1. Introduction

The construction industry encounters many hindrances in production costs. Excessive amounts of nonreusable waste materials are generated by adopting conventional formworks (temporary structures that facilitate molding of concrete in desired shape), whereas the higher production cost of reusable shuttering limits its adaptation in the industry [

1,

2]. Traditional construction procedures have limitations with geometrically complex shapes and insufficient manufacturing precision [

3,

4]. The construction industry uses a significant number of natural resources such as sand, clay, limestone (a major component of cement), rock, and gravel. The increased global urbanization and world population have amplified the demand for construction materials [

5]. The largest amount of waste generated in Europe comes from the construction industry (36%), along with mining and quarrying (26.2%) [

6]. Improvements in the construction procedures and usage of greener products are the key considerations that are closely tied to the avoidance of waste.

Concrete is the most widely used material worldwide in the construction industry [

7]. High cost, surplus waste generation, non-environmentally-friendly materials, and modes adopted to generate concrete are the dominant issues in construction activity [

8]. The entire construction approach, including material transportation, parameter selection, strength requirements, off-site manufacturing, assembly, and installation, dissipates a prodigious extent of energy and greenhouse gases. To make conventional concrete, the most fundamental element is ordinary Portland cement (OPC), which is a high carbon and energy-demanding material [

9]. Increasing demand for cement in the construction industry generated CO

2 emissions of nearly 1599 Mt in 2017 [

10]. Sustainable usage of waste produced as by-products from diverse industries can provide an alternative to Portland cement. The utilization of reusable sustainable materials to preserve raw material is what the present era requires [

11,

12].

Geopolymers are known as green materials for the construction industry, having almost 80–90% less CO

2 discharge [

13]. Asim et al. [

14] revealed the sustainable material usage and economical, reliable manufacturing techniques in the construction industry increase energy efficiency, generate employment, and boost competitiveness. According to Abdollahnejad et al. [

15], energy demand enhancement around the globe is a leading reason for unsustainable development on our planet. Geopolymer concretes (GPC), having significant acid resistance [

16,

17], adequate adhesion to steel and iron [

18], is considered a viable and eco-friendly substitute for OPC [

19,

20]. Ultimately, the energy required to produce GPC can be 43–59% lower in comparison with OPC [

21]. Using industrial by-products for the synthesis of GPC results in cost-effective and sustainable concrete [

22]. GPC has excellent heat resistance, low permeability, and good mechanical properties, which has been gaining increasing attention in the construction industry [

23]. Geopolymer 3D printing for construction products seems to be a promising technology that decreases the labor requirements, reduces the construction costs, and increases the safety level [

24,

25,

26].

Geopolymer 3D printing is among the emerging techniques applied for the precise formulation of frameworks from a digital design. Additive manufacturing (AM) is considered an innovative technology that realizes the construction automation concept [

27,

28]. AM is a fast-growing industrial sector that has many potential advantages in terms of flexibility, efficiency, labor reduction, construction in a harsh environment, safety, geometrical flexibility, and sustainability in the construction sector [

29,

30]. Currently, in the industry, two different 3D printers (framed and nonframed) are in use. Framed printers, limited by difficulties in their assembly outside the factories and transportation, are only used inside factories. Raw material availability and transportation, material pretreatments, machining cost, and framework setup are major factors that influence 3D printing optimization. The adoption of 3D printing techniques can reduce costs by 30–65% in the construction industry [

31].

Typically, constructing a house using a traditional method takes months. Conventional approaches of construction are slow and often comprise many time-consuming steps, such as transportation, material production, formwork manufacturing, labor demand, and safety matters [

32,

33,

34]. In a traditional construction process, formworks may account for 35–54% of the total construction cost and consume 50–75% of the total construction time [

4]. Mobile construction 3D printers have the potential of printing houses economically. The ultimate cost of 3D geopolymer printed houses directly depends upon the availability of raw materials, transportation, pretreatment techniques, and parameter selection. Although corroboration of GP 3D printing practices in countries such as Finland is scarce in literature, there are many countries where these practices have reached an industrial scale, such as “the office of future” assembled in Dubai and printed in China, the canal house printed in Amsterdam, the Apis Cor printed house in Russia [

35], a five-story building printed in China, just to mention a few [

36]. The size of the printed articles is one of the constraints related to 3D printing [

37,

38,

39]. Other barriers to the adoption of 3D printing are building regulations [

40], cementitious printing material limitations [

41], and workforce requirements [

35].

Three-dimensional printing technology for construction products is still in its early stages. It is becoming popular in the construction sector worldwide [

42]. According to [

43], in 2020 the 3D printing market globally grew by 21% compared to 2019, which has an estimated value of

$12.6 billion. In recent years, enormous efforts have been accomplished to incorporate geopolymer compounds into digital fabrication. Voney et al. [

44] found the use of waste stone as mineral aggregates in terms of printing accuracy does not alter the mechanical behaviour of printed materials. According to Chauhan et al. [

45], the functionalization with polyvinyl-alcohol-reinforced fibers and nanoclay additives enhances strength performance (49%) of printable geopolymer mortars. Similarly, Lie et al. [

46] investigated, the automated incorporation of steel microcable lends higher bond strength (19% enhancement), greater tensile strength (82.5% increase) in comparison with non-reinforced configuration, and lower structural impact of inadequate planes among the printed layers. However, the economics of geopolymer 3D printing on an industrial scale is the key question that is limiting this green material’s adoption on an industrial scale. In fact, in Finland, geopolymer 3D printing in the construction industry has not yet started commercially, and either there is no 3D prototype printed house in the country, or it is not officially documented. This acknowledges an interesting gap in literature that needs significant consideration to analyze the economics of using this advanced technology.

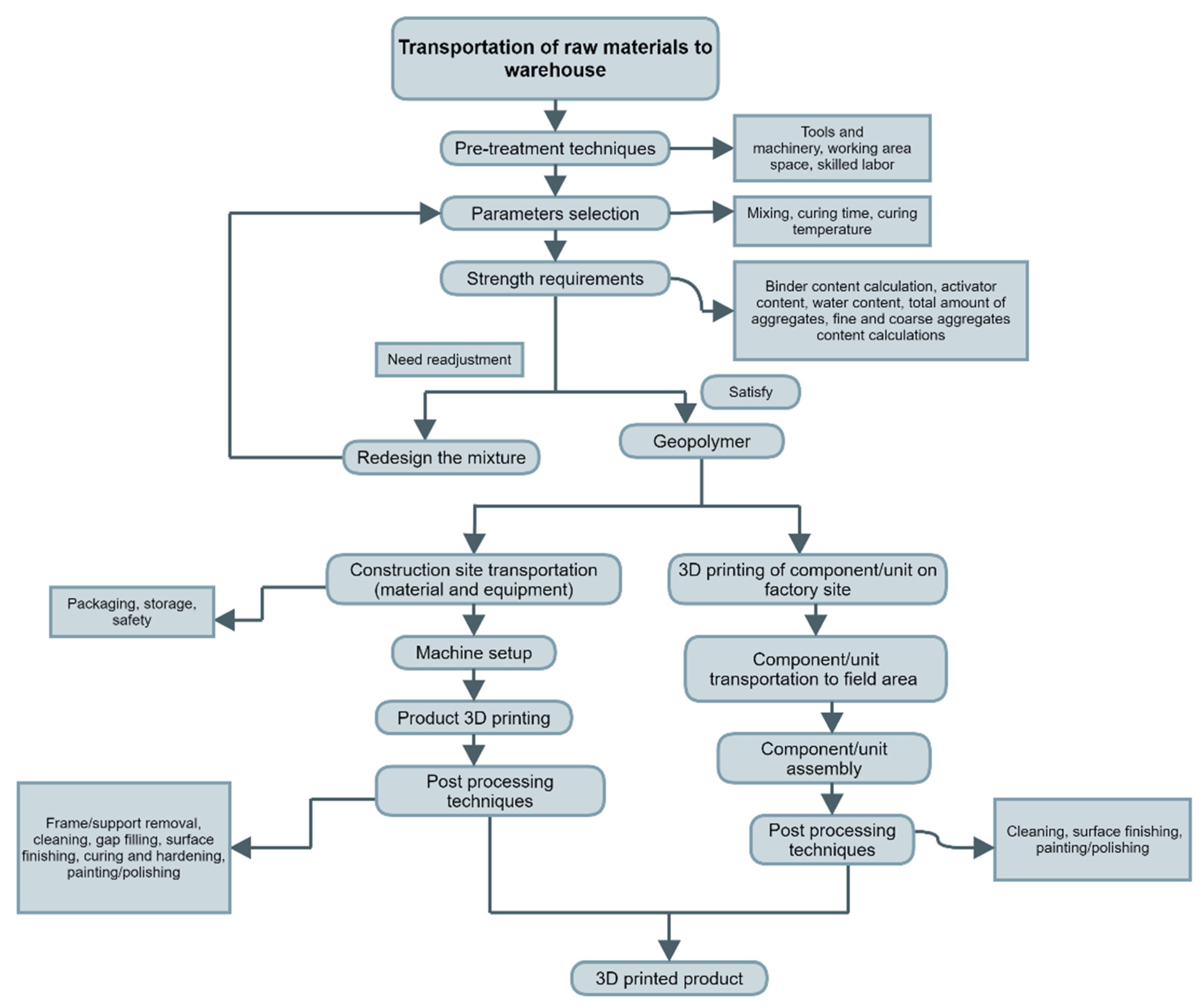

This research aimed to investigate the cost analysis of geopolymer 3D printing for construction products on construction sites and in factories. The economics of geopolymers formulated from locally sourced waste materials was investigated. The study analyzed the effect of pretreatment, mixing and printing of geopolymer under one operational unit on final product cost. This project work identified different stages involved in the 3D printing of geopolymers and the required investment needed to perform all stages economically. This work is focused on a cost analysis of the most crucial parameters of geopolymer 3D printing: raw material availability, transportation, pretreatments, parameter selection, and strength requirements. In addition, we investigated the required time, cost, and quality of a 50 m2 geopolymer 3D printed house in Finland.

3. Results and Discussion

The prerequisites for 3D printing of geopolymers is the availability of raw materials and their transportation to warehouses for pretreatment. Approximately 32,000 tons of raw material annually require further processing for printing. Economical and sustainable functions and processes are determined to establish a continuous flow of materials. The transportation cost of raw materials for geopolymer synthesis is a significant element of the overall cost. The financial aspects of transportation depend on time, accessibility, and distance. Transport is an integral constituent of any production process from an economic frame of reference.

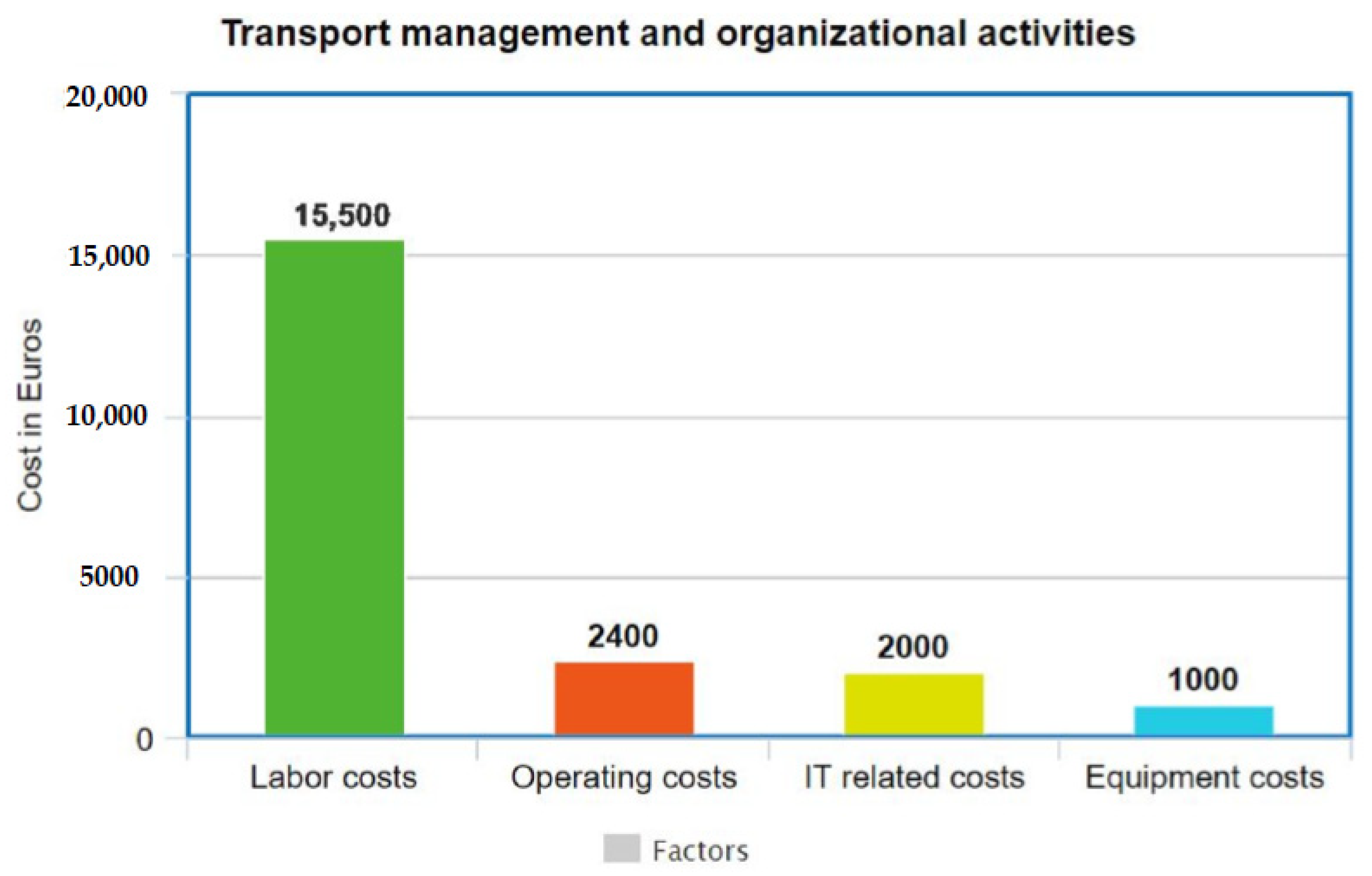

Table 9 illustrates the components which were considered to calculate the cost of various functions perform under transport organizational and operational activities. Factors such as labor, equipment, IT, and operating costs are key specifications for transport expenditure. Labor cost, having the highest value, seems to be the most prominent aspect altering the value of the final product, as shown in

Figure 2. The IT-related cost has the second largest value, whereas the equipment cost has the least effect on the final values.

The effect of labor cost in the freight, carrier, and shipment sectors is significant. Wages, extra time payment, and payroll taxes are the factors considered for calculating labor costs. Besides IT-related expenses, labor cost is the most essential factor affecting the overall price of transport management. Monthly expenses of transport management and organizational activities are illustrated in

Table 2, which shows that over 70% of total expenditures are spent by an employer for employing staff, because of the higher salary rate. The estimated monthly expenditures needed for organizational and management activities are €20,900. Therefore, annually €250,800 are needed for management activities to perform transportation of 32,000 tons of raw materials. The

Table 2 also shows that transport management represents 52%, whereas transport operation and organization represent 48% of the overall transportation cost.

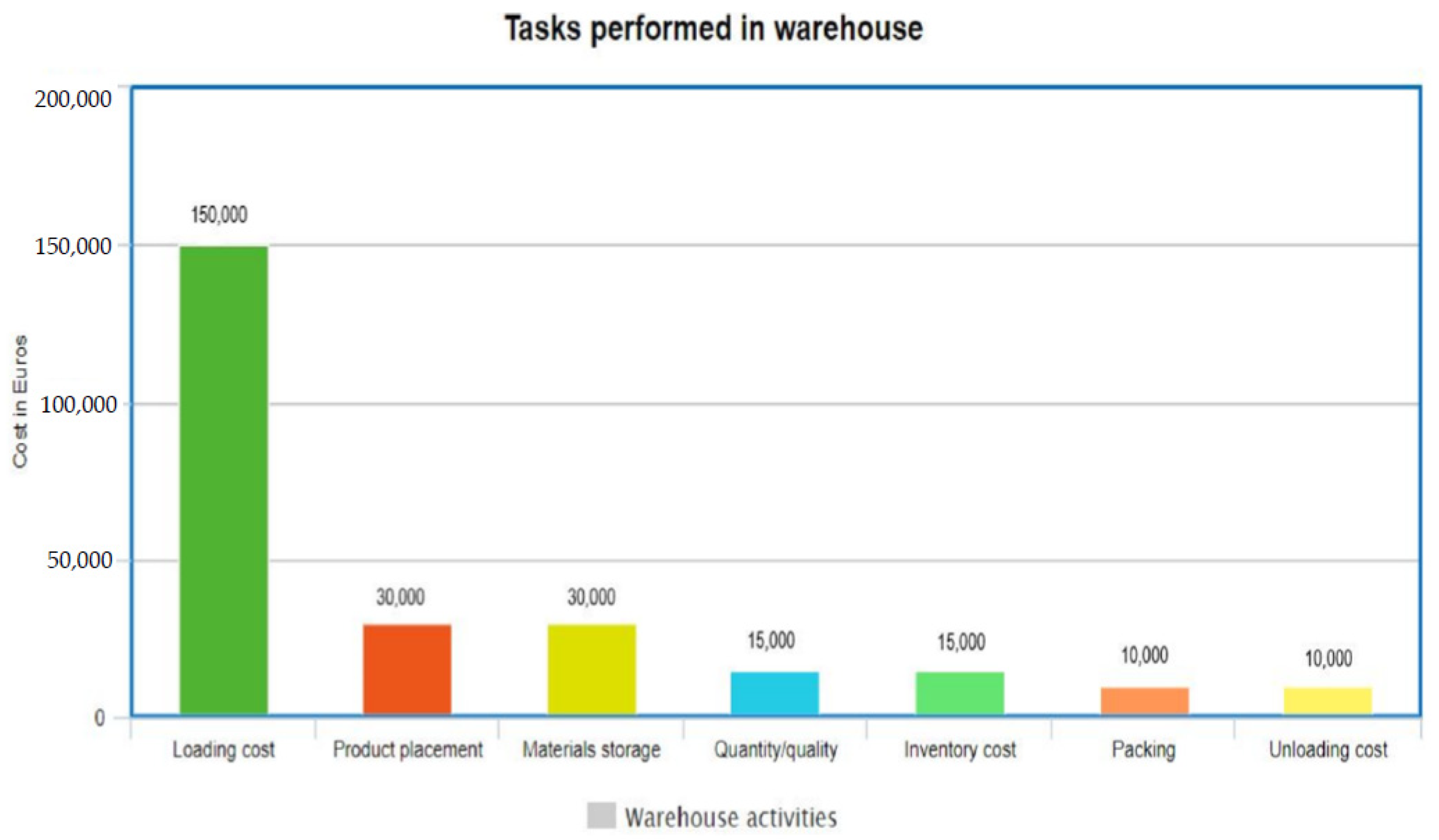

The cost calculation of a warehouse is based on labor, operating, IT-related, equipment, and area utilization costs. Labor cost is the biggest factor, representing 79% of the overall cost of a warehouse, as shown in

Table 3. Each raw material needs different packaging, storage space, equipment, and operating conditions. Processes considered for warehousing cost calculation are loading/unloading, quality and quantity of material, packing, material storage, product placement, and inventory cost, as presented in

Figure 3. In addition to storage, loading is a vital process affecting the entire warehousing cost significantly. The estimated investment cost needed for warehouse activities is €328,500. Therefore, the total estimated amount of investment needed for transportation and warehouse activities of 32,000 tons of raw material annually is €579,300.

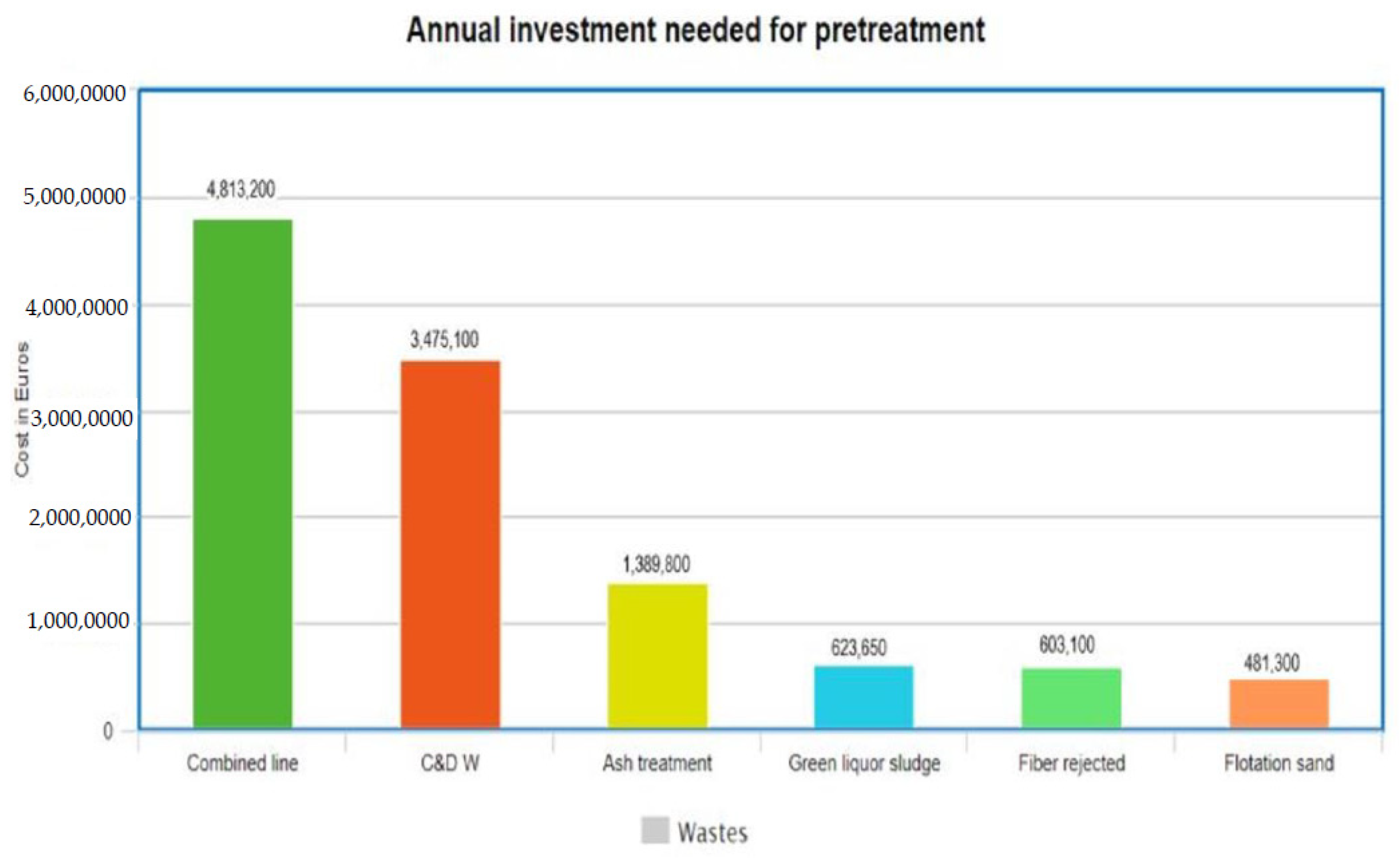

3.1. Pretreatment Cost

After waste material transportation, the second most crucial step is the specific treatment technique for each waste. These treatment techniques make the raw material useful for 3D printing purposes. Many studies have already been conducted on construction and demolition waste (C&D W) and ash utilization for concrete production, but green liquor sludge and rejected fiber are not as widely used as recycled materials. The annual investment required to perform pretreatment techniques is presented in

Figure 4.

Machinery, plant area, maintenance, installation, and labor costs are crucial parameters to investigate annual investment costs for pretreatments. Construction and demolition waste require the highest amount of total investment for pretreatment techniques. The largest plant area (2000 m2) is needed for 8000 tons of C&D W. Similarly, a greater amount of energy is needed for C&D W pretreatments.

3.2. Strength Requirements and Parameter Selection

The geopolymer strength depends upon the selection of various parameters such as curing temperature, concentration of chemicals, ratio of solid solution, curing time, alkali solution molar ratio, elementary materials containing silica and aluminum concentration, type of additives, admixtures, and alkali solution type. In addition to material selection, the strength of geopolymer concrete relies on the curing temperature conditions.

A study conducted by V. Patil et al. [

51] showed that the compressive strength of geopolymer concrete is higher at oven curing temperature compared to that at ambient curing temperature, as dissolution of alumina and silica in an alkaline solution is better at high temperatures. Similarly, as the concrete ages, a slightly higher compression strength can be attained. After curing the concrete for 28 days, 30, 40 and 50 MPa strength should be achieved for M30, M40, and M50 grades of concrete, respectively.

The compression strength after seven days of curing must be 70% of the total required compression strength. The enhancement in the percentage of fine aggregates and coarse aggregates increased the strength to the optimum level. Based on the calculations shown in

Table 6, the production cost of geopolymer concrete is higher than that of OPC because of the raw material pretreatment techniques. A study conducted by Rajini et al. [

52] illustrated that the initial material cost of GPC (M45) was almost 32% higher than that of conventional concrete (M45). However, natural resources, environment, sustainability, cost of maintenance, and GPC properties offset the initial cost production of GPC.

3.3. Factory 3D Printing

Components in the form of batches are printed inside the factory. Components such as walls, foundations, floor, roofs, windows, and doors are printed separately and assembled at the construction site. The formula explained in

Table 10 presents the cost calculation of the printed components. The manufacturing cost of the printed components includes all the steps required inside the company to produce the printed components. In manufacturing, labor is one of the most crucial factors that has a significant impact on the final product cost. Industry experiences illustrate that the labor cost effect may be up to 60% of the final product cost. The cost structure of components printed in a factory is divided into labor, material, and equipment expenses. All components such as internal walls, external walls, foundation, floor, roof, ceiling, doors, and windows are printed separately and assembled on-site. Major factors of the cost composition at the assembly stage of 3D printed components include sub engineering, measuring, and project-related costs.

3.4. Construction Site 3D Printing

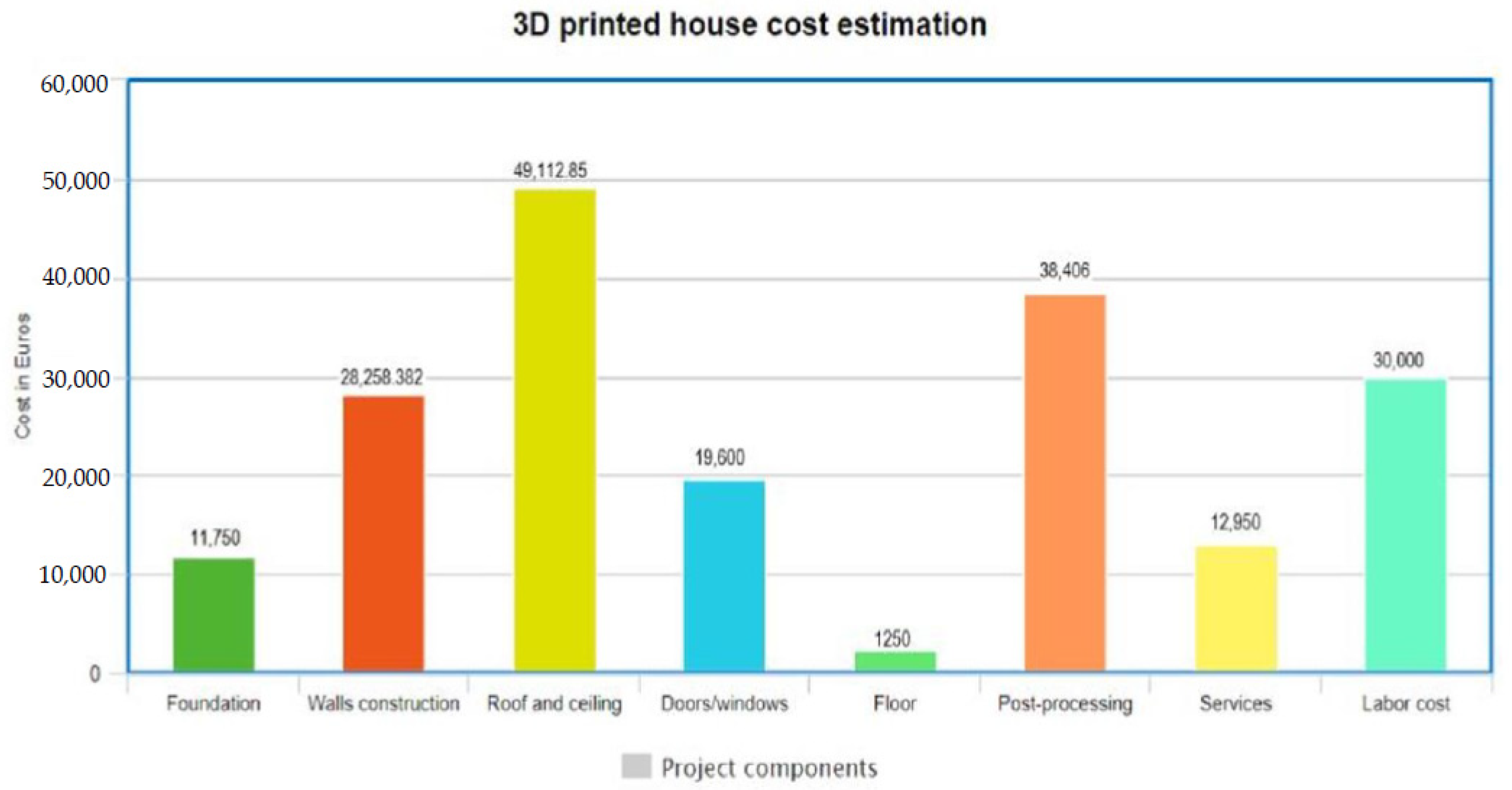

The 3D printed house elemental estimate varies significantly from the traditional construction method, as explained in

Table 8. It can also be noticed that the 3D printed house requires less time for manufacturing compared to traditional manufacturing techniques. The cost composition of all the construction products includes installation, equipment, postprocessing, health, safety, and services-related factors of the project.

Figure 5 shows that roof and ceiling account for the highest cost, with a value of €49,112.85, compared to other factors.

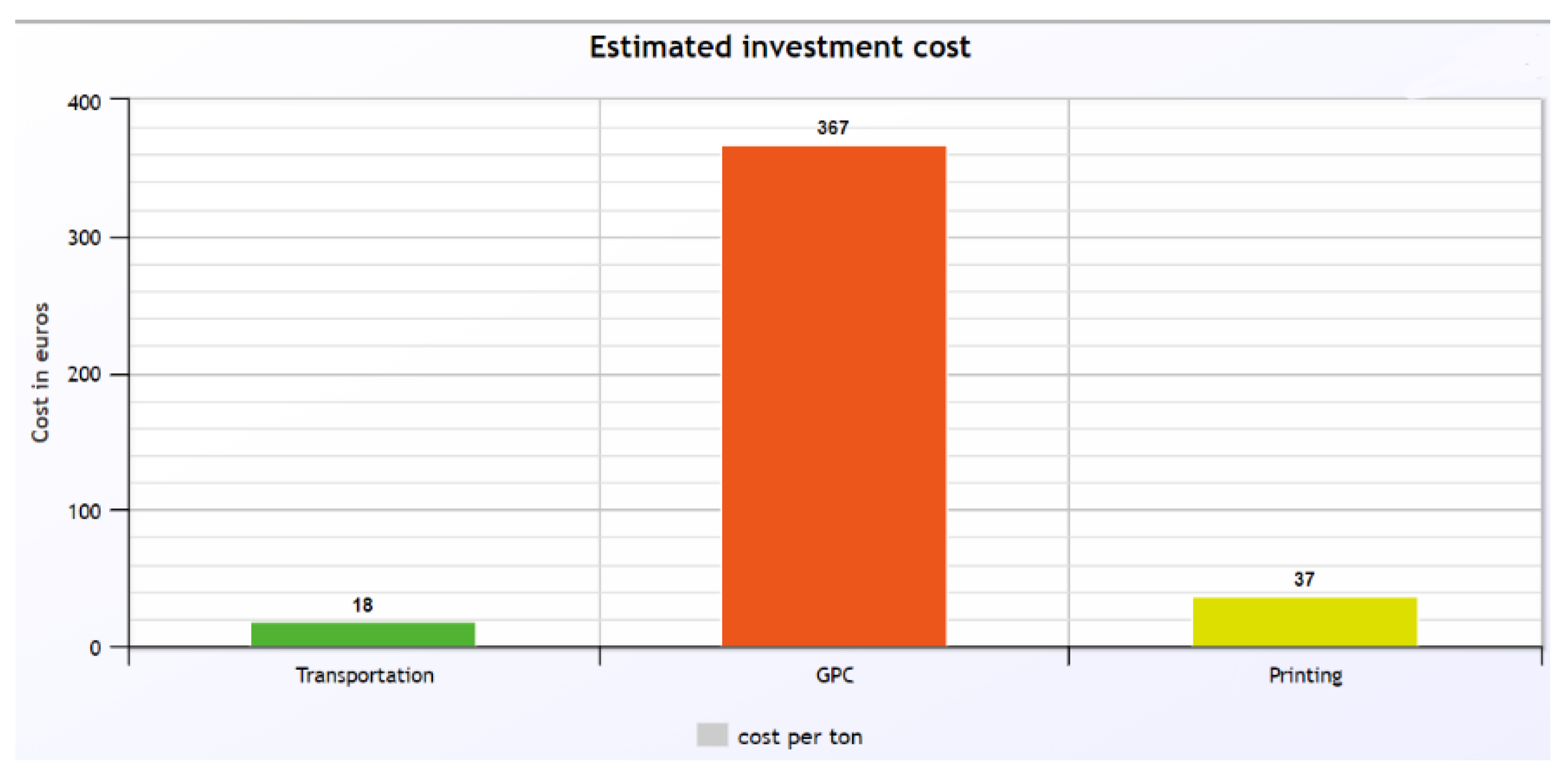

The estimated time needed to build a complete house is between 13 and 16 weeks. The investment cost per ton needed for each stage is presented in

Figure 6. The raw material used after pretreatment to produce geopolymer concrete is the most vital stage that affects the overall cost significantly, whereas transportation has the least effect on the cost structure. To calculate the cost per ton at each stage, the required initial investment is divided by the total amount of material. To transport 32,000 tons of raw material, a €579,300 initial investment is needed for management and operational activities. The transportation cost required for one ton of raw material is €18. Similarly, for pretreatments and geopolymer concrete production the cost is €367 and the costs of planning, sourcing, printing, and finishing are estimated at €37 per ton. Therefore, an estimated total of €422 is required for one ton of geopolymer 3D printing. The 3D printing and labor costs are not included in the total cost.

The total capital expenditures (CAPEX) and operating expenditures (OPEX) required for geopolymer 3D printing on construction sites is shown in

Table 11. The capital expenditures reflect the cost needed to buy or purchase physical assets, such as machineries, installations of machineries and contingency costs. The operating expenditures show the required investment needed to perform various tasks on a monthly basis.

Geopolymer 3D printing cost estimation analysis illustrates that raw materials pretreatment techniques are the most important stage which affects the overall product cost significantly. The raw materials pretreatment techniques consume almost 87% of final product cost. The total estimated cost needed to build a 50 m

2 3D printed house in Finland using the traditional and 3D printed techniques are shown in

Table 12. GPC strength lies in the waste material used because it promises sustainability and consume less energy compared to the same amount of OPC production. The production cost of M30 GPC is slightly higher than the same grade of OPC. Therefore, houses built through GPC 3D printing have marginally higher costs than OPC printed houses.

4. Conclusions

Through this research, the evaluation of the possibility of using industrial wastes for geopolymer 3D printing in factories and on construction sites has provided a complete understanding of the construction time, cost, and energy demand. Our geopolymer 3D printing cost analysis showed that the use of sustainable materials through reliable and economical manufacturing techniques in the construction industry reduced the construction time and decreased nearly 50% energy demand, compared to traditional manufacturing techniques. A GPC 3D-printed house has almost 32% less production cost than a house built through conventional manufacturing techniques with OPC. Geopolymer technology gives a reasonable promise of reduction in global warming and CO2 emissions, for the construction industry as an alternative binder to OPC.

Construction site geopolymer 3D printing presents many benefits, due to their potential to reduce construction time, waste materials, energy, complexity of framework, and required tools. The study also found that the production cost of M30 GPC is slightly higher than the same grade of OPC. Therefore, houses built through GPC 3D printing have marginally (1.7%) higher costs than OPC printed houses. However, the benefits such as sustainability, natural resource-saving, maintenance cost, better mechanical and durable properties can be obtained through the production of geopolymer, which would offset the initial material cost.

The research results demonstrated the energy cost needed to carry out pretreatment processes for waste materials is approximately 2–3% of the total annual investment required for pretreatment techniques. The profitability of waste materials’ pretreatment is highly dependent on the processing capacity. The combined line treatment shows the annual investment cost per ton for pretreatment can significantly decreased through the utilization of higher processing capacity. However, in the future, developments in new technologies for waste material pretreatments, curing conditions, and new digital design workflow for the industry are required to reduce the cost and increase efficiency.