Wood Fiber from Norway Spruce—A Stand-Alone Growing Medium for Hydroponic Strawberry Production

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Physical Properties of Growing Media

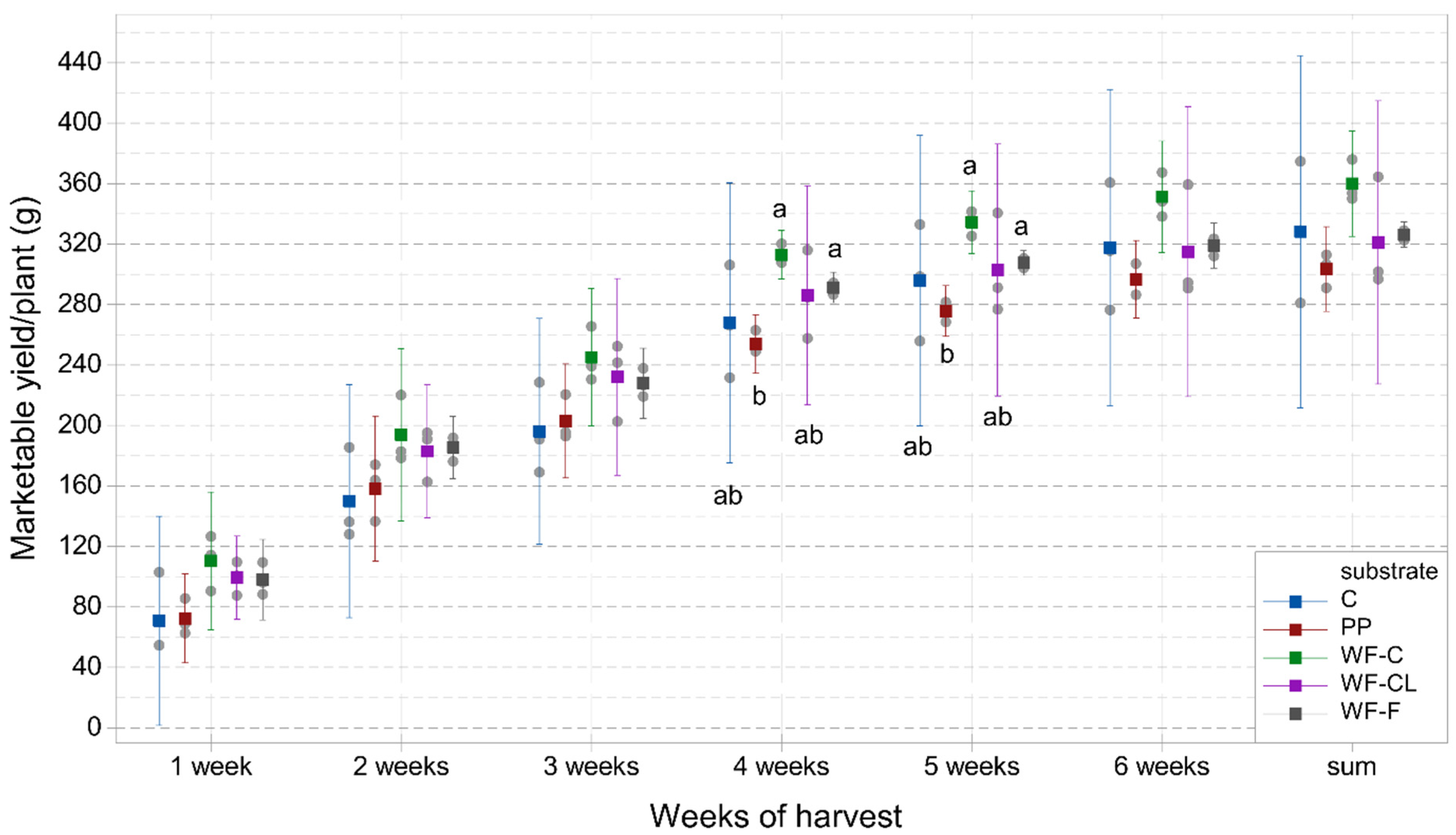

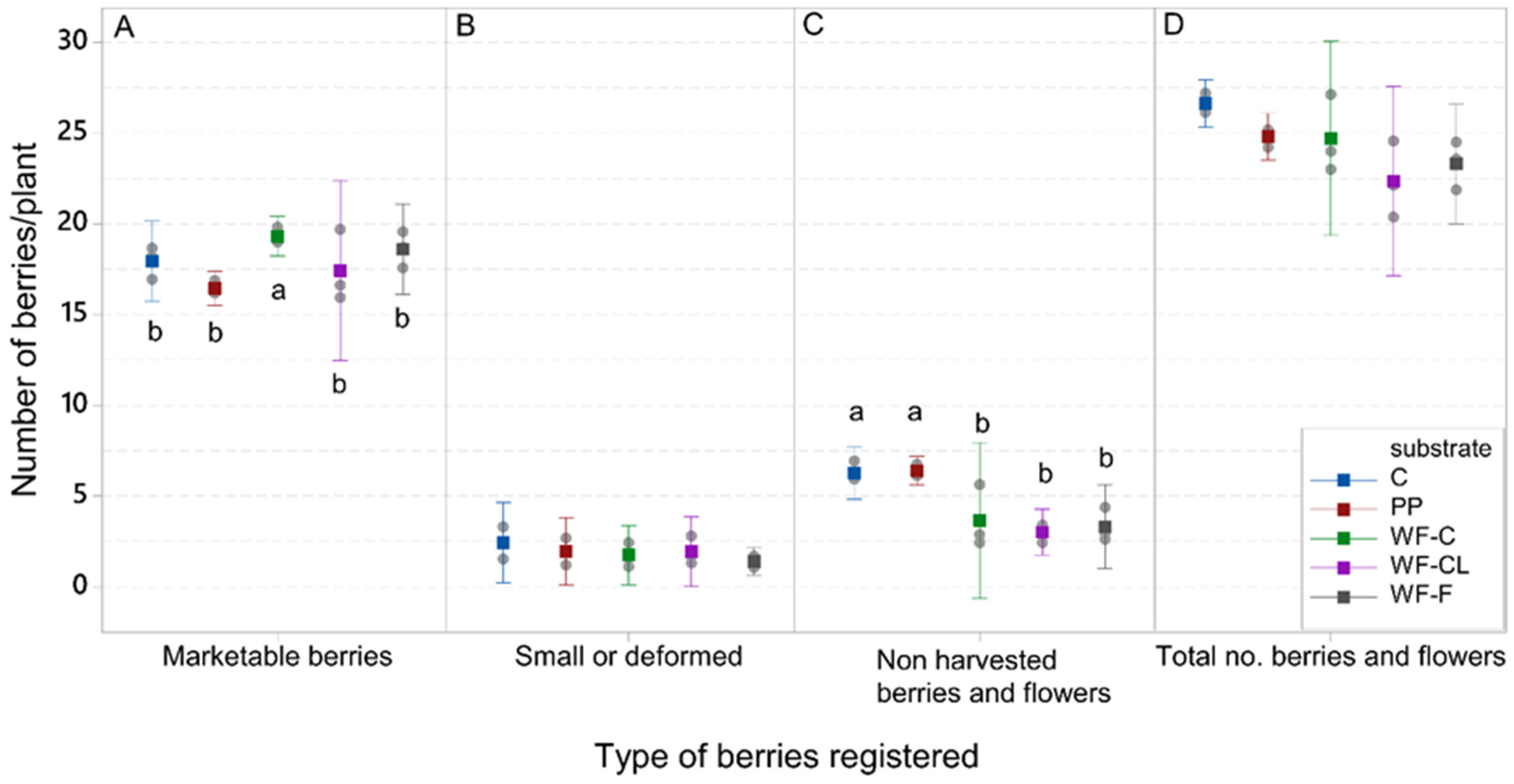

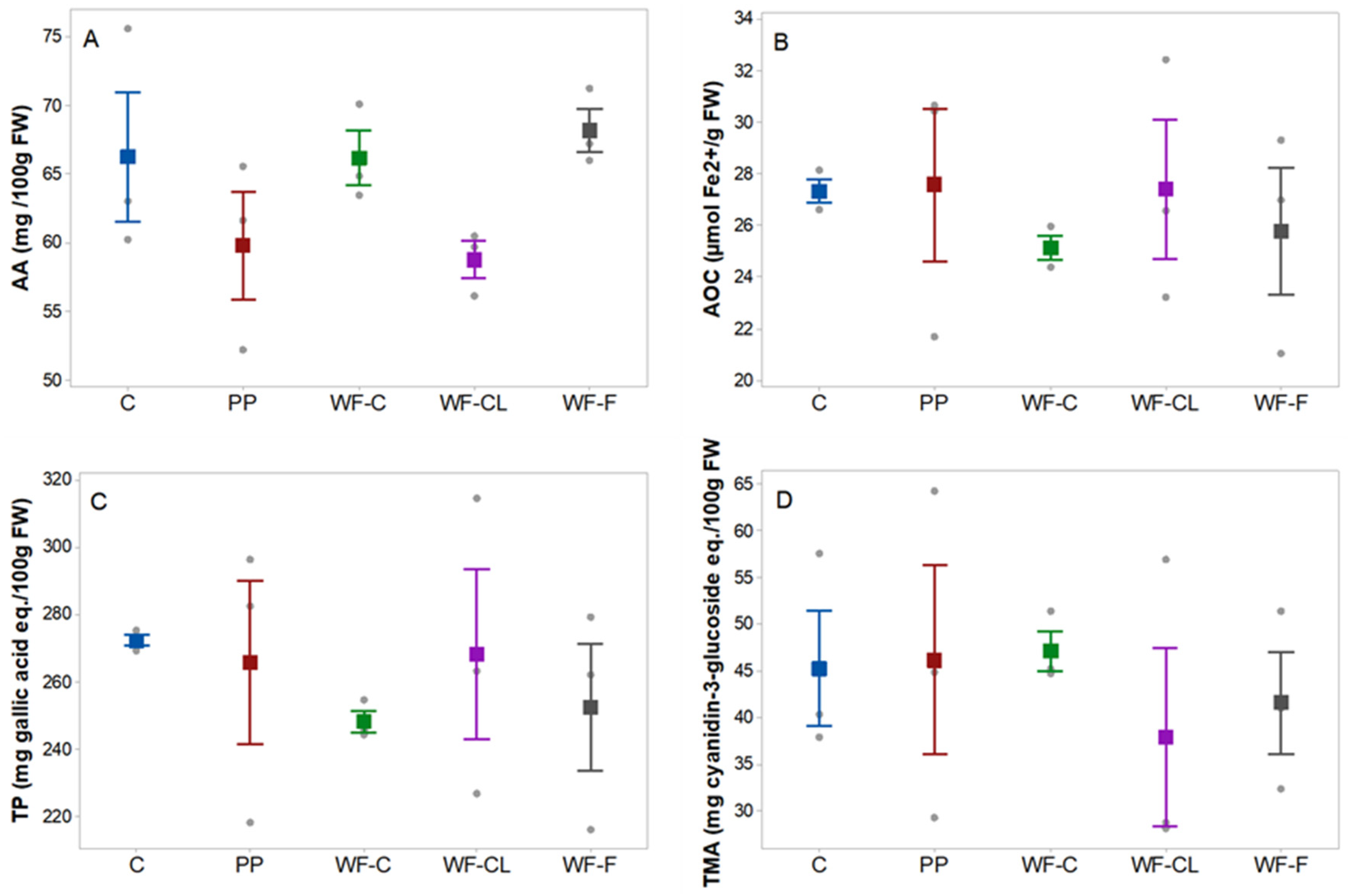

3.2. Strawberry Production

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- FAOSTAT. 2020. Available online: https://www.fao.org/faostat/en/ (accessed on 30 October 2022).

- Hernández-Martínez, N.R.; Blanchard, C.; Wells, D.; Salazar-Gutiérrez, M.R. Current state and future perspectives of commercial strawberry production: A review. Sci. Hortic. 2023, 312, 111893. [Google Scholar]

- Dunn, C.; Freeman, C. Peatlands: Our greatest source of carbon credits? Carbon Manag. 2011, 2, 289–301. [Google Scholar] [CrossRef]

- Nichols, J.E.; Peteet, D.M. Rapid expansion of northern peatlands and doubled estimate of carbon storage. Nat. Geosci. 2019, 12, 917–921. [Google Scholar] [CrossRef]

- Barrett, G.E.; Alexander, P.D.; Robinson, J.S.; Bragg, N.C. Achieving environmentally sustainable growing media for soilless plant cultivation systems–A review. Sci. Hortic. 2016, 212, 220–234. [Google Scholar]

- Gruda, N.S. Increasing sustainability of growing media constituents and stand-alone substrates in soilless culture systems. Agronomy 2019, 9, 298. [Google Scholar] [CrossRef]

- QUANTIS. Comparative Life Cycle Assessment of Horticultural Growing Media Based on Peat and Other Growing Media Constituents. 2012. Available online: https://www.warum-torf.info (accessed on 30 October 2022).

- Vandecasteele, B.; Hofkens, M.; De Zaeytijd, J.; Visser, R.; Melis, P. Towards environmentally sustainable growing media for strawberry cultivation: Effect of biochar and fertigation on circular use of nutrients. Agric. Water Manag. 2023, 284, 108361. [Google Scholar] [CrossRef]

- Pascual, J.A.; Ceglie, F.; Tuzel, Y.; Koller, M.; Koren, A.; Hitchings, R.; Tittarelli, F. Organic substrate for transplant production in organic nurseries. A review. Agron. Sustain. Dev. 2018, 38, 35. [Google Scholar] [CrossRef]

- Lillesund, V.F. Utfasing av Uttak og Bruk av Torv–Kunnskapsutredning om Konsekvenser for Naturmangfold, klima, Næring og Forbrukere; Miljødirektoratet Rapport M-951, Miljødirektoratet: Trondheim, Norway, 2018. (In Norwegian) [Google Scholar]

- Gruda, N.; Schnitzler, W.H. Suitability of wood fiber substrate for production of vegetable transplants: I. Physical properties of wood fiber substrates. Sci. Hortic. 2004, 100, 309–322. [Google Scholar] [CrossRef]

- Jackson, B.E.; Wright, R.D.; Barnes, M.C. Pine tree substrate, nitrogen rate, particle size, and peat amendment affect poinsettia growth and substrate physical properties. HortScience 2008, 43, 2155–2161. [Google Scholar] [CrossRef]

- Blok, C.; van der Salm, C.; Hofland-Zijlstra, J.; Streminska, M.; Eveleens, B.; Regelink, I.; Fryda, L.; Visser, R. Biochar for horticultural rooting media improvement: Evaluation of biochar from gasification and slow pyrolysis. Agronomy 2017, 7, 6. [Google Scholar] [CrossRef]

- Kern, J.; Tammeorg, P.; Shanskiy, M.; Sakrabani, R.; Knicker, H.; Kammann, C.; Sohi, S. Synergistic use of peat and charred material in growing media–an option to reduce the pressure on peatlands? J. Environ. Eng. Landsc. 2017, 25, 160–174. [Google Scholar] [CrossRef]

- Iheshiulo, E.M.-A.; Abbey, L.; Asiedu, S.K. Response of kale to single-dose application of K humate, dry vermicasts, and volcanic minerals. Int. J. Veg. Sci. 2017, 23, 135–144. [Google Scholar] [CrossRef]

- Jackson, B.E.; Wright, R.D.; Alley, M.M. Comparison of fertilizer nitrogen availability, nitrogen immobilization, substrate carbon dioxide efflux, and nutrient leaching in peat-lite, pine bark, and pine tree substrates. HortScience 2009, 44, 781–790. [Google Scholar] [CrossRef]

- Wright, R.D.; Jackson, B.E.; Browder, J.F.; Latimer, J.G. Growth of chrysanthemum in a pine tree substrate requires additional fertilizer. HortTechnology 2008, 18, 111–115. [Google Scholar] [CrossRef]

- Jackson, B.E. Challenges and considerations of using wood substrates: Chemical properties. Greenhouse Grower. 2018, 10, 46–50. [Google Scholar]

- Li, Q.; Hu, C.; Li, M.; Truong, P.; Li, J.; Lin, H.S.; Naik, M.T.; Xiang, S.; Jackson, B.E.; Kuo, W. Enhancing the multi-functional properties of renewable lignin carbon fibers via defining the structure–property relationship using different biomass feedstocks. Green Chem. 2021, 23, 3725–3739. [Google Scholar] [CrossRef]

- Aurdal, S.M.; Woznicki, T.L.; Haraldsen, T.K.; Kusnierek, K.; Sønsteby, A.; Remberg, S.F. Wood Fiber-Based Growing Media for Strawberry Cultivation: Effects of Incorporation of Peat and Compost. Horticulturae 2023, 9, 36. [Google Scholar] [CrossRef]

- Fonteno, W.C.; Hardin, C.T.; Brewster, J.P. Procedures for Determining Physical Properties of Horticultural Substrates Using the NCSU Porometer; Horticultural Substrates Laboratory, North Carolina State University: Raleigh, CA, USA, 1995. [Google Scholar]

- Benzie, I.F.F.; Strain, J.J. The ferric reducing ability of plasma (FRAP) as a measure of ‘antioxidant power’: The FRAP assay. Ann. Biochem. 1996, 239, 70–76. [Google Scholar] [CrossRef]

- Giusti, M.M.; Wrolstad, R.E. Characterization and measurement of anthocyanins by UV–visible spectroscopy. In Handbook of Food Analytical Chemistry: Pigments, Colorants, Flavors, Texture and Bioactive Food Components; Wrolstad, R.E., Acree, T.E., Decker, E.A., Penner, M.H., Reid, D.S., Schwartz, S.J., Shoemaker, C.F., Smith, D., Sporns, P., Eds.; Wiley: New York, NY, USA, 2005; pp. 19–30. [Google Scholar]

- Singleton, V.L.; Orthofer, R.; Lamuela-Raventos, R.M. Analysis of total phenols and other oxidation substrates and antioxidants by means of Folin-Ciocalteu reagent. Methods Enzymol. 1999, 299, 152–178. [Google Scholar]

- Wold, A.-B.; Rosenfeld, H.J.; Baugerød, H.; Blomhoff, R. The effect of fertilization on antioxidant activity and chemical composition of tomato cultivars (Lycopersicon esculentum Mill.). Eur. J. Hortic. Sci. 2004, 69, 67–174. [Google Scholar]

- Williams, R.C.; Baker, D.R.; Schmit, J.A. Analysis of water-soluble vitamins by high-speed ion-exchange chromatography. J. Chromatogr. Sci. 1973, 11, 618–624. [Google Scholar] [CrossRef]

- Weissgerber, T.L.; Milic, N.M.; Winham, S.J.; Garovic, V.D. Beyond bar and line graphs: Time for a new data presentation paradigm. PLoS Biol. 2015, 13, e1002128. [Google Scholar] [CrossRef] [PubMed]

- Amrhein, V.; Greenland, S.; MsShane, B. Retire statistical significance. Nature 2019, 567, 305–307. [Google Scholar] [CrossRef] [PubMed]

- Aurdal, S.M.; Foereid, B.; Sogn, T.; Børresen, T.; Hvoslef-Eide, T.; Fagertun Remberg, S. Growth, yield and fruit quality of tomato Solanum lycopersicum L grown in sewage-based compost in a semi-hydroponic cultivation system. Acta Agric. Scan. Sect. B—Soil Plant Sci. 2022, 72, 902–912. [Google Scholar] [CrossRef]

- Haines, O. Evaluating Alternatives to Peat Based Growing Substrates for Use in Ornamental Horticulture. Master’s Thesis, Lancaster University, Lancaster, UK, 2023. [Google Scholar] [CrossRef]

- Dickson, R.W.; Helms, K.M.; Jackson, B.E.; Machesney, L.M.; Lee, J.A. Evaluation of Peat Blended with Pine Wood Components for Effects on Substrate Physical Properties, Nitrogen Immobilization, and Growth of Petunia (Petunia × Hybrida Vilm.-Andr.). HortScience 2022, 57, 304–311. [Google Scholar] [CrossRef]

- Durand, S.; Jackson, B.E.; Fonteno, W.C.; Michel, J.-C. The Use of Wood Fiber for Reducing Risks of Hydrophobicity in Peat-Based Substrates. Agronomy 2021, 11, 907. [Google Scholar] [CrossRef]

- Iatrou, M.; Papadopoulos, A. Influence of nitrogen nutrition on nitrate levels of strawberry leaf blades and petioles. J. Plant Nutr. 2016, 39, 1131–1136. [Google Scholar] [CrossRef]

- Iatrou, M.; Papadopoulos, A. Influence of nitrogen nutrition on yield and growth of an everbearing strawberry cultivar (cv. Evie II). J. Plant Nutr. 2016, 39, 1499–1505. [Google Scholar] [CrossRef]

- Nestby, R.; Woznicki, T.L.; Sønsteby, A. Influence of fertilization on growth and generative parameters of two short day strawberry cultivars grown in substrate, and evaluation of analysing tools for leaf nitrate and potassium. Acta Hortic. 2018, 1217, 391–398. [Google Scholar] [CrossRef]

- Gruda, N.; Schnitzler, W.H. Suitability of wood fibre substrate for production of vegetable transplants. II. The effect of wood fiber substrates and their volume weights on the growth of tomato transplants. Sci. Hortic. 2004, 100, 333–340. [Google Scholar] [CrossRef]

- Domeno, I.; Irigoyen, I.; Muro, J. New wood fibre substrates: Characterisation and evaluation in hydroponic tomato culture. Eur. J. Hortic. Sci. 2010, 75, 89–94. [Google Scholar]

- Kowalczyk, K.; Gajc-Wolska, J. Effect of the kind of growing medium and transplant grafting on the cherry tomato yielding. Acta Sci. Pol. Hortorum Cultus 2011, 10, 61–70. [Google Scholar]

- Hardgrave, M.; Harriman, M. Development of organic substrates for hydroponic cucumber production. Acta Hortic. 1995, 401, 219–224. [Google Scholar] [CrossRef]

- Gajc-Wolska, J.; Bujalski, D.; Chrzanowska, A. Effect of a substrate on yielding and quality of greenhouse cucumber fruits. J. Elem. 2008, 13, 205–210. [Google Scholar]

- Carlile, W.R.; Raviv, M.; Prasad, M. Soilless Culture. Organic Soilless Media Components; Elsevier: Amsterdam, The Netherlands, 2019; pp. 303–378. [Google Scholar]

- Marinou, E.; Chrysargyris, A.; Tzortzakis, N. Use of sawdust, coco soil and pumice in hydroponically grown strawberry. Plant Soil Environ. 2013, 59, 452459. [Google Scholar] [CrossRef]

- Mostafiz, B.S. Utilization of Modified Wood Shavings as Growing Media for Selected Horticultural Crops. Master’s Thesis, University of Helsinki, Helsinki, Finland, 2014. [Google Scholar]

- Depardieu, C.; Prémont, V.; Boily, C.; Caron, J. Sawdust and bark-based substrates for soilless strawberry production: Irrigation and electrical conductivity management. PLoS ONE 2016, 11, e0154104. [Google Scholar] [CrossRef]

- Soffer, H.; Burger, D.W.; Lieth, J.H. Plant growth and development of Chrysanthemum and Ficus in aero-hydroponics: Response to low dissolved oxygen concentrations. Sci. Hortic. 1991, 45, 287–294. [Google Scholar] [CrossRef]

- Schroeder, F.G.; Engwicht, K. Gas concentration in the root zone of rosa hybrida L. rown in different growing media. Acta Hortic. 2004, 697, 49–55. [Google Scholar]

- Rocksch, T.; Gruda, N.; Schmidt, U. The influence of irrigation on gas composition in the rhizosphere and growth of three horticultural plants, cultivated in different substrates. Acta Hortic. 2008, 801, 1143–1148. [Google Scholar] [CrossRef]

| Medium Type | Medium Acronym | Supplier (Details) | pH |

|---|---|---|---|

| 80% peat: 20% perlite | PP | Peat: H2–H4, Tjerbo, Norway Perlite: Agra-perlite, Pull Rhenen, NL (Grade 3–0–6.5 mm) | Peat: 5.5–6.5 Perlite: 6.5–7.5 |

| 100% coir | C | Botanicoir Precision Plus Ultra, UK (washed and buffered) | 5.6–6.8 |

| 100% Norway spruce wood fiber, fine | WF-F | Hunton Fiber AS, Norway | 4.9 |

| 100% Norway spruce wood fiber, coarse | WF-C | Hunton Fiber AS, Norway | 4.9 |

| 100% Norway spruce wood fiber, coarse-loose | WF-CL | Hunton Fiber AS, Norway (WF-C fiber packed with lower density—33% mass reduction in relation to WF-C) | 4.9 |

| Time of the Day | Watering Criterion |

| 9.00–10.00 | When temp. > 20 °C and solar radiation > 500 W/m2 |

| 10.00–13.00 | Fixed watering at 10.00 and 12.00 |

| 13.00–17.00 | When daily radiation sum > 500 J/m2 (min. 1.5 h between watering) |

| 17.00–21.00 | When temp. > 23 °C (min. 1.5 h between watering) |

| Substrate | Fixed watering time |

| PP | 3 min |

| WF-F | 3 min |

| WF-C | 4 min |

| C | 5 min |

| WF-CL | 7 min |

| Percent | Substrate | TP y | CC x | AS w | BD v |

|---|---|---|---|---|---|

| 100% | Peat-lite | 87.1 c u | 56.4 cd | 30.7 cd | 0.12 a |

| 100% | Coir | 88.7 c | 70.1 a | 18.6 e | 0.09 bc |

| 100% | Peat | 88.1 c | 58.3 cd | 29.8 d | 0.11 a |

| 100% | Coarse WF | 92.9 b | 48.3 ef | 44.6 a | 0.08 c |

| 80% | Coarse WF | 91.4 bc | 51.3 e | 40.1 b | 0.08 c |

| 60% | Coarse WF | 86.1 d | 56.2 cde | 29.9 d | 0.10 b |

| 40% | Coarse WF | 86.7 cd | 59.1 c | 27.6 d | 0.10 b |

| 20% | Coarse WF | 83.2 d | 64.8 b | 18.4 e | 0.10 b |

| 100% | Fine WF | 98.4 a | 53.7 de | 44.7 a | 0.07 d |

| 80% | Fine WF | 92.6 b | 58.0 cd | 34.6 c | 0.07 d |

| 60% | Fine WF | 88.7 c | 59.7 c | 29.0 d | 0.08 c |

| 40% | Fine WF | 84.8 d | 65.3 b | 19.5 e | 0.08 c |

| 20% | Fine WF | 80.7 de | 68.4 ab | 12.3 f | 0.10 b |

| LSD t | 3.52 | 3.16 | 3.11 | 0.002 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Woznicki, T.; Jackson, B.E.; Sønsteby, A.; Kusnierek, K. Wood Fiber from Norway Spruce—A Stand-Alone Growing Medium for Hydroponic Strawberry Production. Horticulturae 2023, 9, 815. https://doi.org/10.3390/horticulturae9070815

Woznicki T, Jackson BE, Sønsteby A, Kusnierek K. Wood Fiber from Norway Spruce—A Stand-Alone Growing Medium for Hydroponic Strawberry Production. Horticulturae. 2023; 9(7):815. https://doi.org/10.3390/horticulturae9070815

Chicago/Turabian StyleWoznicki, Tomasz, Brian E. Jackson, Anita Sønsteby, and Krzysztof Kusnierek. 2023. "Wood Fiber from Norway Spruce—A Stand-Alone Growing Medium for Hydroponic Strawberry Production" Horticulturae 9, no. 7: 815. https://doi.org/10.3390/horticulturae9070815

APA StyleWoznicki, T., Jackson, B. E., Sønsteby, A., & Kusnierek, K. (2023). Wood Fiber from Norway Spruce—A Stand-Alone Growing Medium for Hydroponic Strawberry Production. Horticulturae, 9(7), 815. https://doi.org/10.3390/horticulturae9070815