Effect of Infill Density of the Printed PET-G Structures Containing Iron Oxides on Magnetic Properties

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

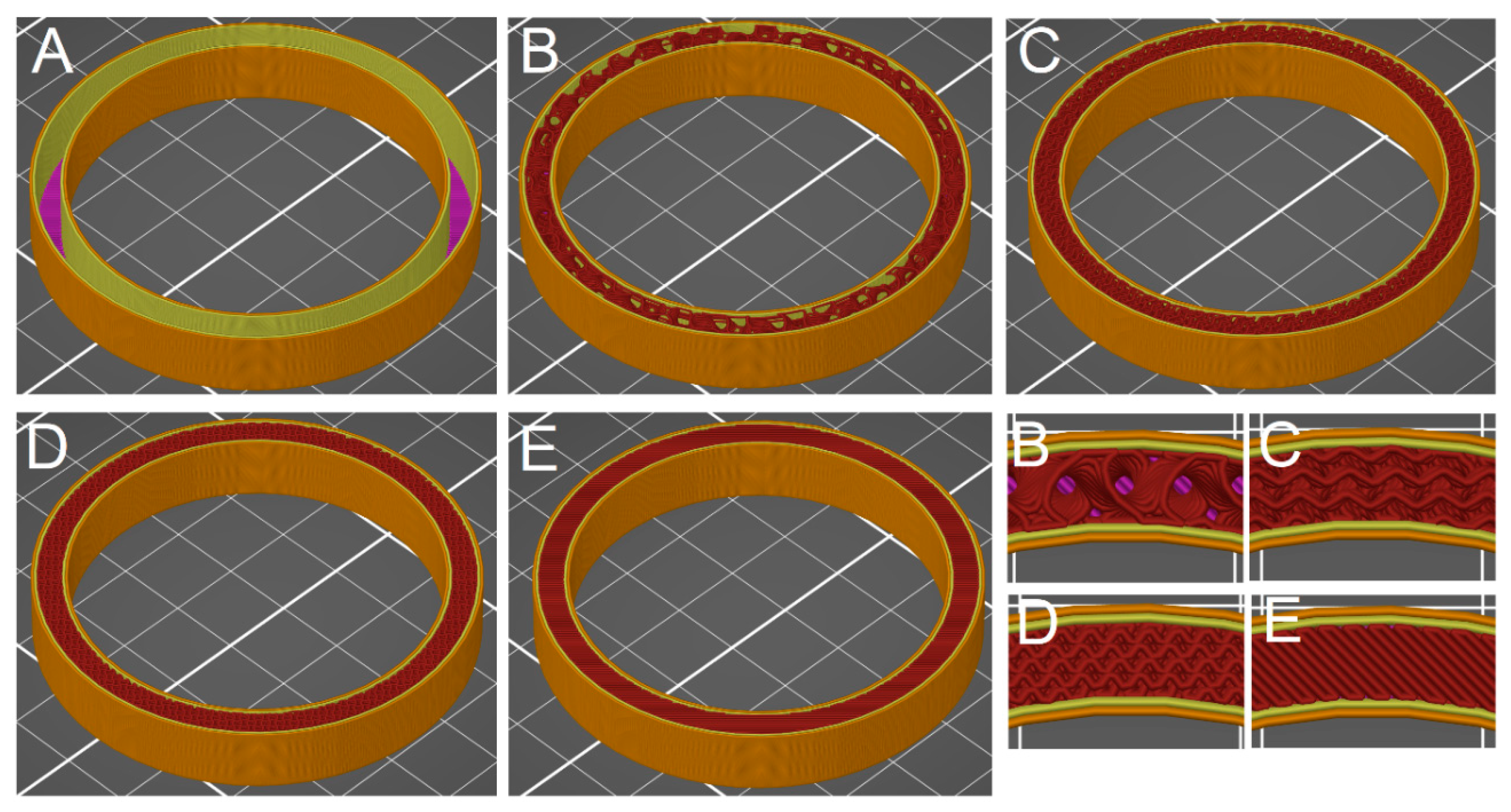

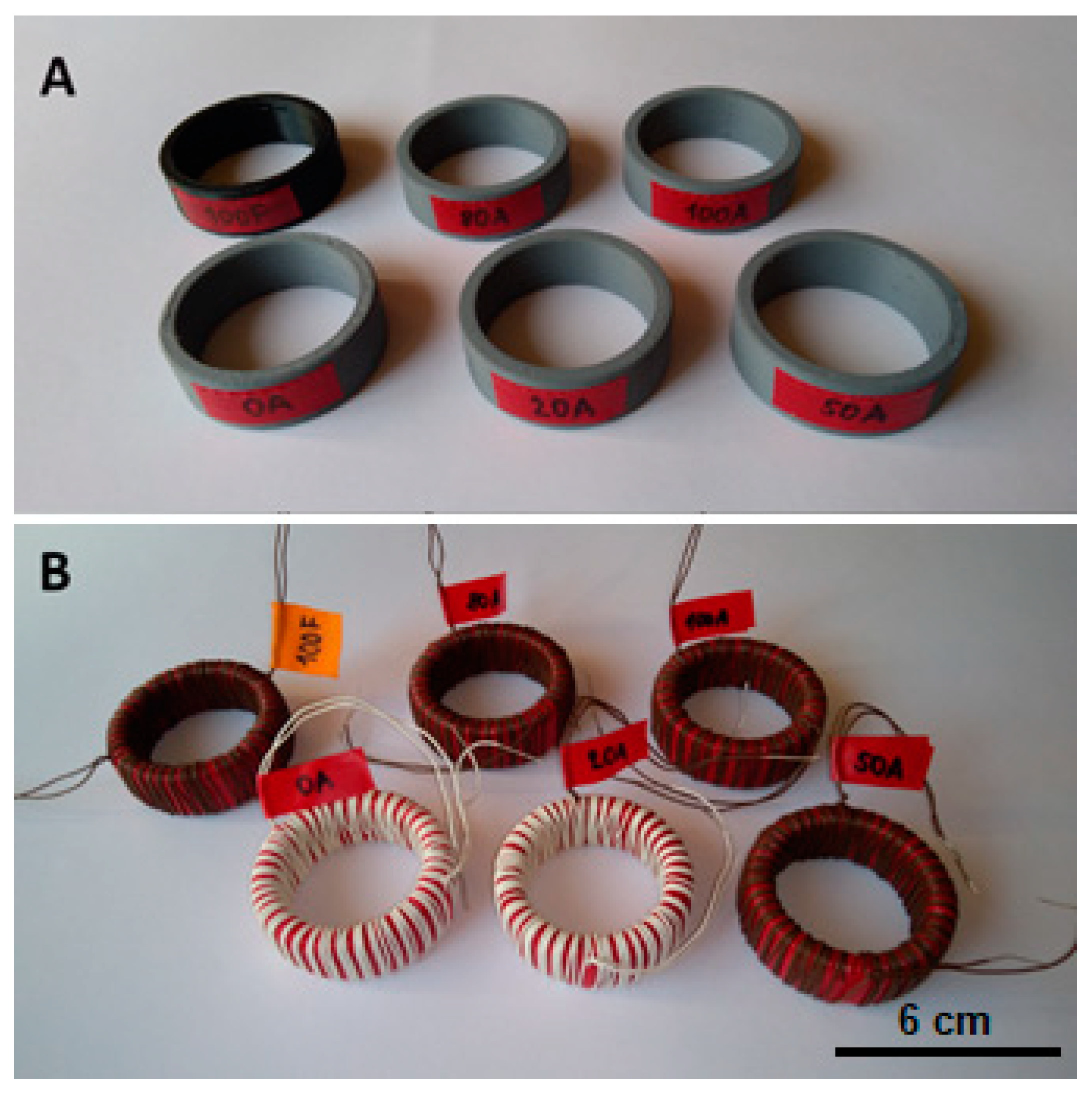

2.2. Praparation of Samples

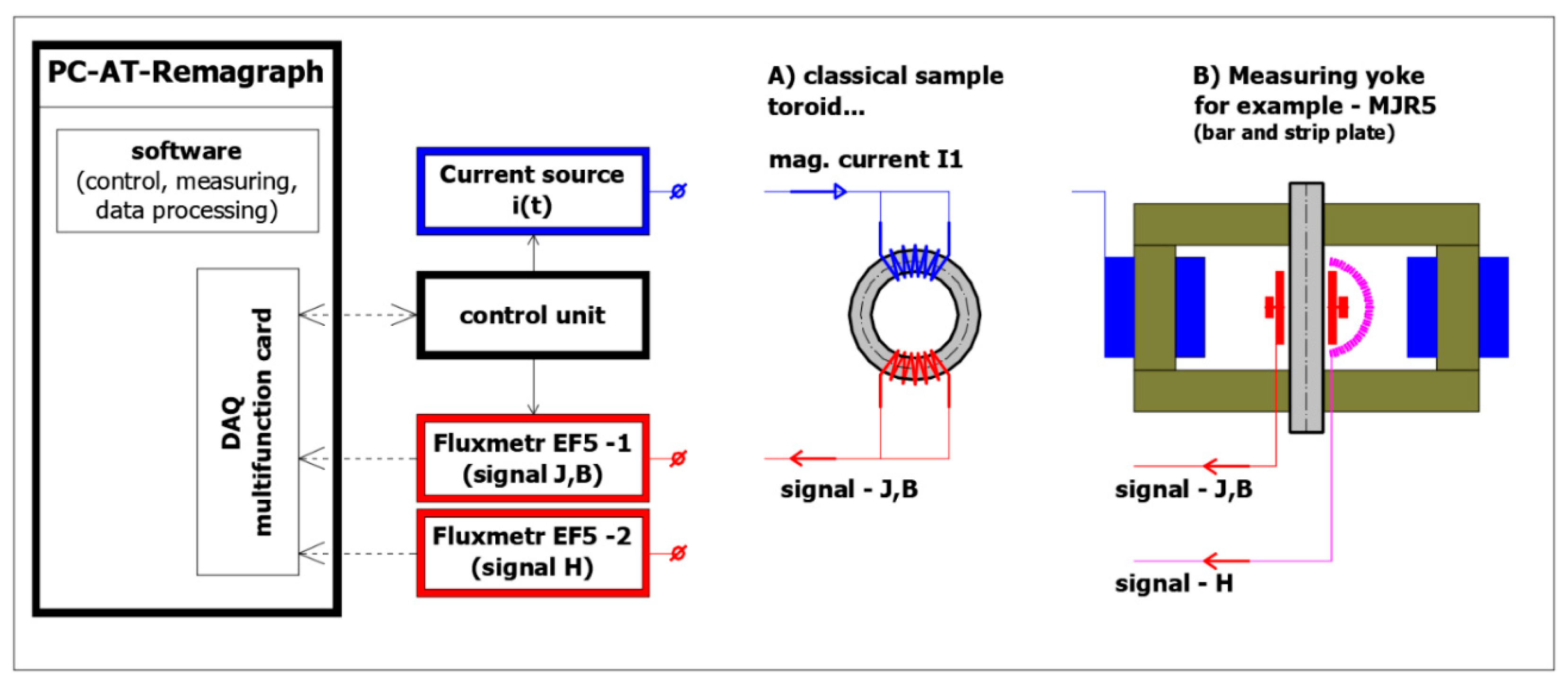

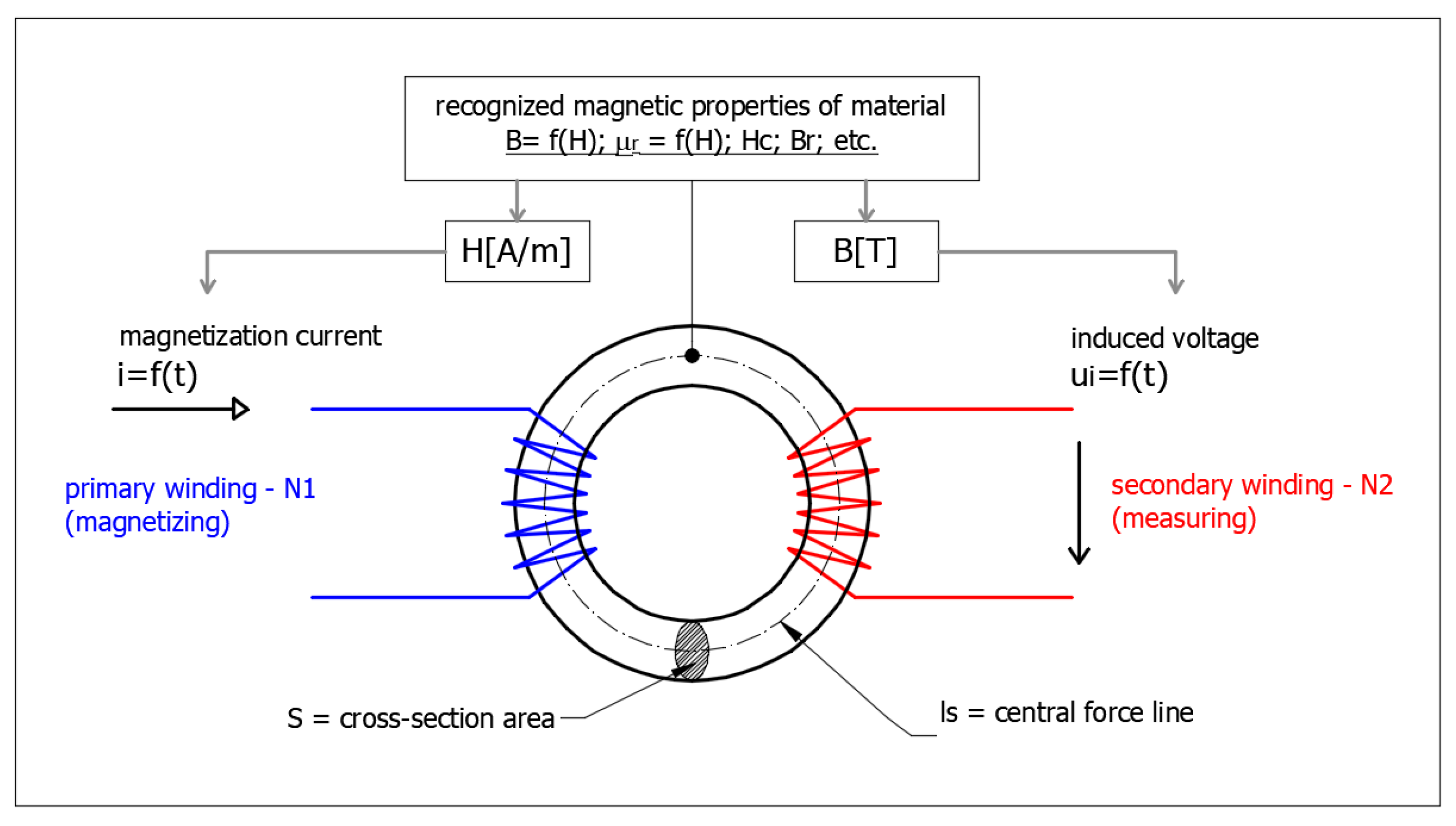

2.3. Methods

3. Results and Discussion

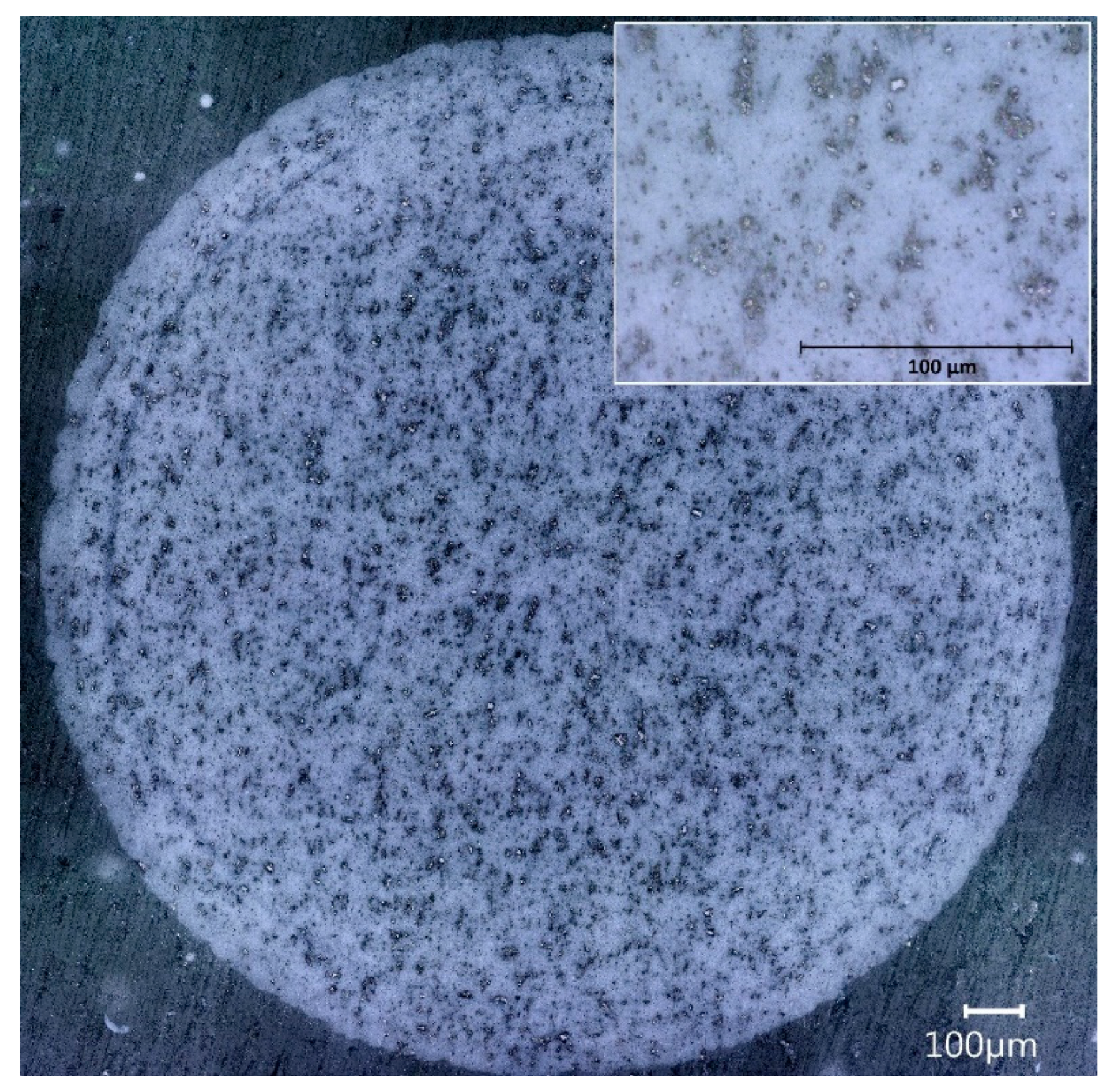

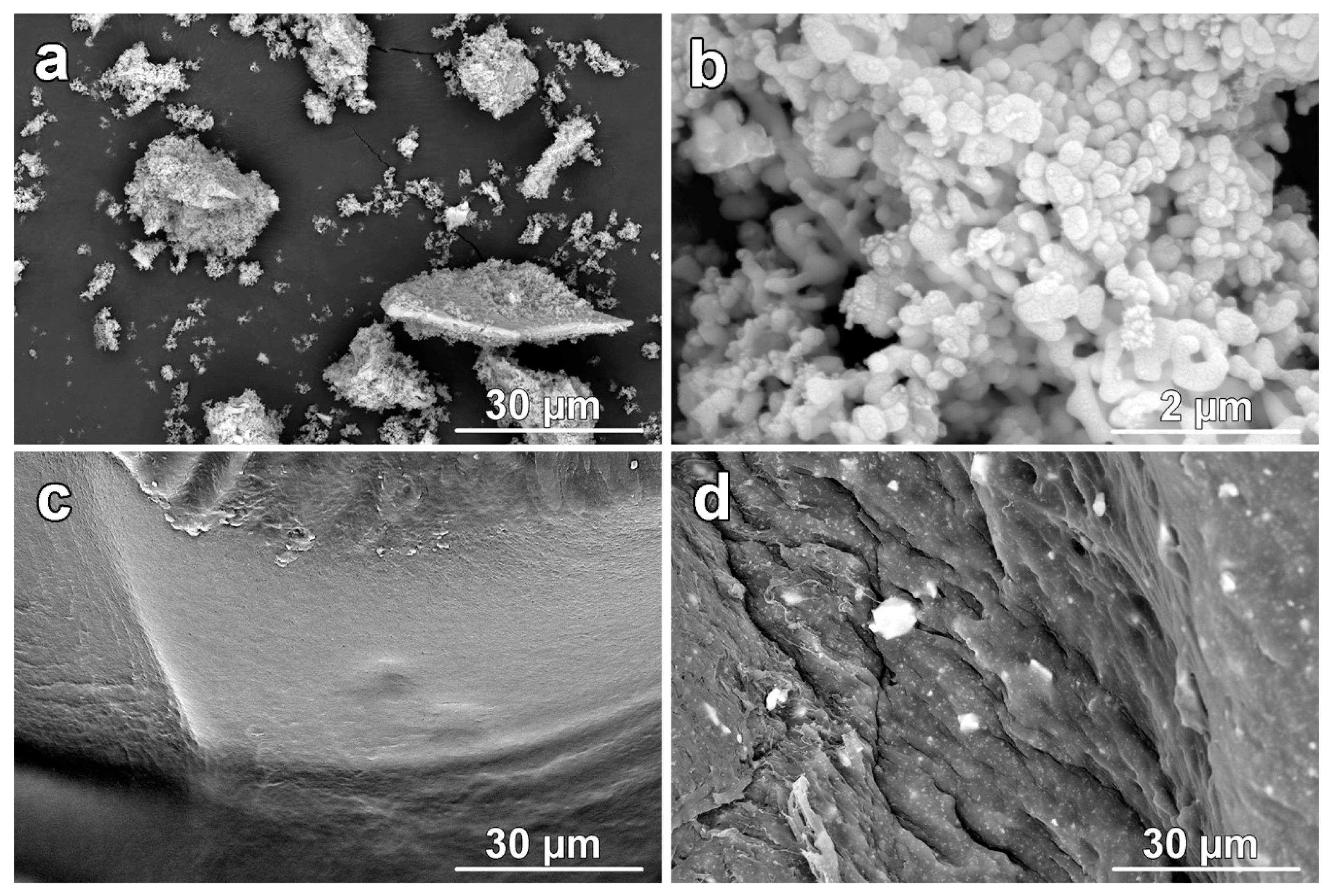

3.1. Characterization of Material

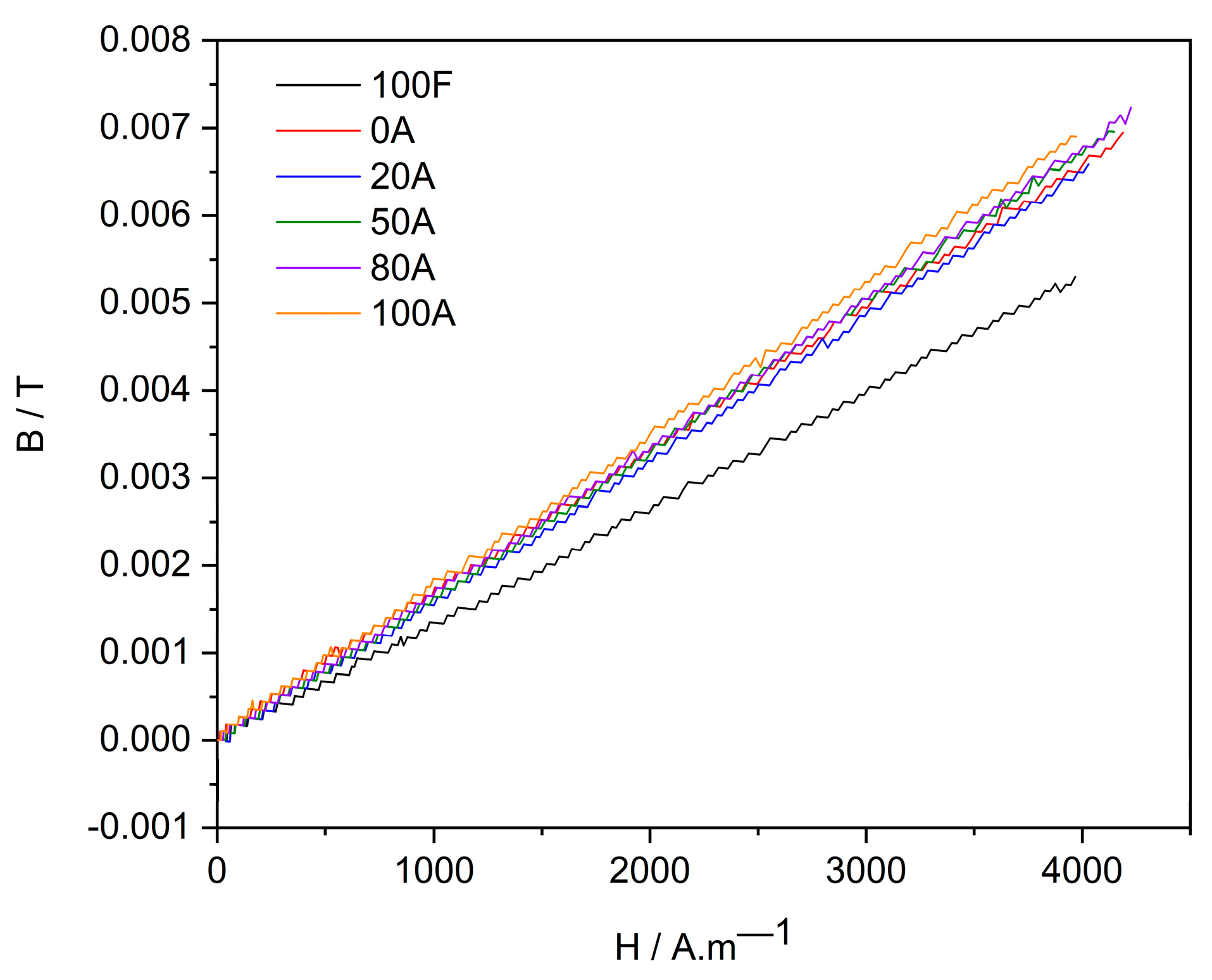

3.2. Magnetic Properties

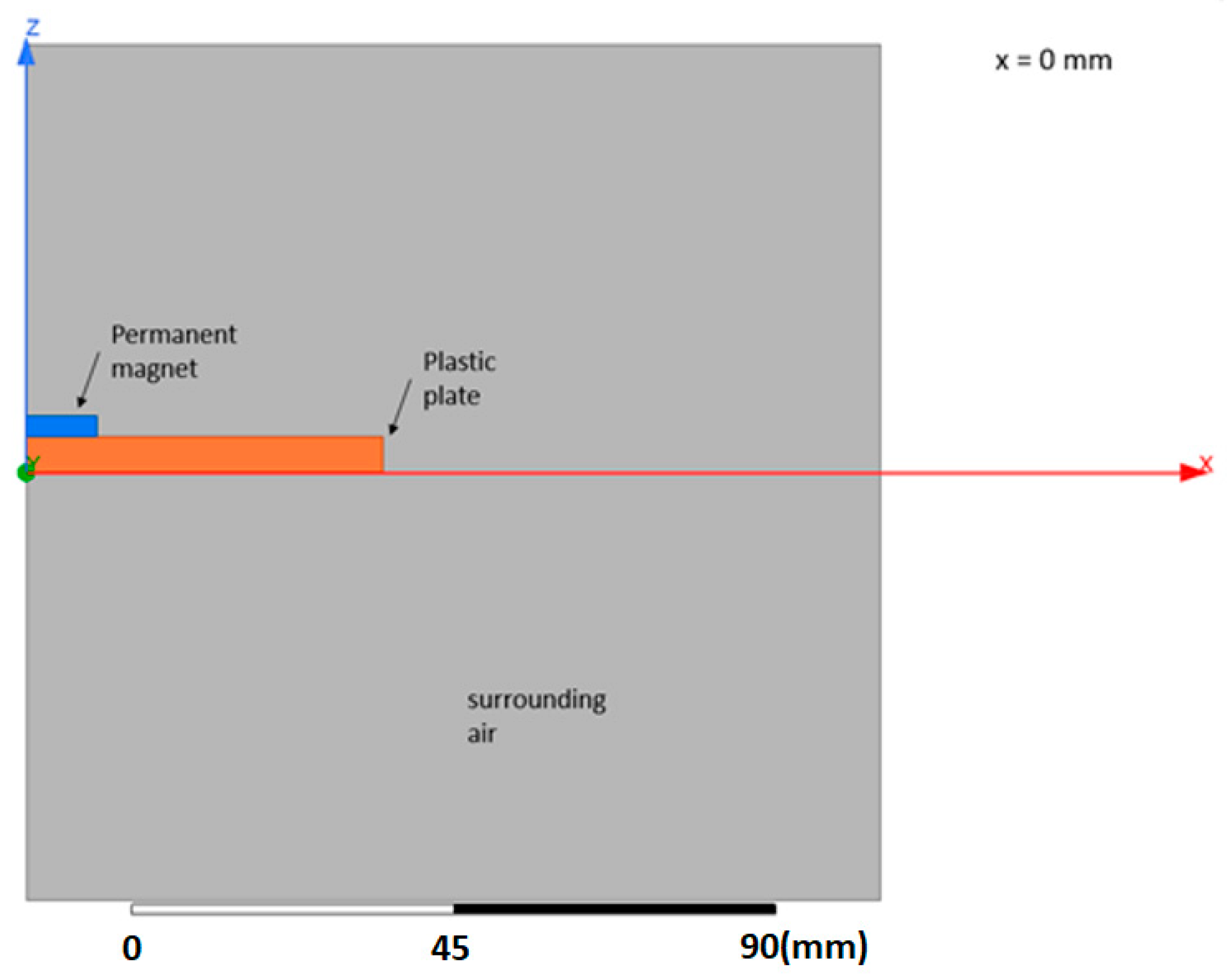

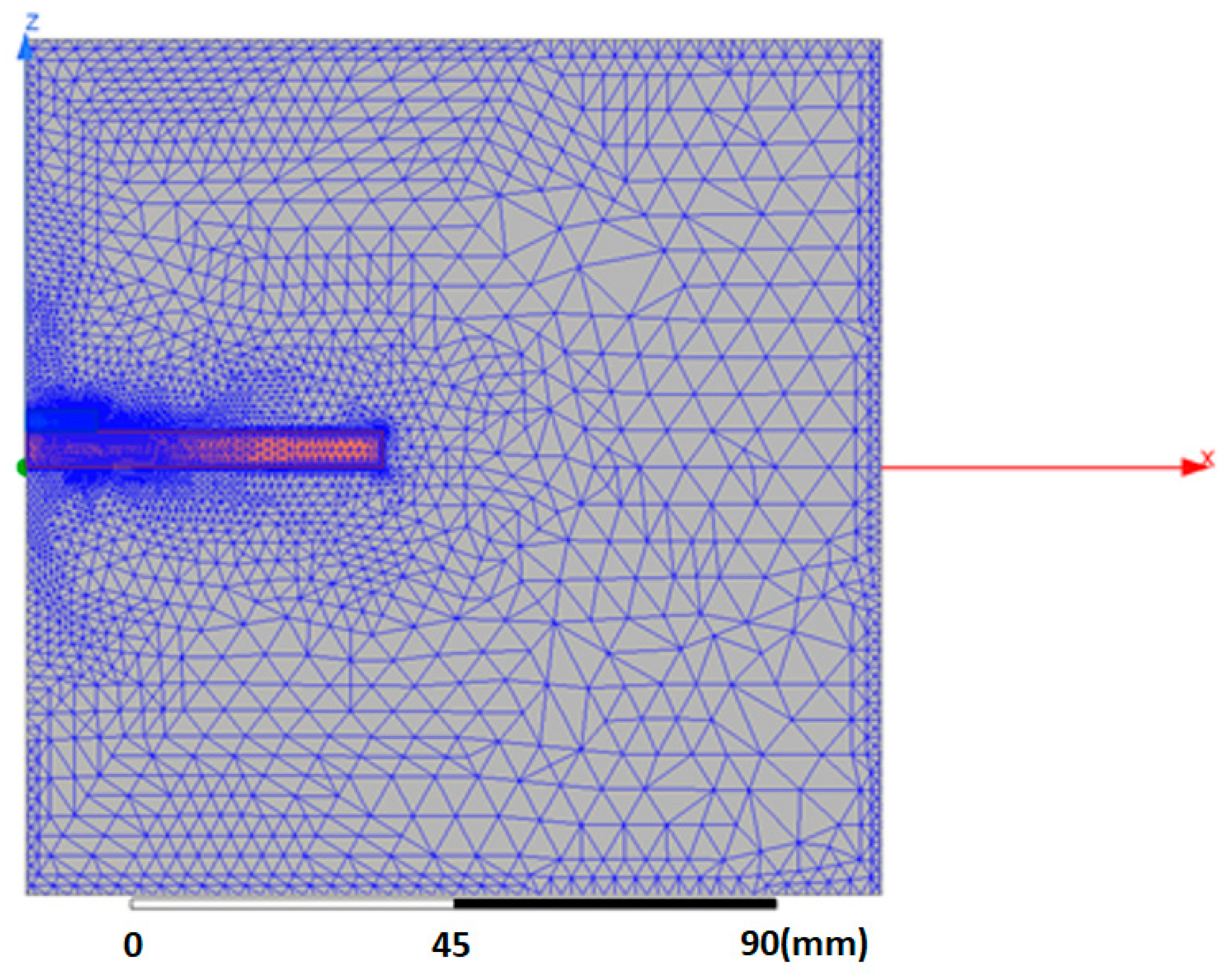

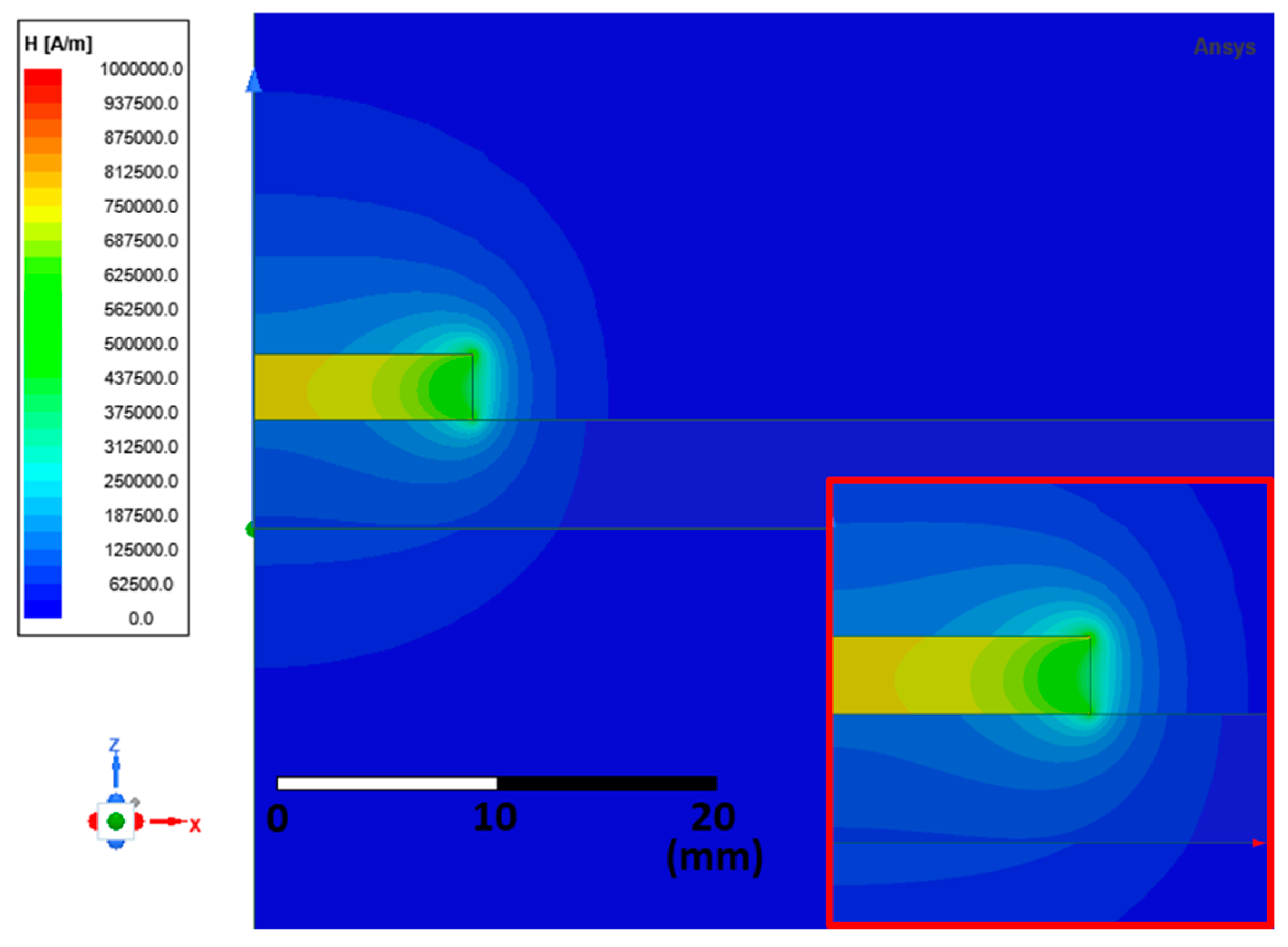

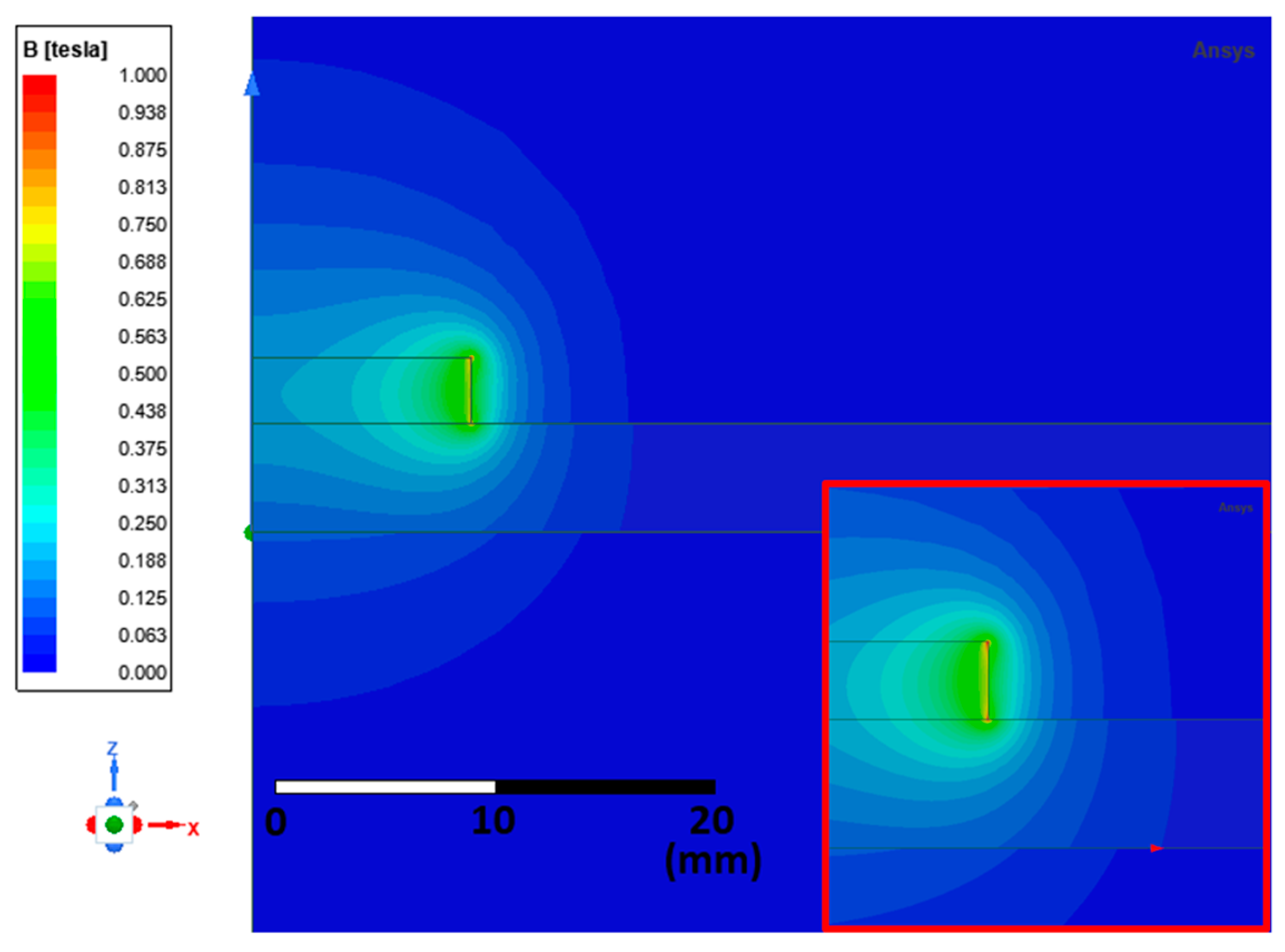

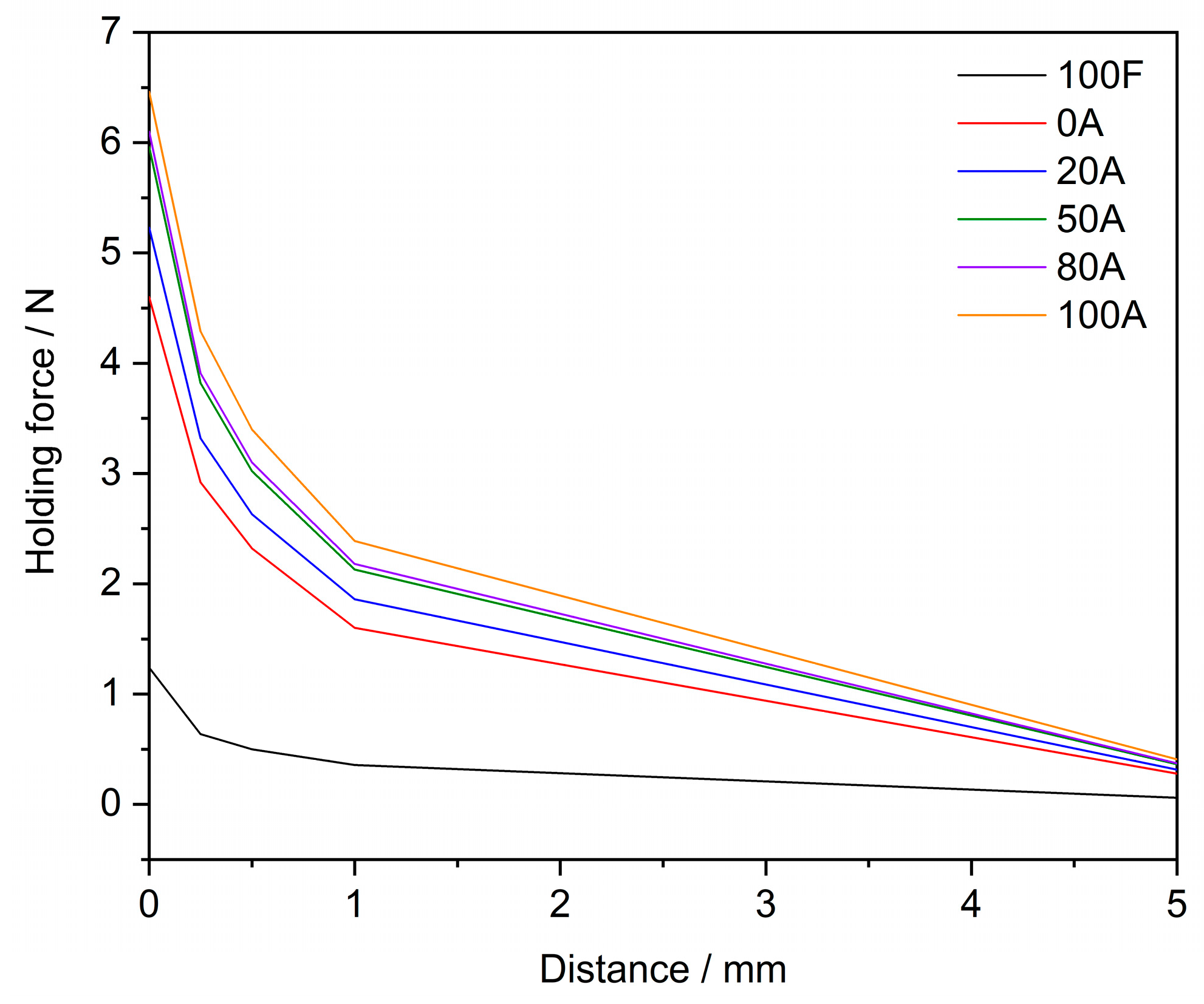

3.3. Magnetic Field Simulation and Calculation of Force Effects

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Culmone, C.; Smit, G.; Breedveld, P. Additive manufacturing of medical instruments: A state-of-the-art review. Addit. Manuf. 2019, 27, 461–473. [Google Scholar] [CrossRef]

- Kessler, A.; Hickel, R.; Reymus, M. 3D printing in dentistry—State of the art. Oper. Dent. 2020, 45, 30–40. [Google Scholar] [CrossRef] [PubMed]

- Serra, T.; Mateos-Timoneda, M.A.; Planell, J.A.; Navarro, M. 3D printed PLA-based scaffolds: A versatile tool in regenerative medicine. Organogenesis 2013, 9, 239–244. [Google Scholar] [CrossRef] [PubMed]

- Rusling, J.F. Developing microfluidic sensing devices using 3D printing. ACS Sens. 2018, 3, 522–526. [Google Scholar] [CrossRef] [PubMed]

- Böckin, D.; Tillman, A.-M. Environmental assessment of additive manufacturing in the automotive industry. J. Clean. Prod. 2019, 226, 977–987. [Google Scholar] [CrossRef]

- Alexander, C. Streamlining automotive production with additive manufacturing. Quality 2018, 57, 37–39. [Google Scholar]

- Zhakeyev, A.; Wang, P.; Zhang, L.; Shu, W.; Wang, H.; Xuan, J. Additive manufacturing: Unlocking the evolution of energy materials. Adv. Sci. 2017, 4, 1700187. [Google Scholar] [CrossRef]

- Hambach, M.; Rutzen, M.; Volkmer, D. Properties of 3D-printed fiber-reinforced Portland cement paste. In 3D Concrete Printing Technology; Elsevier: Amsterdam, The Netherlands, 2019; pp. 73–113. [Google Scholar]

- Lille, M.; Nurmela, A.; Nordlund, E.; Metsä-Kortelainen, S.; Sozer, N. Applicability of protein and fiber-rich food materials in extrusion-based 3D printing. J. Food Eng. 2018, 220, 20–27. [Google Scholar] [CrossRef]

- Gibson, I.; Rosen, D.; Stucker, B.; Khorasani, M. Materials for additive manufacturing. In Additive Manufacturing Technologies; Springer: Berlin/Heidelberg, Germany, 2021; pp. 379–428. [Google Scholar]

- Williams, L.D.; Williams, L. Additive manufacturing or 3d scanning and printing. In Manufacturing Engineering Handbook; McGraw-Hill: New York, NY, USA, 2015. [Google Scholar]

- Laureto, J.; Tomasi, J.; King, J.A.; Pearce, J.M. Thermal properties of 3-D printed polylactic acid-metal composites. Prog. Addit. Manuf. 2017, 2, 57–71. [Google Scholar] [CrossRef]

- Alam, F.; Shukla, V.R.; Varadarajan, K.M.; Kumar, S. Microarchitected 3D printed polylactic acid (PLA) nanocomposite scaffolds for biomedical applications. J. Mech. Behav. Biomed. Mater. 2020, 103, 103576. [Google Scholar] [CrossRef]

- Tao, Y.; Liu, M.; Han, W.; Li, P. Waste office paper filled polylactic acid composite filaments for 3D printing. Compos. Part B Eng. 2021, 221, 108998. [Google Scholar] [CrossRef]

- Zander, N.E.; Gillan, M.; Lambeth, R.H. Recycled polyethylene terephthalate as a new FFF feedstock material. Addit. Manuf. 2018, 21, 174–182. [Google Scholar] [CrossRef]

- Dolzyk, G.; Jung, S. Tensile and fatigue analysis of 3D-printed polyethylene terephthalate glycol. J. Fail. Anal. Prev. 2019, 19, 511–518. [Google Scholar] [CrossRef]

- Mansour, M.; Tsongas, K.; Tzetzis, D.; Antoniadis, A. Mechanical and dynamic behavior of fused filament fabrication 3D printed polyethylene terephthalate glycol reinforced with carbon fibers. Polym. Plast. Technol. Eng. 2018, 57, 1715–1725. [Google Scholar] [CrossRef]

- Carrete, I.A.; Quiñonez, P.A.; Bermudez, D.; Roberson, D.A. Incorporating textile-derived cellulose fibers for the strengthening of recycled polyethylene terephthalate for 3D printing feedstock materials. J. Polym. Environ. 2021, 29, 662–671. [Google Scholar] [CrossRef]

- Małek, M.; Grzelak, K.; Łasica, W.; Jackowski, M.; Kluczyński, J.; Szachogłuchowicz, I.; Torzewski, J.; Łuszczek, J. Cement-glass composite bricks (CGCB) with interior 3D printed PET-G scaffolding. J. Build. Eng. 2022, 52, 104429. [Google Scholar] [CrossRef]

- Kechagias, J.D.; Fountas, N.A.; Ninikas, K.; Petousis, M.; Vidakis, N.; Vaxevanidis, N. Surface characteristics investigation of 3D-printed PET-G plates during CO2 laser cutting. Mater. Manuf. Process. 2022, 37, 1347–1357. [Google Scholar] [CrossRef]

- Soleyman, E.; Aberoumand, M.; Soltanmohammadi, K.; Rahmatabadi, D.; Ghasemi, I.; Baniassadi, M.; Abrinia, K.; Baghani, M. 4D printing of PET-G via FDM including tailormade excess third shape. Manuf. Lett. 2022, 33, 1–4. [Google Scholar] [CrossRef]

- Ferreira, I.; Vale, D.; Machado, M.; Lino, J. Additive manufacturing of polyethylene terephthalate glycol/carbon fiber composites: An experimental study from filament to printed parts. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2019, 233, 1866–1878. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Maniadi, A.; Koudoumas, E.; Liebscher, M.; Tzounis, L. Mechanical properties of 3D-printed acrylonitrile–butadiene–styrene TiO2 and ATO nanocomposites. Polymers 2020, 12, 1589. [Google Scholar] [CrossRef]

- De León, A.S.; Domínguez-Calvo, A.; Molina, S.I. Materials with enhanced adhesive properties based on acrylonitrile-butadiene-styrene (ABS)/thermoplastic polyurethane (TPU) blends for fused filament fabrication (FFF). Mater. Des. 2019, 182, 108044. [Google Scholar] [CrossRef]

- Farcas, M.T.; Stefaniak, A.B.; Knepp, A.K.; Bowers, L.; Mandler, W.K.; Kashon, M.; Jackson, S.R.; Stueckle, T.A.; Sisler, J.D.; Friend, S.A. Acrylonitrile butadiene styrene (ABS) and polycarbonate (PC) filaments three-dimensional (3-D) printer emissions-induced cell toxicity. Toxicol. Lett. 2019, 317, 1–12. [Google Scholar] [CrossRef] [PubMed]

- Vidakis, N.; Petousis, M.; Maniadi, A.; Koudoumas, E.; Vairis, A.; Kechagias, J. Sustainable additive manufacturing: Mechanical response of acrylonitrile-butadiene-styrene over multiple recycling processes. Sustainability 2020, 12, 3568. [Google Scholar] [CrossRef]

- Zander, N.E.; Gillan, M.; Burckhard, Z.; Gardea, F. Recycled polypropylene blends as novel 3D printing materials. Addit. Manuf. 2019, 25, 122–130. [Google Scholar] [CrossRef]

- Jin, M.; Neuber, C.; Schmidt, H.-W. Tailoring polypropylene for extrusion-based additive manufacturing. Addit. Manuf. 2020, 33, 101101. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Tzounis, L.; Maniadi, A.; Velidakis, E.; Mountakis, N.; Papageorgiou, D.; Liebscher, M.; Mechtcherine, V. Sustainable additive manufacturing: Mechanical response of polypropylene over multiple recycling processes. Sustainability 2021, 13, 159. [Google Scholar] [CrossRef]

- Bachhar, N.; Gudadhe, A.; Kumar, A.; Andrade, P.; Kumaraswamy, G. 3D printing of semicrystalline polypropylene: Towards eliminating warpage of printed objects. Bull. Mater. Sci. 2020, 43, 171. [Google Scholar] [CrossRef]

- Reich, M.J.; Woern, A.L.; Tanikella, N.G.; Pearce, J.M. Mechanical properties and applications of recycled polycarbonate particle material extrusion-based additive manufacturing. Materials 2019, 12, 1642. [Google Scholar] [CrossRef]

- Fang, L.; Yan, Y.; Agarwal, O.; Seppala, J.E.; Hemker, K.J.; Kang, S.H. Processing-structure-property relationships of bisphenol-A-polycarbonate samples prepared by fused filament fabrication. Addit. Manuf. 2020, 35, 101285. [Google Scholar] [CrossRef]

- Calafel, I.; Aguirresarobe, R.H.; Peñas, M.I.; Santamaria, A.; Tierno, M.; Conde, J.I.; Pascual, B. Searching for rheological conditions for FFF 3D printing with PVC based flexible compounds. Materials 2020, 13, 178. [Google Scholar] [CrossRef]

- Gray, R.L. Hindered amine light stabilizers: Recent developments. Plast. Addit. 1998, 1, 360–371. [Google Scholar]

- Pritchard, G. Plastics Additives: An AZ Reference; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2012; Volume 1, ISBN 9401158622. [Google Scholar]

- Sharma, K. Effect of FFF Process Parameters on Density and Mechanical Properties of PET-G and Carbon Fiber Reinforced PET-G Composites. Master’s Thesis, University of Manitoba, Winnipeg, MB, Canada, 2021. [Google Scholar]

- Basurto-Vázquez, O.; Sánchez-Rodríguez, E.P.; McShane, G.J.; Medina, D.I. Load distribution on PET-G 3D prints of honeycomb cellular structures under compression load. Polymers 2021, 13, 1983. [Google Scholar] [CrossRef] [PubMed]

- Vinyas, M.; Athul, S.J.; Harursampath, D.; Thoi, T.N. Experimental evaluation of the mechanical and thermal properties of 3D printed PLA and its composites. Mater. Res. Express 2019, 6, 115301. [Google Scholar] [CrossRef]

- Gopathi, P.; Surve, P. Possibilities and Limitations of using Production Waste PET and PES Materials in Additive Manufacturing (3D Printing Technology). Master’s Thesis, Halmstad University, Halmstad, Sweden, 2017. [Google Scholar]

- Bernasconi, R.; Natale, G.; Levi, M.; Magagnin, L. Electroless plating of NiP and Cu on polylactic acid and polyethylene terephthalate glycol-modified for 3D printed flexible substrates. J. Electrochem. Soc. 2016, 163, D526. [Google Scholar] [CrossRef]

- Equbal, A.; Sood, A.K. Metallization on FDM parts using the chemical deposition technique. Coatings 2014, 4, 574–586. [Google Scholar] [CrossRef]

- Domenech, S.C.; Lima, E., Jr.; Drago, V.; De Lima, J.C.; Borges, N.G., Jr.; Avila, A.O.V.; Soldi, V. Electroless plating of nickel–phosphorous on surface-modified poly (ethylene terephthalate) films. Appl. Surf. Sci. 2003, 220, 238–250. [Google Scholar] [CrossRef]

- Fischer, N.A.; Robinson, A.L.; Lee, T.J.; Calascione, T.M.; Koerner, L.; Nelson-Cheeseman, B.B. Magnetic annealing of extruded thermoplastic magnetic elastomers for 3D-Printing via FDM. J. Magn. Magn. Mater. 2022, 553, 169266. [Google Scholar] [CrossRef]

- Habibi, M.R.; Ghassemi, M.; Hamedi, M.H. Analysis of high gradient magnetic field effects on distribution of nanoparticles injected into pulsatile blood stream. J. Magn. Magn. Mater. 2012, 324, 1473–1482. [Google Scholar] [CrossRef]

- Braun, U.; Schartel, B. Flame Retardancy Mechanisms of Aluminium Phosphinate in Combination with Melamine Cyanurate in Glass-Fibre-Reinforced Poly(1,4-butylene terephthalate). Macromol. Mater. Eng. 2008, 293, 206–217. [Google Scholar] [CrossRef]

- Tumanski, S. Handbook of Magnetic Measurements; CRC Press: Boca Raton, FL, USA, 2016; ISBN 1439829527. [Google Scholar]

- Fiorillo, F. Characterization and Measurement of Magnetic Materials; Academic Press: Cambridge, MA, USA, 2004; ISBN 0080528929. [Google Scholar]

- Jiles, D. Introduction to Magnetism and Magnetic Materials; Chapman: Orange, CA, USA, 1991. [Google Scholar]

- Hilzinger, R.; Rodewald, W. Magnetic Materials; Vacuumschmeltze GmbH Co., KG: Hanau, Germany, 2013. [Google Scholar]

- Krishnan, K.M. Fundamentals and Applications of Magnetic Materials; Oxford University Press: Oxford, UK, 2016; ISBN 0199570442. [Google Scholar]

- ČSN EN ISO 3451-1; Plasty—Stanovení Popela—Část 1: Obecné Metody. UNMZ: Praha, Czech Republic, 2019.

- Steingroever, E.; Ross, G. Magnetic Measuring Techniques. Magnet-Physic Köln 1997, 1, 997. [Google Scholar]

- International Electrotechnical Commission. IEC 60404-4:1995+AMD1:2000+AMD2:2008, Magnetic Materials—Part 4: Methods of Measurement of d.c. Magnetic Properties of Magnetically Soft Materials; IEC—International Electrotechnical Commission: Geneva, Switzerland, 2008. [Google Scholar]

- Marek, M. Numerical computation of magnetic field and inductivity of power reactor with respect of real magnetic properties of iron core. In Scientific Computing in Electrical Engineering; Springer: Berlin/Heidelberg, Germany, 2006; pp. 233–239. [Google Scholar]

- Jin, J.-M. The Finite Element Method in Electromagnetics; John Wiley & Sons: Hoboken, NJ, USA, 2015; ISBN 1118842022. [Google Scholar]

- Bastos, J.P.A.; Sadowski, N. Electromagnetic Modeling by Finite Element Methods; CRC Press: Boca Raton, FL, USA, 2003; ISBN 0203911172. [Google Scholar]

- Wang, X.H.; Li, J.-G.; Kamiyama, H.; Katada, M.; Ohashi, N.; Moriyoshi, Y.; Ishigaki, T. Pyrogenic iron (III)-doped TiO2 nanopowders synthesized in RF thermal plasma: Phase formation, defect structure, band gap, and magnetic properties. J. Am. Chem. Soc. 2005, 127, 10982–10990. [Google Scholar] [CrossRef] [PubMed]

- Dupaix, R.B.; Boyce, M.C. Finite strain behavior of poly (ethylene terephthalate)(PET) and poly (ethylene terephthalate)-glycol (PETG). Polymer 2005, 46, 4827–4838. [Google Scholar] [CrossRef]

- Bransden, B.H.; Joachain, C.J. Physics of Atoms and Molecules; Pearson Education India: Bengaluru, India, 2003; ISBN 8177582798. [Google Scholar]

- Brauer, J.R. Magnetic Actuators and Sensors; John Wiley & Sons: Hoboken, NJ, USA, 2006; ISBN 0471777706. [Google Scholar]

| Sample | Infill Density/% | Printing Time | Weight of Filament/g | Price/EUR * |

|---|---|---|---|---|

| 0A | 0 | 38 min 3 s | 11.3 | 0.87 |

| 20A | 20 | 45 min 8 s | 14.2 | 1.09 |

| 50A | 50 | 57 min 38 s | 17.0 | 1.31 |

| 80A | 80 | 71 min 5 s | 19.4 | 1.49 |

| 100A | 100 | 61 min 34 s | 22.9 | 1.76 |

| 100F | 100 | 61 min 34 s | 20.4 | 0.55 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zárybnická, L.; Marek, M.; Ševčík, R.; Stolín, R.; Pokorný, J.; Šál, J. Effect of Infill Density of the Printed PET-G Structures Containing Iron Oxides on Magnetic Properties. Magnetochemistry 2023, 9, 2. https://doi.org/10.3390/magnetochemistry9010002

Zárybnická L, Marek M, Ševčík R, Stolín R, Pokorný J, Šál J. Effect of Infill Density of the Printed PET-G Structures Containing Iron Oxides on Magnetic Properties. Magnetochemistry. 2023; 9(1):2. https://doi.org/10.3390/magnetochemistry9010002

Chicago/Turabian StyleZárybnická, Lucie, Martin Marek, Radek Ševčík, Radek Stolín, Jaroslav Pokorný, and Jiří Šál. 2023. "Effect of Infill Density of the Printed PET-G Structures Containing Iron Oxides on Magnetic Properties" Magnetochemistry 9, no. 1: 2. https://doi.org/10.3390/magnetochemistry9010002

APA StyleZárybnická, L., Marek, M., Ševčík, R., Stolín, R., Pokorný, J., & Šál, J. (2023). Effect of Infill Density of the Printed PET-G Structures Containing Iron Oxides on Magnetic Properties. Magnetochemistry, 9(1), 2. https://doi.org/10.3390/magnetochemistry9010002