1. Introduction

The automotive industry has faced growing concerns regarding energy efficiency and sustainability in recent years, driven by the urgent need to reduce greenhouse gas emissions and reliance on fossil fuels [

1]. As a response, various strategies have been developed to improve vehicle efficiency, including the implementation of energy recovery systems [

2]. These systems aim to recover and reuse energy that would otherwise be lost during vehicle operation, contributing to overall fuel efficiency and a reduced environmental impact [

3]. For instance, regenerative braking systems have been widely adopted in electric and hybrid vehicles, converting kinetic energy during deceleration into electrical energy to be stored and reused [

4]. Similarly, energy-harvesting suspension systems have gained attention as a promising approach to recover energy from road-induced vibrations [

5]. By transforming the energy generated during suspension movements into usable electrical energy, these systems can further enhance vehicle efficiency by capturing and reusing energy that would otherwise be dissipated as waste [

6].

Various types of energy-harvesting suspension systems have been proposed and studied, including hydraulic, electromagnetic, and piezoelectric dampers [

7].

Electromagnetic dampers have gained attention due to their potential for high energy recovery efficiency, compact design, and compatibility with existing suspension systems [

8]. These dampers typically consist of a coil and a magnet, with the coil producing an electromotive force when the magnet moves relative to it, thus generating electrical energy [

9]. The energy recovered can then be used to power auxiliary systems, such as lighting or electronic devices, or even to recharge the battery in electric and hybrid vehicles [

3].

Despite the potential advantages, implementing efficient energy-harvesting suspension systems remains challenging. Some of the key issues include optimizing the energy conversion process, addressing the low-frequency nature of suspension systems (typically around 10 Hz), and minimizing the impact on ride comfort and road handling [

10]. Additionally, further research is needed to identify suitable materials and designs that can maximize energy recovery while maintaining durability and reliability in real-world conditions.

In the quest for improved vehicle energy efficiency, several energy-harvesting suspension system (EHSA) designs have been proposed and studied in the literature, each with its unique advantages and drawbacks. This section provides a brief review of these approaches, highlighting their strengths and limitations, and emphasizing the need for new, innovative solutions.

Hydraulic EHSA: Hydraulic energy-harvesting dampers involve the use of a hydraulic pump and motor to convert the mechanical energy generated by suspension movements into electrical energy [

5]. The primary advantage of hydraulic systems is their ability to handle high forces and displacements, resulting in potentially high energy recovery rates [

11]. However, these systems tend to be bulky, complex, and may suffer from fluid leakage and maintenance issues. Additionally, the efficiency of hydraulic energy recovery is highly dependent on the damping coefficient and the design of the pump and motor, which can be challenging to optimize.

Electromagnetic EHSA: As mentioned earlier, electromagnetic dampers have gained considerable interest in recent years. These systems employ a coil and a magnet to generate electrical energy through electromagnetic induction, offering advantages such as a compact design, compatibility with existing suspension systems, and a potentially high energy recovery efficiency [

12]. However, challenges remain in optimizing the energy conversion process, addressing the low-frequency nature of suspension systems, and minimizing the impact on ride comfort and road handling.

Piezoelectric EHSA: Piezoelectric energy-harvesting dampers utilize piezoelectric materials to convert mechanical energy into electrical energy through the piezoelectric effect [

13]. These systems are lightweight, compact, and have the potential for high energy conversion efficiency. However, they tend to be more suitable for applications with high-frequency vibrations, as the energy recovery efficiency decreases significantly at low frequencies, such as those typically encountered in suspension systems. Additionally, the need for complex power-conditioning circuits and the relatively high cost of piezoelectric materials can be limiting factors for the widespread adoption of piezoelectric EHSAs [

14].

Despite the progress made in the development of EHSAs, there remains significant room for improvement in terms of energy recovery efficiency, durability, and cost-effectiveness. Consequently, there is a need for innovative solutions that address the challenges and limitations, such as the simultaneous application of hard and soft magnetic materials in electromagnetic dampers. By exploring new materials, designs, and control strategies, researchers can potentially develop more efficient and practical EHSAs that contribute to the broader goal of sustainable transportation.

Innovative solutions, such as the proposed simultaneous application of hard and soft magnetic materials in electromagnetic dampers, hold the potential to overcome these limitations and pave the way for more effective energy-harvesting suspension systems. By exploring novel materials, designs, and control strategies, researchers can push the boundaries of current technologies and contribute to the development of more efficient, durable, and cost-effective EHSAs that are well-suited for real-world applications.

Magnetic energy-harvesting shock absorbers (EHSAs) have emerged as a promising approach for recovering energy from suspension systems, employing permanent magnets and coils to generate electrical energy through electromagnetic induction [

15]. This section reviews the design of magnetic EHSAs, discussing the advantages and limitations of various configurations, as well as identifying research opportunities in the literature.

Linear electromagnetic EHSAs: In this design, a coil is wound around a tubular structure, while a permanent magnet is attached to the piston of the damper, which moves linearly within the coil [

16]. When the suspension undergoes vibrations, the relative motion between the magnet and the coil induces an electromotive force, generating electrical energy. Linear electromagnetic EHSAs offer the advantages of a simple design, compatibility with conventional suspension systems, and a potentially high energy recovery efficiency. However, they face challenges in optimizing the energy conversion process.

Rotary electromagnetic EHSAs: Rotary designs convert the linear motion of the suspension system into rotational motion, which drives a generator to produce electrical energy. Various forms of rotational electromagnetic dampers exist. Given that vehicle suspensions engage in translational movement, the creation of a rotationally variable magnetic field necessitates a mechanism that transforms this translational motion into a rotational one. There are several well-established systems that achieve this conversion, including rack–pinion [

17], hydraulic systems [

18], ball-screw mechanisms [

19], and even more unconventional methods such as the “Screw Linkage Mechanism” [

20], “Two-Leg Motion” [

21], or those utilizing a flywheel drive [

22]. Each of these systems comes with its own set of equivalent inertias, backlashes, and frictional forces that can influence the dynamic behavior of the shock absorber, and consequently, the vehicle’s overall performance. Rotary electromagnetic EHSAs can offer a higher energy conversion efficiency than linear designs, particularly at low frequencies, due to the increased mechanical advantage provided by the conversion mechanism. However, the complexity of the mechanical linkage may introduce additional friction losses, reduce reliability, and increase manufacturing costs.

Both linear and rotary magnetic EHSAs have demonstrated the potential for energy recovery from suspension systems, but several challenges remain. Key areas of ongoing research include the optimization of magnet and coil configurations, the development of advanced materials, and the integration of energy-harvesting systems with active suspension control strategies. For instance, the use of hard and soft magnetic materials, as well as amorphous cores in the coil, can potentially enhance energy recovery and overcome the limitations associated with low-frequency operation. Furthermore, the exploration of novel geometries and coil designs may lead to a more efficient energy conversion and reduced impact on ride comfort and handling.

In conclusion, magnetic EHSAs represent a promising avenue for improving vehicle energy efficiency, with both linear and rotary designs offering unique advantages and opportunities for further research. By addressing the challenges and limitations of current EHSA designs, researchers can contribute to the development of more efficient, durable, and practical energy-harvesting suspension systems that pave the way for a more sustainable future in transportation.

In conclusion, energy-harvesting suspension systems have gained significant attention in recent years as a promising avenue for improving vehicle energy efficiency and promoting sustainability in transportation. Various approaches, including hydraulic, electromagnetic, and piezoelectric dampers, have been explored and studied in the literature, with each offering unique advantages and challenges. However, existing designs have yet to fully address the demands of low-frequency operation, high energy recovery efficiency, and minimal impact on ride comfort and road handling.

The state of the art reveals a need for innovative solutions to overcome these limitations and optimize energy recovery in suspension systems. The novelty proposed in this article, focusing on the simultaneous application of hard and soft magnetic materials and the optimal positioning of an amorphous core within the coil, has the potential to address some of the challenges faced by current magnetic EHSAs, particularly in the context of low-frequency operation.

In a previous article [

9], the feasibility of the system was studied, specifically presenting an experimental method to maximize energy recovery by defining the optimal relative position between the primary element (magnet) and the secondary element (energy-harvesting coil). In this article, a prototype is developed to demonstrate and optimize the functioning of the proposed system as a concept. Tests are conducted with the prototype to obtain not only energy recovery results but also conclusions regarding design improvements aimed at optimizing the demonstrator system. Additionally, the optimal shape and position of the amorphous core in the energy-harvesting coil are studied in detail to recover the maximum energy and address the challenge posed by the low operating frequency of a suspension system (on the order of 10 Hz).

Furthermore, the use of NdFeB magnets in the proposed system aligns with the European Union funded REMANENCE initiative (Rare Earth Magnet Recovery for Environmental and Resource Protection), promoting the reusability of these critical materials and contributing to environmental sustainability [

23]. The article presents experimental data from the prototype testing, images of the fabricated prototype, and conclusions drawn from the obtained results.

The electromotive force, EMF, induced in the pick-up coil becomes the relevant parameter on the basis of the electromagnetic damping process. In this article, we study the influence of a ferromagnetic coil nucleus on the induced EMF in a coil subject to an alternating exciting magnetic field with a fixed amplitude and frequency. Instead of an oscillating magnet, we use a small coil fed by an AC source, as explained along the next paragraphs. In fact, as thoroughly discussed below, an oscillating magnet or an AC current coil are not equivalent in many physical aspects, but both generate a time-dependent flux through the pick-up coil that enables us to study the influence of the ferromagnetic nucleus. Moreover, the control of the time-dependent flux can be more easily achieved by using a coil.

To understand the starting point of the present article, it is useful to know the previous study that was carried out on this topic and published in [

9]. In that previous work, an experimental method was proposed to obtain the dependence of the flux variation through a coil according to the relative position between the primary and secondary elements.

The previous equation shows that, in order to calculate the electromotive force or flux variation of the secondary coil, in the case of a primary coil supplied with AC current, it is enough to know how the flux varies with time. However, when we have a magnet or a primary coil connected to DC current and in motion, which is equivalent in both cases to having a fixed oscillating current, the flux will be caused by the variation of the relative distance between the primary and secondary elements.

z being this relative distance, expressed as

, to obtain

, it is necessary to know the dependence

. To obtain this dependence in an analytical way it is necessary to solve very complex calculations. This complexity is noticeable for example in the flux calculation shown below. To calculate the magnetic flux through the secondary coil, it is necessary either to know the value of the perpendicular component of the magnetic field at all points on the surface of the coil, or to find the circulation of the potential vector (

A) along the contour

C of the secondary coil.

If

A is the vector potential created by a primary coil, the value of the vector potential of a point at the primary coil must be calculated for each point on the secondary coil, using the following equation.

Therefore, the flux through the secondary coil would be as follows:

If the vector potential

A is created by a magnet, its corresponding expression becomes:

Note that these parameters (

A and

) are time-dependent functions, which adds some difficulty.

In summary, as is known, in a coil with a contour

C, the flux is the integral along

C of the vector potential

A, and the calculation of both this integral and its integrand is often tedious. Particular methods can be used to solve this problem, including a finite element calculation or the method proposed in the paper [

9] summarized below.

Given the complexity of the previous calculations, it was decided to develop an experimental method, with which it was observed that taking measurements with a magnet–coil system is of high complexity and low accuracy in the data obtained; therefore, a method able to achieve the intended objective was proposed, using a coil–coil system.

To find the optimum position between the primary and secondary elements with which the maximum energy, i.e., the maximum induced electromotive force, is obtained, it is important to understand that:

- (i)

If the flux variation is to be obtained with a fixed coil, fed by AC current, the optimum position to achieve, at a fixed current intensity and frequency, a maximum induced electromotive force is the position of maximum flux.

The current flowing through the primary coil is given by the following expression:

The position of the maximum flux is given with coaxial coils and the minimum distance between them (

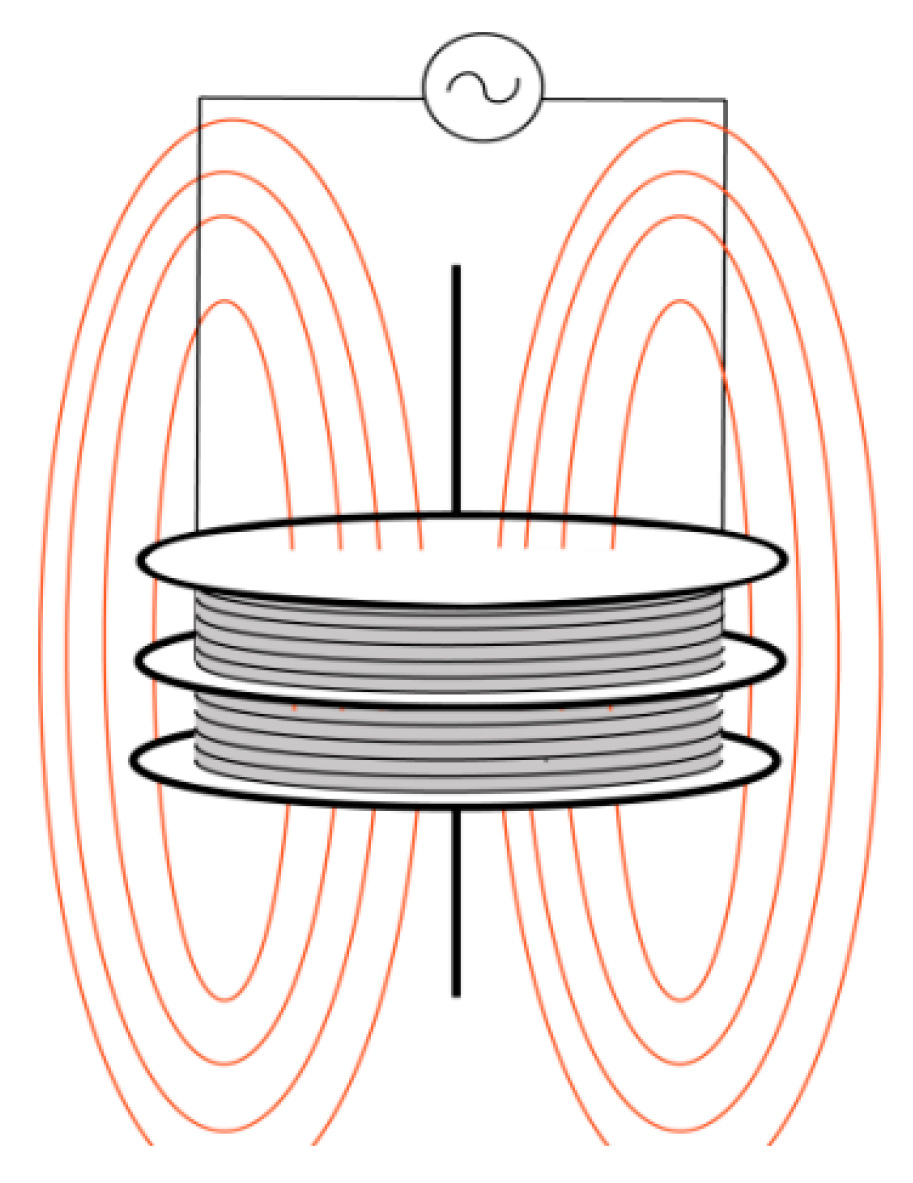

z = 0), as shown in

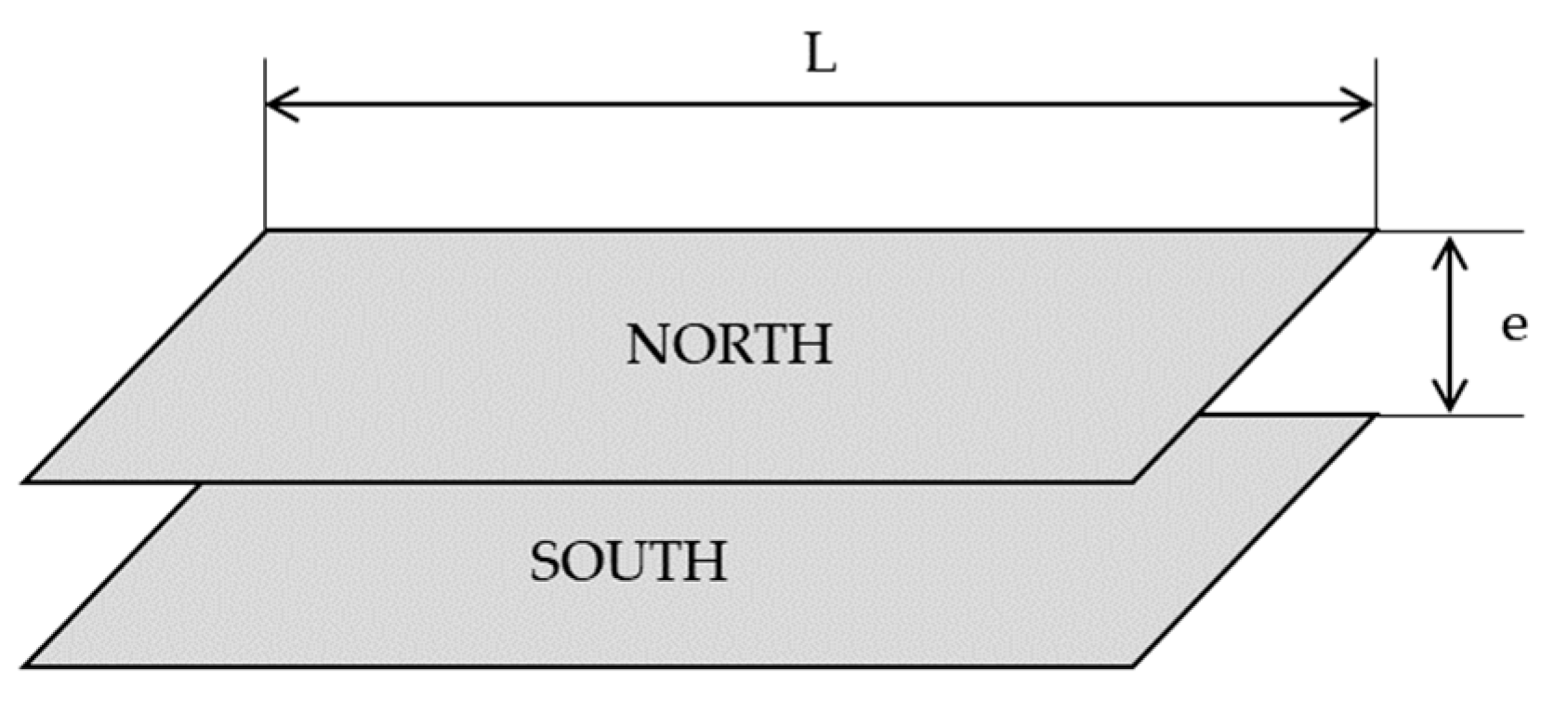

Figure 1 below.

- (ii)

If the flux variation is to obtained by the movement of the source, magnet, or coil, with respect to the secondary coil, the worst position is that of the maximum flux, because, by definition of the maximum, if the flux is maximum for a determined position of the source, x, the derivative of the flux with respect to x is annulled at that point and therefore the electromotive force induced by the displacement of the source (variation of x) is zero.

The movement of the source oscillating in the

z-axis, around the point

z* with amplitude

and oscillation frequency

can be expressed as follows:

These concepts are shown through equations in

Table 1:

It is possible to understand statements (i) and (ii) through the equations of the previous table focusing attention on the term , and knowing that this term expresses the relative position between the primary and secondary elements, it is observed that:

In the AC coil–coil system, both the flux and the EMF are directly proportional to the term , so the EMF is maximum at the same point where the magnetic flux is. However, in the DC coil–coil system, the flux is proportional to the term while the EMF is proportional to the derivative of that term, When is maximum, by definition, its derivative is zero .

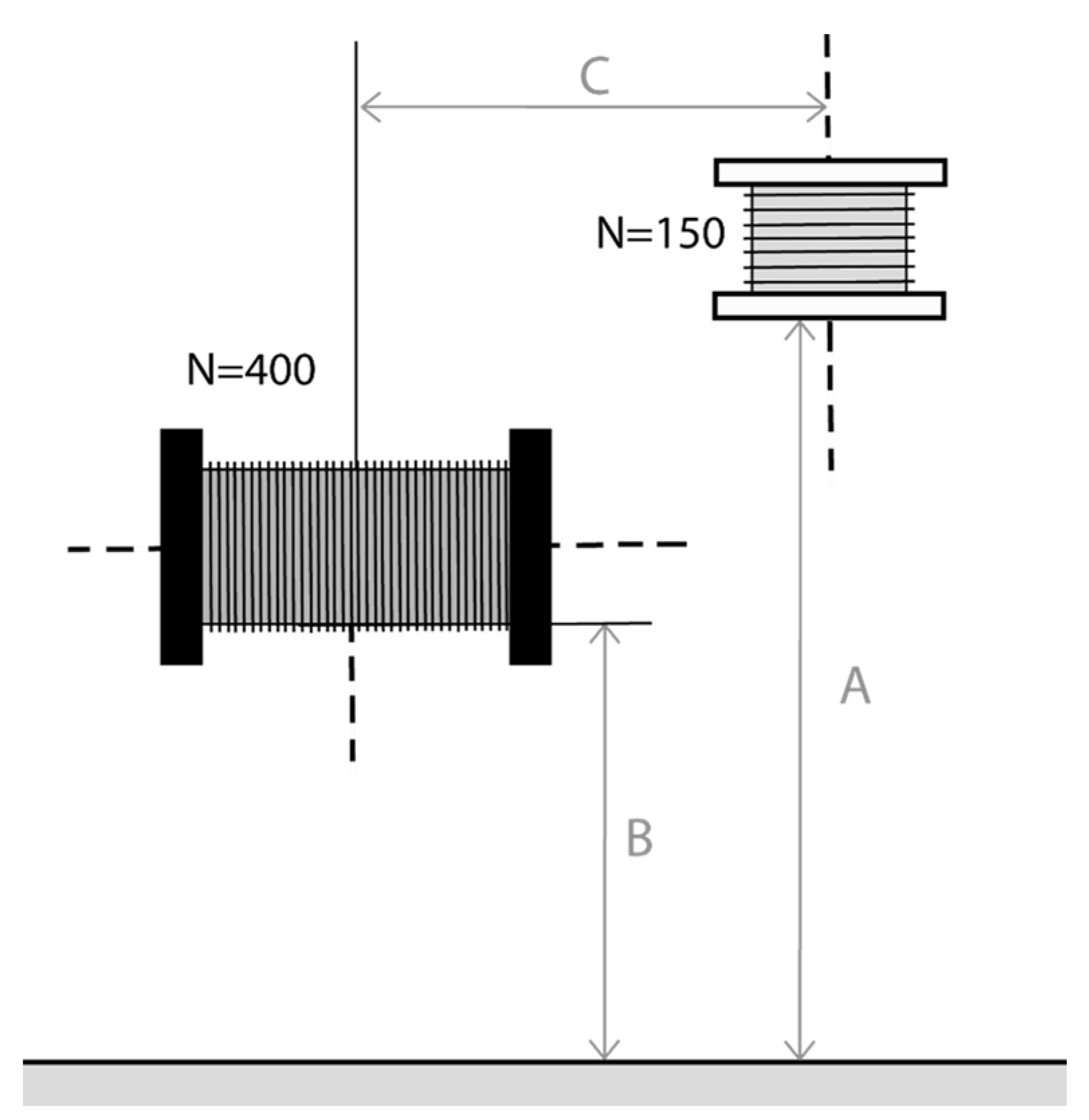

After defining the method, experimental measurements of induced electromotive force and its gradients were taken, in order to find the maximum gradient, for different relative positions of the system. The optimum position was the one corresponding to having the secondary coil oriented horizontally (

Figure 2) and with a height difference with respect to the primary element (A, B in the next scheme) of 3 cm. In that position, the maximum gradient was obtained more specifically in the section where the secondary coil moved from position

C = 0.5 cm to

C = 1 cm.

The results and conclusions of that first paper were taken as a starting point for the second part of the investigation. Using the demonstrator manufactured for this article, and the knowledge obtained from it about the optimum relative position between the primary and secondary elements, we also tried to optimize the secondary element, the energy collector coil. In order to improve the efficiency of the conversion into electromagnetic energy, the influence of a ferromagnetic nucleus was analyzed by using amorphous ferromagnetic ribbons with different relative positions with respect to the secondary coil. For this study, a theoretical study and some experimental tests were carried out.

It should be noted that the induced voltage in the case of an oscillating magnet with a fixed amplitude and frequency serves as a useful indicator of the potential power that can be harnessed from our system. There is a direct proportionality between the usable power and the square of the collected voltage; it is known that the maximum of the obtained power is achieved when the value of the load resistance is equal to the resistance of the secondary coil. However, the interest of this article is focused not in obtaining the maximum power but in inquiring about the maximum induced voltage.

2. Theoretical Approach

Until now, in the tests carried out in the first paper, the input used was a 1 kHz frequency signal, a much higher frequency than the one that the real system would have, so the results of the energy recovered were not quantitatively significant since they were not taken in real conditions. The real frequency generated by the suspension movement produced by the irregularities of the road in a vehicle is of the order of 10 Hz. The reason why such a high frequency was used in the tests is that at a low frequency, the energy recovered by the collector coil is almost insignificant. This is the origin of the problem to be solved in this section: it is necessary to optimize the system to increase the energy recovered from a frequency of the order of 10 Hz, which means that the output (energy obtained) must be multiplied without varying the input conditions (frequency). To do this, it is necessary to study the various ways in which it is possible to multiply the flux through the coil and implement those that optimize the system.

This problem can be divided into two different parts, focusing on the one hand on the multiplication of flux through the primary or inductor system and, on the other hand, through the secondary or induced system.

In the case of optimizing the primary system, some of the possibilities would be to increase the size of the magnets, increase their number, or vary their positions, but these are simple proposals that should be studied in detail.

In terms of optimizing the secondary system, namely, the collector coil, several strategies may be considered: increasing the number of turns in the coil, connecting multiple coils in series, and/or employing a core made of amorphous material. This article primarily focuses on optimizing the system through modifications to the secondary element, specifically by using an amorphous core.

Amorphous material consists of alloys of ferromagnetic materials with metalloids, such as Fe, B, Si, whose properties are due to the “disorder” of their atomic dipoles. The characteristic of interest of these materials for flux multiplication in the coil is magnetic permeability.

The effect of flux multiplication produced by a ferromagnetic nucleus of the pick-up coil increases with the magnetic permeability; therefore, it is necessary to use materials with a high permeability so that with a low external field H, the magnetic flux density is high. For our application, as the field is changing over time, in addition to a high permeability it is necessary that magnetic losses are as low as possible.

The real part of the magnetic permeability should be as high as possible in order to multiply the flux. This real component is inversely proportional to the magnetic anisotropy that, in metallic glasses, vanishes in the first order due to the random orientation of the local easy axes. An additional requirement rises when the exciting field and thereby, the magnetic flux, changes with time at a given frequency. In this case, to save energy, the losses should be low, but losses are reflected in the imaginary component of the permeability that is proportional to the anisotropy, magnetostriction, and electrical conductivity of the nucleus. These losses can come from the hysteresis cycle, proportional to the frequency, and/or from Eddy currents, proportional to the square of the frequency. Amorphous or metallic glasses [

24] are ideal for both; as they have negligible magnetic anisotropy and low conductivity, they exhibit a high real permeability and an extremely low imaginary component since the losses due to eddy currents, proportional to the conductivity, as well as those due to hysteresis, proportional to the anisotropy, are also low.

The ribbons used in this article were ferromagnetic amorphous alloy manufactured by rapid solidification at a speed of approximately . The brand name of this material is Metglas MBF-15, and its chemical composition is Ni76.5Fe4.2Cr13B2.8

Si

45. Such material has moderate magnetic properties, but it is mechanically outstanding thanks to its flexibility and ductility, relevant properties for constructing a robust device. It is characterized by a low positive magnetostriction constant (10

−6), low saturation magnetization (0.5 T), and a value of the complex permeability that remains constant up to 10 kHz [

25]. As is shown in [

25], the main source of losses, contributing to the imaginary component of the permeability in metallic glasses, comes from the magnetoelastic coupling. This mechanism starts to be effective at frequencies close to the first extensional elastic mode of the ribbon, which, for a length of a few centimeters, is above 10 kHz. These properties, besides its low cost, makes Metglas MBF-15 a suitable compound to obtain the general aspects of how reliable the application of amorphous core might be in energy-recovering devices. However, further research and experiments oriented to elucidate a more appropriate material, from a magnetic point of view, should be carried out. For example, using higher-saturation-magnetization Fe-rich compounds or low-magnetostriction cobalt-rich-based alloys or applying suitable stress relief annealing to magnetostrictive iron–nickel alloys. As is well known, these types of samples are outstanding as concerns losses reductions [

26,

27,

28].

It is possible to produce amorphous materials of different geometries, in particular, microwires and thin ribbons. For the experiments conducted in this research, we elected to use ribbons for the amorphous core of the coil instead of other options, such as microwires. The main reason for this decision was rooted in the ease of designing a reel and coil around a rectangular ribbon core as opposed to microwires, given the materials available in our laboratory. Furthermore, using ribbons allowed us to completely fill the core that encapsulates the coil, thereby preventing any air from remaining within the core. In the case of using thin rectangular ribbons of amorphous material, the orientation and thickness of the ribbon is important, as well as the number of ribbons used.

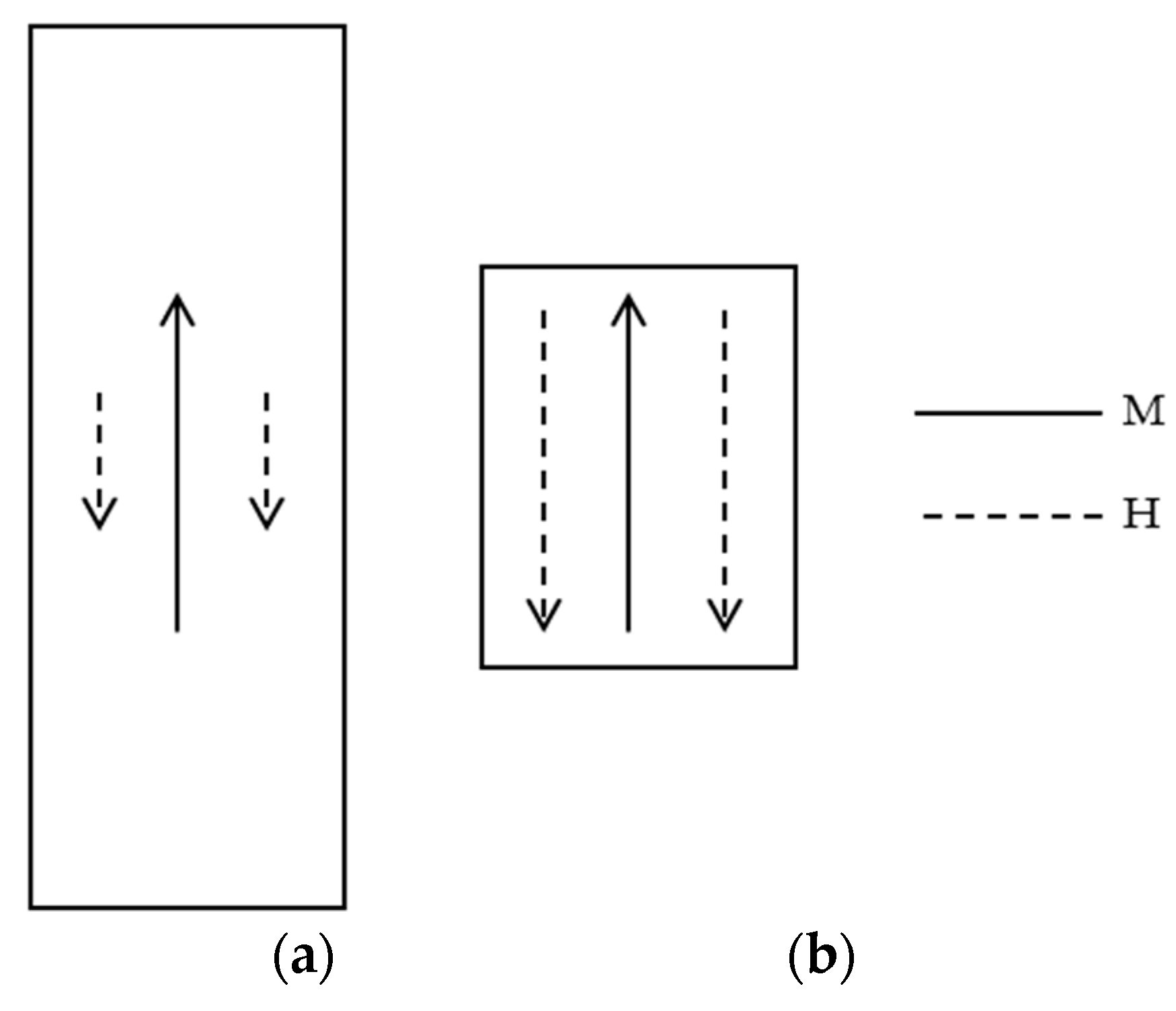

For a given charge density, as the distance between poles of different signs increases, the demagnetizing field

becomes smaller. This means that the longer the length of the ribbon, the lower its demagnetizing field, as shown in the next figure, in which the arrows with a dashed line represent the demagnetizing field and the arrows with a continuous line represent the magnetization of the material itself (

Figure 3).

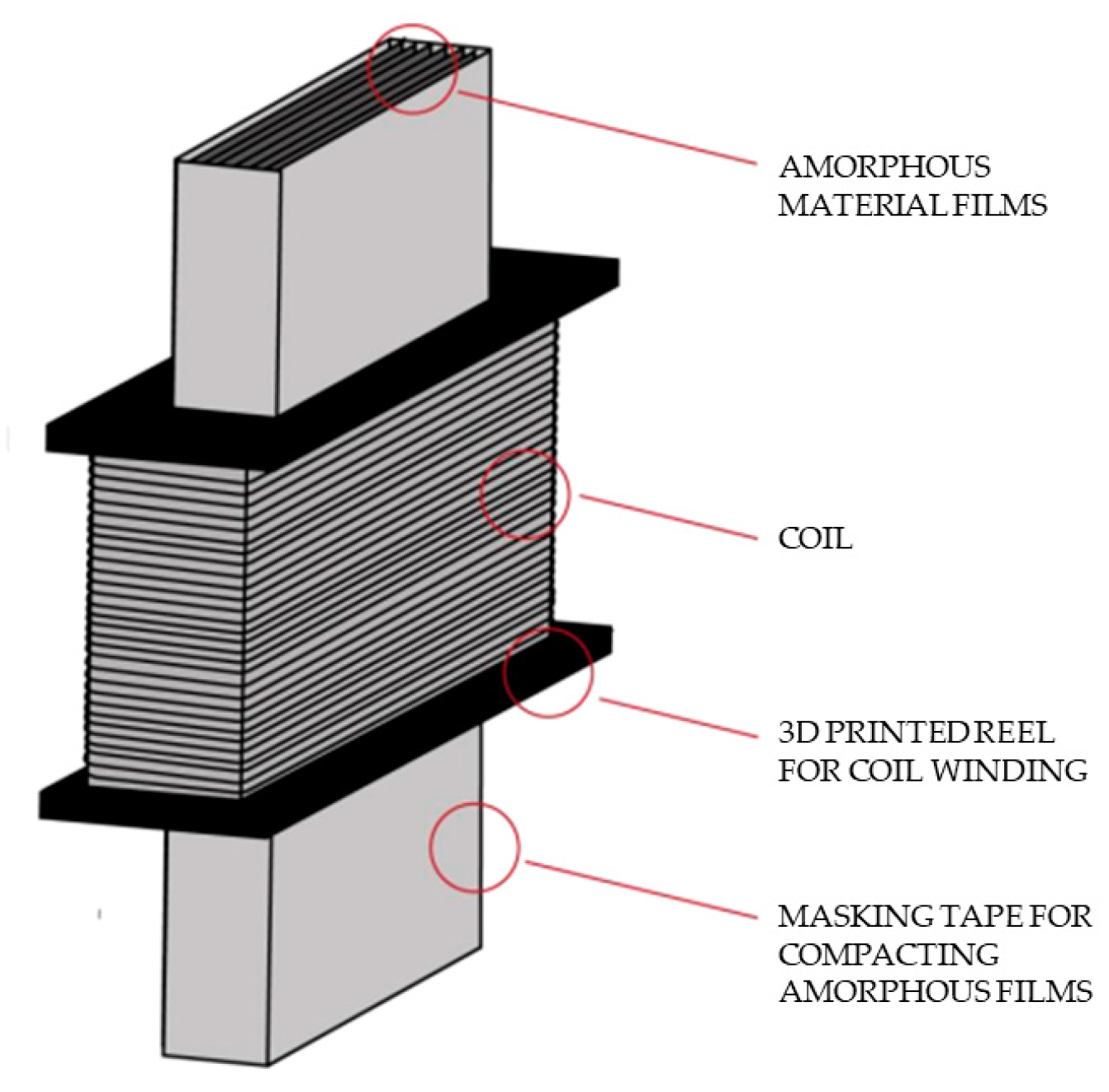

Below, the scheme of the amorphous film core coil that is used as an energy-recovery element in the tests of the present research is shown (

Figure 4).

Regarding the thickness of the ribbons, they should have a small thickness in order to maintain the amorphous structure during the cooling process. Moreover, the thicker they are, the greater the eddy currents (Foucault currents) are, which produce energy losses in the form of heat (Joule effect).

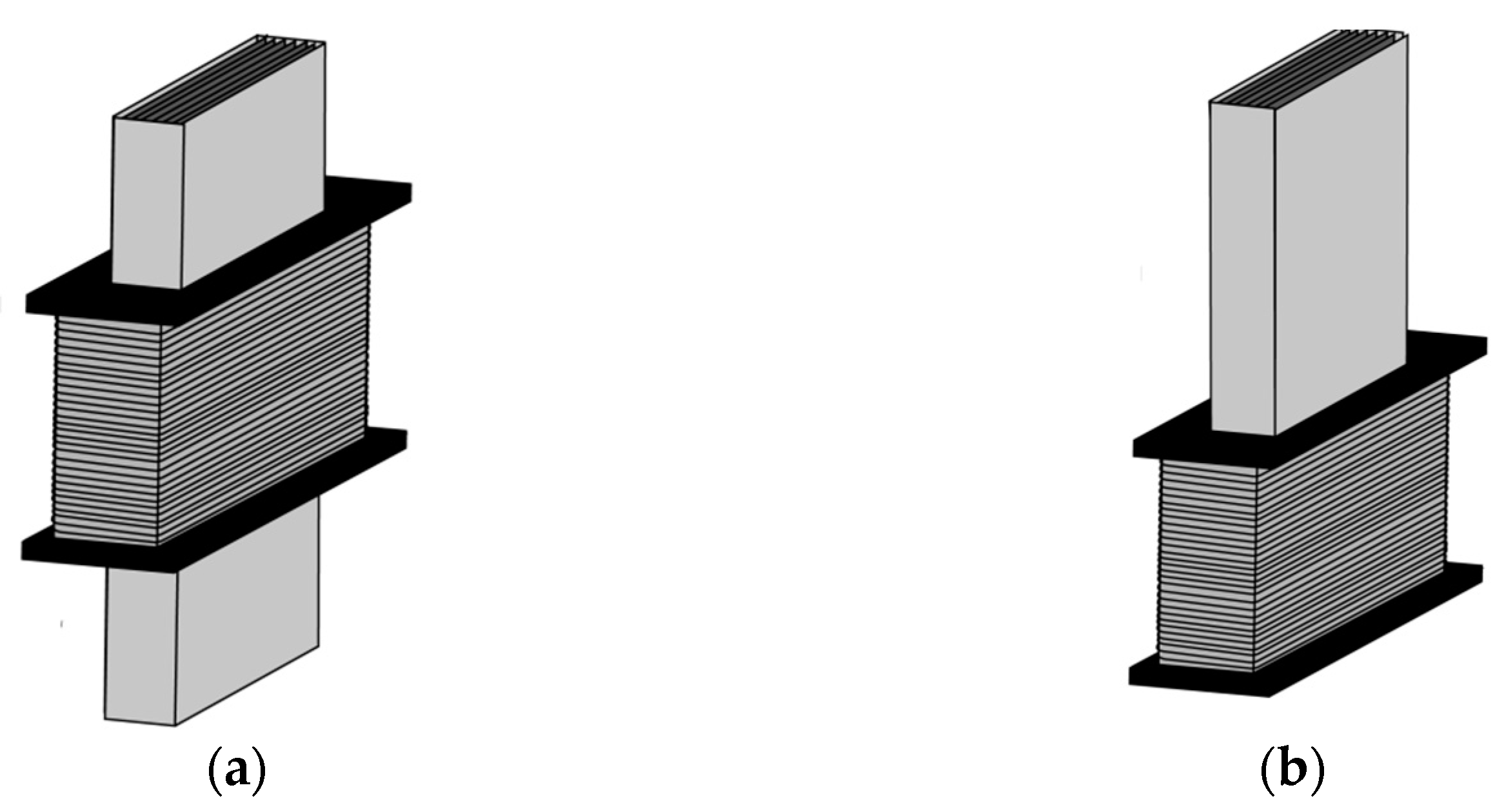

However, in order to enhance the magnetizing effect of the ribbons, many identical films are placed stacked on top of each other, forming a kind of block (

Figure 5). This way, as the surface area crossed by the magnetic field increases, the flux increases, but at the same time, as the surface area increases, the magnetization is decreasing by the magnetization effect.

At the same film magnetization, the flux increases when increasing the surface S’ (thickness, adding more films), because the term increases. At the same time for an applied field , as increases, the magnetization decreases because the opposite sign term increases, and one can reach a point where the demagnetizing factor demagnetizes the set. That is, there is a competitive effect; on the one hand, increasing the section increases the flux supposing a constant magnetization and on the other hand, increasing the section decreases the magnetization for a given applied field as the demagnetizing field increases as a function of , where S′ is the section or the secondary coil that is bigger than S, the width of the magnetic core (thickness of the set of ribbons) and L is the length of the laminates (distance between poles).

Moreover, as it is known, the longer the length of the laminates, the more of them can be stacked, as the demagnetizing factor depends on the ratio indicated in the previous equation. This compromise between the section of the set of laminates and their length would be another point to be studied in future research.

Relative Position of the Coil to the Amorphous Core Material

To continue with the optimization of the secondary element, a theoretical study about the optimum relative position of the coil with respect to the amorphous core was carried out. For this study, an AC coil was used as the primary element because of the facility for varying the parameters and observe the results [

9].

A uniform and longitudinally magnetized elongated body, such as a thin sheet of great length, was used for this purpose. The external magnetic field applied to this film produces poles at the ends of the film, the south pole being where the magnetization is born and the north pole where it dies. These poles also create a demagnetizing field inside the film that goes from north to south (field in the opposite direction to the magnetization).

In the demagnetizing factor approximation, this field inside the film is usually considered uniform, as if it were a capacitor; however, the reality is that it is not uniform but is more intense near the poles than at the midpoint between them, as the surface area of the poles is much smaller than the distance between them. Thus, it would be more accurate to approximate the system with 2-point charges, one positive and one negative, separated from each other by a distance equal to the length of the film, L.

The approximation of the demagnetizing factor to a capacitor would be more suitable if the film in question were transversely magnetized, so that the distance between the plates of the capacitor would be the thickness of the film,

e (

Figure 6).

The equation that defines the

B field inside the secondary system (region of the coil with amorphous core) is expressed as follows:

The magnetic field B outside the coil is described below:

where:

= field created by the primary system composed in this case of a coil through which circulates an AC current. If a field is applied on the secondary, decreases as the secondary moves away from the primary system.

= field created by the magnetization or magnetized matter. This field inside the material is called the demagnetizing field, and outside, it is called the magnetic field created by a magnet.

= magnetization of the secondary system, which depends on .

Therefore, the field lies along the opposite direction to both and The field that magnetizes matter in the case of an amorphous material core is , except if the core were an infinite long wire, in which case there would be no demagnetizing field (the poles that are created at infinity are too far from each other).

The film of amorphous material is used to multiply the flux, i.e., with a very small value of a very large value of M is obtained. When having the core of amorphous material in the coil, most of the voltage induced in the system is due to the magnetization of the material, not to , since .

The value of the electromotive force is the derivative of

B with respect to time, as indicated in the second row of equations in

Table 2. Keeping the number of amorphous material films constant, when varying

, the value of the magnetization

varies and therefore, the value of the derivatives.

This proportional relationship of and has an exception when the material is magnetized at saturation. In that situation, although the secondary system moves away from the primary ( is decreasing), the secondary system is still magnetized in the same way because the major contribution comes from the magnetization of the amorphous material, and this magnetization remains constant in the case of being magnetized at saturation.

Once this difference between using air and amorphous core material has been established, a second order of approximation can be made; depending on the position of the secondary coil with respect to its amorphous core (

Figure 7), the demagnetizing field, i.e., the factor

, will vary.

As seen in the previous paragraphs, as the secondary system moves away from the primary, and decrease. On the other hand, the field (created by magnetization) decreases with , but its value is not constant over the entire surface of the amorphous material; it is more intense at the poles of the sheet than at the center or midpoint between the poles, and it is not homogeneous. Thus, there may be a moment when the magnetization disappears because at the edges is equal to , that is, has reduced its value so much when moving away that it is equal to ; in that situation, there is no magnetization at the edges, and the material is demagnetized. As is larger at the edges than in the center, it is to be expected that the system with the coil at the edge of the film will be demagnetized earlier than the system with the coil at the center of the film.

To summarize, the magnetization of the film, although it can reach the saturation in its central part after a certain value of

, could be much less magnetized at the ends since the real field acting on them would be lower than in the center. In the center of the sample, the field due to the primary element and the magnetization is:

This field is enough to magnetize at saturation. However, at the extreme, the field is:

Moreover, is higher in absolute value than , as the demagnetizing fields are opposite to ; it is observed that the effective field in the center is higher than at the ends, and therefore, in a certain position, the film can be magnetized in the center and not at the ends.

Plotting the expression of the electromotive force collected by the secondary coil as a function of the distance between the primary and secondary systems, for the cases in which the coil is centered with respect to the amorphous core and off-center (at the end of the film), we obtain

Figure 8, which can be used as a simulation of what would be obtained in an experimental test.

If the secondary coil is positioned in the center of the amorphous ribbon, the resulting signal differs from when the coil is situated at the edge of the ribbon. In the latter scenario, the field collection occurs in an area where the demagnetizing H-field is more intense than in the center of the ribbon.

Assuming a uniform applied field (generated by the primary), the magnetization at the ends of the ribbon will be weaker. Consequently, with the same , the B field at the ends will be smaller than at the center, resulting in a lower induced voltage at the ends. This is the reason why as the position of the secondary coil changes, the induced voltage decreases more rapidly when the coil is situated at the edge of the ribbon.

and are equal both in the case where the coil is in the center of the film and in the case where it is located at one of the ends. However, the demagnetizing field of the film varies according to the position in which it is taken, where and therefore, .

Given that the signal is primarily a result of magnetization, and that the

field is smaller at the center, the secondary system will reach magnetization saturation regardless of its position. This happens because the demagnetizing field is minimal for each position assumed by the ribbon. As such, it is expected that the graph showing the

EMF collected by the secondary coil as a function of position will exhibit a later drop when the coil is placed at the end of the ribbon.

Table 3 shows the equations of the

EMF in each case.

3. Experimental Approach and Discussion

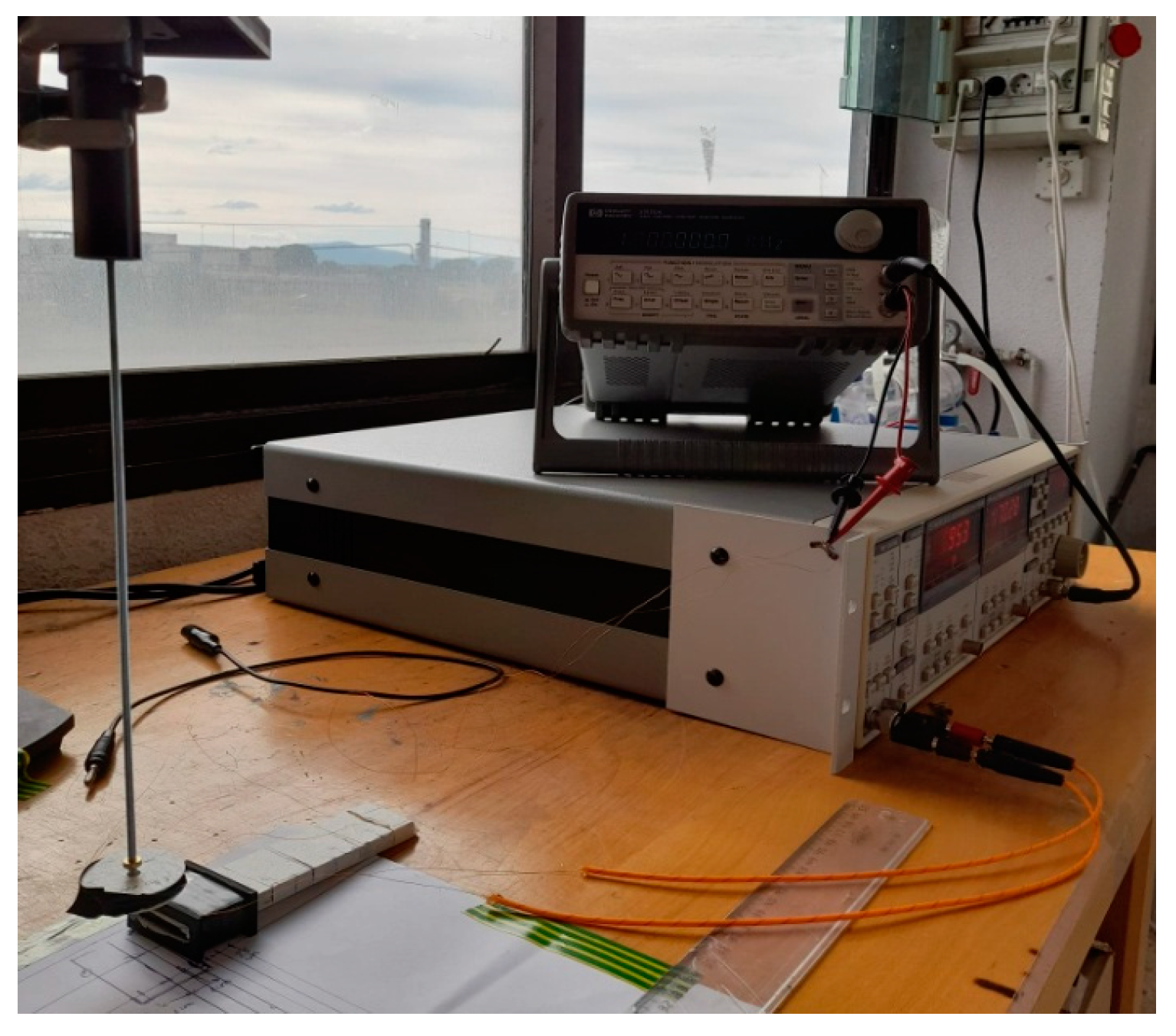

Two coils were used, a circular coil of 150 spires and a rectangular coil of 300 spires. The circular coil was the primary system, so it was connected to a function generator with a frequency of 1 kHz and a peak-to-peak voltage of 5 V (

Figure 9). The rectangular coil was the secondary system which was connected to the lock-in to show the voltage values induced in the secondary, as shown in

Figure 10.

The measuring device (lock-in) used was very sensitive, so the data obtained could change with position variations of 1 mm, inclinations, devices located around it, and environmental conditions in general. For this reason, in order to obtain reliable data, three measurements (P1, P2, P3) were taken for each system with the same core and the same positions.

First, the data of the recovered electromotive force were collected for the secondary coil system with an air core. Then, the same test was repeated but adding the amorphous core to the secondary coil. In order to go one step forward and understand better the influence of the amorphous material on the test, two amorphous core systems were defined, which differed in the position of the amorphous material with respect to the coil.

In

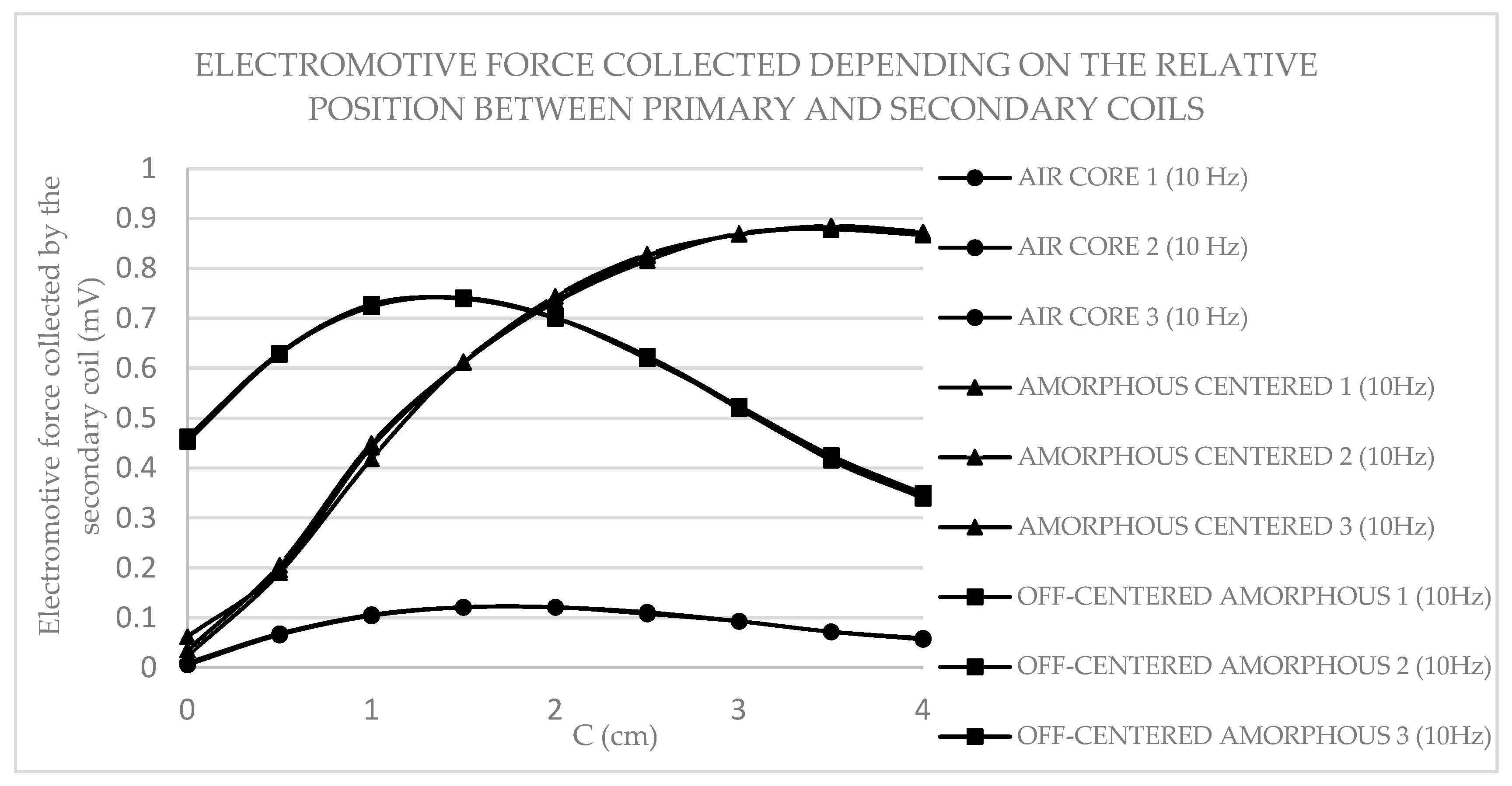

Figure 11, the electromotive force induced in the three cases is represented; it shows the difference in the magnitude of the electromotive force for the same position of the coils according to the core of the energy-collecting coil.

As can be seen, not only the magnitude of the induced electromotive force varied, but also the shape or trend of the graphs for each of the three models. On the one hand, in the case of the curves shown in

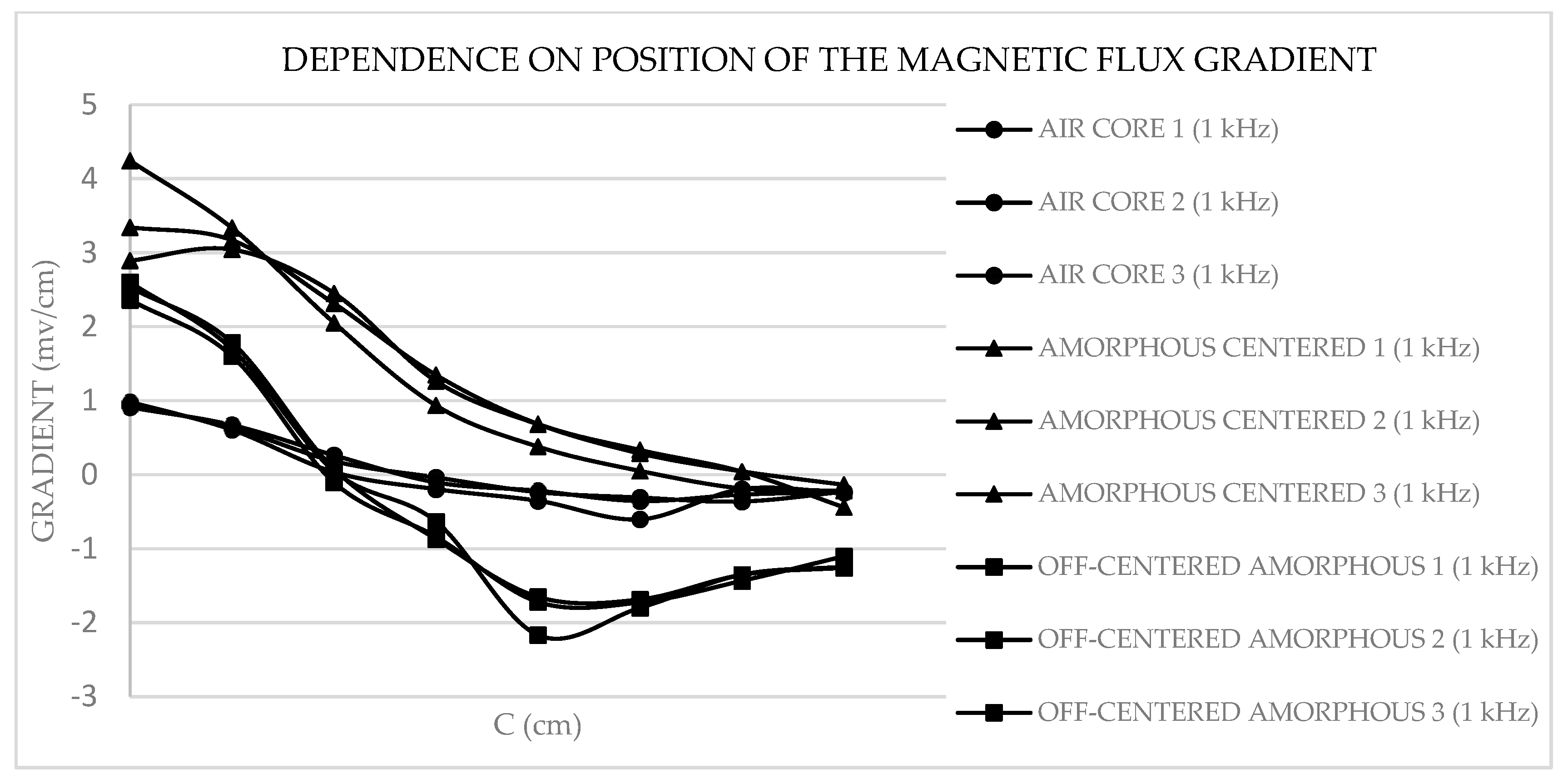

Figure 11 corresponding to the air core, the maximum electromotive force was reached in a position such as in the case of the off-centered amorphous core material, and from this peak, the voltage collected decreased.

In this decreasing region, the observed reduction in the electromotive force was quite higher in the case of the off-center amorphous core, in comparison with the case of the air core in which a smooth progressive decrease was observed.

The graphs representing the centered amorphous core case took longer to reach the maximum voltage and remained at values very close to the maximum for a longer interval of positions.

When the gradients of the three cases tested were compared, a great difference was observed between the air-core coil test and the two tests with an amorphous material core; the variation of the electromotive force collected by the secondary being much higher in the case of the latter two.

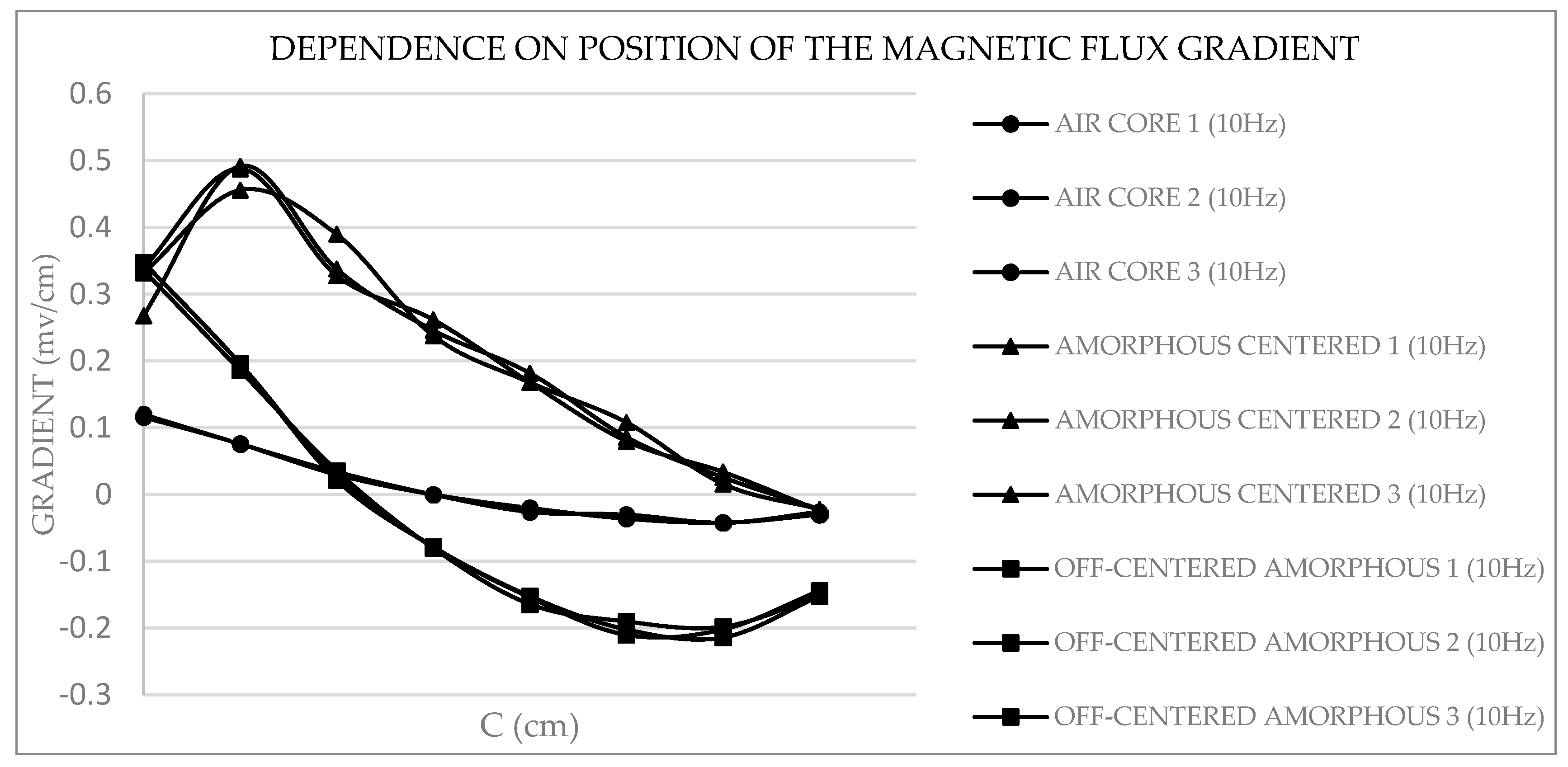

When the gradient of these tests was calculated and plotted (

Figure 12), it was possible to observe more clearly which case presented the maximum value of the gradient, which was the objective of that test, since the maximum gradient corresponded to the maximum variation of the induced electromotive force and consequently, to the maximum energy collected by the secondary element of the system (maximum energy recovered).

The root cause of the very different results observed in the electromotive force induced in the secondary coil when using an air core and when using an amorphous material core is the permeability of each medium. The permeability of the amorphous material is much higher than the permeability of air [

24].

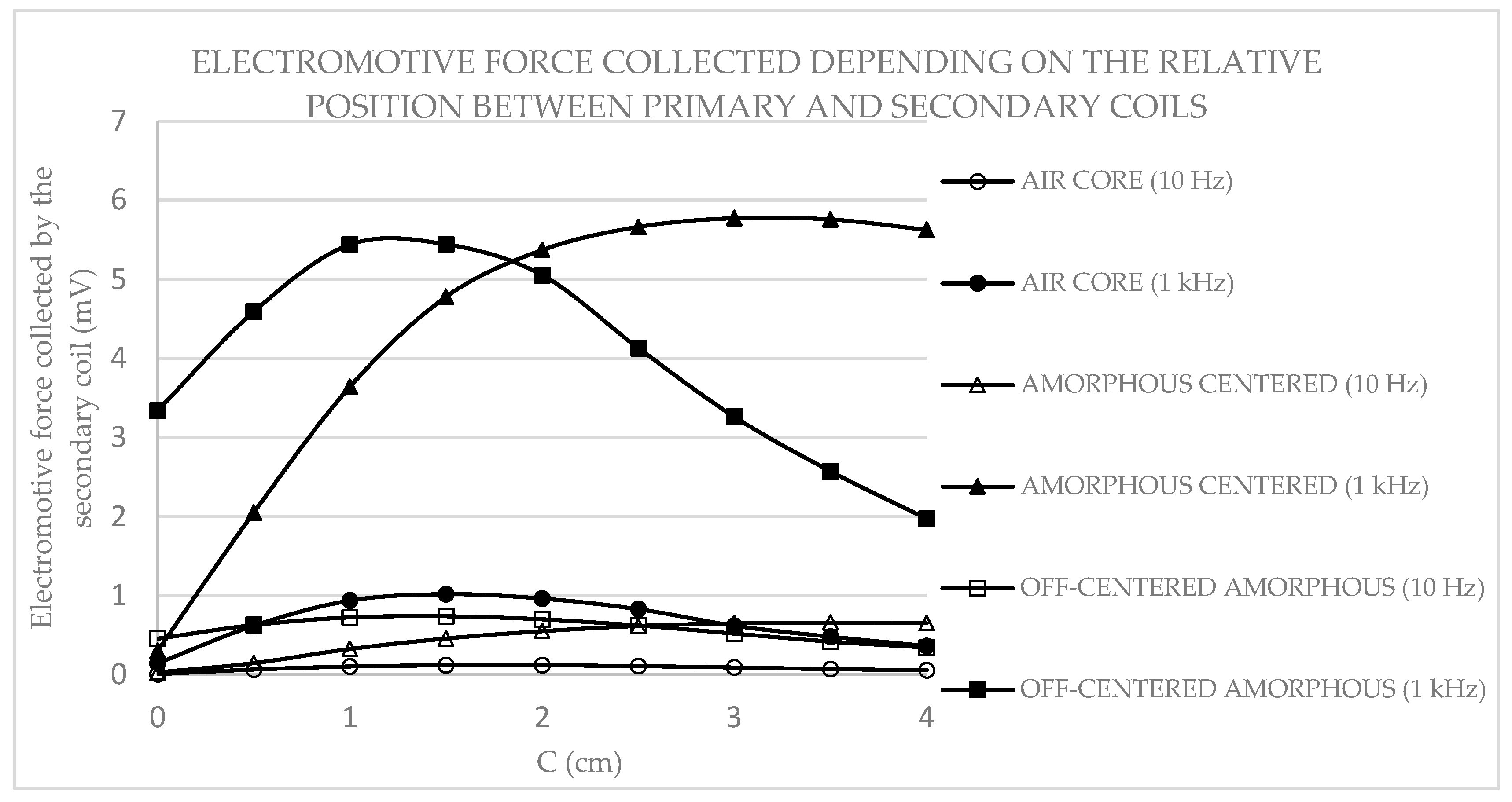

Comparing the results obtained with 10 Hz (

Figure 13), a graph similar to the one obtained with 1 kHz was observed (

Figure 14); in both cases, the multiplying effect of the amorphous material can be easily appreciated.

To show all the results in a single graph, the averages of the three tests (P1, P2, P3) performed for each case were calculated in

Figure 15.

Taking the numerical value of the maximum gradient of each test and comparing them, it was observed that the maximum value of the gradient corresponded to the test in which the coil was centered with respect to the amorphous material. Therefore, the optimum system to recover the maximum possible energy was the one whose secondary coil had a centered core of amorphous material.

The measurements showed that the ratio between the voltage obtained with the amorphous core (either centered or off-center) and the voltage with an air core, on one side for the 1 kHz tests and on the other side for the 10 Hz tests, was independent of the frequency. This means that the multiplicative effect of the core is independent of the frequency; the magnetic permeability being this multiplicative factor meant that the permeability does not depend on the frequency in the range between 10 Hz and 1 kHz.

This fits perfectly with different previous observations [

24].

In future lines of research, this could be a point of study, trying to find for which frequency the behavior or tendency of these curves changes.