Industrial Symbiosis through the Use of Biosolids as Fertilizer in Romanian Agriculture

Abstract

1. Introduction

1.1. Industrial Symbiosis

- (i).

- IS type 1, in which product residues and waste are reused within the same companies. This type of industrial symbiosis requires adaptation of processes and construction of transfer systems for the reuse and use in cascade of product residues. This type of industrial symbiosis is synonymous with environmental management or cleaner production.

- (ii).

- IS type 2, in which product residues and waste are reused by another company. This type of industrial symbiosis requires development of partnerships between companies at local or regional level.

- (iii).

- IS type 3, in which product residues and waste products are sold on the market. This type of industrial symbiosis requires by-products, waste treatment and handling companies which provide materials to other people and companies to be used as input in their production processes.

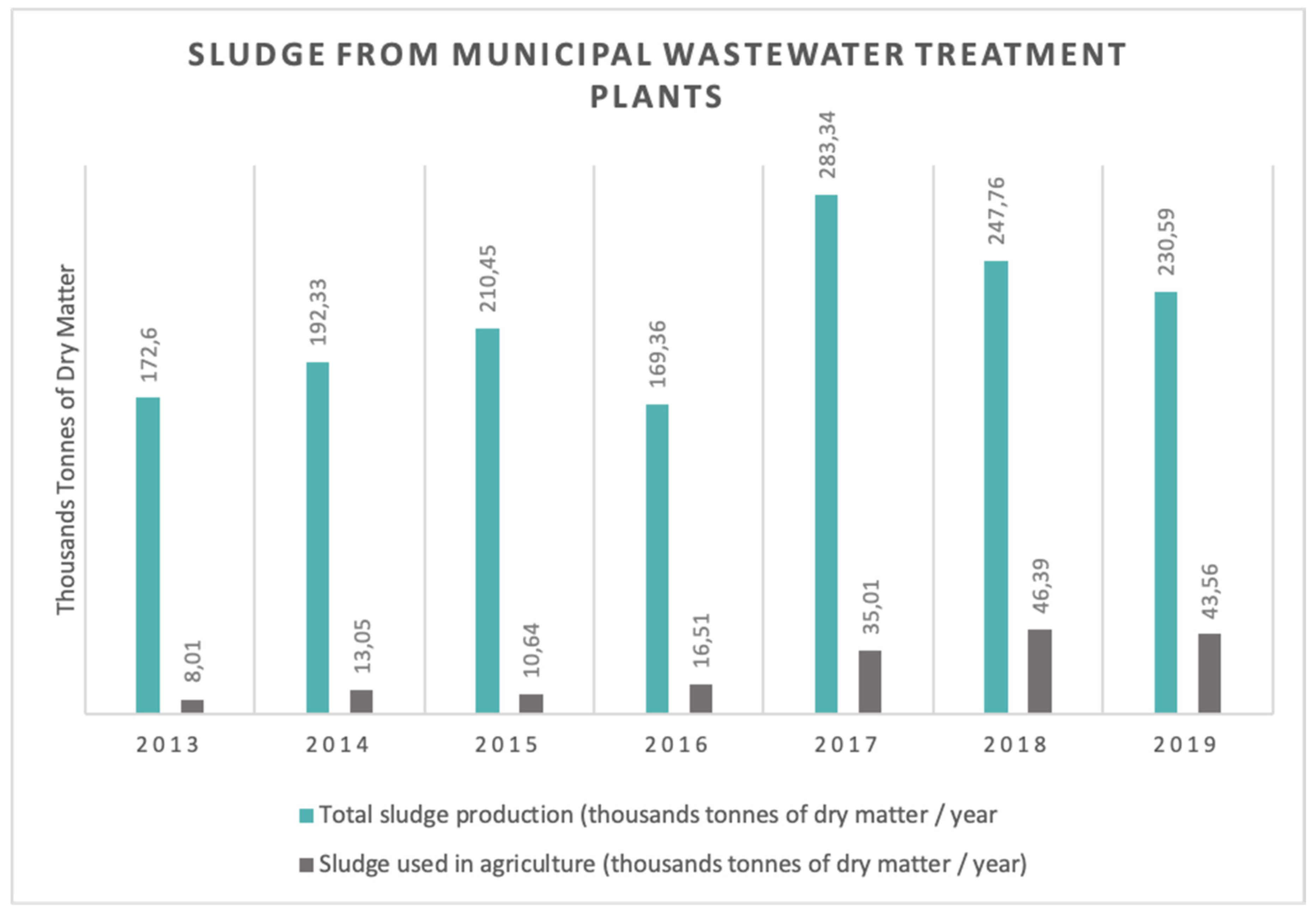

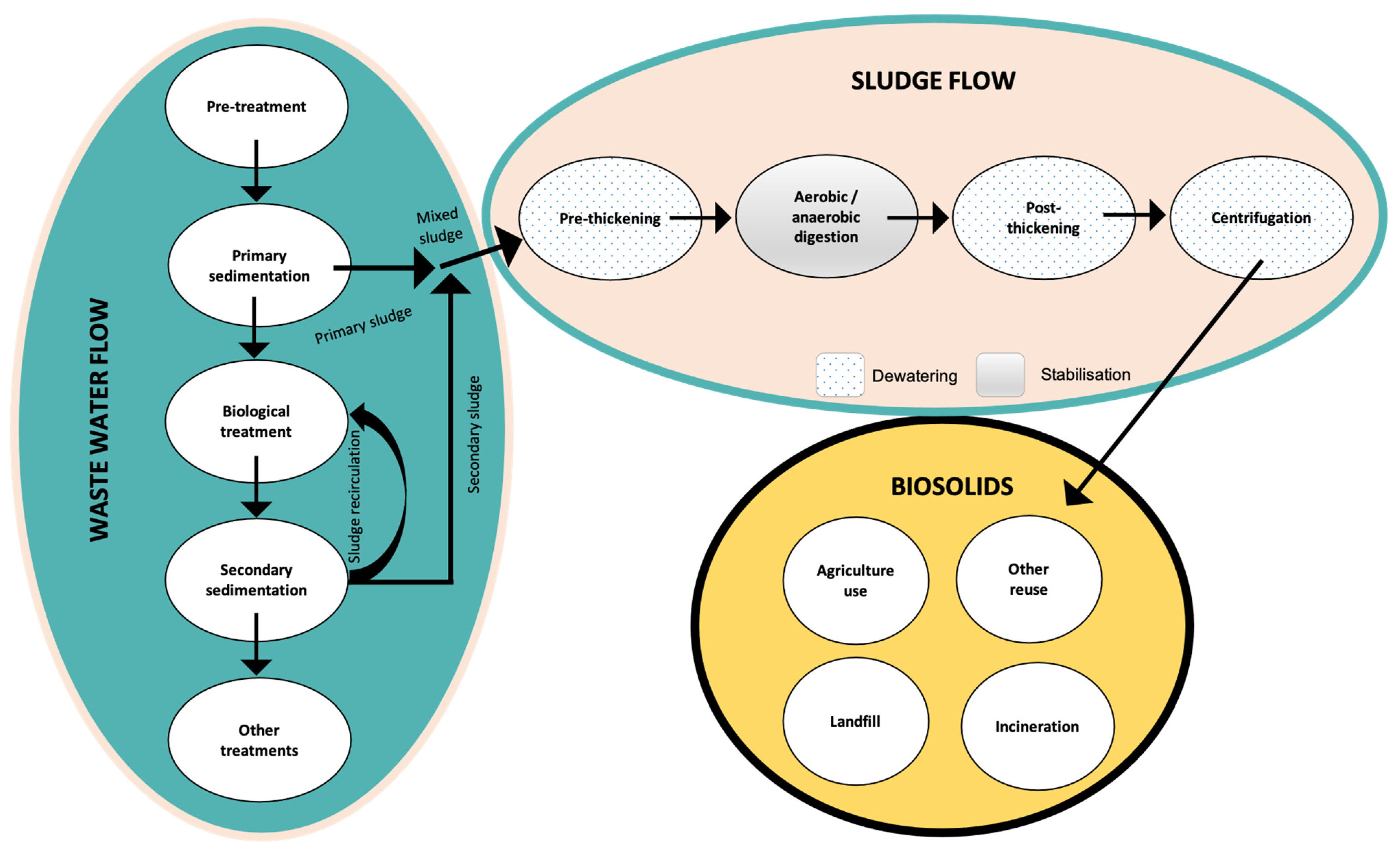

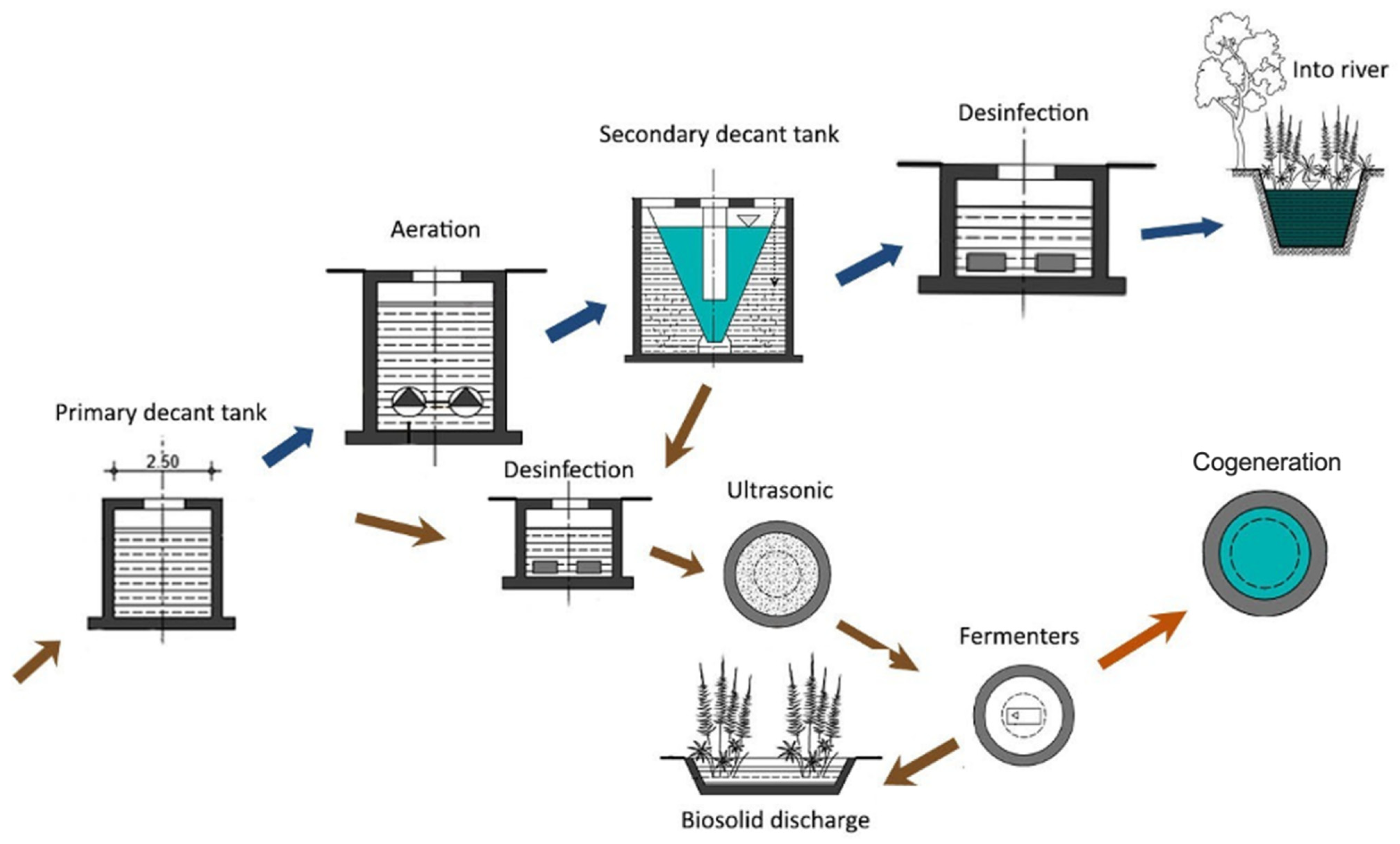

1.2. Production of Sewage Sludge (SS)

- At the country level, in 2008, 9,237,821 inhabitants benefited from the sewerage service, representing 43% of the population of the country and in 2019, a number of 10,514,924 inhabitants had their households connected to the sewerage systems, representing 54.2% of the resident population of Romania, with 221,883 persons more than in 2018 [18].

- In terms of wastewater treatment, at country level, the population connected to the sewage systems provided with wastewater treatment plants was of 10,264,302 persons in 2019, representing 52.9% of the country’s resident population, with 229,014 more people than in 2018, in comparison to 9,237,821 inhabitants in 2008, representing 43% of the population of Romania [18].

1.3. Biosolids Application in Agriculture

- The application of biosolids to crops with an area larger than 20 ha (especially those from agricultural units with legal personality) is, from an operational and administrative points of view, simpler and easier to perform than applying them on many small lands (especially those of individual farmers) [22];

- Care is required regarding the placement of BS in or near areas with protected or vulnerable water sources [22];

- The slope of the land, since the risk of leakage to surface water sources and mechanical application problems increases with the increase in the slope. Biosolids application on slopes less than 15% is acceptable, assuming there are no other limiting factors or risks [26];

- The soil texture—avoid too strong or too loose soil [26];

- The soil chemical composition—pH and heavy metal concentrations are limiting factors according to Ministry Order (MO) 344/2004 of the Romanian Government. Biosolids can be applied on agricultural land with pH ≥ 6.5 (constraint which is much stricter than in other countries) [26];

- The type of crop—MO 344/2004 prohibits the use of biosolids in vegetable and fruit crops growing in shrubs, vines, pastures and restricts the use of sludge in orchards (application no less than 10 months before the first harvest). Biosolids can be applied to all other crops [26];

- Biosolids’ quality should be compliant with the requirements of MO 344/2004;

- The nutritional needs of plants must be taken into account [26];

- Not to compromise the quality of soils and surface waters [26].

- ▪

- To treat sludge properly, in order to significantly reduce fermentation properties, the presence of pathogens and the values of heavy metal concentrations in the sludge [27];

- ▪

- To produce a safe, good quality sludge, which does not negatively impact the soil fertility and which assures environmental safety and human health integrity [27];

- ▪

- ▪

- To ensure the transportation and the spreading of sludge [27];

- ▪

- To provide control and monitoring of soils on which sludge has been applied [27];

- ▪

- To notify the territorial environmental authority and the bs users about the possible pollutants existing in the sludge [26];

- ▪

- To contact the bs user and to evaluate the possibilities of bs use [26].

- ▪

- To inform the competent authorities and the sludge producer (water supply and sewerage utility) about the rotation of agricultural crops;

- ▪

- To ensure that the biosolids are integrated into the soil on the same day as the biosolids are spread;

- ▪

- To inform the sludge producer if they change their mind about using the biosolids before transporting it.

2. Materials and Methods

- Step 1. Planning the review, with two stages: identification of the need for a review and the development of a review protocol;

- Step 2. Conducting the review, with five stages: identification of research, selection of primary studies, studies’ quality assessment, data extraction and monitoring and data synthesis;

- Step 3. Reporting the review, a single stage step.

3. Results

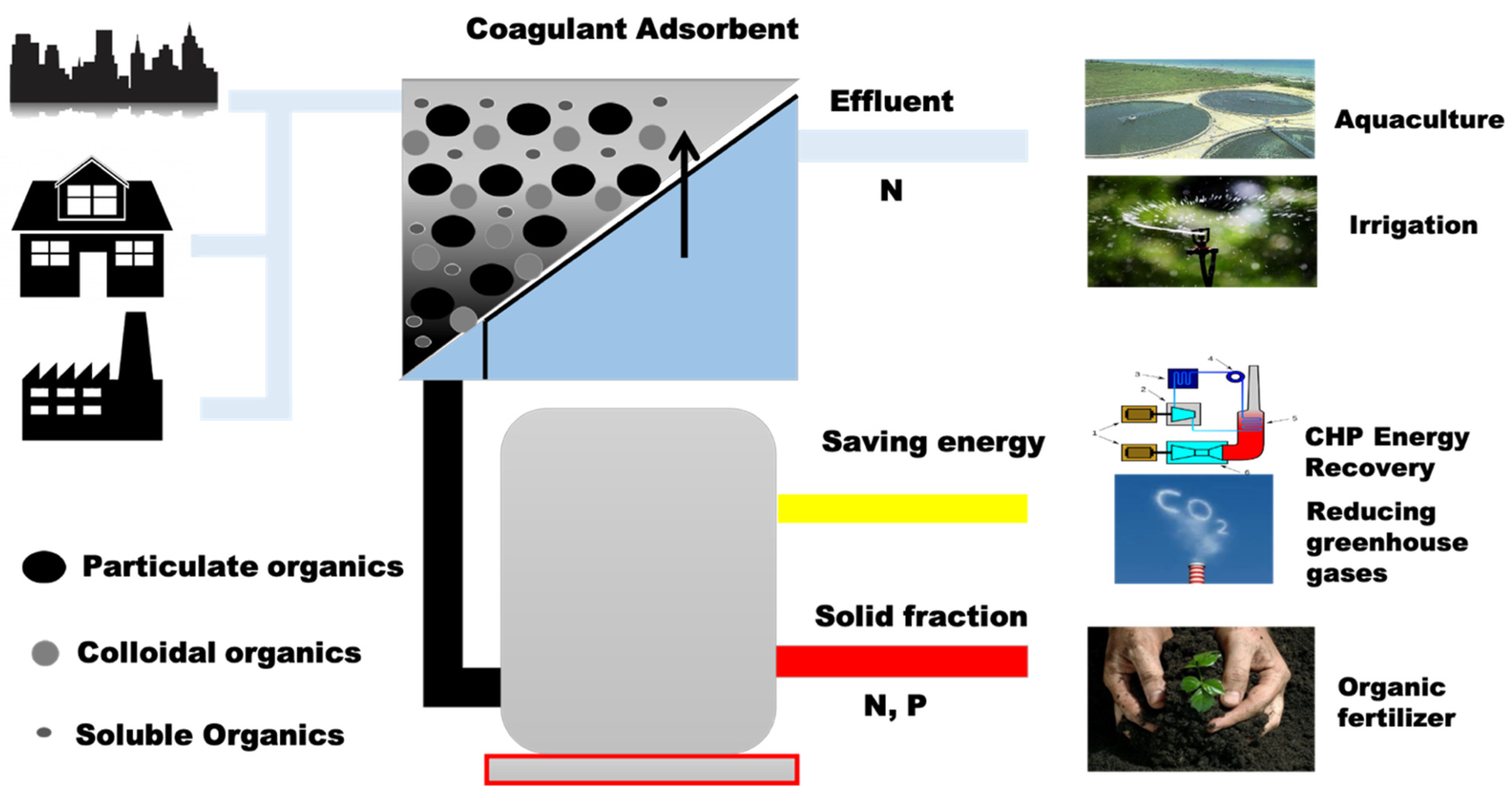

3.1. Fertilizing Properties of Biosolids

| Ord. No. | BS | Type of Fertilizer | Crop Type | P, N | Organic Matter | Soil pH | Heavy Metals in Crops | Pathogens in Crop | Crop Yield | Retention of Carbon | Retention of Water | Reference |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | Lime stabilized biosolids; Composted biosolids; Liquid Mesophilic Anaerobic Digestion (MAD) biosolids; Thermally dried MAD; Thermally Hydrolyzed MAD; Dewatered MAD; Thermally-dried raw biosolids | Mineral fertilizers | wheat | The highest nitrogen contents were found in dewatered MAD biosolids while phosphorous contents were maximum in liquid MAD biosolids. | Alkaline, pH ranged from 7.4 to 8.9 | Increased | [14] | |||||

| 2 | SS combined with three different amounts of mineral fertilizer, no, half or full dose of N; P and K are added at both half and full N input | Not amended, mineral fertilizer | Wheat, sugar beet, Spring barley, oats | Low fertilizer value of P and N | Within limits | Within limits | Increased crop yield, mineral fertilizer had a much greater impact on yield than BS | Higher soil carbon concentration, lower soil bulk density | [32] | |||

| 3 | Sewage sludge | Mineral fertilizer | Maize, sunflower, crotalaria | Efficient in completely replacing P fertilization, partially replace N fertilization | No increase of organic matter | Increased | [33] | |||||

| 4 | Air dried SS | Not amended | Broad bean | Increased | Decreased | Within limits | Increased | Increased | [34] | |||

| 5 | Air dried SS | Conventional fertilizer, slow-release fertilizer | Ornamental flowers: dianthus, kale, or petunia | BS added significant amounts of P to the system, N source | Increasing higher than with conventional fertilizer | Decreased | Higher levels of copper, manganese, magnesium, and zinc than synthetic fertilizers | None detected | Same as conventional fertilizers | improve water-holding capacity | [35] | |

| 6 | Secondary treatment SS with, biological anaerobic stabilization, secondary treatment SS, primary treatment SS | Not amended | Sugarcane, banana, coffee, orange, green coconut, corn, pineapple, tomato | High contents of P, N in BS; low K content in BS | High content in BS | Within limits | Within limits | Increased productivity | Increasing soil carbon stock | [36] | ||

| 7 | Dewatered BS from primary stabilization ponds | Without N, N amended fertilizer | Roses | N higher than in not amended studies | =conventional fertilizers | [37] | ||||||

| 8 | SS with or without N and/or P fertilizer | NPK fertilizer | Cane | Higher than with the NPK fertilizer treatment | [38] |

- Biosolids proved successful in reducing the use of synthetic fertilizers in wheat crop used as fodder crop in Pakistan [14];

- After application of biosolids on maize crops on tropical soils for ten years, biosolids proved efficient in total replacement of P fertilization, macronutrients and partial replacement of N fertilization [33];

- Biosolids can successfully replace fertilizer in broad bean crops in Saudi Arabia [34];

- Larger cities can provide biosolids to smaller cities with larger agricultural areas [36];

- Improvement of the physical, chemical and biological properties of the soils, through the contribution of stabilized organic substances;

- Increase in crop yields and reducing the use of agricultural fertilizers;

- Sustainable development of the environment, with benefits both for the sludge producer, as for the farmer;

- Improvement of the physical and organic properties of soils through the contribution of nutrients (nitrogen, phosphorus, sulfur), oligo-elements, organic compounds;

- Better water retention in soil;

- Improvement of microbial activity in soil;

- Low cost;

- Simple technology required.

3.2. Measurements of the Economic Effects of Biosolids for Farmers

3.3. Measurements of the Economic Effects of Biosolids for Water Utilities

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Frosch, R.A.; Gallopoulos, N.E. Strategies for Manufacturing. Sci. Am. 1989, 261, 144–152. [Google Scholar] [CrossRef]

- Erkman, S. Industrial Ecology: An Historical View. J. Clean. Prod. 1997, 5, 1–10. [Google Scholar] [CrossRef]

- Chertow, M.R. Industrial symbiosis. Encycl. Energy 2004, 407–415. [Google Scholar] [CrossRef]

- Allenby, B.R. Industrial Ecology: Policy Framework and Implementation; Prentice Hall: Englewood Cliffs, NJ, USA, 1999. [Google Scholar]

- Allenby, B.R. The ontologies of industrial ecology? Prog. Ind. Ecol. Int. J. 2006, 3, 28–40. [Google Scholar] [CrossRef]

- Clift, R.; Druckman, A. Taking Stock of Industrial Ecology; Springer: Guildford, UK, 2016; ISBN 978-3-319-20570-0. [Google Scholar]

- Li, X. Industrial Ecology and Industrial Symbiosis for Environmental Sustainability. Definitions, Frameworks and Applications; Palgrave Macmillan: Sheffeld, UK, 2018; ISBN 978-3-319-67500-8. [Google Scholar]

- Jacobsen, N.B. Industrial Symbiosis in Kalundborg, Denmark: A Quantitative Assessment of Economic and Environmental Aspects. J. Ind. Ecol. 2005, 10, 239–255. [Google Scholar] [CrossRef]

- Ashton, W. Understanding the Organization of Industrial Ecosystems: A Social Network Approach. J. Ind. Ecol. 2008, 12, 34–51. [Google Scholar] [CrossRef]

- Danielsson, M. Reuse Water between Businesses, Sustainable Sanitation and Water Management Toolbox. 2019. Available online: https://sswm.info/water-nutrient-cycle/water-use/hardwares/optimisation-water-use-industries/reuse-water-between-businesses (accessed on 30 April 2021).

- DG for Internal Market, Industry, Entrepreneurship and SMEs. Analysis of Certain Waste Streams and the Potential of Industrial Symbiosis to Promote Waste as a Resource for EU Industry; Publications Office of the European Union: Luxembourg, 2015. [Google Scholar] [CrossRef]

- Cioca, L.I.; Ivascu, L.; Rada, E.C.; Torretta, V.; Ionescu, G. Sustainable development and technological impact on CO2 reducing conditions in Romania. Sustainability 2015, 7, 1637–1650. [Google Scholar] [CrossRef]

- Patel, J. 4-Step Wastewater Sludge Treatment Process. Water Online. 2019. Available online: https://www.wateronline.com/doc/step-wastewater-sludge-treatment-process-0001 (accessed on 30 April 2021).

- Dad, K.; Wahid, A.; Khan, A.A.; Anwar, A.; Ali, M.; Sarwar, N.; Ali, S.; Ahmad, A.; Ahmad, M.; Khan, K.A.; et al. Nutritional status of different biosolids and their impact on various growth parameters of wheat (Triticum aestivum L.). Saudi J. Biol. Sci. 2019, 26, 1423–1428. [Google Scholar] [CrossRef] [PubMed]

- Collivignarelli, M.C.; Canato, M.; Abba, A.; Miino, M.C. Biosolids: What are the different types of reuse? J. Clean. Prod. 2019, 238, 117844:1–117844:21. [Google Scholar] [CrossRef]

- National Authority Romanian Waters, Planul Naţional de Management Actualizat Aferent Porţiunii din Bazinul Hidrografic Internaţional al Fluviului Dunărea Care este Cuprinsă în Teritoriul României. Sinteza Planurilor de Management Actualizate la nivel de bazine/spaţii hidrografice, The Updated National Management Plan for the Portion of the International River Basin of the Danube River Which is Included in the Territory of Romania. Synthesis of the Updated Management Plans at the Level of Basins/Hydrographic Spaces. 2016. Available online: www.rowater.ro (accessed on 30 May 2021).

- Ministry of Environment and Forests; National Authority Romanian Waters. Situaţia în România a Apelor Uzate Urbane şi a Nămolului Provenit din Staţiile de Epurare-Broşură Pentru Public/Situation in Romania of Urban Wastewater and Sludge from Sewage Treatment Plants—Brochure for the Public. 2012. Available online: www.rowater.ro (accessed on 30 May 2021).

- National Statistics Institute. Tempo Database Data. 2020. Available online: https://insse.ro/cms/ (accessed on 30 June 2021).

- National Agency for Environment Protection. Raport Anual Privind Starea Mediului în România, Anul 2018, Annual Report on the State of the Environment in Romania, Year 2018, Bucureşti, Romania. 2019. Available online: http://www.anpm.ro/ro/raport-de-mediu (accessed on 30 May 2021).

- Batali, L.; Carastoian, A. Caracterizarea, din punct de vedere geotehnic, a namolurilor de la statiile de epurare, in vederea depozitarii lor, Characterization, from a geotechnical point of view, of the sludge from the treatment plants, in the view of their storage. Rev. Constr. 2015, 117, 56–59. [Google Scholar]

- Collivignarelli, M.C.; Abbà, A.; Miino, M.C.; Torretta, V. What Advanced Treatments Can Be Used to Minimize the Production of Sewage Sludge in WWTPs? Appl. Sci. 2019, 9, 2650. [Google Scholar] [CrossRef]

- AM POS Mediu. Strategia Naţională de Gestionare a Nămolurilor de Epurare—Partea a III-a, The National Sewage Sludge Management Strategy—Part III; Directia Generala AM POS Mediu: Bucuresti, Romania, 2012. [Google Scholar]

- Hall, J. Ecological and Economical Balance for Sludge Management Options. 2006. Available online: Ec.europa.eu (accessed on 30 June 2021).

- EPA, Basic Information about Biosolids. United States Environmental Protection Agency. 2019. Available online: https://www.epa.gov/biosolids/basic-information-about-biosolids (accessed on 28 February 2021).

- Al-Gheethi, A.A.; Efaq, A.N.; Bala, J.D.; Norli, I.; Abdel-Monem, M.O.; Kadir, M.O.A. Removal of pathogenic bacteria from sewage-treated effluent and biosolids for agricultural purposes. Appl. Water Sci. 2018, 8, 74:1–74:25. [Google Scholar] [CrossRef]

- Ministry Order No. 344/ 2004 for the Approval of the Technical Norms on the Protection of the Environment and Especially of the Soils, When the Sewage Sludges Are Used in Agriculture; Monitorul Oficial al României: Bucuresti, Romania, 2004.

- Aquaserv Tȃrgu-Mureş, Utilizarea nămolului de Epurare în Agricultură, Broşură, Use of Sewage Sludge in Agriculture, Brochure. 2016. Available online: www.aquaserv.ro (accessed on 30 April 2021).

- Kitchenham, B. Procedures for Performing Systematic Reviews; 33(TR/SE-0401); Keele University: Keele, UK, 2004. [Google Scholar]

- Chojnacka, K.; Moustakas, K.; Witek-Krowiak, A. Bio-based fertilizers: A practical approach towards circular economy. Bioresour. Technol. 2020, 295, 122223. [Google Scholar] [CrossRef] [PubMed]

- Collivignarelli, M.C.; Abbà, A.; Frattarola, A.; Miino, M.C.; Padovani, S.; Katsoyiannis, I.; Torretta, V. Legislation for the reuse of biosolids on agricultural land in Europe: Overview. Sustainability 2019, 11, 6015. [Google Scholar] [CrossRef]

- Milieu Ltd.; WRc; RPA. Environmental, Economic and Social Impacts of the use of Sewage Sludge on Land—Final Report -Part III: Project Interim Reports. 2008. Available online: https://ec.europa.eu/environment/archives/waste/sludge/pdf/part_iii_report.pdf (accessed on 30 May 2021).

- Borjesson, G.; Katterer, T. Soil fertility effects of repeated application of sewage sludge in two 30-year-old field experiments. Nutr. Cycl. Agroecosyst. 2018, 112, 369–385. [Google Scholar] [CrossRef]

- Melo, W.; Delarica, D.; Guedes, A.; Lavezzo, L.; Donha, R.; de Araujo, A.; de Melo, G.; Macedo, F. Ten years of application of sewage sludge on tropical soil. A balance sheet on agricultural crops and environmental quality. Sci. Total Environ. 2018, 643, 1493–1501. [Google Scholar] [CrossRef] [PubMed]

- Eid, E.M.; Alrumman, S.A.; El-Bebany, A.F.; Fawy, K.F.; Taher, M.A.; Hesham, A.E.; El-Shaboury, G.A.; Ahmed, M.T. The evaluation of sewage sludge application as a fertilizer for broad bean (Faba sativa Bernh.) crops. Food Energy Secur. 2018, 7, e00142. [Google Scholar] [CrossRef]

- Broderick, S.R.; Evans, W.B. Biosolids Promote Similar Plant Growth and Quality Responses as Conventional and Slow-release Fertilizers. Horttechnology 2017, 27, 794–804. [Google Scholar] [CrossRef]

- De Abreu, A.H.M.; Leles, P.S.D.; Alonso, J.M.; Abel, E.L.D.; de Oliveira, R.R. Characterization of sewage sludge generated in Rio de Janeiro, Brazil, and perspectives for agricultural recycling. Semin. Cienc. Agrar. 2017, 38, 2433–2447. [Google Scholar] [CrossRef]

- Da Paixao, J.L.; Gabrielli, G.; Coraucci, B.; Tonetti, A.L. Use of stabilization pond sludge in cultivation of roses. Rev. Bras. Eng. Agric. Ambient. 2014, 18, 85–89. [Google Scholar] [CrossRef][Green Version]

- Franco, A.; Abreu, C.H.; Perecin, D.; Oliveira, F.C.; Granja, A.C.R.; Braga, V.S. Sewage sludge as nitrogen and phosphorus source for cane-plant and first ratoon crops. Rev. Bras. Cienc. Solo 2010, 34, 553–561. [Google Scholar] [CrossRef]

- Bittencourt, S.; Serrat, B.M.; Aisse, M.M.; Gomes, D. Sewage sludge usage in agriculture: A case study of its destination in the Curitiba Metropolitan Region, Paraná, Brazil. Water Air Soil Pollut. 2014, 225, 2074:1–2074:8. [Google Scholar] [CrossRef]

- Severn Trent Water. Biosolids Recycling. Available online: https://www.stwater.co.uk/about-us/environment/biosolids-recycling/ (accessed on 30 March 2021).

- Law 384/2013 on the Approval of the Government Emergency Ordinance (GEO) 31/2013 for the Amendment and Completion of GEO 196/2005 on the Environment Fund; Monitorul Oficial al României: Bucuresti, Romania, 2013.

- Emergency Ordinance 48/2017, Which Amends and Supplements the GEO 196/2005 on the Environment Fund; Monitorul Oficial al României: Bucuresti, Romania, 2017.

- Ionescu, C.A.; Coman, M.D.; Moiceanu Marin, E.L.; Paschia, L.; Gudanescu Nicolau, N.L.; Cucui, G.; Stanescu, S.G. The Analysis of the Economic Effects on the Greening and Recovery of the Sludge Waste Resulting from the Biogas Production Activity. Sustainability 2019, 11, 4922. [Google Scholar] [CrossRef]

- Sigua, G.; Adjei, M.; Rechcigl, J. Cumulative and residual effects of repeated sewage sludge applications: Forage productivity and soil quality implications in South Florida, USA. Environ. Sci. Pollut. Res. 2005, 12, 80–88. [Google Scholar] [CrossRef] [PubMed]

- Morosini, C.; Marsoni, M.; Torretta, V.; Conti, F.; Ragazzi, M.; Rada, E.C.; Cioca, G. Factors Affecting Spatial and Temporal Concentration Variability of Pharmaceuticals: Comparison between Two WWTPs. Sustainability 2017, 9, 1466. [Google Scholar] [CrossRef]

- Semblante, G.U.; Hai, F.I.; Huang, X.; Ball, A.S.; Price, W.E.; Nghiem, L.D. Trace organic contaminants in biosolids: Impact of conventional wastewater and sludge processing technologies and emerging alternatives. J. Hazard. Mater. 2015, 300, 1–17. [Google Scholar] [CrossRef] [PubMed]

- Eurostat, Agriculture—Greenhouse Gas Emission Statistics. 2017. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Archive:Agri-environmental_indicator_-_greenhouse_gas_emissions (accessed on 30 March 2021).

- Glab, L.; Sowinski, J. Sustainable Production of Sweet Sorghum as a Bioenergy Crop Using Biosolids Taking into Account Greenhouse Gas Emissions. Sustainability 2019, 11, 3033. [Google Scholar] [CrossRef]

- Lindsay, B.E.; Zhou, H.J.; Halstead, J.M. Factors influencing resident attitudes regarding the land application of biosolids. Am. J. Altern. Agric. 2000, 15, 88–95. [Google Scholar] [CrossRef]

| Criteria | Reasons |

|---|---|

| (1) Identification of the publications in the fields of “biosolids”, “agriculture” and “fertilizer” | The proposed review article is supported by a comprehensive review of the world literature. Web of Science database has been used to search for the relevant literature. In order to find all relevant publications, the keywords used derived from the purpose statement and identified the concepts of interest, namely: “biosolids”, “agriculture” and “fertilizer” The analysis has been conducted searching the keywords on the fields “Article title, Abstract, Keywords” and we got 118 results. |

| (2) Publications as a full-length journal article or review | We excluded book reviews and conference proceedings papers. Only peer-review full papers published on international journals have been considered, meaning 33 articles. The search was conducted in March 2020. |

| (3) Exclusion of publications with other aims than the calculation of economic yield of biosolids’ application in agriculture | Articles with the following properties:

|

| (4) Publications underlining the economic effects of biosolids’ application in agriculture | 8 full-length peer-reviewed articles written in English comprised experiments related to the economic effects of using biosolids as fertilizer on crops. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cioca, L.-I.; Ciomoş, A.-O.; Șeitoar, D.; Druță, R.M.; David, G.M. Industrial Symbiosis through the Use of Biosolids as Fertilizer in Romanian Agriculture. Recycling 2021, 6, 59. https://doi.org/10.3390/recycling6030059

Cioca L-I, Ciomoş A-O, Șeitoar D, Druță RM, David GM. Industrial Symbiosis through the Use of Biosolids as Fertilizer in Romanian Agriculture. Recycling. 2021; 6(3):59. https://doi.org/10.3390/recycling6030059

Chicago/Turabian StyleCioca, Lucian-Ionel, Alina-Oana Ciomoş, Daiana Șeitoar, Roxana Maria Druță, and Geanina Maria David. 2021. "Industrial Symbiosis through the Use of Biosolids as Fertilizer in Romanian Agriculture" Recycling 6, no. 3: 59. https://doi.org/10.3390/recycling6030059

APA StyleCioca, L.-I., Ciomoş, A.-O., Șeitoar, D., Druță, R. M., & David, G. M. (2021). Industrial Symbiosis through the Use of Biosolids as Fertilizer in Romanian Agriculture. Recycling, 6(3), 59. https://doi.org/10.3390/recycling6030059