastic in ODP, a relatively insignificant category, and for steel in HTP;

- (vi)

- The environmental impact categories most influenced by CW recycling would be those related to the climate emergency, GWP, and energy consumption, in addition to HTP, with a greater influence on human health, as queried by RQ3;

- (vii)

- RQ4 revealed that the CW management that would have the greatest impact would be that of plastic disposal (which emits 10.1 t and consumes 0.5 MJ) and concrete disposal (which emits 0.12 t and consumes 1 MJ), followed by steel disposal (which emits 0.03 t and consumes 0.2 MJ). RQ4 also revealed that the most beneficial CW management would be that of recycling plastic (which prevents 13.0 t of emissions and saves 122.6 GJ), followed by recycling steel (which prevents 1.5 t of emissions and saves 20.2 GJ) and, to a lesser extent, recycling concrete (which prevents 0.1 t of emissions and saves 5.67 GJ).

- (viii)

- The building elements that would have the greatest impact on CW management would be the horizontal structural elements (floors and foundation slab), followed by the vertical structural elements (walls and pillars);

- (ix)

- Finally, CW recycling would contribute towards decarbonizing the building by eliminating 5.1 t of CO2 eq emissions from its embodied carbon.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ogunmakinde, O.E.; Egbelakin, T.; Sher, W. Contributions of the circular economy to the UN sustainable development goals through sustainable construction. Resour. Conserv. Recycl. 2022, 178, 106023. [Google Scholar] [CrossRef]

- European Commission. Construction and Demolition Waste. Available online: https://environment.ec.europa.eu/topics/waste-and-recycling/construction-and-demolition-waste_en (accessed on 18 July 2022).

- European Commission. Buildings and Construction. Available online: https://ec.europa.eu/growth/industry/sustainability/buildings-and-construction_en (accessed on 21 July 2022).

- European Commission. Circular Economy Action Plan. 2020. Available online: https://environment.ec.europa.eu/strategy/circular-economy-action-plan_en (accessed on 18 July 2022).

- European Commission. The European Green Deal. 2019. Available online: https://ec.europa.eu/info/strategy/priorities-2019-2024/european-green-deal_es (accessed on 18 July 2022).

- European Commission. EU Construction and Demolition Waste Protocol and Guidelines. 2018. Available online: https://ec.europa.eu/growth/news/eu-construction-and-demolition-waste-protocol-2018-09-18_en (accessed on 18 July 2022).

- European Commission. Directive (EU) 2018/851 of the European Parliament and of the Council of 30 May 2018 Amending Directive 2008/98/EC on Waste. Official Journal of the European Union 2018, L 150/109, European Union. 2018. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32018L0851&from=EN (accessed on 21 July 2022).

- Dos Santos Gervasio, H.; Dimova, S. Model for Life Cycle Assessment (LCA) of Buildings; EUR 29123 EN; Publications Office of the European Union: Luxembourg, 2018; ISBN 978-92-79-79974-7 (print), 978-92-79-79973-0 (pdf). Available online: https://publications.jrc.ec.europa.eu/repository/handle/JRC110082 (accessed on 21 July 2022). [CrossRef]

- Saidani, M.; Yannou, B.; Leroy, Y.; Cluzel, F. How to assess product performance in the circular economy? proposed requirements for the design of a circularity measurement framework. Recycling 2017, 2, 6. [Google Scholar] [CrossRef]

- ISO/TC 207/SC 5; ISO 14040:2006 Environmental Management—Life Cycle Assessment—Principles and Framework. International Organization for Standardization (ISO): Geneva, Switzerland, 2006.

- ISO/TC 207/SC 5; ISO 14044:2006 Environmental Management—Life Cycle Assessment—Requirements and Guidelines. International Organization for Standardization (ISO): Geneva, Switzerland, 2006.

- Mesa, J.A.; Fúquene-Retamoso, C.; Maury-Ramírez, A. Life cycle assessment on construction and demolition waste: A systematic literature review. Sustainability 2021, 13, 7676. [Google Scholar] [CrossRef]

- Bizcocho, N.; Llatas, C. Inclusion of prevention scenarios in LCA of construction waste management. Int J Life Cycle Assess 2019, 24, 468–484. [Google Scholar] [CrossRef]

- EPA. Advancing Sustainable Materials Management: Facts and Figures Report. The 2018 Fact Sheet. Available online: https://www.epa.gov/sites/default/files/2021-01/documents/2018_ff_fact_sheet_dec_2020_fnl_508.pdf (accessed on 18 July 2022).

- National Institute of Statistics, Spanish Government. Statistics on Building Construction. 2022. Available online: https://www.ine.es/dyngs/INEbase/es/categoria.htm?c=Estadistica_P&cid=1254735576757 (accessed on 21 July 2022). (In Spanish).

- Llatas, C.; Soust-Verdaguer, B.; Passer, A. Implementing Life Cycle Sustainability Assessment during design stages in Building Information Modelling: From systematic literature review to a methodological approach. Build. Environ. 2020, 182, 107164. [Google Scholar] [CrossRef]

- Mora, T.D.; Bolzonello, E.; Cavalliere, C.; Peron, F. Key parameters featuring bim-lca integration in buildings: A practical review of the current trends. Sustainability 2020, 12, 7182. [Google Scholar] [CrossRef]

- Anand, C.K.; Amor, B. Recent developments, future challenges and new research directions in LCA of buildings: A critical review. Renew. Sustain. Energy Rev. 2017, 67, 408–416. [Google Scholar] [CrossRef]

- Olanrewaju, O.I.; Kineber, A.F.; Chileshe, N.; Edwards, D.J. Modelling the relationship between Building Information Modelling (BIM) implementation barriers, usage and awareness on building project lifecycle. Build. Environ. 2022, 207, 108556. [Google Scholar] [CrossRef]

- Seyis, S. Mixed method review for integrating building information modeling and life-cycle assessments. Build. Environ. 2020, 173, 106703. [Google Scholar] [CrossRef]

- Llatas, C.; Soust-Verdaguer, B.; Hollberg, A.; Palumbo, E.; Quiñones, R. BIM-based LCSA application in early design stages using IFC. Autom. Constr. 2022, 138, 104259. [Google Scholar] [CrossRef]

- Nagalli, A.; Ollin-Steffen de Oliveira, L.; Nairne-Schamne, A.; Pereira-Barros, B.; Demay-Hochleitner, H.; Jaster de Oliveira, C. BIM plug-in technology for construction waste quantification. Rev. Bras. Gest. Ambient. Sustent. 2021, 8, 1605–1619. [Google Scholar] [CrossRef]

- Akinade, O.O.; Oyedele, L.O. Integrating construction supply chains within a circular economy: An ANFIS-based waste analytics system (A-WAS). J. Clean. Prod. 2019, 229, 863–873. [Google Scholar] [CrossRef]

- Miara, R.; Scheer, S. Optimization of construction waste management through an integrated BIM API. Iberoam. J. Ind. Eng. 2019, 11, 110–122. [Google Scholar]

- Kim, Y.C.; Won-Hwa, H.; Park, J.W.; Gi-Wook, C. An estimation framework for building information modeling (BIM)-based demolition waste by type. Waste Manag. Res. 2017, 35, 1285–1295. [Google Scholar] [CrossRef]

- Won, J.; Cheng, J.C.P.; Lee, G. Quantification of construction waste prevented by BIM-based validation: Case studies in South Korea. Waste Manag. 2016, 49, 170–180. [Google Scholar] [CrossRef]

- Jalaei, F.; Zoghi, M.; Khoshand, A. Life cycle environmental impact assessment to manage and optimize construction waste using Building Information Modeling (BIM). Int. J. Constr. Manag. 2021, 21, 784–801. [Google Scholar] [CrossRef]

- Gupta, S.; Jha, K.N.; Vyas, G. Proposing building information modeling-based theoretical framework for construction and demolition waste management: Strategies and tools. Int. J. Constr. Manag. 2022, 22, 2345–2355. [Google Scholar] [CrossRef]

- Li, C.Z.; Zhao, Y.; Xiao, B.; Yu, B.; Tam, V.W.Y.; Chen, Z.; Ya, Y. Research trend of the application of information technologies in construction and demolition waste management. J. Clean. Prod. 2020, 263, 121458. [Google Scholar] [CrossRef]

- Lu, W.; Webster, C.; Chen, K.; Zhang, X.; Chen, X. Computational Building Information Modelling for construction waste management: Moving from rhetoric to reality. Renew. Sustain. Energy Rev. 2017, 68, 587–595. [Google Scholar] [CrossRef]

- Won, J.; Cheng, J.C.P. Identifying potential opportunities of building information modeling for construction and demolition waste management and minimization. Autom. Constr. 2017, 79, 3–18. [Google Scholar] [CrossRef]

- Cheng, J.C.P.; Ma, L.Y.H. A BIM-based system for demolition and renovation waste estimation and planning. Waste Manag. 2013, 33, 1539–1551. [Google Scholar] [CrossRef] [PubMed]

- Handayani, T.N.; Putri, K.N.R.; Istiqomah, N.A.; Likhitruangsilp, V. The Building Information Modeling (BIM)-based system framework to implement circular economy in construction waste management. J. Civ. Eng. Forum 2022, 8, 31–44. [Google Scholar] [CrossRef]

- Oluleye, B.I.; Chan, D.W.M.; Saka, A.B.; Olawumi, T.O. Circular economy research on building construction and demolition waste: A review of current trends and future research directions. J. Clean. Prod. 2022, 357, 131927. [Google Scholar] [CrossRef]

- Zhang, K.; Jia, J. Promotion of the Application of BIM in China—A BIM-based model for construction material recycling. Recycling 2021, 6, 16. [Google Scholar] [CrossRef]

- Ganiyu, S.A.; Oyedele, L.; Akinade, O.; Owolabi, H.; Akanbi, L.; Gbadamosi, A. BIM competencies for delivering waste-efficient building projects in a circular economy. Dev. Built Environ. 2020, 4, 100036. [Google Scholar] [CrossRef]

- Akanbi, L.A.; Oyedele, L.O.; Akinade, O.O.; Ajayi, A.O.; Davila Delgado, M.; Bilal, M.; Bello, S.A. Salvaging building materials in a circular economy: A BIM-based whole-life performance estimator. Resour. Conserv. Recycl. 2018, 129, 175–186. [Google Scholar] [CrossRef]

- Balazs, S.; Antonini, E.; Tarantitni, M. Application of life cycle assessment (LCA) methodology for valorization of building demolition materials and products. SPIE Int. Soc. Opt. Eng. 2001, 4193, 382–390. [Google Scholar]

- Martínez, E.; Nuñez, Y.; Sobaberas, E. End of life of buildings: Three alternatives, two scenarios: A case study. Int. J. Life Cycle Assess 2013, 18, 1082–1088. [Google Scholar] [CrossRef]

- Ortiz, O.; Pasqualino, J.C.; Castells, F. Environmental performance of construction waste: Comparing three scenarios from a case study in Catalonia, Spain. Waste Manag. 2010, 30, 646–654. [Google Scholar] [CrossRef]

- Craighill, A.; Powell, J. A Lifecycle Assessment and Evaluation of Construction and Demolition Waste; Working Paper—Centre for Social and Economic Research on the Global Environment (WM 99-03); University of East Anglia: Norwich, UK, 1999; pp. 1–52. [Google Scholar]

- Butera, S.; Christensen, T.H.; Astrup, T.F. Life cycle assessment of construction and demolition waste management. Waste Manag. 2015, 44, 196–205. [Google Scholar] [CrossRef]

- Blengini, G.A. Life cycle of buildings, demolition and recycling potential: A case study in Turin, Italy. Build. Environ. 2009, 44, 319–330. [Google Scholar] [CrossRef]

- Mah, C.M.; Fujiwara, T.; Ho, C.S. Life cycle assessment and life cycle costing toward eco-efficiency concrete waste management in Malaysia. J. Clean. Prod. 2018, 172, 3415–3427. [Google Scholar] [CrossRef]

- Su, S.; Li, S.; Ju, J.; Wang, Q.; Xu, Z. A building information modeling-based tool for estimating building demolition waste and evaluating its environmental impacts. Waste Manag. 2021, 134, 159–169. [Google Scholar] [CrossRef] [PubMed]

- Quiñones, R.; Llatas, C.; Montes, M.V.; Cortés, I. BIM Quantification of construction waste in early design stages using BIM-based tool. Recycling 2022, 7, 63. [Google Scholar] [CrossRef]

- Llatas, C.; Bizcocho, N.; Soust-Verdaguer, B.; Montes, M.V.; Quiñones, R. An LCA-based model for assessing prevention versus non-prevention of construction waste in buildings. Waste Manag. 2021, 126, 608–622. [Google Scholar] [CrossRef]

- European Commission. Waste Classification and the European List of Waste. 2014. Available online: https://ec.europa.eu/environment/waste/framework/list.htm (accessed on 22 July 2022).

- Granados-Menéndez, H.; Fernandez-Castillo, J.; López-Asiain, J. National Ratios Generation of Waste Study from Construction and Demolition, 2020 ed.; General Council of the Technical Architecture of Spain, Higher Council of Architects’ Associations of Spain: Madrid, Spain, 2020; pp. 18–27. Available online: https://www.cgate.es/pdf/Libro-Ratios.pdf (accessed on 22 July 2022).

- Spanish Parliament. Royal Decree 105/2008 of 1 February 2008 Regulating the Production and Management of Construction and Demolition Waste. Official State Gazette 2008; Volume 38, pp. 1–268. Spain. Available online: https://www.boe.es/eli/es/rd/2008/02/01/105/con (accessed on 22 July 2022).

- Llatas, C. A model for quantifying construction waste in projects according to the European waste list. Waste Manag. 2011, 31, 1261–1276. [Google Scholar] [CrossRef]

- Consejería de Fomento y Vivienda. Base de Costes de la Construcción de Andalucía (BCCA). 2021. Available online: https://www.juntadeandalucia.es/organismos/fomentoinfraestructurasyordenaciondelterritorio/areas/vivienda-rehabilitacion/planes-instrumentos/paginas/vivienda-bcca.html (accessed on 13 August 2022).

- Penteado, C.S.G.; Rosado, L.P. Comparison of scenarios for the integrated management of construction and demolition waste by life cycle assessment: A case study in Brazil. Waste Manag. Res. 2016, 34, 1026–1035. [Google Scholar] [CrossRef]

- Rosado, L.P.; Vitale, P.; Penteado, C.S.G.; Arena, U. Life cycle assessment of construction and demolition waste management in a large area of Sao Paulo State, Brazil. Waste Manag. 2019, 85, 477–489. [Google Scholar] [CrossRef]

- Vossberg, C.; Mason-Jones, K.; Cohen, B. An energetic life cycle assessment of C&D waste and container glass recycling in Cape Town, South Africa. Resour. Conserv. Recycl. 2014, 88, 39–49. [Google Scholar] [CrossRef]

- Borghi, G.; Pantini, S.; Rigamonti, L. Life cycle assessment of non-hazardous construction and demolition waste (CDW) management in lombardy region (Italy). J. Clean. Prod. 2018, 184, 815–825. [Google Scholar] [CrossRef]

- Mercante, I.T.; Bovea, M.D.; Ibanez-Fores, V.; Arena, A.P. Life cycle assessment of construction and demolition waste management systems: A Spanish case study. Int. J. Life Cycle Assess. 2012, 17, 232–241. [Google Scholar] [CrossRef]

- Ram, V.G.; Kishore, K.C.; Kalidindi, S.N. Environmental Benefits of Construction and Demolition Debris Recycling: Evidence from an Indian Case Study using Life Cycle Assessment. J. Clean. Prod. 2020, 255, 120258. [Google Scholar] [CrossRef]

- Soust- Verdaguer, B.; Llatas, C.; García- Martínez, A. Critical review of BIM- based LCA method to buildings. Energy Build. 2017, 136, 110–120. [Google Scholar] [CrossRef]

- EPA (Environmental Protection Agency). Solid Waste Management and Greenhouse Gasses: Documentation for Greenhouse Gas Emission and Energy Factors Used in the Waste Reduction Model (WARM). 2019. Available online: https://www.epa.gov/warm/versions-waste-reduction-model-warm#15/ (accessed on 23 August 2022).

- Bizcocho, N. Aplicación del Análisis de Ciclo de Vida a la Gestión de los Residuos de Construcción (Application of the Life Cycle Assessment to the Management of Construction Waste). Ph.D. Thesis, University of Seville, Seville, Spain, 2014. Available online: https://idus.us.es/handle/11441/56324/ (accessed on 13 August 2022). (In Spanish).

- United Nations Environment Programme (UNEP). Global Status Report for Buildings and Construction: Towards a Zero-Emissions, Efficient and Resilient Buildings and Construction Sector. 2020. Available online: https://wedocs.unep.org/handle/20.500.11822/34572https://wedocs.unep.org/handle/20.500.11822/ (accessed on 23 August 2022).

- World Green Building Council. Bringing Embodied Carbon Upfront. 2019. Available online: https://www.worldgbc.org/news-media/bringing-embodied-carbon-upfront (accessed on 23 August 2022).

- International Energy Agency (IEA). Spain 2021: Energy Policy Review. 2021. Available online: https://www.iea.org/reports/spain-2021 (accessed on 23 August 2022).

- World Economic Forum (WEF). Why we Need to Focus on Embedded Energy in Buildings. 2015. Available online: https://www.weforum.org/agenda/2015/05/why-we-need-to-focus-on-embedded-energy-in-buildings/ (accessed on 23 August 2022).

- United Nations Environment Programme (UNEP). Decarbonizing the Building Sector—10 Key Measures. 2021. Available online: https://globalabc.org/resources/publications/decarbonizing-building-sector-10-key-measures (accessed on 23 August 2022).

- Ministerio Para la Transición Ecológica y el Reto Demográfico. Memoria Anual de Generación y Gestión de Residuos de Construcción y Demolición (RCD) 2014–2018. Available online: https://www.miteco.gob.es/es/calidad-y-evaluacion-ambiental/publicaciones/generacionygestiondercd2014-2018_tcm30-527685.pdf (accessed on 23 August 2022).

- Nanjegowda, V.H.; Biligiri, K.P. Recyclability of rubber in asphalt roadway systems: A review of applied research and advancement in technology. Resour. Conserv. Recycl. 2020, 155, 104655. [Google Scholar] [CrossRef]

- Vandewalle, D.; Antunes, V.; Neves, J.; Freire, A.C. Assessment of eco-friendly pavement construction and maintenance using multi-recycled rap mixtures. Recycling 2020, 5, 17. [Google Scholar] [CrossRef]

- Ding, Z.; Zhu, M.; Tam, V.W.Y.; Yi, G.; Tran, C.N.N. A system dynamics-based environmental benefit assessment model of construction waste reduction management at the design and construction stages. J. Clean. Prod. 2018, 176, 676–692. [Google Scholar] [CrossRef]

- Llatas, C.; Osmani, M. Development and validation of a building design waste reduction model. Waste Manag. 2016, 56, 318–336. [Google Scholar] [CrossRef]

- Angulo, S.C.; Gulo, T.; Quattrone, M. Building Design and Construction Process Influence in Construction Waste Generation. Key Eng. Mater. 2015, 668, 297–303. [Google Scholar] [CrossRef]

- Solís-Guzmán, J.; Marrero, M.; Montes, M.V.; Ramírez-de-Arellano, A. A Spanish model for quantification and management of construction waste. Waste Manag. 2009, 29, 2542–2548. [Google Scholar] [CrossRef]

- Quiñones, R.; Llatas, C.; Montes, M.V.; Cortés, I. A multiplatform BIM-integrated construction waste quantification model during design phase. The case of the structural system in a Spanish building. Recycling 2021, 6, 62. [Google Scholar] [CrossRef]

- Guinée, J. Life Cycle Assessment—An Operational Guide to the ISO Standard, Vols. I, II and III. Centrum voor Milieukunde, Universiteit Leiden, May 2001. Impact Assessment Based on Spreadsheet Version 2.2. Available online: http://www.leidenuniv.nl/interfac/cml/ssp/databases/cmlia/index.html (accessed on 22 July 2022).

- Ekvall, T.; Assefa, G.; Björklund, A.; Eriksson, O.; Finnveden, G. What life-cycle assessment does and does not do in assessments of waste management. Waste Manag. 2007, 27, 989–996. [Google Scholar] [CrossRef] [PubMed]

- Autodesk. Published 2021. Available online: https://www.autodesk.eu/products/revit-lt/overview (accessed on 13 August 2022).

- EMVISESA. Municipal Housing Company in Seville. Available online: https://www.emvisesa.org/ (accessed on 23 July 2022).

- Cátedra EMVISESA. Available online: https://catedra.us.es/catedraemvisesa/ (accessed on 23 July 2022).

| Study | CW | DW | LCA | Recycling | Disposal | BIM |

|---|---|---|---|---|---|---|

| [38,39,40,41,42] | X | X | X | X | ||

| [43,44] | X | X | X | X | X | |

| [45] | X | X | X | X | X | |

| Proposed CW-LCA-BIM tool | X | X | X | X | X |

| AP (kg SO2eq) /t Waste | EP (kg PO4eq)/ t Waste | GWP (kg CO2eq)/ t Waste | ODP (kg CFC-11eq)/ t Waste | HTP (kg 1,4-DBeq)/ t Waste | POP (kg C2H4)/ t Waste | CED (MJeq)/ t Waste | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| LoW Code (b), Type of CW | FR | FD | FR | FD | FR | FD | FR | FD | FR | FD | FR | FD | FR | FD |

| 17 01 01 concrete | −5.3 × 10−3 | 2.0 × 10−2 | −4.1× 10−4 | 4.3 × 10−3 | −7.6 × 10−1 | 2.7 × 100 | −6.2 × 108 | 3.5 × 10−7 | −9.7 × 10−2 | 1.6 × 100 | −1.8 × 10−4 | 5.1 × 10−4 | −1.7 × 102 | 4.0 × 101 |

| 17 04 05 steel | −3.5 × 100 | 4.3 × 10−2 | −9.1 × 10−1 | 8.2 × 10−3 | −1.1 × 103 | 6.2 × 100 | −4.0 × 10−6 | 7.0 × 10−7 | 1.5 × 102 | 1.1 × 101 | −8.4 × 10−1 | 1.2 × 10−3 | −1.3 × 104 | 1.0 × 102 |

| 17 02 03/15 01 02 plastic | −2.5 × 100 | 5.3 × 10−2 | −2.1 x 10−1 | 5.2 × 100 | −6.9 × 102 | 1.0 × 102 | 1.3 × 10−5 | 8.9 × 10−7 | 1.9 × 101 | 2.3 × 103 | −1.4 × 10−1 | 2.1 × 10−2 | −2.9 × 104 | 1.2 × 102 |

| Type of Construction Work | Thousand m2 | Percentage |

|---|---|---|

| New building for residential use | 15,614 | 60% |

| New building for non-residential use | 6424 | 25% |

| Demolition work | 2745 | 11% |

| Rehabilitation work | 1325 | 5% |

| Type of Vertical Structure | Number of Buildings | Percentage |

|---|---|---|

| Reinforced concrete | 20,123 | 67% |

| Load-bearing walls | 4275 | 14% |

| Metallic | 3711 | 12% |

| Mixed and others | 1776 | 6% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Llatas, C.; Quiñones, R.; Bizcocho, N. Environmental Impact Assessment of Construction Waste Recycling versus Disposal Scenarios Using an LCA-BIM Tool during the Design Stage. Recycling 2022, 7, 82. https://doi.org/10.3390/recycling7060082

Llatas C, Quiñones R, Bizcocho N. Environmental Impact Assessment of Construction Waste Recycling versus Disposal Scenarios Using an LCA-BIM Tool during the Design Stage. Recycling. 2022; 7(6):82. https://doi.org/10.3390/recycling7060082

Chicago/Turabian StyleLlatas, Carmen, Rocío Quiñones, and Nuria Bizcocho. 2022. "Environmental Impact Assessment of Construction Waste Recycling versus Disposal Scenarios Using an LCA-BIM Tool during the Design Stage" Recycling 7, no. 6: 82. https://doi.org/10.3390/recycling7060082

APA StyleLlatas, C., Quiñones, R., & Bizcocho, N. (2022). Environmental Impact Assessment of Construction Waste Recycling versus Disposal Scenarios Using an LCA-BIM Tool during the Design Stage. Recycling, 7(6), 82. https://doi.org/10.3390/recycling7060082