Research into Efficient Technology for Material Recovery of Waste Polyurethane Foams

Abstract

1. Introduction

- Recycling of pure PUR foam from seats;

- Recycling of polyurethane foam from other parts of the vehicle, which has an integral surface layer, i.e., PUR foam injected directly into moulded parts, upholstery with an adhesive surface layer—textile, leather, and artificial leather (armrests, door upholstery, roof, etc.).

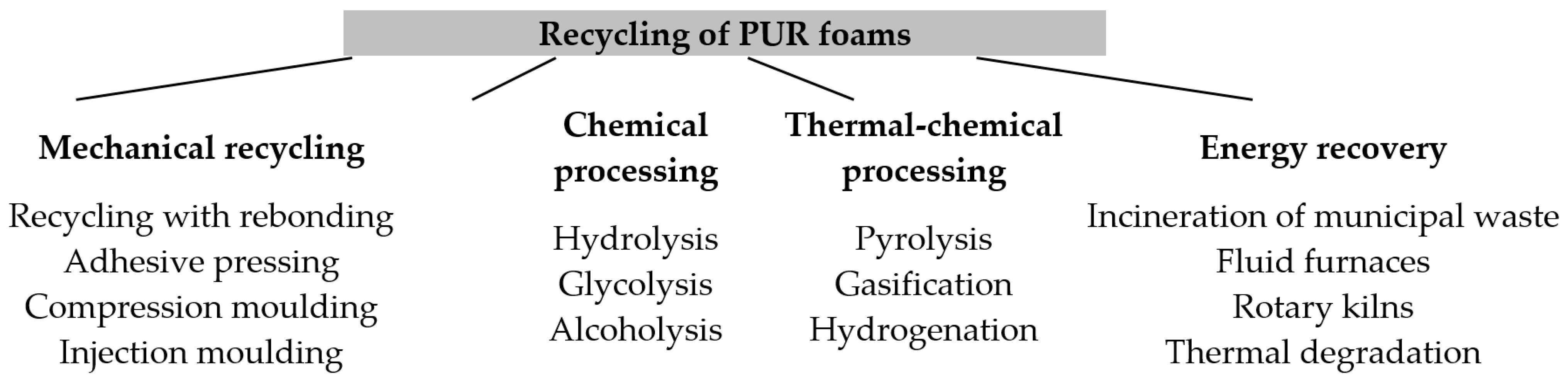

1.1. Analysis of Technological Options for the Recovery of Polyurethane Foams

- (a)

- Increasing the density of the bulk polyurethane foams, enabling cost-effective transport from the collection point to the recycling plant;

- (b)

- Size reduction in polyurethane products (mattresses, car seats, insulation boards, etc.) suitable for further processing in the selected recycling process.

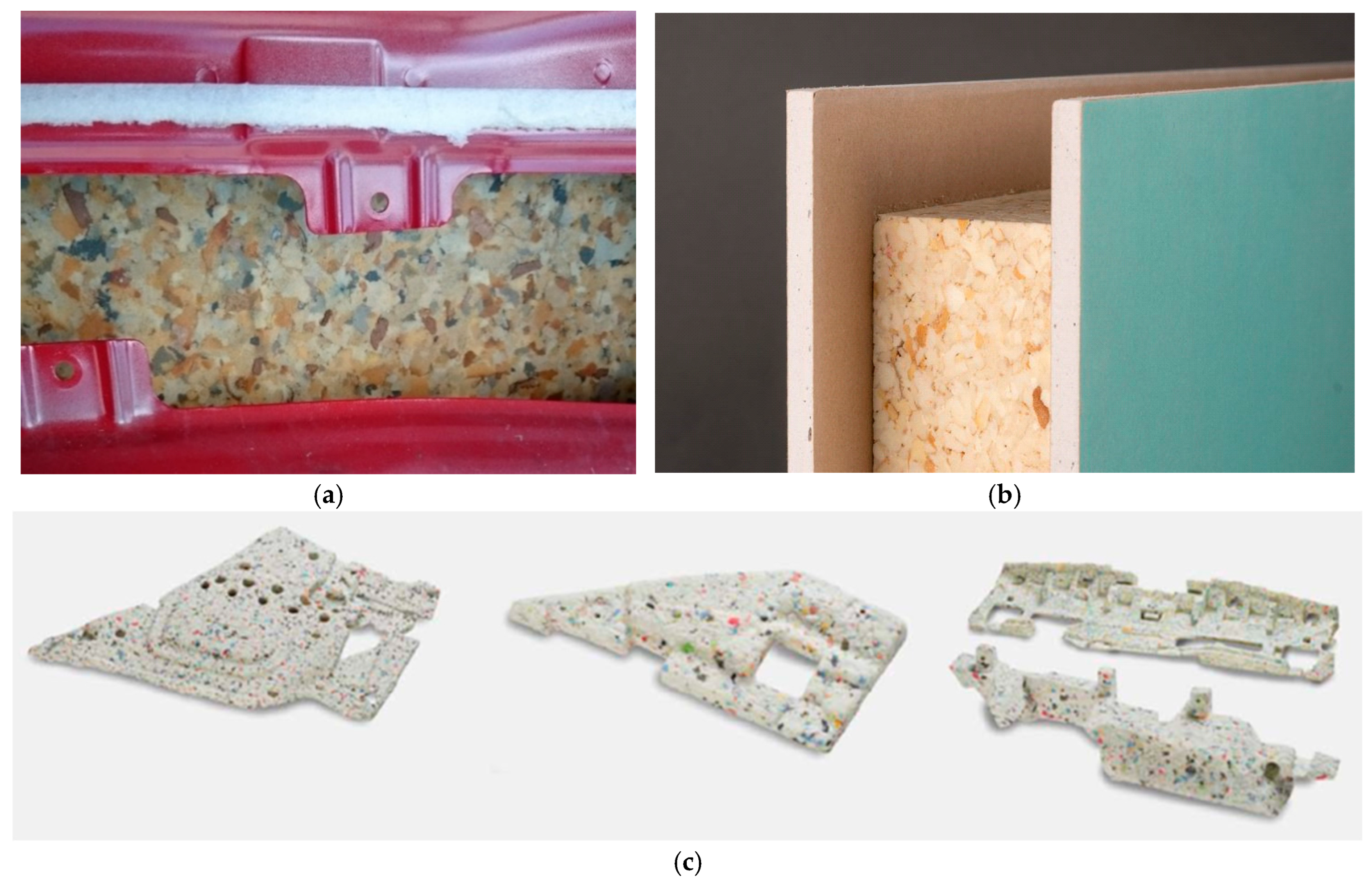

1.2. Mechanical Recycling

2. Proposal of the Appropriate Technology for the Stated Project Objectives

Utilisation of Products from Secondary Raw Materials

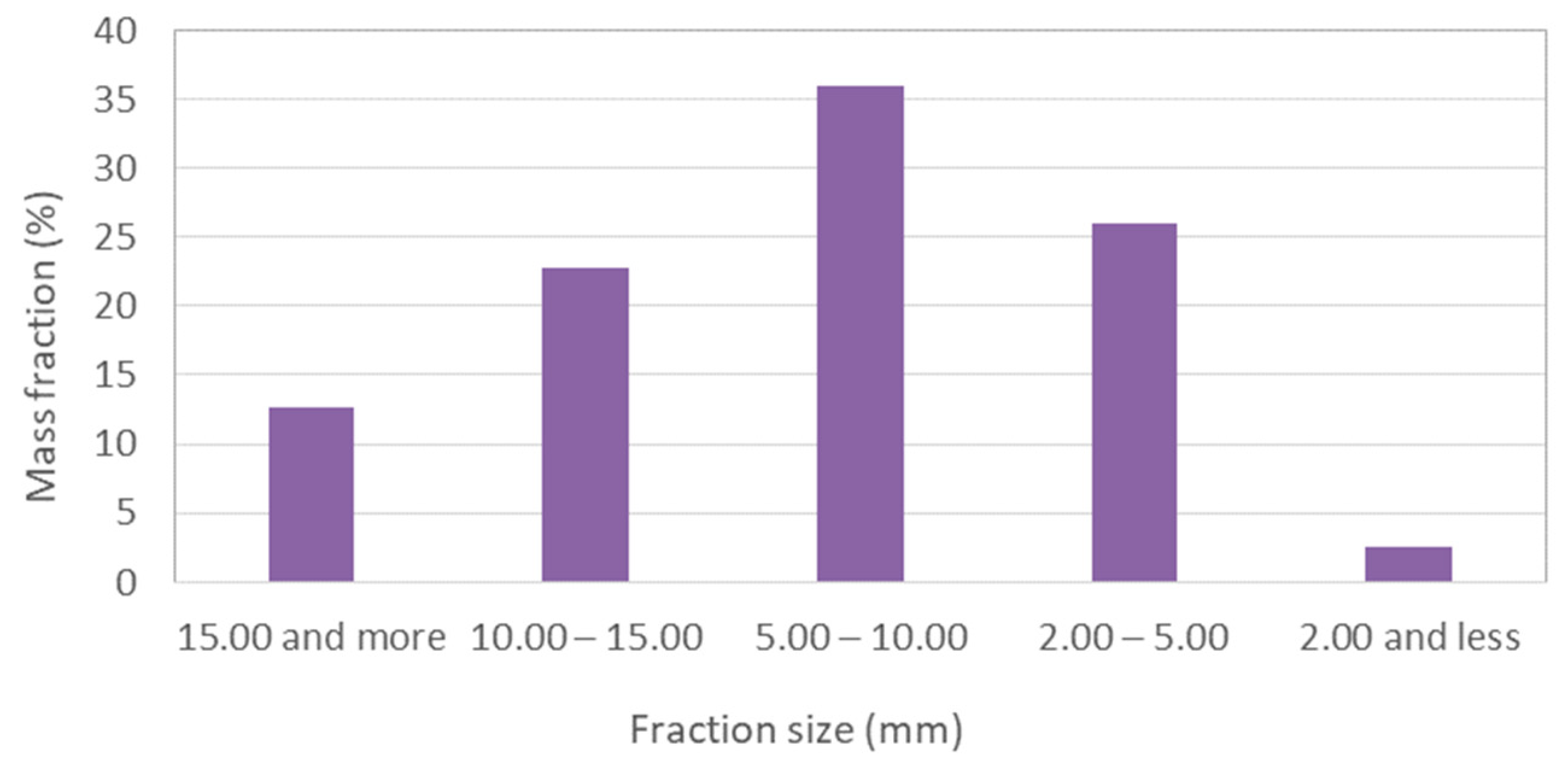

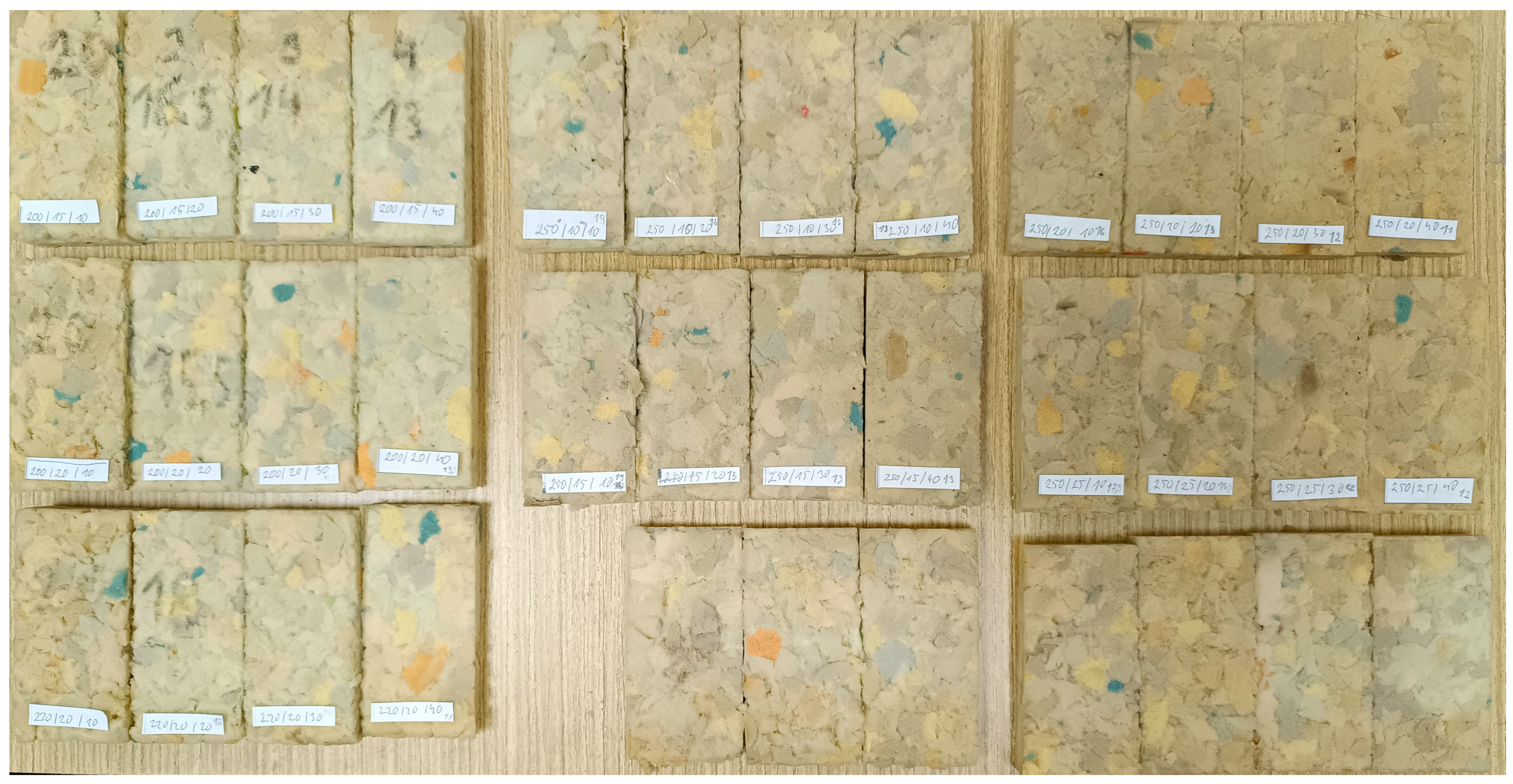

3. Experimental Development and Optimisation of the Proposed Technology

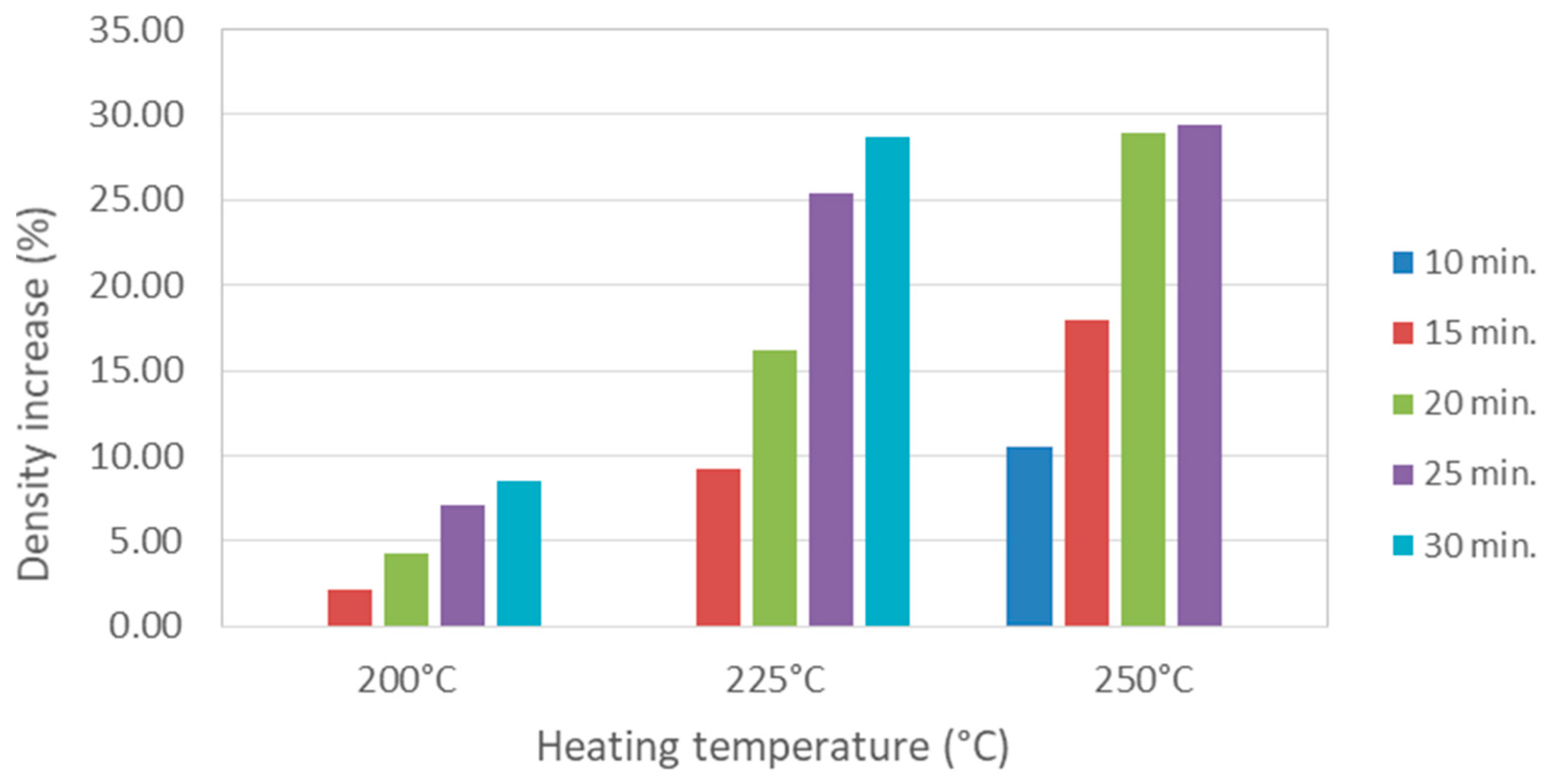

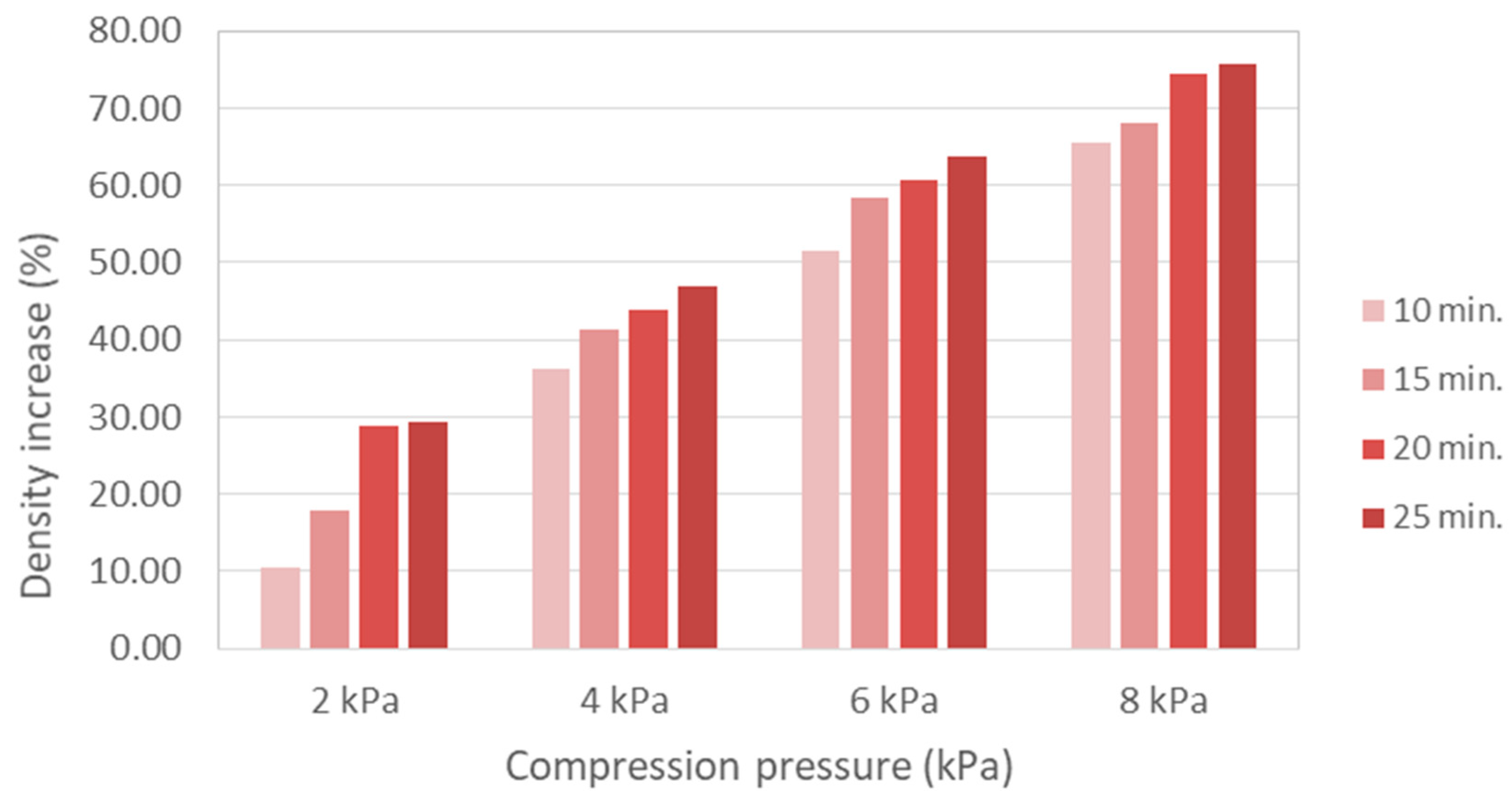

- Pressing pressure (2.0 kPa, 4.0 kPa, 6.0 kPa, 8.0 kPa);

- Heating temperature (200 °C, 225 °C, 250 °C);

- Heating period (10 min, 15 min, 20 min, 25 min, 30 min).

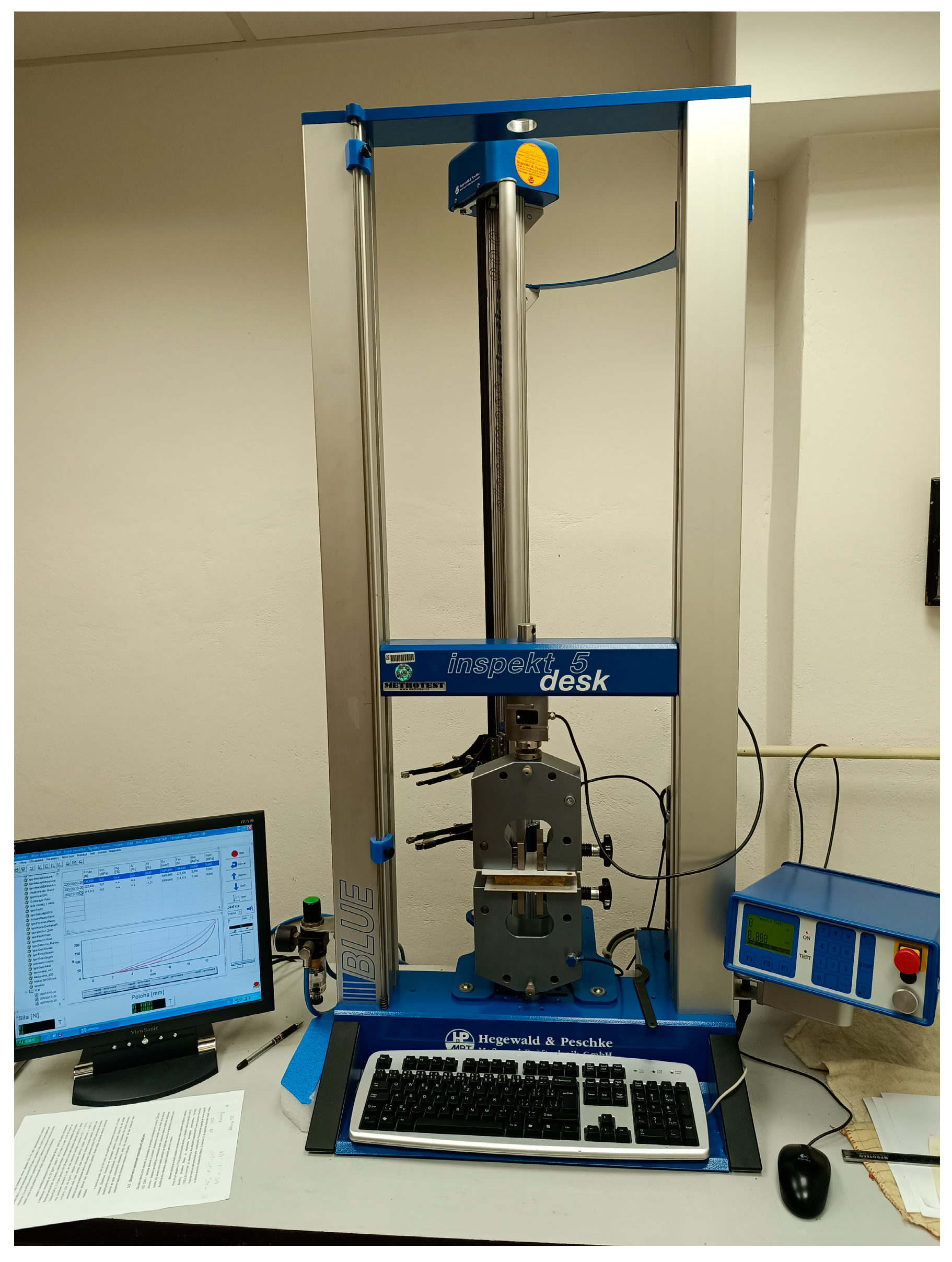

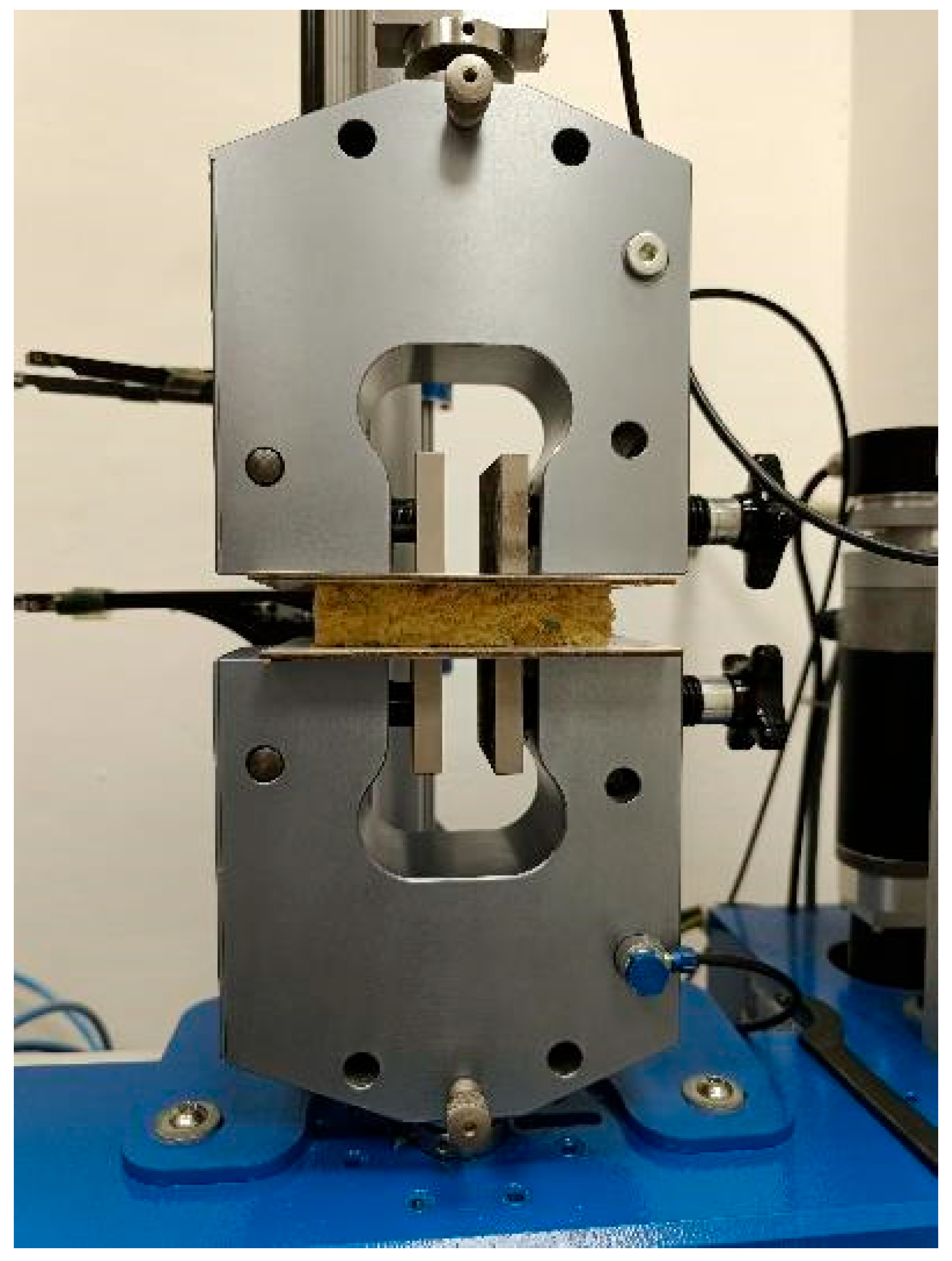

4. Results of Experiments Using Dry Forming of PUR Foam Under Pressure

Further Research Plan

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Eling, B.; Tomović, Ž.; Schädler, V. Current and future trends in polyurethanes: An industrial perspective. Macromol. Chem. Phys. 2020, 221, 2000114. [Google Scholar] [CrossRef]

- KBV Research: Polyurethane Foam Market—Global Polyurethane Foam Market Size, Share & Trends Analysis Report By Product, By Application (Bedding & Furniture, Transportation, Construction, Packaging, Electronics, Footwear, and Others), By Regional Outlook and Forecast, 2023–2030. Report. January 2024. Available online: https://www.kbvresearch.com/polyurethane-foam-market/ (accessed on 11 January 2025).

- Liberati, G.; Regazzi, M.; Biagi, F.; Nanni, A.; Bonoli, A.; Parisi, M.F.; Colonna, M. Mechanical recycling of foam from end-of-life mattresses by AIR-LAY process for the production of new mattresses with a fully circular approach. Clean. Mater. 2024, 12, 100249. [Google Scholar] [CrossRef]

- Percival, E.; Lee, P.; Bell, N.; Judge, O.; Baker, K.; Shi, V. End-of-Life Mattress Report; Oakdene Hollins Ltd.: Oxford, UK, 2022. [Google Scholar]

- Trainer, R. Mattress Disposal Task Force Report: Used Mattress Disposal and Component Recycling—Opportunities and Challenges; Sleep Products Association: Alexandria, VA, USA, 2004. [Google Scholar]

- Deng, Y.; Dewil, R.; Appels, L.; Ansart, R.; Baeyens, J.; Kang, Q. Reviewing the thermo-chemical recycling of waste polyurethane foam. J. Environ. Manag. 2021, 278, 111527. [Google Scholar] [CrossRef] [PubMed]

- Madbouly, S.A. Novel recycling processes for thermoset polyurethane foams. Curr. Opin. Green Sustain. Chem. 2023, 42, 100835. [Google Scholar] [CrossRef]

- Meekum, U.; Kenharaj, R. Comarative study of polystyrene foam degradation in the open-air and artificial weathering exposure. Arab. J. Sci. Eng. 2002, 27, 25–32. [Google Scholar]

- Liptáková, T.; Alexy, P.; Gondár, E.; Khunová, V. Polymérne Konštrukčné Materiály, 1st ed.; EDIS: Žilina, Slovakia, 2012; p. 190. ISBN 978-80-554-0505-6. [Google Scholar]

- López-Rodríguez, I.; Diaz-Saavedra, J.A.; Torres-Agredo, J. Recycling treatments applied to rigid polyurethane foam (PUR) waste: Review article. Rev. UIS Ing. 2024, 23, 99–112. [Google Scholar] [CrossRef]

- Automotive Industry Association of the Slovak Republic. Waste from Old Vehicles; Automotive Industry Association of the Slovak Republic: Bratislava, Slovakia, 2022. [Google Scholar]

- Howard, G.T. Biodegredation of polyurethane: A review. Int. Biodeterior. Biodegrad. 2002, 49, 245–252. [Google Scholar] [CrossRef]

- Weigand, E. Properties and applications of recycled polyurethanes. In Branderup; Bittner, M., Menges, G., Micheali, W., Eds.; Recycling and Recovery of Plastics; Hanser Publishers: Munich, Germany, 1996. [Google Scholar]

- Scheirs, J. Polymer Recycling; John Wiley & Sons: Chichester, UK, 1998; Chapter 10. [Google Scholar]

- Klempner, D.; Frisch, K.C.; Prentice, G. Advances in Plastic Recycling; Technomic Publishing: Chicago, IL, USA, 1999; ISBN 1-56676-737-1-. [Google Scholar]

- Troitsch, J. International Plastics Flammability Handbook; Hanser Publishers: Munich, Germany, 1990. [Google Scholar]

- Alliance for the Polyurethanes Industry. Available online: http://www.polyurethane.org/recycling (accessed on 20 January 2025).

- DeGaspari, J. A New Process Reclaims Former Unrecoverables in the Residue of Scrapped Vehicles. Mech. Eng. Mag. 1999, 121, 48–51. [Google Scholar] [CrossRef]

- Nikje, M.M.A. Recycling of Polyurethane Wastes; A Smithers Group Company: Shawbury, UK, 2016. [Google Scholar]

- Huntsman Polyurethanes. Available online: https://www.huntsman.com/about/polyurethanes (accessed on 22 January 2025).

- Datta, J.; Włoch, M. Recycling of polyurethanes, polyurethane polymers: Blends and interpenetrating polymer networks. Elsevier 2017, 323–358. [Google Scholar] [CrossRef]

- Nikje, M.M.A.; Pooladian, B. Recycling: Polyurethane foam wastes. In Encyclopedia of Polymer Applications; CRC Press: Boca Raton, FL, USA, 2019. [Google Scholar] [CrossRef]

- Zia, K.M.; Bhatti, H.N.; Ahmad Bhatti, I. Methods for polyurethane and polyurethane composites, recycling and recovery: A review. React. Funct. Polym. 2007, 67, 675–692. [Google Scholar] [CrossRef]

- Matúš, M.; Šooš, Ľ.; Bábics, J.; Beniak, J.; Križan, P. Mechanical recycling of waste polyurethane foam by compression moulding. Waste Forum 2017, 5, 441–451. [Google Scholar]

- Yang, W.; Dong, Q.; Liu, S.; Xie, H.; Liu, L.; Li, J. Recycling and disposal methods for polyurethane foam wastes. Procedia Environ. Sci. 2012, 16, 167–175. [Google Scholar] [CrossRef]

- Beran, R.; Zarybnicka, L.; Machova, D. Recycling of rigid polyurethane foam: Micro-milled powder used as active filler in polyurethane adhesives. J. Appl. Polym. Sci. 2020, 137, 49095. [Google Scholar] [CrossRef]

- Layman Report—Life Repolyuse Project. Recovery of Polyurethane for Reuse in Eco-Efficient Materials. Burgos, Spain. 2020. Available online: https://life-repolyuse.com/en/layman-report-life-repolyuse-project/ (accessed on 17 July 2024).

- Metzler, M. Fact sheet. In Encyclopedia of Public Relations; SAGE Publications Inc.: Thousand Oaks, CA, USA, 2001. [Google Scholar] [CrossRef]

- Guo, L.; Wang, W.; Guo, X.; Hao, K.; Liu, H.; Xu, Y.; Liu, G.; Guo, S.; Bai, L.; Ren, D.; et al. Recycling of flexible polyurethane foams by regrinding scraps into powder to replace polyol for re-foaming. Materials 2022, 15, 6047. [Google Scholar] [CrossRef] [PubMed]

- Kemona, A.; Piotrowska, M. Polyurethane recycling and disposal: Methods and prospects. Polymers 2020, 12, 1752. [Google Scholar] [CrossRef] [PubMed]

- Stone, H.; Villwock, R.; Martel, B. Recent technical advances in recycling of scrap polyurethane foam as finely ground powder in flexible foam. Mobius Technologies. In Proceedings of the Polyurethanes Conference 2000, Boston, MA, USA, 8–11 October 2000; 7p. [Google Scholar]

- Hulme, A.J.; Goodhead, T.C. Cost effective reprocessing of polyurethane by hot compression moulding. J. Mater. Process. Technol. 2003, 139, 322–326. [Google Scholar] [CrossRef]

- Held, S.; Hicks, D.A.; Hart, M. Design for recycling—chemical recycling pilot plant for flexible polyurethanes. In Proceedings of the R’99 Recovery Recycling Re-integration, Geneva, Switzerland, 2–5 February 1999; pp. 92–97. Available online: www.wasteforum.cz (accessed on 4 February 2025).

- Quadrini, F.; Bellisario, D.; Santo, L. Recycling of Thermoset Polyurethane Foams. Polym. Eng. Sci. 2013, 53, 1357–1363. [Google Scholar] [CrossRef]

- ISO 3386-1:1986; Polymeric Materials, Cellular Flexible—Determination of Stress-Strain Characteristics in Compression. Part 1: Low-Density Materials. International Organization for Standardization: Geneva, Switzerland, 1986. Available online: https://www.iso.org/standard/8683.html (accessed on 19 May 2025).

| Heating Temperature 200 °C | |||||

|---|---|---|---|---|---|

| Heating period (min) | 10 | 15 | 20 | 25 | 30 |

| Pressing pressure (kPa) | Density (kg·m−3) | ||||

| 2.00 | Incohesive, dimensionally unstable | 102.10 | 104.30 | 107.11 | 108.49 |

| 4.00 | 131.00 | 138.93 | 142.85 | 147.82 | |

| 6.00 | 148.43 | 157.85 | 160.65 | 163.09 | |

| 8.00 | 158.31 | 166.40 | 171.24 | 173.98 | |

| Heating Temperature 225 °C | |||||

|---|---|---|---|---|---|

| Heating period (min) | 10 | 15 | 20 | 25 | 30 |

| Pressing pressure (kPa) | Density (kg·m−3) | ||||

| 2.00 | Incohesive, dimensionally unstable | 109.17 | 116.20 | 125.33 | 128.67 |

| 4.00 | 133.55 | 140.14 | 147.05 | 148.15 | |

| 6.00 | 148.60 | 159.78 | 163.25 | 166.88 | |

| 8.00 | 161.84 | 172.60 | 173.18 | 174.87 | |

| Heating Temperature 250 °C | |||||

|---|---|---|---|---|---|

| Heating period (min) | 10 | 15 | 20 | 25 | 30 |

| Pressing pressure (kPa) | Density (kg·m−3) | ||||

| 2.00 | 110.4865 | 118.00 | 128.90 | 129.38 | Material degradation, caking |

| 4.00 | 136.2667 | 141.33 | 143.77 | 146.86 | |

| 6.00 | 151.4286 | 158.46 | 160.67 | 163.68 | |

| 8.00 | 165.60 | 168.00 | 174.36 | 175.83 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Šooš, Ľ.; Matúš, M.; Legutko, S.; Bábics, J. Research into Efficient Technology for Material Recovery of Waste Polyurethane Foams. Recycling 2025, 10, 107. https://doi.org/10.3390/recycling10030107

Šooš Ľ, Matúš M, Legutko S, Bábics J. Research into Efficient Technology for Material Recovery of Waste Polyurethane Foams. Recycling. 2025; 10(3):107. https://doi.org/10.3390/recycling10030107

Chicago/Turabian StyleŠooš, Ľubomír, Miloš Matúš, Stanislaw Legutko, and Jozef Bábics. 2025. "Research into Efficient Technology for Material Recovery of Waste Polyurethane Foams" Recycling 10, no. 3: 107. https://doi.org/10.3390/recycling10030107

APA StyleŠooš, Ľ., Matúš, M., Legutko, S., & Bábics, J. (2025). Research into Efficient Technology for Material Recovery of Waste Polyurethane Foams. Recycling, 10(3), 107. https://doi.org/10.3390/recycling10030107