Abstract

Mobile phone consumers have been motivated by the rapid growth of technology and encouraged to update their devices regularly to keep up with new innovations, architectures, and capabilities. Consequently, mobile/cell phone waste has risen significantly in the last decade. Due to their small size, it is convenient for users to keep outdated or unused mobile phones at home or the office, rather than recycling them appropriately. A reverse supply chain (RSC) is one possible method of mitigating the questionable e-waste activity present in the ecosystem. RSC has been significant for the mobile phone industry, user states, analysts, and scholars. This paper reviews the available literature in the RSC management (RSCM) domain, along with its processes and strategies. The paper reviews 223 published scholarly papers in the domain of mobile phone waste recycling and investigates 22 papers related to factors influencing consumers’ intention with regard to electronic recycling, focusing on mobile devices, which contribute significantly to electronic waste management practices.

1. Introduction

In today’s modern world, most people tend to use a mobile phone in their daily lives. The technology of this device not only has enabled people to use it as a phone, but also offers them access to the Internet while providing a wide range of applications with which they can manage their work, access social platforms, play their favorite games, and even pay for products and services. Furthermore, with rapid developments in mobile phone technology, mobile manufacturers encourage users to change their devices frequently in order to take advantage of new features, designs, and capabilities. As a result, there has been a massive increase in mobile phone waste, and due to their small size, it is convenient to keep unused mobile phones at home or in the office [1,2,3]. This paper aims to address consumers’ intentions and behaviors in regard to participating in reverse logistics (RL) or recycling of mobile devices through a reverse supply chain (RSC). Different studies define RL and RSC in different ways. One of the most widely accepted definitions of RL was given by Rogers and Tibben-Lembke [4], who described it as “the process of planning, implementing, and controlling the efficient, cost-effective flow of raw materials, in-process inventory, finished goods, and related information from the point of consumption to the point of origin for the purpose of re-capturing or creating value or proper disposal” [5].

On the other hand, Stock [6] focused more on the recovery route; he explicitly specified the role of RL in product return, source reduction, recycling and reuse of materials, product repair, and waste disposal. Prahinski and Kocabasoglu [7] defined RSC as an effective and efficient series of processes by which products can be collected from customers for disposal or to extract value through recycling. Jayant et al. [8] defined RSC as the flow of return management caused by the return, recovery, or overstock of goods.

Since the RL and RSC concepts have evolved over the years, new views have been added to their definitions. Agrawal et al. [9] noted that the earliest definition of RL concerned the reverse flow of goods. Later, the term “environment” was added to the definition. Doan et al. [10] provided a focused definition of RSC as the activities required to reuse, remanufacture, or recycle unwanted products from end-users. This definition, which clarifies that RSC activities involve the collection of discarded devices from customers, is adopted in this paper. Reverse supply chain management (RSCM) is defined as a series of activities implemented in order to collect products from customers at any stage of the forward supply chain, i.e., reuse, repair, remanufacture, recycling, or disposal [11]. RL is an essential system for current industries and manufacturers; it is considered the most important channel for the mobile recycling activity [2].

Acceleration in technology advancement, especially in the electronics market, encourages more companies to produce extended ranges of electronic devices and smartphones. Such advancement has influenced consumers to acquire different types of devices at the same time, which results in the generation of massive electronic waste (e-waste) from end-of-life (EOL) products due to their short life cycle [12,13,14]. According to the United Nations Environment Program (UNEP), the amount of global e-waste produced was 50 million tons in 2018. If there are no global actions to address and solve this issue, then the e-waste volume is expected to increase by more than double by 2050 to 120 million tons. Currently, only 20% of total waste is recycled globally [15].

Saving the environment is currently one of the most primary and challenging subjects of research around the world [9,16,17,18]. The costs of natural resource extraction, environmental improvement, and population increase have forced many companies and industries to collect EOL products for recycling and reuse through RSCM. According to [19], mobile phone waste is considered hazardous due to the potential negative impact of environmental and human exposure to cytotoxic metals. However, mobile phones may still be considered as a source for systematic extraction and reuse of primary minerals, which will help in saving natural resources [19].

Successful and productive RSCM depends on consumers’ participation in and intention to be part of the cycle. Consumers generally tend to keep their used, old, or non-working electronics, especially smartphones, for some time before putting them into the waste stream. This hoarding behavior can be influenced by numerous factors, such as attitude, sociodemographics, lifestyle, environmental awareness, product features, technology, and social pressure [20]. The better we understand the factors encouraging the hoarding of electronic devices, the better we can encourage consumers to participate in recycling.

Several studies have demonstrated that consumer behavior is a critical factor in the success of RSCM [21,22,23,24,25]. For example, Cao and Liu [25] pointed out that recycling attitudes, perceived behavior control, benefits like financial incentives, appropriateness, and advertising policies have a significant positive impact on consumers’ readiness to recycle packaging; subjective norms, perceived trust, and incentives are known to have an explicit impact on attitudes toward RSCM.

RL is an important system for current industries and manufacturers, and overlooking its importance will lead to problems that could prevent its successful implementation [12]. This paper provides a review on the evolution of RSCM and mobile waste issues and conducts a literature review on the factors influencing mobile users’ intentions and behaviors with regard to participating in RL or recycling by demonstrating the influencing factors.

2. Review Method

A literature review is still a valuable method for systematically investigating and structuring a domain problem [9]; further, it is the best approach to answer a research question or provide an overview of a specific problem [26]. Therefore, a structured literature review was used to collect data on critical articles on RSCM, electronic waste management, and consumer behavior toward recycling. This review is intended to understand how various studies have discussed RSC and analyzed consumer behavior when electronic devices such as mobile phones are processed for recycling. Research engines such as Google Scholar, Scopus, Web of Science, and ScienceDirect were used with different keywords (i.e., “reverse supply chain management”, “mobile phone reuse”, “mobile phone recycling”, “waste mobile phone”, and “customer recycling behavior”) to find the right output for this review paper.

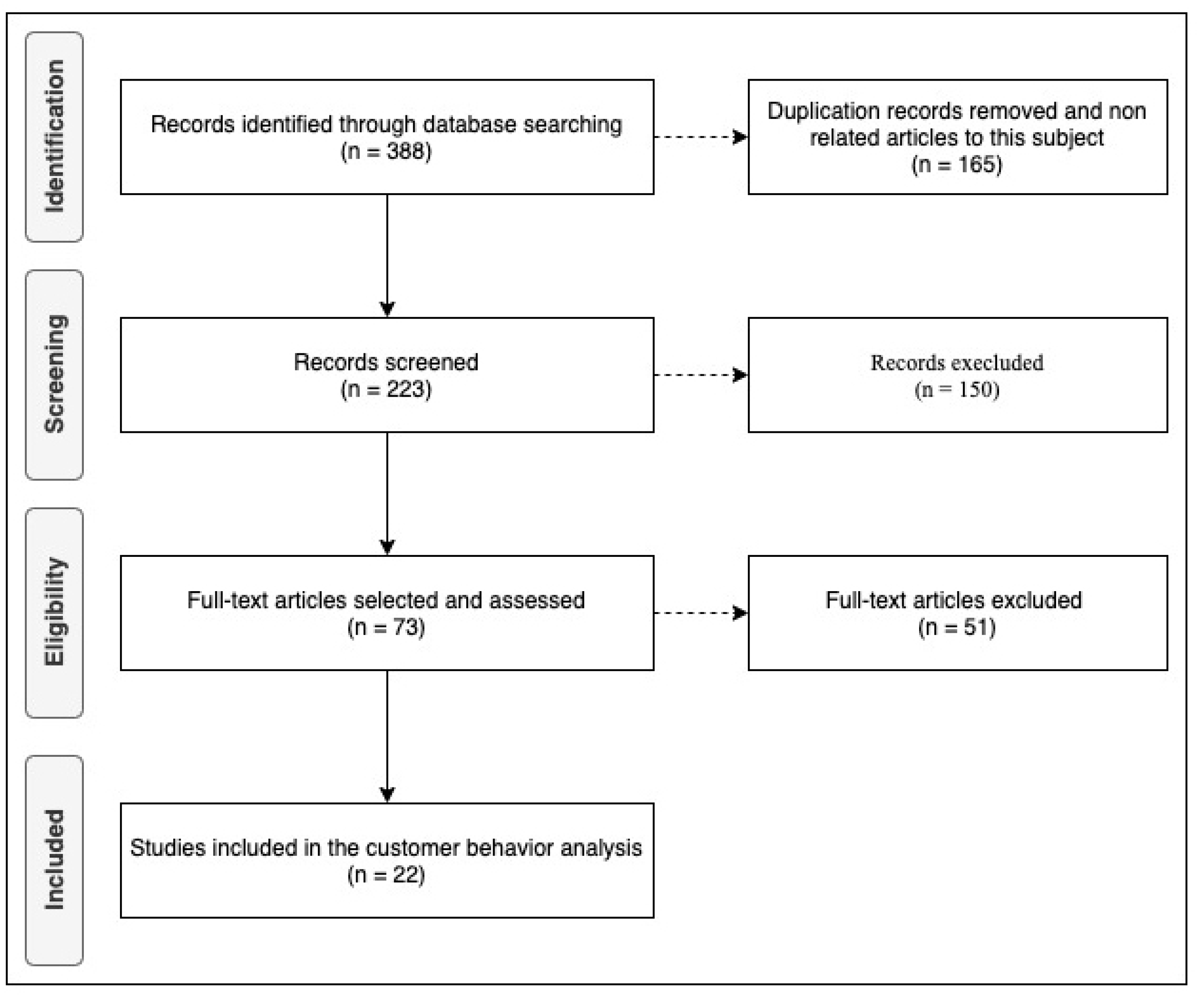

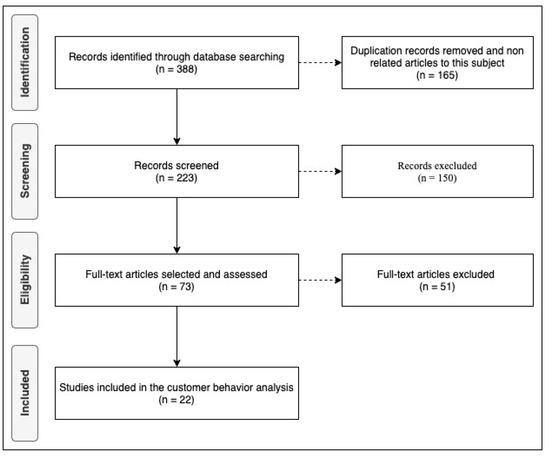

Figure 1 summarizes the selection criteria based on Snyder’s [26] process of conducting a literature review inspired by Preferred Items for Systematic Review Recommendations (PRISMA) [27] for selecting the most appropriate studies for this review. The selection criteria started by removing all duplicate papers and papers that were not related to this review from 388 papers collected from different databases. Next, we screened the titles and abstracts of the papers discussing RSCM, waste issues, and consumer behavior, which left 223 papers. We then did another screening focused on papers published between 2004 and 2021, with the majority published in the last five years; this phase resulted in 73 papers. Finally, using studies on understanding and analyzing customer behavior with a focus on recycling, we collected a final sample of 22 papers.

Figure 1.

Methodological steps for choice of relevant papers for this review based on PRISMA.

3. Descriptive Findings

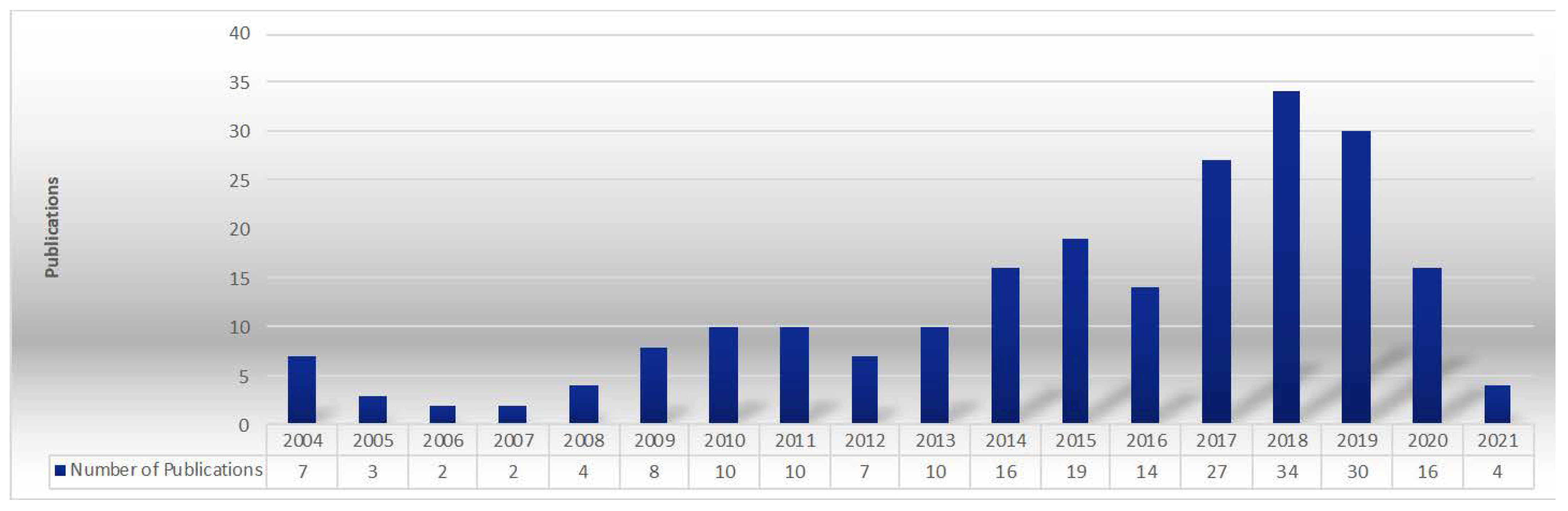

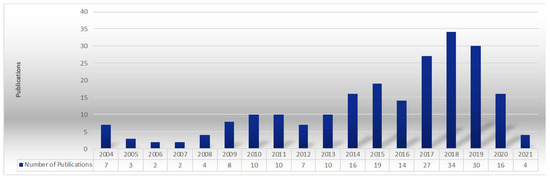

A total of 223 peer-reviewed reports, papers, and articles were reviewed. With a focus on RSCM, mobile waste and recycling behavior keywords were used to filter the papers, resulting in 73 scholarly journal publications considered as the most relevant for this review. Figure 2 shows the frequency of publications for the 223 reviewed papers.

Figure 2.

Frequency of 223 reviewed publications per year.

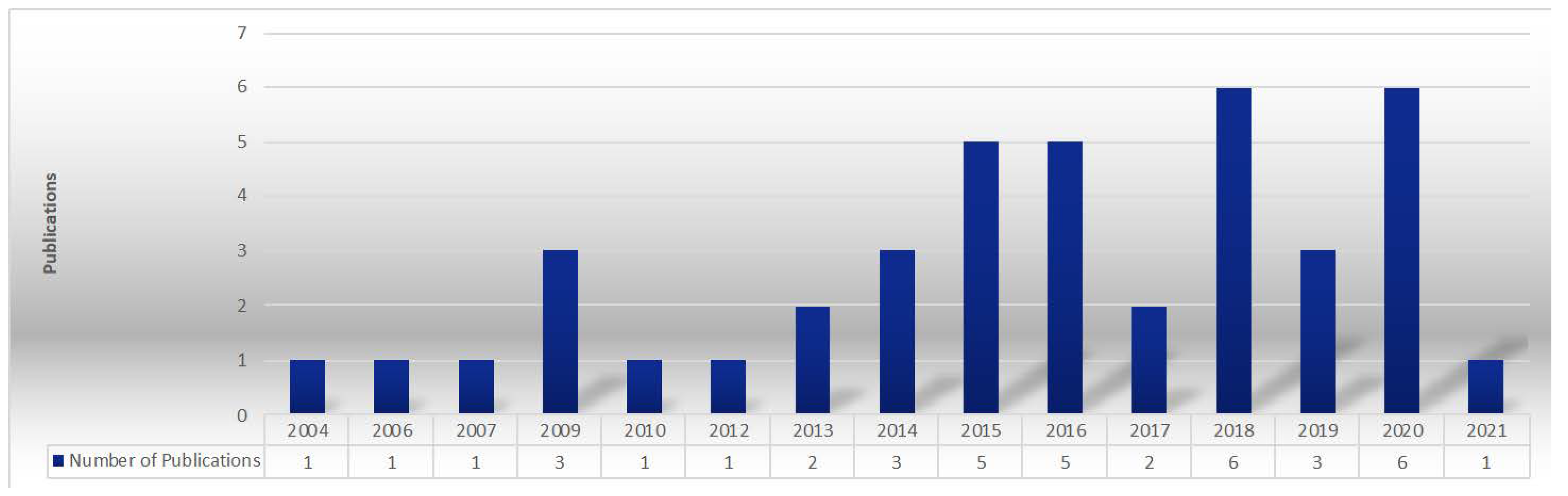

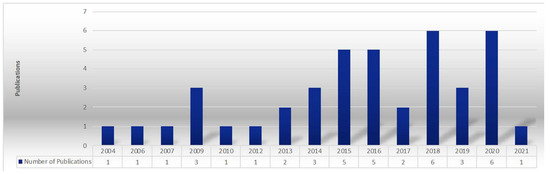

Figure 2 presents the number of publications related to RSC and waste issues from 2004 to 2021 in chronological order. The most publications were recorded in 2018, and since then, the number of those focused on RSC started to decline. The low number of publications recorded in this domain in 2020 shows the importance of further investigating RSC and waste issues. Figure 3 summarizes the published findings in mobile/smartphone recycling; the scarcity of studies highlights the importance of future research into mobile phone device waste.

Figure 3.

Frequency of the number of publications per year in mobile recycling domain.

A meta-search was performed on consumer behavior, resulting in 22 publications. Table 3 summarizes the articles with no conferences involved. Publications were from Brazil, China, India, Iran, Malaysia, Pakistan, Portugal, Singapore, Spain, United Arab Emirates, and the USA. This demonstrates the overall degree of concern with regard to recycling mobile device waste worldwide. In this aspect, the country with the most publications in China, and the country with the least is United Arab Emirates, although, according to the International Telecommunication Union (ITU), the number of mobile subscriptions in United Arab Emirates (per 100 people) was 209 in 2018. The United Arab Emirates ranks first in the Middle East region and third worldwide after China and Hong Kong in terms of mobile device penetration [28].

4. Literature Review and Discussion

4.1. RL and FL Overview

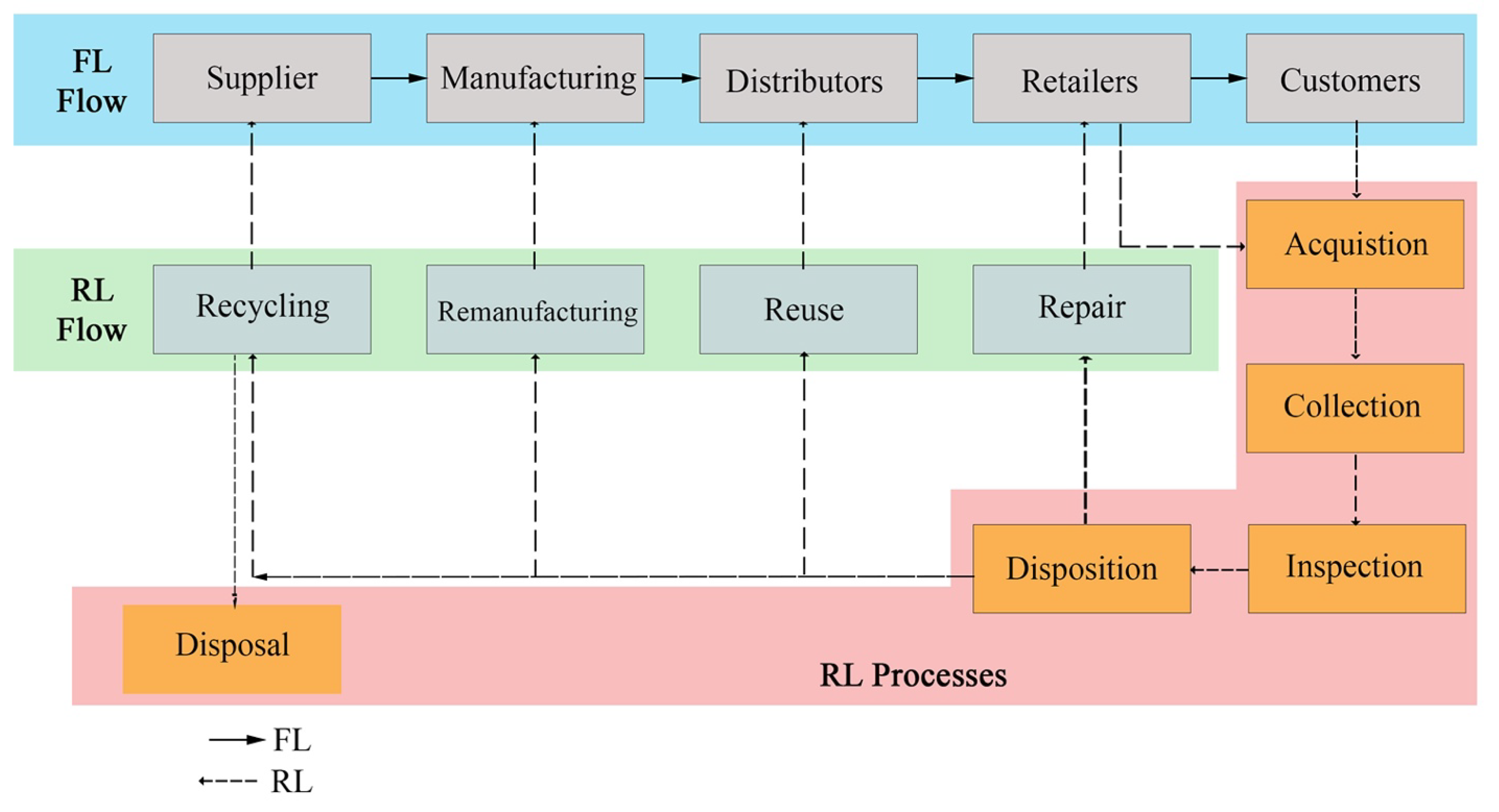

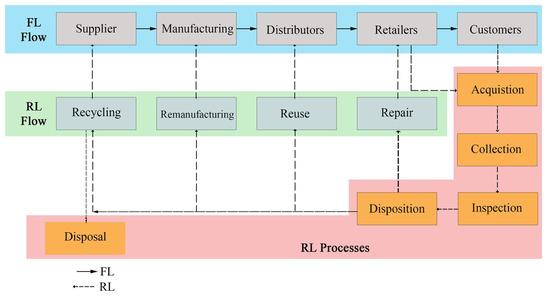

Companies around the world use the reverse logistics (RL) concept to generate profit and search for opportunities to remanufacture or resell returned products, as well as to avoid generating waste and claim a green strategy [9]. It is essential to highlight in the beginning that RL is different from forward logistics (FL). FL considers the customer to be at the end of the supply chain. In contrast, EOL or end-of-use (EOU) products are at the beginning of the RL process. Since this paper investigates consumer behavior with respect to returning EOL or EOU mobile devices, it is crucial to review the literature related to the concepts and processes of RL and RSC [9]. The RL and FL processes were explained and summarized by several studies and research reports [4,9,29,30]. Figure 4 illustrated the FL and RL processes suggested by Agrawal [9], which gives a clear understanding of both activities and channels.

Figure 4.

The flow of forward logistics (FL) and reverse logistics (RL) processes [9].

Earlier, Prahinski and Kocabasoglu [7] highlighted that RSC is a broader concept than RL, since RSC includes coordination and alliances with retailers, distributors, and manufacturers. Moreover, it involves inventory and transportation management. Wei [31] proposed that RL is part of RCM in the business concept. However, Doan et al. [10] pointed out that RSC is also synonymous with RL, confirming that many researchers have proposed and accepted this meaning.

There are many differences between FL and RL; Table 1 summarizes the most critical differences between the two processes. Furthermore, it is important to highlight that planning, forecasting, and inventory management in RL are more complicated than in FL due to uncertainties in the RL process [32,33].

Table 1.

Differences between RL and FL [34,35].

4.2. Need for RL and RSCM

From the consumer perspective, people who are working on saving natural resources and protecting the environment also work on enhancing RSCM as the main element of production sustainability [36]. Several variables have been classified in the literature as reasons for returns by either the manufacturer, the distributor, or the customer. Xing et al. [36] classified four types of returns, highlighting that the different types could change depending on the complexity of the situation: (1) product life cycle return (linked to the sales process and product warranty; it is better that this is linked to the end of the warranty, because the product life cycle is usually linked with the product EOL); (2) reusable components (return is related to the consumption of some parts); (3) EOU products (products that can be traded or resold); and (4) EOL return (applies only to products that could cause environmental issues or commercial loss).

Earlier, Dekker et al. [37] categorized product return into five groups: (1) EOL return, (2) commercial need, (3) end of warranty, (4) production scrap and by-products, and (5) reusable packaging materials. Ardeshirilajimi and Azadivar [38] focused on the value of the product and the time for return, classifying product return into three categories: (1) EOL, (2) commercial (customers return products for any reason according to store policy on time limits for return), and (3) false failure (products are returned by buyers to retailers for reasons other than functional or defect-related issues).

On the other hand, Gupta [35] distinguished five types of product returns: (1) commercial/customer, (2) repair (if the product is still under warranty), (3) EOL (products are no longer used), (4) reusable containers (bottles/cans), and (5) leased product (electronic office equipment with a short life cycle).

Interestingly, John et al. [39] argued that there is almost no suitable design to model an RL network because it depends on the nature and value of product reuse. Therefore, the main limitation comes from specifying the product and the lack of a list of all possible recovery options.

4.3. RSC Processes and Strategies

4.3.1. RL/RSC Processes

Table 2 outlines the definitions and explanations of stages in RSC activities and processes according to the literature.

Table 2.

Explanation of reverse supply chain (RSC) activities according to major operations.

RSC processes, also referred to as activities in other studies, have been discussed by many authors from different perspectives. Figure 4 highlights the four key processes involved in product return: (1) acquisition of returned products from customers; (2) collection; (3) inspection and sorting; in the context of mobile devices, products are divided into categories based on the manufacturer or component; and (4) disposal of devices for reuse, repair, remanufacture, or recycling [9].

Blackburn et al. [30] identified five key activities involved in RSC: (1) acquiring products from customers; (2) logistics, including transporting products to inspection facilities; (3) inspection and dispositioning, i.e., assessing the condition of returned products and evaluating the maximum profit; (4) remanufacturing or refurbishing to return products to their original condition; and (5) marketing, by creating a secondary market through which remanufactured products can be sold. Step 2 in the Blackburn model is important for item collection, because collection involves the transportation and logistics of returned items, whereas steps 4 and 5 are part of the disposal concept.

De Brito and Dekker [5] summarized the RL processes as four activities: (1) collection; (2) inspection and sorting; (3) recovery; and (4) distribution. They also combined the acquisition and collection activities in one process, considering that collection is similar to the acquisition of products or devices from customers. Moreover, those authors assumed that the recovery decision occurs during an inspection. If the assessment results with respect to the condition of the devices are good, the items can be positioned for reselling in the secondary market; otherwise, other recovery methods may apply. However, combining collection and acquisition in one activity is not a logical assumption, especially when considering today’s sophisticated devices (e.g., smartphones) and the low level of awareness regarding data security among consumers. It is difficult to convince consumers to give away their devices for recycling without identifying the factors and methods that can encourage them to participate in such a program.

Recent research by Mousa [41] examined remanufacturing analysis and return decisions, and organized the RSC process into three main activities. First is the take-back action, which is divided into two sub-activities: acquisition to reclaim products from customers or enterprises, and product collection, which covers all logistics activities including transportation, moving the products, and inventory management for storage of collected items. The second is technical activities, including processes such as inspection, classification, remanufacturing, and recycling. The third is distribution and marketing, including all of the logistics involved in reselling remanufactured products. However, the term “engineering/technical stage” can have several definitions. For a better understanding of RSC processes and the specific use of the terms, it is important to understand the gaps in each stage and study them in detail for specific products.

4.3.2. RL/RSC Strategies

Researchers note that the first appearance of RSC strategies was observed in the late 19th century, concerning consumers’ intention to return products and containers and the direct use of packaging with resale value and a proper disposal channel with minimal toxic effects on the environment. Some RL strategies can be adopted to achieve this goal [4,8,9,37,44]. In the following section, some of the strategies are highlighted; however, we are not going to discuss RL strategies in detail; the section presents only the structure of RL.

RSC Environmental Strategy

This strategy includes all environmentally friendly practices that may give the organization involved a competitive advantage. Today, various organizations focus on protecting the environment and work extensively to promote RL/RSC activities, such as marketing, recycling, and distributing products to reduce waste associated with EOL products or RL activities. RSCM has gained considerable attention from manufacturers and retailers; in recent years, it has become part of an organizational commitment to social responsibility. European countries, especially Germany, practice this strategy a lot, and European governments have strict laws and regulations in regard to preserving the environment [44,45]. According to Subramaniam et al. [44], the landfill costs for waste disposal have increased, forcing companies to adopt advanced technologies and practices in order to make products more reusable or resalable. Incorporating an environmental strategy in RL processes can lead to lower operational costs and the promotion of environmental protection.

However, Mohtashami et al. [46] argued that an increase in product returns via RSCM can cause an increase in energy consumption and the amount of pollution that can negatively impact the environment. However, we should further evaluate returns for potential reuse or recycling in order to avoid harming the environment. According to [37,47], there are four environmental influencing factors: (1) weak enforcement of regulations mandated by the government, (2) take-back offers by suppliers, (3) cross-agency competition, and (4) consumers’ decision to save the environment.

RSC Recycling Strategy

The recycling strategy in RL/RSC shown in Figure 4 involves the recovery of materials from EOL or EOU products. Recycling requires tremendous technological tools and equipment, which usually requires high expenditure. Low recovery value with high investment requires a significant volume of processed materials in order to be profitable [9]. Qiang et al. [48] investigated a model with a decentralized decision that involves collecting recycled materials or products from the market directly from consumers or retailers. This helps to increase the quantity of returned products (volume) and reduce the cost of transactions.

RSC Remanufacturing Strategy

In contrast to the recycling strategy, the remanufacturing strategy in RSC is concerned with high-value products or devices, and is usually undertaken by manufacturers because they have the knowledge and experience in regard to remanufacturing of their products. The quality and quantity of returned products are important factors that determine the success of a remanufacturing strategy [9]. Ramezani et al. [49] developed a stochastic model to deal with issues surrounding profit, responsiveness, and uncertainty in quality. This model maximizes profit by increasing the total SCM profit, increases customer responsiveness by studying suitable collection and delivery times for customers, and improves quality by minimizing the number of defective materials to improve the operating activities.

RSC Reuse Strategy

The repair strategy in RL/RSC is concerned with repairing non-functional devices or products and returning them to customers. Usually, a retailer is responsible for communicating with customers, and the transportation cost is the main component of the total cost of repair [9]. Lieckens et al. [50] built a model to increase profit by optimizing the delivery service through two options: a swift service by retaining returned devices using available remanufactured parts, and reinstalling original parts after repairing or remanufacturing the product.

RSC Repair Strategy

A reuse strategy can apply to returned products that are still functional and usually require minor maintenance and cleaning. Therefore, the secondary market, such as retailers and outlets owned by manufacturers, can resell reusable products to other customers. Silva et al. [51] developed a model for reusing product packaging in order to reduce the waste generated from throwing away such materials. The results showed that there was 18% less consumption of materials used for packaging compared to the use of disposable packaging, which helps to reduce production costs. Park [52] studied reuse behavior by evaluating different technical, financial, and regulatory factors, and found that such behavior is greatly influenced by the decision-makers in an organization and the nature of the returned products.

4.4. Key Issues in RSCM

One of the critical issues in RSCM is the massive expenditure involved in RL processes. Many companies are concerned about minimizing expenditure and are therefore adopting systems and technologies that allow them to save on energy consumption and costs related to collection and transportation [8,53]. According to Jayant et al. [8], the cost of RL is around 4% of the total logistics cost. In addition, the authors also mentioned that the total processing cost of returned products is usually higher than the total cost of manufacturing. However, companies find that a strategic collection of products can drive a second purchase, which will reduce the cost of raw materials.

Blackburn et al. [30] argued that time is one of the main issues in RSCM. The value of a product declines over time, especially electronic products. Due to the delay in the processing of returned products, manufacturers should consider the value of returned products over time. These authors also found that the average waiting time for the processing of returned products is in the range of three to four months. During this period, the product value simply declines. Products with a short product life cycle (PLC), such as computers and mobile phones, have high marginal value over time compared to power gadgets or disposable electronics, which are less time-sensitive and have low marginal value over time. Therefore, it can be concluded that there is a direct relationship between the selling price and product return. In order to overcome the delay in processing, it is important to determine the capacity for collection and inspection, and to provide high-tech facilities in order to speed up recycling or reuse activities [54,55].

Compared to forwarding supply chains, organizations have less extensive knowledge of and experience with RSC. It is not easy to find a company with recycling experience of more than 10 years. Reusing goods is not a common practice, as most companies produce products. Moreover, it is still challenging to collect data on the environmental impact of RSC activities adopted by various businesses [56,57]. However, this paper can help to increase the level of awareness in regard to RSCM activities and encourage consumers to participate in RL, as the consumer is the vital factor in the RL process. On the other hand, the high level of uncertainty in product return poses another challenge, as it largely influences the overall cost throughout the supply chain [33,58].

Jayasinghe et al. [59] stressed the lack of quality and environmental standards in RSC operating activities, which could negatively affect the whole RSCM process. Not applying proper standards with respect to the handling of waste materials, especially in the dismantling process, could lead to exposure to hazardous materials. Weak manufacturing and a lack of direction are other issues related to RL operations. Nevertheless, using the right resources and designing the right infrastructure specifically for RSC activities will help to improve efficiency and enhance operational quality.

4.5. Mobile Phone Industry and the Need for RSCM

Chan and Chan [12] identified three main reasons for mobile phone companies to practice RL: (1) recovering assets and capturing value (this study found that around 40% of returned devices can be remanufactured or resold); (2) using RL as a strategic position (the first mover gains a competitive advantage); and (3) promoting the environmental benefits (building a good reputation by practicing social accountability).

Govindan and Popiuc [60] focused on the profit that can be generated from repair, reuse, and recycle activities (the 3Rs) in RSC or from the disposal of EOL products. They argued that maximum RSC profit can be achieved by applying a revenue-sharing contract (also known as a coordination contract) signed by all parties involved in the RSC. For example, a retailer may offer a financial return to customers in exchange for recycled devices, part of which comes from the manufacturer as stipulated in the revenue-sharing contract.

Kumar [21] explained that businesses and enterprises in the last 10 years have considered RSCM to be a vital and essential economic activity, in addition to promoting environmental sustainability. This is particularly true for the recycling of products with a short life cycle, such as smartphones, which are characterized as fast-moving items based on high consumer demand. To maintain environmental sustainability, governments worldwide are required to introduce new regulations for strategic environmental safety and recycling activities. These discussions led to our first major finding, as follows:

Major finding 1:

From the analysis, it is identified that government regulation plays a major role in accelerating recycling behaviors among users. Further promotion among supply chain partners in terms of revenue-sharing contracts stipulates the intention of recycling behavior.

4.6. RL Technology in Mobile and Smartphone Industries

Generally, the amount of e-waste generated is almost three times greater than the number of other wastes. Because of the ultra-high rate of mobile phone adoption by users, mobile device waste has been dramatically growing in recent years, reaching millions of tons [10]. This increase has occurred because consumers frequently buy the latest mobile models with sophisticated designs and advanced features. According to Shi et al. [61], 80% of mobile phones are upgraded every two years, leading to a huge number of discarded phones; unfortunately, only 20% of e-waste is officially collected and recycled [10]. Therefore, there is a need for systematic collection of such e-waste.

Earlier, John et al. [39] published a network design for RSC that takes into consideration the problem related to product structure, starting with the bill of materials (BOM). The authors insisted that the BOM should be listed and incorporated in the RL network design for two main reasons. First, recovered materials might not be commercially used and therefore will not generate revenue, especially in low quantities. Second, flow analysis at the component level rather than the product level provides a better understanding for managers to determine the appropriate number and types of recovery options. The recovery option is determined by the product residual value (PRV), which is related to rating returned products based on a quality assessment. The PRV is higher for EOU mobile devices than EOL devices. A high PRV is associated with manufacturing activities, while a low PRV is associated with repair and recycling activities.

Hira et al. [19] concluded that RSC in the mobile industry is important in order to save the environment. According to their study, mobile phone waste is considered to be dangerous because of the potential negative impact of environmental and human exposure to cytotoxic metals. On the other hand, mobile devices are considered to be assets due to systematic extraction and reuse of primary metals, which reduces dependence on natural resources. However, this paper does not discuss RL designs or activities regarding mobile devices. As the paper focuses on mobile phone waste, we classify the waste as dangerous due to the potential negative impact of toxic metals on human health and the environment.

Garrido-Hidalgo et al. [62] demonstrated that incorporating information and communication technology (ICT) into the supply chain (SC) domain, particularly the Internet of Things (IoT), will considerably enhance the performance process, scale back energy consumption, and enable the development of models with comprehensive statistical infrastructure and detailed information at each stage of SC. By empowering organizations with IoT technologies, pollution can be minimized, and commercial response to and time for market revolution can be accelerated. This study focuses on e-waste management and provides a detailed framework that describes the various product stages from EOL to reuse via RSCM.

He et al. [63] emphasized that as part of an RSC recycling analysis, companies should assess the life cycle cost (LCC) of the high-tech minerals (HTMs) involved in manufacturing mobile devices. The LCC is the summation cost incurred during an inspection at the disposal stage. Their study, on feature phones and smartphones, found that the LCC of recycling one feature phone and one smartphone is approximately USD 2.24 and USD 6.60, respectively [63]. Those values are essential for managers to analyze, especially when evaluating end-to-end profit and planning for the recycling of feature phones. However, the results of this evaluation should not neglect the environmental impact.

4.7. Mobile RL through e-Commerce

E-commerce is one of the latest technologies that people, especially young people, are using today to purchase goods and products, and has developed dramatically in the last 10 years, becoming the main channel for businesses to use through either the Web or mobile apps [58]. RSCM through e-commerce can save time, resources, inventory space, and logistics costs for consumers and businesses. Moreover, it enhances customer satisfaction and encourages customers to rebuy from the same business [33]. There are two methods of RL through e-commerce: (1) returning unwanted products (mobiles) before use without visiting the store, with the capability of tracking the status of returned items; and (2) returning EOL or EOU products (mobiles). An example of the latter is the Apple website, where customers can estimate the value of an old mobile device; however, they are still required to visit a store for a physical return if the item is determined to have value.

4.8. Electronic and Mobile Waste Management

There is no standard definition, but in general, e-waste refers to electronic and electrical products and their components that are disposed of by end-users in order to be recycled or reused [10,64]. Echegaray and Hansstein [24] summarized the definition of e-waste as any electronic product that has reached EOL. This paper adopts that definition and extends it to describe mobile waste. However, for mobile waste, the term EOU is used in addition to EOL, as suggested by Echegaray and Hansstein [24].

Over the past 10 years, the remarkable growth in the production of electronic products, especially mobile and smart devices, has led to a huge increase in e-waste. Nowadays, e-waste is considered to be one of the biggest sources of toxic materials, which is one of the fastest-growing pollution problems threatening human health and the environment [10,65,66]. According to Doan et al. [10], around 80% of mobile device consumers upgrade their phone every two years, generating an enormous volume of devices being discarded. As previously described, RSC is considered to be a complicated process when it comes to e-waste recycling due to the high level of uncertainty in the quantity and quality of returned products and devices [10,56]. Therefore, to save the environment and protect human health, the key factors that encourage consumer participation in recycling must be determined.

Major finding 2:

It is essential for authorized organizations and developed countries to build secure and accessible channels for consumers and businesses to undertake regular recycling of mobile devices instead of keeping them at home or in offices.

4.9. Mobile Waste Issues

The continual development of mobile technologies poses some of the main challenges in regard to the increased generation of mobile waste, considering the short life cycle of mobile devices. Two separate studies conducted by Yin et al. [2] and Hira et al. [19] found that the mobile life cycle ranges from two to three years, after which the device will be either recycled or neglected.

Another issue related to the advances in mobile technology concerns the sophisticated designs and materials used, such as liquid crystal display (LCD) or light-emitting diode (LED) screens and built-in batteries [19,67]. These sophisticated components of mobile devices contain hazardous materials that require special attention and handling during recycling or disposal.

Dismantling a mobile device must be carried out by an organized channel due to the emission of harmful gases such as CO2 or SO2 during the extraction of core elements [21]. Recycling undertaken by an unauthorized entity or channel may cause greater problems due to the lack of knowledge of measures related to safety and environmental aspects. Unregulated channels usually focus solely on making money from reselling extracted components such as copper, gold, and other materials. The total value of raw materials extracted from e-waste was 48 billion euros in 2015 [43], which increased to about 55 billion euros by 2016 [10,68]. Therefore, there is a need for governments to issue rules and policies that govern mobile waste collection and recycling. According to Graedel et al. [69] and Hira et al. [19], the regulations should be standardized in order to control e-waste production and recycling processes.

One of the main issues related to mobile waste is the difficulty in collecting the devices. Because of their small size and consumers’ intention to keep them, it is usually difficult to collect unwanted or non-functional mobiles from consumers. According to Sabbaghi et al. [20], some manufacturers are willing to pay incentives to retailers so that they will encourage customers to hand over old devices. Due to the rapid emergence of new models, the newer versions can be resold faster than the older ones.

The privacy and protection of data stored in a mobile’s memory, considered sensitive information, creates concern regarding the privacy of individuals. This concern affects mobile users in the Gulf countries because of the conservative nature of those who reside there, which in turn affects their willingness to recycle EOL and EOU mobiles via official recycling channels [70].

4.10. Consumers’ Behavior Factors and Models

Previous sections discussed the processes and activities of RSCM, which are composed of different stages, beginning with collecting products from customers, as well as the latest findings on RL. This section discusses consumer behavior supported by findings from the literature, where a shift toward green purchasing is the key to changing consumer decisions with regard to saving the environment. Thus, as mentioned at the beginning of this paper, the consumer is the key to starting the RL process, and studying consumer behavior is essential to understand the gaps or problems with respect to participating in 3R activities.

The analysis of consumer behavior is defined as “the study of individuals, groups, or organizations and the processes they use to select, secure, use, and dispose of products, services, experiences, or ideas to satisfy needs and the impacts that these processes have on the consumer and society” [71,72,73].

On the other hand, Schiffman and Kanuk [74] defined consumer behavior as a process by which consumers analyze and study desired products in order to make purchasing decisions. As illustrated by these two definitions, a behavioral decision comes after a series of processes in which the pros and cons of a specific purchase are analyzed, which can be extended to decision making with regard to mobile recycling. Thus, these decisions are influenced by different factors, which will be summarized in the following section.

Previous Behavioral Factors and Models/Frameworks

Due to the importance of studying consumer behavior, many studies have investigated the internal and external factors that influence individual adoption of green behavior. This section highlights some of the studies and elaborates on the factors influencing consumer behavior.

A study conducted by Park and Ha [22] established practical findings by combining the theory of planned behavior (TPB) and the norm activation model (NAM). The results demonstrated that recycling intention is significantly influenced by personal norms, in addition to other factors such as attitude and perceived behavioral control. Notably, attitude and perceived behavioral control do not directly influence recycling intention. The authors also examined how awareness of the consequences is positively correlated with and affects other factors in the TPB. However, responses to surveys in their study constituted only 5.61% of overall findings, indicating a response rate too low for any conclusion to be formed. Furthermore, the types of recycled materials were not specified in the study.

Du and Lang [75] provided an example of an online e-commerce platform for mobile phone recycling that can effectively improve logistics management to reduce handling costs. It is a model that does not require investment in infrastructure and therefore reduces processing cost, and is convenient for consumers so they are encouraged to participate in mobile recycling. Although the study was published in a highly ranked publication, only one channel for collecting mobile waste was discussed, e-commerce or online portals. Today, however, most companies recommend having an online portal for communication with consumers, so consumers can be guided in the process of returning products. The online platform could also be used to provide estimates of the product value.

Echegaray and Hansstein [24] demonstrated that there is a positive recycling intention with regard to e-waste. By studying the sociodemographic factors, they found that women and middle-aged people with low income were more willing to participate in electronic waste recycling than other demographic groups. The study focused on the TPB, and also demonstrated that perceived social acceptance significantly influences consumers’ intention to recycle. However, the study did not include all details on the main component of TPB or an in-depth analysis of the factors associated with the theory; rather, it focused solely on sociodemographic factors.

Martinho et al. [3] reported that the number of smartphone owners is higher than the number of tablet owners, with an average of 3.34 smartphones compared to 1.06 tablets per person. In terms of recycling behavior, the study found no significant difference between the two types of devices. Many people prefer to keep old devices at home or give used ones to friends or relatives over sending them for recycling due to a lack of knowledge about recycling channels. The study also examined different sociodemographic variables (gender, age, income, education, and region of residence) in regard to recycling intention. The study demonstrated that family size and gender have the biggest influence on consumer behavior, and income influences consumer recycling behavior. However, no specific theory was linked to the findings made in the study in addition to a discussion on sociodemographic variables.

Bovea et al. [76] demonstrated that regulations on e-waste management and economic factors encourage consumers to participate in reusing, repairing, and recycling old electronic devices with regard to preserving the environment and natural resources. The study found that consumers are still not ready to adopt such practices, particularly for small electronic equipment. According to the findings, there is an inclination to keep such devices rather than recycle them. Repairing is an alternative to recycling, considering the cost to fix an item compared to the price of a newly manufactured product. Socioeconomic variables should be taken into consideration, as household size, level of education, and age can influence a consumer’s decision to repair an old device; on the contrary, household income does not have a similar influence on consumer behavior. The study did not associate the findings with specific behavioral theories, and the factors presented were not analyzed in depth. However, the study managed to address the socioeconomic variables and their influence on consumer behavior.

Khan et al. [77] observed that perceived behavioral management is a critical predictive factor regarding the practice of reuse, return, or recycle. Self-efficacy and accessible opportunities are two factors of perceived behavioral control that influence consumers’ intention to recycle. The study made an assumption that an individual’s reluctance to be part of recycling is due to the lack of infrastructure, recycling channels, or facilities. The study only investigated one product (plastic) and did not discuss channels for recycling. As for behavior, the authors discuss several aspects in addition to TPB. However, some criteria were not discussed, such as self-confidence, with regard to participating in recycling activities.

Sun and Wang [78] presented additional factors incorporated in the TPB in order to predict consumer behavior, such as product knowledge and price consciousness; the latter negatively impact consumer buying intention. Furthermore, it was highlighted in [78] that in-store experiential marketing, in addition to intrinsic TPB factors (attitude, subjective norms, and perceived behavioral control), can be useful in predicting consumer decisions on green purchasing. However, these factors have limitations in predicting purchasing behavior when dealing with online social platforms due to the broad range of product information and reviews exchanged by consumers. As a result, the study focused only on purchase behavior in regard to green products and not general purchase behavior.

Zhang et al. [23] pointed out that conscientiousness and good faith positively affect the intention to recycle and reuse among consumers, which is closely associated with attitude and subjective norms. More conscientious individuals tend to reflect better subjective norms and emotional standards with regard to saving the environment by participating in recycling activities. However, the authors did not discuss information security and the process of data cleaning in detail. They did not discuss how to overcome consumers’ reluctance to participate in recycling programs when the main concern is data security. The research focused only on consumers’ intention to recycle smartphones, not on actual recycling behavior in general.

Sharma and Foropon [79], following a different perspective, replaced two main factors in the TPB, subjective norms and perceived behavioral control, with environmental knowledge and perceived consumer effectiveness in order to examine green purchase attitudes. They also suggested three types of purchase patterns: unconditional, conditional, and accidental purchases. The proposed model emphasizes the influence of product value on green buying, which indicates an inclination toward conditional purchase regardless of environmental concerns. This concern can be understood either as saving the environment or as an environmental constraint. The research focuses on the psychological effects on environmental behavior.

Table 3 summarizes the significant research contributions on behavioral factors. However, other behavioral factors either have never been found or are not discussed in the reviewed studies, e.g., religion, knowledge and skills related to a specific behavior, habits, reciprocity options, and data security. The authors assume that information security is the central focus in regard to consumers’ intention to participate in mobile recycling; therefore, we focus on and examine this factor intensively. In addition, we examine the benefits such as offering financial incentives or free vouchers, or attentiveness to the environment, as influencing factors for customers to return EOL or EOU mobile devices. This factor (benefits perceived) might be inconsistent from country to country depending on the lifestyle.

Table 3.

Summary of significant contributions made through research on behavioral factors.

Major finding 3:

It is identified that consumer behavior supported by financial incentives affects participation in recycling and thus complete participation in 3R activities.

5. Conclusions

Mobile waste has generated considerable interest from the government, industry players, and end-users, due to environmental concerns, economic gain, sustainable growth, and competitive development. This means businesses need to make more effort to adopt RSC procedures, as such practices are inefficient at the moment despite the field of research being relatively mature. The topic of mobile waste and its effect on the environment is addressed in this review. This paper focuses on three main sections: first, it provides a holistic view of RL, listing its main processes and critical issues in RSC as described by researchers to determine the successful implementation of recycling programs via RSCM. Second, the paper discusses mobile waste and different studies that have evaluated this issue. Finally, the paper demonstrates and reviews factors and frameworks that drive consumer behavior as suggested by several studies and additional research conducted in this domain, and proposes three major findings. This study contributes to the body of knowledge with selected and reviewed published articles on RSC focusing on mobile waste. In addition, we provide insight into the factors that various stakeholders believe influence mobile users to participate in mobile recycling. This article will help academics explore the importance of mobile recycling and further explore factors influencing mobile users to participate in mobile recycling, especially for the managers who are working in the mobile industry. The article is essential for protecting the environment and preserving natural resources by promoting materials for manufacturing new devices. The authors acknowledge that this paper is limited by the small number of factors that influence recycling behavior focusing on mobile recycling specifically, and this article is limited to scholarly papers published from 2004 to 2021. However, studying the theoretical side of RL will help to discover the sustainability factors that influence customer behavior toward mobile recycling.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Coffey, P.; Toland, J. The Sustainable Management of Used Mobile Phones: A Repertory Grid Analysis. In Proceedings of the Proceedings of the 40th International Conference on Information Systems, Munich, Germany, 15–18 December 2019. [Google Scholar]

- Yin, J.F.; Gao, Y.N.; Xu, H. Survey and analysis of consumers’ behaviour of waste mobile phone recycling in China. J. Clean. Prod. 2014, 65, 517–525. [Google Scholar] [CrossRef]

- Martinho, G.; Magalhaes, D.; Pires, A.; Pires, A. Consumer behavior with respect to the consumption and recycling of smartphones and tablets: An exploratory study in Portugal. J. Clean. Prod. 2017, 156, 147–158. [Google Scholar] [CrossRef]

- Rogers, D.S.; Tibben-Lembke, R.S. Going Backwards: Reverse Logistics Trends and Practices; Reverse Logistics Executive Council: Pittsburgh, PA, USA, 1999; Volume 2. [Google Scholar]

- De Brito, M.P.; Dekker, R. A Framework for Reverse Logistics. In Reverse Logistics; Springer: Berlin/Heidelberg, Germany, 2004; pp. 3–27. [Google Scholar]

- Stock, J.R. Development and implementation of reverse logistics programs. In Proceedings of the Annual Conference Proceedings, Council of Logistics Management, Anaheim, CA, USA, 11–14 October 1998. [Google Scholar]

- Prahinski, C.; Kocabasoglu, C. Empirical research opportunities in reverse supply chains. Omega 2006, 34, 519–532. [Google Scholar] [CrossRef]

- Jayant, A.; Gupta, P.; Garg, S. Perspectives in reverse supply chain management (R-SCM): A state of the art literature review. JJMIE 2012, 6, 87–102. [Google Scholar]

- Agrawal, S.; Singh, R.K.; Murtaza, Q. A literature review and perspectives in reverse logistics. Resour. Conserv. Recycl. 2015, 97, 76–92. [Google Scholar] [CrossRef]

- Doan, L.T.T.; Amer, Y.; Lee, S.-H.; Phuc, P.N.K.; Dat, L.Q. E-Waste Reverse Supply Chain: A Review and Future Perspectives. Appl. Sci. 2019, 9, 5195. [Google Scholar] [CrossRef]

- Kianpour, K.; Jusoh, A.; Mardani, A.; Streimikiene, D.; Cavallaro, F.; Nor, K.M.; Zavadskas, E.K. Factors influencing consumers’ intention to return the end of life electronic products through reverse supply chain management for reuse, repair and recycling. Sustainability 2017, 9, 1657. [Google Scholar] [CrossRef]

- Chan, F.T.; Chan, H.K. A survey on reverse logistics system of mobile phone industry in Hong Kong. Manag. Decis. 2008, 46, 702–708. [Google Scholar] [CrossRef]

- Adcroft, A.; Fulconis, F.; Saglietto, L.; Paché, G. Strategy dynamics in the logistics industry: A transactional center perspective. Manag. Decis. 2007, 45, 104–117. [Google Scholar]

- Zhang, Y.; Qu, Y.; Wang, W.; Yu, S.; Liu, Y. Joint collection mode of waste mobile phones based on residents’ preferences: A case of Dalian in China. J. Clean. Prod. 2019, 223, 350–359. [Google Scholar] [CrossRef]

- Unep, P.; Itu, I.; Unido, U. A New Circular Vision for Electronics Time for a Global Reboot; World Economic Forum: Cologny, Switzerland, 2019. [Google Scholar]

- Gonzalez-Torre, P.L.; Adenso-Dıaz, B.; Artiba, H. Environmental and reverse logistics policies in European bottling and packaging firms. Int. J. Prod. Econ. 2004, 88, 95–104. [Google Scholar] [CrossRef]

- Robinson, B.H. E-waste: An assessment of global production and environmental impacts. Sci. Total Environ. 2009, 408, 183–191. [Google Scholar] [CrossRef]

- Kazemi, N.; Modak, N.M.; Govindan, K. A review of reverse logistics and closed loop supply chain management studies published in IJPR: A bibliometric and content analysis. Int. J. Prod. Res. 2019, 57, 4937–4960. [Google Scholar] [CrossRef]

- Hira, M.; Yadav, S.; Morthekai, P.; Linda, A.; Kumar, S.; Sharma, A. Mobile Phones—An asset or a liability: A study based on characterization and assessment of metals in waste mobile phone components using leaching tests. J. Hazard. Mater. 2018, 342, 29–40. [Google Scholar] [CrossRef] [PubMed]

- Sabbaghi, M.; Esmaeilian, B.; Mashhadi, A.R.; Behdad, S.; Cade, W. An investigation of used electronics return flows: A data-driven approach to capture and predict consumers storage and utilization behavior. Waste Manag. 2015, 36, 305–315. [Google Scholar] [CrossRef]

- Kumar, A. Extended TPB model to understand consumer “selling” behaviour Implications for reverse supply chain design of mobile phones. Asia Pac. J. Mark. Logist. 2017, 29, 721–742. [Google Scholar] [CrossRef]

- Park, J.; Ha, S. Understanding Consumer Recycling Behavior: Combining the Theory of Planned Behavior and the Norm Activation Model. Fam. Consum. Sci. Res. J. 2014, 42, 278–291. [Google Scholar] [CrossRef]

- Zhang, Y.; Wu, S.; Rasheed, M.I. Conscientiousness and smartphone recycling intention: The moderating effect of risk perception. Waste Manag. 2020, 101, 116–125. [Google Scholar] [CrossRef] [PubMed]

- Echegaray, F.; Hansstein, F.V. Assessing the intention-behavior gap in electronic waste recycling: The case of Brazil. J. Clean. Prod. 2017, 142, 180–190. [Google Scholar] [CrossRef]

- Cao, X.; Liu, C. Research on customers’ willingness to participate in express package recycling. In Proceedings of the IOP Conference Series: Earth and Environmental Science, Kuala Lumpur, Malaysia, 12–14 April 2019; IOP Publishing: Bristol, UK, 2019; Volume 295, p. 032030. [Google Scholar]

- Snyder, H. Literature review as a research methodology: An overview and guidelines. J. Bus. Res. 2019, 104, 333–339. [Google Scholar] [CrossRef]

- PRISMA. PRISMA Statement. 2021. Available online: http://www.prisma-statement.org/Extensions/ (accessed on 26 February 2021).

- ITU―The World Bank Group. Mobile Cellular Subscriptions (Per 100 People)—United Arab Emirates. 2019. Available online: https://data.worldbank.org/indicator/IT.CEL.SETS.P2?locations=AE (accessed on 18 January 2020).

- Fleischmann, M.; Van Nunen, J.; Gräve, B.; Gapp, R. Reverse Logistics—Capturing Value in the Extended Supply Chain. In Supply Chain Management on Demand; Springer International Publishing: Berlin/Heidelberg, Germany, 2005; pp. 167–186. [Google Scholar]

- Blackburn, J.D.; Guide, V.D.R.; Souza, G.C.; Van Wassenhove, L.N. Reverse Supply Chains for Commercial Returns. Calif. Manag. Rev. 2004, 46, 6–22. [Google Scholar] [CrossRef]

- Wei, Y. Reverse Supply Chain Management—Explore the Feasibility to Incorporate Forward Supply Chain Strategy into the Reverse Supply Chain in the Electronic Industry. Master’s Thesis, School of Business, Economics and Law, University of Gothenburg, Gothenburg, Sweden, 2011. [Google Scholar]

- Guide, V.D.R., Jr.; Daniel, R. Supply-chain management for recoverable manufacturing systems. Interfaces 2000, 30, 125–142. [Google Scholar] [CrossRef]

- Han, H.; Trimi, S. A fuzzy TOPSIS method for performance evaluation of reverse logistics in social commerce platforms. Expert Syst. Appl. 2018, 103, 133–145. [Google Scholar] [CrossRef]

- Singh, D.; Singh, H.; Walia, N. Weighted Flow Distribution Model of the Reverse Logistics System. In Proceedings of the World Congress on Engineering, London, UK, 6–8 July 2011. [Google Scholar]

- Gupta, S.M. Reverse Supply Chains: Issues and Analysis; CRC Press: Boca Raton, FL, USA, 2016. [Google Scholar]

- Xing, B.; Gao, W.J.; Battle, K.; Marwala, T.; Nelwamondo, F.V. Artificial intelligence in reverse supply chain management: The state of the art. arXiv 2010, arXiv:1012.4046. [Google Scholar]

- Dekker, R.; Fleischmann, M.; Inderfurth, K.; van Wassenhove, L.N. (Eds.) Reverse Logistics: Quantitative Models for Closed-Loop Supply Chains; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2013. [Google Scholar]

- Ardeshirilajimi, A.; Azadivar, F. Reverse supply chain plan for remanufacturing commercial returns. Int. J. Adv. Manuf. Technol. 2014, 77, 1767–1779. [Google Scholar] [CrossRef]

- John, S.T.; Sridharan, R.; Kumar, P.N.R. Reverse logistics network design: A case of mobile phones and digital cameras. Int. J. Adv. Manuf. Technol. 2017, 94, 615–631. [Google Scholar] [CrossRef]

- Guide, V.; Wassenhove, L. Full Cycle Supply Chains; Carnegie Mellon Press: Pittsburgh, PA, USA, 2003. [Google Scholar]

- Mousa, N.D. Inventory Management in Reverse Supply Chains: Decision-Making with Data Science; State University of New York: Binghamton, NY, USA, 2019; p. 170. [Google Scholar]

- Webster, S.; Mitra, S. Competitive strategy in remanufacturing and the impact of take-back laws. J. Oper. Manag. 2007, 25, 1123–1140. [Google Scholar] [CrossRef]

- Kumar, A.; Holuszko, M.; Espinosa, D.C.R. E-waste: An overview on generation, collection, legislation and recycling practices. Resour. Conserv. Recycl. 2017, 122, 32–42. [Google Scholar] [CrossRef]

- Subramaniam, U.; Bhadury, J.; Peng, S.; Subramaniam, U.; Bhadury, J.; Peng, S. Reverse logistics strategies and their implementations: A Pedagogical Survey. J. Acad. Bus. Econ. 2004, 4, 169–173. [Google Scholar]

- Van Engeland, J.; Beliën, J.; De Boeck, L.; De Jaeger, S. Literature review: Strategic network optimization models in waste reverse supply chains. Omega 2020, 91, 102012. [Google Scholar] [CrossRef]

- Mohtashami, Z.; Aghsami, A.; Jolai, F. A green closed loop supply chain design using queuing system for reducing environmental impact and energy consumption. J. Clean. Prod. 2020, 242, 118452. [Google Scholar] [CrossRef]

- Carter, C.R.; Ellram, L.M. Reverse logistics: A review of the literature and framework for future investigation. J. Bus. Logist. 1998, 19, 85. [Google Scholar]

- Qiang, Q.; Ke, K.; Anderson, T.; Dong, J. The closed-loop supply chain network with competition, distribution channel investment, and uncertainties. Omega 2013, 41, 186–194. [Google Scholar] [CrossRef]

- Ramezani, M.; Bashiri, M.; Tavakkoli-Moghaddam, R. A new multi-objective stochastic model for a forward/reverse logistic network design with responsiveness and quality level. Appl. Math. Model. 2013, 37, 328–344. [Google Scholar] [CrossRef]

- Lieckens, K.T.; Colen, P.J.; Lambrecht, M.R. Optimization of a stochastic remanufacturing network with an exchange option. Decis. Support Syst. 2013, 54, 1548–1557. [Google Scholar] [CrossRef]

- Silva, D.A.L.; Renó, G.W.S.; Sevegnani, G.; Sevegnani, T.B.; Truzzi, O.M.S. Comparison of disposable and returnable packaging: A case study of reverse logistics in Brazil. J. Clean. Prod. 2013, 47, 377–387. [Google Scholar] [CrossRef]

- Park, J.Y. Assessing determinants of industrial waste reuse: The case of coal ash in the United States. Resour. Conserv. Recycl. 2014, 92, 116–127. [Google Scholar] [CrossRef]

- Lee, D.-H.; Dong, M. A heuristic approach to logistics network design for end-of-lease computer products recovery. Transp. Res. Part E Logist. Transp. Rev. 2008, 44, 455–474. [Google Scholar] [CrossRef]

- Alumur, S.A.; Nickel, S.; Saldanha-Da-Gama, F.; Verter, V. Multi-period reverse logistics network design. Eur. J. Oper. Res. 2012, 220, 67–78. [Google Scholar] [CrossRef]

- Kilic, H.S.; Cebeci, U.; Ayhan, M.B. Reverse logistics system design for the waste of electrical and electronic equipment (WEEE) in Turkey. Resour. Conserv. Recycl. 2015, 95, 120–132. [Google Scholar] [CrossRef]

- Pishvaee, M.S.; Razmi, J. Environmental supply chain network design using multi-objective fuzzy mathematical programming. Appl. Math. Model. 2012, 36, 3433–3446. [Google Scholar] [CrossRef]

- Kumar, M.; Tiwari, M.K.; Wong, K.Y.; Govindan, K.; Kuah, C.T. Evaluating Reverse Supply Chain Efficiency: Manufacturer’s Perspective. Math. Probl. Eng. 2014, 2014, 1–9. [Google Scholar] [CrossRef]

- Batarfi, R.; Jaber, M.Y.; Aljazzar, S.M. A profit maximization for a reverse logistics dual-channel supply chain with a return policy. Comput. Ind. Eng. 2017, 106, 58–82. [Google Scholar] [CrossRef]

- Jayasinghe, R.S.; Chileshe, N.; Rameezdeen, R. Information-based quality management in reverse logistics supply chain: A systematic literature review. Benchmarking Int. J. 2019, 26, 2146–2187. [Google Scholar] [CrossRef]

- Govindan, K.; Popiuc, M.N. Reverse supply chain coordination by revenue sharing contract: A case for the personal computers industry. Eur. J. Oper. Res. 2014, 233, 326–336. [Google Scholar] [CrossRef]

- Shi, J.; Liu, Z.; Tang, L.; Xiong, J. Multi-objective optimization for a closed-loop network design problem using an improved genetic algorithm. Appl. Math. Model. 2017, 45, 14–30. [Google Scholar] [CrossRef]

- Garrido-Hidalgo, C.; Olivares, T.; Ramirez, F.J.; Roda-Sanchez, L. An end-to-end Internet of Things solution for Reverse Supply Chain Management in Industry 4.0. Comput. Ind. 2019, 112, 103127. [Google Scholar] [CrossRef]

- He, P.; Feng, H.; Hu, G.; Hewage, K.; Achari, G.; Wang, C.; Sadiq, R. Life cycle cost analysis for recycling high-tech minerals from waste mobile phones in China. J. Clean. Prod. 2020, 251, 119498. [Google Scholar] [CrossRef]

- Widmer, R.; Oswald-Krapf, H.; Sinha-Khetriwal, D.; Schnellmann, M.; Böni, H. Global perspectives on e-waste. Environ. Impact Assess. Rev. 2005, 25, 436–458. [Google Scholar] [CrossRef]

- Camgöz-Akdag, H.; Aksoy, H.M. Green supply chain management for electric and electronic equipment: Case study for Turkey. In Proceedings of the International Annual Conference of the American Society for Engineering Management, Virginia Beach, VA, USA, 15–18 October 2014. [Google Scholar]

- Kiddee, P.; Naidu, R.; Wong, M.H. Electronic waste management approaches: An overview. Waste Manag. 2013, 33, 1237–1250. [Google Scholar] [CrossRef]

- Lankey, R.; McMichael, F. Rechargeable Battery Management and Recycling: A Green Design Educational Module; Green Design Initiative Technical Report; Carnegie Mellon University: Pittsburgh, PA, USA, 1999. [Google Scholar]

- Baldé, C.P.; Forti, V.; Gray, V.; Kuehr, R.; Stegmann, P. The Global E-Waste Monitor 2017: Quantities, Flows and Resources; United Nations University, International Telecommunication Union, and International Solid Waste Association: Tokyo, Japan, 2017; p. 116. [Google Scholar]

- Graedel, T.E.; Allwood, J.; Birat, J.-P.; Buchert, M.; Hagelüken, C.; Reck, B.K.; Sibley, S.F.; Sonnemann, G. What Do We Know About Metal Recycling Rates? J. Ind. Ecol. 2011, 15, 355–366. [Google Scholar] [CrossRef]

- Alghazo, J.; Ouda, O.K. Electronic waste management and security in GCC countries: A growing challenge. In Proceedings of the ICIEM International Conference, Sousse, Tunisia, 27–30 October 2016. [Google Scholar]

- Hawkins, D.I.; Mothersbaugh, D.L. Consumer Behavior: Building Marketing Strategy; McGraw-Hill Irwin: Boston, MA, USA, 2010. [Google Scholar]

- Gabbott, M.; Hogg, G. Consumer Behaviour, in the Marketing Book; Routledge: Singapore, 2016; pp. 173–187. [Google Scholar]

- Deepika, J.; Neeraja, T. Lighting impact on consumer’s shopping behaviour in retail cloth stores. Int. J. Sci. Res. 2014, 3, 933–938. [Google Scholar]

- Schiffman, L.G.; Kanuk, L.L. Consumer Behaviour; Prentice Hall: Upper Saddle River, NJ, USA, 2010. [Google Scholar]

- Du, Z.; Lang, M. Building reverse supply chain of waste mobile phones based on e-commerce platform. In Proceedings of the 2015 International Conference on Logistics, Informatics and Service Sciences (LISS), Berkeley, CA, USA, 27–29 July 2015. [Google Scholar]

- Bovea, M.D.; Ibáñez-Forés, V.; Pérez-Belis, V.; Juan, P. A survey on consumers’ attitude towards storing and end of life strategies of small information and communication technology devices in Spain. Waste Manag. 2018, 71, 589–602. [Google Scholar] [CrossRef] [PubMed]

- Khan, F.; Ahmed, W.; Najmi, A. Understanding consumers’ behavior intentions towards dealing with the plastic waste: Perspective of a developing country. Resour. Conserv. Recycl. 2019, 142, 49–58. [Google Scholar] [CrossRef]

- Sun, Y.; Wang, S. Understanding consumers’ intentions to purchase green products in the social media marketing context. Asia Pac. J. Mark. Logist. 2019, 32, 860–878. [Google Scholar] [CrossRef]

- Sharma, A.; Foropon, C. Green product attributes and green purchase behavior: A theory of planned behavior perspective with implications for circular economy. Manag. Decis. 2019, 57, 1018–1042. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).