The Application of Artificial Intelligence in the Effective Battery Life Cycle in the Closed Circular Economy Model—A Perspective

Abstract

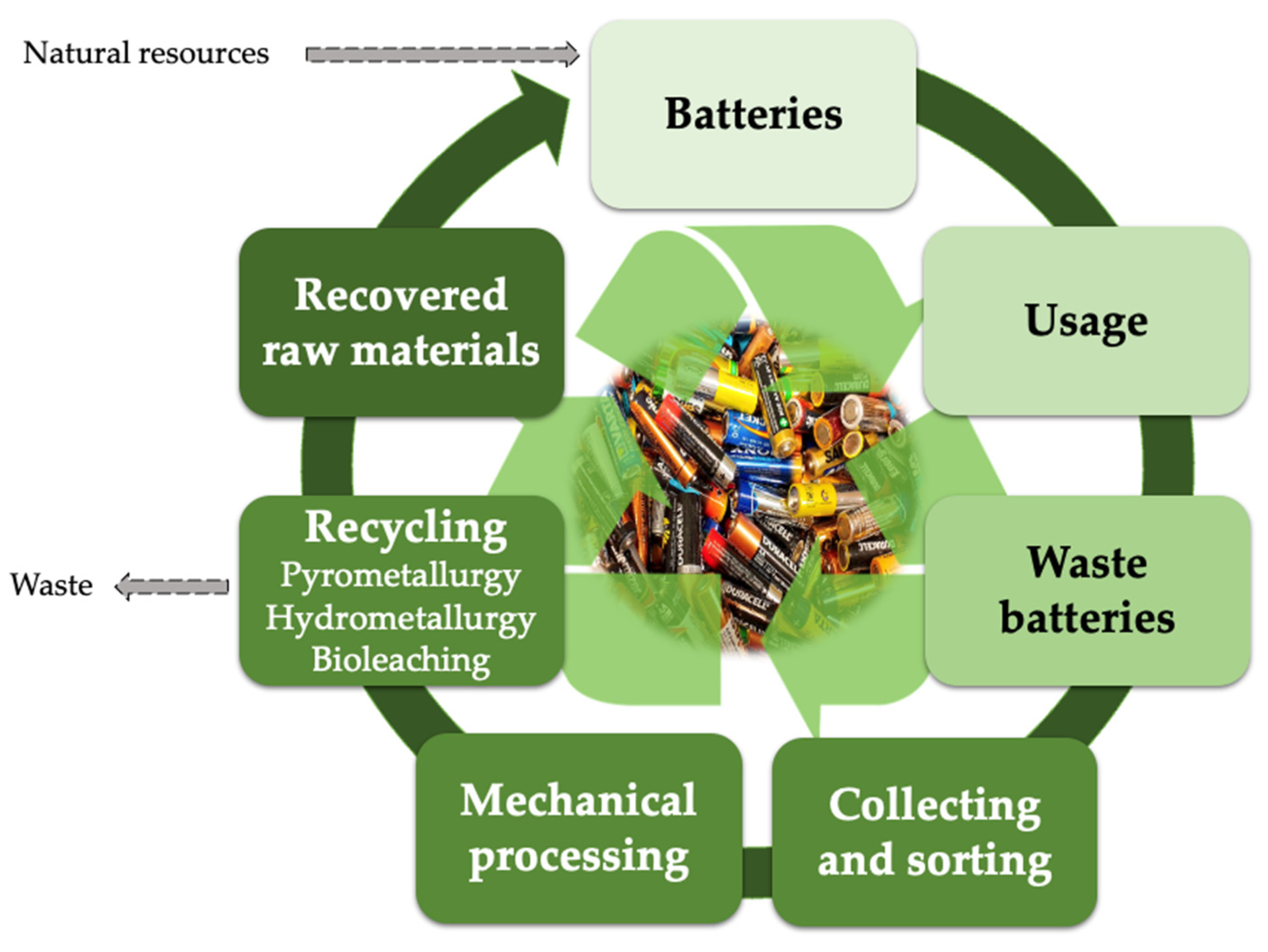

1. Introduction

2. Materials and Methods

3. Artificial Intelligence in Battery Production and Monitoring

4. Artificial Intelligence in Waste Management, Including Battery Waste Management Systems

5. Artificial Intelligence in the Waste Sorting

6. Artificial Intelligence in Battery Waste Recycling

7. Discussion

8. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Battery Recycling Market Size Is Projected to Reach USD 18.96 Billion by 2030, Growing at a CAGR of 7.12%: Straits Research. Available online: https://www.globenewswire.com/en/news-release/2022/07/26/2486248/0/en/Battery-Recycling-Market-Size-is-projected-to-reach-USD-18-96-Billion-by-2030-growing-at-a-CAGR-of-7-12-Straits-Research.html (accessed on 18 September 2022).

- Fan, E.; Li, L.; Wang, Z.; Lin, J.; Huang, Y.; Yao, Y.; Chen, R.; Wu, F. Sustainable Recycling Technology for Li-Ion Batteries and Beyond: Challenges and Future Prospects. Chem. Rev. 2020, 120, 7020–7063. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Y.; Pohl, O.; Bhatt, A.I.; Collis, G.E.; Mahon, P.J.; Rüther, T.; Hollenkamp, A.F. A Review on Battery Market Trends, Second-Life Reuse, and Recycling. Sustain. Chem. 2021, 2, 167–205. [Google Scholar] [CrossRef]

- Waste Statistics—Recycling of Batteries and Accumulators. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Waste_statistics_-_recycling_of_batteries_and_accumulators (accessed on 18 September 2022).

- Zhang, Y.; Wang, B.; Cheng, Q.; Li, X.; Li, Z. Removal of toxic heavy metal ions (Pb, Cr, Cu, Ni, Zn, Co, Hg, and Cd) from waste batteries or lithium cells using nanosized metal oxides: A review. J. Nanosci. Nanotechnol. 2020, 20, 7231–7254. [Google Scholar] [CrossRef] [PubMed]

- Palisoc, S.T.; Cansino, E.J.F.; Dy, I.M.O.; Razal, C.F.A.; Reyes, K.C.N.; Racines, L.R.; Natividad, M.T. Electrochemical determination of tannic acid using graphite electrodes sourced from waste zinc-carbon batteries. Sens. Bio-Sens. Res. 2020, 28, 100326. [Google Scholar] [CrossRef]

- Xiao, J.; Li, J.; Xu, Z. Challenges to Future Development of Spent Lithium Ion Batteries Recovery from Environmental and Technological Perspectives. Environ. Sci. Technol. 2020, 54, 9–25. [Google Scholar] [CrossRef] [PubMed]

- Pagliaro, M.; Meneguzzo, F. Lithium battery reusing and recycling: A circular economy insight. Heliyon 2019, 5, 01866. [Google Scholar] [CrossRef] [PubMed]

- Baars, J.; Domenech, T.; Bleischwitz, R.; Melin, H.E.; Heidrich, O. Circular economy strategies for electric vehicle batteries reduce reliance on raw materials. Nat. Sustain. 2021, 4, 71–79. [Google Scholar] [CrossRef]

- Habib, K.; Hansdóttir, S.T.; Habib, H. Critical metals for electromobility: Global demand scenarios for passenger vehicles, 2015–2050. Resour. Conserv. Recycl. 2020, 154, 104603. [Google Scholar] [CrossRef]

- Liu, P. Recycling waste batteries: Recovery of valuable resources or reutilization as functional materials. ACS Sustain. Chem. Eng. 2018, 6, 11176–11185. [Google Scholar] [CrossRef]

- Olivetti, E.A.; Ceder, G.; Gaustad, G.G.; Fu, X. Lithium-Ion Battery Supply Chain Considerations: Analysis of Potential Bottlenecks in Critical Metals Author links open overlay panel. Joule 2017, 1, 229–243. [Google Scholar] [CrossRef]

- Liberati, A.; Altman, D.G.; Tetzlaff, J.; Mulrow, C.; Gotzsche, P.C.; Ioannidis, J.P.A.; Clarke, M.; Devereaux, P.J.; Kleijnen, J.; Moher, D. The PRISMA Statement for Reporting Systematic Reviews and Meta-Analyses of Studies That Evaluate Health Care Interventions: Explanation and Elaboration. PLoS Med. 2009, 6, e1–e34. [Google Scholar] [CrossRef] [PubMed]

- Rethlefsen, M.L.; Kirtley, S.; Waffenschmidt, S.; Ayala, A.P.; Moher, D.; Page, M.J.; Koffel, J.B. PRISMA-S: An extension to the PRISMA Statement for Reporting Literature Searches in Systematic Reviews. Syst. Rev. 2021, 10, 39. [Google Scholar] [CrossRef] [PubMed]

- Shamseer, L.; Moher, D.; Clarke, M.; Ghersi, D.; Liberati, A.; Petticrew, M.; Shekelle, P.; Stewart, L.A. Preferred Reporting Items for Systematic Review and Meta-Analysis Protocols (PRISMA-P) 2015: Elaboration and explanation. BMJ 2015, 349, 7647. [Google Scholar] [CrossRef] [PubMed]

- Duffner, F.; Mauler, L.; Wentker, M.; Leker, J.; Winter, M. Large-scale automotive battery cell manufacturing: Analyzing strategic and operational effects on manufacturing costs. Int. J. Prod. Econ. 2021, 232, 107982. [Google Scholar] [CrossRef]

- Lombardo, T.; Duquesnoy, M.; El-Bouysidy, H.; Arén, F.; Gallo-Bueno, A.; Jørgensen, P.B.; Bhowmik, A.; Demortière, A.; Ayerbe, E.; Alcaide, F.; et al. Artificial Intelligence Applied to Battery Research: Hype or Reality? Chem. Rev. 2022, 122, 10899–10969. [Google Scholar] [CrossRef] [PubMed]

- Chemali, E.; Kollmeyer, P.J.; Preindl, M.; Emadi, A.J. State-of-charge estimation of Li-ion batteries using deep neural networks: A machine learning approach. J. Power Sources 2018, 400, 242–255. [Google Scholar] [CrossRef]

- Girijaprasanna, T.; Dhanamjayulu, C. A Review on Different State of Battery Charge Estimation Techniques and Management Systems for EV Applications. Electronics 2022, 11, 1795. [Google Scholar]

- Severson, K.A.; Attia, P.M.; Jin, N.; Perkins, N.; Jiang, B.; Yang, Z.; Chen, M.H.; Aykol, M.; Herring, P.K.; Fraggedakis, D.; et al. Data-driven prediction of battery cycle life before capacity degradation. Nat. Energy 2019, 4, 383–391. [Google Scholar] [CrossRef]

- Tan, S.W.; Huang, S.W.; Hsieh, Y.Z.; Lin, S.S. The Estimation Life Cycle of Lithium-Ion Battery Based on Deep Learning Network and Genetic Algorithm. Energies 2021, 14, 4423. [Google Scholar] [CrossRef]

- Cunha, R.P.; Lombardo, T.; Primo, E.N.; Franco, A.A. Artificial Intelligence Investigation of NMC Cathode Manufacturing Parameters Interdependencies. Batter. Supercaps 2020, 3, 60–67. [Google Scholar] [CrossRef]

- He, W.; Williard, N.; Chen, C.; Pecht, M. State of charge estimation for Li-ion batteries using neural network modeling and unscented Kalman filter-based error cancellation. Int. J. Electr. Power Energy Syst. 2014, 62, 783–791. [Google Scholar] [CrossRef]

- Salkind, A.J.; Fennie, C.; Singh, P.; Atwater, T.; Reisner, D.E. Determination of state-of charge and state-of-health of batteries by fuzzy logic methodology. J. Power Sources 1999, 80, 293–300. [Google Scholar] [CrossRef]

- Zheng, Y.; Lu, L.; Han, X.; Li, J.; Ouyang, M. LiFePO4 battery pack capacity estimation for electric vehicles based on charging cell voltage curve transformation. J. Power Sources 2013, 226, 33–41. [Google Scholar] [CrossRef]

- Xu, J.; Cao, B.; Chen, Z.; Zou, Z. An online state of charge estimation method with reduced prior battery testing information. Int. J. Electr. Power Energy Syst. 2014, 63, 178–184. [Google Scholar] [CrossRef]

- Wu, X.; Mi, L.; Tan, W.; Qin, J.L.; Na Zhao, M. State of Charge (SOC) Estimation of Ni-MH Battery Based on Least Square Support Vector Machines. Adv. Mater. Res. 2011, 211–212, 1204–1209. [Google Scholar] [CrossRef]

- How, D.N.; Hannan, M.; Lipu, M.H.; Sahari, K.S.; Ker, P.J.; Muttaqi, K.M. State-of-charge estimation of li-ion battery in electric vehicles: A deep neural network approach. IEEE Trans. Ind. Appl. 2020, 56, 5565–5574. [Google Scholar] [CrossRef]

- Song, X.; Yang, F.; Wang, D.; Tsui, K.L. Combined CNN-LSTM Network for State-of-Charge Estimation of Lithium-Ion Batteries. IEEE Access 2019, 7, 88894–88902. [Google Scholar] [CrossRef]

- Afshar, S.; Morris, K.; Khajepour, A. State-of-Charge Estimation Using an EKF-Based Adaptive Observer. IEEE Trans. Control Syst. Technol. 2019, 27, 1907–1923. [Google Scholar] [CrossRef]

- Li, Y.; Guo, H.; Qi, F.; Guo, Z.; Li, M. Comparative Study of the Influence of Open Circuit Voltage Tests on State of Charge Online Estimation for Lithium-Ion Batteries. IEEE Access 2020, 8, 17535–17547. [Google Scholar] [CrossRef]

- Wang, B.; Zhang, G.; Wang, H.; Xuan, J.; Jiao, K. Multi-physics-resolved digital twin of proton exchange membrane fuel cells with a data-driven surrogate model. Energy AI 2020, 1, 100004. [Google Scholar] [CrossRef]

- Hsu, C.W.; Xiong, R.; Chen, N.Y.; Li, J.; Tsou, N.T. Deep neural network battery life and voltage prediction by using data of one cycle only. Appl. Energy 2022, 306, 118134. [Google Scholar] [CrossRef]

- Blomeke, S.; Rickert, J.; Mennenga, M.; Thiede, S.; Spengler, T.S.; Herrmann, C. Recycling 4.0—Mapping smart manufacturing solutions to remanufacturing and recycling operations. Procedia CIRP 2020, 90, 600–605. [Google Scholar] [CrossRef]

- Garg, A.; Mou, J.; Su, S.; Gao, L. Reconfigurable battery systems: Challenges and safety solutions using intelligent system framework based on digital twins. IET Collab. Intell. Manuf. 2022, 4, 232–248. [Google Scholar] [CrossRef]

- Niri, M.F.; Liu, K.; Apachitei, G.; Roman-Ramirez, L.A.A.; Lain, M.; Widanage, D.; Marco, J. Quantifying key factors for optimised manufacturing of Li-ion battery anode and cathode via artificial intelligence. Energy AI 2022, 7, 100129. [Google Scholar] [CrossRef]

- Cerchecci, M.; Luti, F.; Mecocci, A.; Parrino, S.; Peruzzi, G.; Pozzebon, A. A low power IoT sensor node architecture for waste management within smart cities context. Sensors 2018, 18, 1282. [Google Scholar] [CrossRef] [PubMed]

- Khoa, T.A.; Phuc, C.H.; Lam, P.D.; Nhu, L.M.B.; Trong, N.M.; Phuong, N.T.H.; Dung, N.V.; Tan-Y, N.; Nguyen, H.N.; Duc, D.N.M. Waste Management System Using IoT-Based Machine Learning in University. Wirel. Commun. Mob. Comput. 2020, 2020, 6138637. [Google Scholar]

- Gutierrez, J.M.; Jensen, M.; Henius, M.; Riaz, T. Smart waste collection system based on location intelligence. Procedia Comput. Sci. 2015, 61, 120–127. [Google Scholar] [CrossRef]

- Aziz, F.; Arof, H.; Mokhtar, N.; Mubin, M.; Abu Talip, M.S. Rotation invariant bin detection and solid waste level classification. Measurement 2015, 65, 19–28. [Google Scholar] [CrossRef]

- Nowakowski, P.; Pamuła, T. Application of deep learning object classifier to improve e-waste collection planning Author links open overlay panel. Waste Manag. 2020, 109, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Hua, D.; Gao, J.; Mayo, R.; Smedley, A.; Puranik, P.; Zhan, J. Segregating Hazardous Waste Using Deep Neural Networks in Real-Time Video. In Proceedings of the 2020 10th Annual Computing and Communication Workshop and Conference (CCWC), Las Vegas, NV, USA, 6–8 January 2020; pp. 1016–1022. [Google Scholar]

- Chen, J.; Huang, S.; BalaMurugan, S.; Tamizharasi, G.S. Artificial intelligence based e-waste management for environmental planning. Environ. Impact Assess. Rev. 2021, 87, 106498. [Google Scholar] [CrossRef]

- Han, W.; Gao, G.; Geng, J.; Li, Y.; Wang, Y. Ecological and health risks assessment and spatial distribution of residual heavy metals in the soil of an e-waste circular economy park in Tianjin, China. Chemosphere 2018, 197, 325–335. [Google Scholar] [CrossRef]

- Ihsanullah, I.; Alam, G.; Jamal, A.; Shaik, F. Recent advances in applications of artificial intelligence in solid waste management: A review. Chemosphere 2022, 309, 136631. [Google Scholar] [CrossRef]

- Sinthiya, N.J.; Chowdhury, T.A.; Haque, A.K.M.B. Artificial Intelligence Based Smart Waste Management—A Systematic Review. In Computational Intelligence Techniques for Green Smart Cities. Green Energy and Technology; Lahby, M., Al-Fuqaha, A., Maleh, Y., Eds.; Springer: Cham, Switzerland, 2022. [Google Scholar]

- Menegaki, M.; Damigos, D. A review on current situation and challenges of construction and demolition waste management. Curr. Opin. Green Sustain. Chem. 2018, 13, 8–15. [Google Scholar] [CrossRef]

- Islam, R.; Nazifa, T.H.; Yuniarto, A.; Uddin, A.S.; Salmiati, S.; Shahid, S. An empirical study of construction and demolition waste generation and implication of recycling. Waste Manag. 2019, 95, 10–21. [Google Scholar] [CrossRef]

- Qu, D. Application of Artificial Intelligence in Waste Classification Management at University. In Proceedings in Adaptation, Learning and Optimization, Proceedings of the International Conference on Intelligent Vision and Computing (ICIVC 2021), Qingdao, China, 23–25 July 2021; Sharma, H., Vyas, V.K., Pandey, R.K., Prasad, M., Eds.; Springer: Cham, Switzerland, 2021; Volume 5. [Google Scholar]

- Jude, A.B.; Singh, D.; Islam, S.; Jameel, M.; Srivastava, S.; Prabha, B.; Kshirsagar, P.R. An Artificial Intelligence Based Predictive Approach for Smart Waste Management. Wirel. Pers. Commun. 2021. [Google Scholar] [CrossRef]

- Huang, J.; Koroteevabc, D.D. Artificial intelligence for planning of energy and waste management. Sustain. Energy Technol. Assess. 2021, 47, 101426. [Google Scholar] [CrossRef]

- Ali, T.H.; Akhund, M.A.; Memon, N.A.; Memon, A.H.; Imad, H.U.; Khahro, S.H. Application of Artifical Intelligence in Construction Waste Management. In Proceedings of the 8th International Conference on Industrial Technology and Management (ICITM) 2019, Cambridge, UK, 2–4 March 2019; pp. 50–55. [Google Scholar]

- Coskuner, G.; Jassim, M.S.; Zontul, M.; Karateke, S. Application of artificial intelligence neural network modeling to predict the generation of domestic, commercial and construction wastes. Waste Manag. Res. 2021, 39, 499–507. [Google Scholar] [CrossRef]

- Soni, U.; Roy, A.; Verma, A.; Jain, V. Forecasting municipal solid waste generation using artificial intelligence models—A case study in India. SN Appl. Sci. 2019, 1, 162. [Google Scholar] [CrossRef]

- Abbasi, M.; El Hanandeh, A. Forecasting municipal solid waste generation using artificial intelligence modelling approaches. Waste Manage. 2016, 56, 13–22. [Google Scholar] [CrossRef]

- Golbaz, S.; Nabizadeh, R.; Sajadi, H.S. Comparative study of predicting hospital solid waste generation using multiple linear regression and artificial intelligence. J. Environ. Health Sci. Eng. 2019, 17, 41–51. [Google Scholar] [CrossRef]

- Abdallaha, M.; Talib, M.A.; Feroz, S.; Nasir, Q.; Abdalla, H.; Mahfood, B. Artificial intelligence applications in solid waste management: A systematic research review. Waste Manag. 2020, 109, 231–246. [Google Scholar] [CrossRef] [PubMed]

- McKinnon, D.; Fazakerley, J.; Hultermans, R. Waste Sorting Plants—Extracting Value from Waste; ISWA: Vienna, Austria, 2017. [Google Scholar]

- Abdoli, S. RFID Application in municipally solid waste management system. Int. J. Environ. Res. 2009, 3, 447–454. [Google Scholar]

- Sakr, G.E.; Mokbel, M.; Darwich, A.; Khneisser, M.N.; Hadi, A. Comparing deep learning and support vector machines for autonomous waste sorting. In Proceedings of the IEEE International Multidisciplinary Conference on Engineering Technology (IMCET) 2016, Beirut, Lebanon, 2–4 November 2016; pp. 207–212. [Google Scholar]

- Gundupalli, S.P.; Hait, S.; Thakur, A. A review on automated sorting of source-separated municipal solid waste for recycling. Waste Manag. 2017, 60, 56–74. [Google Scholar] [CrossRef] [PubMed]

- Zenrobotics. Available online: https://zenrobotics.com (accessed on 19 October 2022).

- Artificial Intelligence amd Robotization in Waste Sorting Centers as an Alternative to Brown Bins. Available online: https://www.biogasworld.com/news/artificial-intelligence-robotization-waste-sorting-centers-alternative-brown-bins/ (accessed on 19 October 2022).

- Wilts, H.; Garcia, B.R.; Garlito, R.G.; Gómez, L.S.; Prieto, E.G. Artificial Intelligence in the Sorting of Municipal Waste as an Enabler of the Circular Economy. Resources 2021, 10, 28. [Google Scholar] [CrossRef]

- Kshirsagar, P.R.; Kumar, N.; Almulihi, A.H.; Alassery, F.; Khan, A.I.; Islam, S.; Rothe, J.P.; Jagannadham, D.B.V.; Dekeba, K. Artificial Intelligence-Based Robotic Technique for Reusable Waste Materials. Comput. Intell. Neurosci. 2022, 2022, 2073482. [Google Scholar] [CrossRef] [PubMed]

- Sousa, J.; Rebelo, A.; Cardoso, J.S. Automation of Waste Sorting with Deep Learning. In Proceedings of the XV Workshop de Visão Computacional (WVC) 2019, São Bernardo do Campo, Brazil, 9–11 September 2019; pp. 43–48. [Google Scholar]

- Wang, Z.; Li, H.; Zhang, X. Construction waste recycling robot for nails and screws: Computer vision technology and neural network approach. Autom. Constr. 2019, 97, 220–228. [Google Scholar] [CrossRef]

- Kumar, N.M.; Mohammed, M.A.; Abdulkareem, K.H.; Damasevicius, R.; Mostafa, S.A.; Maashi, M.S.; Chopra, S.S. Artificial intelligence-based solution for sorting COVID related medical waste streams and supporting data-driven decisions for smart circular economy practice. Process Saf. Environ. Prot. 2021, 152, 482–494. [Google Scholar] [CrossRef]

- Subramanian, A.; Thayalan, D.; Edwards, A.; Al-Malki, A.E.; Venugopal, A. Biomedical waste management in dental practice and its significant environmental impact: A perspective. Environ. Technol. Innov. 2021, 24, 101807. [Google Scholar] [CrossRef]

- Shaida, M.N.; Singla, S. Global biomedical waste management issues and practices. Int. J. Innov. Technol. Expl. Eng. 2019, 8, 1053–1059. [Google Scholar]

- Abeygunawardhana, A.G.D.T.; Shalinda, R.M.M.M.; Bandara, W.H.M.D.; Anesta, W.D.S.; Kasthurirathna, D.; Abeysiri, L. AI—Driven Smart Bin for Waste Management. In Proceedings of the 2nd International Conference on Advancements in Computing (ICAC) 2020, Malabe, Sri Lanka, 10–11 December 2020; pp. 482–487. [Google Scholar]

- Zhang, C.; Hu, M.; Di Maio, F.; Sprecher, B.; Yang, X.; Tukker, A. An overview of the waste hierarchy framework for analyzing the circularity in construction and demolition waste management in Europe. Sci. Total Environ. 2022, 803, 149892. [Google Scholar] [CrossRef] [PubMed]

- Deshwal, D.; Sangwan, P.; Dahiya, N. Economic Analysis of Lithium Ion Battery Recycling in India. Wirel. Pers. Commun. 2022, 124, 3263–3286. [Google Scholar] [CrossRef]

- Harper, G.; Sommerville, R.; Kendrick, E.; Driscoll, L.; Slater, P.; Stolkin, R.; Walton, A.; Christensen, P.; Heidrich, O.; Lambert, S.; et al. Recycling lithium-ion batteries from electric vehicles. Nature 2019, 575, 75–86. [Google Scholar] [CrossRef]

- Doose, S.; Mayer, J.K.; Michalowski, P.; Kwade, A. Challenges in Ecofriendly Battery Recycling and Closed Material Cycles: A Perspective on Future Lithium Battery Generations. Metals 2021, 11, 291. [Google Scholar] [CrossRef]

- Golmohammadzadeh, R.; Faraji, F.; Jong, B.; Pozo-Gonzalo, C.; Chakraborty, P.; Banerjee. Current challenges and future opportunities toward recycling of spent lithium-ion batteries. Renew. Sust. Energ. Rev. 2022, 159, 112202. [Google Scholar] [CrossRef]

- Heelan, J.; Gratz, E.; Zheng, Z.; Wang, Q.; Chen, M.; Apelian, D.; Wang, Y. Current and Prospective Li-Ion Battery Recycling and Recovery Processes. JOM 2016, 68, 2632–2638. [Google Scholar] [CrossRef]

- Brückner, L.; Frank, J.; Elwert, T. Industrial Recycling of Lithium-Ion Batteries—A Critical Review of Metallurgical Process Routes. Metals 2020, 10, 1107. [Google Scholar] [CrossRef]

- Hiskey, B. Metallurgy, Survey. In Encyclopedia of Chemical Technology; Kirk, R.E., Othmer, D.F., Eds.; Wiley: New York, NY, USA, 2003. [Google Scholar]

- Zhang, G.; He, Y.; Wang, H.; Feng, Y.; Xie, W.; Zhu, X. Application of mechanical crushing combined with pyrolysis-enhanced flotation technology to recover graphite and LiCoO2 from spent lithium-ion batteries. J. Clean. Prod. 2019, 231, 1418–1427. [Google Scholar] [CrossRef]

- Makuza, B.; Tian, Q.; Guo, X.; Chattopadhyay, K.; Yu, D. Pyrometallurgical options for recycling spent lithium-ion batteries: A comprehensive review. J. Power Sources 2021, 491, 229622. [Google Scholar] [CrossRef]

- Rajaeifar, M.A.; Raugei, M.; Steubing, B.; Hartwell, A.; Anderson, P.A.; Heidrich, O. Life cycle assessment of lithium-ion battery recycling using pyrometallurgical technologies. J. Ind. Ecol. 2021, 25, 1560–1571. [Google Scholar] [CrossRef]

- Yao, Y.; Zhu, M.; Zhao, Z.; Tong, B.; Fan, Y.; Hua, Z. Hydrometallurgical Processes for Recycling Spent Lithium-Ion Batteries: A Critical Review. ACS Sustainable Chem. Eng. 2018, 6, 13611–13627. [Google Scholar] [CrossRef]

- Shin, S.M.; Kim, N.H.; Sohn, J.S.; Yang, D.H.; Kim, Y.H. Development of a metal recovery process from Li-ion battery wastes. Hydrometallurgy 2005, 79, 172–181. [Google Scholar] [CrossRef]

- Peng, C.; Hamuyuni, J.; Wilson, B.P.; Lundström, M. Selective reductive leaching of cobalt and lithium from industrially crushed waste Li-ion batteries in sulfuric acid system. Waste Manag. 2018, 76, 582–590. [Google Scholar] [CrossRef]

- Fan, X.; Song, C.; Lu, X.; Shi, Y.; Yang, S.; Zheng, F.; Huang, Y.; Liu, K.; Wang, H.; Li, Q. Separation and recovery of valuable metals from spent lithium-ion batteries via concentrated sulfuric acid leaching and regeneration of LiNi1/3Co1/3Mn1/3O2. J. Alloys Compd. 2021, 863, 158775. [Google Scholar] [CrossRef]

- Choi, J.W.; Cho, C.W.; Yun, Y.S. Organic acid-based linear free energy relationship models for green leaching of strategic metals from spent lithium-ion batteries and improvement of leaching performance. J. Hazard. Mater. 2022, 423, 127214. [Google Scholar] [CrossRef]

- Sidiq, A.L.; Floweri, O.; Karunawan, J.; Abdillah, O.B.; Santosa, S.P.; Iskandar, F. NCM cathode active materials reproduced from end-of-life Li-ion batteries using a simple and green hydrometallurgical recycling process. Mater. Res. Bull. 2022, 153, 111901. [Google Scholar] [CrossRef]

- Roy, J.J.; Srinivasan, M.; Cao, B. Bioleaching as an Eco-Friendly Approach for Metal Recovery from Spent NMC-Based Lithium-Ion Batteries at a High Pulp Density. ACS Sustain. Chem. Eng. 2021, 9, 3060–3069. [Google Scholar]

- Horeh, N.B.; Mousavi, S.M.; Shojaosadati, S.A. Bioleaching of valuable metals from spent lithium-ion mobile phone batteries using Aspergillus niger. J. Power Sources 2016, 320, 257–266. [Google Scholar] [CrossRef]

- Xin, Y.; Guo, X.; Chen, S.; Wang, J.; Wu, F.; Xin, B. Bioleaching of valuable metals Li, Co, Ni and Mn from spent electric vehicle Li-ion batteries for the purpose of recovery. J. Clean. Prod. 2016, 116, 249–258. [Google Scholar] [CrossRef]

- Roy, J.J.; Cao, B.; Madhavi, S. A review on the recycling of spent lithium-ion batteries (LIBs) by the bioleaching approach. Chemosphere 2021, 282, 130944. [Google Scholar] [CrossRef]

- Ozdemir, M.E.; Ali, Z.; Subeshan, B.; Asmatulu, E. Applying machine learning approach in recycling. J. Mater. Cycles Waste Manag. 2021, 23, 855–871. [Google Scholar] [CrossRef]

- Priyadarshini, J.; Elangovan, M.; Mahdal, M.; Jayasudha, M. Machine-Learning-Assisted Prediction of Maximum Metal Recovery from Spent Zinc–Manganese Batteries. Processes 2022, 10, 1034. [Google Scholar] [CrossRef]

- Garg, A.; Yun, L.; Gao, L.; Putungan, D.B. Development of Recycling Strategy for Large Stacked Systems: Experimental and Machine Learning Approach to Form Reuse Battery Packs for Secondary Applications. J. Clean. Prod. 2020, 275, 124152. [Google Scholar] [CrossRef]

- Zhou, Z.; Duan, B.; Kang, Y.; Shang, Y.; Cui, N.; Chang, L.; Zhang, C. An efficient screening method for retired lithium-ion batteries based on support vector machine. J. Clean. Prod. 2020, 67, 121882. [Google Scholar] [CrossRef]

- Chen, H.; Shen, J. A degradation-based sorting method for lithium-ion battery reuse. PLoS ONE 2017, 12, e0185922. [Google Scholar] [CrossRef]

- Senthilselvi, A.; Sellam, V.; Alahmari, S.A.; Rajeyyagari, S. Accuracy enhancement in mobile phone recycling process using machine learning technique and MEPH process. Environ. Technol. Innov. 2020, 20, 101137. [Google Scholar] [CrossRef]

- Gawel, E.; Strunz, S.; Lehmann, P.; Purkus, A. (Eds.) The European Dimension of Germany’s Energy Transition. Opportunities and Conflicts; Springer International Publishing: Cham, Switzerland, 2019. [Google Scholar]

- Titirici, M.M. Sustainable Batteries—Quo Vadis? Adv. Energy Mater. 2021, 11, 2003700. [Google Scholar] [CrossRef]

- Esmaeilian, B.; Wang, B.; Lewis, K.; Duarte, F.; Ratti, C.; Behdad, S. The future of waste management in smart and sustainable cities: A review and concept paper. Waste Manag. 2018, 81, 177–195. [Google Scholar] [CrossRef]

- Xue, Y.; Wen, Z.; Bressers, H.; Ai, N. Can intelligent collection integrate informal sector for urban resource recycling in China? J. Clean. Prod. 2019, 208, 307–315. [Google Scholar] [CrossRef]

- Pardini, K.; Rodrigues, J.J.P.C.; Kozlov, S.A.; Kumar, N.; Furtado, V. IoT-Based Solid Waste Management Solutions: A Survey. J. Sens. Actuator Netw. 2019, 8, 5. [Google Scholar] [CrossRef]

- Sohn, S. A contextual perspective on consumers’ perceived usefulness: The case of mobile online shopping. J. Retail. Consum. Serv. 2017, 38, 22–33. [Google Scholar] [CrossRef]

- Wu, B.; Widanage, W.D.; Yang, S.; Liu, X. Battery digital twins: Perspectives on the fusion of models, data and artificial intelligence for smart battery management systems. Energy AI 2020, 1, 100016. [Google Scholar] [CrossRef]

- Saha, B.; Goebel, K. Battery data set. In NASA Ames Prognostics. Data Repository; NASA Ames Research Center: Moffett Field, CA, USA, 2007. [Google Scholar]

- Christidis, K.; Devetsikiotis, M. Blockchains and smart contracts for the internet of things. IEEE Access 2016, 4, 2292–2303. [Google Scholar] [CrossRef]

- Junior, C.A.R.; Sanseverino, E.R.; Gallo, P.; Koch, D.; Schweiger, H.G.; Zanin, H. Blockchain review for battery supply chain monitoring and battery trading. Renew. Sustain. Energy Rev. 2022, 157, 112078. [Google Scholar] [CrossRef]

- Ghosh, N.; Garg, A.; Li, W.; Gao, L.; Nguyen-Thoi, T. Engineering design of battery module for EVs: Comprehensive framework development based on DFT, topology optimization, machine learning, multidisciplinary design optimization and digital twins. J. Electrochem. Energy Convers. Storage 2021, 19, 1–34. [Google Scholar] [CrossRef]

- Garg, A.; Wei, L.; Goyal, A.; Cui, X.; Gao, L. Evaluation of batteries residual energy for battery pack recycling: Proposition of stack stress-coupled-AI approach. J. Energy Storage 2019, 26, 101001. [Google Scholar] [CrossRef]

- Li, W.; Chen, J.; Quade, K.; Luder, D.; Gong, J.; Sauer, D.U. Battery degradation diagnosis with field data, impedance-based modeling and artificial intelligence. Energy Storage Mater. 2022, 53, 391–403. [Google Scholar] [CrossRef]

- Panasonic 18650PF Li-ion Battery Data. Available online: https://data.mendeley.com/datasets/wykht8y7tg/1 (accessed on 19 October 2022).

- Ruhatiya, C.; Shaosen, S.; Wang, C.-T.; Jishnu, A.K.; Bhalerao, Y. Optimization of process conditions for maximum metal recovery from spent zinc-manganese batteries: Illustration of statistical based automated neural network approach. Energy Storage 2020, 2, 111. [Google Scholar] [CrossRef]

- Jackson, M.; Simmons, J.P.; de Graef, M. MXA: A customizable HDF5-based data format for multi-dimensional data sets. Modell. Simul. Mater. Sci. Eng. 2010, 18, 065008. [Google Scholar] [CrossRef]

- Franca, A.S.L.; Neto, J.A.; Goncalves, R.F.; Almeida, C.M.V.B. Proposing the use of blockchain to improve the solid waste management in small municipalities. J. Clean. Prod. 2020, 244, 118529. [Google Scholar] [CrossRef]

- Schafer, B. D-waste: Data disposal as challenge for waste management in the inter-net of things. Int. Rev. Inform. Ethics 2014, 22, 12. [Google Scholar]

- Banu, M.I.N.; Florence, S.M. Convergence of Artificial Intelligence in IoT Network for the Smart City—Waste Management System. In Expert Clouds and Applications. Lecture Notes in Networks and Systems; Jacob, I.J., Gonzalez-Longatt, F.M., Shanmugam, S.K., Izonin, I., Eds.; Springer: Singapore, 2019; Volume 209. [Google Scholar]

- Vo, A.H.; Son, L.H.; Vo, M.T.; Le, T. A Novel Framework for Trash Classification Using Deep Transfer Learning. IEEE Access 2019, 7, 178631–178639. [Google Scholar] [CrossRef]

- Mao, W.-L.; Chen, W.-C.; Wang, C.-T.; Lin, Y.-H. Recycling waste classification using optimized convolutional neural network. Resour. Conserv. Recycl. 2021, 164, 105132. [Google Scholar] [CrossRef]

- Zhang, S.; Chen, Y.; Yang, Z.; Gong, H. Computer Vision Based Two-stage Waste Recognition-Retrieval Algorithm for Waste Classification. Resour. Conserv. Recycl. 2021, 169, 105543. [Google Scholar] [CrossRef]

- Khan, R.; Kumar, S.; Srivastava, A.K.; Dhingra, N.; Gupta, M.; Bhati, N.; Kumari, P. Machine Learning and IoT-Based Waste Management Model. Comput. Intell. Neurosci. 2021, 2021, 5942574. [Google Scholar] [CrossRef]

- Mittal, G.; Yagnik, K.B.; Garg, M.; Krishnan, N.C. SpotGarbage: Smartphone app to detect garbage using deep learning. In Proceedings of the 2016 ACM International Joint Conference on Pervasive and Ubiquitous Computing (UbiComp ‘16), Heidelberg, Germany, 12–16 September 2016; Association for Computing Machinery: New York, NY, USA, 2016; pp. 940–945. [Google Scholar]

- Costa, B.S.; Bernardes, A.C.S.; Pereira, J.V.A.; Zampa, V.H.; Pereira, V.A.; Matos, G.F.; Soares, E.A.; Soares, C.L.; Silva, A.F. Artificial Intelligence in Automated Sorting in Trash Recycling. In Anais do XV Encontro Nacional de Inteligência Artificial e Computacional; SBC: Porto Alegre, Brazil, 2018; pp. 198–205. [Google Scholar]

- Wang, Z.; Peng, B.; Hwuang, Y.; Sun, G. Classification for plastic bottles recycling based on image recognition. Waste Manag. 2019, 88, 170–181. [Google Scholar] [CrossRef]

- Huang, G.-L.; He, J.; Xu, Z.; Huang, G. A combination model based on transfer learning for waste classification. Concurrency Computat. Pract. Exper. 2020, 32, 5751. [Google Scholar] [CrossRef]

- Bobulski, J.; Kubanek, M. Waste Classification System Using Image Processing and Convolutional Neural Networks. In Advances in Computational Intelligence. IWANN 2019; Lecture Notes in Computer Science; Rojas, I., Joya, G., Catala, A., Eds.; Springer: Cham, Switzerland, 2019; Volume 11507. [Google Scholar]

- Bircanoğlu, C.; Atay, M.; Beser, F.; Genc, O.; Kizrak, M.A. RecycleNet: Intelligent Waste Sorting Using Deep Neural Networks. In Proceedings of the Innovations in Intelligent Systems and Applications (INISTA) 2018, Thessaloniki, Greece, 3–5 July 2018; pp. 1–7. [Google Scholar]

- Madhav, A.S.; Rajaraman, R.; Harini, S.; Kiliroor, C.C. Application of artificial intelligence to enhance collection of E-waste: A potential solution for household WEEE collection and segregation in India. Waste Manag. Res. 2022, 40, 1047–1053. [Google Scholar] [CrossRef]

- Gondal, A.U.; Sadiq, M.I.; Ali, T.; Irfan, M.; Shaf, A.; Aamir, M.; Shoaib, M.; Glowacz, A.; Tadeusiewicz, R.; Kantoch, E. Real Time Multipurpose Smart Waste Classification Model for Efficient Recycling in Smart Cities Using Multilayer Convolutional Neural Network and Perceptron. Sensors 2021, 21, 4916. [Google Scholar] [CrossRef]

- National Sleep Research Resource. Available online: https://sleepdata.org/ (accessed on 19 October 2022).

- Torayev, A.; Magusin, P.C.M.M.; Grey, C.P.; Merlet, C.; Franco, A.A. Text Mining Assisted Review of the Literature on Li-O2 Batteries. J. Phys. Mater. 2019, 2, 044004. [Google Scholar] [CrossRef]

- El-Bousiydy, H.; Lombardo, T.; Primo, E.N.; Duquesnoy, M.; Morcrette, M.; Johansson, P.; Simon, P.; Grimaud, A.; Franco, A.A. What can text mining tell us about Lithium-Ion battery researchers’ habits? Batter. Supercaps 2021, 4, 689. [Google Scholar] [CrossRef]

- Gayon-Lombardo, A.; Mosser, L.; Brandon, N.P.; Cooper, S.J. Pores for Thought: The Use of Generative Adversarial Networks for the Stochastic Reconstruction of 3D Multi-Phase Electrode Microstructures with Periodic Boundaries. Comput. Mater. 2020, 6, 82. [Google Scholar] [CrossRef]

- Baduge, S.K.; Thilakarathna, S.; Perera, J.S.; Arashpour, M.; Sharafi, P.; Teodosio, B.; Shringi, A.; Mendis, P. Artificial intelligence and smart vision for building and construction 4.0: Machine and deep learning methods and applications. Autom. Contr. 2022, 141, 104440. [Google Scholar] [CrossRef]

- Yu, X.; Li, W.; Gupta, V.; Gao, H.; Tran, D.; Sarwar, S.; Chen, Z. Current Challenges in Efficient Lithium-Ion Batteries’ Recycling: A Perspective. Glob. Chall. 2022, 2022, 2200099. [Google Scholar] [CrossRef]

- Yu, K.H.; Zhang, Y.; Li, D.; Montenegro-Marin, C.E.; Kumar, P.M. Environmental planning based on reduce, reuse, recycle and recover using artificial intelligence. Environ. Impact Assess. Rev. 2021, 86, 106492. [Google Scholar] [CrossRef]

- Rahman, M.W.; Islam, R.; Hasan, A.; Bithi, N.I.; Hasan, M.; Rahman, M.M. Intelligent waste management system using deep learning with IoT. J. King Saud Univ. Comput. Inf. Sci. 2022, 34, 2072–2087. [Google Scholar] [CrossRef]

- Bird, R.; Baum, Z.J.; Yu, X.; Ma, J. The Regulatory Environment for Lithium-Ion Battery Recycling. ACS Energy Lett. 2022, 7, 736–740. [Google Scholar] [CrossRef]

- Ali, H.; Khan, H.A.; Pecht, M. Preprocessing of spent lithium-ion batteries for recycling: Need, methods, and trends. Renew. Sustain. Energy Rev. 2022, 168, 112809. [Google Scholar] [CrossRef]

| Ref. | AI-Based Algorithms | Type of Operation | Accuracy [%] | Datasets |

|---|---|---|---|---|

| [66] | Region-based Convolutional Neural Network | waste classification based on image recognition | 81.40 | 800 pictures of waste (3456 × 4608, 600 pixels) |

| [122] | Convolution Neural Networks | waste classification based on image recognition | 87.69 | Garbage In Images (GINI) dataset https://github.com/spotgarbage/spotgarbage-GINI (accessed on 1 September 2022) |

| [67] | Region-based Convolutional Neural Network | construction waste classification based on image recognition (nails and screws) | 89.10 | A number of pictures of nails and screws |

| [42] | Convolution Neural Networks | waste classification based on image recognition | 90.00 | 2298 pictures (i.e., 223 batteries, 91 syringes, 1984 non-hazardous trash) |

| [123] | Support Vector Machine k-Nearest Neighbor Random Forest | waste classification based on image recognition | 93.00 93.00 93.00 | 1200 pictures (400 pictures for each class, i.e., glass, paper, metal, plastic) |

| [118] | Deep Neural Networks for Trash Classification | waste classification based on image recognition | 94.00 (Trashnet dataset) 98.00 (VN-trash dataset) | 5904 images of waste, divided into three classes, including Organic, Inorganic and Medical wastes (VN-trash dataset) 2400 images of waste, divided into six classes, including glass, paper, cardboard, plastic, metal, and trash (Trash-net dataset) |

| [124] | Support Vector Machine | waste classification based on image recognition | 94.70 | Pictures of waste |

| [125] | Convolution Neural Networks | waste classification based on image recognition | 96.50 | waste pictures from Google search and existing published image databases |

| [41] | Convolution Neural Networks Region-based Convolutional Neural Network | waste classification based on image recognition | 93.30 96.70 | 16,384 (128 × 128) pictures of e-waste |

| [40] | Support Vector Machine | Solid waste classification based on image recognition | 99.40 | 220 pictures of waste (i.e., 60 rotated bin images, 100 unrotated bin images, 800 × 600 pixels) |

| [119] | Convolution Neural Networks | waste classification based on image recognition | 99.60 | 10,108 waste images (i.e., 2527 pictures of flipping horizontal, 2527 pictures of flipping vertical, and 2527 random 25° rotations) |

| [126] | Convolution Neural Networks | waste sorting based on image recognition | 91.72 | Pictures of waste (227 × 227 pixels) |

| [120] | Convolution Neural Networks | waste sorting based on image recognition | 94.71 | 1040 images of waste |

| [63] | Convolution Neural Networks, Support Vector Machines | waste sorting based on image recognition | 94.80 83.00 | 2000 images of waste |

| [127] | Convolution Neural Networks | waste sorting based on image recognition | 95.00 | 2400 images of waste, divided into six classes, including glass, paper, cardboard, plastic, metal, and trash (Trash-net dataset) |

| [68] | Support Vector Machines | COVID-19 pandemic waste sorting based on image recognition | 96.50 | 2400 images of waste |

| [128] | Convolution Neural Networks | e-waste sorting based on image recognition | 96.00 | 8000 pictures of electronic devices |

| [129] | Convolution Neural Networks | waste sorting based on image recognition | 99.00 | 1241 pictures of waste |

| [50] | Convolution Neural Networks | waste management | 96.00 | 200 pictures of waste |

| [53] | Multi-layer Perceptron Artificial Neural Network | forecast of the number of annual waste generation | 95.00 | solid waste generation rates (kg per capita–1 day–1) in Bahrain (1997–2016) |

| [121] | Support vector machine Random Forest Multilayer perceptron Naive Bayes | waste management | 89.52 97.49 96.44 81.46 | 2947 pictures of waste |

| [56] | Fuzzy Logic–Support Vector Regression | estimation of waste generation rates | 92.00 | 105 × 7 matrices, representing static data: 105 samples of 7 elements |

| [55] | Support Vector Machine Adaptive Neuro-fuzzy Inference System Artificial Neural Network k-Nearest Neighbours | waste generation forecasting | 71.00 98.00 46.00 51.00 | collection of monthly time series of waste generation from the period of eighteen years (1996–2014) |

| [71] | Convolutional Neural Network | waste sorting based on image recognition | 70.00 | 2400 images of waste, divided into six classes, including glass, paper, cardboard, plastic, metal, and trash (Trash-net dataset) |

| [36] | Gradient-boosted decision trees (GBT) Random Forest | prediction of the characteristics of the electrodes | 93.48 91.75 | 96 cathode-related, and 75 anode-related electrodes and half-cell data |

| [113] | Automated Neural Network (SANN) | optimization of metal recovery of Zn from battery waste | 94.00 | Experimental data-two sets of 29 data samples for Zn and Mn yield |

| [94] | Linear Regression Random Forest Regression AdaBoost Regression Gradient Boosting Regression XG Boost Regression | optimization of metal recovery of Zn from battery waste | −42.33 88.02 82.67 96.76 99.88 | Experimental data-sets of 29 data samples for Zn yield |

| [94] | Linear Regression Random Forest Regression AdaBoost Regression Gradient Boosting Regression XG Boost Regression | optimization of metal recovery of Mn from battery waste | 19.36 22.96 12.32 61.25 95.97 | Experimental data-sets of 29 data samples for Mn yield |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pregowska, A.; Osial, M.; Urbańska, W. The Application of Artificial Intelligence in the Effective Battery Life Cycle in the Closed Circular Economy Model—A Perspective. Recycling 2022, 7, 81. https://doi.org/10.3390/recycling7060081

Pregowska A, Osial M, Urbańska W. The Application of Artificial Intelligence in the Effective Battery Life Cycle in the Closed Circular Economy Model—A Perspective. Recycling. 2022; 7(6):81. https://doi.org/10.3390/recycling7060081

Chicago/Turabian StylePregowska, Agnieszka, Magdalena Osial, and Weronika Urbańska. 2022. "The Application of Artificial Intelligence in the Effective Battery Life Cycle in the Closed Circular Economy Model—A Perspective" Recycling 7, no. 6: 81. https://doi.org/10.3390/recycling7060081

APA StylePregowska, A., Osial, M., & Urbańska, W. (2022). The Application of Artificial Intelligence in the Effective Battery Life Cycle in the Closed Circular Economy Model—A Perspective. Recycling, 7(6), 81. https://doi.org/10.3390/recycling7060081