Design Principles and Engineering Strategies for Stabilizing Ni-Rich Layered Oxides in Lithium-Ion Batteries

Abstract

1. Introduction

2. Goals and Issues

2.1. Why Decrease the Co Concentration?

2.2. Problems Limiting the Electrochemical Performance

2.2.1. Cation Mixing

2.2.2. Phase Stability

2.2.3. Oxygen Release

2.2.4. Modifications During Cycling

2.2.5. Microcracks

3. Synthesis Methods

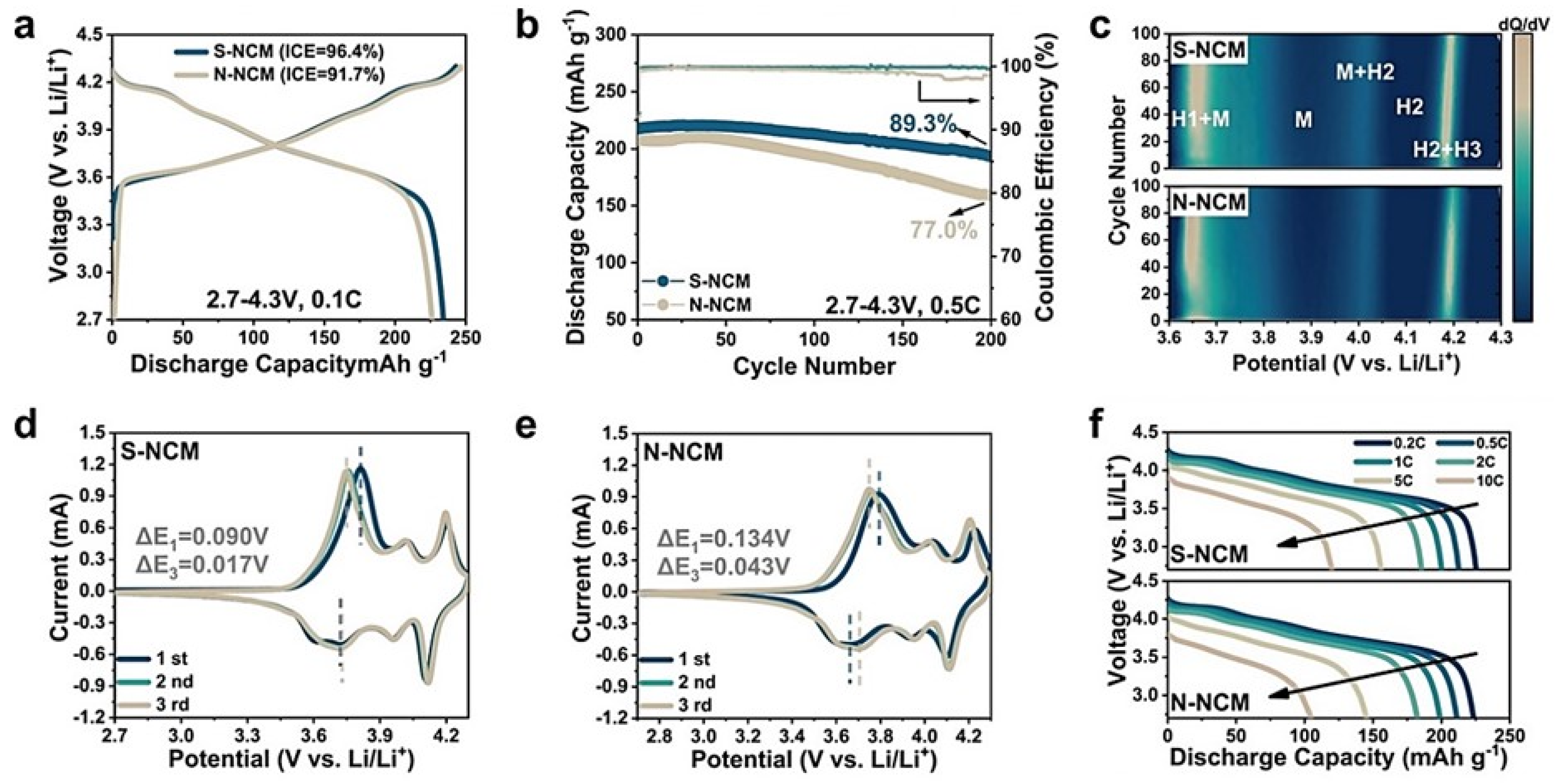

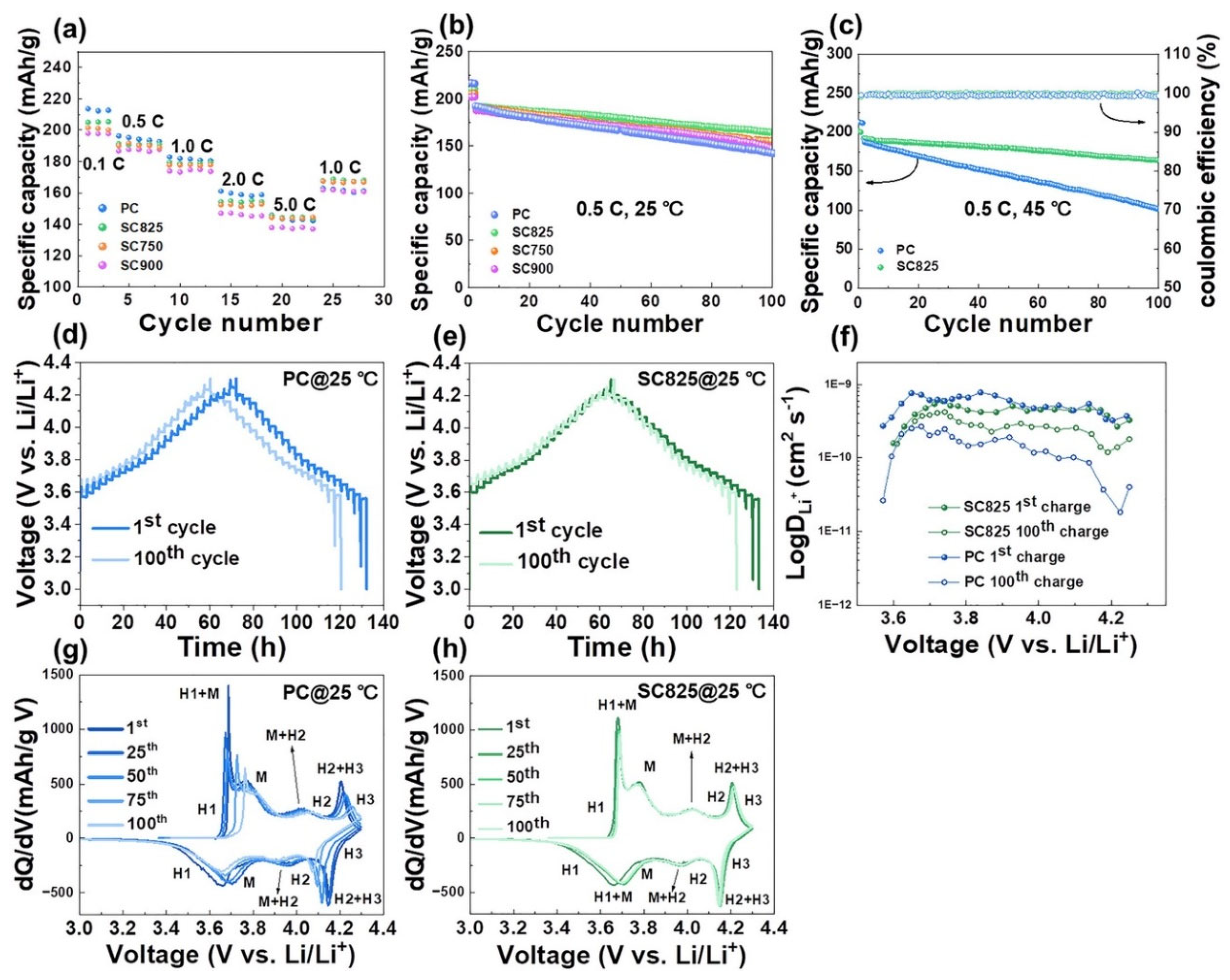

3.1. Single Crystals Versus Polycrystals

3.2. Synthesis of Single Crystals

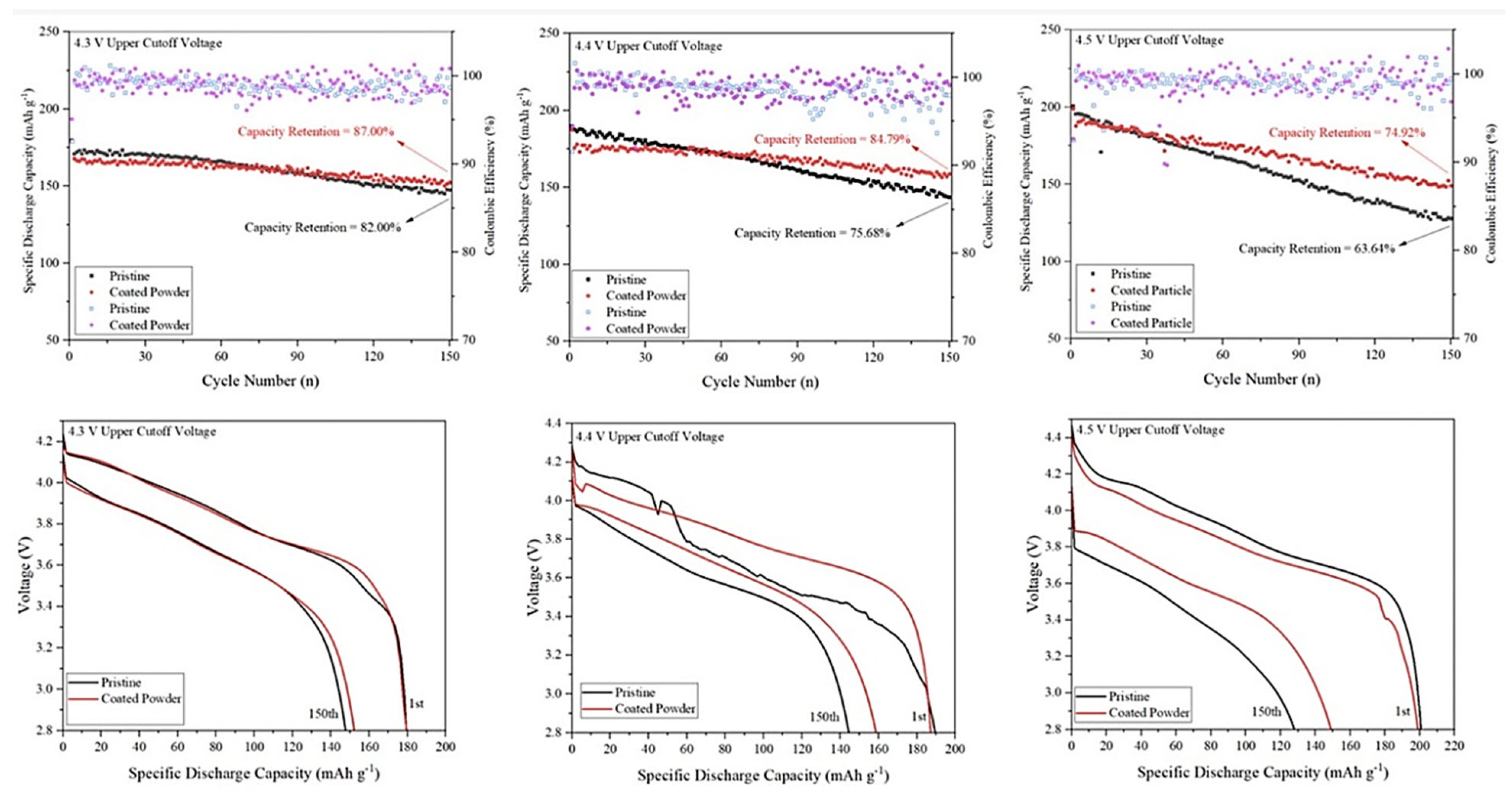

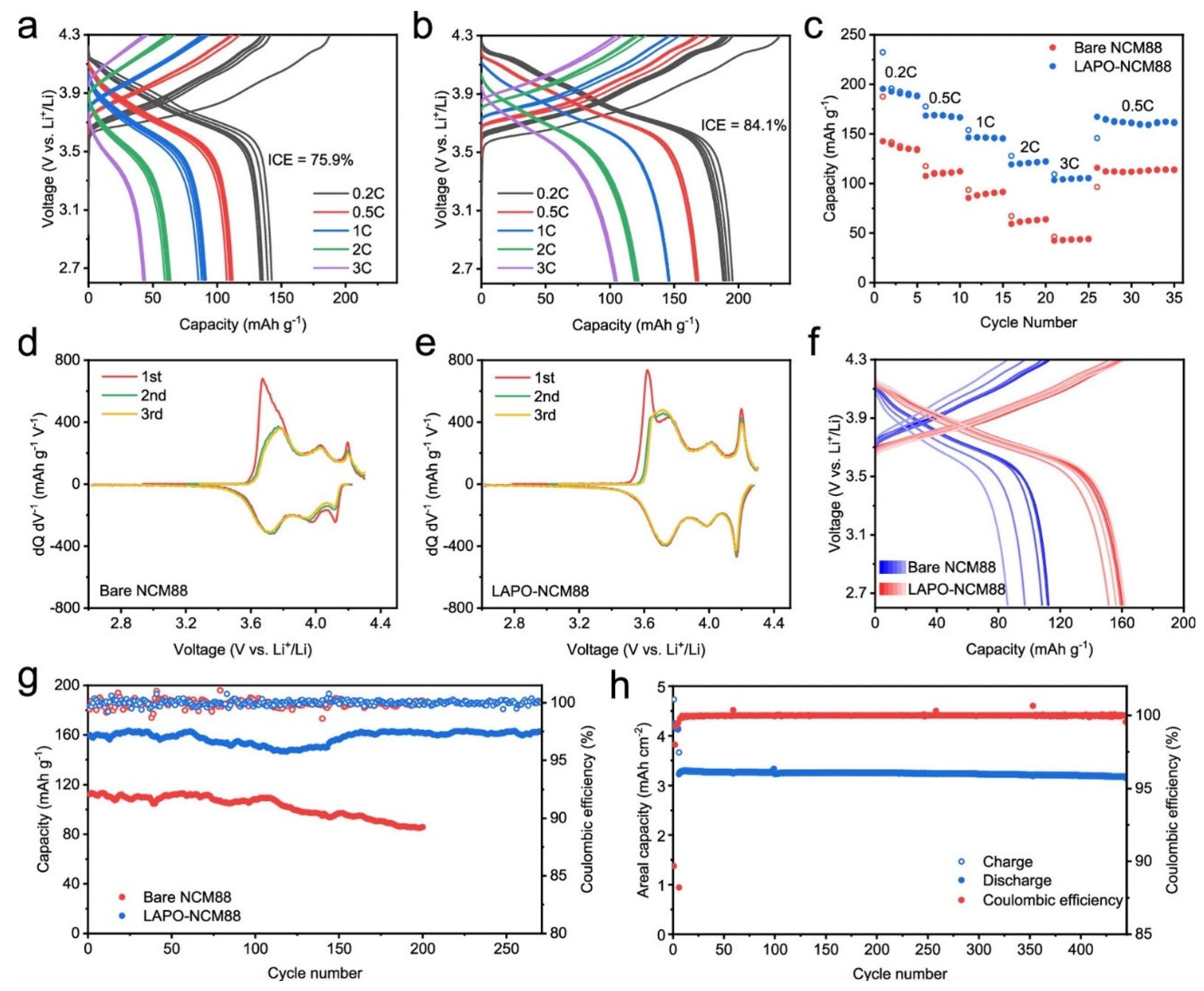

4. Coating

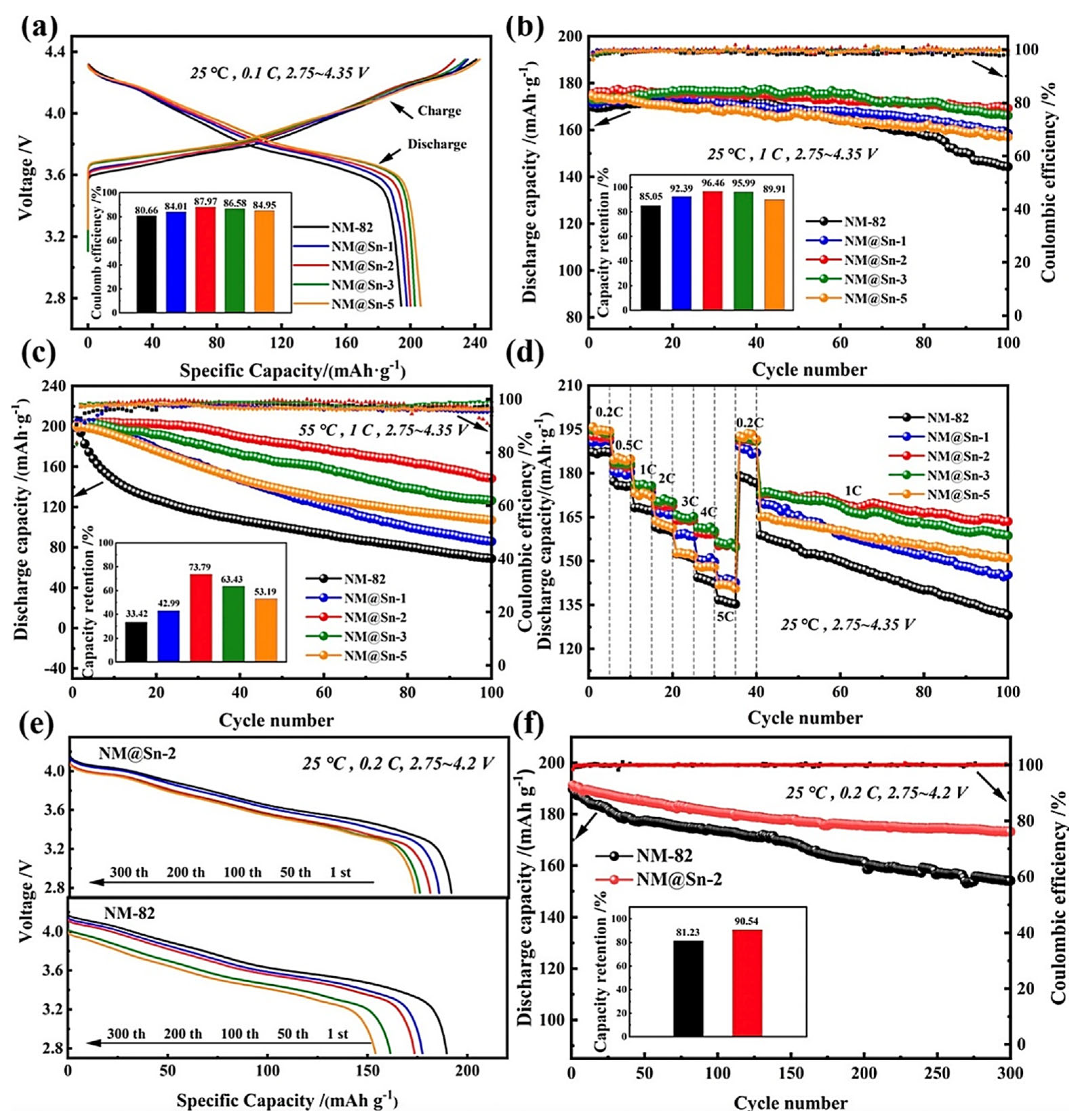

4.1. Li-Free Surface Layers

4.2. Li-Based Surface Layers

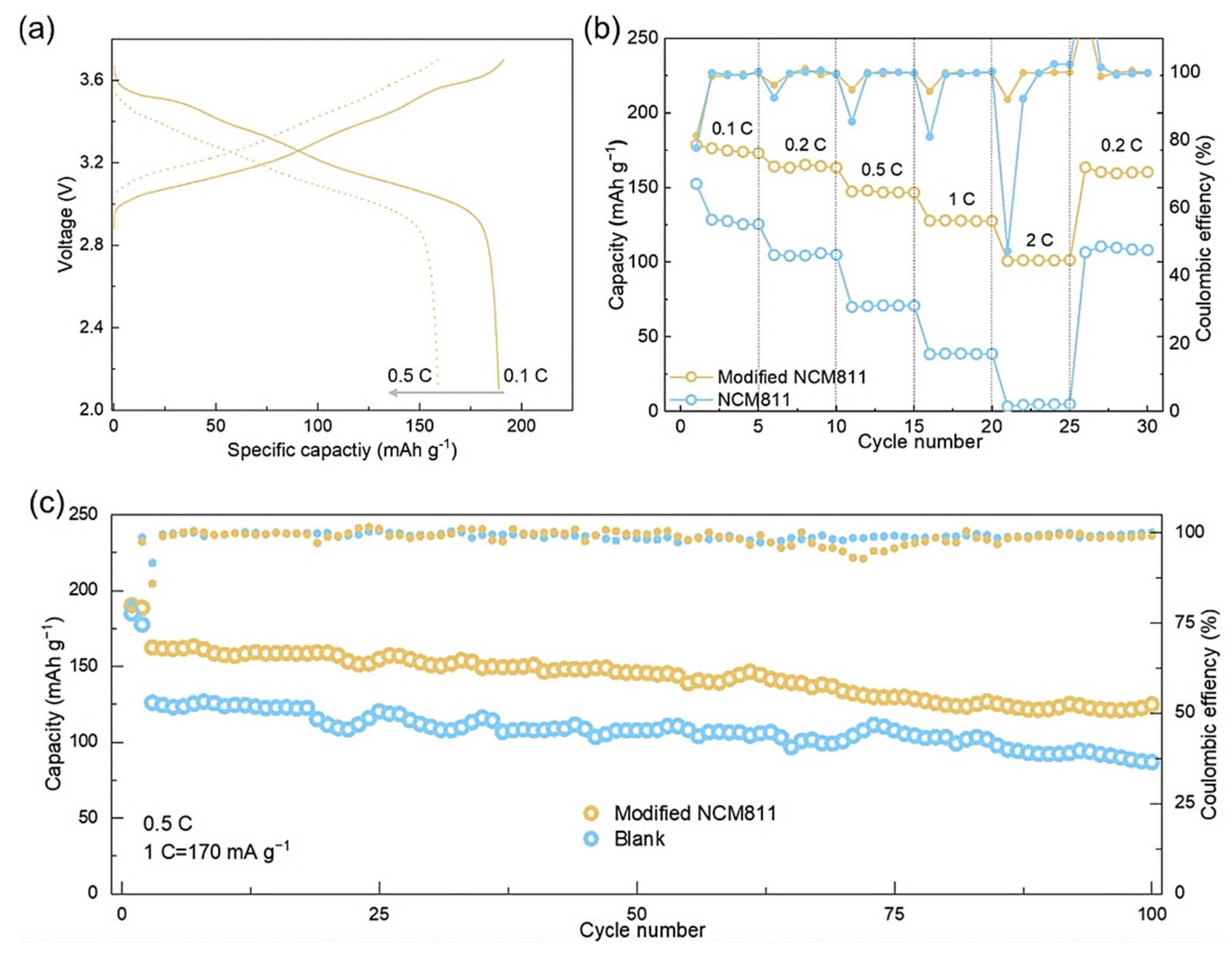

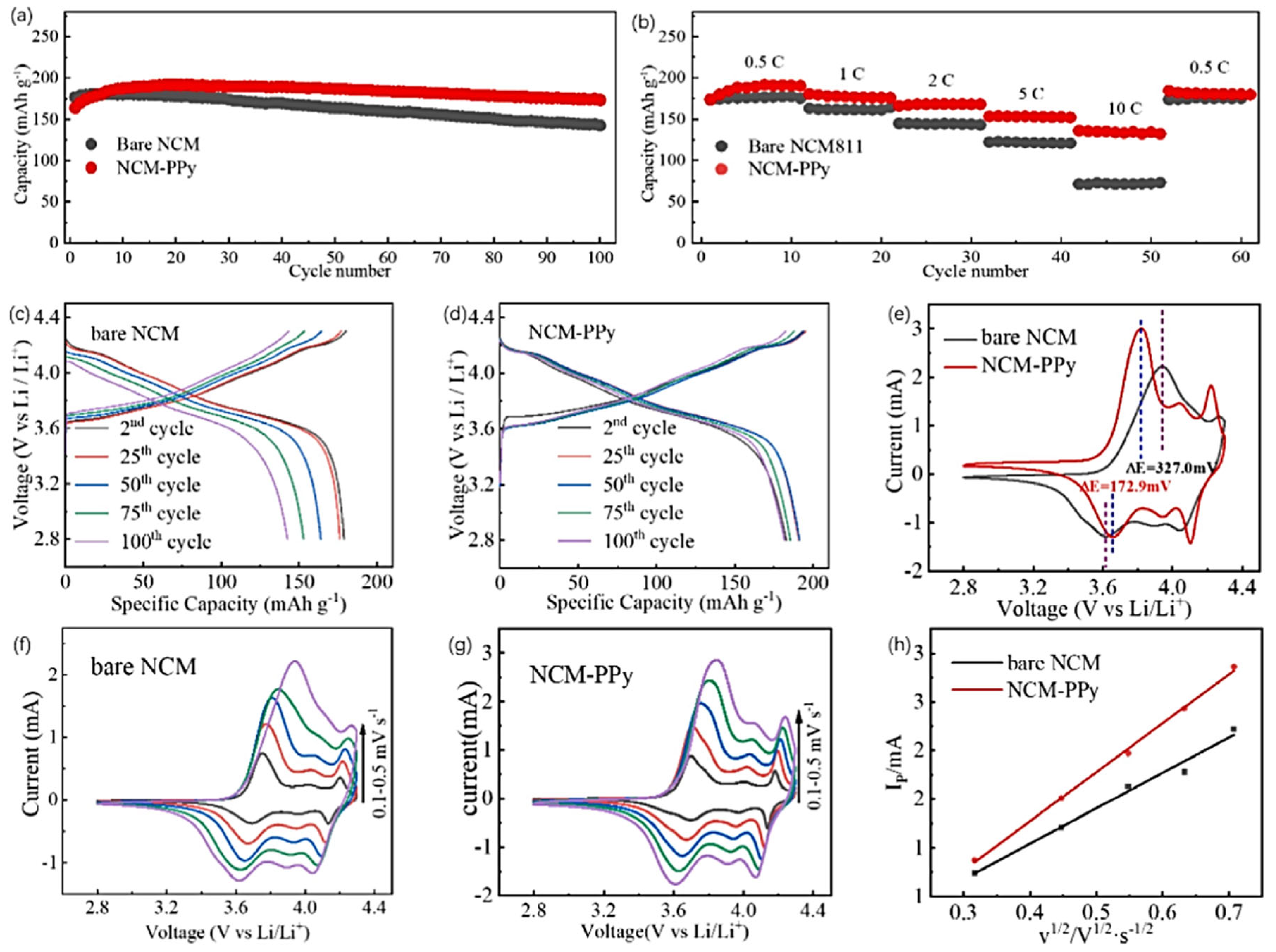

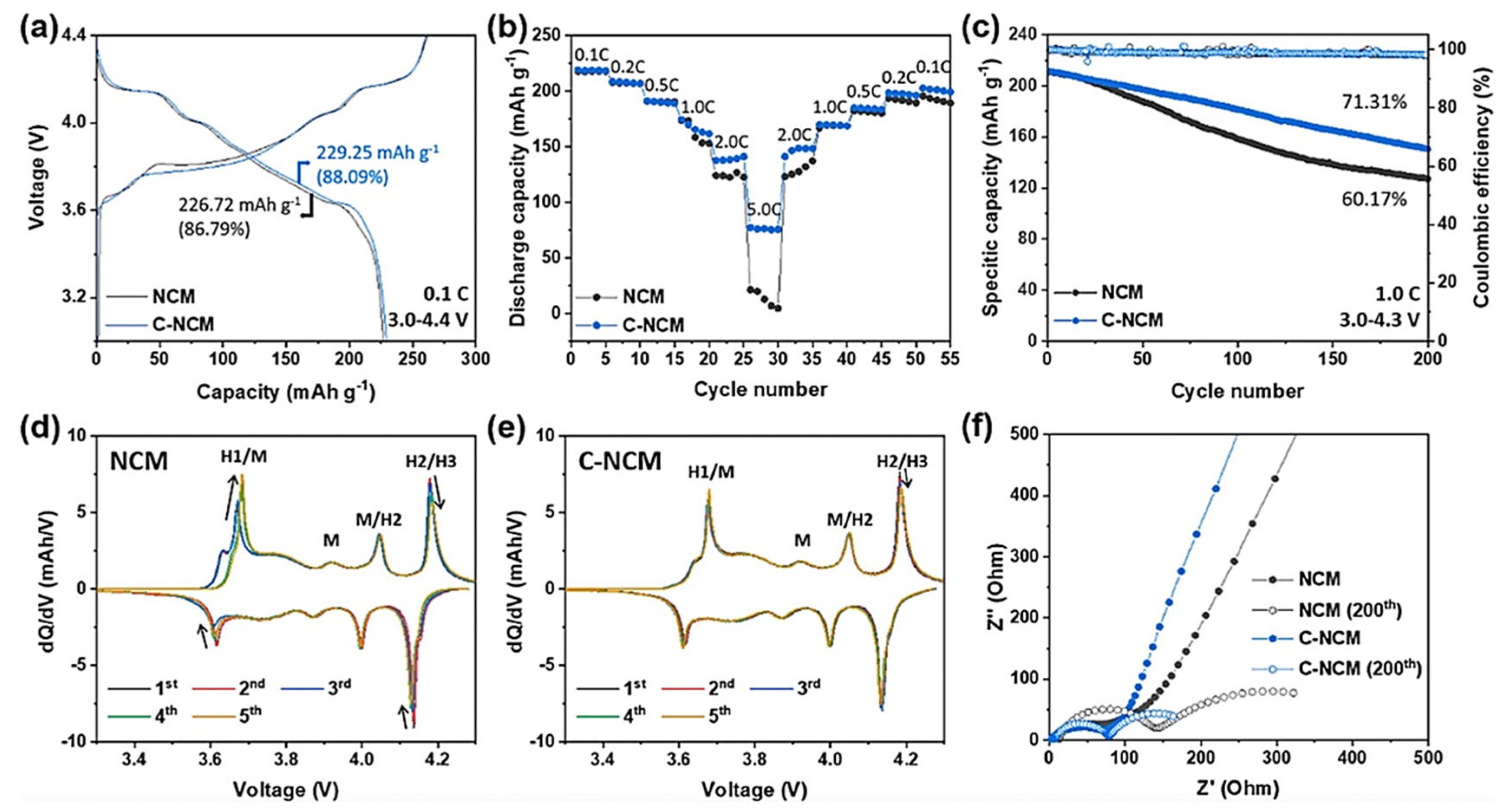

4.3. Organic Layers

4.4. Dual Coating

5. Doping

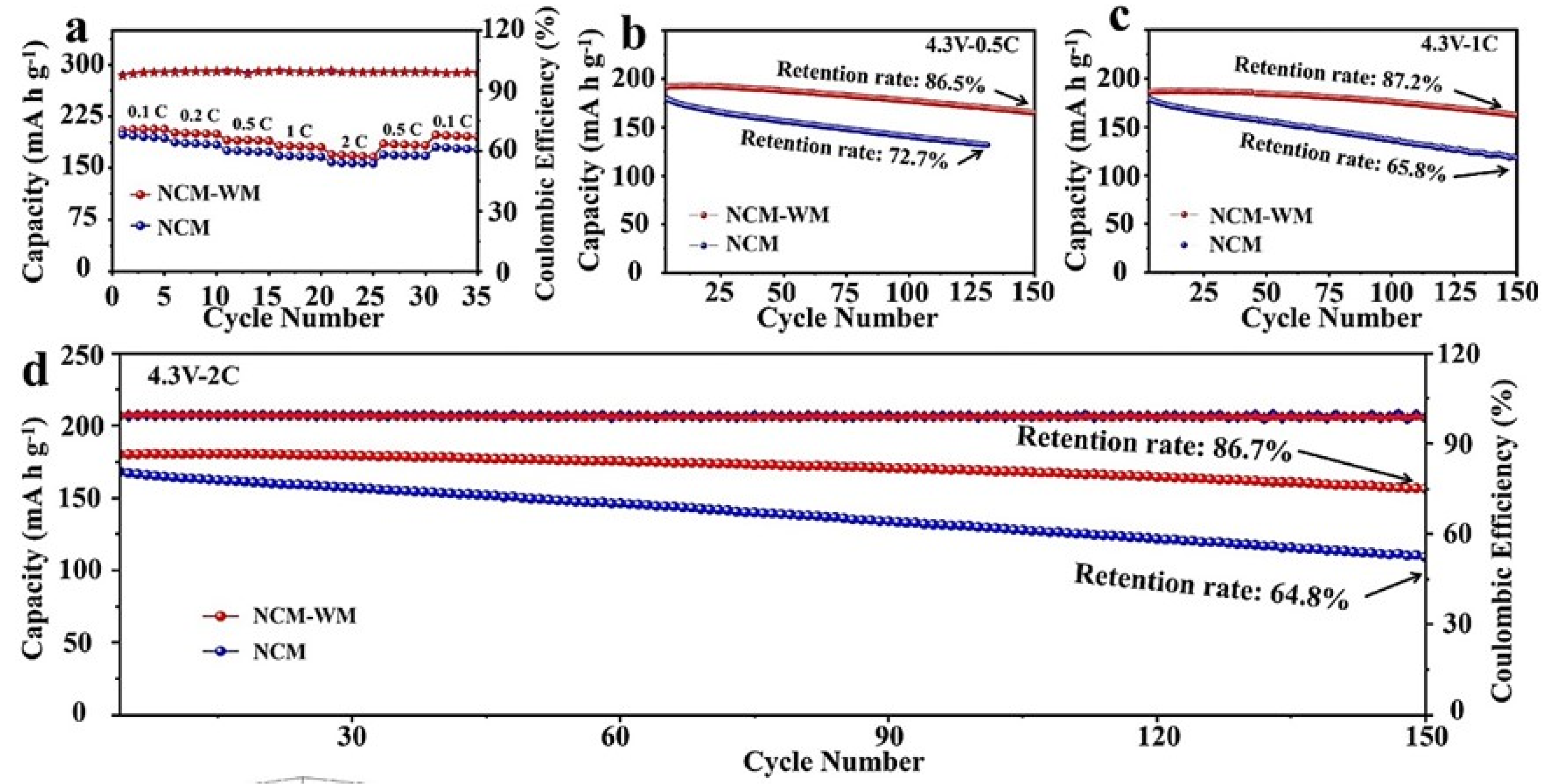

5.1. Experimental Results

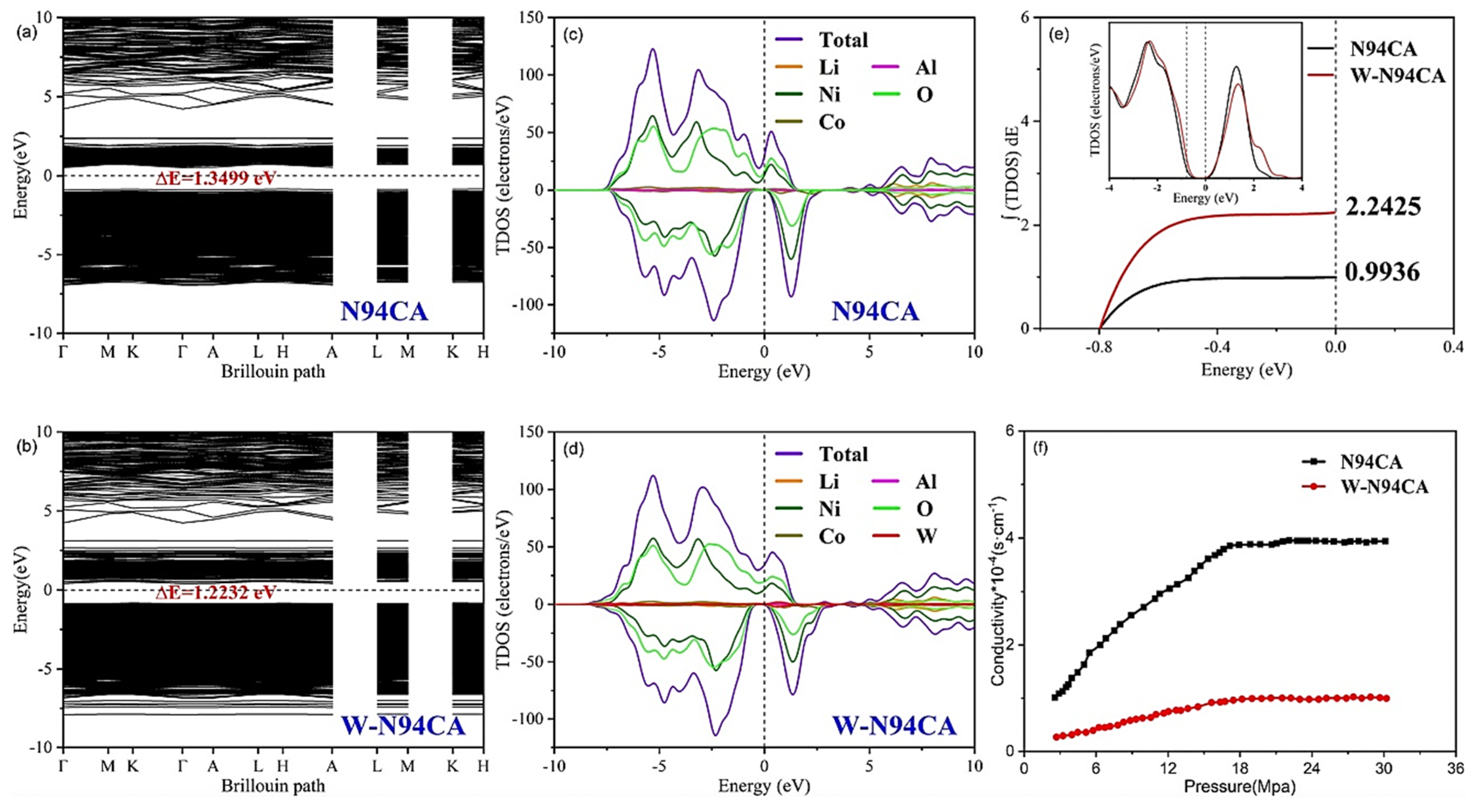

5.2. Theoretical Calculations

5.3. Morphology Aspects

5.4. Synergetic Effects of Co-Doping and-or Multiple Coating

5.4.1. Dual Doping

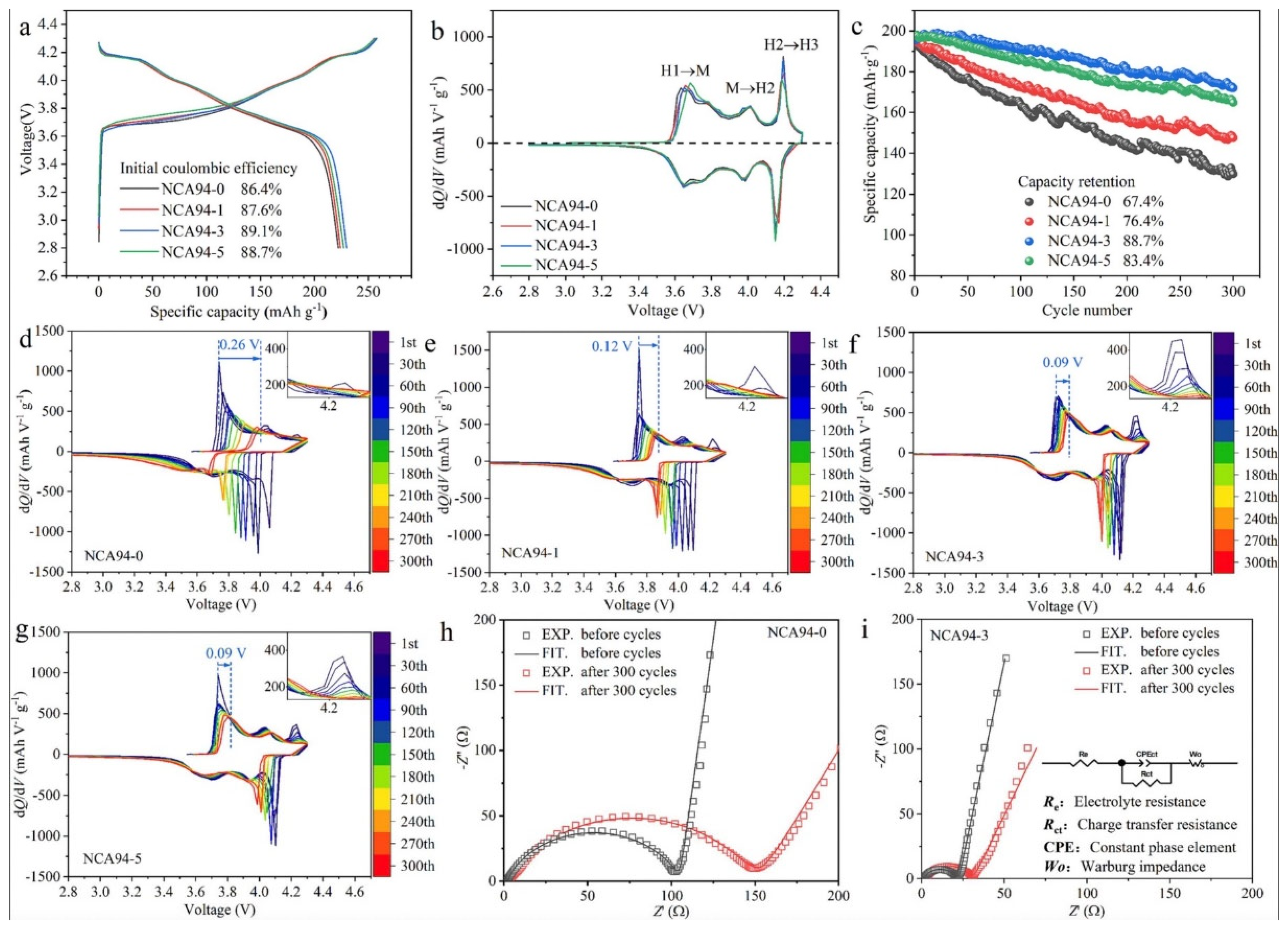

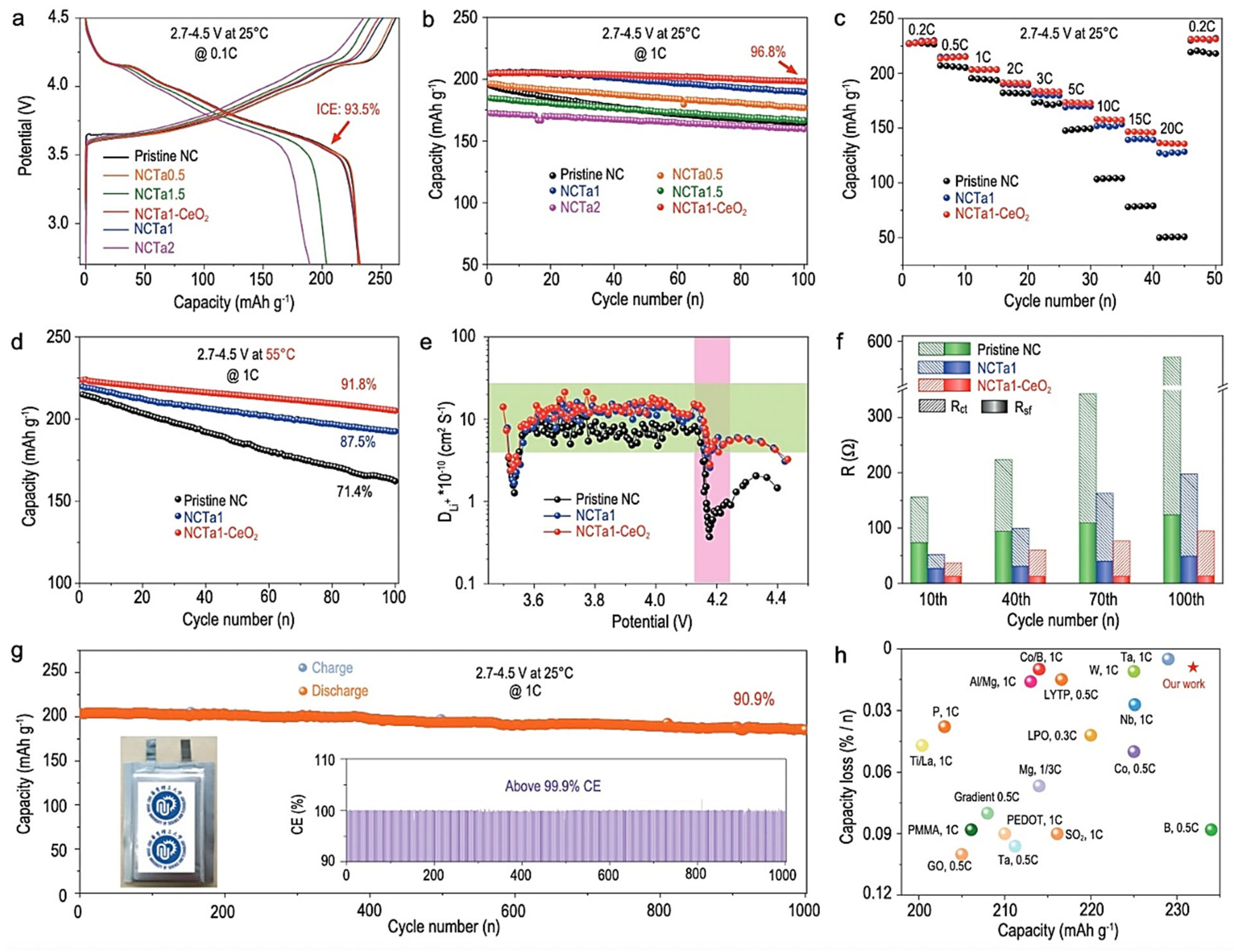

5.4.2. Doping Plus Coating

5.4.3. Multiple Coatings

6. Core–Shell and Gradient Structures

6.1. Core–Shell Structures

6.2. Gradient Layers

7. Cells with Ni-Rich Cathodes

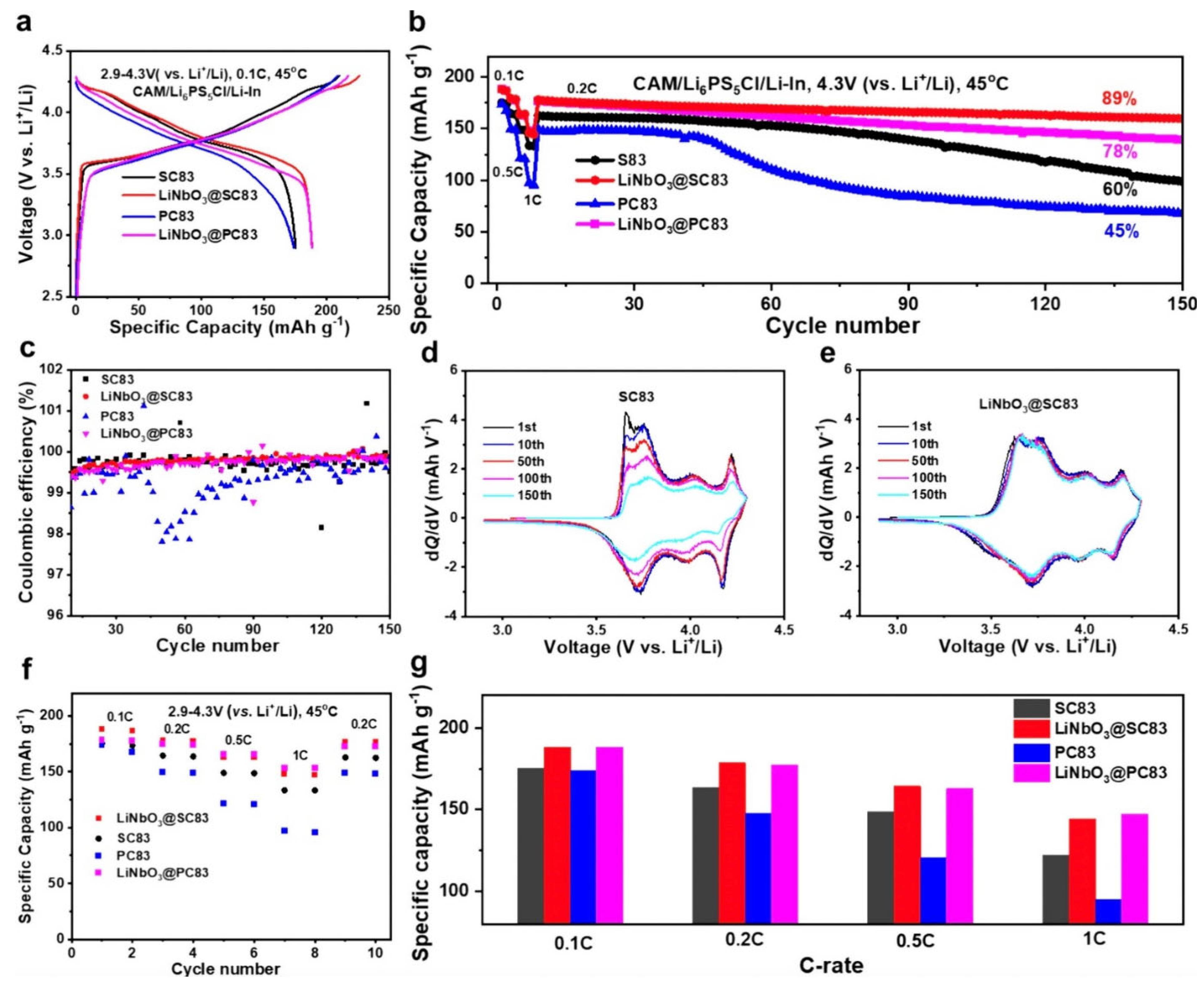

7.1. Solid Electrolytes

7.2. Liquid Electrolytes

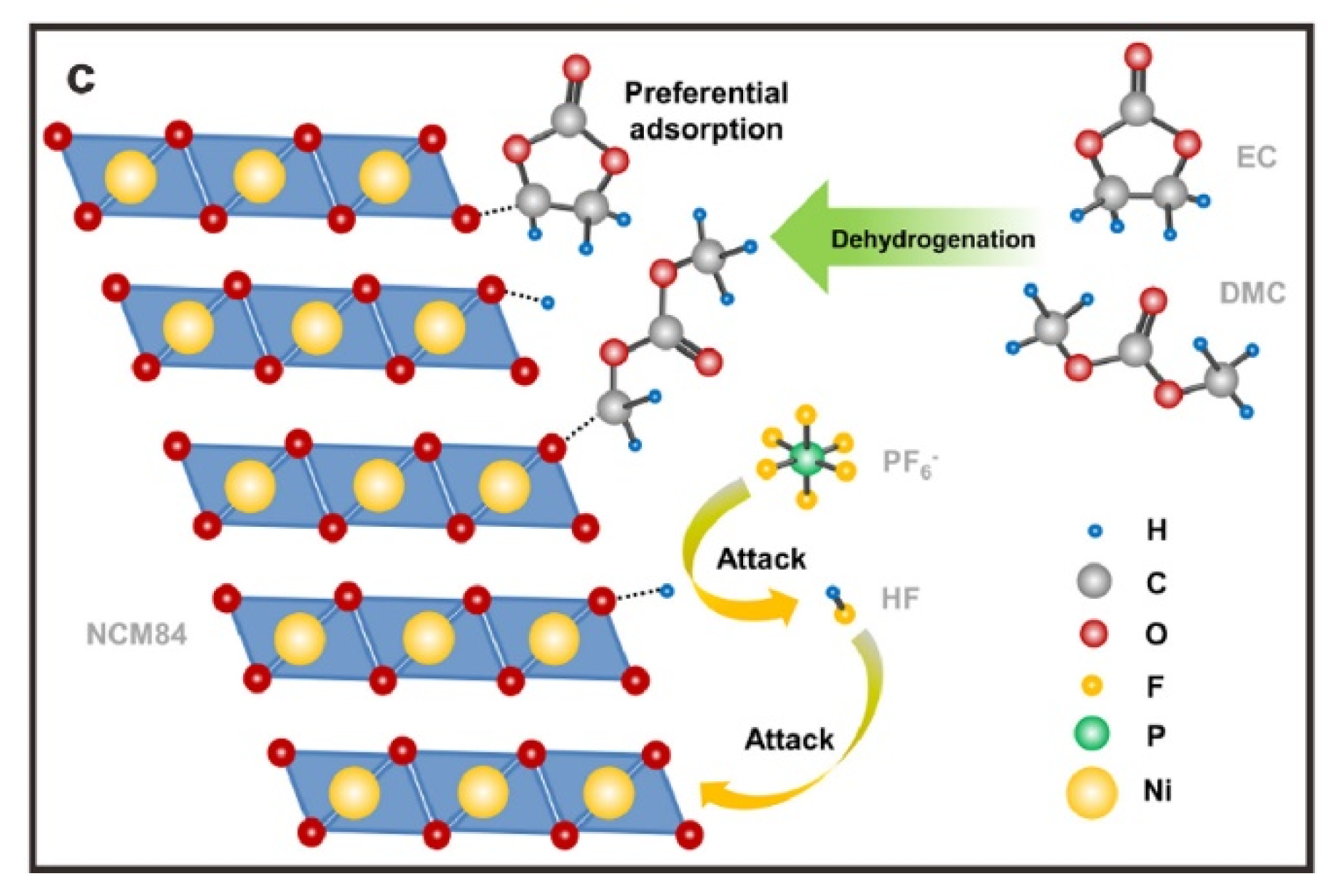

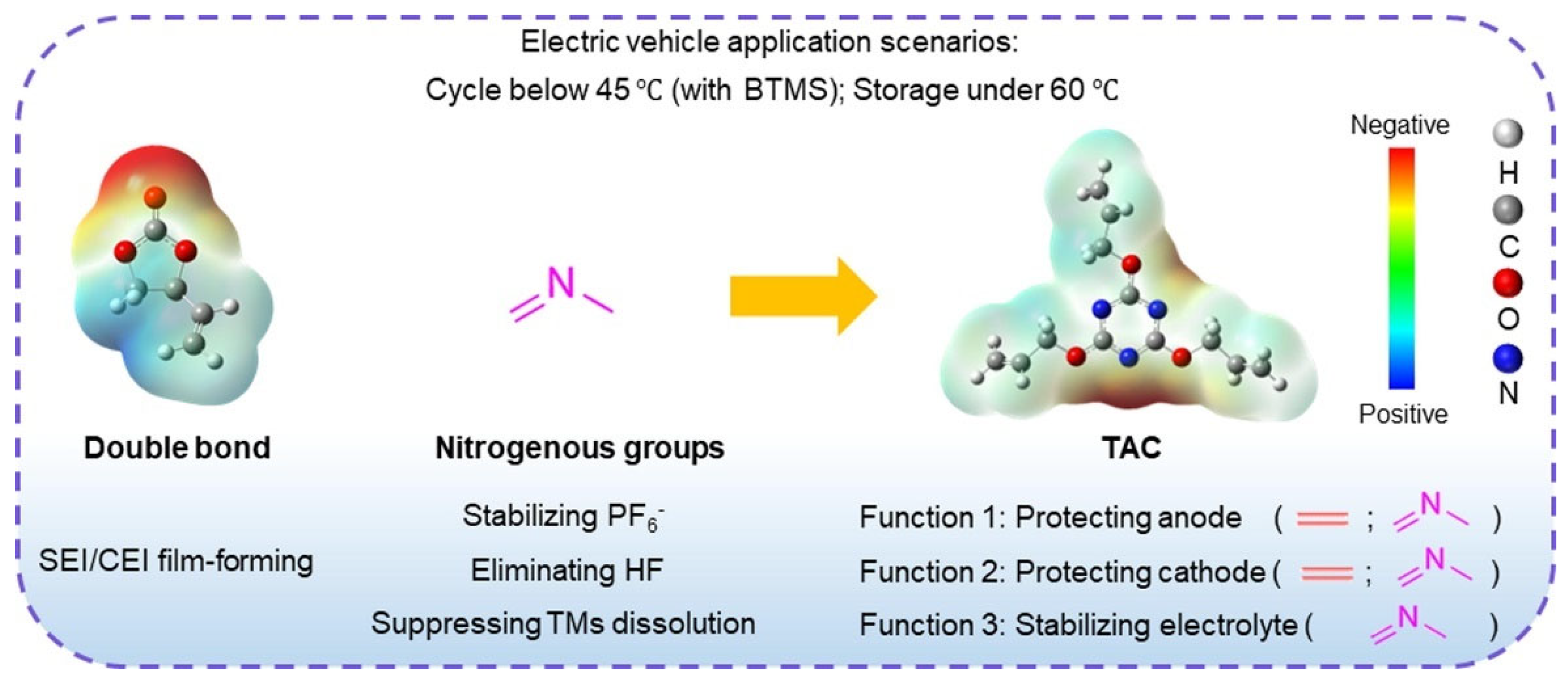

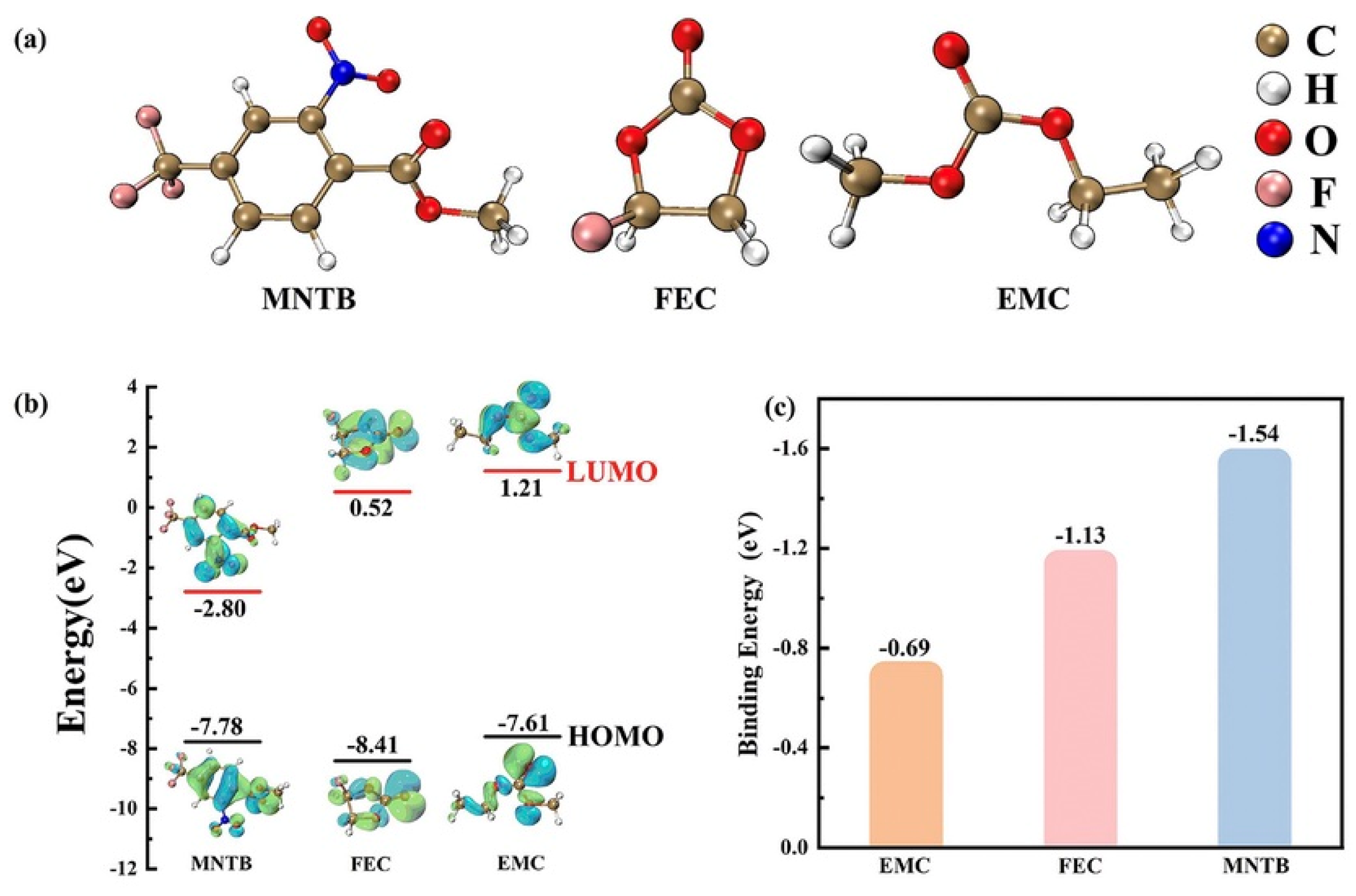

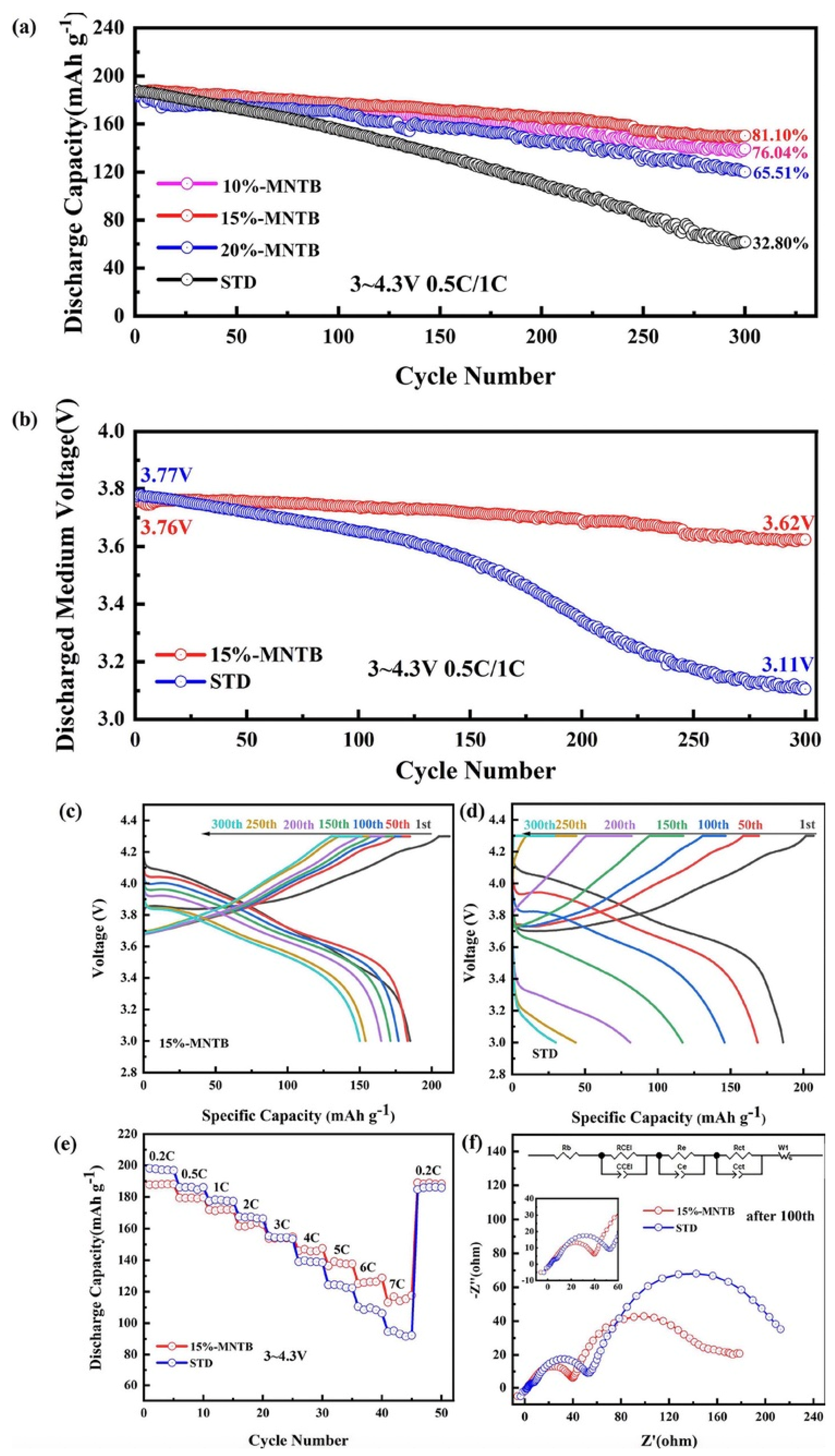

7.2.1. Additives

7.2.2. Electrolyte Formulations

7.3. Recycling Ni-Rich Batteries

7.4. Safety Issues

8. Conclusions

- The interaction between the electrolytes and the Ni-rich materials and the related CEI needs further investigation. Newly-developed experimental set-ups, such as cryogenic transmission electron microscopy revealing atomic-resolution CEI structures, should help for this purpose. An example is the dynamic evolution of over cycling and its impact on the performance of NMC811, revealed by the ultrafine images of CEI obtained by this process in presence of FEC-based electrolytes [948].

- Safety issues with high-voltage cathode materials would plead in favor of the use of solid electrolytes. As shown in this review, some attempts are promising, but the research should continue in the next years. The space charge layer between the cathode and a ceramic solid electrolyte may result in high polarization and capacity degradation. Another difficulty comes from the deterioration of the contact between the cathode and solid electrolyte upon cycling, due to the rigid ceramic nature of the solid electrolyte and the change in the lattice parameters of the cathode material, in particular at high charge. The columnar shape of the Ni-rich particles or actually any elongated form will help [949], pointing to the need for further investigation on the correlations between morphology, synthesis, and electrochemical performance Elongated polymer electrolytes have already made possible the commercialization of LiFePO4-based batteries, due to the low voltage (3.5 V) of the cells. With higher voltage cells, the same polymers cannot be used, because of their poor antioxidative ability. Further investigations on polymer electrolytes with wide electrochemical window are thus needed, and under studies [950]. Further research is needed to pair Ni-rich cathodes with lithium metal or silicon anodes. The reaction of the electrolytes with the Ni-rich cathode and the anode materials is not well understood, and further studies on the additives able to generate both a SEI and a CEI protecting the electrodes against side reactions with an electrolyte stable at high voltage are still needed.

- The application of AI to the research on Li-rich batteries is needed and most promising. It is possible today to predict material degradation pathways according to operating environments, which will help to optimize the design and composition of electrode materials for enhanced performance and durability of the Ni-rich cathode materials. Machine learning (ML) can accelerate the design of new Ni-rich cathode chemistries, and can also be used to build next-generation battery architectures. Many trials have been made to dope Ni-rich cathode materials with different single and multiple doping elements. ML models can predict dopants that improve stability without expensive trial-and-error experiments. In particular, deep learning models trained on large materials databases (e.g., Materials Project) predict stable Ni-rich structures with minimal degradation. ML will also help designing single-crystal vs. polycrystalline Ni-rich cathodes to reduce cracking. Computer vision models will be used to analyze SEM/TEM images to detect defects and suggest improvements in synthesis processes.

- Surface coating to prevent electrolyte attack, suppress transition metal (TM) dissolution, and stabilize the cathode–electrolyte interface. The benefits are the reduction of surface reactivity, minimization of HF attack, and improvement of the cycling stability. To fulfill this goal, however, the coating must be uniform, thin (<10 nm), and ionically conductive to avoid impeding Li+ transport.

- Doping, to enhance structural stability, suppress phase transitions, and reduce oxygen release. The cation doping stabilizes the layered structure and suppresses Li/Ni disorder, while anion doping, in particular F− (fluorination), strengthens TM–O bonds and suppresses oxygen evolution. The benefits are improved structural integrity, better capacity retention, and reduced gas generation.

- Single-crystal morphology minimizes grain boundaries and microcracks, which are common initiation sites for degradation. The benefits are improved mechanical integrity, longer cycle life, and better thermal stability. However, there are drawbacks: this morphology is more difficult and costly to synthesize. It may require higher sintering temperatures.

- Gradient composition or core–shell design combines a Ni-rich core for capacity with a stable outer shell (lower-Ni or doped) to buffer against side reactions. These architectures enhance thermal and chemical stability and delay impedance rise.

- Optimized electrolyte formulations reduce parasitic reactions, stabilize CEI (cathode–electrolyte interface), and suppress gas generation.

- Particle size and morphology engineering is useful to reduce mechanical stress and optimize Li+ diffusion. Spherical secondary particles with controlled porosity or dense, crack-resistant structures are preferred, resulting in improved structural stability and rate capability.

- Thermal and pressure management during cycling, to reduce gas generation and mechanical damage. The strategy for this purpose is to use stack pressure or thermal management in cell design.

- Advanced synthesis techniques, to achieve controlled doping, precise morphology, and homogeneous element distribution.

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| ALD | atomic layer deposition |

| ASSLBs | all-solid-state lithium batteries |

| CB | carbon black |

| CBDA | cyclobutane-tetracarboxylic dianhydride |

| CEI | cathode electrolyte interphase |

| COF | covalent organic framework |

| DFT | density functional theory |

| DMC | dimethyl carbonate |

| DTBQ | di-tert-butyl-o-benzoquinone |

| EPD | electrophoretic deposition |

| EV | electric vehicle |

| HOMO | Highest Occupied Molecular Orbital |

| HoMS | hollow multi-shell structure |

| LIBs | Lithium-ion batteries |

| LIPON | lithium phosphorus oxynitride |

| LLAO | Li0.5La2Al0.5O4 |

| LUMO | Lowest Unoccupied Molecular Orbital |

| NASICON | sodium (Na) superionic conductor |

| NATM | LiNi0.93Al0.05Ti0.01Mg0.01O2 |

| NCA | LiNixCoyAlzO2 |

| NMC | LiNi1–x–yMxCoyxO2 |

| NMCA | LiNixMnyCozAl(1–x–y–z)O2 |

| NMC811 | LiNi0.8Mn0.1Co0.1O2 |

| NMC333 | LiNi1/3Mn1/3Co1/3O2 |

| NMC622 | LiNi0.6Mn0.2Co0.2O2 |

| PANI | polyaniline |

| PEG | polyethylene glycol |

| PPC | pyrrole-co-citral nitrile |

| PPy | polypyrrole |

| SEI | solid–electrolyte interphase |

| SEM | scanning electron microscopy |

| SOC | state-of-charge |

| TM | transition metal |

| VC | vinylene carbonate |

| XRD | X-ray diffraction |

References

- You, L.Z.; Chu, B.B.; Li, G.X.; Huang, T.; Yu, A.S. H3BO3 washed LiNi0.8Co0.1Mn0.1O2 with enhanced electrochemical performance and storage characteristics. J. Power Sources 2021, 482, 228940. [Google Scholar] [CrossRef]

- Yu, H.F.; Cao, Y.Q.; Chen, L.; Hu, Y.J.; Duan, X.Z.; Dai, S.; Jiang, H. Surface enrichment and diffusion enabling gradient-doping and coating of Ni-rich cathode toward Li ion batteries. Nat. Commun. 2021, 12, 4564. [Google Scholar] [CrossRef] [PubMed]

- Rajkamal, A.; Sharma, A.; Pullagura, B.K.; Thapa, R.; Kim, H. Engineering lithium nickel cobalt manganese oxides cathodes: A computational and experimental approach to bridging gaps. Chem. Eng. J. 2024, 481, 148223. [Google Scholar] [CrossRef]

- Ding, H.; Wang, X.; Wang, J.; Zhang, H.; Liu, G.; Yu, W.; Wang, J. Morphology-controllable synthesis and excellent electrochemical performance of Ni-rich layered NCM622 as cathode materials for lithium-ion batteries via glycerin-assisted solvothermal method. J. Power Sources 2023, 553, 232307. [Google Scholar] [CrossRef]

- Kim, J.; Lee, I.; Kim, Y.-H.; Bae, J.H.; Hwang, K.; Kang, H.; Yoon, S. Ni-rich cathode material with isolated porous layer hindering crack propagation under 4.5 V high cut-off voltage cycling. Chem. Eng. J. 2023, 455, 140578. [Google Scholar] [CrossRef]

- Liu, H.D.; Zhu, Z.Y.; Yan, Q.Z.; Yu, S.C.; He, X.; Chen, Y.; Liu, P. A disordered rock salt anode for fast-charging lithium-ion batteries. Nature 2020, 585, 63–67. [Google Scholar] [CrossRef]

- Xie, H.; Peng, H.; Jiang, D.; Xiao, Z.; Liu, X.; Liang, H.; Wu, M.; Liu, D.; Li, Y.; Sun, Y.; et al. Structures, issues, and optimization strategies of Ni-rich and Co-low cathode materials for lithium-ion battery. Chem. Eng. J. 2023, 470, 144051. [Google Scholar] [CrossRef]

- Tian, X.; Guo, R.; Bai, Y.; Li, N.; Wang, X.; Wang, J.; Wu, C. High-performance high-nickel multi-element cathode materials for lithium-ion batteries. Batteries 2023, 9, 319. [Google Scholar] [CrossRef]

- Ryu, H.-H.; Namkoong, B.; Kim, J.H.; Belharouak, I.; Yoon, C.S.; Sun, Y.K. Capacity fading mechanisms in Ni-rich single-crystal NCM cathodes. ACS Energy Lett. 2021, 6, 2726–2734. [Google Scholar] [CrossRef]

- Ding, Y.; Wang, R.; Wang, L.; Cheng, K.; Zhao, Z.; Mu, D.; Wu, B. A short review on layered LiNi0.8Mn0.1Co0.1O2 positive electrode material for lithium-ion batteries. Energy Proc. 2017, 105, 2941–2952. [Google Scholar] [CrossRef]

- Mubarac, S.; Silva, M.N.; Silva, G.T.; Freitas, B.; Gonçalves, J.M.; Zanin, H. Super Ni-rich and Co-poor LiNixCoyMn1-x-yO2, LiNixCoyAl1-x-yO2, and LiNixCoyMnzAl(1-x-y-z)O2 (x ≥ 0.85) based cathodes for lithium-ion batteries: A review on emerging trends, recent developments, and future perspectives. J. Energy Storage 2024, 96, 112612. [Google Scholar] [CrossRef]

- Li, J.; Manthiram, A. A comprehensive analysis of the interfacial and structural evolution over long-term cycling of ultrahigh-nickel cathodes in lithium-ion batteries. Adv. Energy Mater. 2019, 9, 1902731. [Google Scholar] [CrossRef]

- Cui, Z.; Xie, Q.; Manthiram, A. Zinc-doped high-nickel, low-cobalt layered oxide cathodes for high-energy-density lithium-ion batteries. ACS Appl. Mater. Interfaces 2021, 13, 15324–15332. [Google Scholar] [CrossRef]

- Li, J.; Liu, H.; Xia, J.; Cameron, A.R.; Nie, M.; Botton, G.A.; Dahn, J.R. The impact of electrolyte additives and upper cut-off voltage on the formation of a rocksalt surface layer in LiNi0.8Mn0.1Co0.1O2 electrodes. J. Electrochem. Soc. 2017, 164, A655–A665. [Google Scholar] [CrossRef]

- Xu, C.; Märker, K.; Lee, J.; Mahadevegowda, A.; Reeves, P.J.; Day, S.J.; Groh, M.F.; Emge, S.P.; Ducati, C.; Mehdi, B.L.; et al. Bulk fatigue induced by surface reconstruction in layered Ni-rich cathodes for Li-ion batteries. Nat. Mater. 2021, 20, 84–92. [Google Scholar] [CrossRef]

- Li, J.; Downie, L.E.; Ma, L.; Qiu, W.; Dahn, J.R. Study of the failure mechanisms of LiNi0.8Mn0.1Co0.1O2 Cathode material for lithium ion batteries. J. Electrochem. Soc. 2015, 162, A1401–A1408. [Google Scholar] [CrossRef]

- Zhang, N.; Li, J.; Li, H.; Liu, A.; Huang, Q.; Ma, L.; Li, Y.; Dahn, J.R. Structural, electrochemical, and thermal properties of nickel-rich LiNixMnyCozO2 materials. Chem. Mater. 2018, 30, 8852–8860. [Google Scholar] [CrossRef]

- Schipper, F.; Erickson, E.M.; Erk, C.; Shin, J.-Y.; Chesneau, F.F.; Aurbach, D. Review: Recent advances and remaining challenges for lithium-ion battery cathodes. J. Electrochem. Soc. 2017, 164, A6220–A6228. [Google Scholar] [CrossRef]

- Kim, M.; Zhu, J.; Li, L.; Wang, C.; Chen, G. Understanding reactivities of Ni-rich Li[NixMnyCo1-x-y]O2 single-crystal cathode materials. ACS Appl. Energy Mater. 2020, 3, 12238–12245. [Google Scholar] [CrossRef]

- Xu, J.; Lin, F.; Doeff, M.M.; Tong, W. A review of Ni-based layered oxides for rechargeable Li-ion batteries. J. Mater. Chem. A 2017, 5, 874–901. [Google Scholar] [CrossRef]

- Duh, Y.S.; Sun, Y.; Lin, X.; Zheng, J.; Wang, M.; Wang, Y.; Lin, X.; Jiang, X.; Zheng, Z.; Zheng, S.; et al. Characterization on thermal runaway of commercial 18650 lithium-ion batteries used in electric vehicles: A review. J. Energy Storage 2021, 41, 102888. [Google Scholar] [CrossRef]

- Ohneseit, S.; Finster, P.; Floras, C.; Lubenau, N.; Uhlmann, N.; Seifert, H.J.; Zizebert, C. Thermal and mechanical safety assessment of type 21700 lithium-ion batteries with NMC, NCA and LFP cathodes–investigation of cell abuse by means of accelerating rate calorimetry (ARC). Batteries 2023, 9, 237. [Google Scholar] [CrossRef]

- Huggins, R.A. Energy Storage: Fundamentals, Materials and Applications, 2nd ed.; Springer International Publishing: Cham, Switzerland, 2016; pp. 181–208. [Google Scholar]

- Manthiram, A. An outlook on lithium-ion battery technology. ACS Cent. Sci. 2017, 3, 1063–1069. [Google Scholar] [CrossRef] [PubMed]

- Singh, J.P.; Devnani, H.; Sharma, A.; Lim, W.C.; Dhyani, A.; Chae, K.H.; Lee, S. Challenges and opportunities using Ni-rich layered oxide cathodes in Li-ion rechargeable batteries: The case of nickel cobalt manganese oxides. Energy Adv. 2024, 3, 1869–1893. [Google Scholar] [CrossRef]

- Ahangari, M.; Szalai, B.; Lujan, J.; Zhou, M.; Luo, H. Advancements and challenges in high-capacity Ni-rich cathode materials for lithium-ion batteries. Materials 2024, 17, 801. [Google Scholar] [CrossRef]

- Butt, A.; Ali, G.; Kubra, K.T.; Sharif, R.; Salman, A.; Bashir, M.; Jamil, S. Recent advances in enhanced performance of Ni-rich cathode materials for Li-ion batteries: A review. Energy Technol. 2022, 10, 2100775. [Google Scholar] [CrossRef]

- Jamil, S.; Wang, G.; Fasehullah, M.; Xu, M. Challenges and prospects of nickel-rich layered oxide cathode material. J. Alloys Compd. 2022, 909, 164727. [Google Scholar] [CrossRef]

- Liu, W.; Oh, P.; Liu, X.; Lee, M.-J.; Cho, W.; Chae, S.; Kim, Y.; Cho, J. Nickel-rich layered lithium transition-metal oxide for high-energy lithium-ion batteries. Angew. Chem. Int. Ed. 2015, 54, 4440–4457. [Google Scholar] [CrossRef]

- Yan, W.; Yang, S.; Huang, Y.; Yang, Y.; Yuan, G. A review on doping/coating of nickel-rich cathode materials for lithium-ion batteries. J. Alloys Compd. 2020, 819, 153048. [Google Scholar] [CrossRef]

- Britala, L.; Marinaro, M.; Kucenskis, G. A review of the degradation mechanisms of NCM cathodes and corresponding mitigation strategies. J. Energy Storage 2023, 73A, 108875. [Google Scholar] [CrossRef]

- Myung, S.T.; Maglia, F.; Park, K.J.; Yoon, C.S.; Lamp, P.; Kim, S.-J.; Sun, Y.-K. Nickel-rich layered cathode materials for automotive lithium-ion batteries: Achievements and perspectives. ACS Energy Lett. 2017, 2, 196–223. [Google Scholar] [CrossRef]

- Hou, P.Y.; Yin, J.M.; Ding, M.; Huang, J.; Xu, X. Surface/interfacial structure and chemistry of high-energy nickel-rich layered oxide cathodes: Advances and perspectives. Small 2017, 13, 1701802. [Google Scholar] [CrossRef]

- Jung, R.; Metzger, M.; Maglia, F.; Stinner, C.; Gasteiger, H.A. Oxygen release and its effect on the cycling stability of LiNixMnyCozO2(NMC) cathode materials for Li-ion batteries. J. Electrochem. Soc. 2017, 164, A1361–A1377. [Google Scholar] [CrossRef]

- Strehle, B.; Kleiner, K.; Jung, R.; Chesneau, F.; Mendez, M.; Gasteiger, H.A.; Piana, M. The role of oxygen release from Li- and Mn-rich layered oxides during the first cycles investigated by on-line electrochemical mass spectrometry. J. Electrochem. Soc. 2017, 164, A400–A406. [Google Scholar] [CrossRef]

- Luo, Y.-H.; Pan, Q.-L.; Wei, H.-X.; Huang, Y.-D.; Tang, L.-B.; Wang, Z.-Y.; He, Z.-J.; Yan, C.; Mao, J.; Dai, K.-H.; et al. Towards Ni-rich layered oxides cathodes with low Li/Ni intermixing by mild molten-salt ion exchange for lithium-ion batteries. Nano Energy 2022, 102, 107626. [Google Scholar] [CrossRef]

- Xiao, P.; Li, W.-H.; Chen, S.; Li, G.; Dai, Z.-J.; Feng, M.-D.; Chen, X.; Yang, W.-S. Effects of Oxygen pressurization on Li+/Ni2+ cation mixing and the oxygen vacancies of LiNi0.8Co0.15Al0.05O2 cathode materials. ACS Appl. Mater. Interfaces 2022, 14, 31851–31861. [Google Scholar] [CrossRef]

- Chen, J.-N.; Yang, Y.; Tang, Y.-S.; Wang, Y.-F.; Li, H.; Xiao, X.-H.; Wang, S.-N.; Mariyam, S.D.D.; Etter, M.; Missyul, A.; et al. Constructing a thin disordered self-protective layer on the LiNiO2 primary particles against oxygen release. Adv. Funct. Mater. 2022, 33, 2211515. [Google Scholar] [CrossRef]

- Li, X.-H.; Wang, Q.; Guo, H.-Y.; Artrith, N.; Urban, A. Understanding the onset of surface degradation in LiNiO2 cathodes. ACS Appl. Energy Mater. 2022, 5, 5730–5741. [Google Scholar] [CrossRef]

- Duan, Y.; Chen, S.P.; Zhang, L.; Guo, L.; Shi, F.N. Review on oxygen release mechanism and modification strategy of nickel-rich NCM cathode materials for lithium-ion batteries: Recent advances and future directions. Energy Fuel 2024, 38, 5607–5631. [Google Scholar] [CrossRef]

- Buchberger, I.; Seidlmayer, S.; Pokharel, A.; Piana, M.; Hattendorff, J.; Kudejova, P.; Gilles, R.; Gasteiger, H.A. Aging analysis of graphite/LiNi1/3Mn1/3Co1/3O2 cells using XRD, PGAA, and AC impedance. J. Electrochem. Soc. 2015, 162, A2737–A2746. [Google Scholar] [CrossRef]

- Komagata, S.; Itou, Y.; Kondo, H. Impact of surface layer formation during cycling on the thermal stability of the LiNi0.8Co0.1Mn0.1O2 cathode. ACS Appl. Mater. Interfaces 2022, 14, 8931–8937. [Google Scholar] [CrossRef]

- Chen, S.; Zhang, P.; Zhou, X.; Wu, W.; Liu, X.; Liu, Y.; Feng, G.; Zhang, B.; Xing, W.; Zuo, M.; et al. Slightly Li-enriched chemistry enabling super stable LiNi0.5Mn0.5O2 cathodes under extreme conditions. Chem. Sci. 2024, 15, 14415–14424. [Google Scholar] [CrossRef] [PubMed]

- Deng, Z.; Liu, Y.; Wang, L.; Fu, N.; Li, Y.; Luo, Y.; Wang, J.; Xiao, X.; Wang, X.; Yang, X.; et al. Challenges of thermal stability of high-energy layered oxide cathode materials for lithium-ion batteries: A review. Mater. Today 2023, 69, 236–261. [Google Scholar] [CrossRef]

- Lim, J.M.; Hwang, T.; Kim, D.; Park, M.-S.; Cho, K.; Cho, M. Intrinsic origins of crack generation in Ni-rich LiNi0.8Co0.1Mn0.1O2 layered oxide cathode material. Sci. Rep. 2017, 7, 39669. [Google Scholar] [CrossRef] [PubMed]

- Lee, S.; Li, W.; Dolocan, A.; Celio, H.; Park, H.; Warner, J.H.; Manthiram, A. In-depth analysis of the degradation mechanisms of high-nickel, low/no-cobalt layered oxide cathodes for lithium-ion batteries. Adv. Energy Mater. 2021, 11, 2100858. [Google Scholar] [CrossRef]

- Laakso, E.; Efimova, S.; Colalongo, M.; Kauranen, P.; Lahtinen, K.; Napolitano, E.; Ruiz, V.; Moskon, J.; Gaberscek, M.; Park, J.; et al. Aging mechanisms of NMC811/Si-Graphite Li-ion batteries. J. Power Sources 2024, 599, 234159. [Google Scholar] [CrossRef]

- Wu, Z.; Zhang, C.; Yuan, F.; Lyu, M.; Yang, P.; Zhang, L.; Zhou, M.; Wang, L.; Zhang, S.; Wang, L. Ni-rich cathode materials for stable high-energy lithium-ion batteries. Nano Energy 2024, 126, 109620. [Google Scholar] [CrossRef]

- Li, T.; Yuan, X.-Z.; Zhang, L.; Song, D.; Shi, K.; Bock, D. Degradation mechanisms and mitigation strategies of nickel-rich NMC-based lithium-ion batteries. Electrochem. Energy Rev. 2020, 3, 43–80. [Google Scholar] [CrossRef]

- Xia, Y.; Zheng, J.; Wang, C.; Gu, M. Designing principle for Ni-rich cathode materials with high energy density for practical applications. Nano Energy 2018, 49, 434–452. [Google Scholar] [CrossRef]

- Kim, J.; Zhang, X.; Zhang, J.; Manthiram, A.; Meng, Y.S.; Xu, W. A Review on the stability and surface modification of layered transition-metal oxide cathodes. Mater. Today 2021, 46, 155–182. [Google Scholar] [CrossRef]

- Liu, X.; Zeng, Y.; Yuan, W.; Zhang, G.; Zheng, H.; Chen, Z. Advances in multi-scale design and fabrication processes for thick electrodes in lithium-ion batteries. Energy Rev. 2024, 3, 100066. [Google Scholar] [CrossRef]

- Das, J.; Kleiman, A.; Rehman, A.U.; Verma, R.; Young, M.H. The cobalt supply chain and environmental life cycle impacts of lithium-ion battery energy storage systems. Sustainability 2024, 16, 1910. [Google Scholar] [CrossRef]

- The Organisation for Economic Co-Operation and Development (OECD). Interconnected Supply Chains: A Comprehensive Look at Due Diligence Challenges and Opportunities Sourcing Cobalt and Copper from the Democratic Republic of the Congo. In Responsible Business Conduction; OECD: Paris, France, 2019; Available online: https://mneguidelines.oecd.org/Interconnected-supply-chains-a-comprehensive-look-at-due-diligence-challenges-and-opportunities-sourcing-cobalt-and-copper-from-the-DRC.pdf (accessed on 1 January 2019).

- U.S. Geological Survey (USGS). Mineral Commodity Summaries 2022-Cobalt; U.S. Geological Survey: Reston, VA, USA, 2022. Available online: https://pubs.usgs.gov/periodicals/mcs2022/mcs2022-cobalt.pdf (accessed on 25 May 2023).

- Cobalt Institute. State of Cobalt Market Report. 2021. Available online: https://www.cobaltinstitute.org/wp-content/uploads/2021/09/Cobalt-Institute-State-of-the-Cobalt-Market-Report_2020.pdf (accessed on 25 May 2023).

- U.S. Department of Energy. Energy Storage Grand Challenge: Energy Storage Market Report; U.S. Department of Energy: Washington, DC, USA, 2020. Available online: https://www.energy.gov/sites/prod/files/2020/12/f81/Energy%20Storage%20Market%20Report%202020_0.pdf (accessed on 1 December 2020).

- The White House. FACT SHEET: Securing a Made in America Supply Chain for Critical Minerals. 2022. Available online: https://bidenwhitehouse.archives.gov/briefing-room/statements-releases/2022/02/22/fact-sheet-securing-a-made-in-america-supply-chain-for-critical-minerals/ (accessed on 22 February 2022).

- Nriagu, J.O. Toxic metal pollution in Africa. Sci. Total. Environ. 1992, 121, 1–37. [Google Scholar] [CrossRef]

- Banza, C.L.N.; Nawrot, T.S.; Haufroid, V.; Decrée, S.; De Putter, T.; Smolders, E.; Kabyla, B.I.; Luboya, O.N.; Ilunga, A.N.; Mutombo, A.M.; et al. High human exposure to cobalt and other metals in Katanga, a mining area of the Democratic Republic of Congo. Environ. Res. 2009, 109, 745–752. [Google Scholar] [CrossRef]

- United Nations Environment Programme (UNEP). Water Issues in the Democratic Republic of Congo: Challenges and Opportunities—Technical Report. 2011. Available online: https://www.ircwash.org/sites/default/files/Partow-2011-Water.pdf (accessed on 1 January 2011).

- Slack, J.F.; Kimball, B.E.; Shedd, K.B. Cobalt Report 1802F. Professional Paper; USGS Publications Warehouse: Reston, VA, USA, 2017. Available online: https://pubs.er.usgs.gov/publication/pp1802F (accessed on 25 May 2023).

- Shengo, M.; Kime, M.-B.; Mambwe, M.; Nyembo, T. A review of the beneficiation of copper-cobalt-bearing minerals in the Democratic Republic of Congo. J. Sustain. Min. 2019, 18, 226–246. [Google Scholar] [CrossRef]

- Muimba-Kankolongo, A.; Nkulu, C.B.L.; Mwitwa, J.; Kampemba, F.M.; Nabuyanda, M.M.; Haufroid, V.; Smolders, E.; Nemery, B. Contamination of water and food crops by trace elements in the African Copperbelt: A collaborative cross-border study in Zambia and the Democratic Republic of Congo. Environ. Adv. 2021, 6, 100103. [Google Scholar] [CrossRef]

- Schmidt, T.; Buchert, M.; Schebek, L. Investigation of the primary production routes of nickel and cobalt products used for Li-ion batteries. Resour. Conserv. Recycl. 2016, 112, 107–122. [Google Scholar] [CrossRef]

- Voronina, N.; Sun, Y.-K.; Myung, S.-T. Co-free layered cathode materials for high energy density lithium-ion batteries. ACS Energy Lett. 2020, 5, 1814–1824. [Google Scholar] [CrossRef]

- Ryu, H.-H.; Sun, H.H.; Myung, S.-T.; Yoon, C.S.; Sun, Y.-K. Reducing cobalt from lithium-ion batteries for the electric vehicle era. Energy Environ. Sci. 2021, 14, 844–852. [Google Scholar] [CrossRef]

- Gent, W.E.; Busse, G.M.; House, K.Z. The predicted persistence of cobalt in lithium-ion batteries. Nat. Energy 2022, 7, 1132. [Google Scholar] [CrossRef]

- Chu, B.; Guo, Y.-J.; Shi, J.-L.; Yin, Y.-X.; Huang, T.; Su, H.; Yu, A.; Guo, Y.-G. Cobalt in high-energy-density layered cathode materials for lithium-ion batteries. J. Power Sources 2022, 544, 231873. [Google Scholar] [CrossRef]

- Liu, T.; Yu, L.; Liu, J.; Lu, J.; Bi, X.; Dai, A.; Li, M.; Li, M.; Hu, Z.; Ma, L.; et al. Understanding Co roles towards developing Co-free Ni-rich cathodes for rechargeable batteries. Nat. Energy 2021, 6, 277–286. [Google Scholar] [CrossRef]

- Ge, H.; Shen, Z.; Wang, Y.; Sun, Z.; Cao, X.; Wang, C.; Fan, X.; Bai, J.; Li, R.; Yang, T.; et al. Design of high-performance and sustainable Co-free Ni-rich cathodes for next-generation lithium-ion batteries. SusMat 2024, 4, 48–71. [Google Scholar] [CrossRef]

- Wang, R.; Wang, L.; Fan, Y.; Yang, W.; Zhan, C.; Liu, G. Controversy on necessity of cobalt in nickel-rich cathode materials for lithium-ion batteries. J. Ind. Eng. Chem. 2022, 110, 120–130. [Google Scholar] [CrossRef]

- Mallick, S.; Patel, A.; Sun, X.-G.; Paranthaman, M.P.; Mou, M.; Mugumya, J.H.; Jiang, M.; Rasche, M.L.; Lopez, H.; Gupta, R.B. Low-cobalt active cathode materials for high-performance lithium-ion batteries: Synthesis and performance enhancement methods. J. Mater. Chem. A 2023, 11, 3789–3821. [Google Scholar] [CrossRef]

- Hussain, S.K.; Bang, J.H. Recent progress in Co-free, Ni-rich cathode materials for lithium-ion batteries. Bull. Korean Chem. Soc. 2024, 45, 4–15. [Google Scholar] [CrossRef]

- Liu, X.; Xu, G.-L.; Yin, L.; Hwang, I.; Li, Y.; Lu, L.; Xu, W.; Zhang, X.; Chen, Y.; Ren, Y.; et al. Probing the thermal-driven structural and chemical degradation of Ni-rich layered cathodes by Co/Mn exchange. J. Am. Chem. Soc. 2020, 142, 19745. [Google Scholar] [CrossRef]

- Choi, J.U.; Voronina, N.; Sun, Y.-K.; Myung, S.-T. Recent progress and perspective of advanced high-energy Co-less Ni-rich cathodes for Li-ion batteries: Yesterday, today, and tomorrow. Adv. Energy Mater. 2020, 10, 2002027. [Google Scholar] [CrossRef]

- Song, Y.; Cui, Y.; Geng, L.; Li, B.; Ge, L.; Zhou, L.; Qiu, Z.; Nan, J.; Wu, W.; Xu, H.; et al. Li/Ni intermixing: The real origin of lattice oxygen stability in Co-free Ni-rich cathode materials. Adv. Energy Mater. 2024, 14, 2303207. [Google Scholar] [CrossRef]

- Kim, Y.; Seong, W.M.; Manthiram, A. Cobalt-free, high-nickel layered oxide cathodes for lithium-ion batteries: Progress, challenges, and perspectives. Energy Storage Mater. 2021, 34, 250–259. [Google Scholar] [CrossRef]

- Xiao, Y.; Liu, T.; Liu, J.; He, L.; Chen, J.; Zhang, J.; Chen, H. Insight into the origin of lithium/nickel ions exchange in layered Li(NixMnyCoz)O2 cathode materials. Nano Energy 2018, 49, 77–85. [Google Scholar] [CrossRef]

- Zheng, J.; Ye, Y.; Liu, T.; Xiao, Y.; Wang, F.; Pan, F. Ni/Li disordering in layered transition metal oxide: Electrochemical impact, origin, and control. Acc. Chem. Res. 2019, 52, 2201–2209. [Google Scholar] [CrossRef]

- Wang, D.; Xin, C.; Zhang, M.; Bai, J.; Zheng, J.; Kou, R.; Ko, J.Y.P.; Huq, A.; Zhong, G.; Sun, C.-J.; et al. Intrinsic role of cationic substitution in tuning Li/Ni mixing in high-Ni layered oxides. Chem. Mater. 2019, 31, 2731–2740. [Google Scholar] [CrossRef]

- Ben Kamel, K.; Amdouni, N.; Abdel-Ghany, A.; Zaghib, K.; Mauger, A.; Gendron, F.; Julien, C. Local structure and electrochemistry of LiNiyMnyCo1-2yO2 electrode materials for Li-ion batteries. Ionics 2008, 14, 89–97. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, S.; Yang, X.; Liu, Y.; Wu, Z.; Li, H.; Indris, S.; Ehrenberg, H.; Hua, W. Unravelling the peculiar role of Co and Al in highly Ni-rich layered oxide cathode materials. Chem. Eng. J. 2024, 484, 149599. [Google Scholar] [CrossRef]

- Lin, J.; Lian, X.; Wang, X.; Ma, Y.; Fang, L.; Suo, X. Effects of Al content on the electrochemical performance and thermal stability of Li(Ni0.9Co0.06Mn0.04)1–xAlxO2 cathode materials for Li-ion batteries. Ionics 2023, 29, 2153–2162. [Google Scholar] [CrossRef]

- Aishova, A.; Park, G.; Yoon, C.S.; Sun, Y. Cobalt-free high-capacity Ni-rich layered Li[Ni0.9Mn0.1]O2 cathode. Adv. Energy Mater. 2020, 10, 1903179. [Google Scholar] [CrossRef]

- Li, W.; Lee, S.; Manthiram, A. High-nickel NMA: A cobalt-free alternative to NMC and NCA cathodes for lithium-ion batteries. Adv. Mater. 2020, 32, 2002718. [Google Scholar] [CrossRef] [PubMed]

- Mu, L.; Kan, W.H.; Kuai, C.; Yang, Z.; Li, L.; Sun, C.-J.; Sainio, S.; Avdeev, M.; Nordlund, D.; Lin, F. Structural and electrochemical impacts of Mg/Mn dual dopants on the LiNiO2 cathode in Li-metal batteries. ACS Appl. Mater. Interfaces 2020, 12, 12874–12882. [Google Scholar] [CrossRef]

- Muralidharan, N.; Essehli, R.; Hermann, R.P.; Parejiya, A.; Amin, R.; Bai, Y.; Du, Z.; Belharouak, I. LiNixFeyAlzO2, a new cobalt-free layered cathode material for advanced Li-ion batteries. J. Power Sources 2020, 471, 228389. [Google Scholar] [CrossRef]

- Mu, L.; Zhang, R.; Kan, W.H.; Zhang, Y.; Li, L.; Kuai, C.; Zydlewski, B.; Rahman, M.M.; Sun, C.-J.; Sainio, S.; et al. Dopant distribution in Co-free high-energy layered cathode materials. Chem. Mater. 2019, 31, 9769–9776. [Google Scholar] [CrossRef]

- Yang, Z.; Mu, L.; Hou, D.; Rahman, M.M.; Xu, Z.; Liu, J.; Nordlund, D.; Sun, C.; Xiao, X.; Lin, F. Probing dopant redistribution, phase propagation, and local chemical changes in the synthesis of layered oxide battery cathodes. Adv. Energy Mater. 2020, 11, 2002719. [Google Scholar] [CrossRef]

- Li, H.; Cormier, M.; Zhang, N.; Inglis, J.; Li, J.; Dahn, J.R. Is cobalt needed in Ni-rich positive electrode materials for lithium ion batteries? J. Electrochem. Soc. 2019, 166, A429–A439. [Google Scholar] [CrossRef]

- Cui, Z.; Xie, Q.; Manthiram, A. A cobalt- and manganese-free high-nickel layered oxide cathode for long-life, safer lithium-ion batteries. Adv. Energy Mater. 2021, 11, 2102421. [Google Scholar] [CrossRef]

- Bianchini, M.; Roca-Ayats, M.; Hartmann, P.; Brezesinski, T.; Janek, J. There and back again—The journey of LiNiO2 as a cathode active material. Angew. Chem. Int. Ed. 2019, 58, 10434–10458. [Google Scholar] [CrossRef]

- Cui, J.; Ding, X.; Luo, D.; Xie, H.; Zhang, Z.; Zhang, B.; Tan, F.; Liu, C.; Lin, Z. Effect of cationic uniformity in precursors on Li/Ni mixing of Ni-rich layered cathodes. Energy Fuels 2021, 35, 1842–1850. [Google Scholar] [CrossRef]

- Wang, S.; Hua, W.; Missyul, A.; Darma, M.S.D.; Tayal, A.; Indris, S.; Ehrenberg, H.; Liu, L.; Knapp, M. Kinetic control of long-range cationic ordering in the synthesis of layered Ni-rich oxides. Adv. Funct. Mater. 2021, 31, 2009949. [Google Scholar] [CrossRef]

- Paidi, A.K.; Lee, A.T.; Paidi, V.K.; Ahn, H.; Lim, J.; Lee, K.-S.; Lee, S.; Ahn, D. Atomic-level insights into the first cycle irreversible capacity loss of Ni-rich layered cathodes for Li-ion batteries. J. Mater. Chem. A 2023, 11, 12002–12012. [Google Scholar] [CrossRef]

- Hu, Q.; Wu, Y.Z.; Ren, D.S.; Liao, J.Y.; Song, Y.Z.; Liang, H.M.; Wang, A.P.; He, Y.F.; Wang, L.; Chen, Z.H.; et al. Revisiting the initial irreversible capacity loss of LiNi0.6Co0.2Mn0.2O2 cathode material batteries. Energy Storage Mater. 2022, 50, 373–379. [Google Scholar] [CrossRef]

- Zhang, S.; Yang, Z.; Lu, Y.; Xie, W.; Yan, Z.; Chen, J. Insights into cation migration and intermixing in advanced cathode materials for lithium-ion batteries. Adv. Energy Mater. 2024, 14, 2402068. [Google Scholar] [CrossRef]

- Wu, K.; Ran, P.; Yin, W.; He, L.; Wang, B.; Wang, F.; Zhao, E.; Zhao, J. Dynamic evolution of antisite defect and coupling anionic redox in high-voltage ultrahigh-Ni cathode. Angew. Chem. Int. Ed. 2024, 63, e202410326. [Google Scholar]

- Shi, C.-G.; Peng, X.-X.; Dai, P.; Xiao, P.H.; Zheng, W.-C.; Li, H.-Y.; Li, H.; Indris, S.; Mangold, S.; Hong, Y.-H.; et al. Investigation and suppression of oxygen release by LiNi0.8Co0.1Mn0.1O2 cathode under overcharge conditions. Adv. Energy Mater. 2022, 12, 2200569. [Google Scholar] [CrossRef]

- Gabrisch, H.; Yi, T.H.; Yazami, R. Transmission electron microscope studies of LiNi1/3Mn1/3Co1/3O2 before and after long-term aging at 70 °C. Electrochem. Solid State Lett. 2008, 11, A119–A124. [Google Scholar] [CrossRef]

- Jung, S.K.; Gwon, H.; Hong, J.; Park, K.-Y.; Seo, D.-H.; Kim, H.; Kang, K. Understanding the degradation mechanisms of LiNi0.5Co0.2 Mn0.3O2 cathode material in lithium-ion batteries. Adv. Energy Mater. 2014, 4, 1300787. [Google Scholar] [CrossRef]

- Robert, R.; Villevieille, C.; Novák, P. Enhancement of the high potential specific charge in layered electrode materials for lithium-ion batteries. J. Mater. Chem. A 2014, 2, 8589–8598. [Google Scholar] [CrossRef]

- Konishi, H.; Yoshikawa, M.; Hirano, T. The effect of thermal stability for high-Ni-content layer-structured cathode materials, LiNi0.8Mn0.1–xCo0.1MoxO2 (x = 0, 0.02, 0.04). J. Power Sources 2013, 244, 23–28. [Google Scholar] [CrossRef]

- Wang, D.; Li, X.-H.; Wang, Z.X.; Guo, H.; Huang, Z.; Kong, L.; Ru, J. Improved high voltage electrochemical performance of Li2ZrO3-coated LiNi0.5Co0.2Mn0.3O2 cathode material. J. Alloys Compd. 2015, 647, 612–619. [Google Scholar] [CrossRef]

- Lin, F.; Markus, I.M.; Nordlund, D.; Weng, T.-C.; Asta, M.D.; Xin, H.L.; Doeff, M.M. Surface reconstruction and chemical evolution of stoichiometric layered cathode materials for lithium-ion batteries. Nat. Commun. 2014, 5, 3529. [Google Scholar] [CrossRef]

- Hwang, S.; Chang, W.; Kim, S.M.; Su, D.; Kim, D.Y.; Lee, J.Y.; Chung, K.Y.; Stach, E.A. Investigation of changes in the surface structure of LixNi0.8Co0.15Al0.05O2 cathode materials induced by the initial charge. Chem. Mater. 2014, 26, 1084–1092. [Google Scholar] [CrossRef]

- Yang, J.; Hou, M.Y.; Haller, S.; Wang, Y.; Wang, C.; Xia, Y. Improving the cycling performance of the layered Ni-rich oxide cathode by introducing low content Li2MnO3. Electrochim. Acta 2016, 189, 101–110. [Google Scholar] [CrossRef]

- Yang, J.; Xia, Y.Y. Enhancement on the cycling stability of the layered Ni-rich oxide cathode by in situ fabricating nano-thickness cation-mixing layers. J. Electrochem. Soc. 2016, 163, A2665–A2672. [Google Scholar] [CrossRef]

- Liu, J.; Du, Z.; Wang, X.; Tan, S.; Wu, X.; Geng, L.; Song, B.; Chien, P.-H.; Everett, S.M.; Hu, E. Anionic redox induced anomalous structural transition in Ni-rich cathodes. Energy Environ. Sci. 2021, 14, 6441–6454. [Google Scholar] [CrossRef]

- Lu, Z.; Zhang, J.; Zhang, Q.; Wong, D.; Yin, W.; Zhang, N.; Chen, Z.; Gu, L.; Hu, Z.; Liu, X. Oxygen anion redox chemistry correlated with spin state in Ni-rich layered cathodes. Adv. Sci. 2023, 10, 2206442. [Google Scholar] [CrossRef]

- Chu, Y.; Mu, Y.; Zou, L.; Wu, F.; Yang, L.; Feng, Y.; Zeng, L. Oxygen release in Ni-rich layered cathode for lithium-ion batteries: Mechanisms and mitigating strategies. ChemElectroChem 2024, 11, e20230065. [Google Scholar] [CrossRef]

- Flores, E.; Vonrüti, N.; Novák, P.; Aschauer, U.; Berg, E.J. Elucidation of LixNi0.8Co0.15Al0.05O2 redox chemistry by operando raman spectroscopy. Chem. Mater. 2018, 30, 4694–4703. [Google Scholar] [CrossRef]

- Li, J.; Hua, H.; Kong, X.; Yang, H.; Dai, P.; Zeng, J.; Zhao, J. In-situ probing the near-surface structural thermal stability of high-nickel layered cathode materials. Energy Storage Mater. 2022, 46, 90–99. [Google Scholar] [CrossRef]

- Lee, E.; Muhammad, S.; Kim, T.; Kim, H.; Lee, W.; Yoon, W.S. Tracking the influence of thermal expansion and oxygen vacancies on the thermal stability of Ni-rich layered cathode materials. Adv. Sci. 2020, 7, 1902413. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Gao, A.; Tang, Z.; Meng, F.; Shang, T.; Guo, S.; Ding, J.; Luo, Y.; Xiao, D.; Wang, X.; et al. Robust surface reconstruction induced by subsurface Ni/Li antisites in Ni-rich cathodes. Adv. Funct. Mater. 2021, 31, 2010291. [Google Scholar] [CrossRef]

- Chae, B.G.; Park, S.Y.; Song, J.H.; Lee, E.; Jeon, W.S. Evolution and expansion of Li concentration gradient during charge-discharge cycling. Nat. Commun. 2021, 12, 3814. [Google Scholar] [CrossRef]

- Yin, S.; Deng, W.; Chen, J.; Gao, X.; Zou, G.; Hou, H.; Ji, X. Fundamental and solutions of microcrack in Ni-rich layered oxide cathode materials of lithium-ion batteries. Nano Energy 2021, 83, 105854. [Google Scholar] [CrossRef]

- Hwang, S.; Kim, S.M.; Bak, S.-M.; Chung, K.Y.; Chang, W. Investigating the reversibility of structural modifications of LixNiyMnzCo1–y–zO2 cathode materials during initial charge/discharge, at multiple length scales. Chem. Mater. 2015, 27, 6044–6052. [Google Scholar] [CrossRef]

- Ghanty, C.; Markovsky, B.; Erickson, E.M.; Talianker, M.; Haik, O.; Tal-Yossef, Y.; Mor, A.; Aurbach, D.; Lampert, J.; Volkov, A.; et al. Li+-ion extraction/insertion of Ni-rich Li1+x(NiyCozMnz)wO2 (0.005 < x < 0.03; y:z = 8:1, w ≈ 1) electrodes: In situ XRD and Raman spectroscopy study. ChemElectroChem 2015, 2, 1479–1486. [Google Scholar]

- Wang, X.L.; An, K.; Cai, L.; Feng, Z.; Nagler, S.E.; Daniel, C.; Rhodes, K.J.; Stoica, A.D.; Skorpenske, H.D.; Liang, C.; et al. Visualizing the chemistry and structure dynamics in lithium-ion batteries by in situ neutron diffraction. Sci. Rep. 2012, 2, 747. [Google Scholar] [CrossRef]

- Yang, J.; Xia, Y.Y. Suppressing the phase transition of the layered Ni-rich oxide cathode during high-voltage cycling by introducing low-content Li2MnO3. ACS Appl. Mater. Interfaces 2016, 8, 1297–1308. [Google Scholar] [CrossRef]

- Li, J.; Shunmugasundaram, R.; Doig, R. In situ X-ray diffraction study of layered Li–Ni–Mn–Co oxides: Effect of particle size and structural stability of core–shell materials. Chem. Mater. 2016, 28, 162–171. [Google Scholar] [CrossRef]

- Yoon, S.; Park, H.G.; Koo, S.; Hwang, J.; Lee, Y.; Park, K.; Kim, D. An in-depth understanding of chemomechanics in Ni-rich layered cathodes for lithium-ion batteries. J. Alloys Compd. 2023, 939, 168531. [Google Scholar] [CrossRef]

- Laubach, S.; Laubach, S.; Schmidt, P.; Ensling, D.; Schmid, S.; Jaegermann, W.; Thissen, A.; Nikolowski, K.; Ehrenberg, H. Changes in the crystal and electronic structure of LiCoO2 and LiNiO2 upon Li intercalation and de-intercalation. Phys. Chem. Chem. Phys. 2009, 11, 3278–3289. [Google Scholar] [CrossRef] [PubMed]

- Yabuuchi, N.; Makimura, Y.; Ohzuku, T. Solid-state chemistry and electrochemistry of LiCo1/3Ni1/3Mn1/3O2 for advanced lithium-ion batteries. J. Electrochem. Soc. 2007, 154, A314–A321. [Google Scholar] [CrossRef]

- Wang, S.Y.; Yan, M.Y.; Li, Y.; Vinado, C.; Yang, J. Separating electronic and ionic conductivity in mix-conducting layered lithium transition-metal oxides. J. Power Sources 2018, 393, 75–82. [Google Scholar] [CrossRef]

- Cui, S.; Wei, Y.; Liu, T.; Deng, W.; Hu, Z.; Su, Y.; Li, H.; Li, M.; Guo, H.; Duan, Y.; et al. Optimized temperature effect of Li-ion diffusion with layer distance in Li(NixMnyCoz)O2 cathode materials for high performance Li-ion battery. Adv. Energy Mater. 2016, 6, 1501309. [Google Scholar] [CrossRef]

- Wu, F.; Liu, N.; Chen, L.; Su, Y.; Tan, G.; Bao, L.; Zhang, Q.; Lu, Y.; Wang, J.; Chen, S.; et al. Improving the reversibility of the H2–H3 phase transitions for layered Ni-rich oxide cathode towards retarded structural transition and enhanced cycle stability. Nano Energy 2019, 59, 50–57. [Google Scholar] [CrossRef]

- Yoon, C.S.; Ryu, H.H.; Park, G.T.; Kim, J.H.; Kim, K.H.; Sun, Y.K. Extracting maximum capacity from Ni-rich Li[Ni0.95Co0.025Mn0.025]O2 cathodes for high-energy-density lithium-ion batteries. J. Mater. Chem. A 2018, 6, 4126–4132. [Google Scholar] [CrossRef]

- Park, S.-H.; Lee, H.; Park, J.; Roh, Y.; Byun, S.; Lim, J.; Jung, S.; Kim, N.; Lee, K.-T.; Lee, Y.-M. A microcrack propagation-based life prediction model for lithium-ion batteries with Ni-rich cathode materials. J. Energy Storage 2023, 58, 106420. [Google Scholar] [CrossRef]

- Park, N.-Y.; Kim, M.-C.; Han, S.-M.; Park, G.-T.; Kim, D.-H.; Kim, M.-S.; Sun, Y.-K. Mechanism behind the loss of fast charging capability in nickel-rich cathode materials. Angew. Chem. Int. Ed. 2024, 63, e202319707. [Google Scholar] [CrossRef] [PubMed]

- Liu, T.; Yu, L.; Lu, J.; Zhou, T.; Huang, X.; Cai, Z.; Dai, A.; Gim, J.; Ren, Y.; Xiao, X.; et al. Rational design of mechanically robust Ni-rich cathode materials via concentration gradient strategy. Nat Commun. 2021, 12, 6024. [Google Scholar] [CrossRef] [PubMed]

- Park, G.T.; Ryu, H.H.; Park, N.Y.; Yoon, C.S.; Sun, Y.K. Tungsten doping for stabilization of Li[Ni0.90Co0.05Mn0.05]O2 cathode for Li-ion battery at high voltage. J. Power Sources 2019, 442, 227242. [Google Scholar] [CrossRef]

- Lv, C.; Li, Z.; Ren, X.; Li, K.; Ma, J.; Duan, X. Revealing the degradation mechanism of Ni-rich cathode materials after ambient storage and related regeneration method. J. Mater. Chem. A 2021, 9, 3995–4006. [Google Scholar] [CrossRef]

- Su, M.; Chen, Y.; Liu, H.; Li, J.; Fu, K.; Zhou, Y.; Dou, A.; Liu, Y. Storage degradation mechanism of layered Ni-rich oxide cathode material LiNi0.8Co0.1Mn0.1O2. Electrochim. Acta 2022, 422, 140559. [Google Scholar] [CrossRef]

- Yang, J.; Liang, X.; Ryu, H.-H.; Yoon, C.S.; Sun, Y.-K. Ni-rich layered cathodes for lithium-ion batteries: From challenges to the future. Energy Storage Mater. 2023, 63, 102969. [Google Scholar] [CrossRef]

- Lv, Y.; Huang, S.; Zhao, Y.; Ray, S.; Lu, X.; Hou, Y.; Zhang, J. A review of nickel-rich layered oxide cathodes: Synthetic strategies, structural characteristics, failure mechanism, improvement approaches and prospects. Appl. Energy 2022, 305, 117849. [Google Scholar] [CrossRef]

- Quilty, C.-D.; West, P.-J.; Li, W.-Z.; Dunkin, M.-R.; Wheeler, G.-P.; Ehrlich, S.; Ma, L.; Jaye, C.; Fischer, D.-A.; Takeuchi, E.-S.; et al. Multimodal electrochemistry coupled microcalorimetric and X-ray probing of the capacity fade mechanisms of Nickel rich NMC–progress and outlook. Phys. Chem. Chem. Phys. 2022, 24, 11471–11485. [Google Scholar] [CrossRef]

- Sun, H.-H.; Manthiram, A. Impact of microcrack generation and surface degradation on a nickel-rich layered Li[Ni0.9Co0.05Mn0.05]O2 cathode for lithium-ion batteries. Chem. Mater. 2017, 29, 8486–8493. [Google Scholar] [CrossRef]

- Korsunsky, A.M.; Sui, T.; Song, B. Explicit formulae for the internal stress in spherical particles of active material within lithium-ion battery cathodes during charging and discharging. Mater. Des. 2015, 69, 247–252. [Google Scholar] [CrossRef]

- Brandt, L.R.; Marie, J.-J.; Moxham, T.; Förstermann, D.P.; Salvati, E.; Besnard, C.; Papadaki, C.; Wang, Z.; Bruce, P.G.; Korsunsky, A.M. Synchrotron X-ray quantitative evaluation of transient deformation and damage phenomena in a single nickel-rich cathode particle. Energy Environ. Sci. 2020, 13, 3556–3566. [Google Scholar] [CrossRef]

- Park, N.-Y.; Park, G.-T.; Kim, S.-B.; Jung, W.; Park, B.-C.; Sun, Y.-K. Degradation mechanism of Ni-rich cathode materials: Focusing on particle interior. ACS Energy Lett. 2022, 7, 2362–2369. [Google Scholar] [CrossRef]

- Zhao, J.; Wang, Z.; Wang, J.; Guo, H.; Li, X.; Gui, W.; Chen, N.; Yan, G. Anchoring K+ in Li+ sites of LiNi0.8Co0.15Al0.05O2 cathode material to suppress its structural degradation during high-voltage cycling. Energy Technol. 2018, 6, 2358–2366. [Google Scholar] [CrossRef]

- Lee, E.J.; Chen, Z.; Noh, H.-J.; Nam, S.C.; Kang, S.; Kim, D.H.; Amine, K.; Sun, Y.-K. Development of microstrain in aged lithium transition metal oxides. Nano Lett. 2014, 14, 4873–4880. [Google Scholar] [CrossRef]

- Xu, G.-L.; Liu, Q.; Lau, K.K.S.; Liu, Y.; Liu, X.; Gao, H.; Zhou, X.; Zhuang, M.; Ren, Y.; Li, J.; et al. Building ultraconformal protective layers on both secondary and primary particles of layered lithium transition metal oxide cathodes. Nat. Energy 2019, 4, 484–494. [Google Scholar] [CrossRef]

- Hu, J.; Li, L.; Hu, E.; Chae, S.; Jia, H.; Liu, T.; Wu, B.; Bi, J.; Amine, K.; Wang, C.; et al. Mesoscale-architecture-based crack evolution dictating cycling stability of advanced lithium-ion batteries. Nano Energy 2020, 79, 105420. [Google Scholar] [CrossRef]

- Bi, Y.J.; Tao, J.H.; Wu, Y.Q.; Li, L.Z.; Xu, Y.B.; Hu, E.Y.; Wu, B.B.; Hu, J.T.; Wang, C.M.; Zhang, J.G.; et al. Reversible planar gliding and microcracking in a single-crystalline Ni-rich cathode. Science 2020, 370, 1313–1317. [Google Scholar] [CrossRef]

- Tian, H.; Gao, L.T.; Guo, Z.-S. Microstructural adjusting crack Evolution of polycrystalline NCM particle during charge/discharge cycle. J. Electrochem. Soc. 2022, 169, 090513. [Google Scholar] [CrossRef]

- Han, G.-M.; Kim, Y.-S.; Ryu, H.-H.; Sun, Y.-K.; Yoon, C.S. Structural stability of single-crystalline Ni-rich layered cathode upon delithiation. ACS Energy Lett. 2022, 7, 2919–2926. [Google Scholar] [CrossRef]

- Su, Y.F.; Zhang, Q.Y.; Chen, L.; Bao, L.Y.; Lu, Y.; Chen, S.; Wu, F. Stress accumulation in Ni-rich layered oxide cathodes: Origin, impact, and resolution. J. Energy Chem. 2022, 65, 236–253. [Google Scholar] [CrossRef]

- Koo, J.K.; Ran, W.T.A.; Yun, Y.; Seo, J.K.; Kim, M.; Lee, J.; Lee, S.; Kim, J.; Hwang, S.M.; Kim, Y.-J. Probing intraparticle heterogeneity in Ni-rich layered cathodes with different carbon black contents using scanning probe microscopy. J. Energy Storage 2022, 51, 104395. [Google Scholar] [CrossRef]

- Lee, S.; Song, G.; Yun, B.; Kim, T.; Choi, S.H.; Kim, H.; Doo, S.W.; Lee, K.T. Revealing the nanoscopic corrosive degradation mechanism of nickel-rich layered oxide cathodes at low state-of-charge levels: Corrosion cracking and pitting. ACS Nano 2024, 18, 10566–10581. [Google Scholar] [CrossRef] [PubMed]

- Sharma, N.; Vasconcelos, L.S.; Hassan, S.; Zhao, K. Asynchronous-to-synchronous transition of li reactions in solid-solution cathodes. Nano Lett. 2022, 22, 5883–5890. [Google Scholar] [CrossRef]

- Cheng, X.; Li, Y.; Cao, T.; Wu, R.; Wang, M.; Liu, H.; Liu, X.; Lu, J.; Zhang, Y. Real-time observation of chemomechanical breakdown in a layered nickel-rich oxide cathode realized by in situ scanning electron microscopy. ACS Energy Lett. 2021, 6, 1703–1710. [Google Scholar] [CrossRef]

- Mu, L.; Lin, R.; Xu, R.; Han, L.; Xia, S.; Sokaras, D.; Steiner, J.D.; Weng, T.C.; Nordlund, D.; Doeff, M.M.; et al. Oxygen release induced chemomechanical breakdown of layered cathode materials. Nano Lett. 2018, 18, 3241–3249. [Google Scholar] [CrossRef]

- Kim, U.H.; Ryu, H.H.; Kim, J.H.; Mücke, R.; Kaghazchi, P.; Yoon, C.S.; Sun, Y.-K. Microstructure-controlled Ni-rich cathode material by microscale compositional partition for next-generation electric vehicles. Adv. Energy Mater. 2019, 9, 1803902. [Google Scholar] [CrossRef]

- Morzy, J.K.; Dose, W.M.; Vullum, P.E.; Lai, M.C.; Mahadevegowda, A.; De Volder, M.F.L.; Ducati, C. Origins and importance of intragranular cracking in layered lithium transition metal oxide cathodes. ACS Appl. Energy Mater. 2024, 7, 3945–3956. [Google Scholar] [CrossRef]

- Park, K.-J.; Hwang, J.-Y.; Ryu, H.-H.; Maglia, F.; Kim, S.-J.; Lamp, P.; Yoon, C.S.; Sun, Y.-K. Degradation mechanism of Ni-enriched NCA cathode for lithium batteries: Are microcracks really critical? ACS Energy Lett. 2019, 4, 1394–1400. [Google Scholar] [CrossRef]

- Li, W.; Asl, H.-Y.; Xie, Q.; Manthiram, A. Collapse of LiNi1-x-yCoxMnyO2 lattice at deep charge irrespective of nickel content in lithium-ion batteries. J. Am. Chem. Soc. 2019, 141, 5097–5101. [Google Scholar] [CrossRef]

- Yan, P.; Zheng, J.; Gu, M.; Xiao, J.; Zhang, J.-G.; Wang, C.-M. Intragranular cracking as a critical barrier for high-voltage usage of layer-structured cathode for lithium-ion batteries. Nat. Commun. 2017, 8, 14101. [Google Scholar] [CrossRef]

- Li, W.; Song, B.; Manthiram, A. High-voltage positive electrode materials for lithium-ion batteries. Chem. Soc. Rev. 2017, 46, 3006–3059. [Google Scholar] [CrossRef]

- Li, M.; Liu, T.; Bi, X.; Chen, Z.; Amine, K.; Zhong, C.; Lu, J. Cationic and anionic redox in lithium-ion based batteries. Chem. Soc. Rev. 2020, 49, 1688–1705. [Google Scholar] [CrossRef] [PubMed]

- Ryu, H.H.; Park, K.J.; Yoon, C.S.; Sun, Y.K. Capacity fading of Ni-rich Li[NixCoyMn1-x-y]O2 (0.6 ≤ x ≤ 0.95) cathodes for high-energy-density lithium-ion batteries: Bulk or surface degradation? Chem. Mater. 2018, 30, 1155–1163. [Google Scholar] [CrossRef]

- Ryu, H.H.; Park, G.T.; Yoon, C.S.; Sun, Y.K. Microstructural degradation of Ni-rich Li[NixCoyMn1-x-y]O2 cathodes during accelerated calendar aging. Small 2018, 14, 1803179. [Google Scholar] [CrossRef] [PubMed]

- Hu, J.; Zhang, L.; Zhong, S.; Li, Z.; Zeng, M.; Fan, F.; Yan, T. Extebded fast-charging life of ultrahigh-Ni layered oxides by adjusting the current density during the H2 -> H3 phase transition. Energy Storage Mater. 2022, 50, 757–759. [Google Scholar]

- Dai, P.P.; Kong, X.B.; Yang, H.Y.; Li, J.Y.; Zeng, J.; Zhao, J.B. Single-crystal Ni-rich layered LiNi0.9Mn0.1O2 enables superior performance of Co-free cathodes for lithium-ion batteries. ACS Sustain. Chem. Eng. 2022, 10, 4381–4390. [Google Scholar] [CrossRef]

- Ryu, H.H.; Lee, S.B.; Yoon, C.S.; Sun, Y.K. Morphology-dependent battery performance of Ni-rich layered cathodes: Single-crystal versus refined polycrystal. ACS Energy Lett. 2022, 7, 3072–3079. [Google Scholar] [CrossRef]

- Niu, S.; Xu, J.; Wu, K.; Liang, C.; Zhu, G.; Qu, Q.; Zheng, H. Different mechanical and electrochemical behavior between the two major Ni-rich cathode materials in Li-ion batteries. Mater. Chem. Phys. 2021, 260, 124046. [Google Scholar] [CrossRef]

- Liang, W.; Zhao, Y.; Shi, L.; Wang, Z.; Yuan, S. Spheroidization: The impact of precursor morphology on solid-state lithiation process for high-quality ultrahigh-nickel oxide cathodes. Angew. Chem. Int. Ed. 2024, 63, e202407477. [Google Scholar] [CrossRef]

- Zou, L.; Zhao, W.; Jia, H.; Zheng, J.; Li, L.; Abraham, D.P.; Chen, G.; Croy, J.R.; Zhang, J.-G.; Wang, X.C. The role of secondary particle structures in surface phase transitions of Ni-rich cathodes. Chem. Mater. 2020, 32, 2884–2892. [Google Scholar] [CrossRef]

- Kim, U.-H.; Park, J.-H.; Aishova, A.; Ribas, R.M.; Monteiro, R.S.; Griffith, K.J.; Yoon, C.S.; Sun, Y.-K. Microstructure engineered Ni-rich layered cathode for electric vehicle batteries. Adv. Energy Mater. 2021, 11, 2100884. [Google Scholar] [CrossRef]

- Park, G.-T.; Yoon, D.R.; Kim, U.-H.; Namkoong, B.; Lee, J.; Wang, M.M.; Lee, A.C.; Gu, X.W.; Chueh, W.C.; Yoon, C.S.; et al. Ultrafine-grained Ni-rich layered cathode for advanced Li-ion batteries. Energy Environ. Sci. 2021, 14, 6616–6626. [Google Scholar] [CrossRef]

- Wang, L.; Liu, T.; Wu, T.; Lu, J. Strain-retardant coherent perovskite phase stabilized Ni-rich cathode. Nature 2022, 611, 61–67. [Google Scholar] [CrossRef] [PubMed]

- Hou, D.; Xu, Z.; Yang, Z.; Kuai, C.; Du, Z.; Sun, C.-J.; Ren, Y.; Liu, J.; Xiao, X.; Lin, F. Effect of the grain arrangements on the thermal stability of polycrystalline nickel-rich lithium-based battery cathodes. Nat. Commun. 2022, 13, 3437. [Google Scholar] [CrossRef]

- Namkoong, B.; Park, N.-Y.; Park, G.-T.; Shin, J.-Y.; Beierling, T.; Yoon, C.S.; Sun, Y.-K. High-energy Ni-rich cathode materials for long-range and long-life electric vehicles. Adv. Energy Mater. 2022, 12, 2200615. [Google Scholar] [CrossRef]

- Trevisanello, E.; Ruess, R.; Conforto, G.; Richter, F.H.; Janek, J. Polycrystalline and single crystalline NCM cathode materials—Quantifying particle cracking, active surface area, and lithium diffusion. Adv. Energy Mater. 2021, 11, 2003400. [Google Scholar] [CrossRef]

- Deng, X.; Zhang, R.; Zhou, K.; Gao, Z.; He, W.; Zhang, L.; Han, C.; Kang, F.; Li, B. A comparative investigation of single crystal and polycrystalline Ni-rich NCMs as cathodes for lithium-ion batteries. Energy Environ. Mater. 2022, 6, e12331. [Google Scholar] [CrossRef]

- Zhang, R.; Wang, C.; Ge, M.; Xin, H.L. Accelerated degradation in a quasi-single-crystalline layered oxide cathode for lithium-ion batteries caused by residual grain boundaries. Nano Lett. 2022, 22, 3818–3824. [Google Scholar] [CrossRef] [PubMed]

- Li, S.; Yao, Z.; Zheng, J.; Fu, M.; Cen, J.; Hwang, S.; Jin, H.; Orlov, A.; Gu, L.; Wang, S.; et al. Direct observation of defect-aided structural evolution in a nickel-rich layered cathode. Angew. Chem. Int. Ed. 2020, 59, 22092–22099. [Google Scholar] [CrossRef]

- Lin, Q.; Guan, W.; Zhou, J.; Meng, J.; Huang, W.; Chen, T.; Gao, Q.; Wei, X.; Zeng, Y.; Li, J.; et al. Ni–Li anti-site defect induced intragranular cracking in Ni-rich layer-structured cathode. Nano Energy 2020, 76, 105021. [Google Scholar] [CrossRef]

- Meng, X.H.; Lin, T.; Mao, H.; Shi, J.L.; Sheng, H.; Zou, Y.G.; Fan, M.; Jiang, K.; Xiao, R.J.; Xiao, D.; et al. Kinetic origin of planar gliding in single-crystalline Ni-rich cathodes. J. Am. Chem. Soc. 2022, 144, 11338–11347. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.; Wang, X.; Zhang, R.; Lei, T.; Kisslinger, K.; Xin, H.L. Resolving complex intralayer transition motifs in high-Ni-content layered cathode materials for lithium-ion batteries. Nat. Mater. 2023, 22, 235–241. [Google Scholar] [CrossRef] [PubMed]

- Sun, J.; Cao, X.; Yang, H.; He, P.; Dato, M.A.; Cabana, J.; Zhou, H. The origin of high-voltage stability in single-crystal layered Ni-rich cathode materials. Angew. Chem. 2022, 134, e202207225. [Google Scholar] [CrossRef]

- Saaid, F.I.; Kasim, M.F.; Winie, T.; Elong, K.A.; Azahidi, A.; Basri, N.D.; Yaakob, M.K.; Mastuli, M.S.; Shaffee, S.N.A.; Yaakob, M.K.; et al. Ni-rich lithium nickel manganese cobalt oxide cathode materials: A review on the synthesis methods and their electrochemical performances. Heliyon 2024, 10, e23968. [Google Scholar] [CrossRef]

- Zhang, Y.J.; Du, K.; Cao, Y.B.; Lu, Y.; Peng, Z.D.; Fan, J.; Hu, G. Hydrothermal preparing agglomerate LiNi0.8Co0.1Mn0.1O2 cathode material with submicron primary particle for alleviating microcracks. J. Power Sources 2020, 477, 228701. [Google Scholar] [CrossRef]

- Li, Y.; He, J.J.; Luo, L.; Li, X.; Chen, Z.; Zhang, Y.B.; Deng, L.; Dong, P.; Yang, S.; Wu, K.; et al. Highly dispersed micrometer nickel-rich single-crystal construction: Benefits of supercritical reconstruction during hydrothermal synthesis. ACS Appl. Energy Mater. 2022, 5, 6302–6312. [Google Scholar] [CrossRef]

- Gu, H.; Wang, J.; Wang, Z.; Tong, J.; Qi, N.; Han, G.; Zhang, M. Self-assembled porous LiNi0.8Co0.1Mn0.1O2 cathode materials with micro/nano-layered hollow morphologies for high-power lithium-ion batteries. Appl. Surf. Sci. 2021, 539, 148034. [Google Scholar] [CrossRef]

- Li, S.Y.; Liang, W.B.; Xie, J.; Wei, Y.; Cui, X.L. Synthesis of hollow microspheres LiNi0.5Mn1.5O4 coated with Al2O3 and characterization of the electrochemical capabilities. J. Electrochem. Energy Convers. Storage 2020, 17, 031007. [Google Scholar]

- Guo, J.; Li, W. Synthesis of single-crystal LiNi0.7Co0.15Mn0.15O2 materials for Li-ion batteries by a sol-gel method. ACS Appl. Energy Mater. 2022, 5, 397–406. [Google Scholar] [CrossRef]

- Bai, X.; Wei, A.J.; He, R.; Li, W.; Li, X.H.; Zhang, L.H.; Liu, Z. The structural and electrochemical performance of Mg-doped LiNi0.85Co0.10Al0.05O2 prepared by a solid-state method. J. Electroanal. Chem. 2020, 858, 113771. [Google Scholar] [CrossRef]

- Zheng, L.; Bennett, J.C.; Obrovac, M.N. All-dry synthesis of single crystal NMC cathode materials for Li-ion batteries. J. Electrochem. Soc. 2020, 167, 130536. [Google Scholar] [CrossRef]

- Wang, Z.; Yang, L.; Xu, C.; Cheng, J.; Zhao, J.; Huang, Q.; Yang, C. Advances in reactive co-precipitation technology for preparing high-performance cathodes. Green Carbon 2023, 1, 193–209. [Google Scholar] [CrossRef]

- He, F.R.; Tian, Z.Q.; Xiang, W.; Yang, W.; Zheng, B.P.; Cai, J.Y.; Guo, X.D. Insight into the surface reconstruction-induced structure and electrochemical performance evolution for Ni-rich cathodes with postannealing after washing. ACS Appl. Mater. Interfaces 2023, 15, 9160–9170. [Google Scholar] [CrossRef]

- Liang, W.; Zhao, Y.; Shi, L.; Wang, Z.; Wang, Y.; Zhang, M.; Yuan, S. Advances of high-performance LiNi1-x-yCoxMyO2 cathode materials and their precursor particles via co-precipitation process. Particuology 2024, 86, 67–85. [Google Scholar] [CrossRef]

- Wang, L.; Shi, Q.; Zhan, C.; Liu, G. One-step solid-state synthesis of Ni-rich cathode materials for lithium-ion batteries. Materials 2023, 16, 3079. [Google Scholar] [CrossRef]

- El Kouihen, F.; Chakir, M.; Faik, A. The effect of synthesis methods on cation mixing degree in cobalt-free, nickel-rich NMA materials. Chem. Pap. 2025, 79, 2411–2420. [Google Scholar] [CrossRef]

- Li, X.; Zhang, K.; Wang, S.; Wang, M.; Jiang, F.; Liu, Y.; Huang, Y.; Zheng, J. Optimal synthetic conditions for a novel and high-performance Ni-rich cathode material of LiNi0.68Co0.10Mn0.22O2. Sustain. Energy Fuels 2018, 2, 1772–1780. [Google Scholar]

- Ying, B.X.; Fitzpatrick, J.R.; Teng, Z.J.; Chen, T.X.; Lo, T.W.B.; Siozios, V.; Murray, C.A.; Brand, H.E.A.; Day, S.; Tang, C.C.; et al. Monitoring the formation of nickel-poor and nickel-rich oxide cathode materials for lithium-ion batteries with synchrotron radiation. Chem. Mater. 2023, 35, 1514–1526. [Google Scholar] [CrossRef]

- Han, Q.; Cai, L.L.; Yang, Z.F.; Hu, Y.J.; Jiang, H.; Li, C.Z. New insights into the pre-lithiation kinetics of single-crystalline Ni-rich cathodes for long-life Li-ion batteries. Green Energy Environ. 2024, 9, 556–564. [Google Scholar] [CrossRef]

- Xiao, X.; Wang, L.; Li, J.T.; Zhang, B.; Hu, Q.; Liu, J.L.; Wu, Y.Q.; Gao, J.H.; Chen, Y.B.; Song, S.L.; et al. Rational synthesis of high-performance Ni-rich layered oxide cathode enabled via probing solid-state lithiation evolution. Nano Energy 2023, 113, 108528. [Google Scholar] [CrossRef]

- Liu, J.J.; Yuan, Y.F.; Zheng, J.H.; Wang, L.G.; Ji, J.; Zhang, Q.; Yang, L.; Bai, Z.Y.; Lu, J. Understanding the synthesis kinetics of single-crystal Co-free Ni-rich cathodes. Angew. Chem. Int. Ed. 2023, 62, e202302547. [Google Scholar] [CrossRef] [PubMed]

- Wolfman, M.; Wang, X.P.; Garcia, J.C.; Barai, P.; Stubbs, J.E.; Eng, P.J.; Kahvecioglu, O.; Kinnibrugh, T.L.; Madsen, K.E.; Iddir, H.; et al. Spheroidization: The impact of precursor morphology on solid-state lithiation process for high-quality ultrahigh-nickel oxide cathodes. Adv. Energy Mater. 2022, 12, 2102951. [Google Scholar] [CrossRef]

- Xu, Z.R.; Jiang, Z.S.; Kuai, C.G.; Xu, R.; Qin, C.D.; Zhang, Y.; Rahman, M.M.; Wei, C.; Nordlund, D.; Sun, C.-J.; et al. Charge distribution guided by grain crystallographic orientations in polycrystalline battery materials. Nat. Commun. 2020, 11, 83. [Google Scholar] [CrossRef] [PubMed]

- Polierer, S.; Guse, D.; Wild, S.; Delgado, K.H.; Otto, T.N.; Zevaco, T.A.; Kind, M.; Sauer, J.; Studt, F.; Pitter, S. Enhanced direct dimethyl ether synthesis from CO2 rich syngas with Cu/ZnO/ZrO2 catalysts prepared by continuous co-precipitation. Catalysts 2020, 10, 816. [Google Scholar] [CrossRef]

- Ahmed, R.R.; Mubarak, T.H.; Mohamed, I.H. A study of structural and chemical properties of Ni1-xZnxFe2O4 ferrite powder prepared by co-precipitation method. Digest J. Nanomater. Biostruct. 2022, 17, 741–748. [Google Scholar] [CrossRef]

- Entwistle, T.; Sanchez-Perez, E.; Murray, G.J.; Anthonisamy, N.; Cussen, S.A. Co-precipitation synthesis of nickel-rich cathodes for Li-ion batteries. Energy Rep. 2022, 8, 67–73. [Google Scholar] [CrossRef]

- Lee, S.H.; Kwon, K.Y.; Choi, B.K.; Yoo, H.D. A kinetic descriptor to optimize Co-precipitation of Nickel-rich cathode precursors for lithium-ion batteries. J. Electroanal. Chem. 2022, 924, 116828. [Google Scholar] [CrossRef]

- Heo, K.; Lee, J.S.; Kim, H.S.; Kim, M.Y.; Jeong, H.; Kim, J.; Lim, J. Ionic conductor-LiNi0.8Co0.1Mn0.1O2 composite synthesized by simultaneous co-precipitation for use in lithium-ion batteries. J. Electrochem. Soc. 2018, 165, A2955–A2960. [Google Scholar] [CrossRef]

- Xu, L.P.; Zhou, F.; Kong, J.Z.; Zhou, H.B.; Zhang, Q.C.; Wang, Q.Z.; Yan, G. Influence of precursor phase on the structure and electrochemical properties of LiNi0.6Mn0.2Co0.2O2 cathode materials. Solid State Ion. 2018, 324, 49–58. [Google Scholar] [CrossRef]

- Zhang, X.; Hu, G.R.; Peng, Z.D.; Cao, Y.B.; Li, L.Y.; Tan, C.P.; Du, K. Synthesis and characterization of mono-dispersion LiNi0.8Co0.1Mn0.1O2 micrometer particles for lithium-ion batteries. Ceram. Int. 2021, 47, 25680–25688. [Google Scholar] [CrossRef]

- Pollen, H.N.; Tolchard, J.R.; Svensson, A.M.; Wagner, N.P. A single-pot co-precipitation synthesis route for Ni-rich layered oxide materials with high cycling stability. ChemElectroChem 2022, 9, e202200859. [Google Scholar] [CrossRef]

- Para, M.L.; Alidoost, M.; Shiea, M.; Boccardo, G.; Buffo, A.; Barresi, A.A.; Marchisio, D. A modelling and experimental study on the co-precipitation of Ni0.8Mn0.1Co0.1(OH)2 as precursor for battery cathodes. Chem. Eng. Sci. 2022, 254, 117634. [Google Scholar] [CrossRef]

- Zhang, H.W.; Cen, T.; Tian, Y.H.; Zhang, X.J. Synthesis of high-performance single-crystal LiNi0.8Co0.1Mn0.1O2 cathode materials by controlling solution super-saturation. J. Power Sources 2022, 532, 231037. [Google Scholar] [CrossRef]

- Kumar, D.; Kurian, E.; Ramesha, K. Synthesis of quasi-spherical LiNi0.86Mn0.1Co0.04O2 cathode particles via hydroxide coprecipitation: Influence of pH on precursor particle size in enhancing capacity and stability of Ni-rich cathode for lithium-ion batteries. Energy Technol. 2025, 2402418. [Google Scholar] [CrossRef]

- Duan, J.H.; Zhang, R.C.; Zhu, Q.H.; Xiao, H.; Huang, Q.S. The effect of controlling strategies of pH and ammonia concentration on preparing full concentration gradient Ni0.8Co0.1Mn0.1(OH)2 via co-precipitation in a pilot-scale reactor. Energy Technol. 2020, 8, 1901437. [Google Scholar] [CrossRef]

- Park, B.H.; Kim, T.; Park, H.; Sohn, Y.; Shin, J.; Kang, M. Electrochemical performance of layer-structured Ni0.8Co0.1Mn0.1O2 cathode active materials synthesized by carbonate co-precipitation. Nanomaterials 2022, 12, 3610. [Google Scholar] [CrossRef]

- Shen, W.-Z.; Ma, Y.; Yao, C.; Liang, F. Controlling the precursor morphology of Ni-rich LiNi0.8Co0.1Mn0.1O2 cathode for lithium-ion battery. Nano 2019, 14, 100–108. [Google Scholar] [CrossRef]

- Hu, K.H.; He, Y.Y.; Zhu, C.Q.; Zhou, K.; Chen, Q.; Yang, Z.M.; Wan, B.-R.; Yang, E.-Q.; Zhang, T.-T.; Qin, Y.-D. Insight into the evolution of precursor and electrochemical performance of Ni-rich cathode modulated by ammonia during hydroxide precipitation. J. Alloys Compd. 2019, 803, 538–545. [Google Scholar] [CrossRef]

- Liang, H.L.; Yuan, S.; Shi, L.Y.; Zhao, Y.; Wang, Z.Y.; Zhu, J.F. Highly-ordered microstructure and well performance of LiNi0.6Mn0.2Co0.2O2 cathode material via the continuous microfluidic synthesis. Chem. Eng. J. 2020, 394, 124846. [Google Scholar] [CrossRef]

- Zou, L.; Li, J.; Liu, Z.; Wang, G.; Manthiram, A.; Wang, C. Lattice doping regulated interfacial reactions in cathode for enhanced cycling stability. Nat. Commun. 2019, 10, 3447. [Google Scholar] [CrossRef] [PubMed]

- Park, H.W.; Hwang, J.U.; Im, J.S.; Lee, J.D. Electrochemical properties of LiNi0.9Co0.1O2 cathode material prepared by co-precipitation using an eco-friendly chelating agent. J. Solid State Electrochem. 2022, 26, 1567–1576. [Google Scholar] [CrossRef]

- Li, F.; Liu, Z.; Shen, J.; Xu, X.; Zeng, L.; Zhang, B.; Zhu, H.; Liu, Q.; Liu, J.; Zhu, M. A nanorod-like Ni-rich layered cathode with enhanced Li+ diffusion pathways for high-performance lithium-ion batteries. J. Mater. Chem. 2021, 9, 2830–2839. [Google Scholar] [CrossRef]

- Wang, X.; Wang, S.; Ren, L.; Wu, W.; Zuo, M.; Xing, W.; Zhang, B.; Fan, W.; He, Z.; Yu, Z.; et al. Micro-structure tuning and evolution of hydroxide precursor with radially oriented grains during industrial-scale continuous precipitation process. J. Alloys Compd. 2024, 977, 173458. [Google Scholar] [CrossRef]

- Zhou, X.; Hong, F.; Wang, S.; Zhao, T.; Peng, J.; Zhang, B.; Fan, W.; Xing, W.; Zuo, M.; Zhang, P.; et al. Precision engineering of high-performance Ni-rich layered cathodes with radially aligned microstructure through architectural regulation of precursors. eScience 2024, 4, 100276. [Google Scholar] [CrossRef]

- Zhu, Q.H.; Xiao, H.; Zhang, R.C.; Geng, S.J.; Huang, Q.S. Effect of impeller type on preparing spherical and dense Ni1-x-yCoxMny(OH)2 precursor via continuous co-precipitation in pilot scale: A case of Ni0.6Co0.2Mn0.2(OH)2. Electrochim. Acta 2019, 318, 1–13. [Google Scholar] [CrossRef]

- Wu, J.; Li, H.; Liu, Y.; Ye, Y.; Yang, Y. Facile synthesis and electrochemical performance of lithium-rich layered oxides with stable hierarchical structure through HEPES-assisted co-precipitation method. Electrochim. Acta 2022, 401, 139485. [Google Scholar] [CrossRef]

- Zhang, J.; Zhai, X.; Zhao, T.; Yang, X.; Wang, Q.; Chen, Z.; Chen, M.-C.; Ma, J.-J.; Lu, Y.-R.; Hung, S.-F.; et al. What impact does ammonia have on the microstructure of the precursor and the electrochemical performance of Ni-rich layered oxides? J. Mater. Chem. A 2025, 13, 1181–1190. [Google Scholar] [CrossRef]

- Kim, E.; Cho, Y.H.; Shin, J.H.; Eun, H.J.; Song, H.I.; Lee, S.-H.; Suk, J.; Moon, S. Unlocking the superior performance of Ni-rich layered materials through precise precursor engineering. J. Eur. Ceram. Soc. 2025, 45, 117280. [Google Scholar] [CrossRef]

- Lao, J.; Lu, Y. Synthesis of nano cubic microstructure LiNi0.8Co0.1Mn0.1O2 cathode materials via rapid precipitation assisted with hydrothermal treatment. Heliyon 2024, 10, e40201. [Google Scholar] [CrossRef]

- Chen, A.; Wang, K.; Li, J.; Mao, Q.; Xiao, Z.; Zhu, D.; Wang, G.; Liao, P.; He, J.; You, Y.; et al. The formation, detriment and solution of residual lithium compounds on Ni-rich layered oxides in lithium-ion batteries. Front. Energy Res. 2020, 8, 593009. [Google Scholar] [CrossRef]

- Li, W.D.; Erickson, E.M.; Manthiram, A. High-nickel layered oxide cathodes for lithium-based automotive batteries. Nat. Energy 2020, 5, 26–34. [Google Scholar] [CrossRef]

- Wang, L.; Liu, T.; Dai, A.; De Andrade, V.; Ren, Y.; Xu, W.; Lee, S.; Zhang, Q.; Gu, L.; Wang, S.; et al. Reaction inhomogeneity coupling with metal rearrangement triggers electrochemical degradation in lithium-rich layered cathode. Nat. Commun. 2021, 12, 5370. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Lu, X.; Zhang, Y.; Zhou, J.; Wang, J.; Xu, S. Grain size regulation for balancing cycle performance and rate capability of LiNi0.9Co0.055Mn0.045O2 single crystal nickel-rich cathode materials. J. Energy Chem. 2022, 65, 681–687. [Google Scholar] [CrossRef]

- Jeyakumar, J.; Seenivasan, M.; Wu, Y.-S.; Wu, S.-H.; Chang, J.-K.; Jose, R.; Yang, C.-C. Preparation of long-term cycling stable Ni-rich concentration-gradient NCMA cathode materials for li-ion batteries. J. Colloid Interface Sci. 2023, 639, 145–159. [Google Scholar] [CrossRef] [PubMed]

- Liang, W.; Jin, F.; Zhao, Y.; Shi, L.; Liu, Q.; Wang, Z.; Wang, Y.; Zhang, M.; Zhu, J.; Yuan, S. Synthesis of single-crystal LiNi0.8Co0.1Mn0.1O2 materials for Li-ion batteries by microfluidic technology. Chem. Eng. J. 2023, 464, 142656. [Google Scholar] [CrossRef]

- Riewald, F.; Kurzhals, P.; Bianchini, M.; Sommer, H.; Janek, J.; Gasteiger, H.A. The LiNiO2 cathode active material: A comprehensive study of calcination conditions and their correlation with physicochemical properties part II. Morphology. J. Electrochem. Soc. 2022, 169, 020529. [Google Scholar] [CrossRef]

- Yu, Z.; Qu, X.; Wan, T.; Dou, A.; Zhou, Y.; Peng, X.; Su, M.; Liu, Y.; Chu, D. Synthesis and mechanism of high structural stability of nickel-rich cathode materials by adjusting Li-excess. ACS Appl. Mater. Interfaces 2020, 12, 40393–40403. [Google Scholar] [CrossRef]

- Kan, H.; Yang, Z.; Meng, Q.; Dong, P.; Zhang, Y. Preparation and electrochemical performance of the Ni-rich Co-free cathode material LiNi0.94Mn0.04Al0.02O2. Energy Fuels 2024, 38, 6420–6426. [Google Scholar] [CrossRef]

- Kim, Y.; Park, H.; Warner, J.H.; Manthiram, A. Unraveling the intricacies of residual lithium in high-Ni cathodes for lithium-ion batteries. ACS Energy Lett. 2021, 6, 941–948. [Google Scholar] [CrossRef]

- Li, J.; Liang, G.; Zheng, W.; Zhang, S.; Davey, K.; Pang, W.K.; Guo, Z. Addressing cation mixing in layered structured cathodes for lithium-ion batteries: A critical review. Nano Mater. Sci. 2023, 5, 404–420. [Google Scholar] [CrossRef]

- Li, X.Q.; Xiong, X.; Wang, Z.; Chen, Q. Effect of sintering temperature on cycling performance and rate performance of LiNi0.8Co0.1Mn0.1O2. Trans. Nonferr. Met. Soc. China 2014, 24, 4023–4029. [Google Scholar] [CrossRef]

- Ding, Y.; Mu, D.; Wu, B.; Wang, R.; Zhao, Z.; Wu, F. Recent progresses on nickel-rich layered oxide positive electrode materials used in lithium-ion batteries for electric vehicles. Appl. Energy 2017, 195, 586–599. [Google Scholar] [CrossRef]

- Wang, L.; Lei, X.; Liu, T.; Dai, A.; Su, D.; Amine, K.; Lu, J.; Wu, T. Regulation of surface defect chemistry toward stable Ni-rich cathodes. Adv. Mater. 2022, 34, 2200744. [Google Scholar] [CrossRef]

- Xu, Z.; Wang, Z.; Tan, X.; Guo, H.; Peng, W.; Li, X.; Wang, J.; Yan, G. Correlating morphological and structural evolution with the electrochemical performance of nickel-rich cathode materials: From polycrystal to single crystal. J. Electrochem. Soc. 2022, 169, 090520. [Google Scholar] [CrossRef]

- Allen, E.; Shin, Y.; Judge, W.; Wolfman, M.; De Andrade, V.; Cologna, S.M.; Cabana, J. 3D quantification of elemental gradients within heterostructured particles of battery cathodes. ACS Energy Lett. 2023, 8, 1371–1378. [Google Scholar] [CrossRef]

- Lee, W.; Lee, D.; Kim, Y.; Choi, W.; Yoon, W.-S. Enhancing the structural durability of Ni-rich layered materials by post-process: Washing and heat-treatment. J. Mater. Chem. A 2020, 8, 10206–10216. [Google Scholar] [CrossRef]

- Karger, L.; Korneychuk, S.; Sicolo, S.; Li, H.; van der Bergh, W.; Zhang, R.; Indris, S.; Kondrakov, A.; Janek, J.; Brezesinski, T. Decoupling substitution effects from point defects in layered Ni-rich oxide cathode materials for lithium-ion batteries. Adv. Funct. Mater. 2024, 34, 2402444. [Google Scholar] [CrossRef]

- Wang, T.; Ren, K.; Xiao, W.; Dong, W.; Qiao, H.; Duan, A.; Pan, H.; Yang, Y.; Wang, H. Tuning the Li/Ni disorder of the NMC811 cathode by thermally driven competition between lattice ordering and structure decomposition. J. Phys. Chem. C 2020, 124, 5600–5607. [Google Scholar] [CrossRef]

- Mo, Y.; Liu, S.; Yuan, G.; Li, Z.; Zhang, M.; Guo, L. Enhancing the reversibility of the chemical evolution of the Ni-rich LiNi0.8Co0.1Mn0.1O2 cathode via a simple pre-oxidation process. RSC Adv. 2024, 14, 2889–2895. [Google Scholar] [CrossRef] [PubMed]

- Xu, X.; Huo, H.; Jian, J.-Y.; Wang, L.-G.; Zhu, H.; Xu, S.; He, X.-S.; Yin, G.-P.; Du, C.-Y.; Sun, X.-L. Radially oriented single-crystal primary nanosheets enable ultrahigh rate and cycling properties of LiNi0.8Co0.1Mn0.1O2 cathode material for lithium-ion batteries. Adv. Energy Mater. 2019, 9, 1803963. [Google Scholar] [CrossRef]

- Wang, T.; Ren, K.; He, M.; Dong, W.; Xiao, W.; Pan, H.; Yang, J.; Yang, Y.; Liu, P.; Cao, Z.; et al. Synthesis and manipulation of single-crystalline lithium nickel manganese cobalt oxide cathodes: A review of growth mechanism. Front. Chem. 2020, 8, 747. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Harlow, J.; Dahn, J. Microstructural observations of “single crystal” positive electrode materials before and after long term cycling by cross-section scanning electron microscopy. J. Electrochem. Soc. 2020, 167, 020512. [Google Scholar] [CrossRef]

- Kong, X.; Zhang, Y.; Peng, S.; Zeng, J.; Zhao, J. Superiority of single crystal to polycrystalline LiNixCoyMn1-x-yO2 cathode materials in storage behaviors for lithium-ion batteries. ACS Sustain. Chem. Eng. 2020, 8, 14938–14948. [Google Scholar] [CrossRef]

- Lüther, M.J.; Jiang, S.-K.; Lange, M.A.; Buchmann, J.; Martin, A.G.; Schmuch, R.; Placke, T.; Hwang, B.J.; Winter, M.; Kasnatscheew, J. Systematic “apple-to-apple” comparison of single-crystal and polycrystalline Ni-rich cathode active materials: From comparable synthesis to comparable electrochemical conditions. Small 2024, 5, 2400119. [Google Scholar] [CrossRef]

- Qian, G.; Zhang, Y.; Li, L.; Zhang, R.; Xu, J.; Chen, Z.; Xie, S.; Wang, H.; Rao, Q.; He, Y.; et al. Single-crystal nickel-rich layered-oxide battery cathode materials: Synthesis, electrochemistry, and intra-granular fracture. Energy Storage Mater. 2020, 27, 140–149. [Google Scholar] [CrossRef]

- Fan, X.-M.; Hu, G.-R.; Zhang, B.; Ou, X.; Zhang, J.-F.; Zhao, W.-G.; Jia, H.-P.; Zou, L.F.; Li, P.; Yang, Y. Crack-free single crystalline Ni-rich layered NCM cathode enable superior cycling performance of lithium-ion batteries. Nano Energy 2020, 70, 104450. [Google Scholar] [CrossRef]

- Pang, P.; Tan, X.; Wang, Z.; Cai, Z.; Nan, J.; Xing, Z.; Li, H. Crack-free single-crystal LiNi0.83Co0.10Mn0.07O2 as cycling/thermal stable cathode materials for high-voltage lithium-ion batteries. Electrochim. Acta 2021, 365, 137380. [Google Scholar] [CrossRef]

- Han, Y.; Xu, J.; Wang, W.; Long, F.; Qu, Q.; Wang, Y.; Zheng, H. Implanting an electrolyte additive on a single crystal Ni-rich cathode surface for improved cycle ability and safety. J. Mater. Chem. A 2020, 8, 24579–24589. [Google Scholar] [CrossRef]

- Chen, X.; Tang, Y.; Fan, C.; Han, S. A highly stabilized single crystalline nickel-rich LiNi0.8Co0.1Mn0.1O2 cathode through a novel surface spinel-phase modification. Electrochim. Acta 2020, 341, 136075. [Google Scholar] [CrossRef]

- Ge, M.; Wi, S.; Liu, X.; Bai, J.; Ehrlich, S.; Lu, D.; Lee, W.K.; Chen, Z.; Wang, F. Kinetic limitations in single-crystal high-nickel cathodes. Angew. Chem. Int. Ed. 2021, 60, 17350–17355. [Google Scholar] [CrossRef]

- You, B.; Wang, Z.; Shen, F.; Chang, Y.; Peng, W.; Li, X.; Guo, H.; Hu, Q.; Deng, C.; Yang, S.; et al. Research progress of single-crystal nickel-rich cathode materials for lithium-ion batteries. Small Methods 2021, 5, 2100234. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Wang, E.; Zhang, X.; Yu, H. High-voltage “single-crystal” cathode materials for lithium-ion batteries. Energy Fuels 2021, 35, 918–932. [Google Scholar] [CrossRef]

- Han, Y.; Lei, Y.; Ni, J.; Zhang, Y.; Geng, Z.; Ming, P.; Zhang, C.; Tian, X.; Shi, J.-L.; Guo, Y.; et al. Single-crystalline cathodes for advanced Li-ion batteries: Progress and challenges. Small 2022, 18, 2107048. [Google Scholar] [CrossRef]

- Zhao, W.; Zou, L.; Zhang, L.; Fan, X.; Zhang, H.; Pagani, F.; Brack, E.; Seidl, L.; Ou, X.; Egorov, K.; et al. Assessing long-term cycling stability of single-crystal versus polycrystalline nickel-rich NCM in pouch cells with 6 mAh cm−2 electrodes. Small 2022, 18, 2107357. [Google Scholar] [CrossRef]

- Zhang, F.; Lou, S.; Li, S.; Yu, Z.; Liu, Q.; Dai, A.; Cao, C.; Toney, M.F.; Ge, M.; Xiao, X.; et al. Surface regulation enables high stability of single-crystal lithium-ion cathodes at high voltage. Nat. Commun. 2020, 11, 3050. [Google Scholar] [CrossRef]

- Hu, J.; Li, L.; Bi, Y.; Tao, J.; Lochala, J.; Liu, D.; Wu, B.; Cao, X.; Chae, S.; Wang, C.; et al. Locking oxygen in lattice: A quantifiable comparison of gas generation in polycrystalline and single crystal Ni-rich cathodes. Energy Storage Mater. 2022, 47, 195–202. [Google Scholar] [CrossRef]

- Ge, J.; Xie, M.; Zhao, Q.; Zhang, S.; Sun, H. Advances in Co-free layered cathode materials for Li-ion batteries. Int. J. Electrochem. Sci. 2023, 18, 100292. [Google Scholar] [CrossRef]

- Huang, H.; Zhang, L.; Tian, H.; Yan, J.; Tong, J.; Liu, X.; Zhang, H.; Huang, H.; Hao, S.; Gao, J.; et al. Pulse high temperature sintering to prepare single-crystal high nickel oxide cathodes with enhanced electrochemical performance. Adv. Energy Mater. 2023, 13, 2203188. [Google Scholar] [CrossRef]

- Li, H.; Wang, L.; Song, Y.; Zhang, Z.; Du, A.; Tang, Y.; Wang, J.; He, X. Why the synthesis affects performance of layered transition metal oxide cathode materials for Li-ion batteries. Adv. Mater. 2024, 36, 2312292. [Google Scholar] [CrossRef] [PubMed]

- Ma, Y.; Lv, F.; Wang, Z.; Feng, J.; Wu, M.; Liu, Z.; Chen, L.; Gu, Y. Open-channel [011] facet CeO2 with a shorter pathway of Li+ migration as a modification material for LiNi0.8Co0.1Mn0.1O2 toward high-rate lithium-ion batteries. ACS Sustain. Chem. Eng. 2020, 8, 8795–8802. [Google Scholar] [CrossRef]

- Liu, H.-W.; Parthasarathi, S.-K.; Thi, S.; Weng, Y.-T.; Bolloju, S.; Chen, C.C.; Jeng, R.-J.; Wu, N.-L. A comparative study of polycrystal/single-crystal LiNi0.8Co0.1Mn0.1O2 in all-solid-state Li-ion batteries with halide-based electrolyte under low stacking pressure. Energy Technol. 2023, 11, 2201439. [Google Scholar] [CrossRef]

- Zhang, Q.; Wang, Y.; Deng, Q.; Chu, Y.; Dong, P.; Chen, C.; Wang, Z.; Xia, Z.; Yang, C. In situ and real-time monitoring the chemical and thermal evolution of lithium-ion batteries with single-crystalline Ni-rich layered oxide cathode. Angew. Chem. Int. Ed. 2024, 63, e202401716. [Google Scholar] [CrossRef]

- Liu, X.; Zheng, B.; Zhao, J.; Zhao, W.; Liang, Z.; Su, Y.; Xie, C.; Zhou, K.; Xiang, Y.; Zhu, J.; et al. Electrochemo-mechanical effects on structural integrity of Ni-rich cathodes with different microstructures in all solid-state batteries. Adv. Energy Mater. 2021, 11, 2003583. [Google Scholar] [CrossRef]

- Zhu, H.; Tang, Y.; Wiaderek, K.M.; Borkiewicz, O.J.; Ren, Y.; Zhang, J.; Ren, J.; Fan, L.; Li, C.C.; Li, D.; et al. Spontaneous strain buffer enables superior cycling stability in single-crystal nickel-rich NCM cathode. Nano Lett. 2021, 21, 9997–10005. [Google Scholar] [CrossRef]